Automobile part press machine with high machining precision

A technology for auto parts and processing accuracy, which is applied in the direction of presses, manufacturing tools, etc., and can solve problems that affect the accuracy of auto parts processing and the impact of auto parts processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

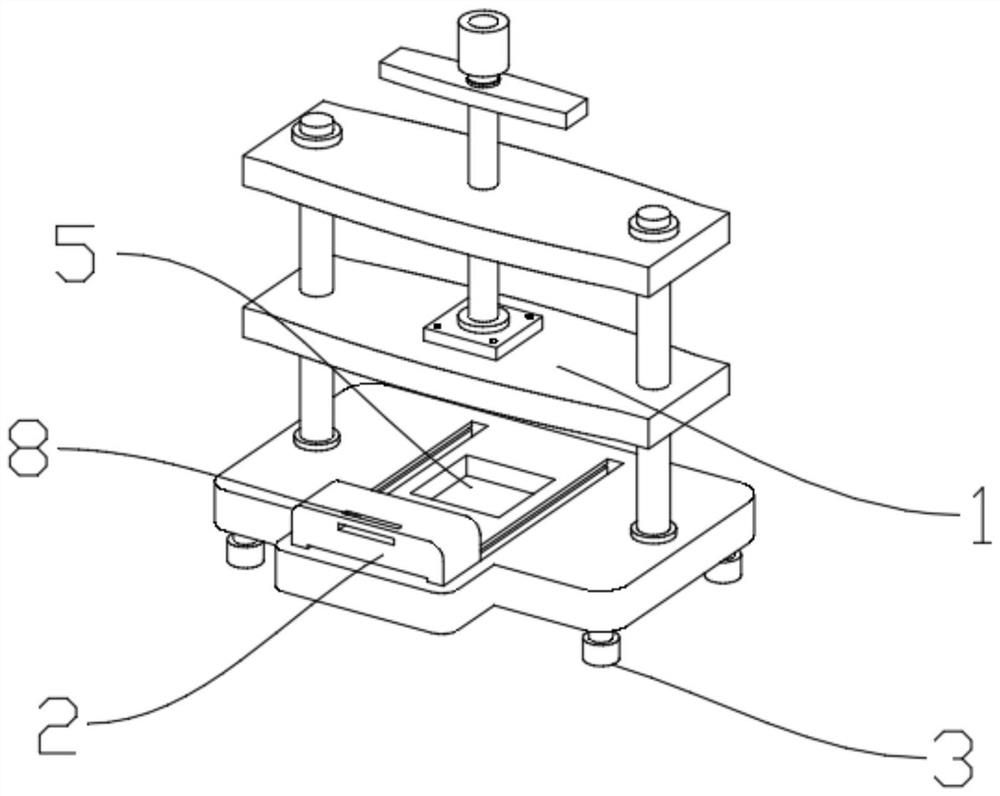

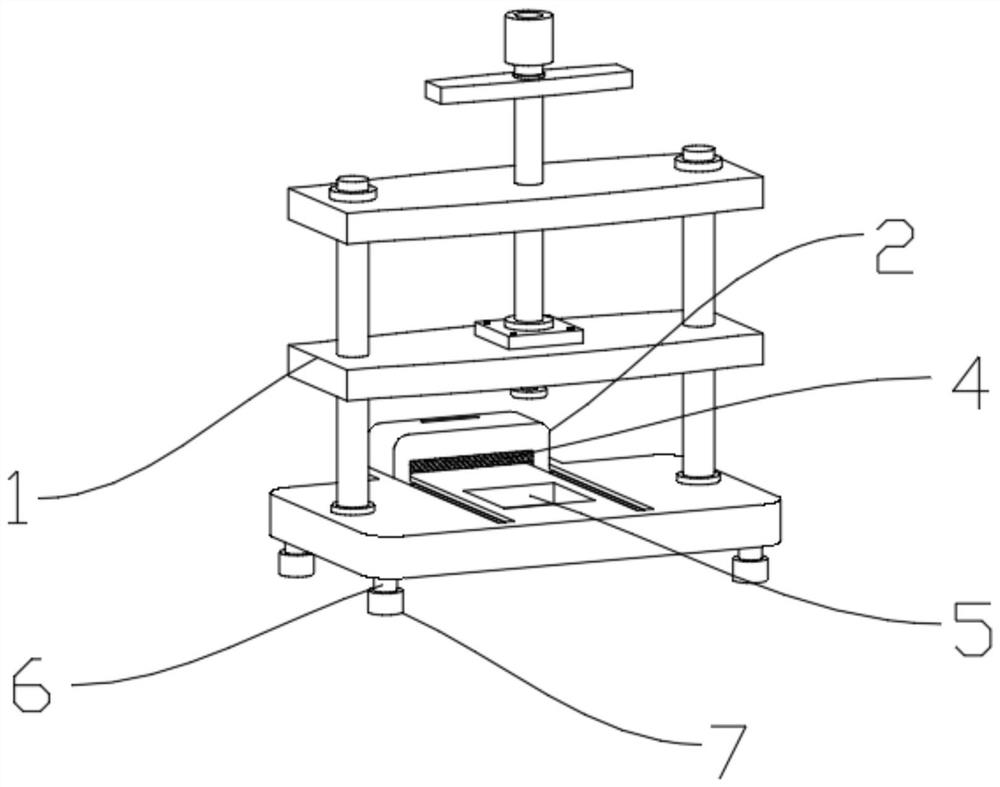

[0024] refer to Figure 1-3 , The present invention provides an auto parts press with high machining accuracy, including a press main body 1, the press main body 1 includes a three-layer structure, and a cleaning block 2 is slidably connected to the top of the bottommost layer of the press main body 1, and the press main