Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

77 results about "Activation product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Activation products are materials made radioactive by neutron activation. Fission products and actinides produced by neutron absorption of nuclear fuel itself are normally referred to by those specific names, and activation product reserved for products of neutron capture by other materials, such as structural components of the nuclear reactor or nuclear bomb, the reactor coolant, control rods or other neutron poisons, or materials in the environment. All of these, however, need to be handled as radioactive waste. Some nuclides originate in more than one way, as activation products or fission products.

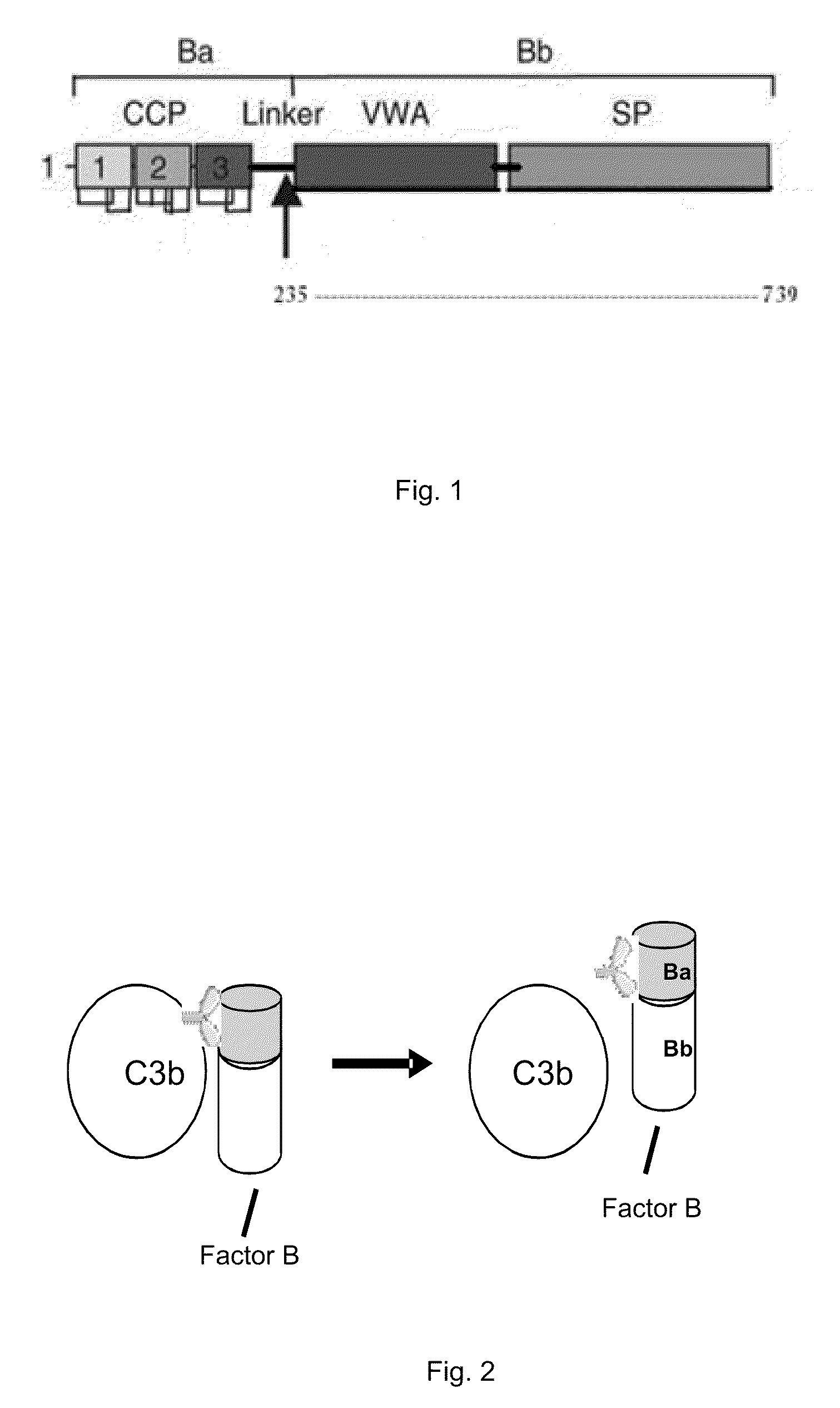

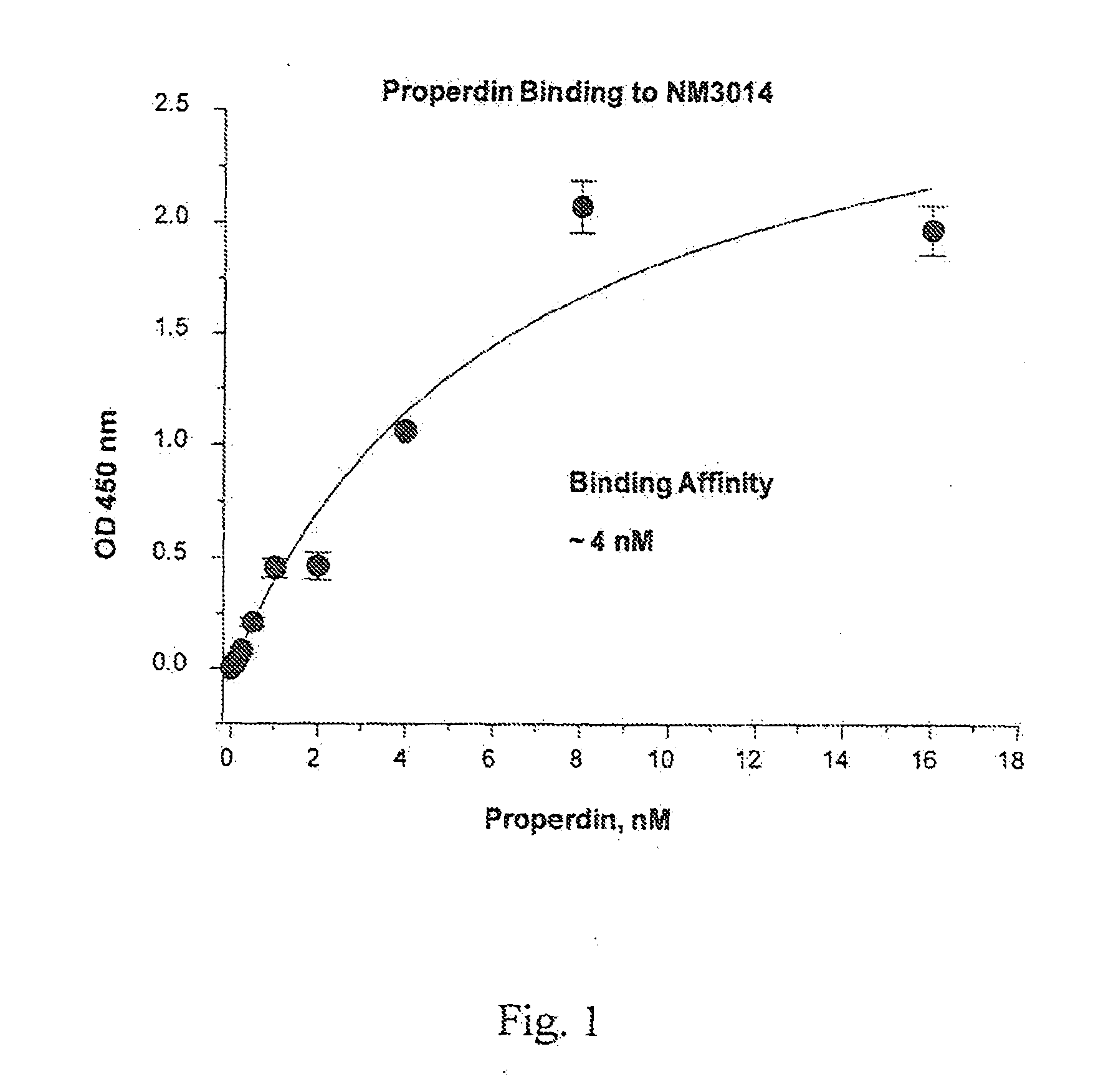

METHOD OF INHIBITING COMPLEMENT ACTIVATION WITH FACTOR Ba SPECIFIC ANTIBODIES AND USE THEREOF

InactiveUS20100015139A1Inhibiting complement activationEliminate side effectsAntibody ingredientsImmunoglobulins against enzymesFactor iiNeutrophil granulocyte

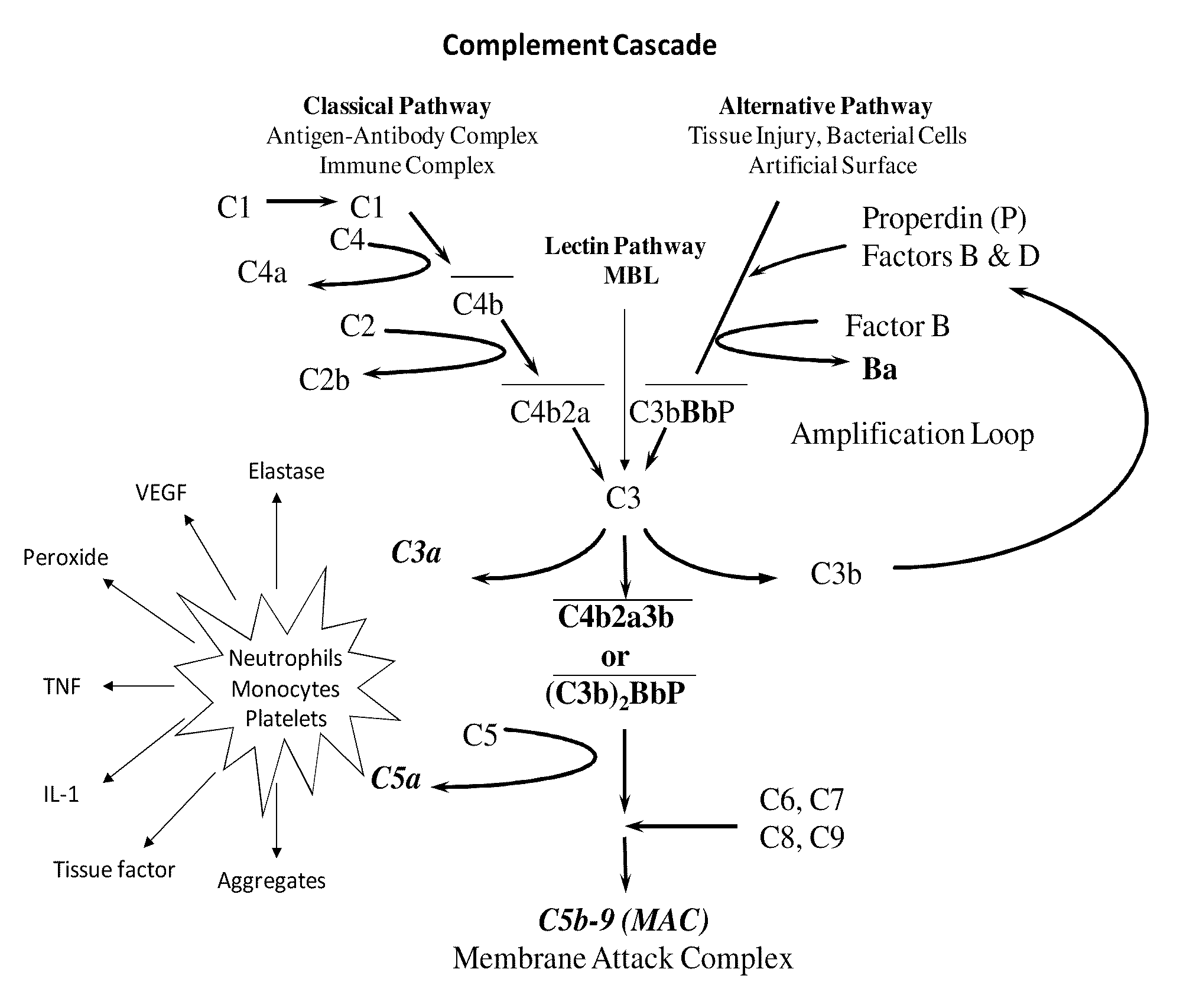

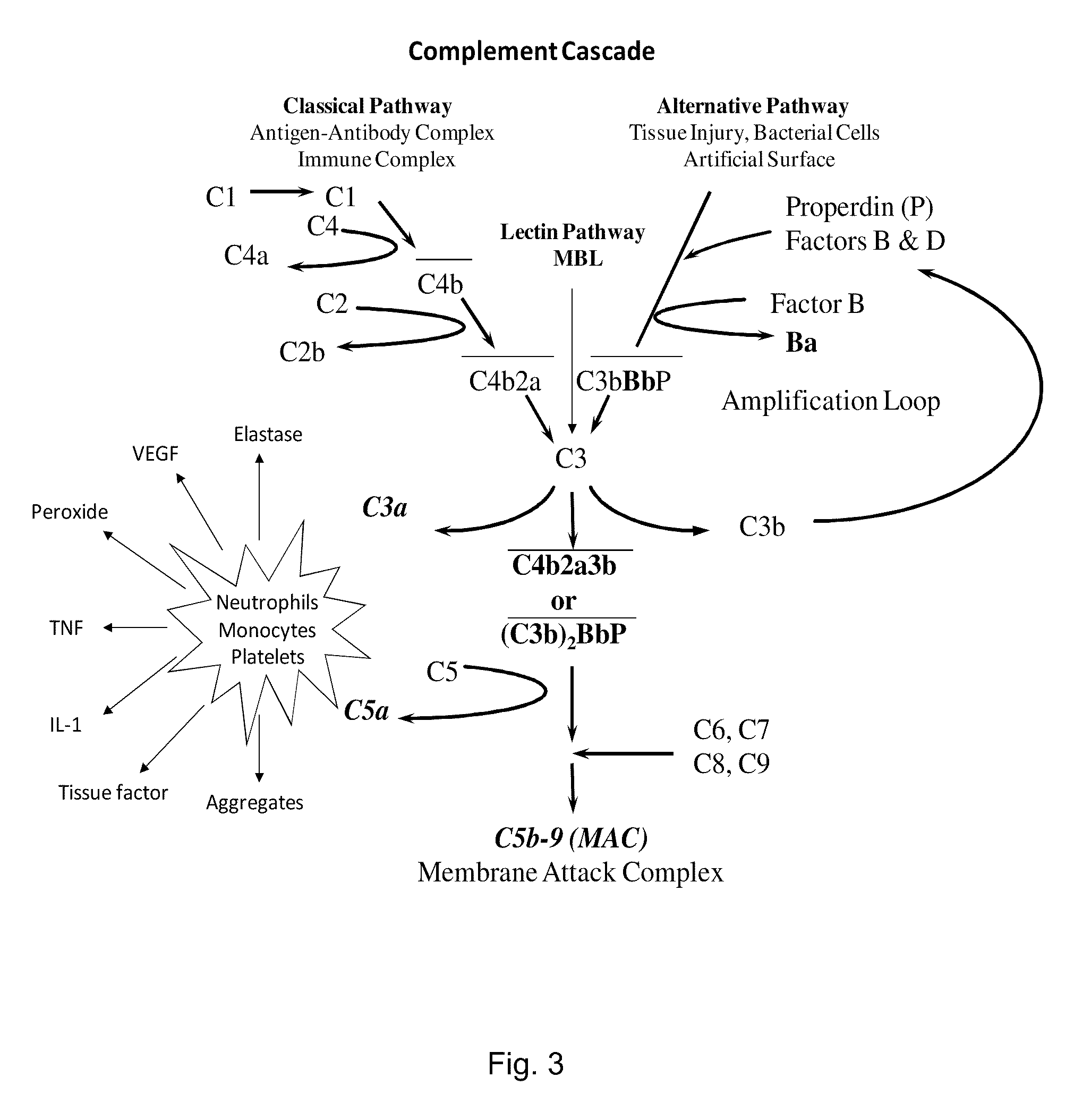

A method of inhibiting the adverse effects of alternative complement pathway activation products in a subject comprising administering to the subject an amount of anti-factor Ba antibody effective to selectively inhibit formation of an alternative complement pathway activation products C3a, C5a, and C5b-9, and activation of neutrophils, monocytes, and platelets.

