Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Will not affect the production schedule" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of lignin metal element chelate fertilizer and device thereof

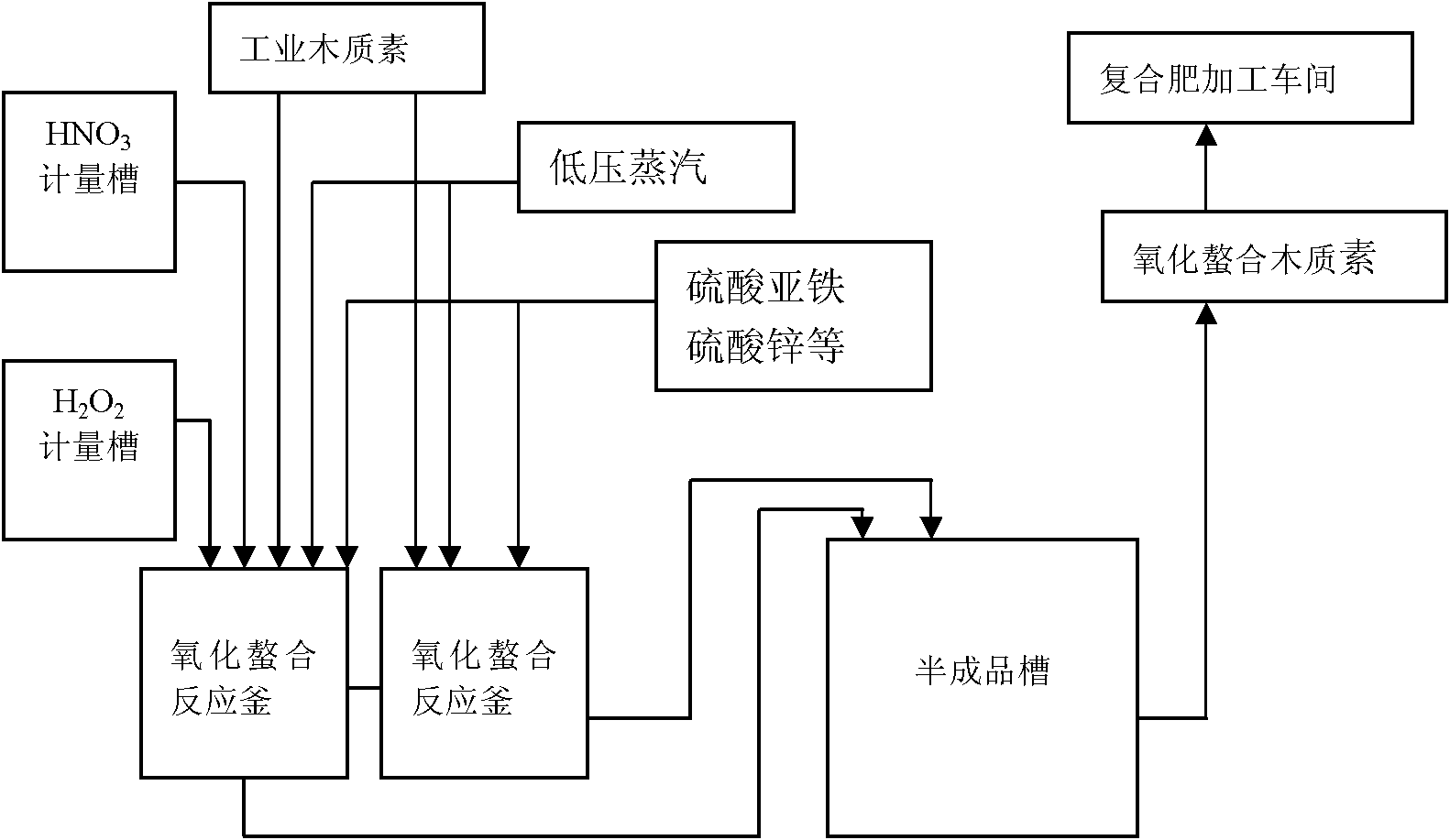

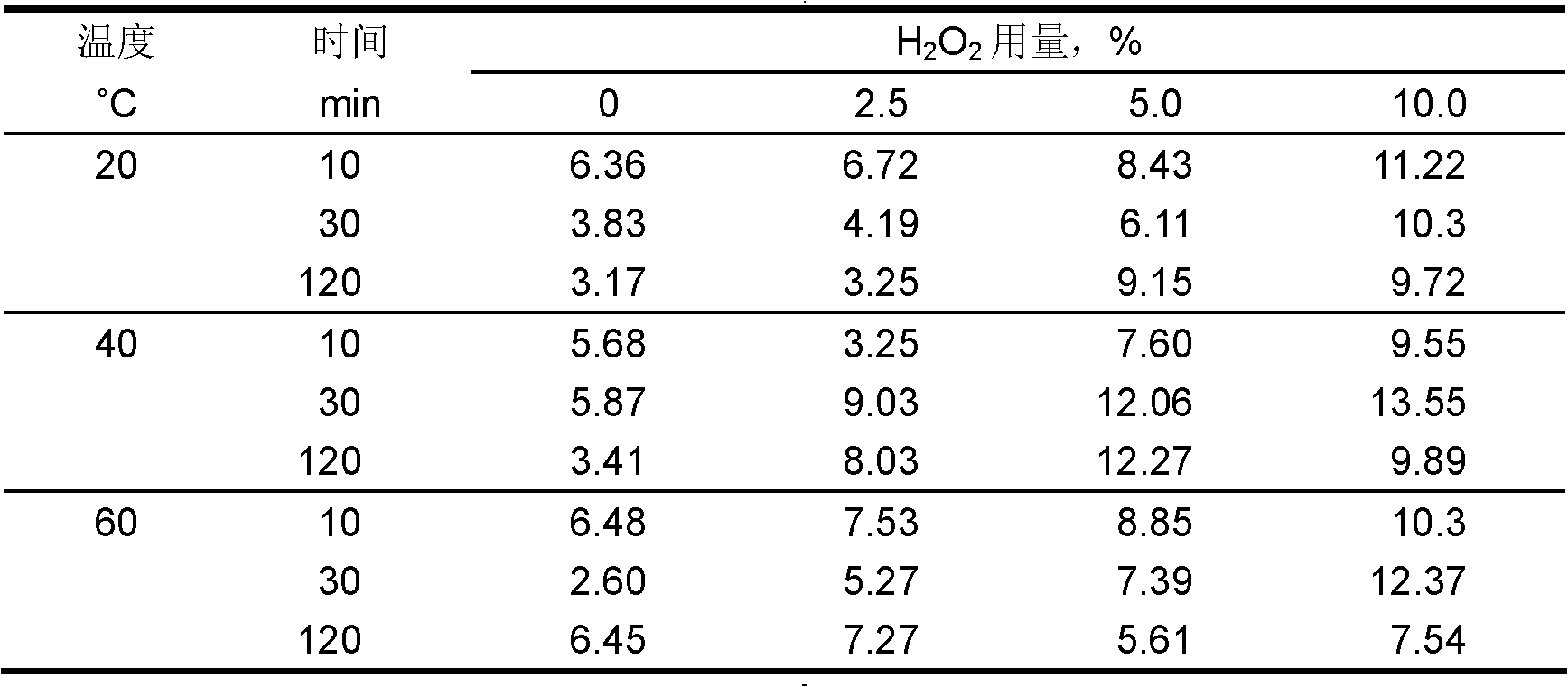

The invention provides a preparation method of lignin metal chelate fertilizer, sequentially comprising the following steps of: (1) preparing industrial lignin salts into an aqueous solution of a certain concentration in a dissolving tank; (2) transferring the prepared aqueous solution of industrial lignin to a reaction vessel and regulating a pH value of the solution by using a pH regulator; (3) adding an oxidant and an initiator, starting a stirring device of the reaction vessel, sufficiently and uniformly mixing and then adding inorganic salts containing micro metal elements; and (4) heating to a certain temperature and reacting for specified time. The invention also provides a device for carrying out the method. The modified lignin salt-medium micro metal element chelate fertilizer which is prepared by using the method and the device has the advantages of low cost and strong chelating capability, and can be compounded with various fertilizers and improve the content of micro elements in the fertilizer.

Owner:SHENZHEN BATIAN ECOTYPIC ENG +1

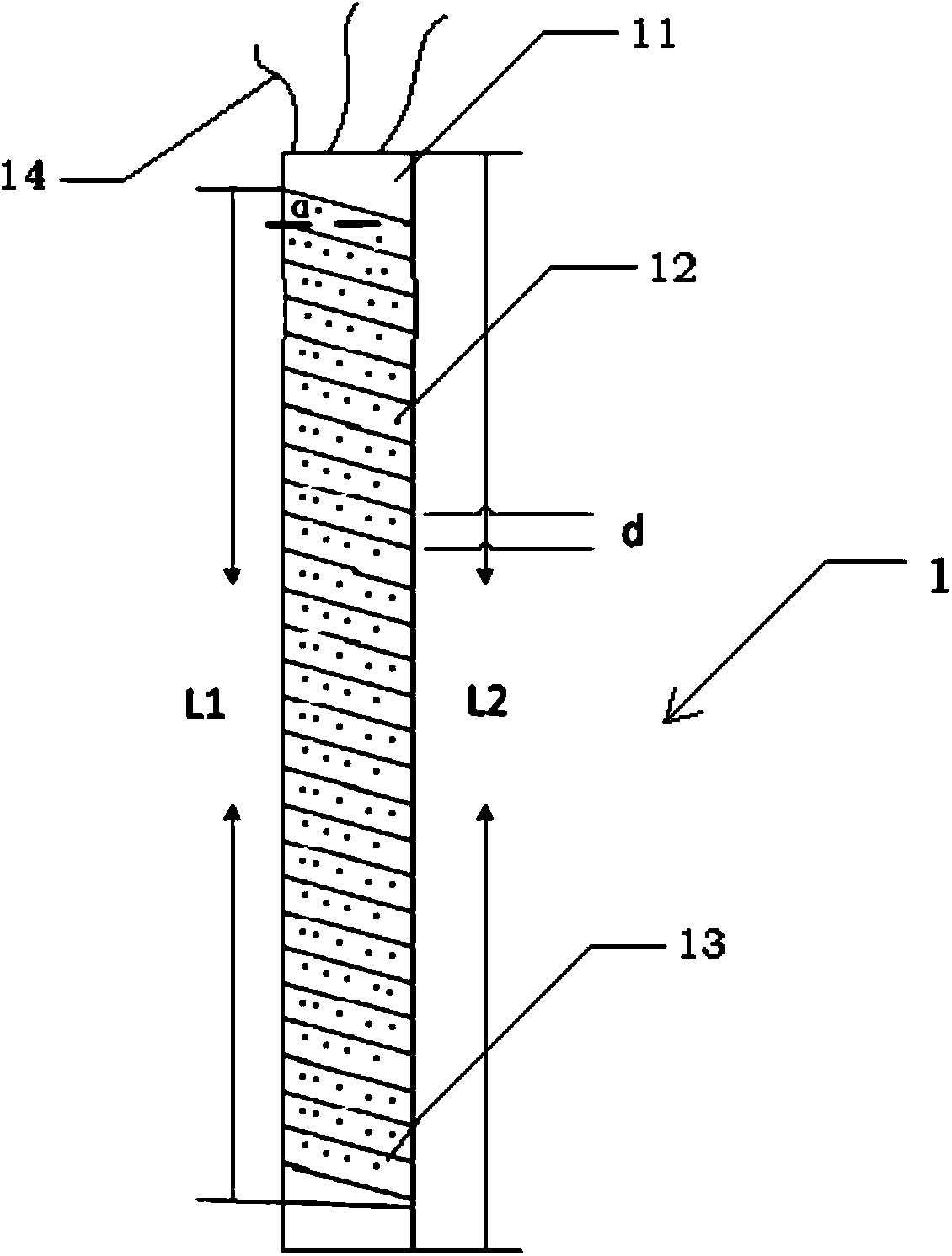

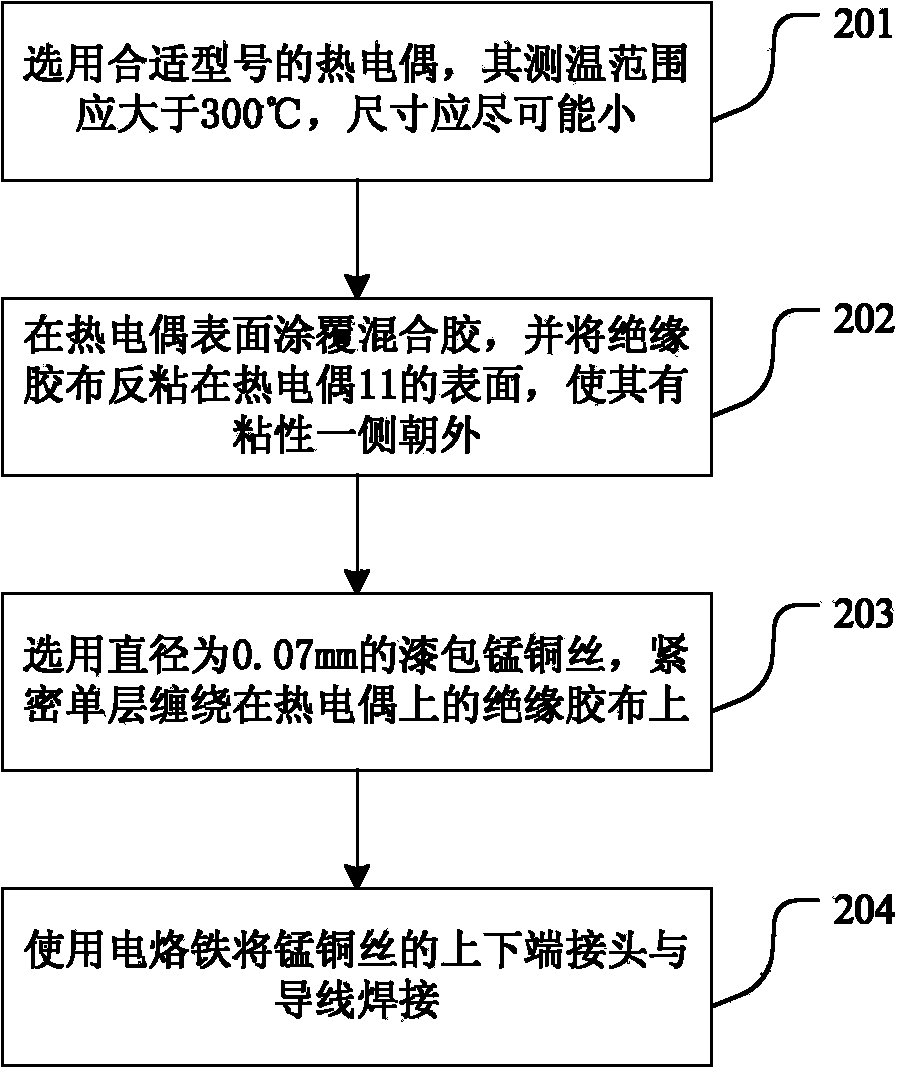

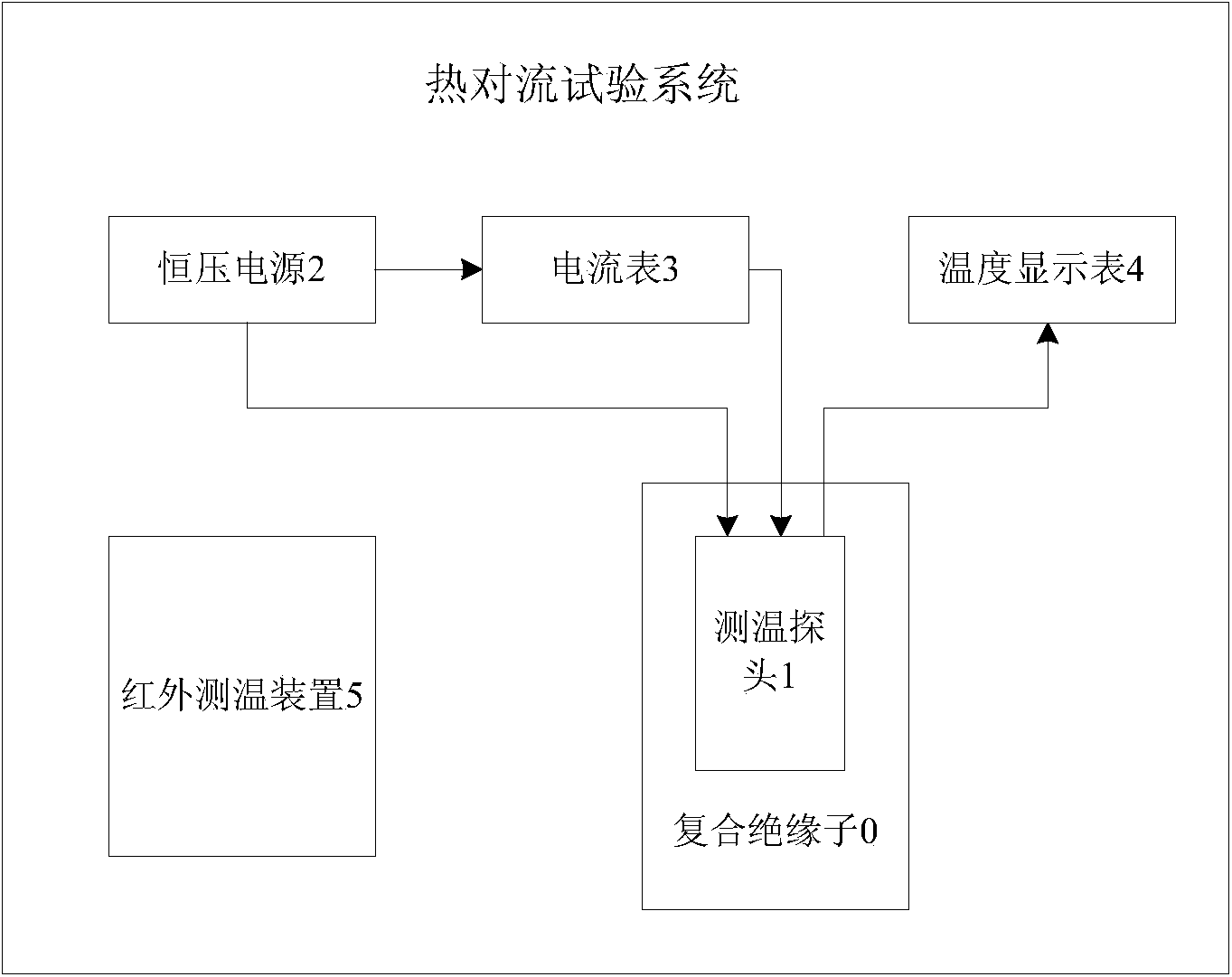

Heat convection testing method and system for composite insulator including artificial defect

InactiveCN103941126AReduce the chance of damageAvoid disconnectionThermometer detailsThermometers using electric/magnetic elementsInternal temperatureEngineering

The invention provides a heat convection testing method and a system for a composite insulator including an artificial defect. The testing method comprises the steps of fixedly embedding a temperature measuring probe in the composite insulator and enabling the temperature measuring probe to be located on the junction face of a silicone rubber sheath and an epoxy resin core rod; adopting a direct current constant voltage source to perform power supply for the resistance defect of the composite insulator; utilizing the temperature measuring probe to perform real-time detection on the internal temperature of the composite insulator in the power supply process, recording the internal defect temperatures under different currents and using an infrared temperature measurement device to shoot and record the surface temperature distribution situation of the composite insulator; and performing compilation and analysis on recorded data to obtain the relation of the outer surface temperature rise and internal actual temperature rise of the composite insulator. The temperature measuring probe improvable in temperature and a special fixing method are adopted, reliable connecting strength, insulating strength and heating power can be achieved, and the measurement accuracy is finally ensured.

