Flexible buffering punching machine

A flexible cushioning and punching technology, which is applied in the field of plate processing, can solve problems such as unreliable positioning, easily damaged molds, and large noise and vibration, and achieve the effects of avoiding hard contact, improving service life, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

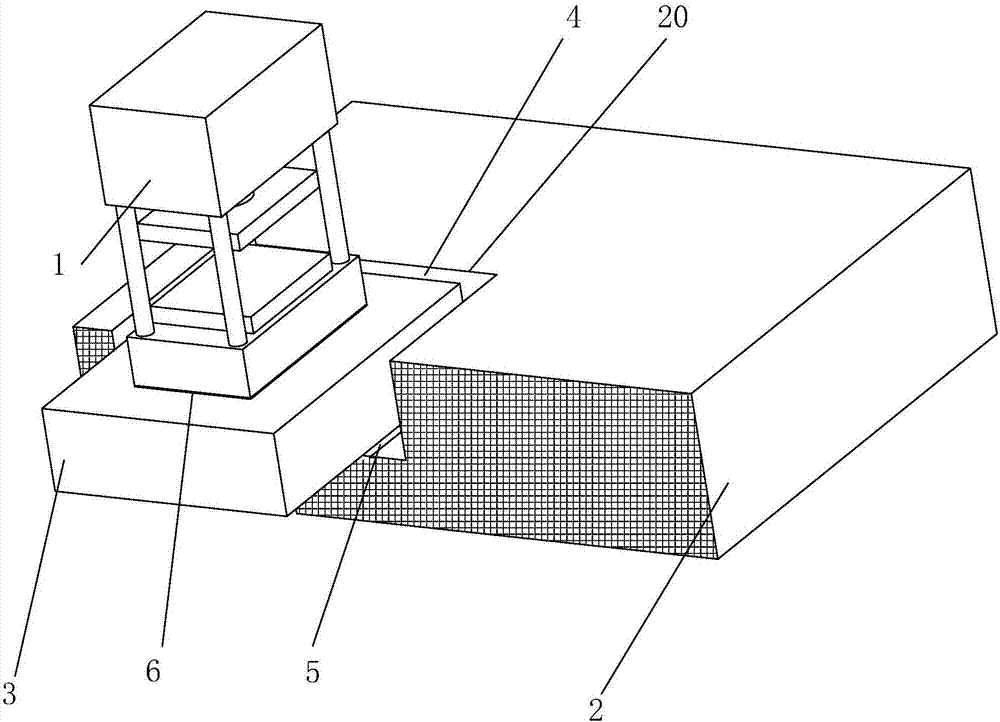

[0014] The present invention as Figure 1-2 As shown, it includes a stamping machine. The stamping machine 1 is set on the foundation 2 through a vibration isolation mechanism. The vibration isolation mechanism is: the foundation 2 is provided with a vibration isolation groove 20. The platform 3 is arranged in the vibration isolation groove;

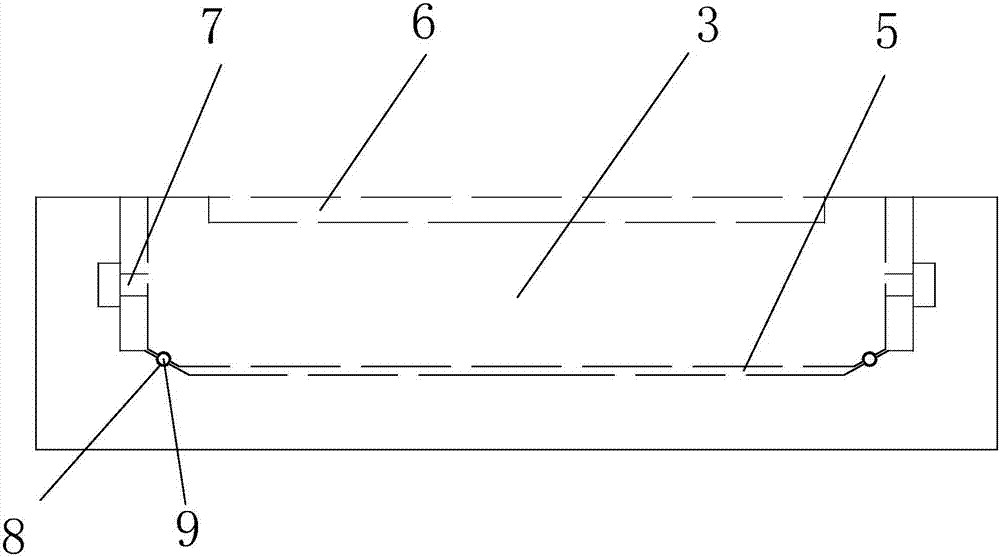

[0015] The bottom surface of the vibration isolation tank is provided with accommodating groove one 5, and the counterweight platform is located in the accommodating groove one 5. Both sides of the lower part are respectively provided with slopes, so that the cross-section of the lower part of the counterweight platform is trapezoidal, and the counterweight platform is adaptively arranged in the first vibration isolation groove;

[0016] A corresponding semicircular groove 8 is provided between the bottom slope of the counterweight platform and the slope of the accommodation tank 1, and a round roller 9 is arranged in the adjacent semic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com