Owner:NOVELMED THERAPEUTICS

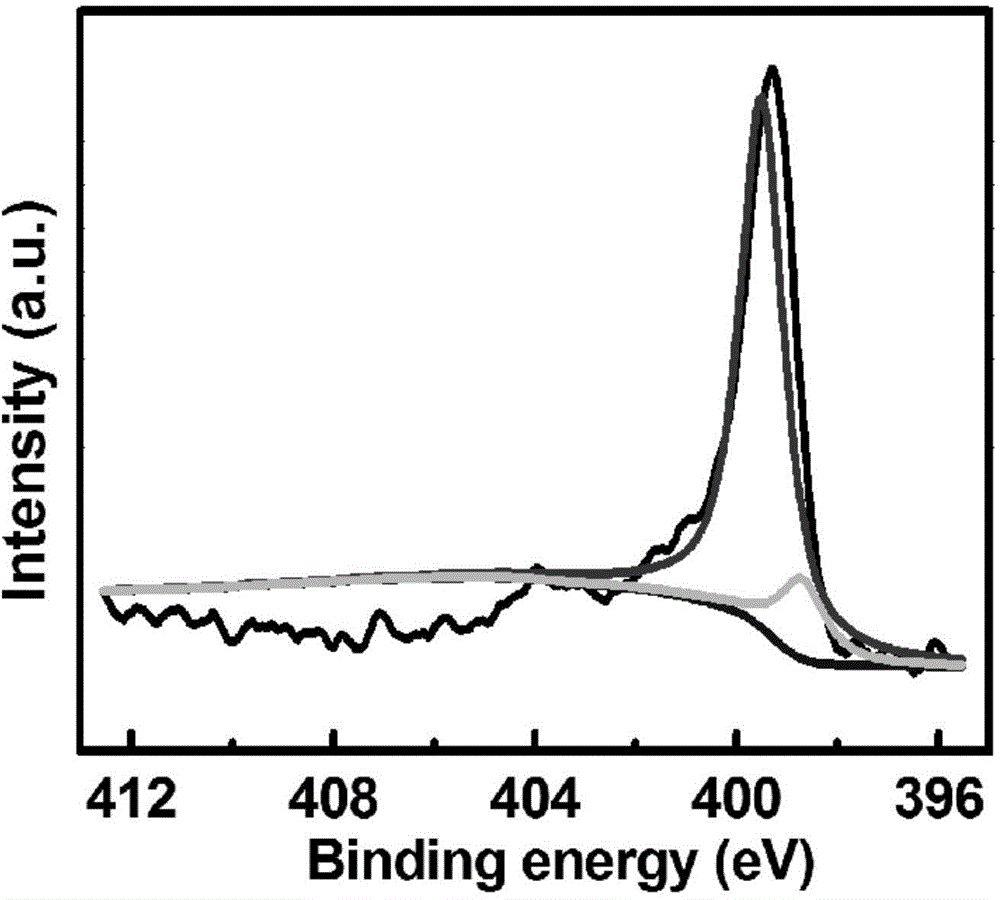

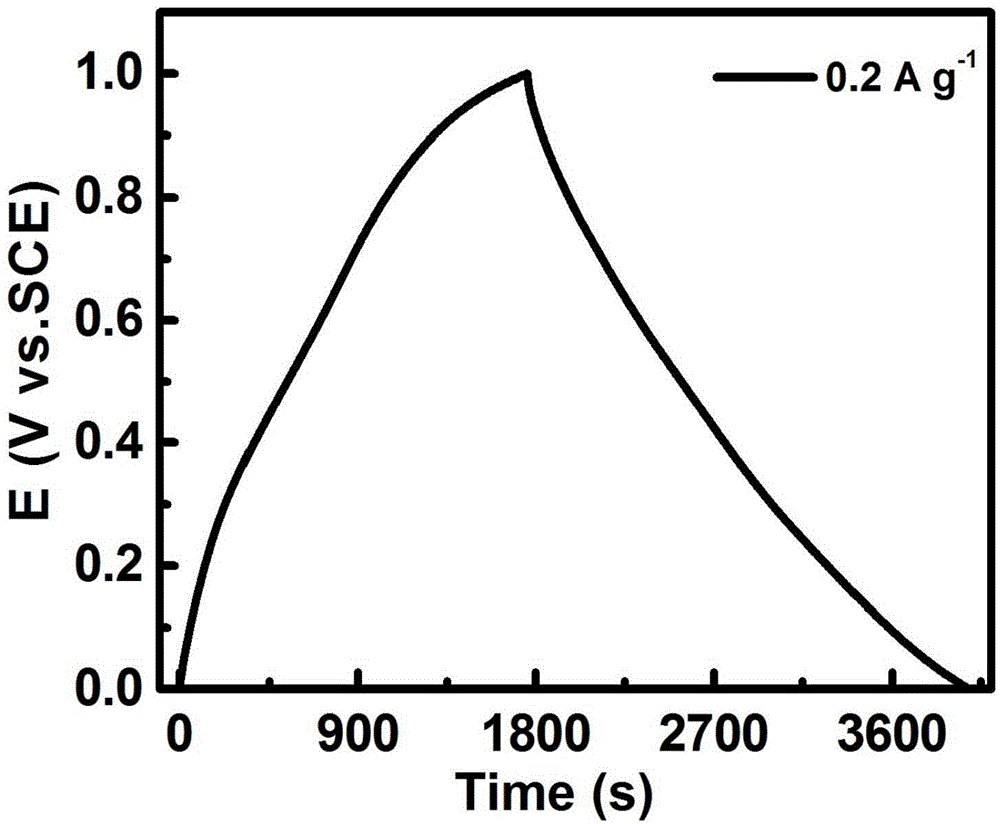

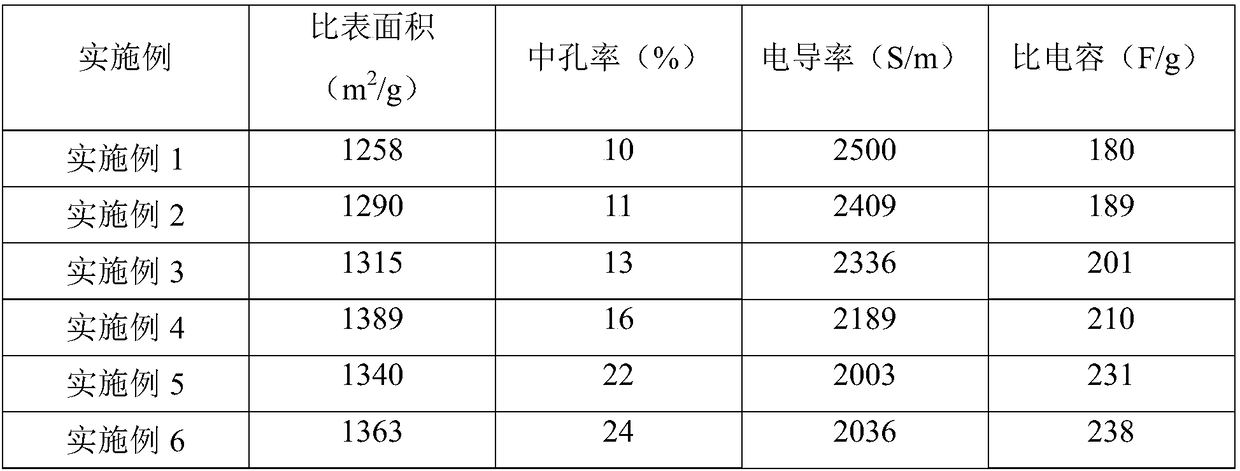

Nitrogen-containing carbon material for supercapacitosr, preparation method thereof, and supercapacitor electrode material