Owner:SHENZHEN POWER SUPPLY BUREAU

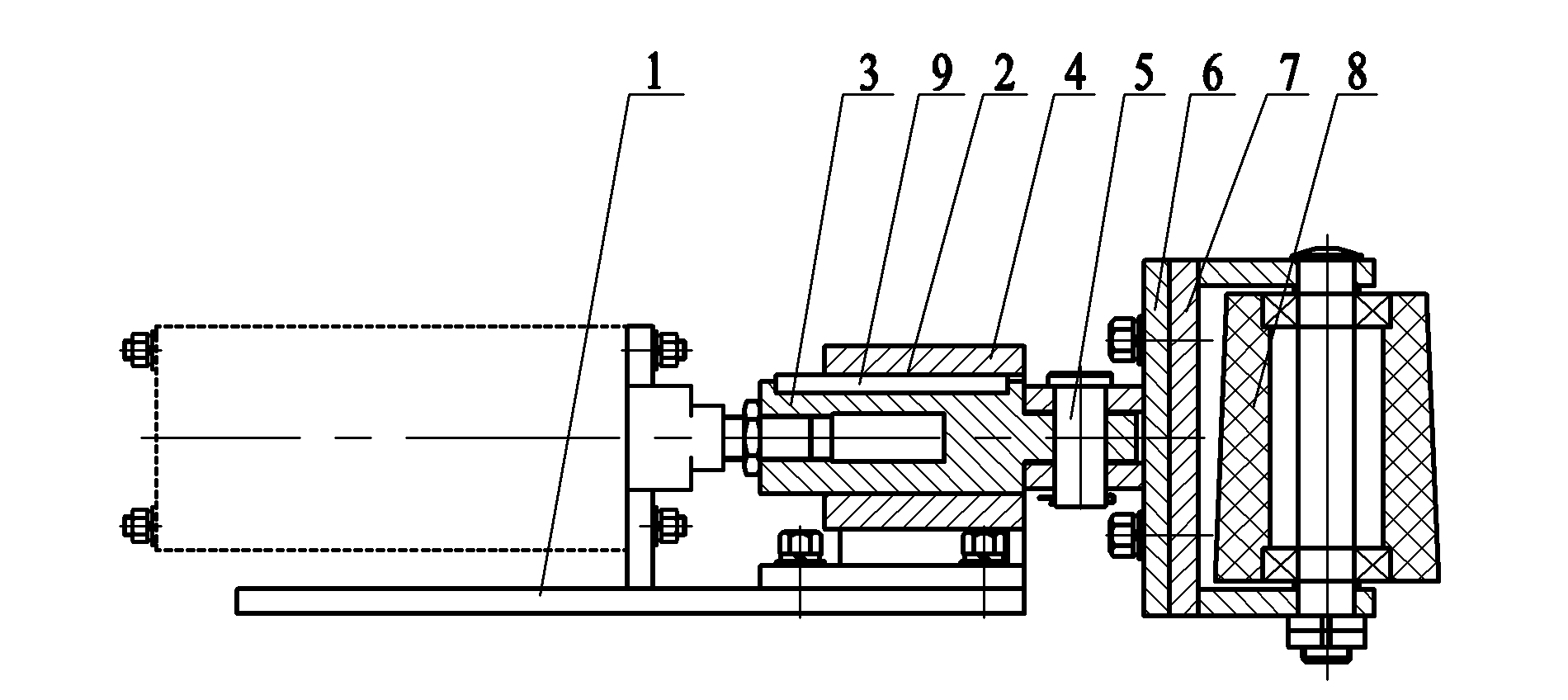

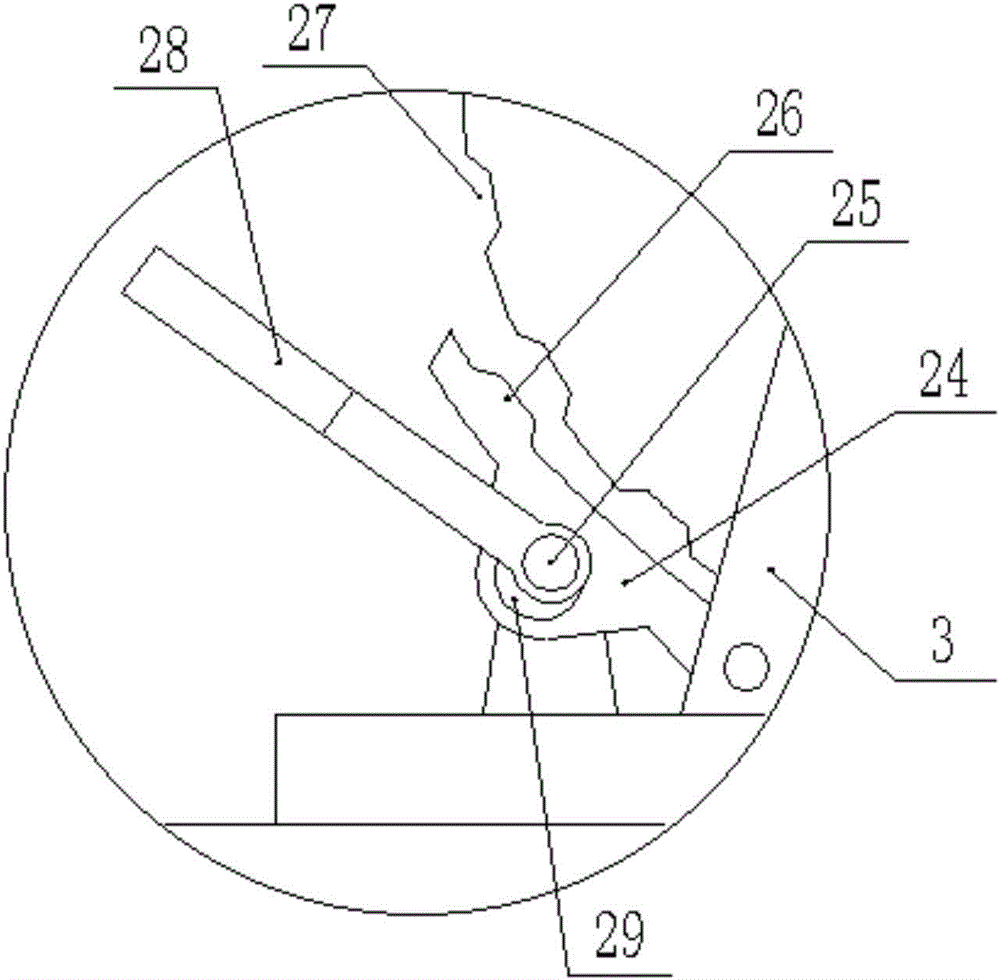

Wire pressing wheel component of inverted wire drawing machine

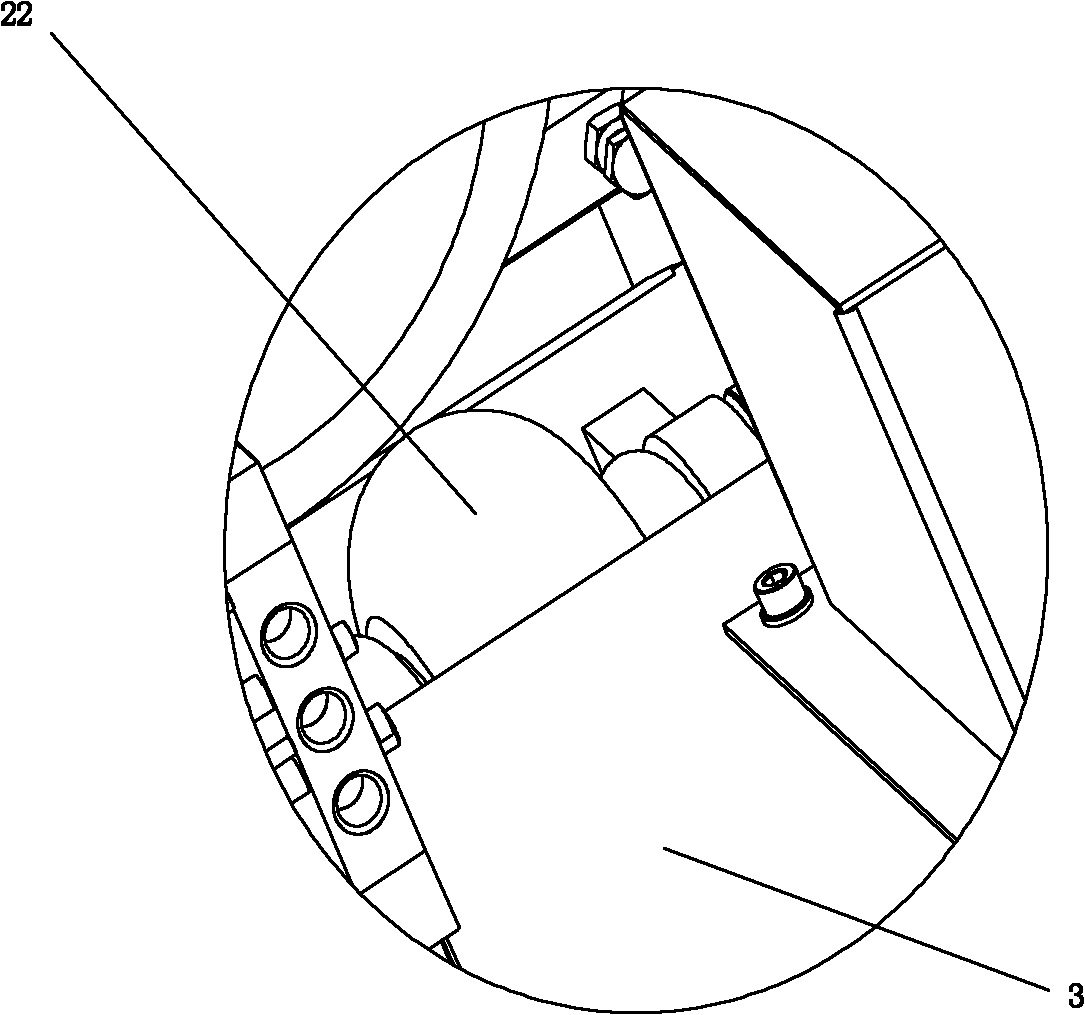

The invention relates to a wire pressing wheel component of an inverted wire drawing machine. The wire pressing wheel component comprises a fixedly-arranged base plate, wherein an air cylinder sliding seat is fixedly arranged on the base plate; an air cylinder joint is slidably arranged in the air cylinder seat; a fixed plate is hinged with the front part of the air cylinder joint through a pin shaft; a wheel pressing plate is fixedly arranged on the fixed plate; pressed wheels are rotationally arranged at the internal and external sides of the wheel pressing plate; the pressed wheels are in a conical structure the smaller ends of which are located at the same side; the wheel pressing shafts of the two pressed wheels are arranged in a parallel manner; and the distances from the axes of the wheel pressing shafts of the two pressed wheels to the axes of the pin shaft are the same. The wire pressing wheel component provided by the invention has simple structure, and can be used for stably pressing the wire in working; and the production schedule can not be influenced, thus the quality stability of the product is ensured.

Owner:WUXI PINGSHENG SCI & TECH

Small cut-rounding machine

InactiveCN107662026ASimple structureEasy to operateLarge fixed membersPositioning apparatusProduction scheduleEngineering

The invention discloses a small-sized circle cutting machine, which comprises a workbench. The workbench includes a bin body and a bin door. The right sides of the warehouse door are connected by buckles. A bracket is arranged inside the warehouse body, and a battery is installed on the bracket. An electric lifting rod is arranged in the middle position on the left side of the warehouse body, and an electric lifting rod is arranged above the electric lifting rod. Circular top seat, the present invention has simple structure, convenient operation, and is easy to move. After cutting, the table top can be cleaned, the cleaning speed is fast, and the labor intensity is small. For power supply, the track running mechanism is installed on the circular track to realize that the cutting machine can work normally even in the event of a power failure without affecting the production progress.

Owner:SUQIAN GENERAL MACHINERY

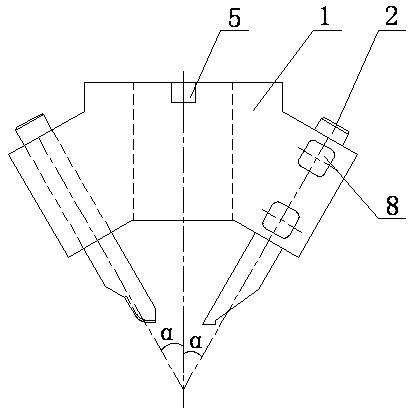

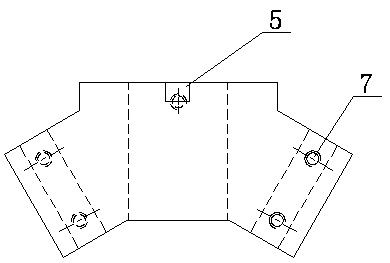

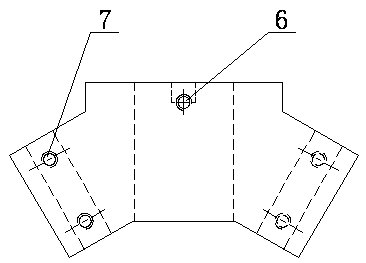

Scissor of sampling sheet metal

InactiveCN1916589AEasy to operateIncrease productivityWithdrawing sample devicesHinge angleEngineering

A sampling scissors of metal slab is prepared as setting master hydraulic cylinder for driving top shearing blade on top of body frame through hinge and setting bottom shearing blade corresponding to position of top shearing blade on bottom of body frame, setting metal slab material pressing unit in front of top and bottom shearing blades, setting size-setting mechanism and gap regulation mechanism of top and bottom shearing blades at back of top and bottom shearing blades, setting metal slab material conveying unit with rollers in front of body frame.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

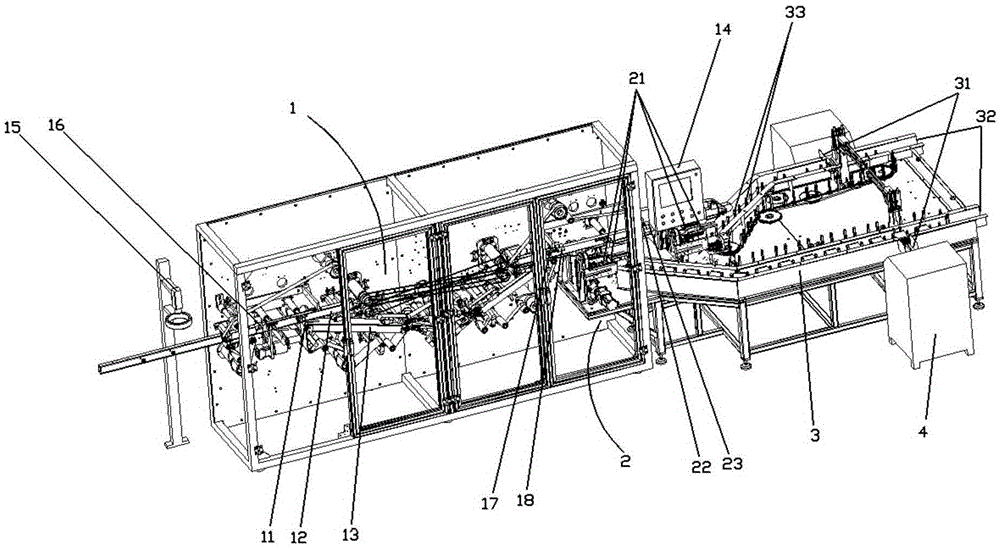

Hygiene product packaging device

The invention relates to the field of manufacturing of hygiene product production devices, and discloses a hygiene product packaging device which comprises a piece arranging machine, a piece folding mechanism, power and free chains and a packaging machine, wherein the piece arranging machine comprises a blocking piece, an upper transportation channel, a lower transportation channel and a control device; the upper transportation channel and the lower transportation channel are used for transporting hygiene products to be packaged; the blocking piece is used for controlling the transportation direction of the hygiene products to be packaged; the control device is used for controlling the opening and closing of the blocking piece; the lower transportation channel is composed of a crossed belt; the piece folding mechanism comprises forks; and the forks are used for transporting every group of alternately folded hygiene products to be packaged to the inlets of the power and free chains. According to the hygiene product packaging device, two transportation channels, namely, the upper transportation channel and the lower transportation channel, are adopted, and one of the two transportation channels overturns the hygiene products to be packaged by 180 degrees, so that the phenomenon that the thickness of the folded and packaged hygiene products is nonuniform is solved; and the packaging device is simple in structure, reasonable in design and high in reliability and automation degree, the production efficiency is improved, the production cost and labor intensity are reduced.

