Amine-terminated polyether and continuous preparation method thereof

A technology for amino-terminated polyether and polyether, which is applied in the field of amino-terminated polyether and its preparation, can solve the problems of reduced amino group conversion rate, deactivation, long preparation period, etc., and achieves the effect of high efficiency and high purity of amino-terminated polyether.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

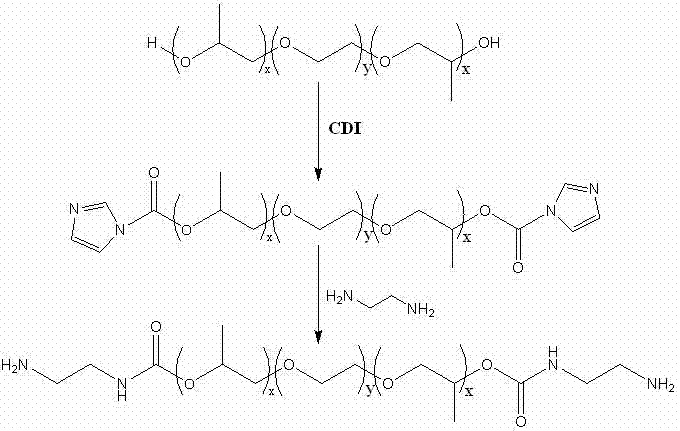

Method used

Image

Examples

Embodiment 1

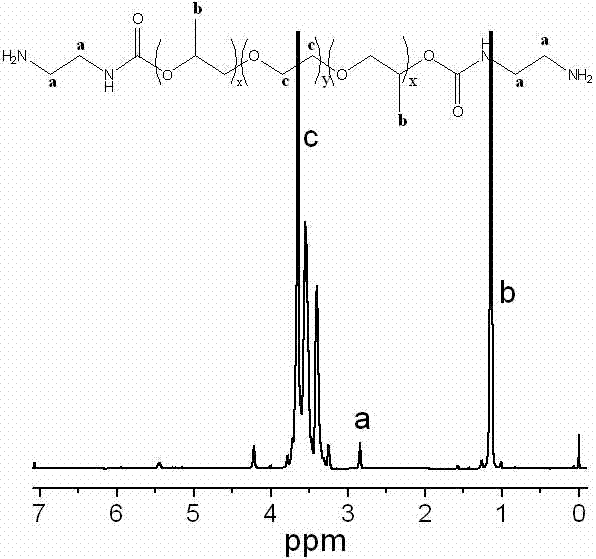

[0023] Example 1. Polyethylene glycol-polypropylene glycol-polyethylene glycol (PEO-PPO-PEO, molecular weight 5800, code P123) was vacuumed at 120 o C for four hours to remove water in a three-necked bottle. After cooling with argon protection, add 50mL of anhydrous acetonitrile with a syringe to form a solution. After repeated three times of vacuum-replacing argon, add CDI in the flask in an amount 4 times molar to the P123 hydroxyl group in an argon atmosphere, add 60 mL of acetonitrile, and stir to dissolve. Slowly add the P123 acetonitrile solution to the CDI solution dropwise, and the dropwise addition lasts for more than 4 hours. After the dropwise addition was completed, stirring was continued overnight. A P123-CDI solution was obtained. Vacuumize the three-necked bottle - replace argon three times, add 50 mL of ethylenediamine under argon atmosphere, slowly add P123-CDI solution into ethylenediamine dropwise for about 4 hours, and continue stirring for 4 hours after ...

Embodiment 2

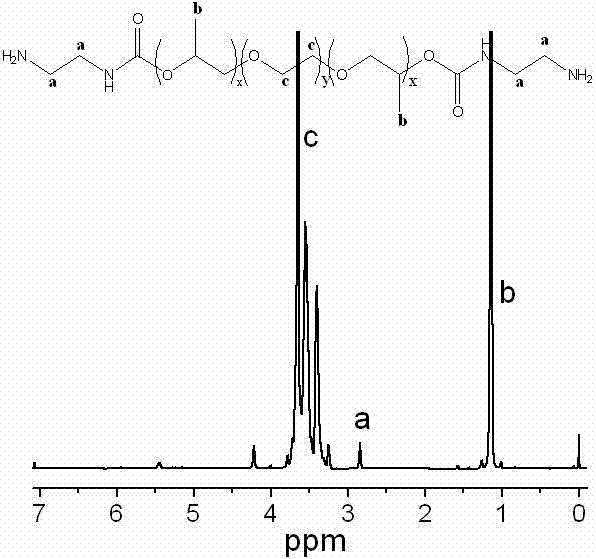

[0025] Example 2 Dihydroxypolyethylene glycol (PEG, molecular weight 1500) was vacuumed to remove water at 120 o C for four hours in a three-necked bottle. After cooling with argon protection, add 50mL of anhydrous acetonitrile with a syringe to form a solution. Under an argon atmosphere, add CDI in a dry flask in an amount 4 times the molar amount relative to the PEG hydroxyl group, add 60 mL of acetonitrile, and stir to dissolve. The polyethylene glycol acetonitrile solution is slowly added dropwise to the CDI solution, and the dropwise addition lasts for more than 4 hours. After the dropwise addition was completed, stirring was continued overnight. Obtain PEG-CDI solution. Add 50 mL of ethylenediamine under an argon atmosphere, slowly drop the PEG-CDI stock solution into the ethylenediamine for about 4 hours, and continue stirring for 4 hours after the addition is complete. PEG-NH 2 solution.

[0026] PEG-NH 2 The solution was rotary steamed at 70-80 degrees Celsius. ...

Embodiment 3

[0027] Example 3 Dihydroxypolyethylene glycol (PEG, molecular weight 5000) was vacuumed to remove water at 120 o C for four hours in a three-necked bottle. After cooling with argon protection, add 50mL of anhydrous acetonitrile with a syringe to form a solution. Under an argon atmosphere, add CDI in a dry flask in an amount 4 times the molar amount relative to the PEG hydroxyl group, add 60 mL of acetonitrile, and stir to dissolve. The polyethylene glycol acetonitrile solution is slowly added dropwise to the CDI solution, and the dropwise addition lasts for more than 4 hours. After the dropwise addition was completed, stirring was continued overnight. Obtain PEG-CDI solution. Add 100 mL of ethylenediamine under an argon atmosphere, slowly add the PEG-CDI solution slurry into the ethylenediamine dropwise, add dropwise for about 4 hours, and continue stirring for 4 hours after the dropwise addition. PEG-NH 2 solution.

[0028] PEG-NH 2 The solution was rotary steamed at 70...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com