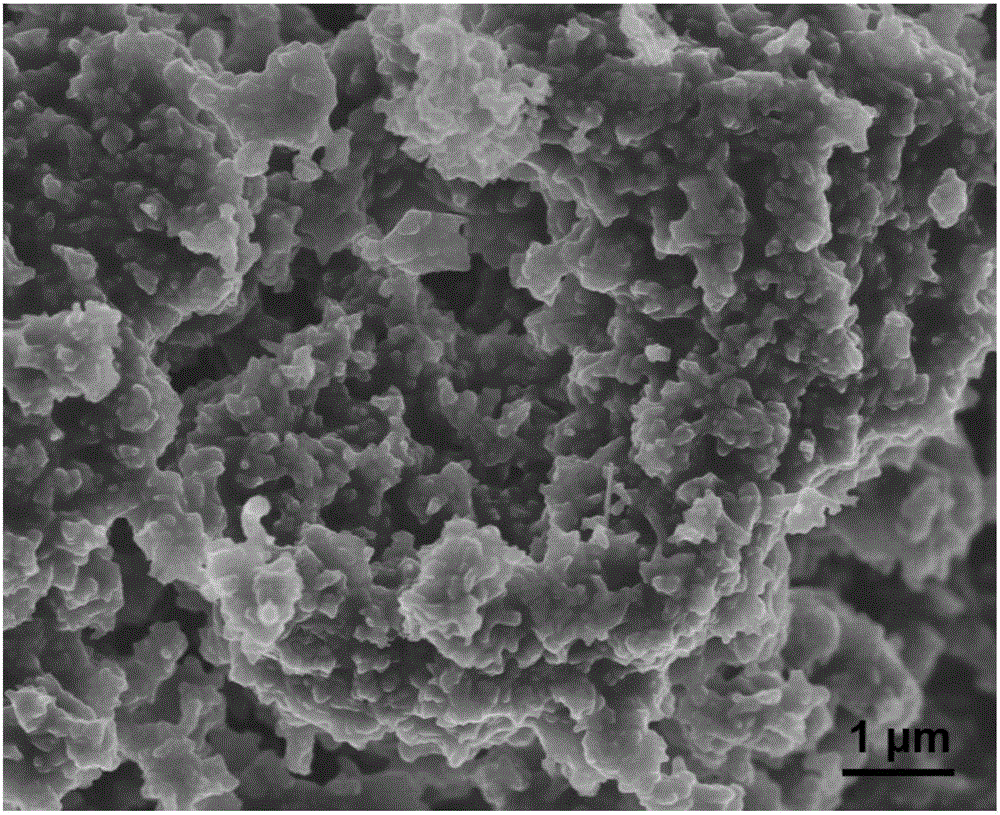

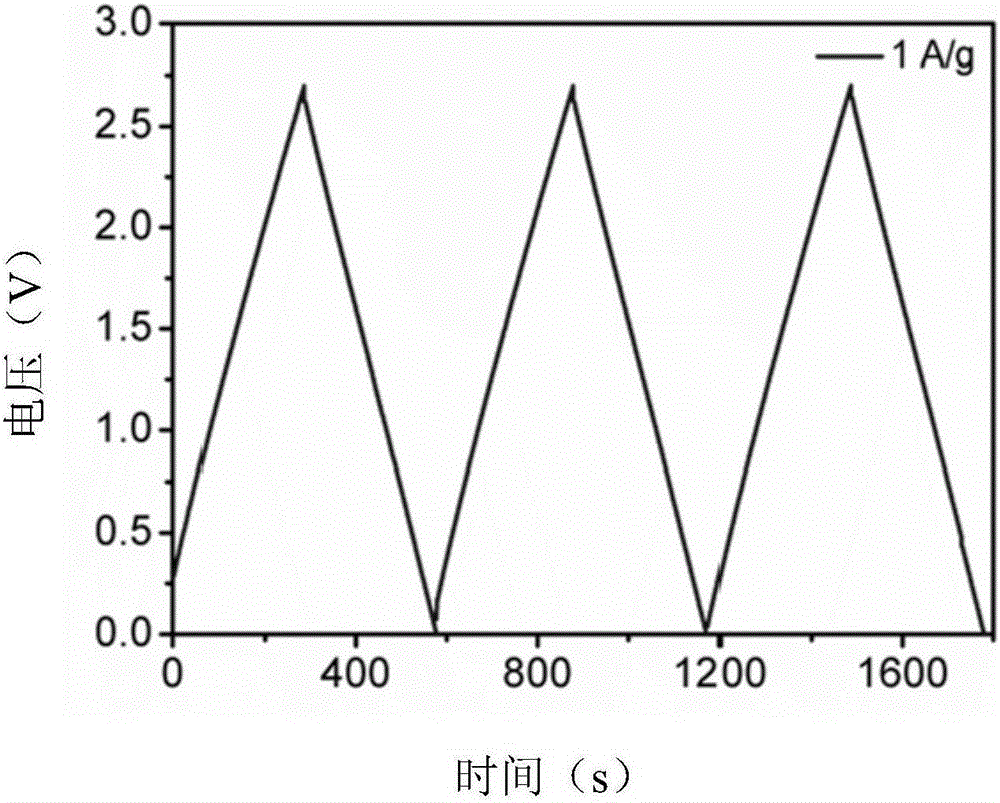

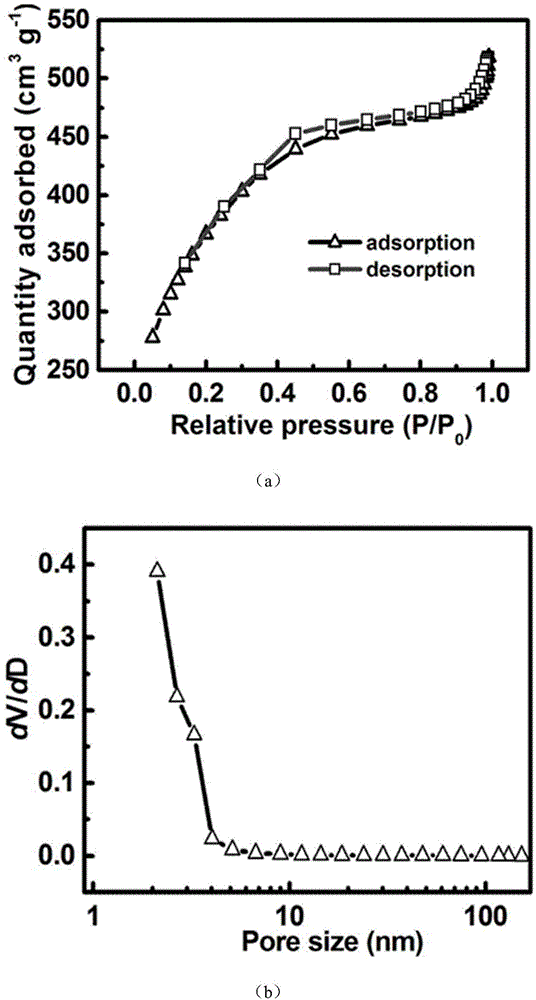

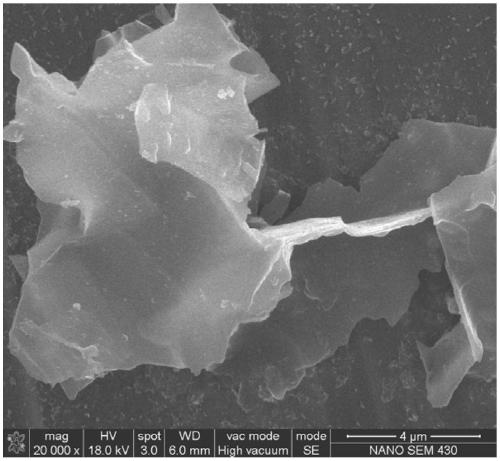

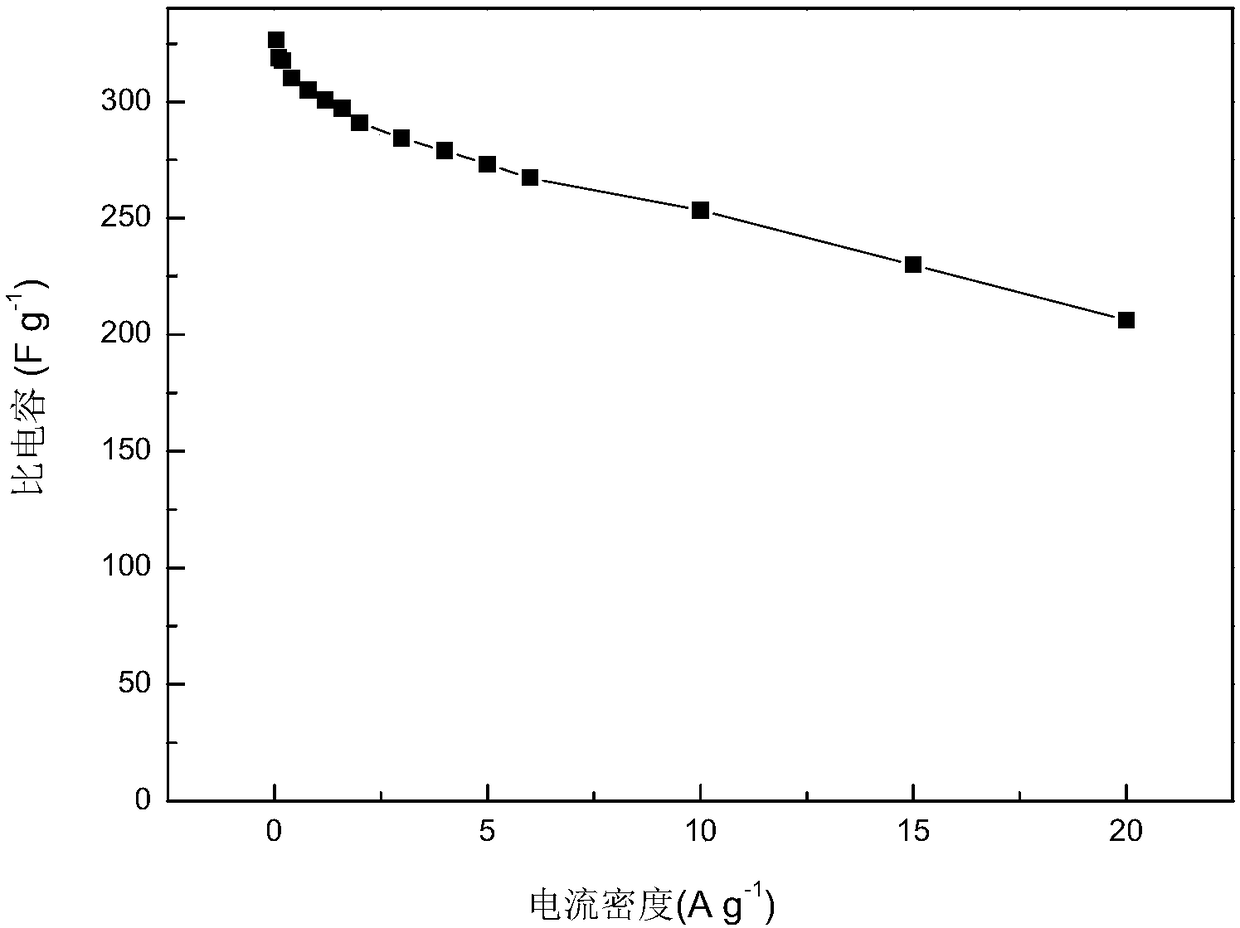

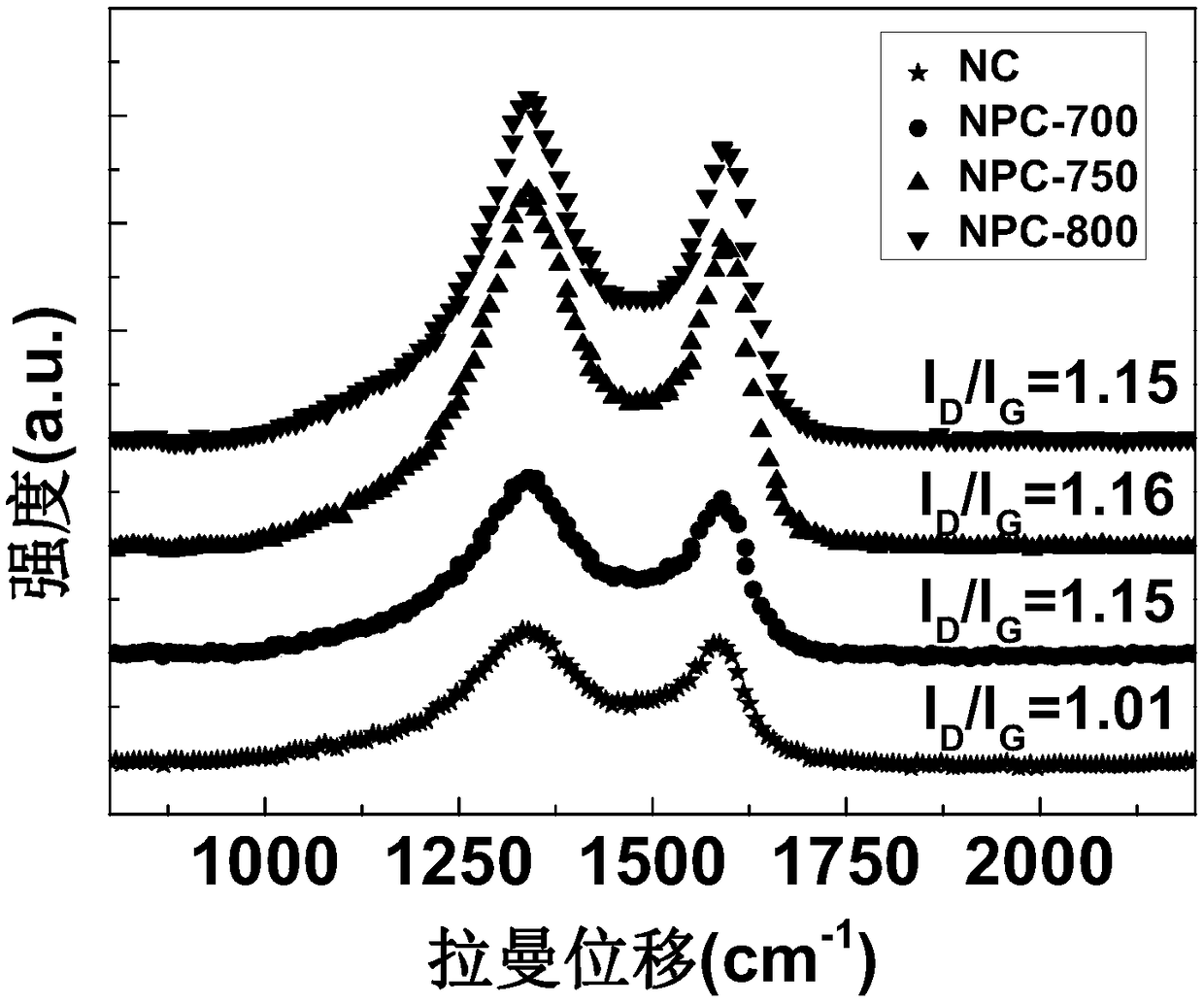

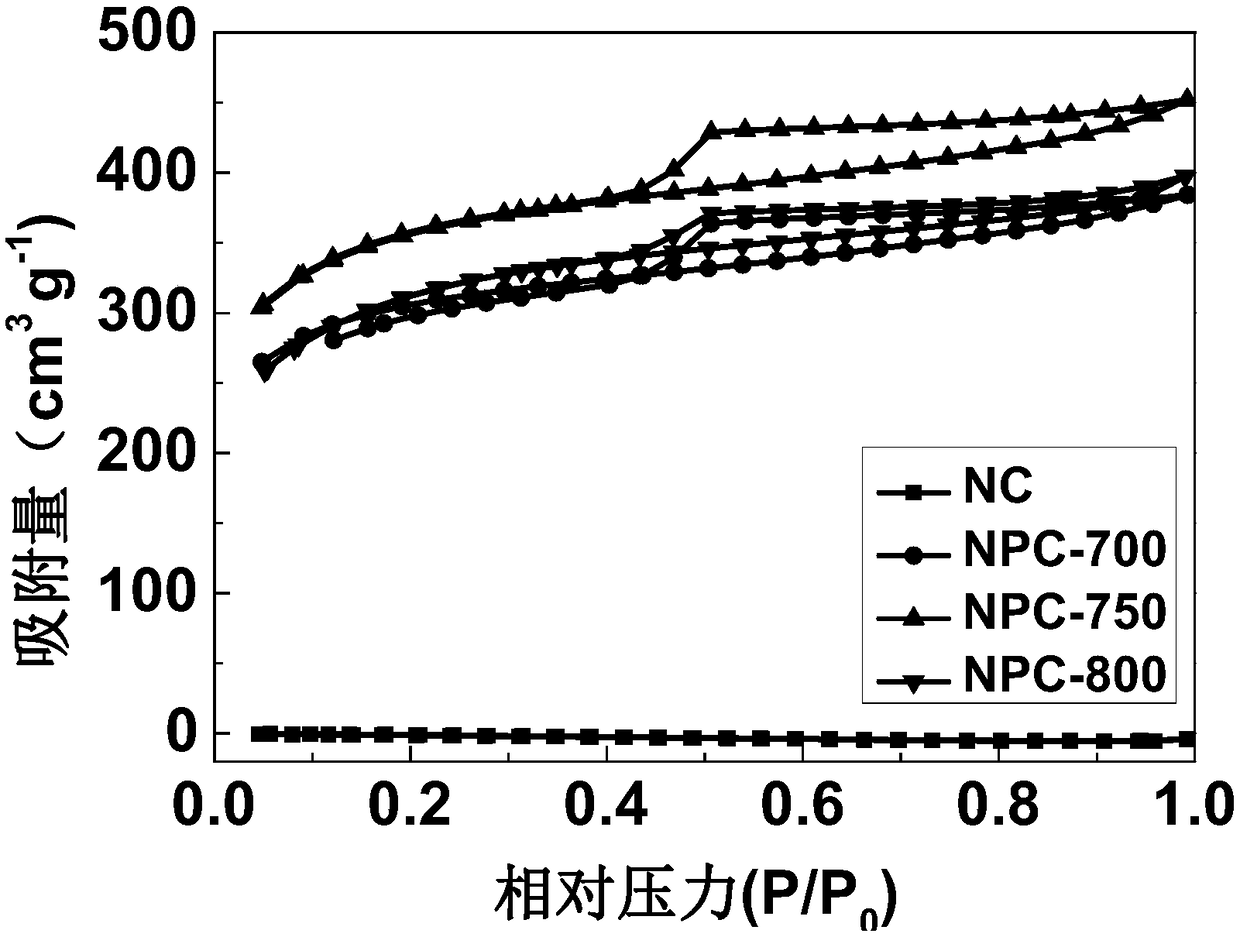

Belonging to the technical field of supercapacitors, the invention relates to a nitrogen-containing carbon material for supercapacitors, a preparation method thereof, and a supercapacitor electrode material. The preparation method of the nitrogen-containing carbon material for supercapacitors includes the steps of: 1) under the protection of an inert gas, subjecting a nitrogen-containing polymer to heat preservation at 500-900DEG C for 2-6 h to obtain a carbonization product; 2) mixing the carbonization product obtained in step 1) with an activating agent, conducting heat preservation under inert gas protection at 700-900DEG C for 1-2h, and performing cooling to obtain an activation product, with the carbonization product and the activating agent being in a mass ratio of 1:2-1:6; and 3) will step 2) washing the activation product obtained in step 2) with acid, and carrying out filtering and vacuum drying, thus obtaining the nitrogen-containing carbon material for supercapacitors. The preparation method provided by the invention increases the specific surface area of the nitrogen-containing carbon material.

Owner:深圳博磊达新能源科技有限公司 +1

Method for diagnosis and monitoring of disease activity and response to treatment in systemic lupus erythematosus (SLE) and other autoimmune diseases

InactiveUS20100233752A1Sensitive methodMicrobiological testing/measurementDisease diagnosisAutoimmune thyroid diseaseWhite blood cell

The present invention provides methods of diagnosing and monitoring systemic lupus erythematosus and drug-induced lupus erythematosus by measuring cell-based complement activation products in a subject's blood. In particular, the invention describes a diagnostic method employing the measurement of multiple complement activation products, such as C3d and C4d, on the surfaces of red blood cells, white blood cells, and platelets. Kits and automated systems for performing the methods of the invention are also disclosed.

Owner:EXAGEN DIAGNOSTICS +1

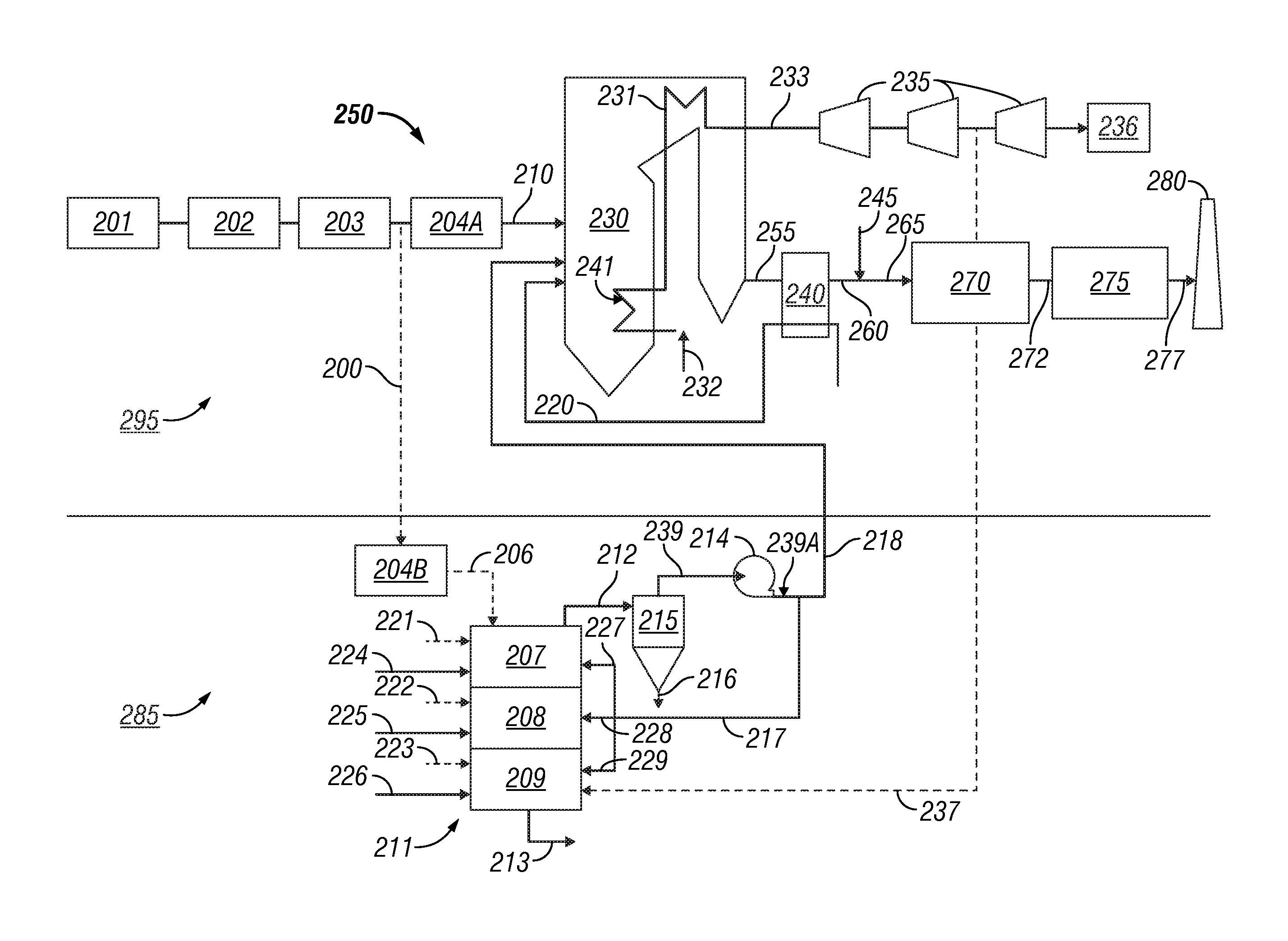

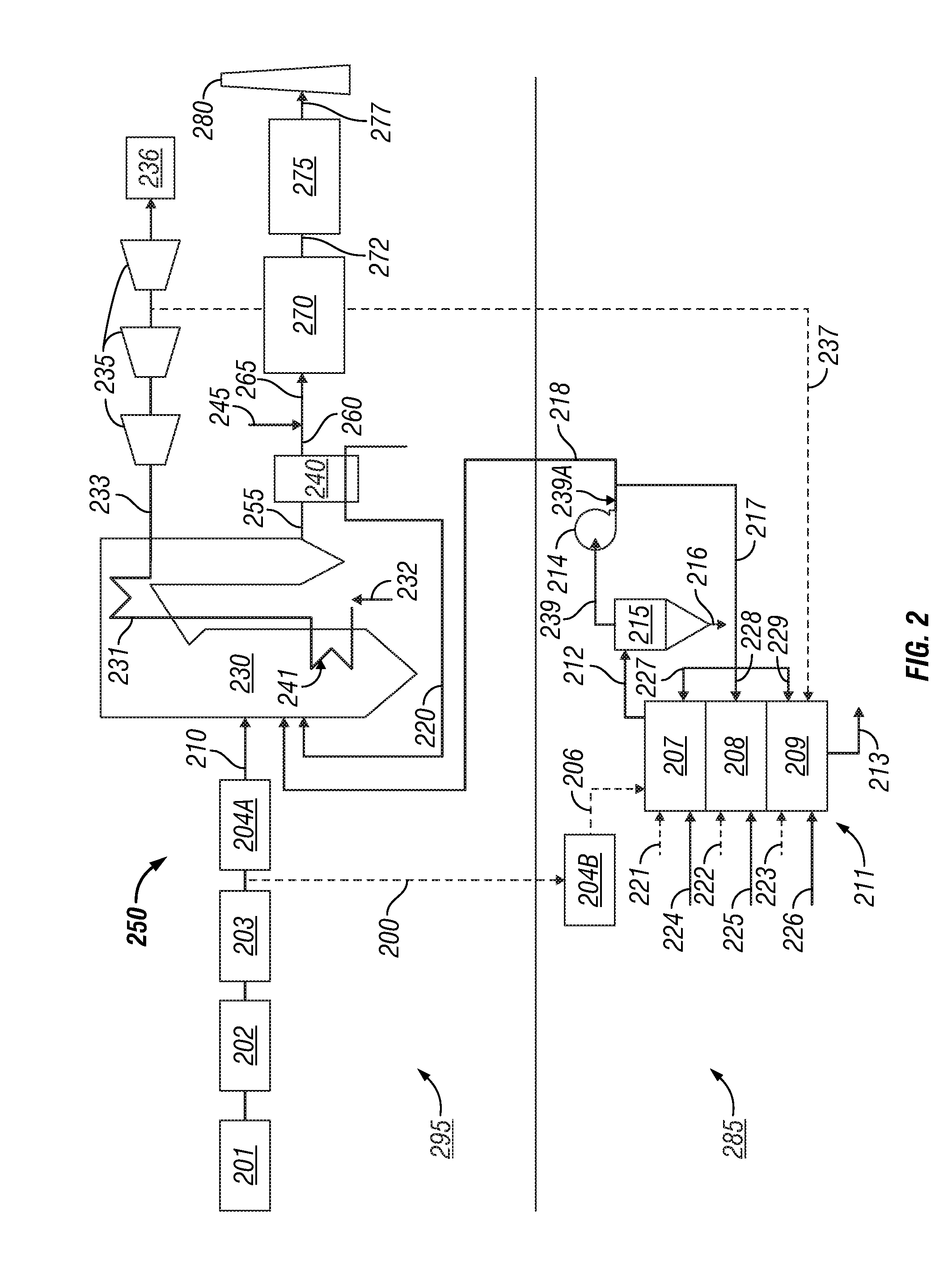

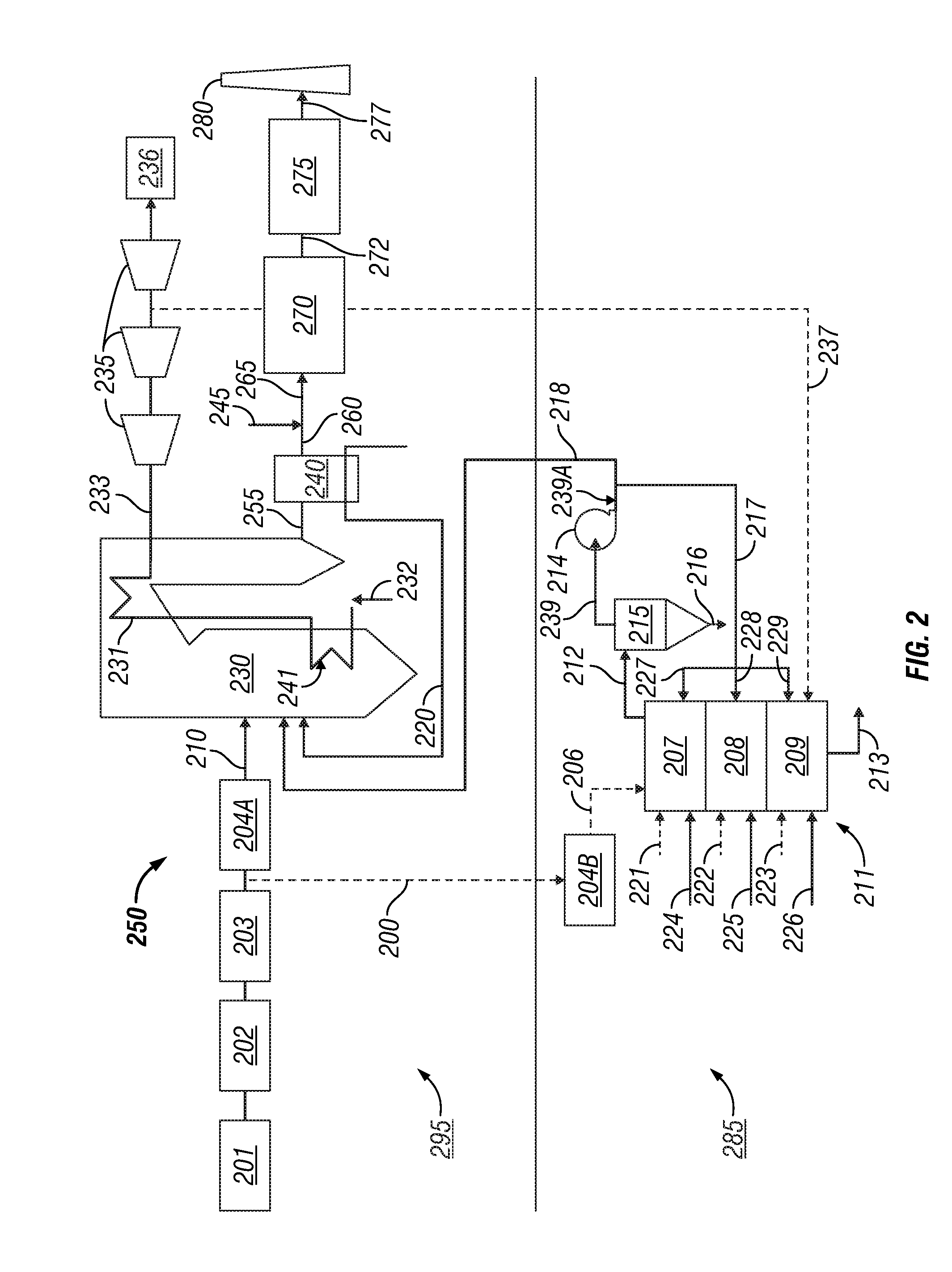

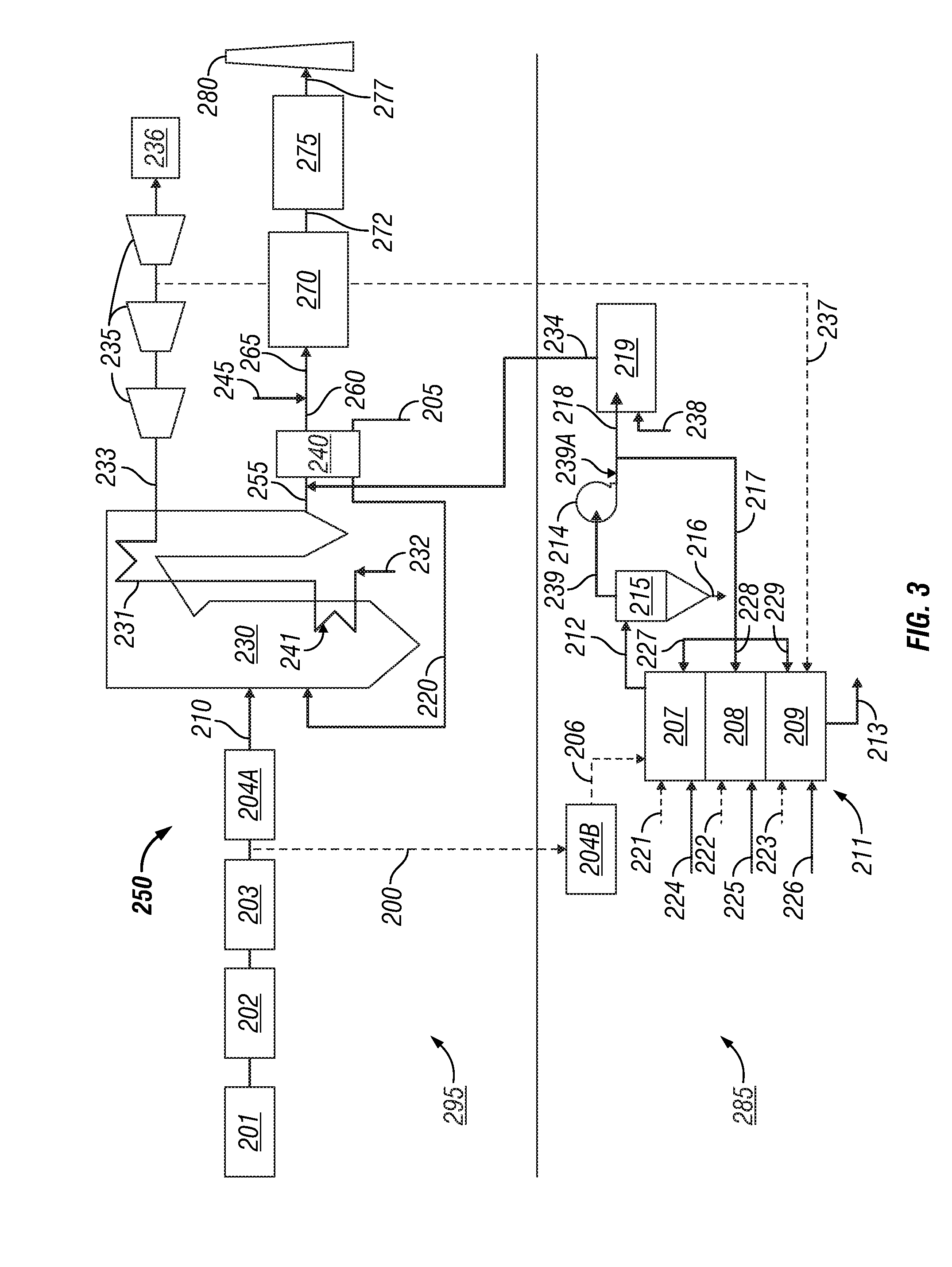

System and method for coproduction of activated carbon and steam/electricity

InactiveUS7981835B2Increase heat productionNo accumulationPigmenting treatmentSteam generation heating methodsCarbonizationBiological activation

A system and method for producing activated carbon comprising carbonizing a solid carbonaceous material in a carbonization zone of an activated carbon production apparatus (ACPA) to yield a carbonized product and carbonization product gases, the carbonization zone comprising carbonaceous material inlet, char outlet and carbonization gas outlet; activating the carbonized product via activation with steam in an activation zone of the ACPA to yield activated carbon and activation product gases, the activation zone comprising activated carbon outlet, activation gas outlet, and activation steam inlet; and utilizing process gas comprising at least a portion of the carbonization product gases or a combustion product thereof; at least a portion of the activation product gases or a combustion product thereof; or a combination thereof in a solid fuel boiler system that burns a solid fuel boiler feed with air to produce boiler-produced steam and flue gas, the boiler upstream of an air heater within a steam / electricity generation plant, said boiler comprising a combustion zone, a boiler-produced steam outlet and at least one flue gas outlet.