Owner:KUNSHAN HEJIN ELECTROMECHANICAL

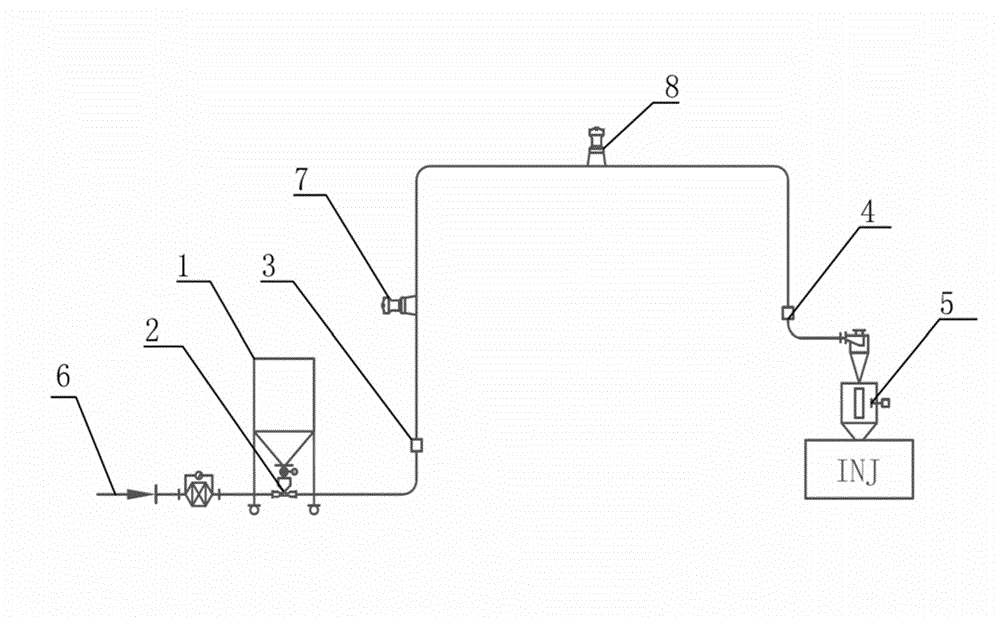

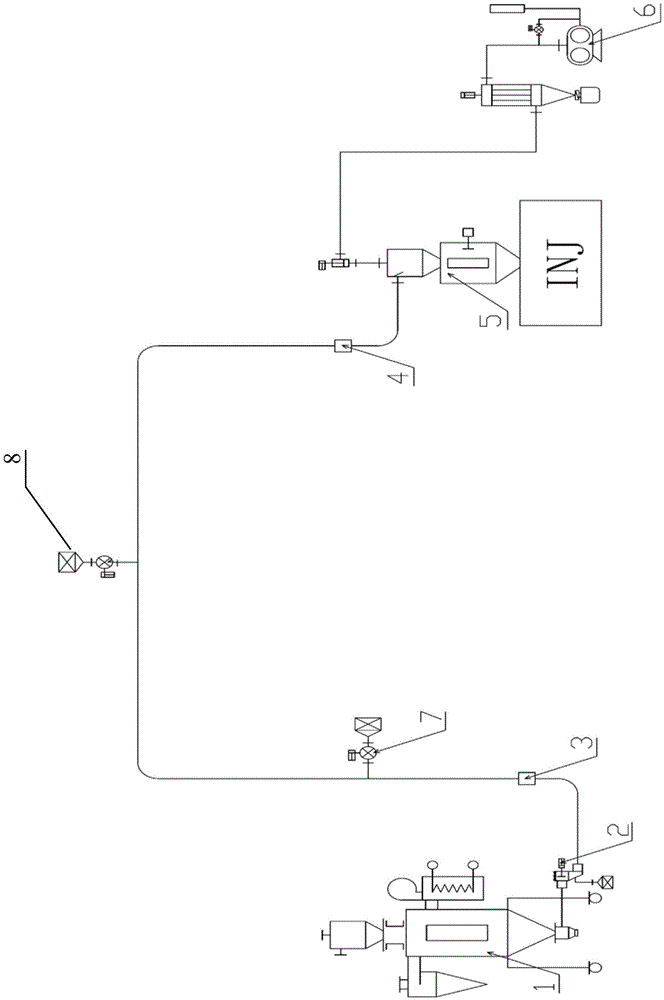

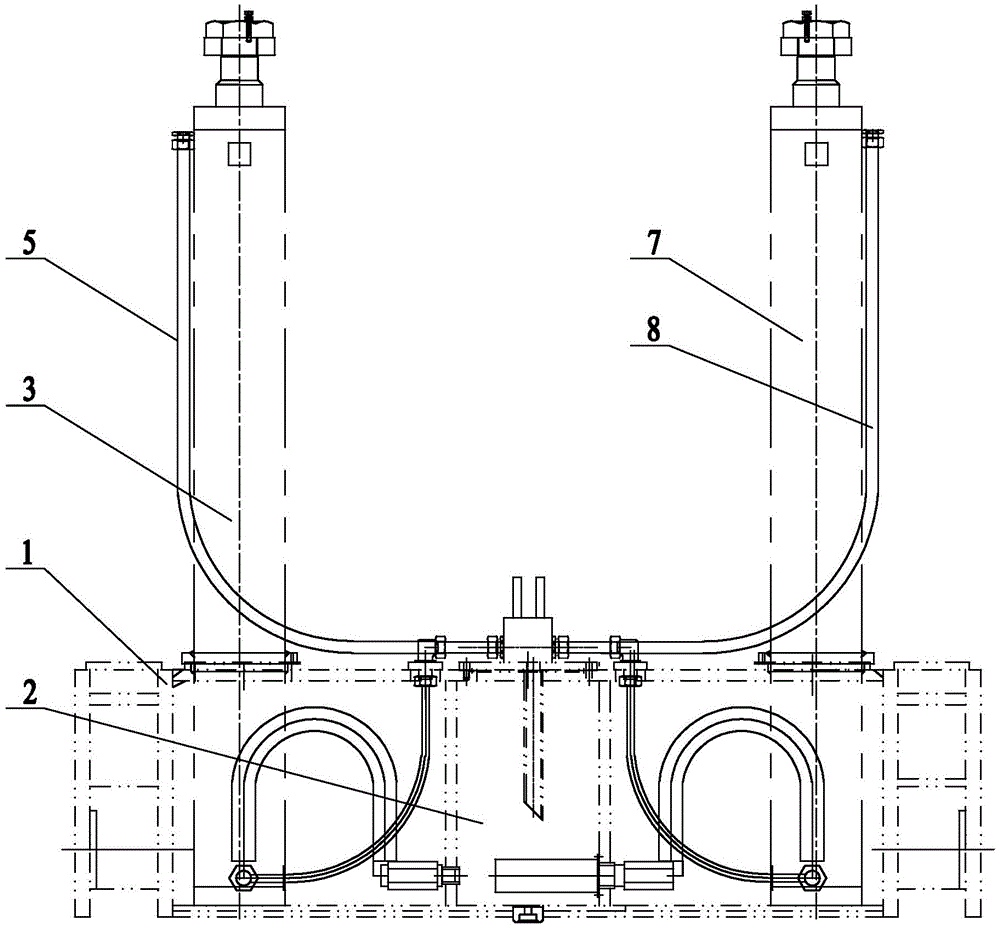

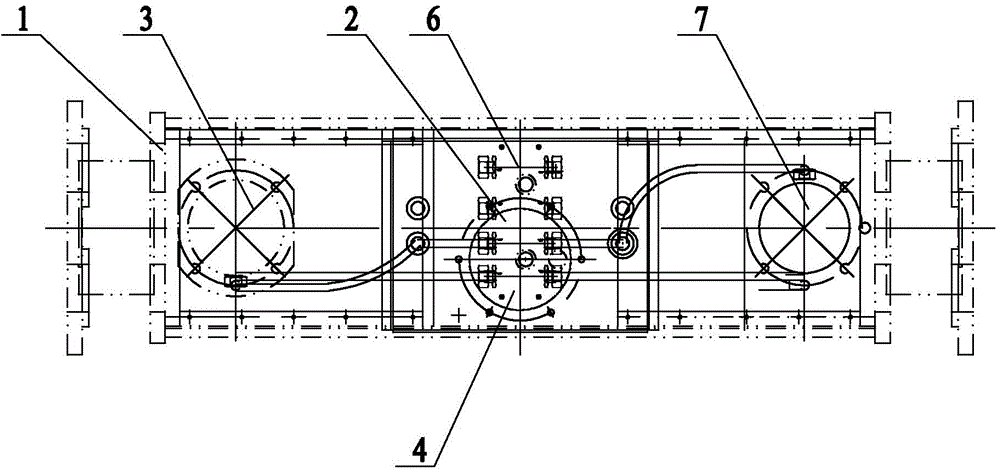

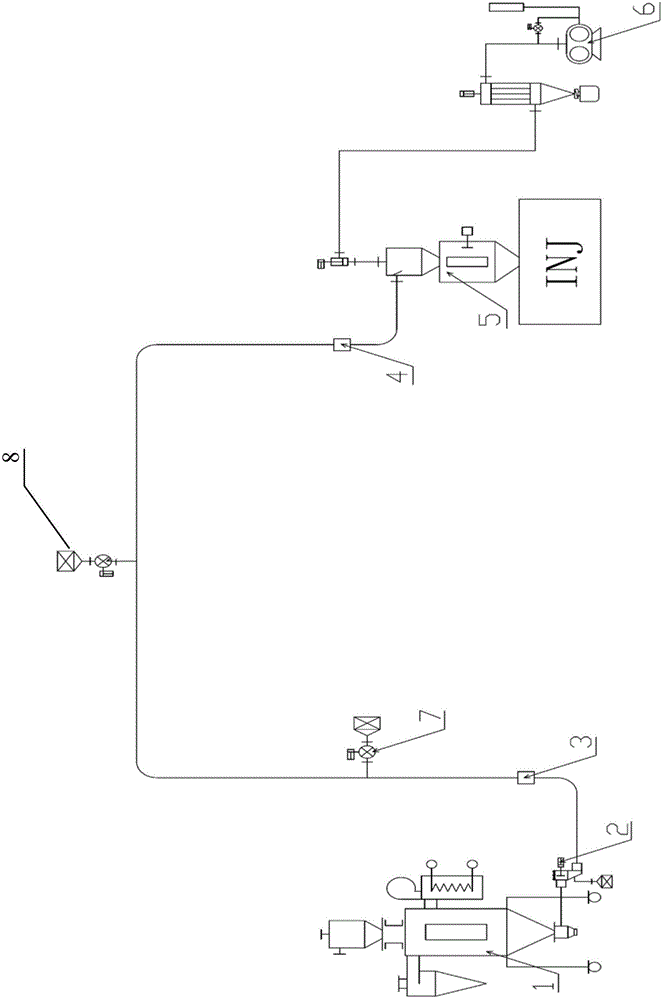

Pipeline conveying block preventing equipment under pressure feed state and using method thereof

ActiveCN104150225AEliminate the blocking situationWill not affect the production scheduleBulk conveyorsMaterial resourcesEngineering

The invention relates to pipeline conveying block preventing equipment under a pressure feed state. The pipeline conveying block preventing equipment under the pressure feed state is characterized by comprising a conveying pipe part, at least two detection devices and at least one vibration device, wherein the at least two detection devices and the at least one vibration device are all arranged on the conveying pipe part. The conveying pipe part comprises a pipeline, a conveying hopper, a conveying valve, a charging barrel and an air inlet connected with the conveying valve. One end of the pipeline is connected with the charging barrel through the conveying valve, the other end of the pipeline is connected with the conveying hopper, the at least two detection devices and the at least one vibration device are arranged on the pipeline, and the at least one vibration device is located between the at least two detection devices. By the adoption of the pipeline conveying block preventing equipment under the pressure feed state, pipeline blocking can be detected automatically, the pipeline blocking can be processed automatically in a vibration mode, manpower and material resources are saved, and the production progress of clients cannot be influenced.