body 1 is the most A number of buffer assemblies 3 are fixedly connected to the bottom end of the lower layer, a cleaning sponge 4 is fixedly connected to the bottom end of the cleaning block 2 , and a corresponding position of the lowermost layer of the press main body 1 is provided with a fixing groove 5 .

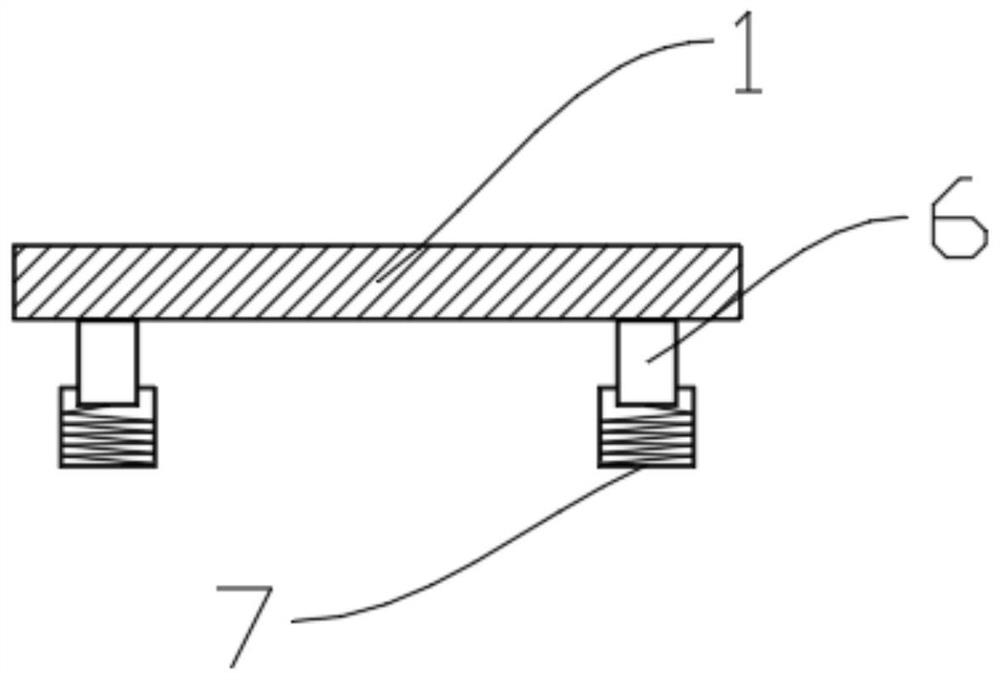

[0025] The number of buffer assemblies 3 is four, and each buffer assembly 3 includes a top rod 6 , a foot pad 7 and a spring.

[0026] It can be understood that: by providing four buffer components 3, it is ensured that the press main body 1 can buffer the mechanical vibration from the outside during the working process, so as to avoid affecting the mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com