Owner:ENERGY & ENVIRONMENTAL RES CENT FOUNDATIO

Method for preparing activated carbon with large specific surface area through rapid activation

The invention relates to a method for preparing activated carbon with a large specific surface area through rapid activation. The activated carbon with a large specific surface area is prepared through rapidly activating high-carbon raw materials, such as anthracite, petroleum coke and the like, by auxiliaries and alkali together. The method comprises the steps of uniformly mixing the high-carbon raw materials, the activating auxiliaries and KOH, so as to obtain an alkali-carbon mixture, and heating the alkali-carbon mixture under the protection of an inert atmosphere, so as to obtain an activation product; quickly cooling the activation product to room temperature under the protection of the inert atmosphere; washing the activation product with water, and drying, thereby preparing the activated carbon with a large specific surface area. According to the method, the activation temperature is low, the activation time is short, a relatively high yield of activated carbon with a large specific surface area is obtained under the condition of a lower alkali / carbon ratio, the utilization ratio of alkali, carbon and energy is increased, the production cost is reduced, and the pollution is reduced.

Owner:DALIAN UNIV

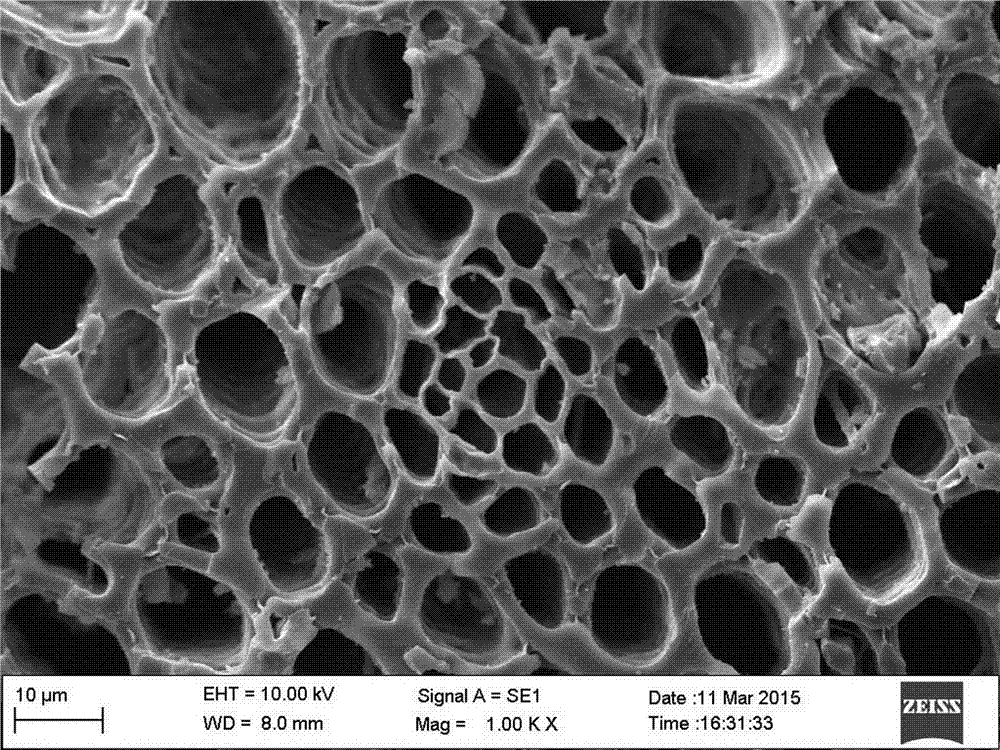

Method for preparing nitrogen-enriched porous carbon material for supercapacitor by taking lignite as raw material

The invention discloses a method for preparing a nitrogen-enriched porous carbon material for a supercapacitor by taking lignite as the raw material and belongs to the technical field of new energy. The method comprises the following steps: smashing the lignite, washing by deionized water to remove the surface impurities, washing and baking, heating up to a pre-carbonization temperature in an inert gas at the speed of 1-10 DEG C / min, and keeping the temperature for 2h to obtain the carbon precursor; grinding the carbon precursor, uniformly mixing with the alkali metal hydroxide, putting into the inert gas, heating up to an activation temperature in the inert gas at the speed of 1-10 DEG C / min, and keeping the temperature for 1-10h to obtain the activation product; and performing acid pickling and neutralization on the activation product, washing to be neutral by deionized water, drying and grinding to obtain the nitrogen-enriched porous carbon material for the supercapacitor. The high-performance nitrogen-enriched porous carbon material for the supercapacitor can be prepared from the lignite so that the nitrogen-enriched porous carbon material is excellent in performance, energy-saving, environmentally friendly, simple in process and low in cost and has a wide industrial application prospect by being used as the supercapacitor electrode material.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

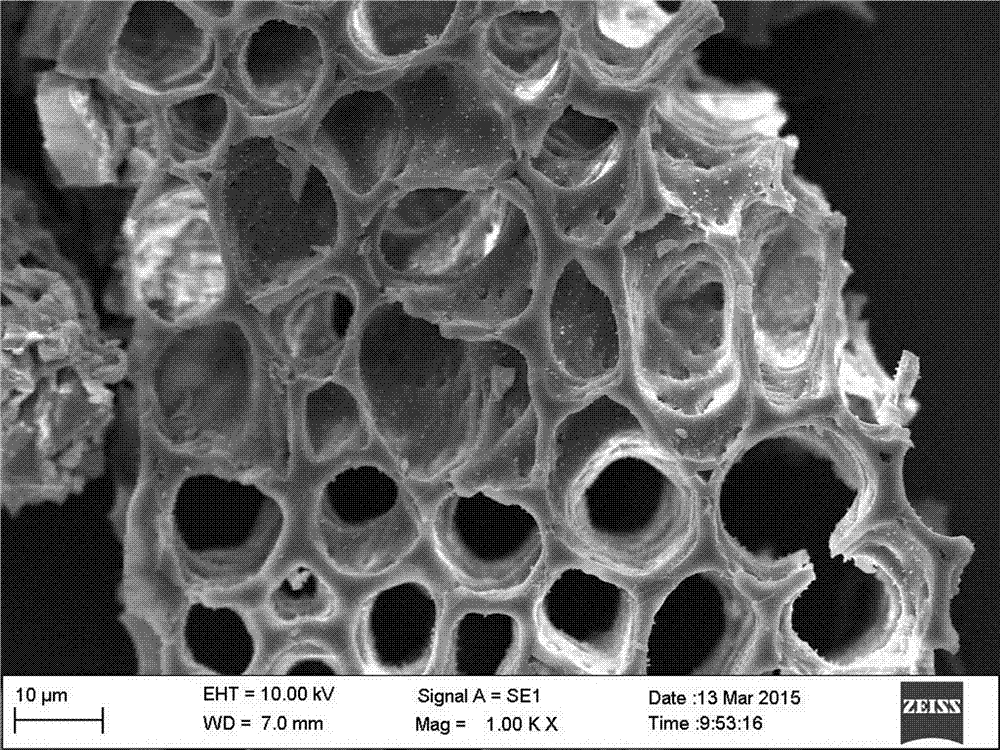

Method for preparing large-particle foam carbon by using corncob

The invention discloses a method for preparing large-particle foam carbon by using a corncob. The method specifically comprises the following steps: drying the corncob, crushing into corncob powder, and then mixing with a catalyst to react for 30-40 minutes; adding an adhesive to react for 60 minutes, then cooling and dehydrating to obtain biomass base expandable slurry; adding a surfactant, a foaming agent and a curing agent to mix and then pouring in a mold, foaming and curing for 15-30 minutes, and drying and curing for 20-30 minutes to obtain charring precursor; then charring at the temperature of 150-350 DEG C for 20-60 minutes, curing for 4 hours at 500-600 DEG C, washing an activation product to be neutral, and drying to obtain the large-particle foam carbon. The agricultural and forestry biomass material corncob is used as a foam carbon matrix, so the consumption of a petroleum base chemical product is reduced, and high value of low-value agricultural waste is realized; the prepared foam carbon has high aperture ratio, large specific surface and strong adsorption capacity and can be applied to the field of environmental engineering such as purification of polluted water body in place of conventional active carbon.

Owner:JIANGSU ACAD OF AGRI SCI

Method for preparing activated carbon by utilizing waste tire rubber

The invention discloses a method for preparing activated carbon by utilizing waste tire rubber, which separates the carbonization and activation processes in a preparation process, namely first performs carbonization and then activation. The method comprises the following steps of: 1) crushing the waste tire rubber into particles, placing the particles into reaction equipment, and carbonizing the particles in nitrogen atmosphere at a high temperature; 2) mixing the carbide and an activating agent, namely potassium hydroxide, grinding the mixture, and then performing high-temperature activation treatment in nitrogen atmosphere; and 3) cooling an activation product to room temperature in nitrogen atmosphere, acid-cleaning the activation product, then repeatedly washing the activation product to be neutral by using high-purity water, and drying the activation product to obtain a final activated carbon product. The method has the advantages of simple process, energy conservation, less environmental pollution, and low production cost; the prepared activated carbon has stable property and developed mesopores, and is particularly suitable for absorbing macromolecular compounds that activated carbon with ordinary coal quality fails to absorb and suitable to be used as a supporting material of microorganisms and a catalysts for preparing compound activated carbon; and the method fulfills the aim of changing waste into valuable, greatly increases the utilization value of the waste tire rubber, and has broad application prospect.

Owner:NANKAI UNIV

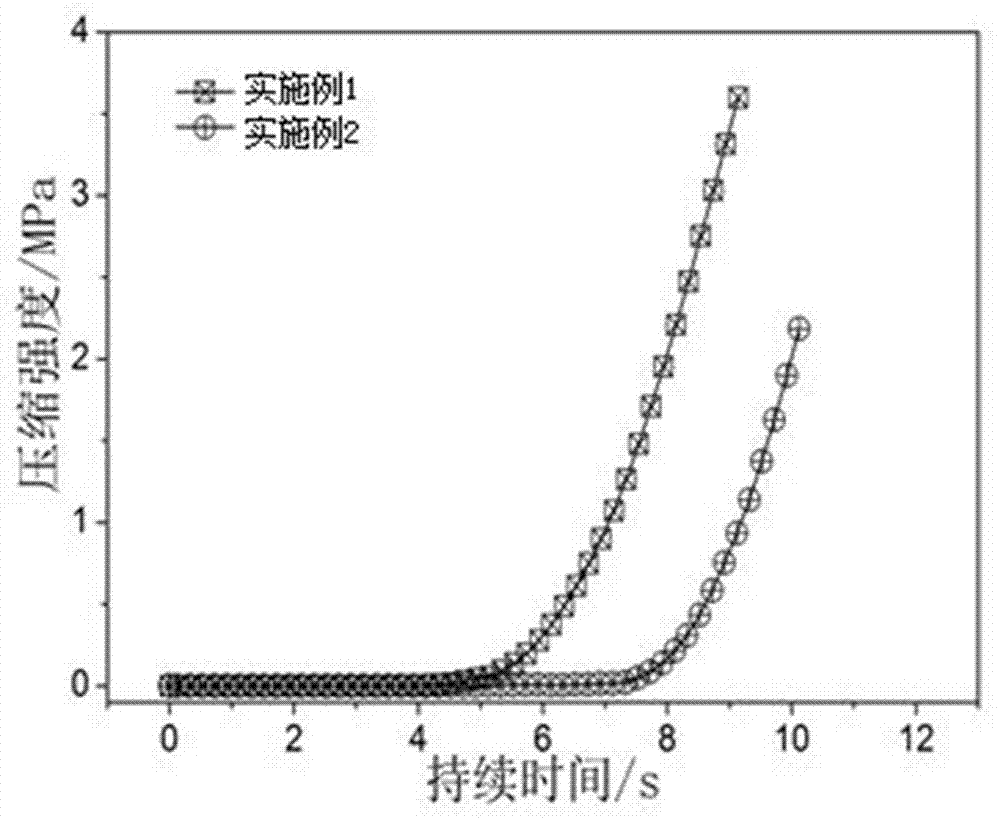

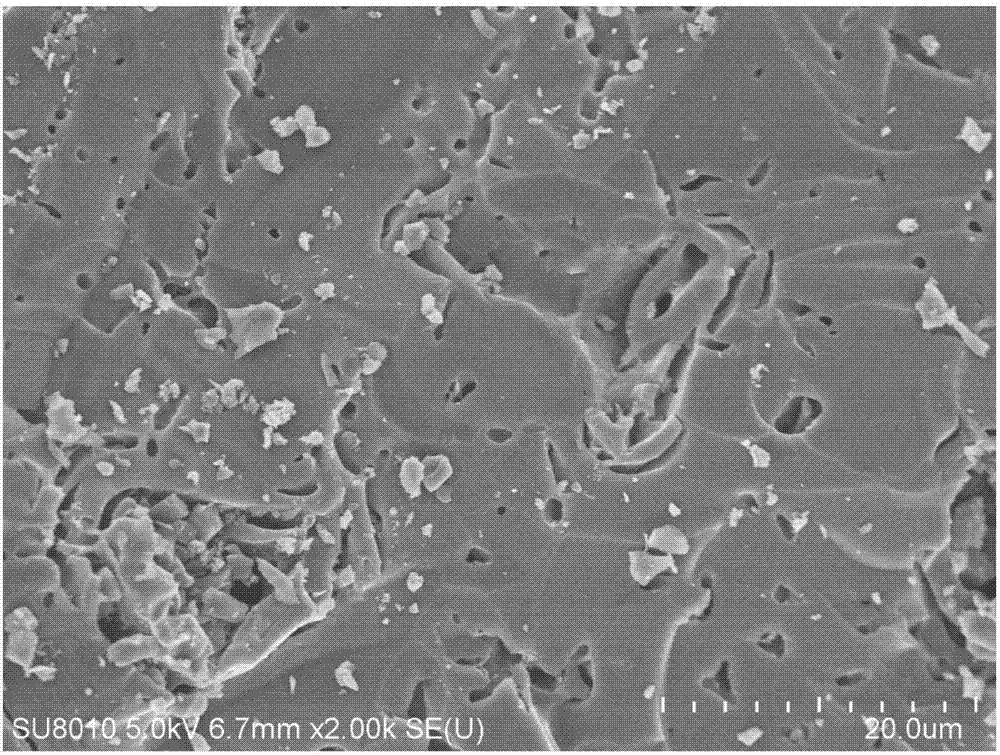

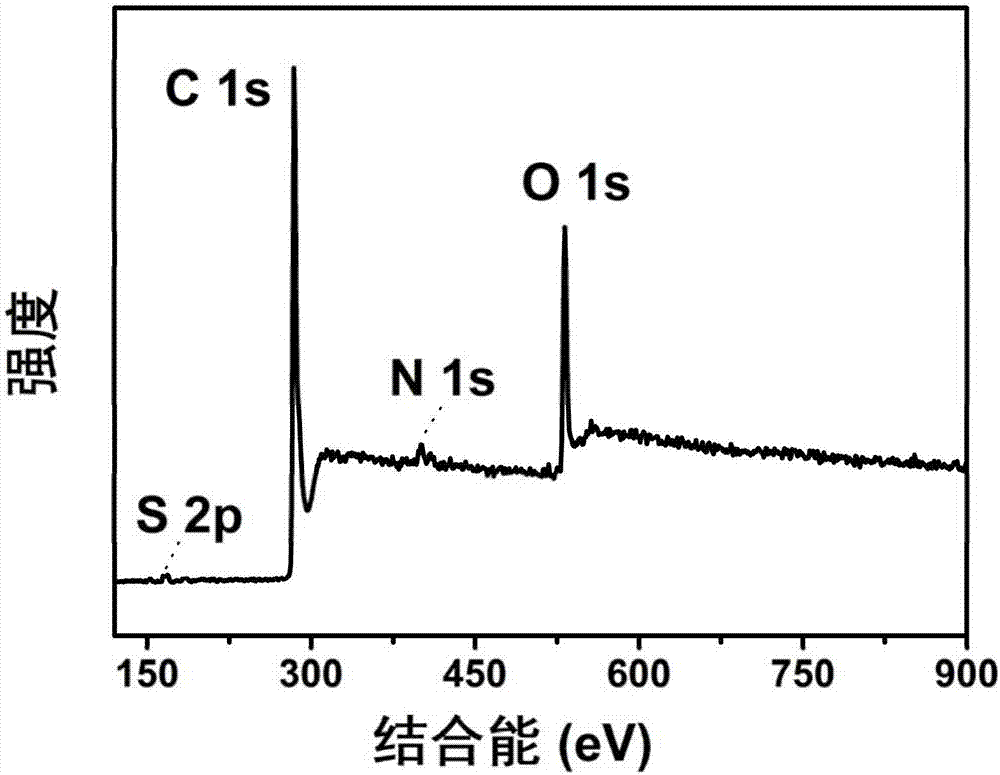

Method of preparing nitrogen and sulfur co-doped activated carbon for supercapacitor

The invention relates to a method of preparing nitrogen and sulfur co-doped activated carbon for a supercapacitor. The method comprises specific steps: (1) biomass cellulose and / or lignin powder are / is subjected to soaking treatment in a sulphuric acid-urea solution, and after drying, a dried product is obtained; (2) the dried product is subjected to preoxidation for 1 h under 250 DEG C to obtaina preoxidation product; (3) the preoxidation product is placed in a tube furnace and is subjected to carbonization for 2 h in an inert atmosphere under 600 DEG C to obtain a carbonization product; (4)the carbonization product and potassium hydroxide are mixed and are then placed in the tube furnace for activation for 1 h in the inert atmosphere under 800 DEG C to obtain an activation product; and(5) the activation product is placed in a hydrochloric acid solution for being stirred for 24 h, deionized water is then used for cleaning to neutrality, vacuum drying for 12 h under 60 DEG C is carried out, and thus, the nitrogen and sulfur co-doped activated carbon for the supercapacitor can be obtained. The method is simple and convenient to operate, the nitrogen and sulfur element doping proportion is easy to regulate, the yield of the prepared activated carbon is high, and when the activated carbon is used as a capacitor electrode material, the specific capacitance is high.