Owner:KAWATA MASCH MFG (SHANGHAI) CO LTD

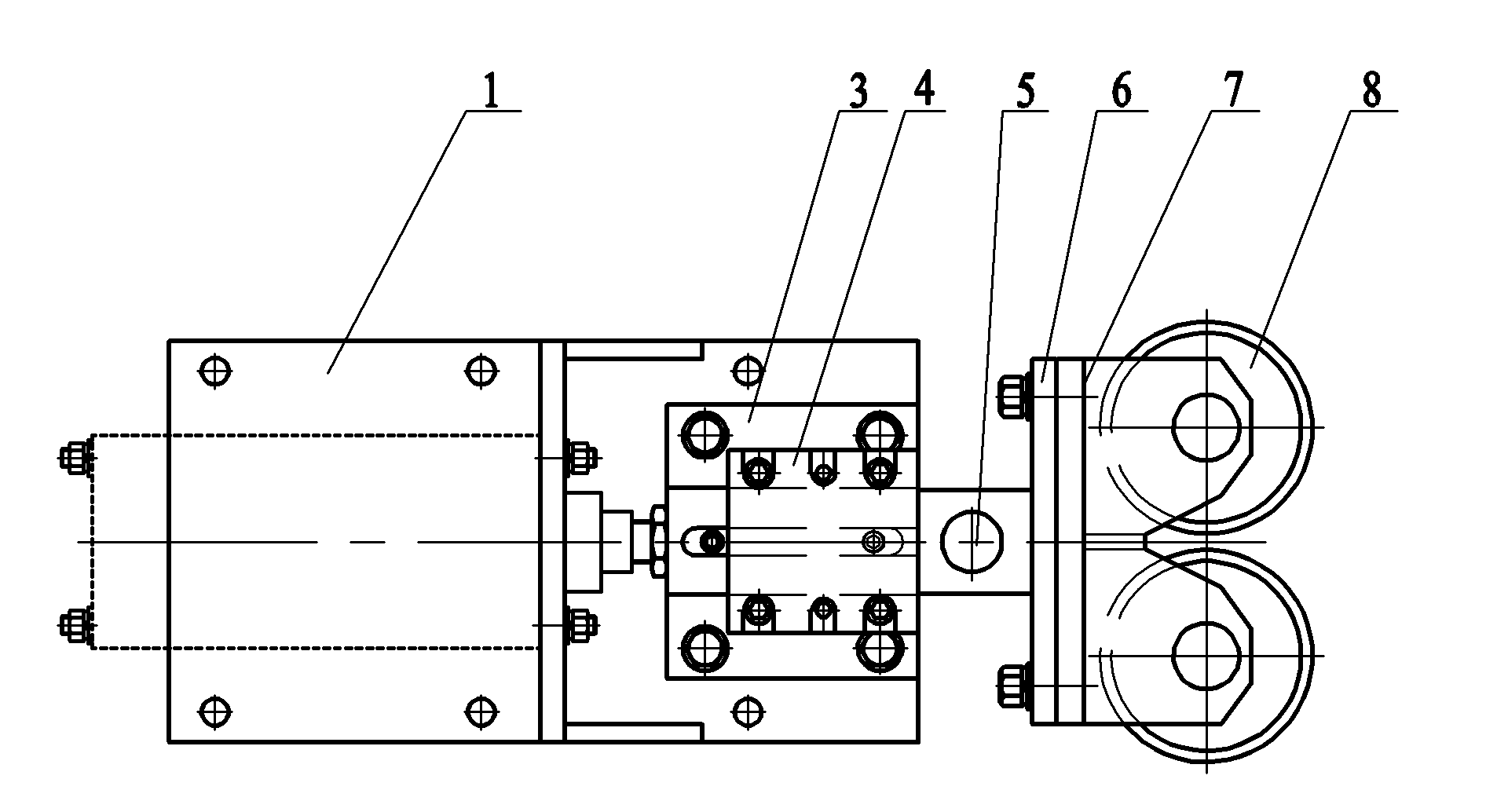

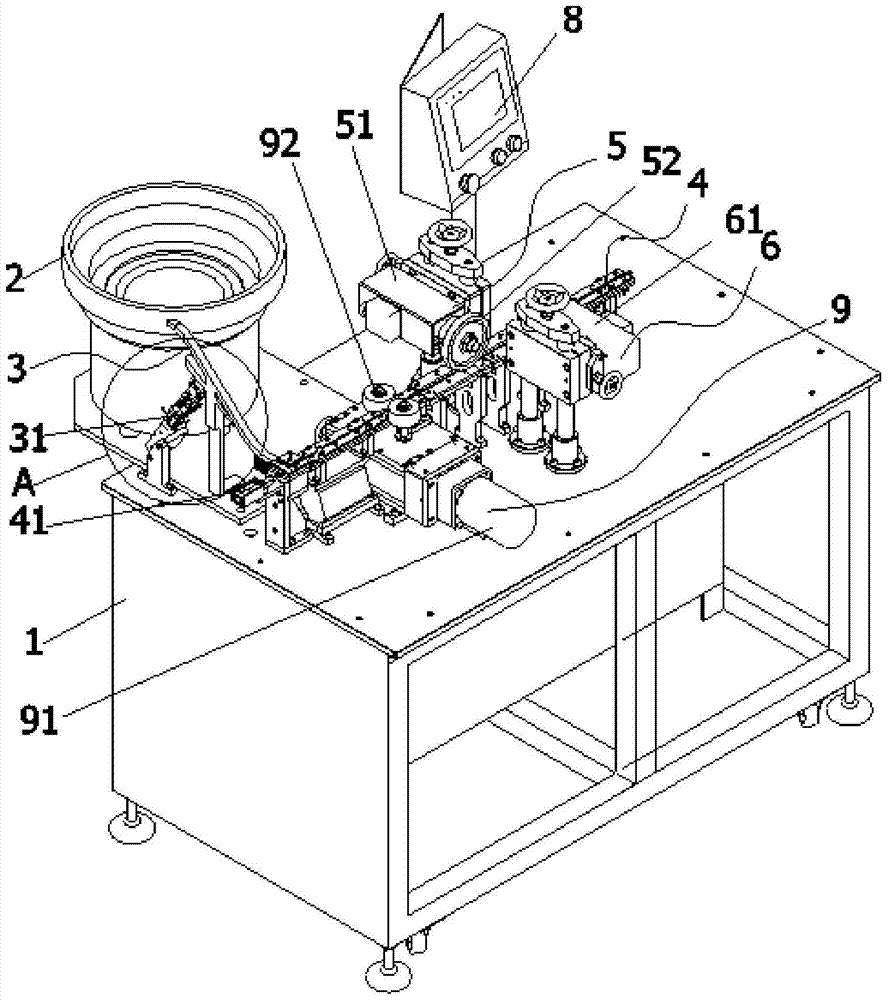

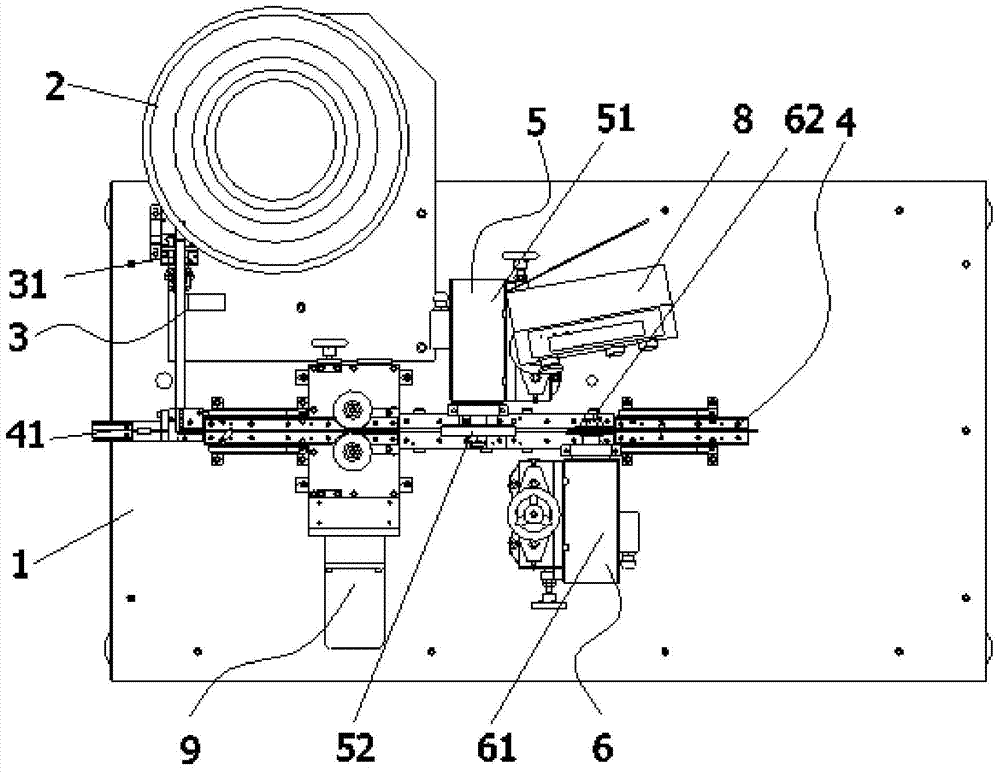

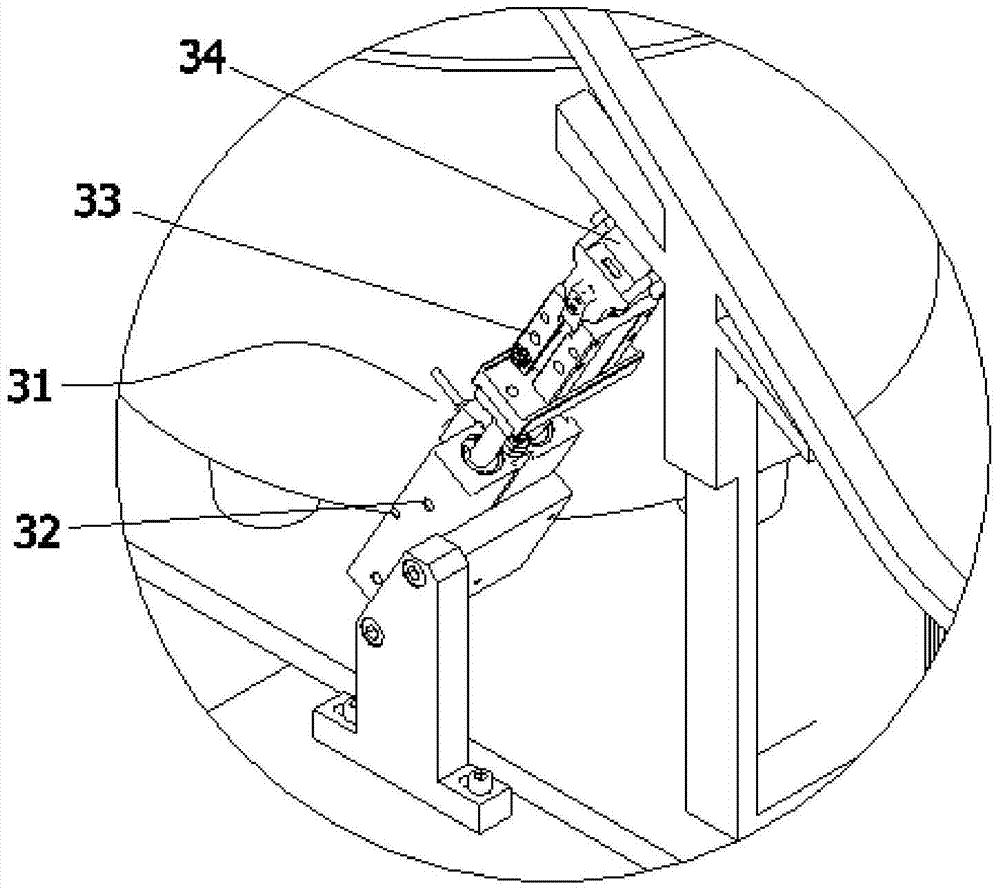

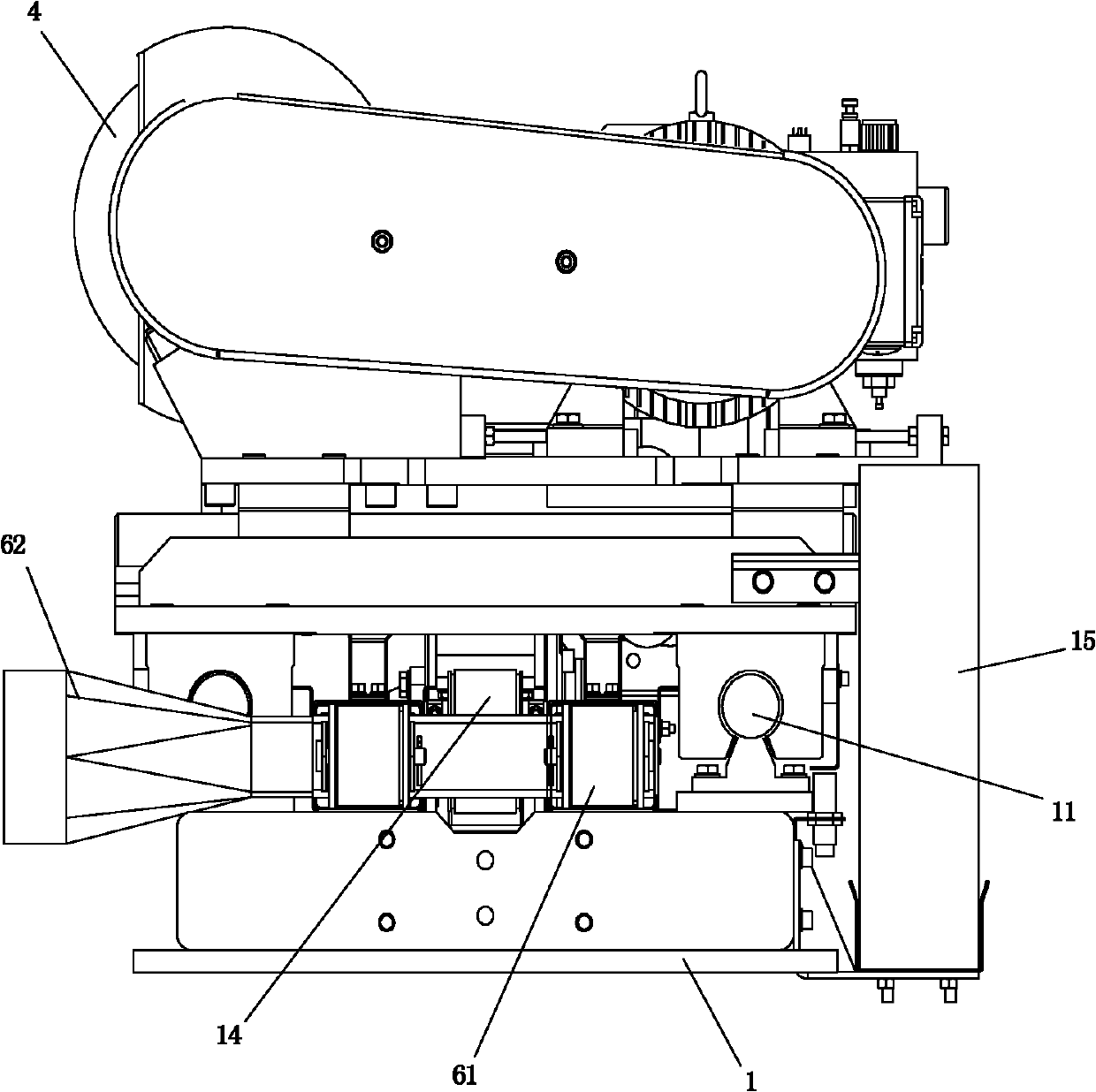

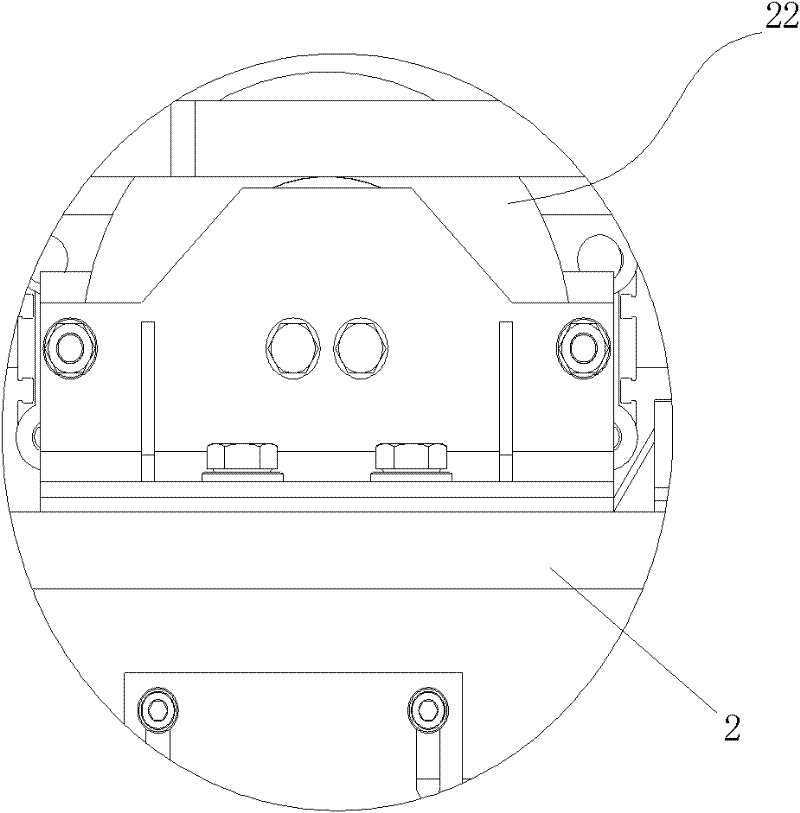

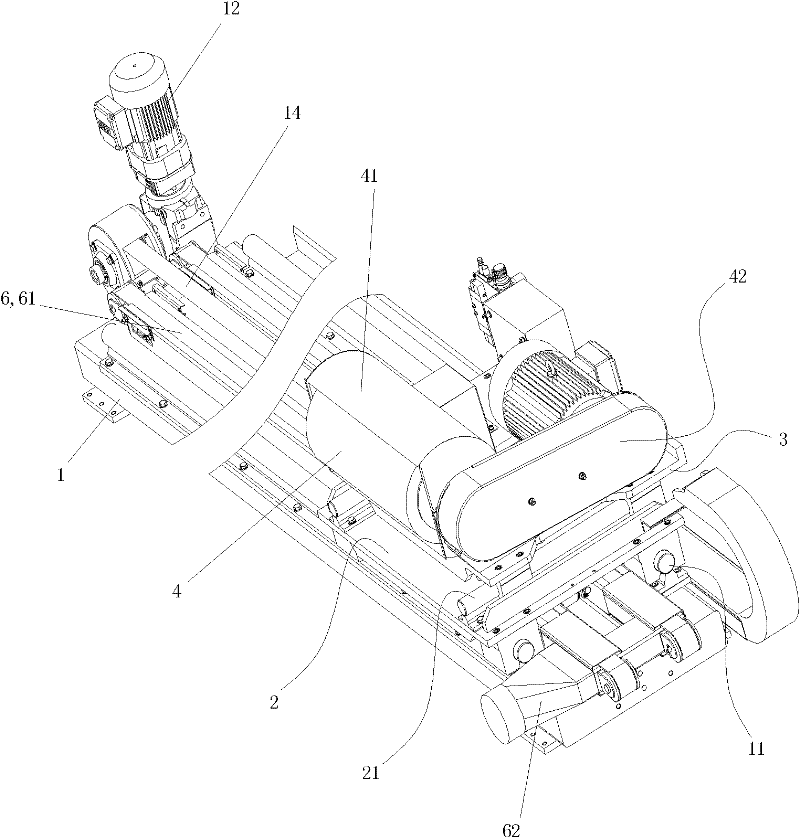

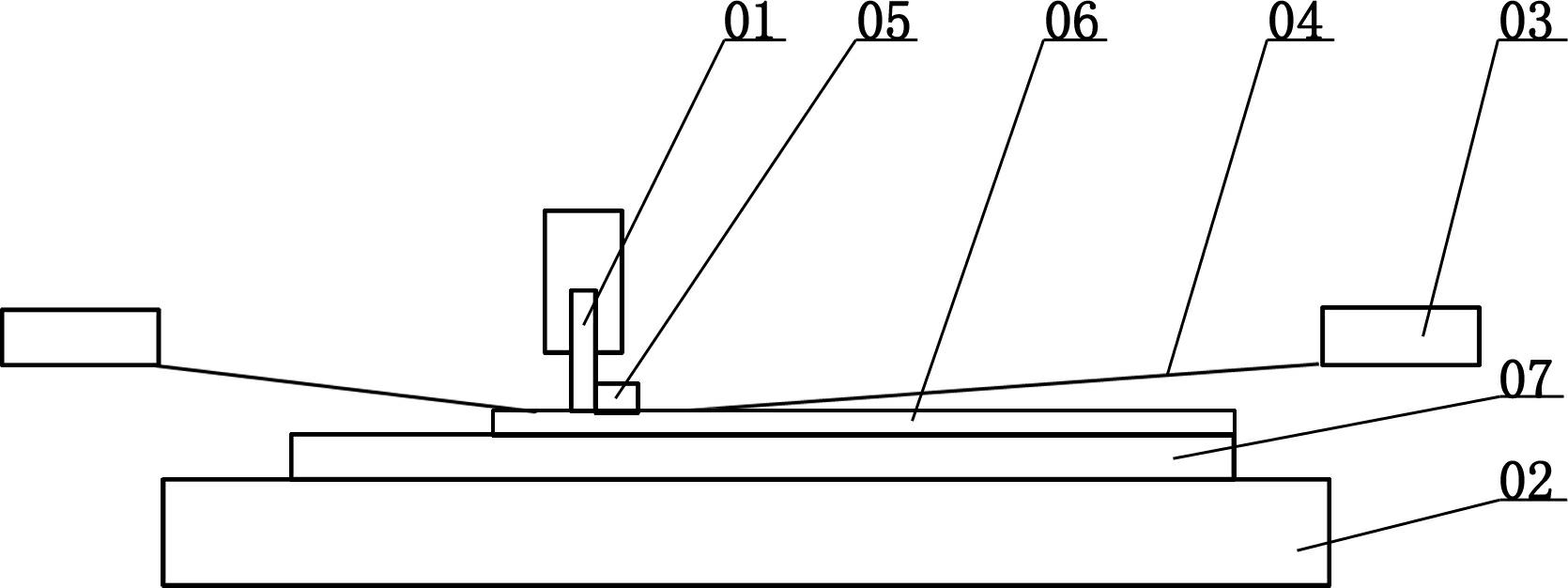

Carbon brush grinding chamfering machine

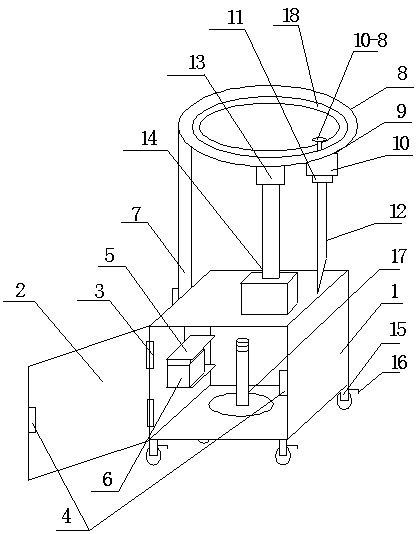

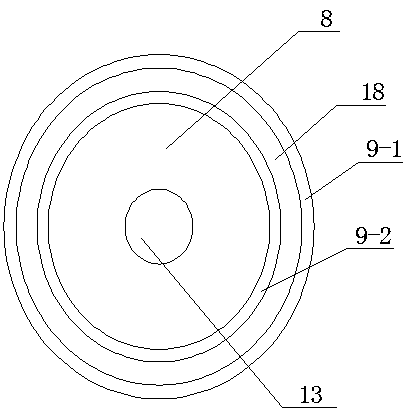

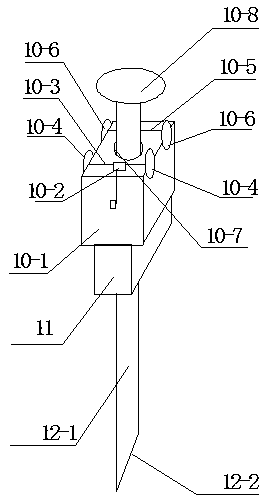

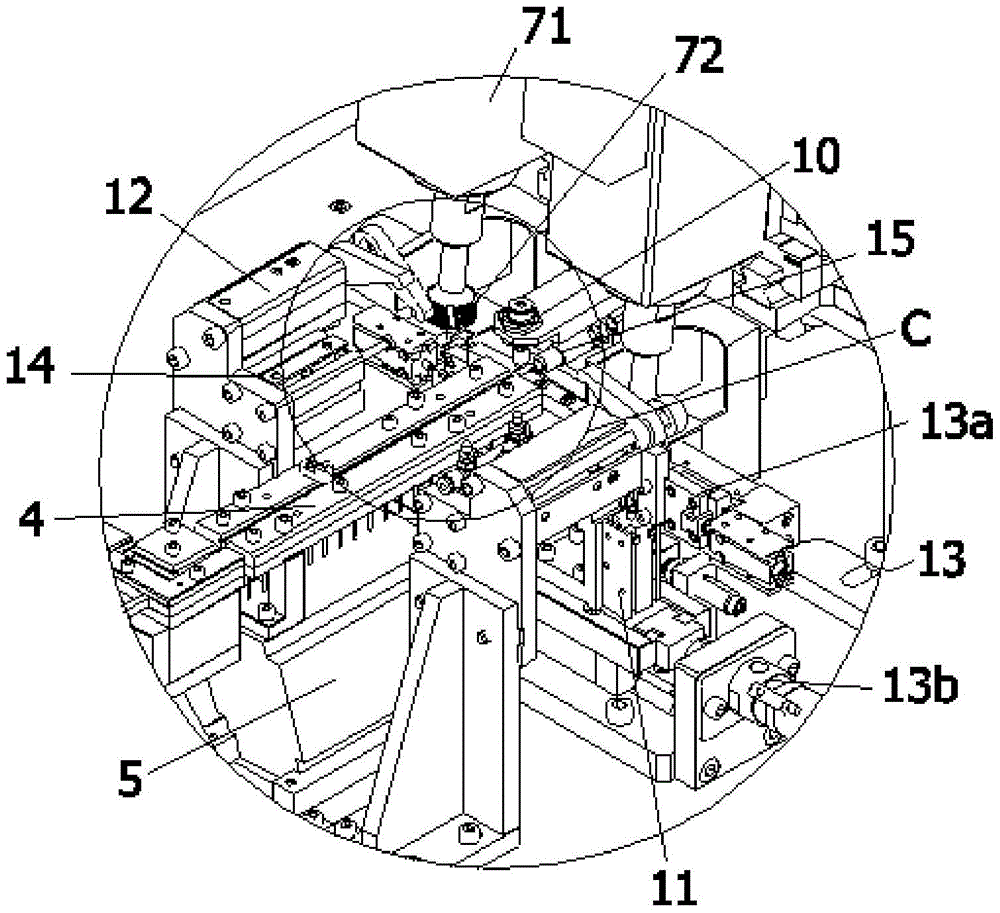

ActiveCN104589177BSimple structureEasy to useEdge grinding machinesGrinding drivesEngineeringAutomation

The invention discloses a carbon brush grinding and chamfering machine. The carbon brush grinding and chamfering machine comprises a working table, a carrying device, a plane grinding device and a chamfering device, wherein the carrying device is mounted on the working table, is used for automatically and directionally sorting multiple carbon brushes and carrying the carbon brushes to machining stations, and is provided with a linear guide rail for carrying the multiple carbon brushes; the plane grinding device is arranged on the working table, and is used for grinding the upper end surfaces of the carbon brushes carried on the linear guide rail; and the chamfering device is arranged on the working table, and is used for chamfering the carbon brushes with the grinded upper end surfaces. The advantages are that the carbon brush grinding chamfering machine is convenient to use, capable of automatically and quickly grinding and chamfering the upper end surfaces of the carbon brushes, simple in structure, high in automation, high in grinding and chamfering efficiency, high in production efficiency and low in production cost, and enables machined products to be high in quality.