Owner:DONGHUA UNIV

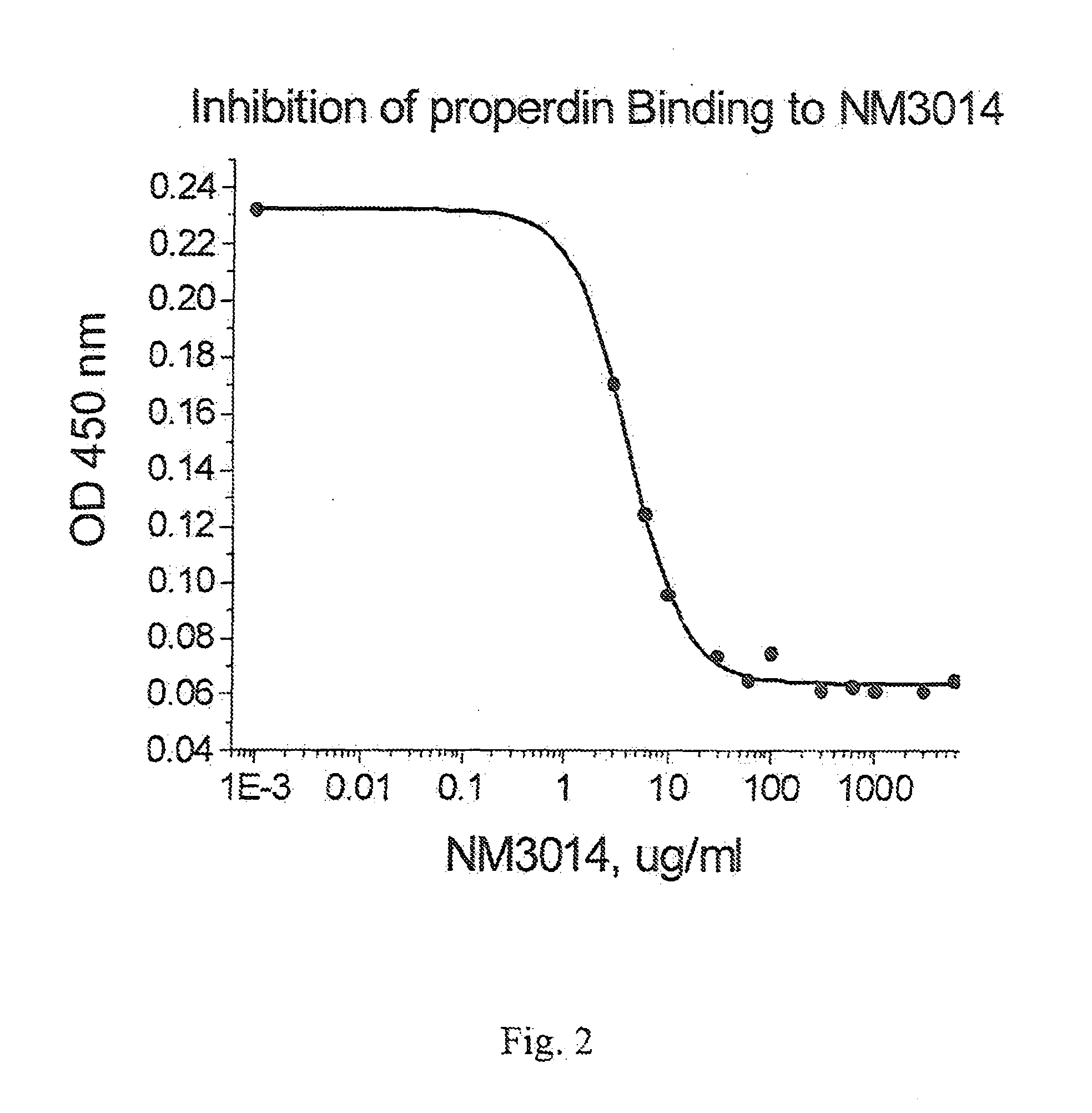

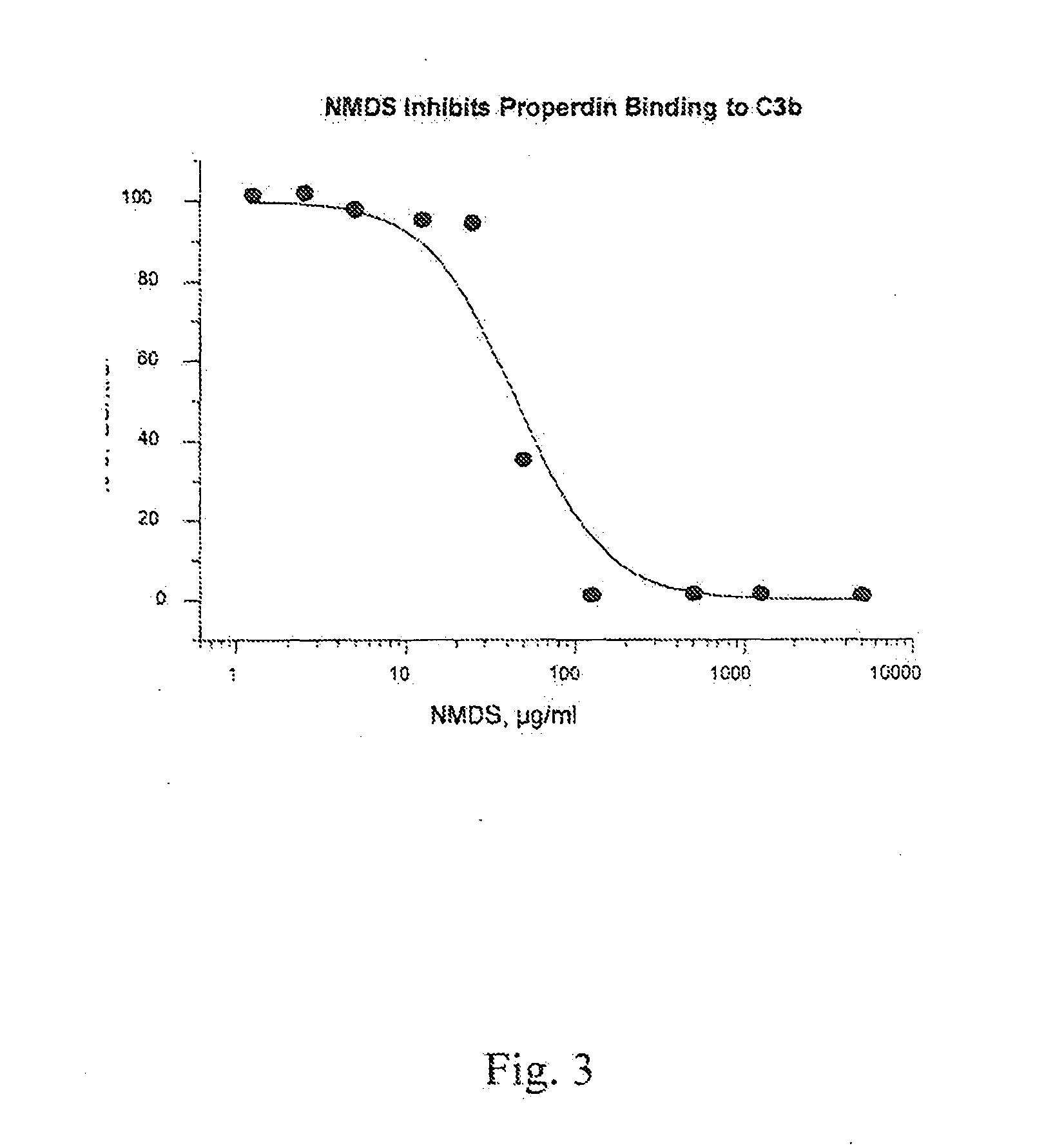

Methods and compositions of inhibiting complement and cellular activation with dextran sulfate

InactiveUS20100087393A1Minimized and reduced hemorrhagic propertyHigh selectivityBiocideOrganic active ingredientsBiological activationCell biology

A method of inhibiting the adverse effects of complement pathway, activation products in a subject comprising administering to the subject an amount of Dextran Sulfate effective to inhibit formation of alternative complement pathway activation product.

Owner:NOVELMED THERAPEUTICS

System and method for coproduction of activated carbon and steam/electricity

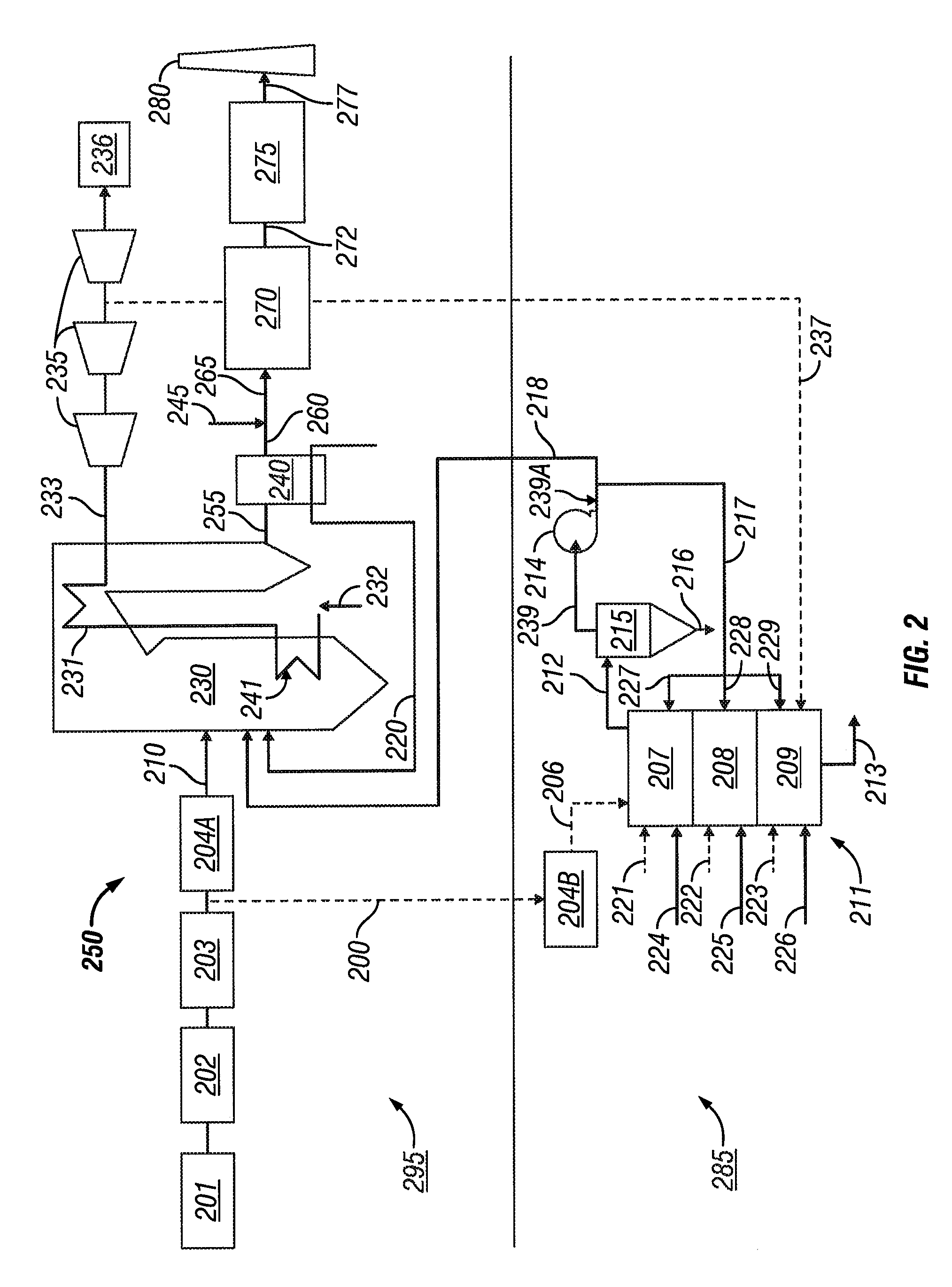

InactiveUS20090317320A1Increase heat productionReduce nitrogen oxide emissionsPigmenting treatmentSteam generation heating methodsCarbonizationBiological activation

A system and method for producing activated carbon comprising carbonizing a solid carbonaceous material in a carbonization zone of an activated carbon production apparatus (ACPA) to yield a carbonized product and carbonization product gases, the carbonization zone comprising carbonaceous material inlet, char outlet and carbonization gas outlet; activating the carbonized product via activation with steam in an activation zone of the ACPA to yield activated carbon and activation product gases, the activation zone comprising activated carbon outlet, activation gas outlet, and activation steam inlet; and utilizing process gas comprising at least a portion of the carbonization product gases or a combustion product thereof; at least a portion of the activation product gases or a combustion product thereof; or a combination thereof in a solid fuel boiler system that burns a solid fuel boiler feed with air to produce boiler-produced steam and flue gas, the boiler upstream of an air heater within a steam / electricity generation plant, said boiler comprising a combustion zone, a boiler-produced steam outlet and at least one flue gas outlet.

Owner:ENERGY & ENVIRONMENTAL RES CENT FOUNDATIO

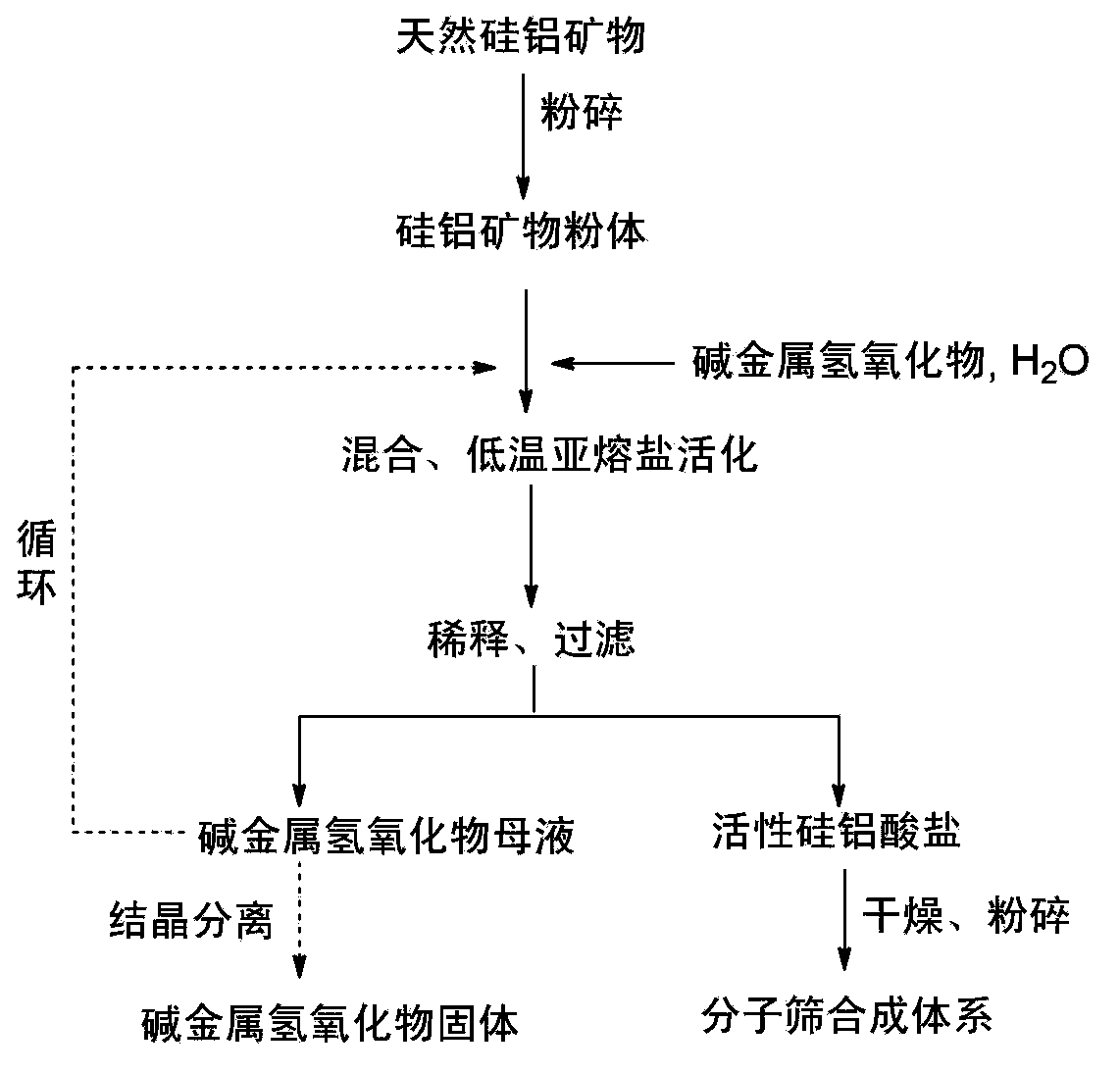

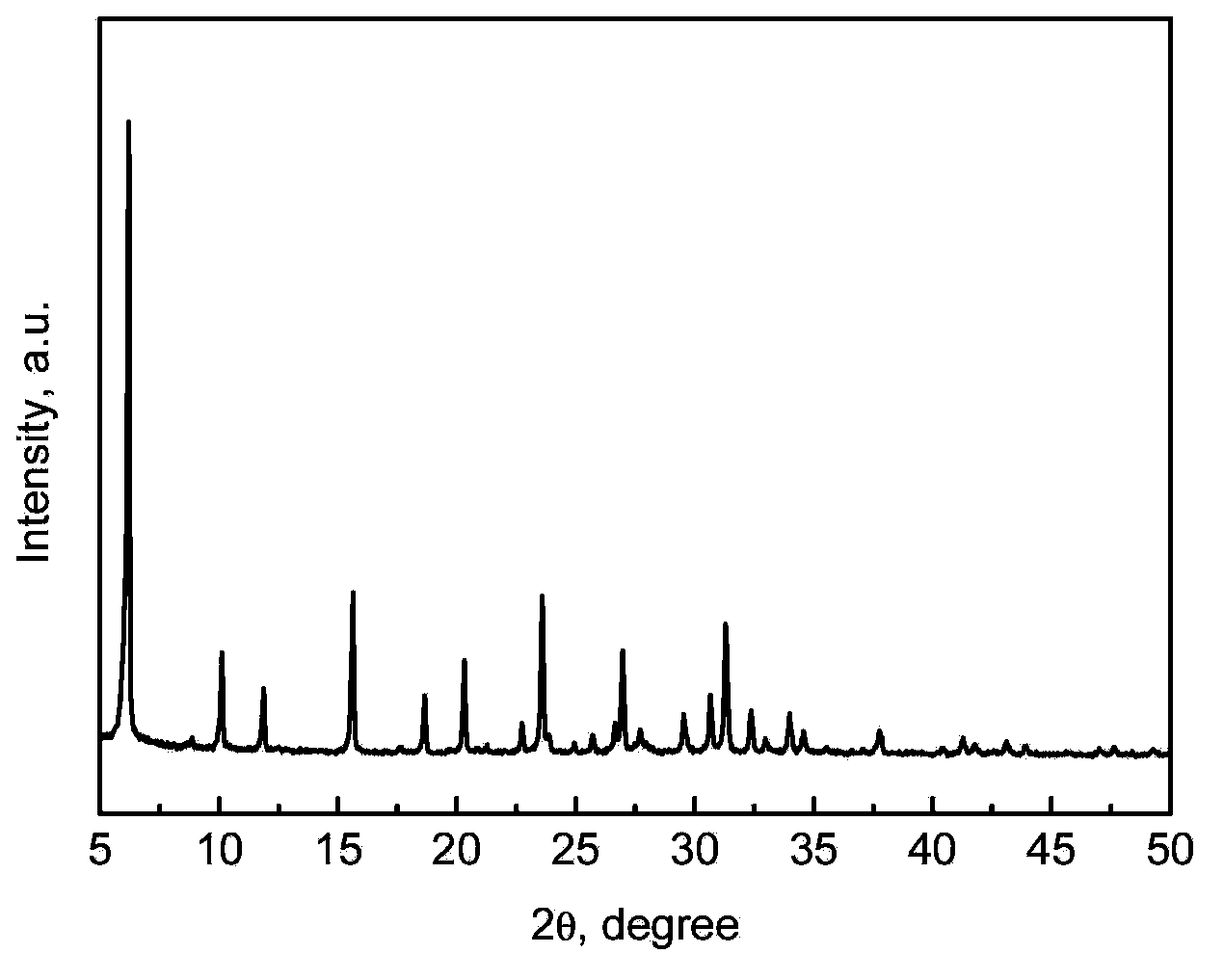

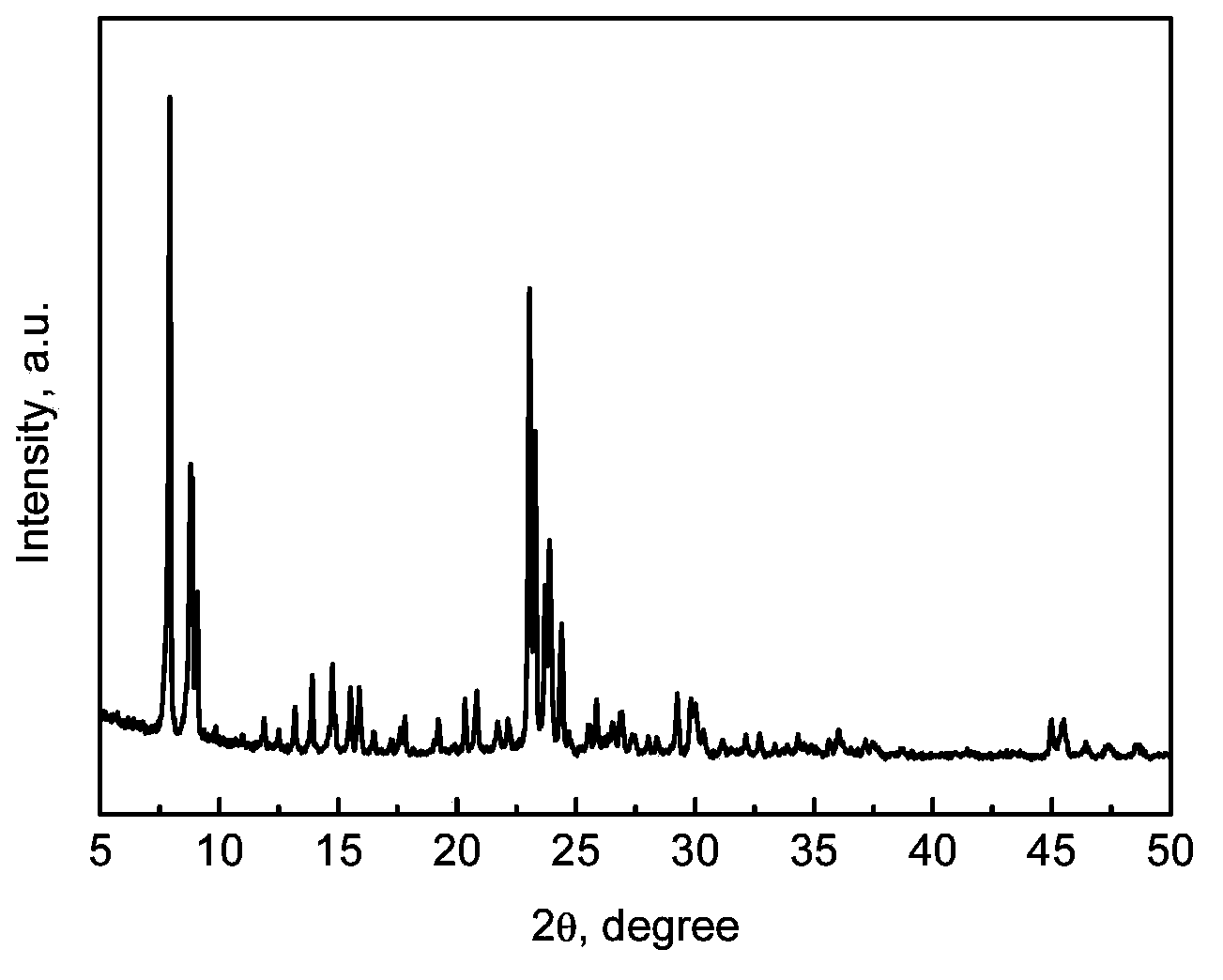

Preparation method for active aluminosilicate

InactiveCN103570032AWide variety of sourcesSimple processAluminium silicatesFaujasite aluminosilicate zeoliteHigh concentrationDecomposition

Belonging to the comprehensive utilization field of natural minerals, the invention provides a preparation method for active aluminosilicate. The method makes use of a sub-molten salt system to activate natural a silicon-aluminum mineral at low energy consumption and efficiently utilizes the activation product. The method adopts a high concentration alkaline solution as a medium to perform liquid phase activation reaction on a natural silicon-aluminum mineral so as to destroy the crystal structure of the natural silicon-aluminum mineral, thus forming the high activity aluminosilicate able to be used for molecular sieve synthesis. The decomposition temperature of the mineral is far below the roasting temperature of traditional thermal activation and alkali fusion activation, the crystal structure of the mineral can be fully destroyed at low temperature, simultaneous extraction of silicon and aluminum in the natural silicon-aluminum mineral can be realized, and the process is easy to operate. The method provided by the invention also extends the range of raw materials for molecular sieve preparation, not only greatly reduces the molecular sieve production cost, but also provides an effective way for high value added utilization of natural silicon-aluminum minerals.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

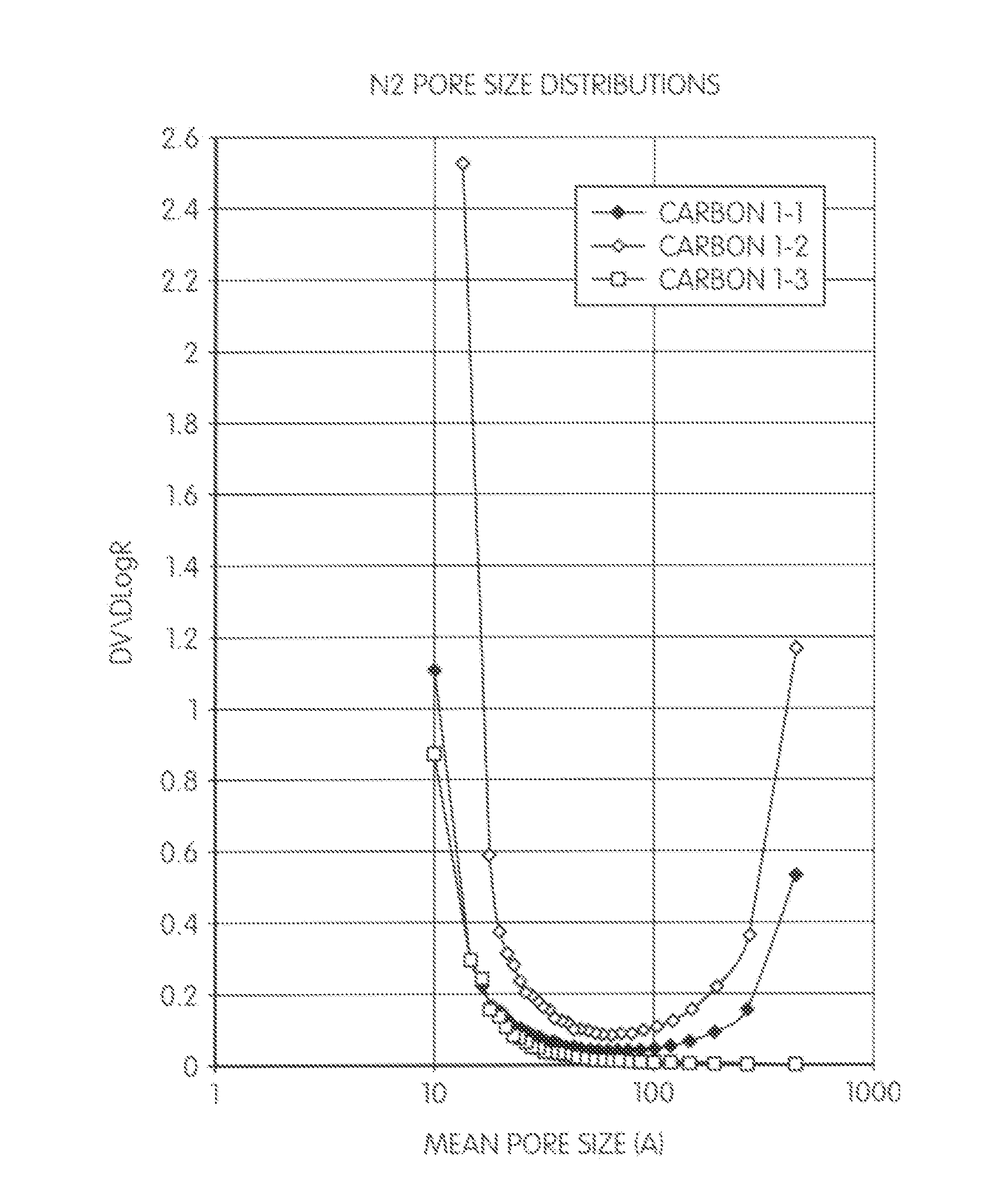

Porous carbons

InactiveUS20110097583A1Improve solubilityGood compatibilitySynthetic resin layered productsCellulosic plastic layered productsCross-linkPorous carbon

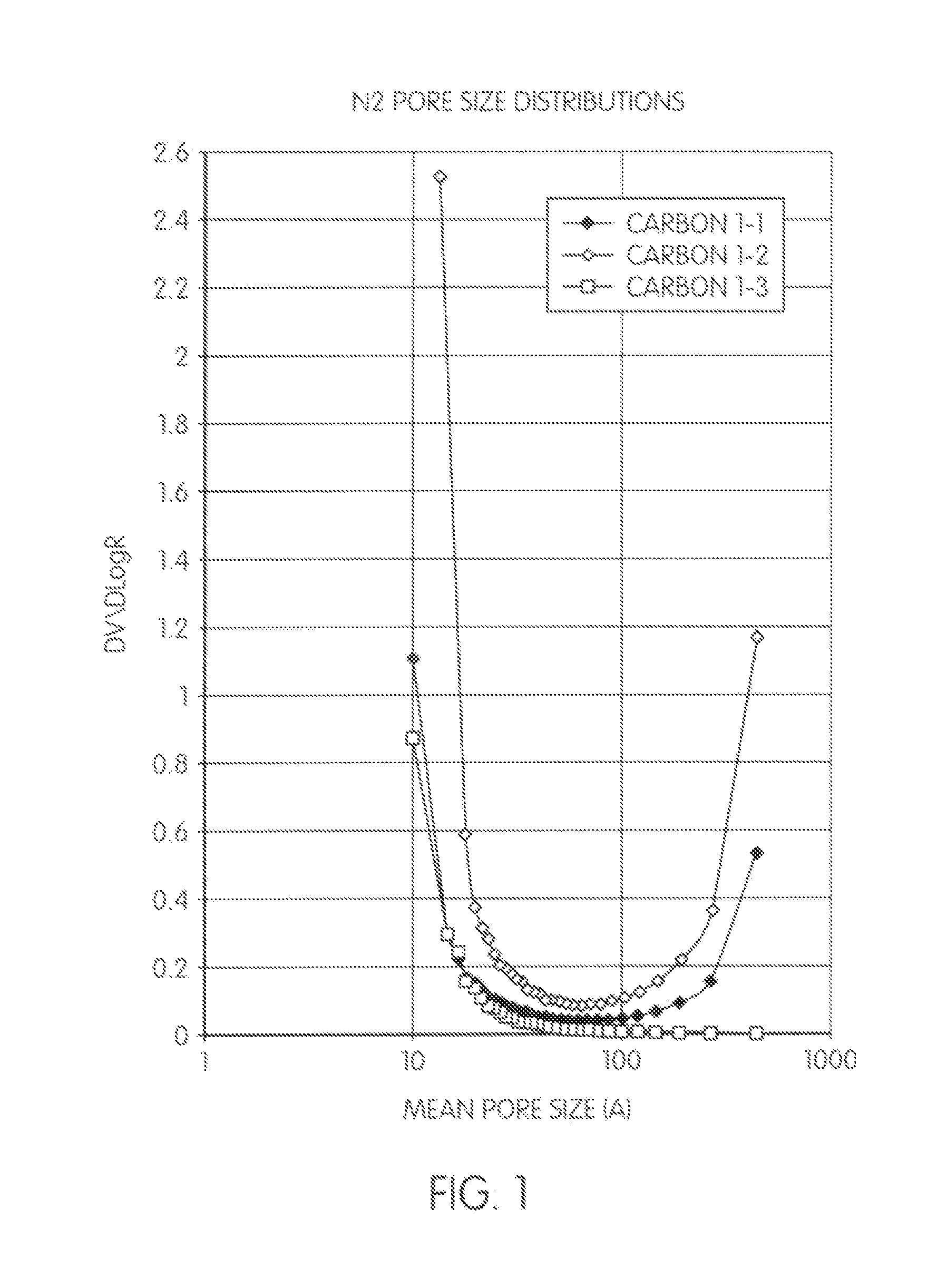

Porous carbon is provided which is a carbonization and optionally an activation product of a precursor resin, which has a pore structure that, as estimated by nitrogen adsorption porosimetry, comprises micropores and mesopores / macropores, said micropores and mesopores / macropores being in a bimodal distribution with few pores of size 2-10 nm, and the mesopores / macropores providing escape routes for volatile products during carbonisation of the precursor resin.The porous carbon can be made by a method which comprises (a) forming a precursor resin by reacting a nucleophilic component which comprises a phenolic compound or a phenol condensation prepolymer optionally with one or more modifying reagents with an electrophilic cross-linking agent selected from formaldehyde, paraformaldehyde, furfural and hexamethylene tetramine in solution in a pore former e.g. ethylene glycol so that a phase separation occurs between high molecular weight domains and voids of lower molecular weight material and the pore former increases the material in the voids and gives rise to the mesopores in the precursor resin; (b) removing the pore former from the precursor resin; and (c) carbonizing the precursor resin in an inert atmosphere at a temperature from 600° C. upwards, micropores developing during said carbonization so that the carbonized material comprises (a) micropores of diameter of up to 2 nm and (b) mesopores of diameter of 2-50 nm and optionally macropores of diameter >50 nm.

Owner:BRITISH AMERICAN TOBACCO (INVESTMENTS) LTD

Preparation method of doped high-specific-surface-area activated carbon

The invention provides a preparation method of doped high-specific-surface-area activated carbon, belonging to the technical field of chemical industry production. The method comprises the following steps: mixing a pulverized carbonous raw material with KOH to obtain an alkali carbon mixture; heating to 700-850 DEG C at the rate of 2-15 DEG C / minute in an inert gas or mixed gas atmosphere under normal pressure, and activating for 0.5-4 hours; cooling the activating furnace to 25-40 DEG C, and introducing a de-intercalation reagent and metal potassium in the activation product to react until all the metal potassium reacts; cooling the activating furnace to room temperature, and taking out the solid material; and washing the solid material with hydrochloric acid, washing with deionized water until the pH value of the filtrate is 6-7, and drying to obtain the doped high-specific-surface-area activated carbon. By introducing the de-intercalation reagent, the specific heteroatoms or heteroatom groups are introduced into the activated carbon, thereby implementing safe conversion of metal potassium and obtaining the doped high-specific-surface-area activated carbon with specific pore structure and surface properties.