Owner:湖北东南佳新材料有限公司

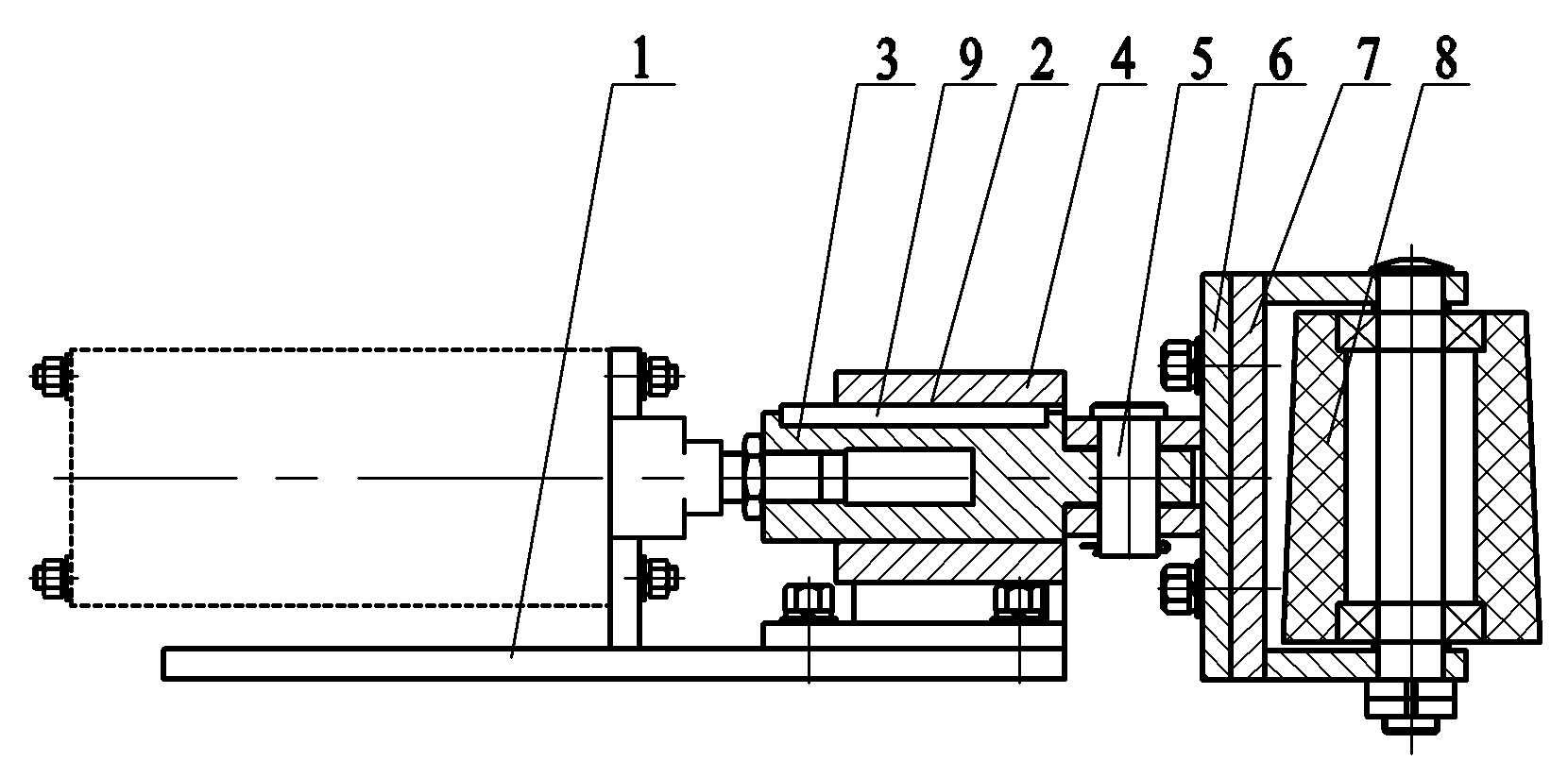

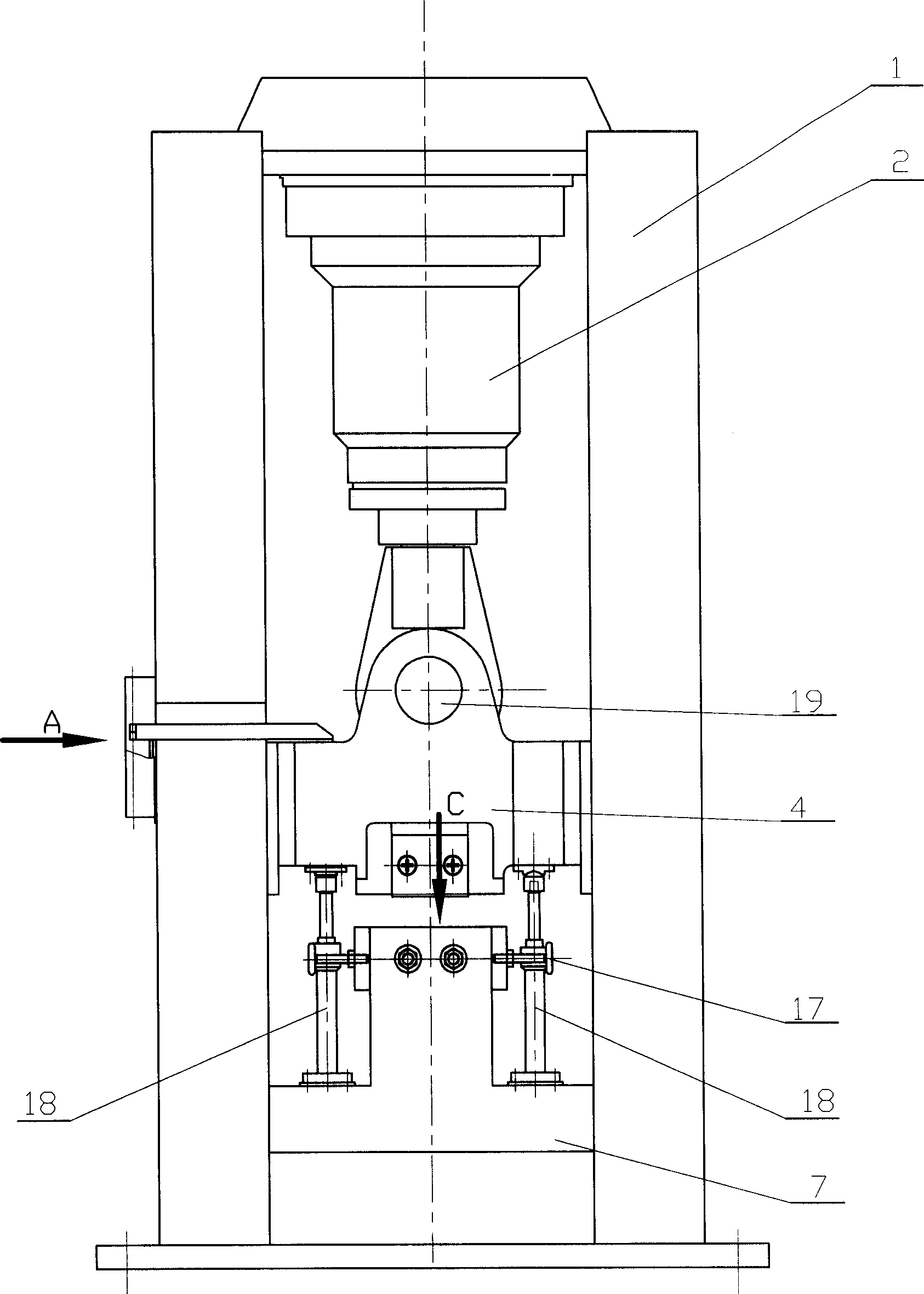

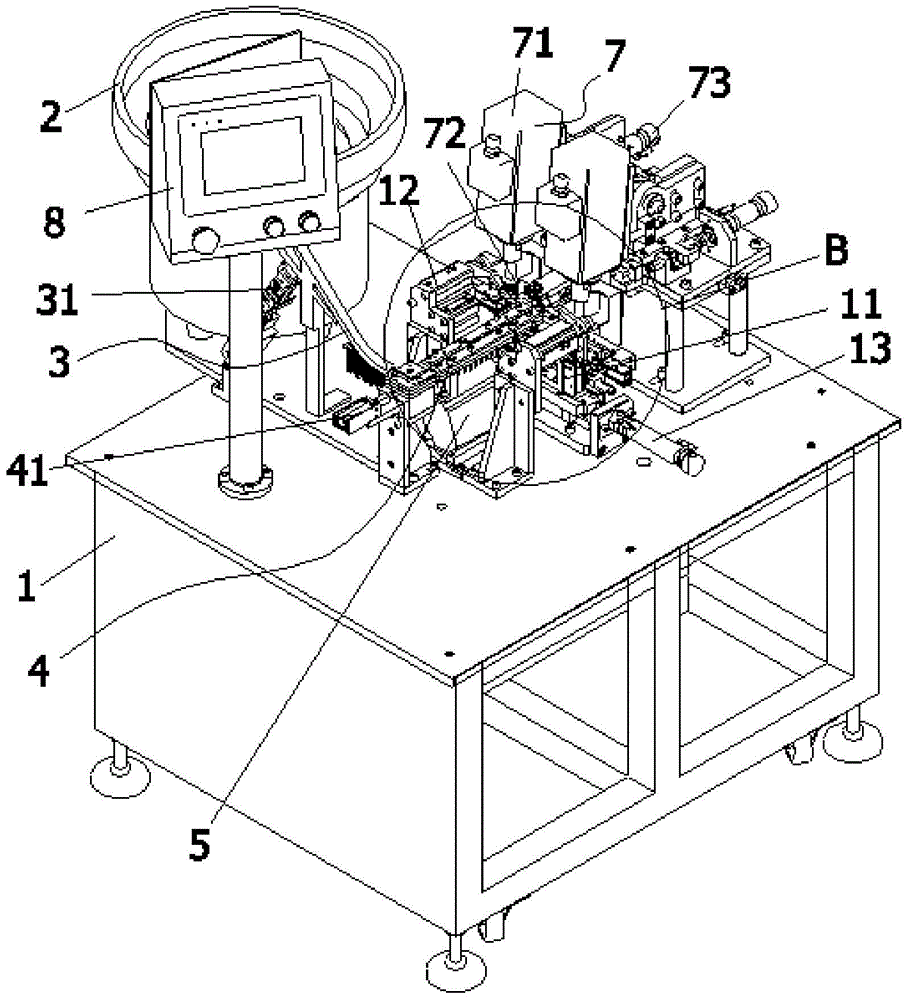

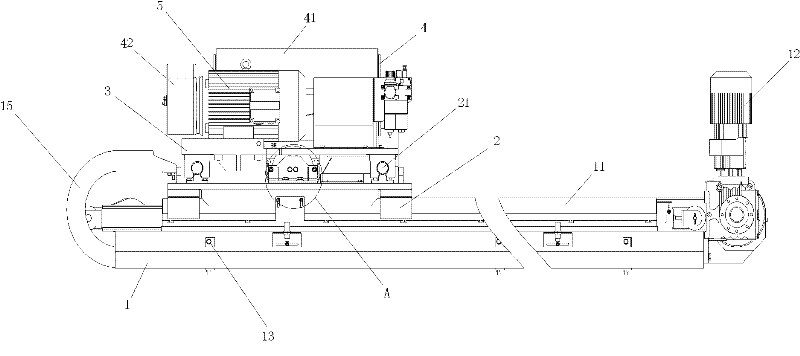

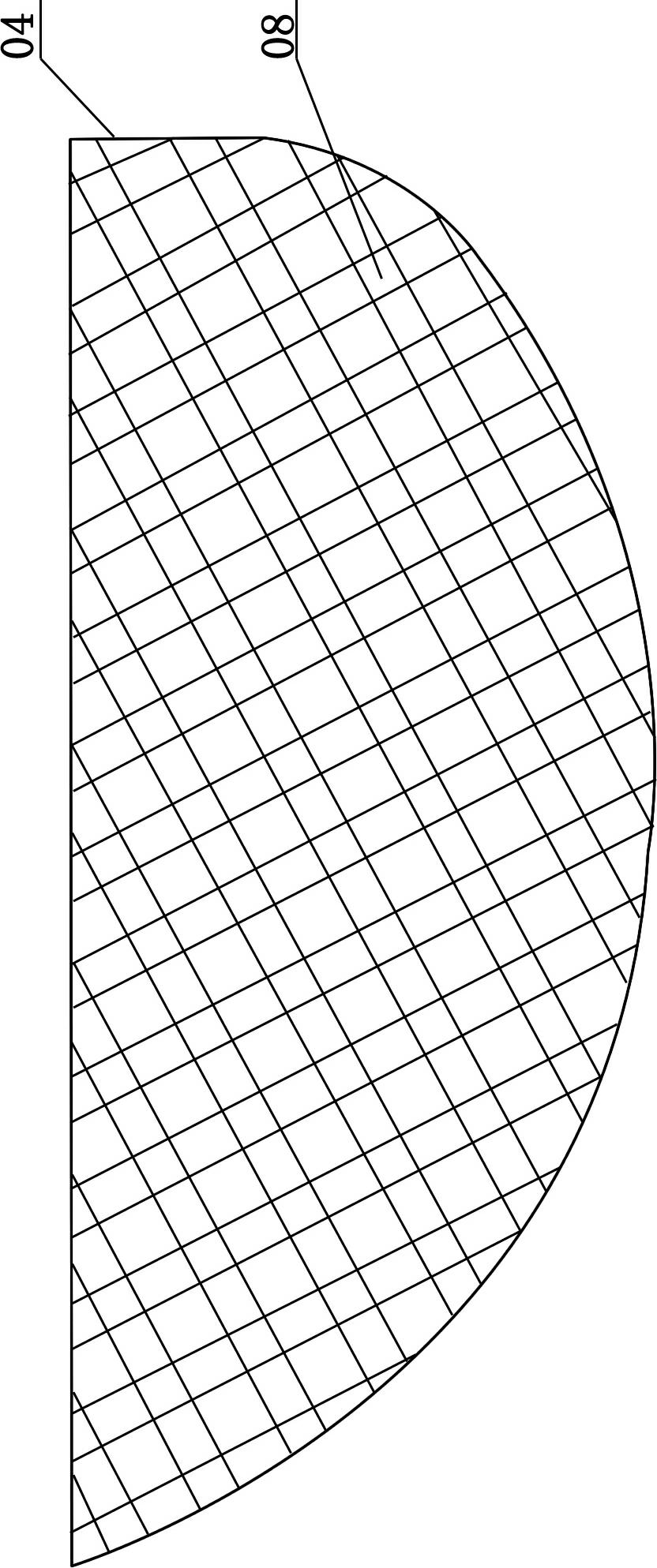

Carbon brush front face grinding machine

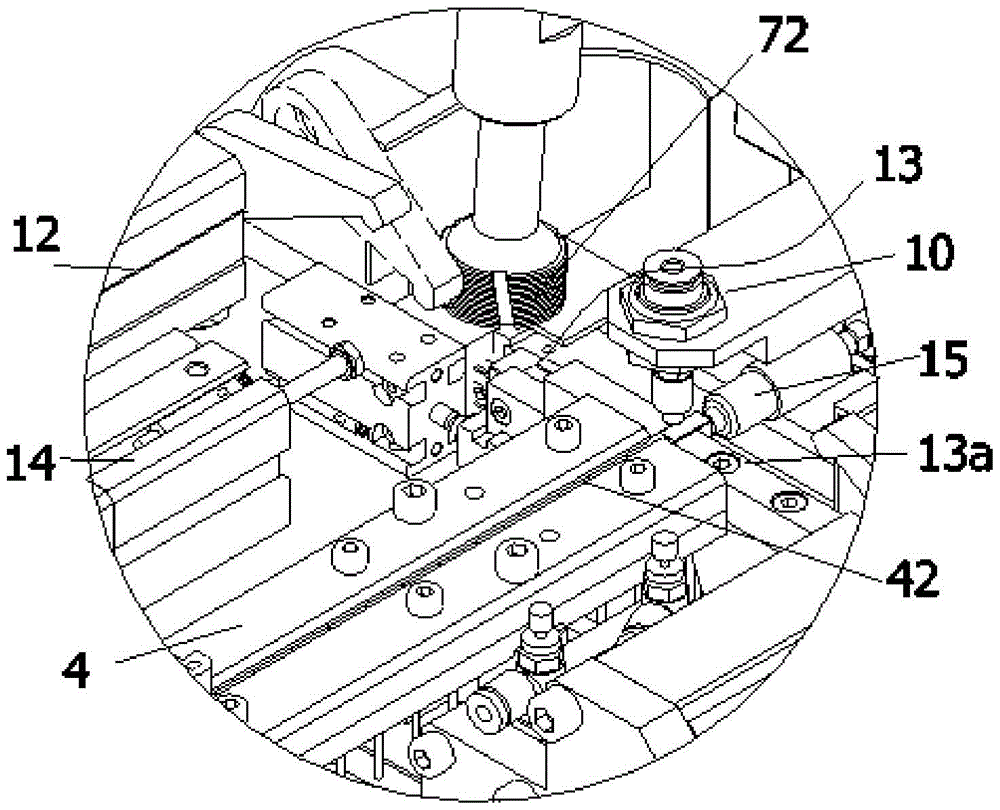

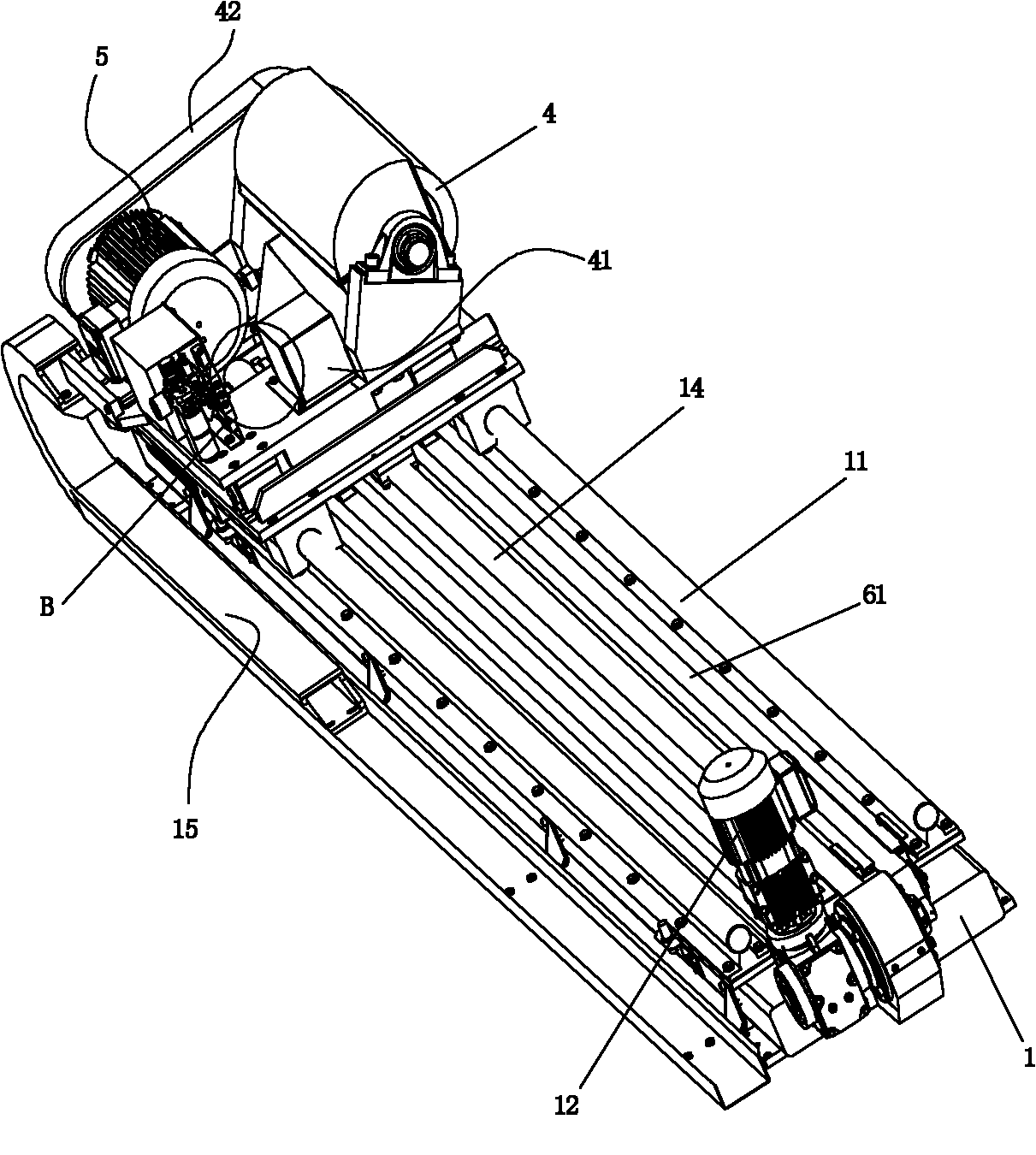

ActiveCN104589168BSimple structureEasy to useGrinding feedersGrinding work supportsEngineeringSurface grinding

The invention discloses a carbon brush front end surface grinding machine. The carbon brush front end surface grinding machine comprises a working table, a conveying device, a carbon brush fixture, a positioning device and a grinding device, wherein the conveying device is mounted on the working table, is used for automatically and directionally sorting multiple carbon brushes and conveying the carbon brushes in sequence, and is provided with a linear guide rail for conveying the multiple carbon brushes; the carbon brush fixture is arranged on the working table, can horizontally move, is positioned at the tail end of the linear guide rail, is perpendicular to the linear guide rail, and is provided with a carbon brush positioning groove capable of being butted to a guide rail groove of the linear guide rail and used for placing the carbon brushes; when the carbon brush fixture horizontally moves, the carbon brushes in the carbon brush positioning groove are conveyed to a grinding station; the positioning device is arranged on the working table, is positioned at the tail end of the linear guide rail, and is used for positioning the carbon brushes in the grinding station; and the grinding device is arranged on the working table, and is positioned at the tail end of the linear guide rail. The carbon brush front end surface grinding machine has the advantages of simple structure, convenience for use, capability of automatically and quickly grinding front end surfaces of the carbon brushes, high efficiency and good product quality.

Owner:湖北东南佳新材料有限公司

Movable steel strip brush

InactiveCN101905217AAvoid damagePrevent out of boundsWood working apparatusCleaning using toolsFiberEngineering

The invention relates to cleaning equipment of a continuous press, in particular to a movable steel strip brush used for cleaning a steel strip on the press, and aims to provide a movable steel strip brush with the advantages of reliable use and capacity of working on line. The movable steel strip brush is provided with a base, wherein a transverse guide rail is arranged on the base; a movable seat is connected to the transverse guide rail in a sliding mode; a longitudinal guide rail is arranged on the movable seat; a steel strip brush base is arranged on the longitudinal guide rail; a cylinder which is used for driving the steel strip brush base to slide longitudinally is arranged on the movable seat; a cleaning brush and a motor which is used for driving the cleaning brush to rotate are arranged on the steel strip brush base; and a variable frequency moving motor which is used for driving the movable seat to slide is arranged at the right end of the base. The movable steel strip brush can be arranged on one side of the continuous press to clean the steel strip on line, does not need to stop the work of the press, and cannot influence the production progress of fiber boards.

Owner:DIEFFENBACHER MACHINERY SERVICES BEIJING

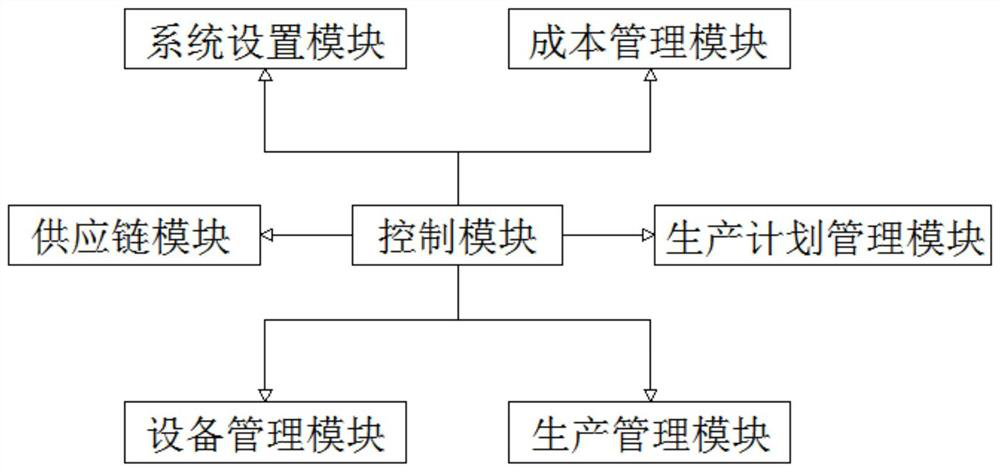

Warehouse management system based on financial data

PendingCN112434995AThe processing method is simpleImprove safety performanceResourcesLogisticsPurchasing managementManagement system

The invention discloses a warehouse management system based on financial data. According to the technical scheme, the warehouse management system is characterized by comprising a supply chain module used for product information maintenance, a production management module used for unified scheduling of production materials, a system setting module used for material information input and a control module used for control. The supply chain module comprises a purchasing management unit, an outsourcing processing unit and a sales management unit. The purchasing management unit comprises purchasingmanagement including purchasing application, purchasing orders, outsourcing warehousing, purchasing invoices, inventory query, report analysis, query analysis, supplier management and accounting parameters. And the effects of helping enterprise financial personnel to improve the working efficiency, being highly combined with the production data and financial data, not influencing the production progress and updating the material inventory in real time are achieved.