Owner:DALIAN UNIV OF TECH

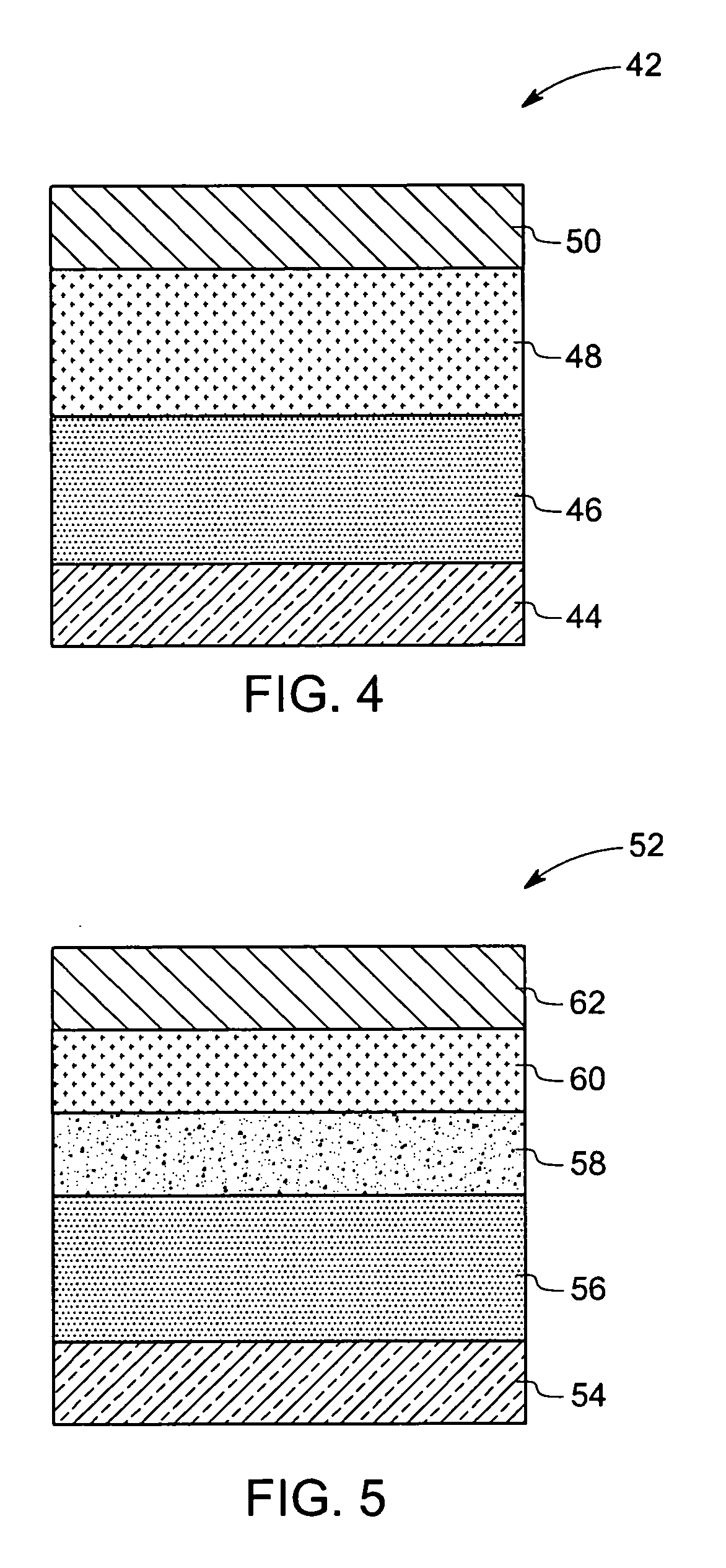

Organic light emitting devices having latent activated layers

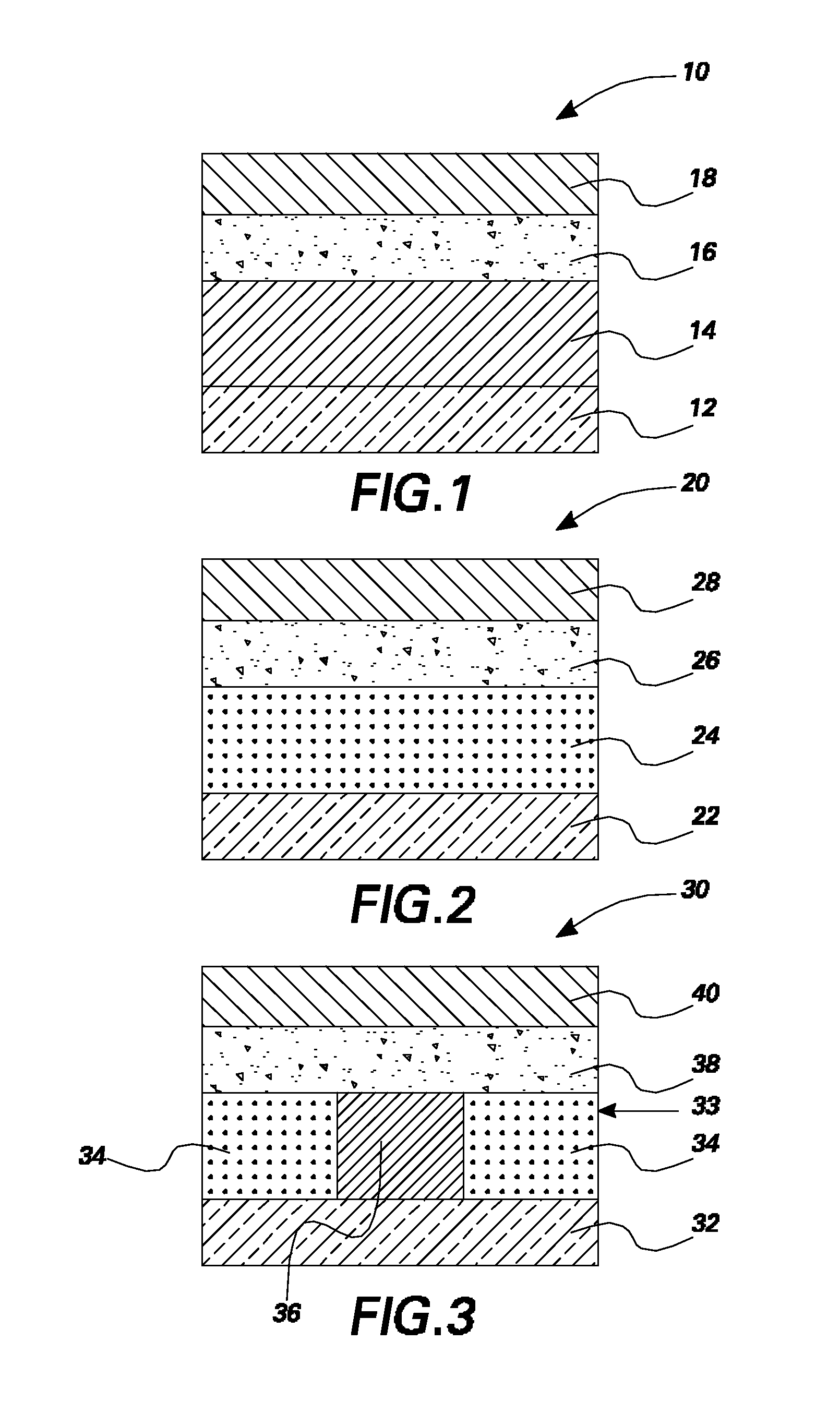

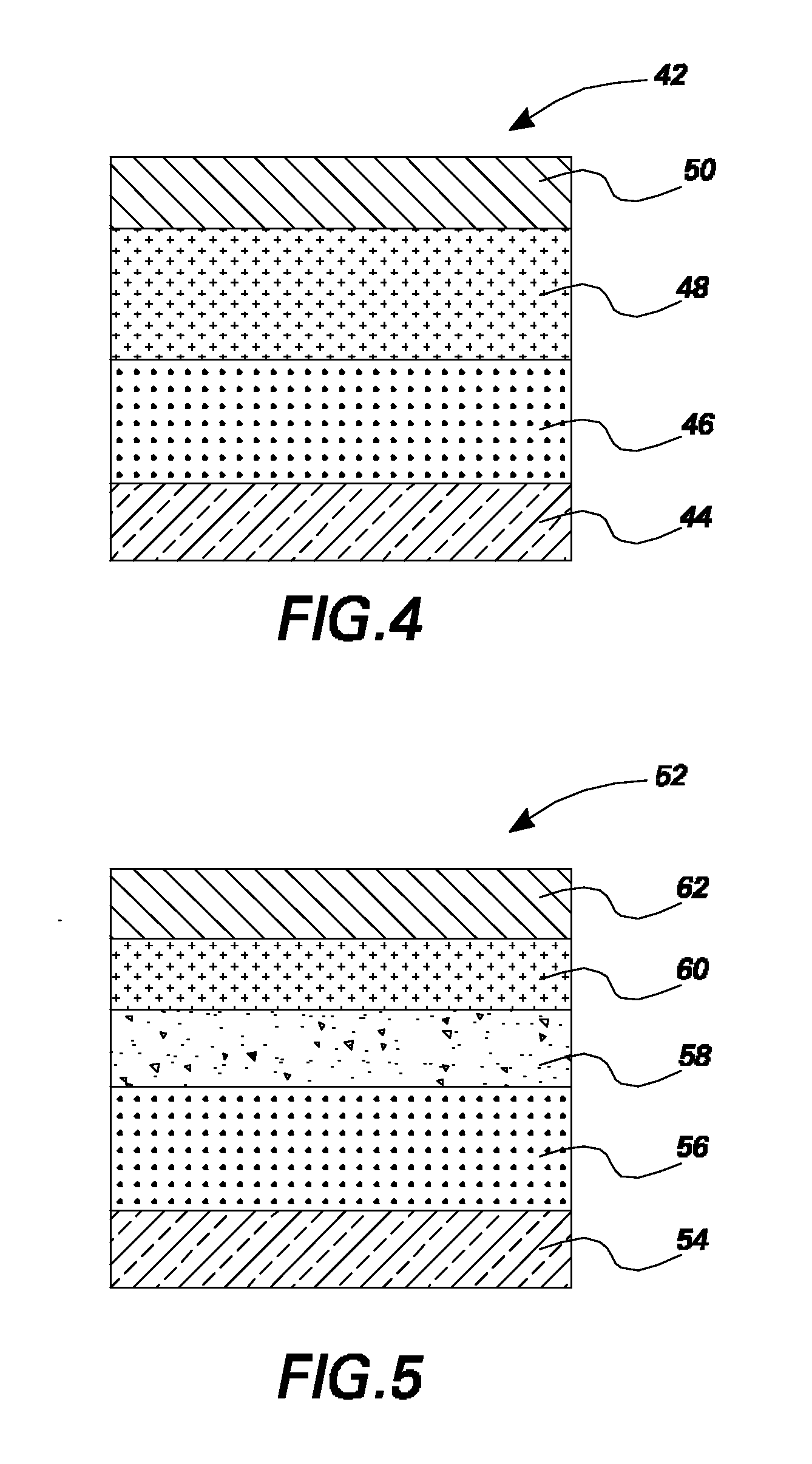

InactiveUS20070075628A1Improve conductivityConvenient lightingDischarge tube luminescnet screensLamp detailsOrganic light emitting deviceBiological activation

An organic light emitting device with a latent activator material is presented. An organic light emitting device including activation products of a latent activator material is also presented. Embodiments of patterned organic light emitting devices are also contemplated wherein patterning can occur prior or post fabrication of the devices. A method of fabricating an organic light emitting device with a latent activator material or with activation products of an activator material is also provided.

Owner:GENERAL ELECTRIC CO

Method and system for treating circuit board

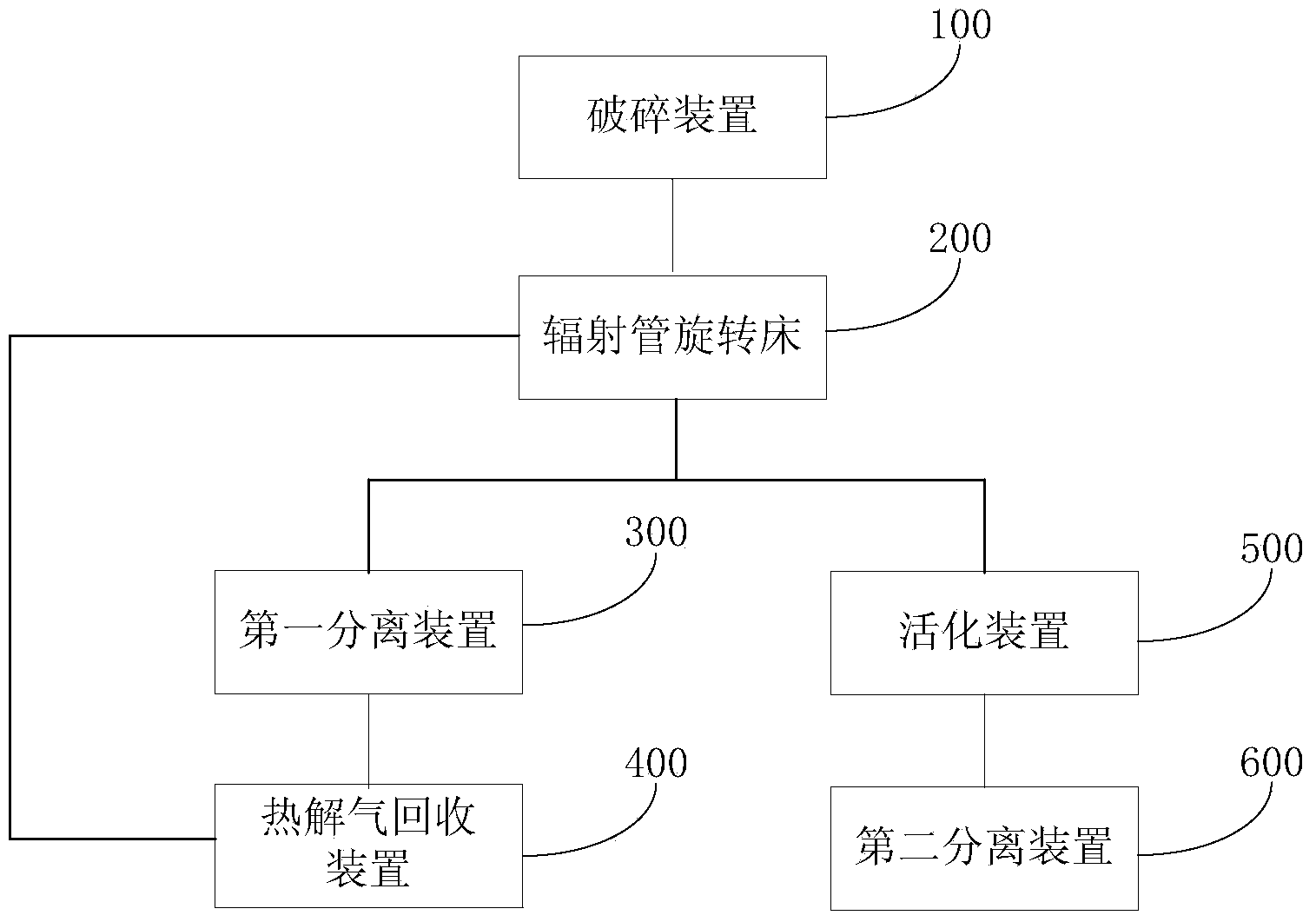

ActiveCN103846273AEnables continuous processingMaximize utilizationWaste processingSolid waste disposalGlass fiberActivated carbon

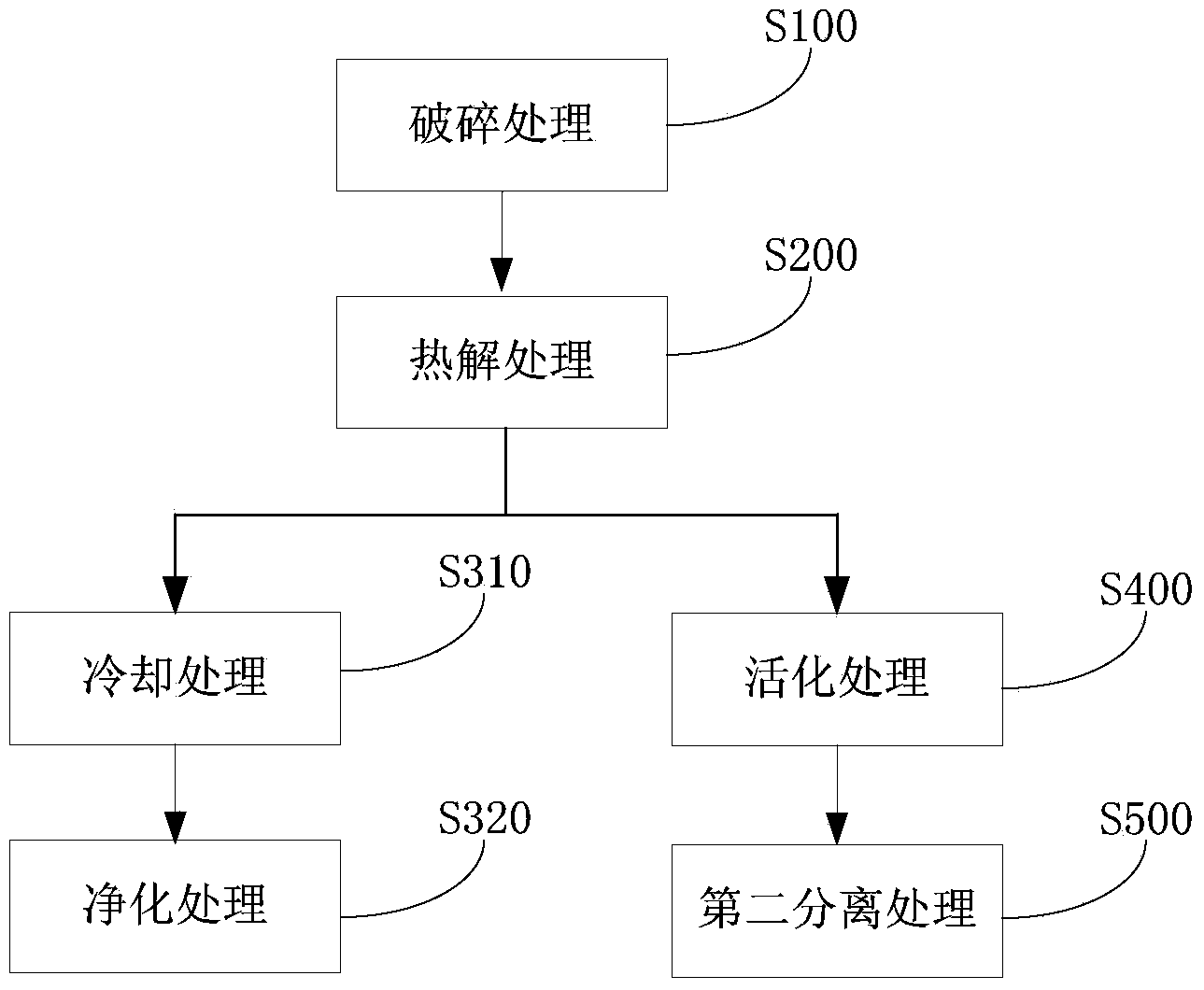

The invention discloses a method and a system for treating a circuit board. The method comprises the following steps: (1) breaking the circuit board; (2) pyrolyzing the broken circuit board in a radiant tube revolving bed to obtain high-temperature oil gas and a solid mixture; (3) performing first separation on the high-temperature oil gas to respectively obtain pyrolysis oil and pyrolysis gas and supplying the pyrolysis gas to the radiant tube revolving bed to be used as fuel; (4) contacting flue gas with the obtained solid mixture to activate the solid mixture, thereby transforming the pyrolysis carbide in the solid mixture into activated carbon; (5) performing second separation on activation products so as to respectively obtain activated carbon, metal and inorganic glass fibers. According to the method disclosed by the embodiment of the invention, circuit board resources can be recovered and energy can be utilized to the maximum.

Owner:SHENWU TECH GRP CO LTD

System and method for coproduction of activated carbon and steam/electricity

InactiveUS20100113267A1Increase heat productionNo accumulationCarbon compoundsSteam useCarbonizationBiological activation

A system and method for producing activated carbon comprising carbonizing a solid carbonaceous material in a carbonization zone of an activated carbon production apparatus (ACPA) to yield a carbonized product and carbonization product gases, the carbonization zone comprising carbonaceous material inlet, char outlet and carbonization gas outlet; activating the carbonized product via activation with steam in an activation zone of the ACPA to yield activated carbon and activation product gases, the activation zone comprising activated carbon outlet, activation gas outlet, and activation steam inlet; and utilizing process gas comprising at least a portion of the carbonization product gases or a combustion product thereof; at least a portion of the activation product gases or a combustion product thereof; or a combination thereof in a solid fuel boiler system that burns a solid fuel boiler feed with air to produce boiler-produced steam and flue gas, the boiler upstream of an air heater within a steam / electricity generation plant, said boiler comprising a combustion zone, a boiler-produced steam outlet and at least one flue gas outlet.