Owner:苏州市伟杰电子有限公司

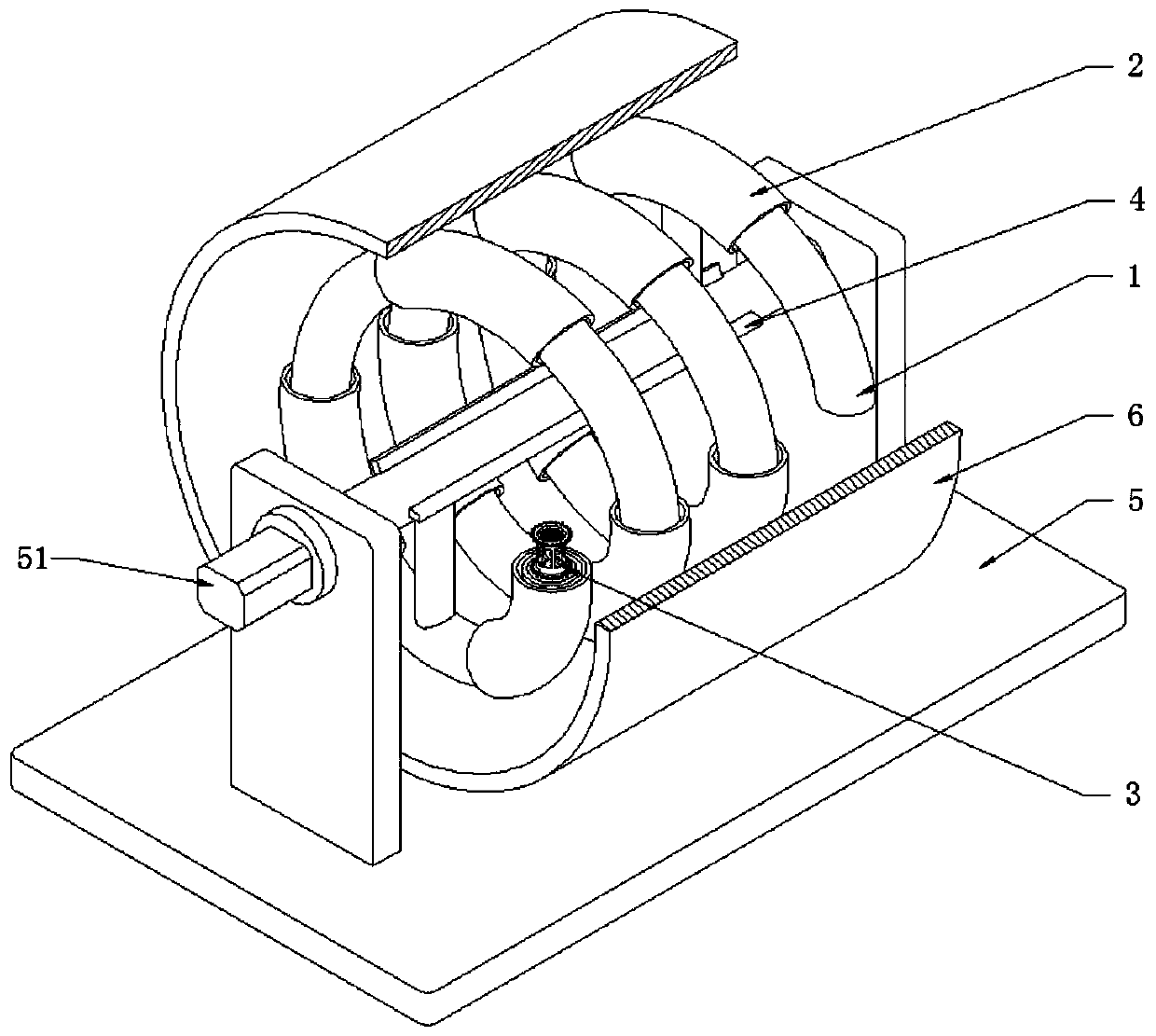

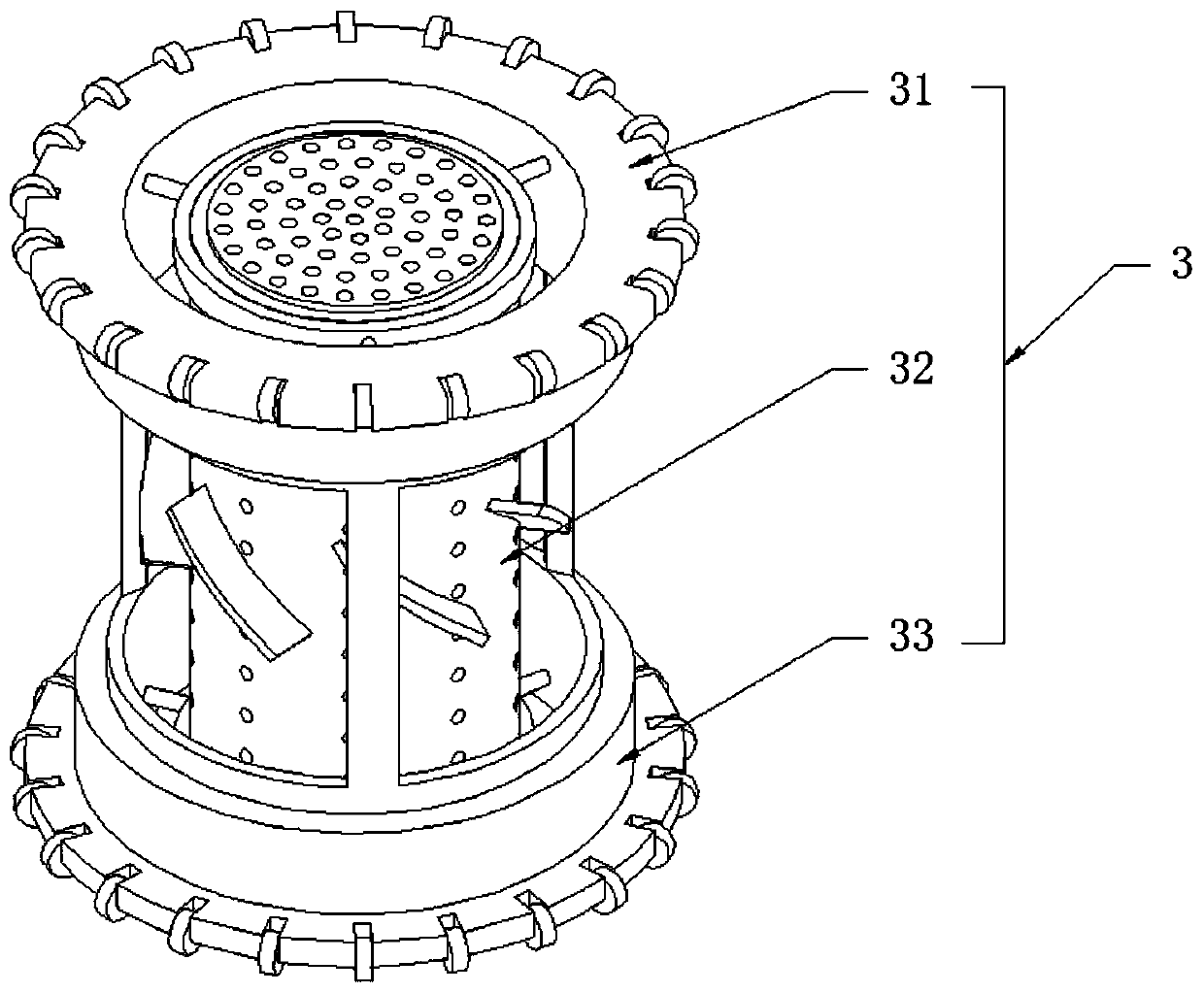

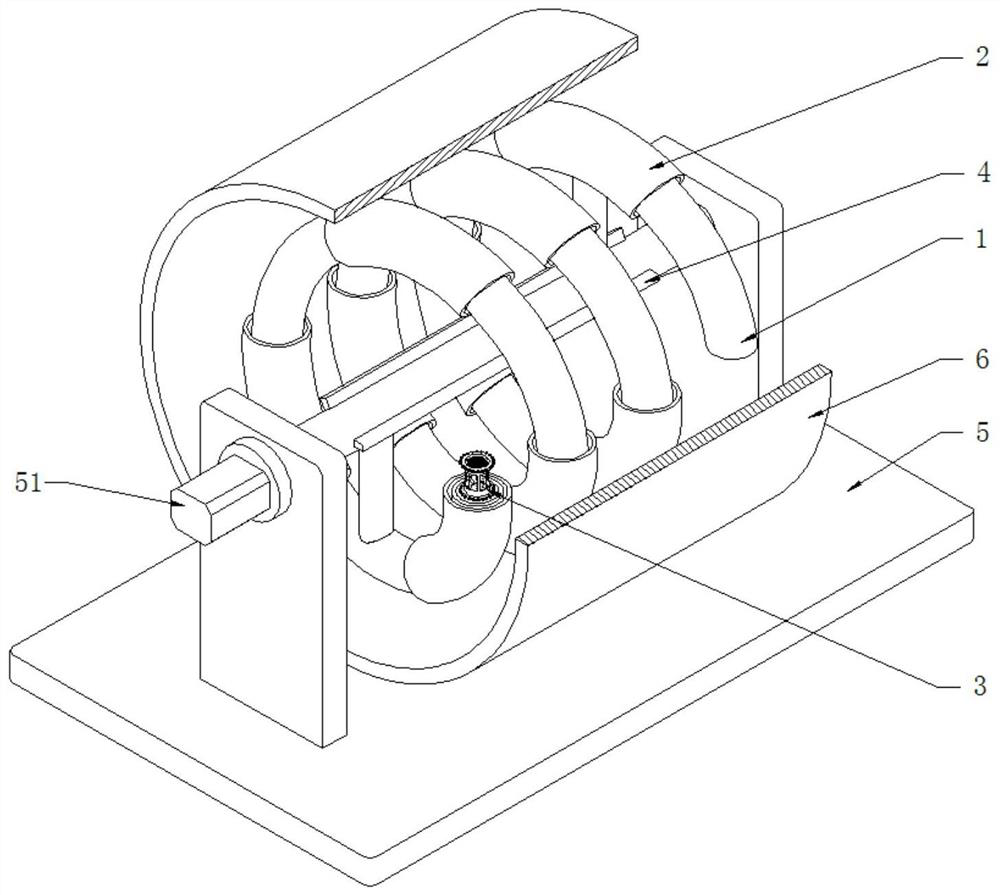

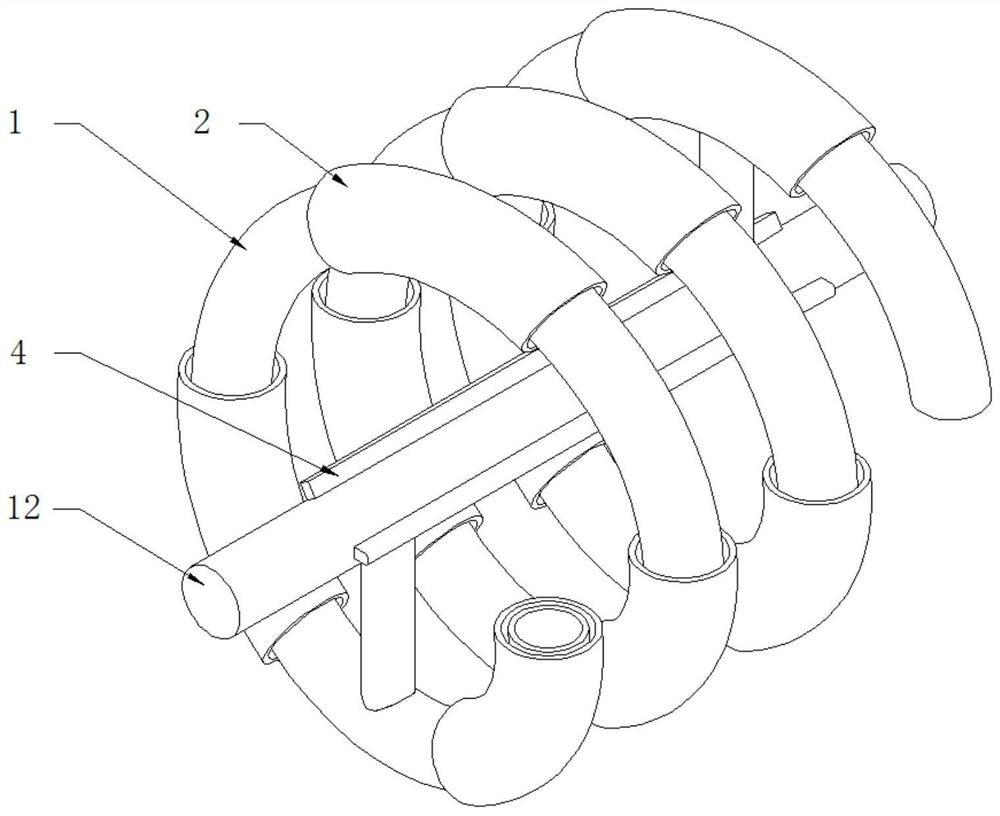

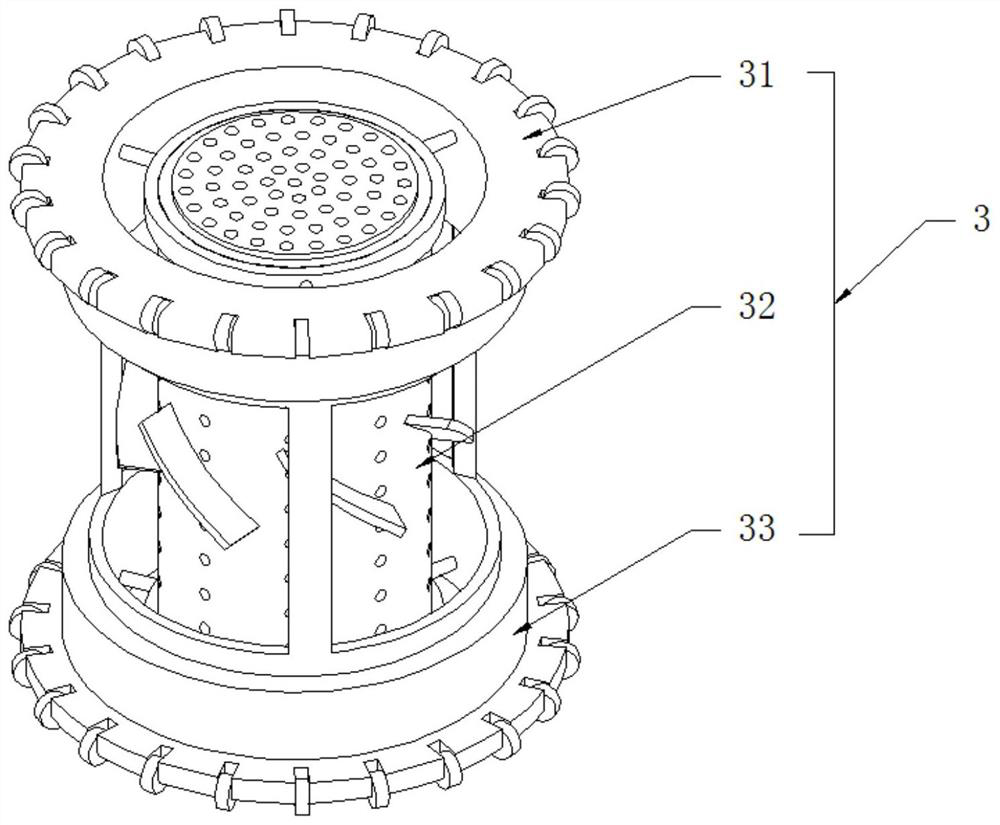

Device for processing, cleaning and disinfecting fish and shrimp aquatic products

ActiveCN111084217AIncrease contact areaSimple production processFish washing/descalingShrimp/lobster processingFisheryAquatic product

The invention discloses a device for processing, cleaning and disinfecting fish and shrimp aquatic products. The device includes a horizontal type spiral washing pipe, driving magnetic casing pipes, adiamagnetic cleaning cage, ultraviolet disinfection pipes and a supporting rack; the external of the spiral washing pipe is sleeved by the driving magnetic casing pipes; the diamagnetic cleaning cageincludes a bearing sleeve, a hole punching cylinder located in the bearing sleeve to perform rotational cooperation and a diamagnetic sleeve fixedly sleeving the bearing sleeve; and the hole punchingcylinder is used for placing fish and shrimp aquatic products. After the whole diamagnetic cleaning cage is put from the inlet end of the spiral washing pipe, the driving magnetic casing pipes generate magnetic thrust on the diamagnetic cleaning cage according to a principle of electromagnetic gun, so that the diamagnetic cleaning cage can pushed to perform spiral line track motion; nozzles are arranged in the spiral washing pipe, so that the cleaning fluid sprayed by the nozzles can perform washing on the fish and shrimp aquatic products in the hole punching cylinder; and the periphery of the hole punching cylinder is provided with blades, so that the contact area of washing liquid and the aquatic products can be increased through the turning of the hole punching cylinder, and therefore,the quality of cleaning and disinfecting can be greatly enhanced.

Owner:HUBEI JINLIYU FOOD

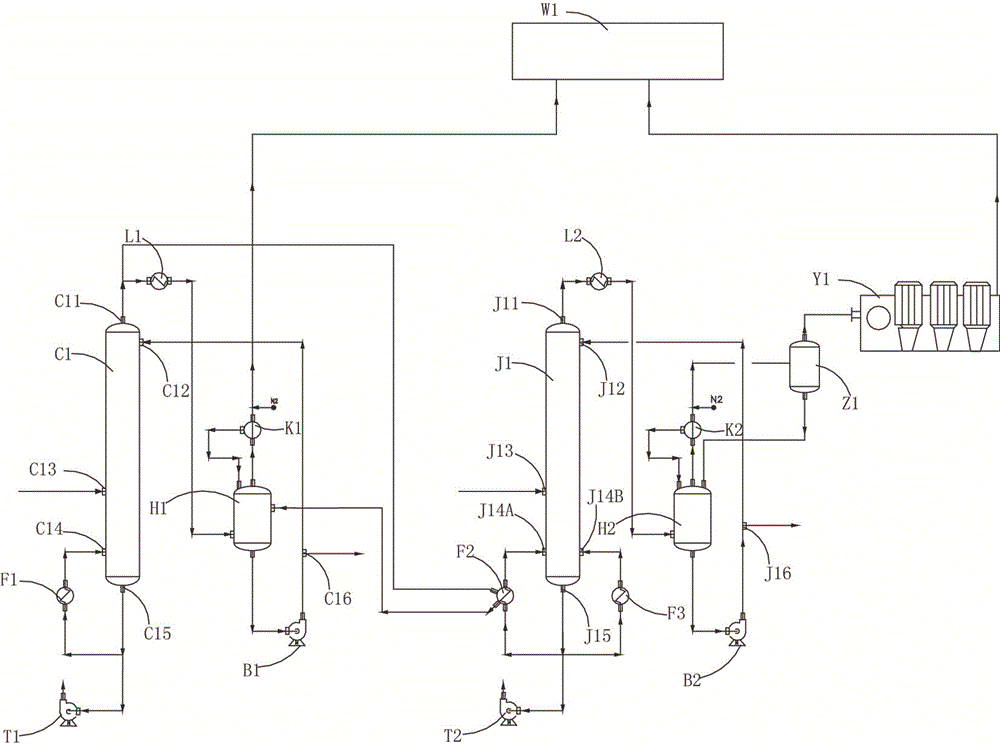

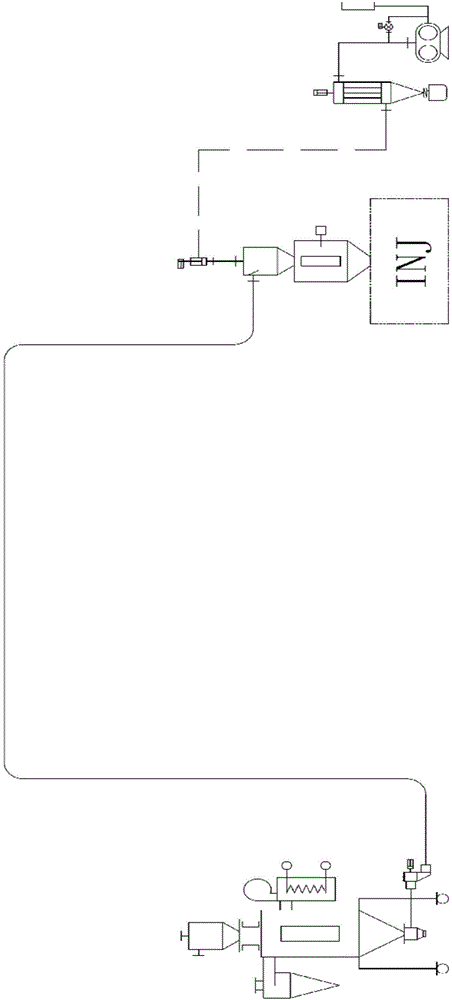

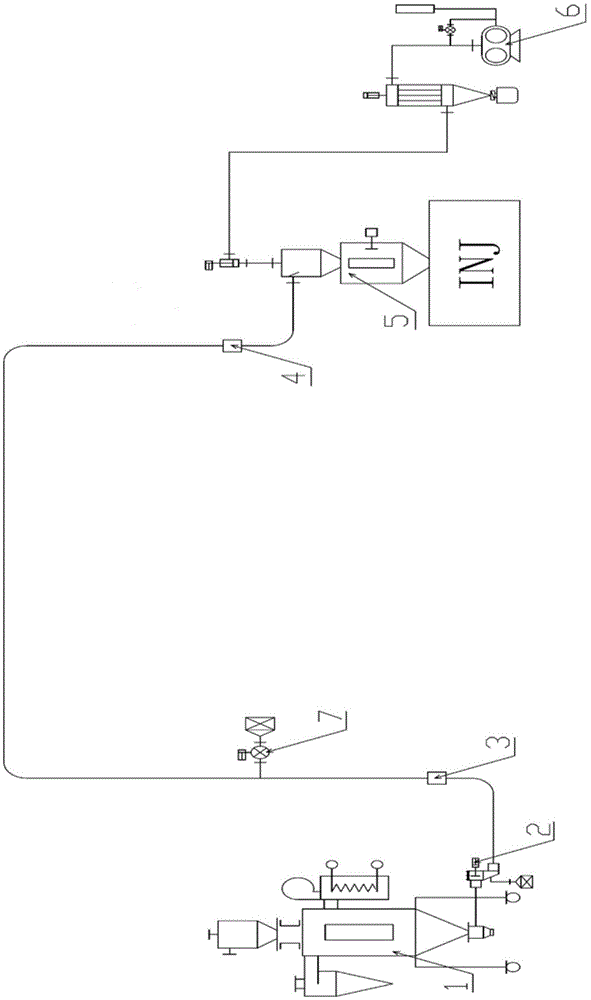

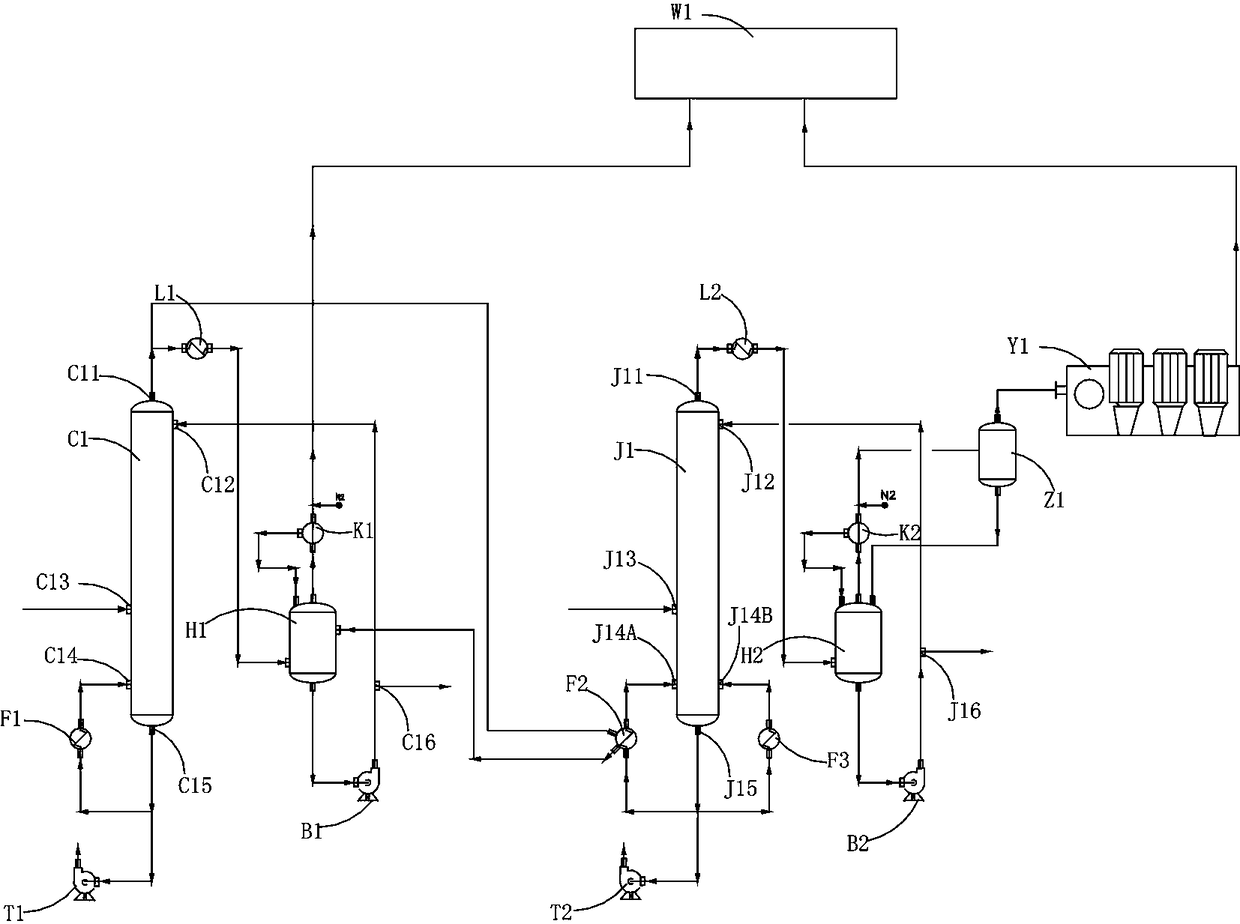

Differential pressure type thermal coupling rectification device

ActiveCN106334328AHigh purityAchieve recyclingDistillation regulation/controlHalogenated hydrocarbon preparationDifferential pressureEvaporation

The invention discloses a differential pressure type thermal coupling rectification device. The device comprises an atmospheric tower equipment group and a vacuum tower equipment group, wherein the atmospheric tower equipment group comprises an atmospheric tower body and all atmospheric equipment which is connected with one another through pipelines; a plurality of extensible baffles are arranged on the inner wall of the atmospheric tower body; the expansion of the baffles is controlled through a flow meter arranged in the atmospheric tower body; the vacuum tower equipment group comprises a vacuum tower body and all vacuum equipment groups connected with the vacuum tower body; a liquid distributor is arranged on the inner wall of the vacuum tower body. The device adopting the structure can obtain high-purity products, cancels steam in the conventional sense, applies energy at the top of a prior tower to the evaporation of a second tower, can save the steam amount for a rectifying tower, and realizes energy saving, moreover, as an atmospheric tower and a vacuum tower are respectively provided with two sets of pipelines, when any one of the atmospheric tower or the vacuum tower breaks down, standby pipelines can be started, shutting down due to equipment failure cannot occur, and the production efficiency is effectively improved.