Owner:SRINIVASACHAR SRIVATS +3

Waste rubber powder activated and modified epoxy asphalt functional material and preparation method thereof

ActiveCN104592775AHigh surface activation treatment efficiencyImprove low temperature cracking resistanceWorking-up pitch/asphalt/bitumen by chemical meansBuilding insulationsEpoxyPolymer science

The invention discloses a waste rubber powder activated and modified epoxy asphalt functional material and a preparation method thereof. The functional material comprises an epoxy asphalt component A and an epoxy asphalt component B, wherein the epoxy asphalt component A is the mixture of epoxy resin and terminal-group epoxy modified silicone oil; the epoxy asphalt component B is a polymer dispersant, a matrix asphalt, a curing agent and a waste rubber powder activation product. The preparation method comprises the following steps: activating waste rubber powder to obtain activated waste rubber powder with surface activity; adding the obtained activated waste rubber powder into the matrix asphalt to obtain the epoxy asphalt component B, adequately mixing the epoxy asphalt component A with the epoxy asphalt component B to obtain the waste rubber powder activated and modified epoxy asphalt functional material. The preparation method disclosed by the invention can be used for comprehensively improving the compatibility between the matrix asphalt and the rubber powder, and improving the low-temperature crack resistance, fatigue resistance and stability of the epoxy asphalt functional material.

Owner:JURONG NINGWU CHEM

Organic light emitting devices having latent activated layers and methods of fabricating the same

InactiveUS20070077452A1Solid-state devicesLiquid/solution decomposition chemical coatingOrganic light emitting deviceBiological activation

An organic light emitting device with a latent activator material is presented. An organic light emitting device including activation products of a latent activator material is also presented. Embodiments of patterned organic light emitting devices are also contemplated wherein patterning can occur prior or post fabrication of the devices. A method of fabricating an organic light emitting device with a latent activator material or with activation products of an activator material is also provided.

Owner:GENERAL ELECTRIC CO

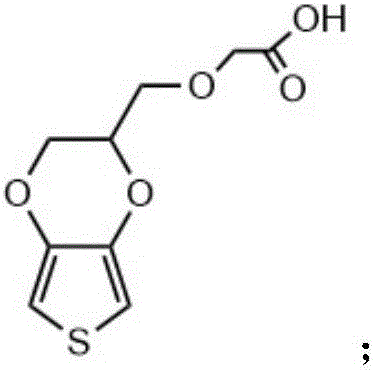

Conductive silk fibroin material and preparation method thereof

ActiveCN106046390AImprove conductivityPromote regenerationTissue regenerationProsthesisAcetic acidBiological materials

The invention relates to a conductive silk fibroin material and a preparation method thereof. The preparation method mainly comprises the following steps: (1) insoluble treatment of silk fibroin material; (2) 2-((2,3-dihydrothieno[3,4-b][1,4]dioxene-2-yl)methoxy)acetic acid activation product graft modification of silk fibroin material subjected to insoluble treatment; and (3) in-situ oxidation polymerization of thieno[3,4-b]-1,4-dioxin-2-methanol on silk fibroin material surface subjected to graft modification. The method can be used for preparing the silk fibroin conductive composite material with the polythieno[3,4-b]-1,4-dioxin-2-methanol grafted on the surface; the surface sheet resistance is 0.9*10<5>-5*10<7>ohm; the preparation technique is simple and mild; and the obtained novel biological material has high application value, and especially can be used as a nervous tissue engineering material and a neural restoration material.

Owner:DONGHUA UNIV

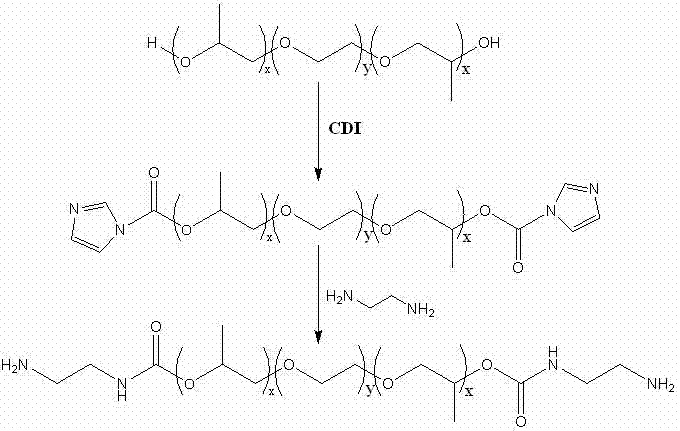

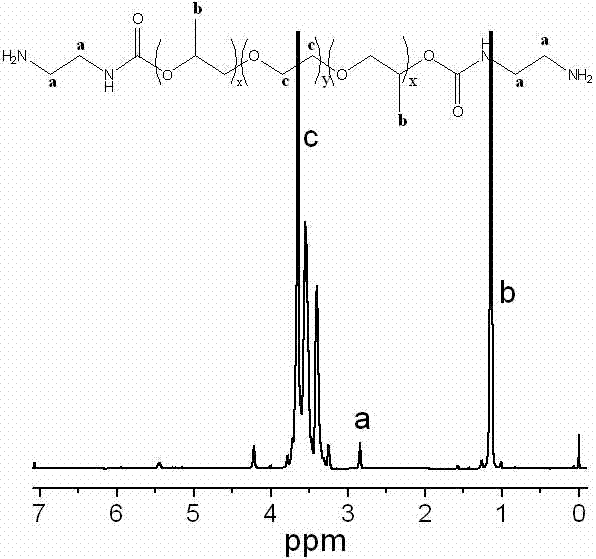

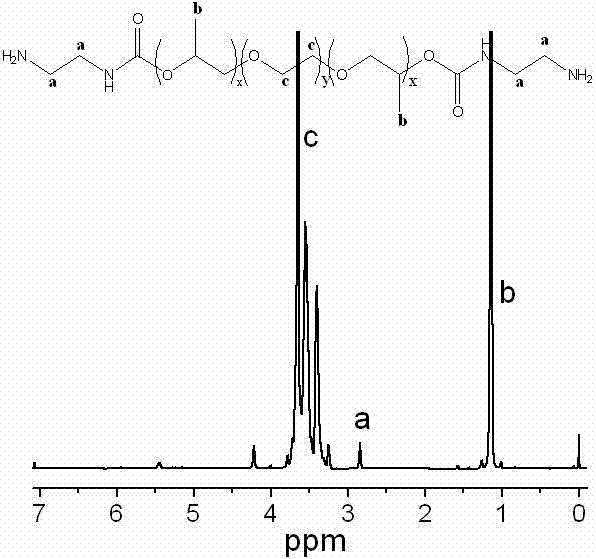

Amine-terminated polyether and continuous preparation method thereof

InactiveCN102212191AHigh efficiency of terminal amino groupHigh purityPeptide preparation methodsPharmaceutical non-active ingredientsEthylenediamineFreeze-drying

The invention belongs to the technical field of polymer synthesis and biomaterial preparation, and particularly discloses amine-terminated polyether and a continuous preparation method thereof. The preparation method comprises the following steps of: activating terminal hydroxyl of polyether by using N,N-carbonyl diimidazole (CDI), directly performing next reaction with ethanediamine without separating and purifying an activation product, performing rotary steaming on a product, dialyzing, and freeze-drying to obtain a product with high terminal amino group efficiency and high terminal amino group purity. The amine-terminated polyether can be used as a polymer synthesis intermediate or a biomaterial modified intermediate.

Owner:FUDAN UNIV

Method for recovering ammonium chloride in rare-earth ammonium salt wastewater to prepare agricultural chemical fertilizer

InactiveCN104071941ATake advantage ofTurn waste into treasureWater contaminantsDispersed particle separationRare earthSlurry

The invention relates to a method for recovering ammonium chloride in rare-earth ammonium salt wastewater to prepare an agricultural chemical fertilizer, which mainly comprises the following steps: pretreating rare-earth ammonium salt wastewater with activated carbon, sending to an electrodialysis concentrator to enhance the concentration of wastewater ammonium salt to 10-13%, carrying out triple effect evaporation to enhance the concentration to 45-48%, cooling the concentrated slurry to crystallize, mixing with other three activated waste residues according to the ammonium salt mass concentration of greater than 60%, mixing uniformly, sending into a drum granulator with a belt conveyor, and spraying the ammonium salt mother solution for granulation, wherein the other three activated waste residues are a gelatin plant phosphorus-containing waste residue activation product, a power plant straw ash activation product and a weathered coal activation product. The method has the advantages of low treatment cost, no secondary pollution, simple fertilizer preparation technique and favorable fertilizer efficiency.

Owner:YANSHAN UNIV

Preparation method and application of lignin-based hierarchical-pore carbon material

The invention provides a preparation method and application of a lignin-based hierarchical-pore carbon material. The preparation method comprises the following steps: step 1, activating potassium hydroxide: uniformly mixing potassium hydroxide with carbon precursor so as to obtain a mixture of the carbon precursor and potassium hydroxide and subjecting the mixture of the carbon precursor and potassium hydroxide to carbonization and activation in a tubular furnace under the protection of inert gas; and step 2, soaking an activation product obtained in the step 1 in hydrochloric acid to remove impurities, carrying out vacuum pumping filtration, then washing obtained filtrate with water until the filtrate is neutral and carrying out drying so as to obtain the lignin-based hierarchical-pore carbon material. The prepared lignin-based hierarchical-pore carbon material has a great specific surface area, high adsorption capacity, fast adsorption rate, stable performance and good reusability.

Owner:JIANGSU UNIV

Method for preparing load type activated carbon from furfural residues and application of load type activated carbon

ActiveCN109126699AFull loadInhibit sheddingWater treatment parameter controlGas treatmentCarbonizationPotassium hydroxide

The invention discloses a method for preparing load type activated carbon from furfural residues and application of the load type activated carbon. The furfural residues are used as carbon sources, and pre-carbonization, activation, nanometer metal oxide impregnation and adsorption and recarbonization treatment are carried out on the furfural residues. The method particularly includes steps of S1,carbonizing the furfural residues at the temperatures of 250-300 DEG C in nitrogen atmosphere for 4-6 h; S2, carrying out activation, to be more specific, activating obtained black carbon residue, potassium hydroxide and potassium bicarbonate mixtures at the temperatures of 400-500 DEG C for 1-3 h, carrying out acid pickling on activation products until the PH (potential of hydrogen) of the activation products shows the activation products are neutral and carrying out drying at the temperatures of 60 DEG C; S3, carrying out loading, to be more specific, dispersing composite nanometer metal oxide in microcrystalline cellulose sol to obtain mixed coated sol, adding obtained activated carbon into the mixed coated sol, carrying out pressurization impregnation and adsorption for 1-3 h, carrying out dehydration and then carrying out carbonization again at the temperatures of 150-200 DEG C in nitrogen atmosphere for 1-2 h. The method and the application have the advantages that the nanometermetal oxide can be loaded in activated carbon structures by double means of sol coating and impregnation and adsorption, the method is high in loading and low in energy consumption, the nanometer metal oxide can be completely supported, composite structures can be further reinforced in recarbonization procedures, and the stability can be improved.

Owner:蚌埠越昇科技服务有限公司

Device for removing leukocytes from blood

The invention relates to a device for removing leukocytes from blood, comprising a number of hollow fibres made from organic polymers, wherein the hollow fibres have a lumen and a wall enclosing the lumen with an inner lumen-side surface and an outer surface, the hollow fibres are arranged in a cylindrical housing with an inlet device and an outlet device and an external volume is formed between the hollow fibres and the housing, accessible to a fluid by means of the inlet device and the outlet device, characterised in that only the outer surfaces of the hollow fibres are accessible to a fluid, the lumina of the hollow fibres are accessible to a fluid, the arrangement of the hollow fibres has a high degree of organisation and the hollow fibres form the complement activation product C5a with a concentration of at least 10 [mu]g per m of fibre surface from organic polymers.

Owner:3M INNOVATIVE PROPERTIES CO

Biomass-based magnetic activated carbon and preparation method thereof

InactiveCN108144582AStrong magnetismImprove adsorption capacityOther chemical processesAlkali metal oxides/hydroxidesWater bathsSystem pressure

The invention relates to biomass-based magnetic activated carbon and a preparation method thereof. The method includes: dissolving a certain amount of ZnCl2 into water to obtain a solution A, dissolving Fe(NO3)3 9H2O and dodecyl trimethyl ammonium chloride into water according to a certain mass proportion, subjecting to water bath at 80 DEG C for half an hour to obtain a solution B, impregnating waste biomass in the mixed solution of the solution A and the solution B for a certain period of time, drying in a drying oven of 105 DEG C, weighing a certain mass of the dried material, and activating the weighed material in a resistance furnace under certain system pressure and activation temperature for a certain period of time; boiling the activation product in boiling water for half an hour,washing with deionized water until the activation product is neutral, filtering, drying, and grinding to obtain the magnetic activated carbon. The preparation method has the advantages that the methodis simple in preparation process, low in cost and the like; the magnetic activated carbon prepared by the method is excellent in magnetic performance, less prone to magnetic substance falling off andexcellent in adsorption performance.

Owner:CENT SOUTH UNIV

Preparation of copper complexing natural polymer adsorbing material

InactiveCN101279245ALarge adsorption capacityImprove adsorption capacityOther chemical processesWater/sewage treatment by sorptionCelluloseOrganic fluid

The invention discloses a method for preparing copper complex natural polymer adsorption material, which consists of the following steps: 1) cupric salt is dissolved into ammonia water to prepare cuprammonium solution; 2) fibrin is dissolved into the cuprammonium solution and then is added with lignin; 3) the mixture is stirred for 6-48 hours at the constant temperature of 20-80 DEG C for centrifugal filtration and then washed twice to three times with distilled water; 4) filtrated solid product is dried at the temperature of 50-105 DEG C; 5) dried activation product is grinded and passes 100 mesh sieve to acquire the copper complex natural polymer adsorption material. The copper complex natural polymer adsorption material prepared by the invention has strong adsorption capacity of organic contamination in water and large adsorption capacity and can be popularized and used in the treatment of difficult degradable organic waste water and the adsorption and fixation treatment for sudden discharging of large quantity of organic liquid, at the same time natural polymer waste materials such as the lignin, the fibrin, etc. produced in the process of paper making, etc. can be recycled.

Owner:ZHEJIANG UNIV

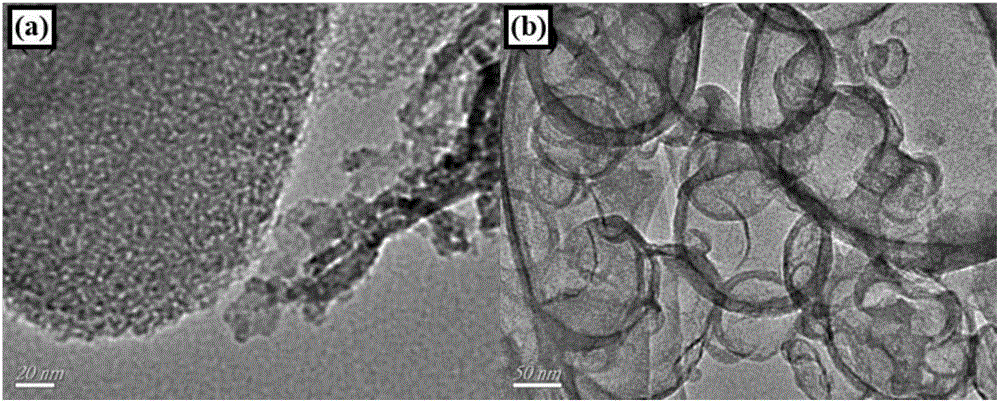

Graphene composite porous carbon as well as preparation method and application thereof

InactiveCN108862233AImprove power characteristicsImprove conductivityHybrid capacitor electrodesCarbon preparation/purificationActivation methodPorous carbon

The invention relates to the field of electrode materials, in particular to graphene composite porous carbon as well as a preparation method and application thereof. The preparation method of the graphene composite porous carbon comprises the following steps of mixing phenolic resin, template agents and modified graphene to prepare a mixed solution; performing curing and crushing on the mixed solution to obtain carbon precursors; performing carbonization on the carbon precursors to obtain carbonized materials; mixing the carbonized materials with alkaline substances for activation; performingacid treatment on the obtained activation products; then flushing the products into a neutral state; performing drying to obtain the graphene composite porous carbon. The method has the advantages that the activation method is introduced on the basis of a template method; the activation method and the template method achieve the cooperated effects to prepare the micropore-medium pore multi-stage pore passage distribution porous carbon material; the reaction process is mild; graphene is introduced, so that the material conductivity can be greatly improved; the power characteristics of the porous carbon materials as an electrode material can be improved; the material has wide prospects when being used as supercapacitors.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Preparation method of sulfur and nitrogen co-doped thin nanocarbon sheet for supercapacitor electrode

ActiveCN109449007AImprove stabilityImprove performanceCarbon compoundsHybrid capacitor electrodesThioureaPorous carbon

The invention discloses a preparation method of a sulfur and nitrogen co-doped thin nanocarbon sheet for a supercapacitor electrode, and belongs to the technical field of new energy. The method comprises the following steps of taking waste cigarette ends as a carbon source, washing the waste cigarette ends with deionized water to remove surface impurities, carrying out grinding after washing and drying, and uniformly mixing ground powder with alkali metal hydroxide and thiourea; in inert gas, heating to an activation temperature at a speed of 5 DEG C / min, and keeping the temperature for 2 hours to obtain an activation product; and finally, carrying out acid pickling neutralization on the activation product, washing the activation product to be neutral with the deionized water, and carryingout drying, grinding and sieving to obtain the nanocarbon sheet for a supercapacitor. The invention provides a method for preparing a two-dimensional porous carbon material from the waste cigarette ends by adopting a strategy of molten alkali; the method is energy-saving, environment-friendly, simple in process and low in cost; and the prepared porous carbon material has high stability and excellent comprehensive performance, and has a wide market application prospect as a supercapacitor electrode material.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Nitrogen-doped porous carbon catalyst prepared from potatoes and preparation and application of catalyst

ActiveCN109346732AImproving ORR electrocatalytic performanceLow priceCell electrodesElectricityFuel cells

The invention relates to a nitrogen-doped porous carbon catalyst prepared from potatoes and preparation and application of the catalyst. A preparation method of the catalyst comprises the following steps: 1) pretreating potatoes so as to obtain a potato paste; 2) carrying out high-temperature carbonization on the potato paste so as to obtain a nitrogen-doped carbon material; 3) mixing the nitrogen-doped carbon material with an activator, and carrying out high-temperature calcining activation so as to obtain an activation product; 4) removing excessive activator, thereby obtaining the nitrogen-doped porous carbon catalyst. The catalyst can be used as a fuel battery cathode catalyst for catalyzing oxygen reduction reactions. Compared with the prior art, the preparation method provided by theinvention is simple to operate, low in cost and convenient in large-scale industrial production; the prepared catalyst is of a multi-stage pore structure, has a high specific surface area and porosity, has an adjustable nitrogen element content and excellent ORR (Oxygen Reduction Reaction) electro-catalytic properties.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com