Owner:NINGBO JUHUA CHEM TECH CO LTD +1

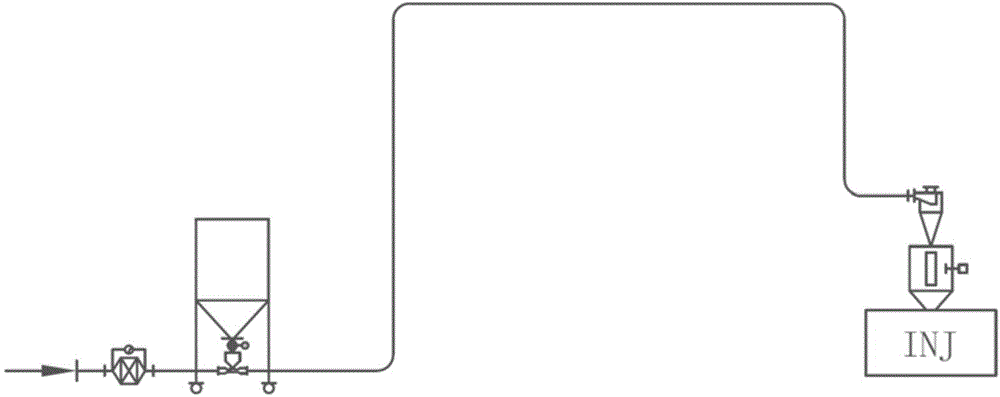

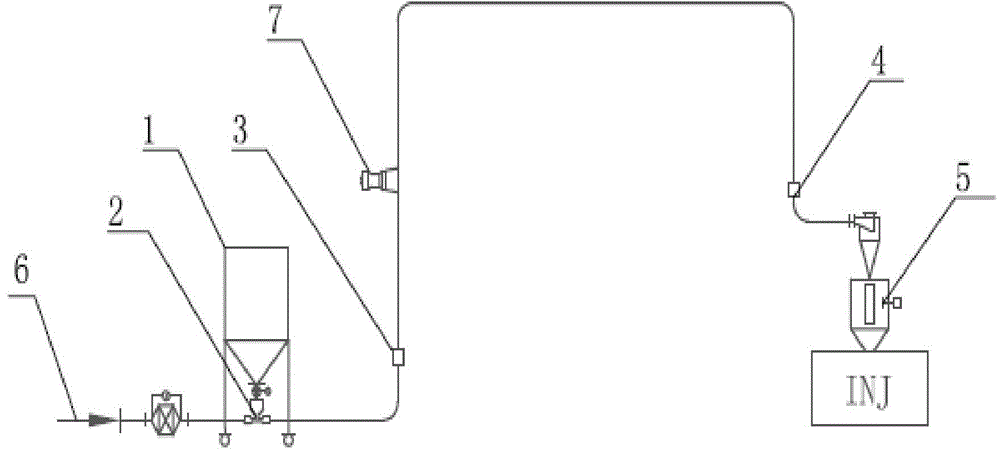

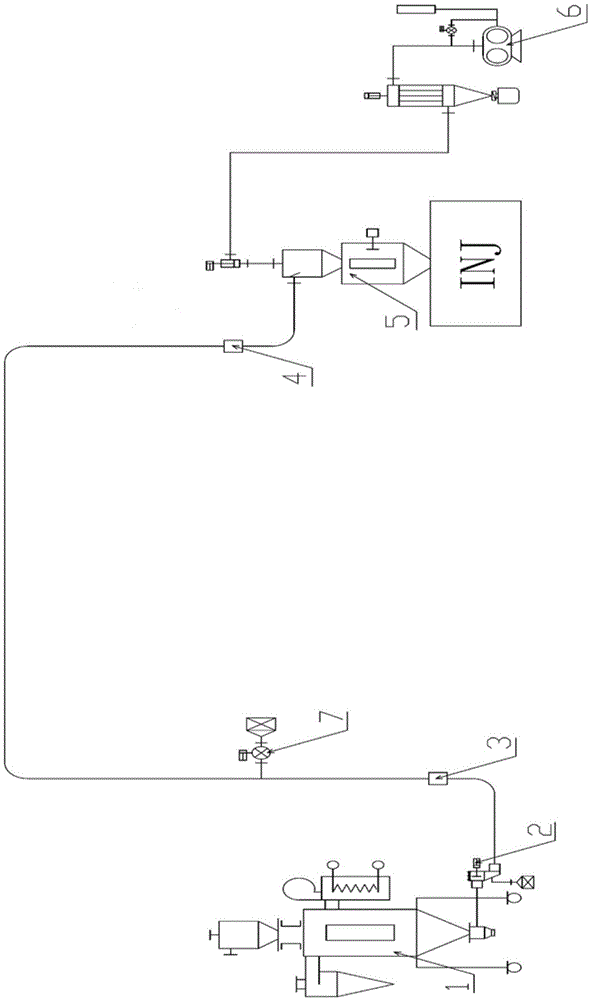

Pipeline transportation anti-clogging device and method of use thereof

ActiveCN104310063BEliminate the blocking situationWill not affect the production scheduleHollow article cleaningBulk conveyorsProduction scheduleEngineering

The invention relates to anti-clogging equipment used in pipe conveying. The equipment comprises a pipe conveying part, at least two detecting devices and at least one gas supplementing device, wherein the at least two detecting devices and the at least one gas supplementing device are arranged on the pipe conveying part; the pipe conveying part comprises a pipe, a conveying hopper, a conveying valve and a conveying fan connected with the conveying hopper; one end of the pipe is connected with a charging barrel through the conveying valve, and the other end of the pipe is connected with the conveying hopper; the at least two detecting devices and the at least one gas supplementing device are arranged on the pipe, and the gas supplementing device is positioned between the two detecting devices. By adopting the anti-clogging equipment, the clogging of pipes can be automatically detected, and automatic processing measure can be taken when the pipes are clogged, so that manpower and material resources are saved, and production schedules of clients cannot be influenced.

Owner:KAWATA MASCH MFG (SHANGHAI) CO LTD

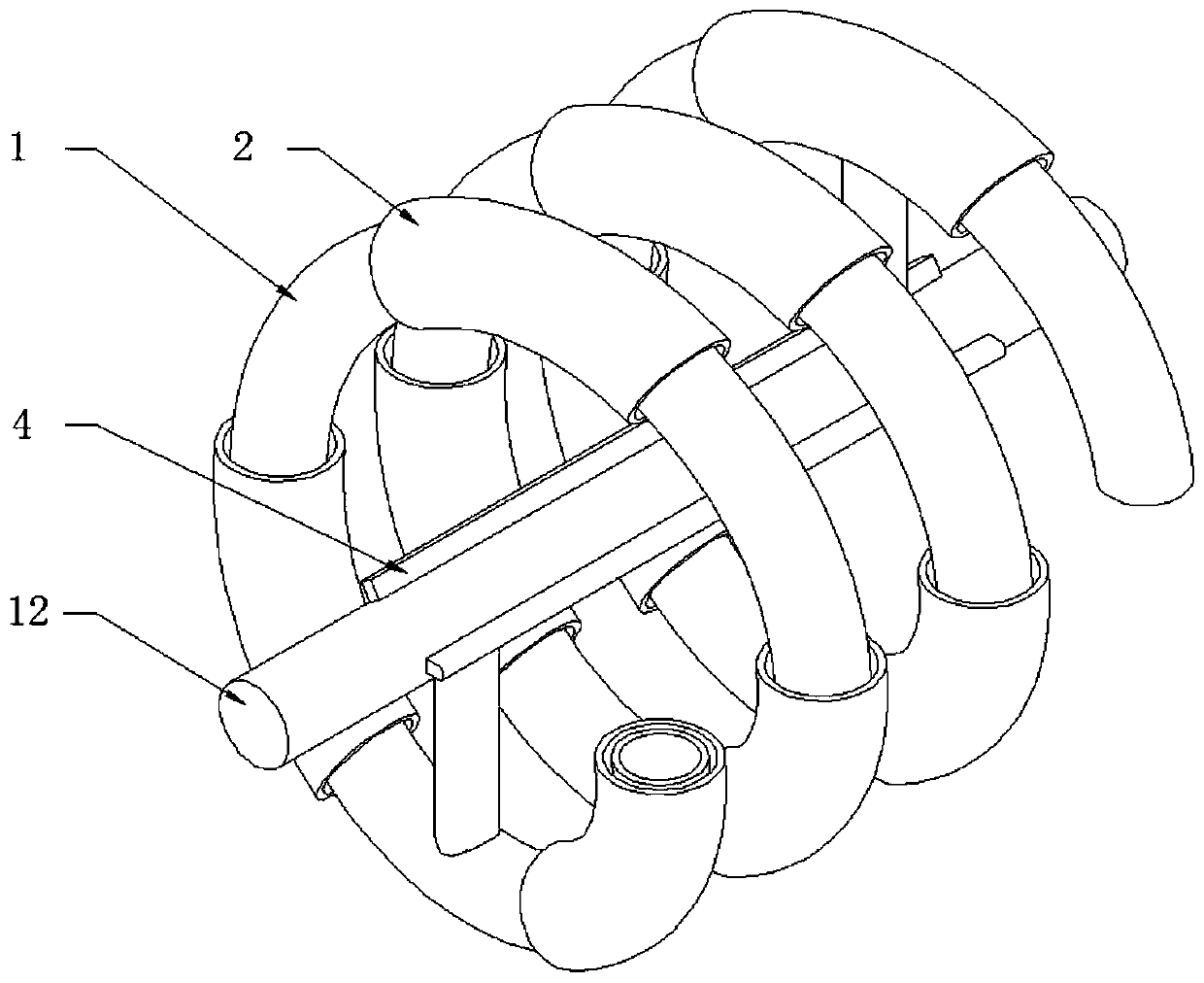

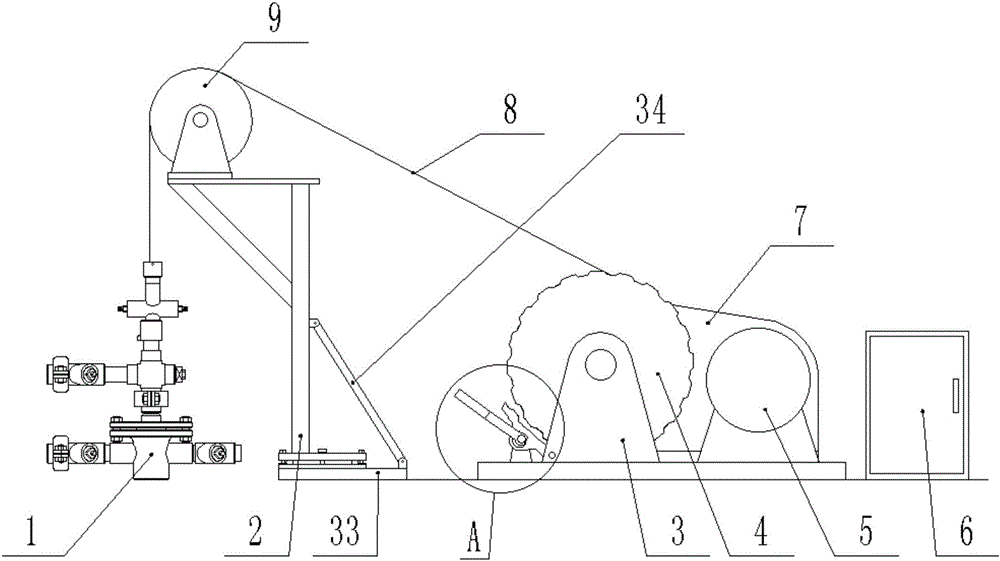

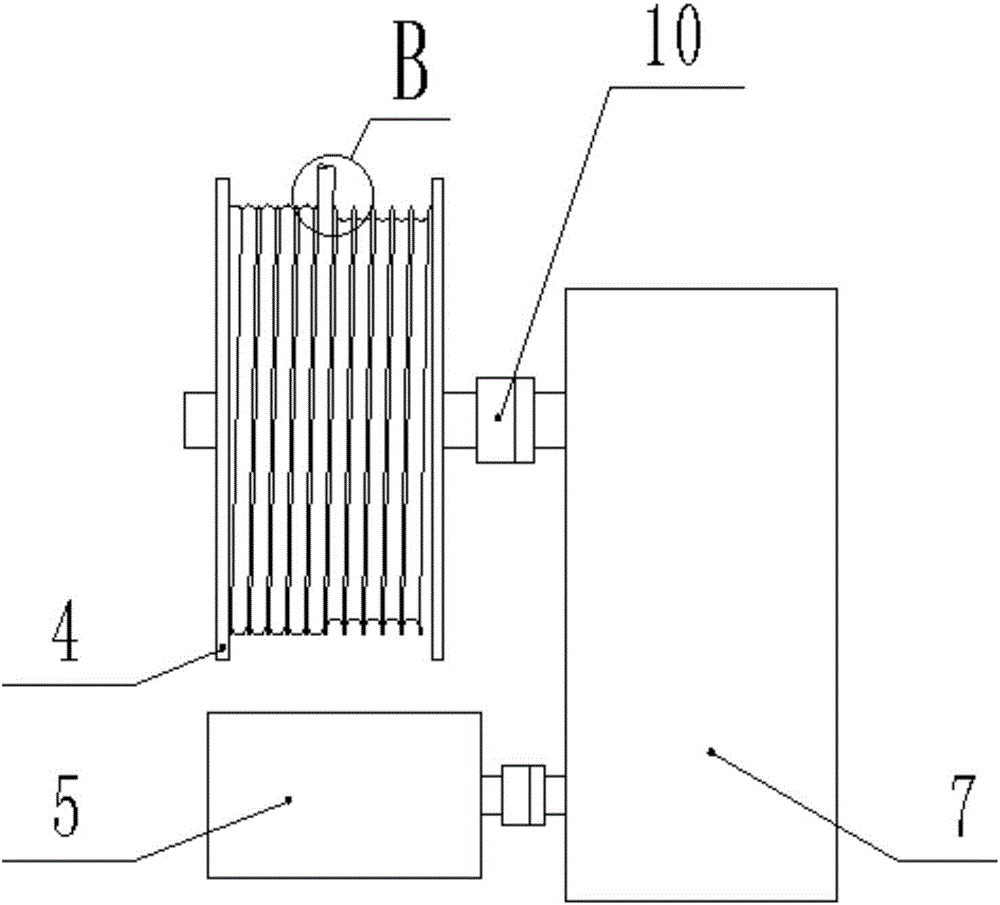

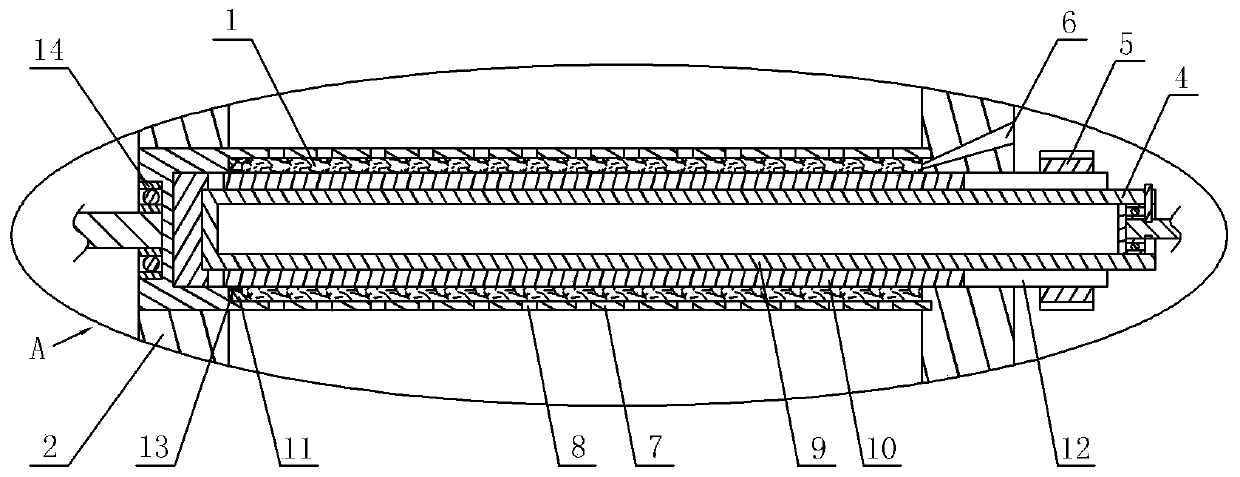

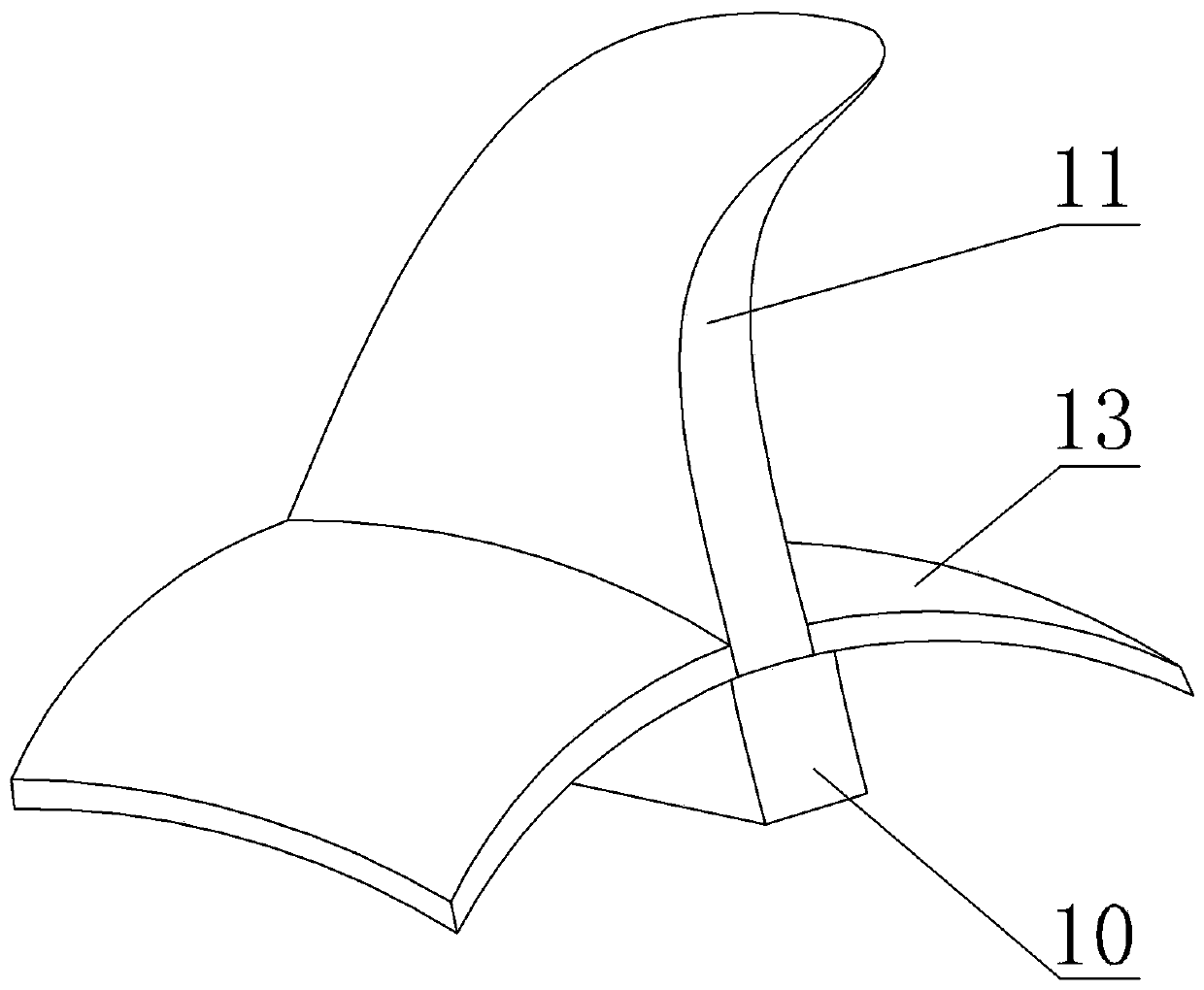

Intelligent driving device for oil-well pump and winding type pumping unit system

ActiveCN106593361ASmooth outer surfaceImprove flexibilityDrilling rodsFlexible member pumpsFiberElectricity

The invention belongs to the field of oil extraction equipment in the oil field and especially relates to an intelligent driving device for an oil-well pump and a winding type pumping unit system. The intelligent driving device comprises a motor, a speed reducer, a winch, a wellhead bracket, a sucker rod and a frequency converting control device, wherein the sucker rod is divided into two sections which are respectively called as an upper sucker rod section and a lower sucker rod section; the two sucker rod sections are connected with each other through a sucker rod joint; the upper sucker rod section is arranged as a glass fiber rod; the lower sucker rod section is arranged as a steel sucker rod or a carbon fiber rod; communication cables and ribbon heaters are arranged in both of the upper sucker rod section and the lower sucker rod section; the communication cables and the ribbon heaters are butt-jointed through an electric connector at the sucker rod joint; the communication cables and the ribbon heaters are arranged in both of the upper sucker rod section and the lower sucker rod section. A flexible sucker rod in the intelligent driving device has a two-section type structure; the upper sucker rod section is made of a glass fiber rod with the minimal bending radius being less than that of the other material; compared with a carbon fiber rod, the glass fiber rod has the minimal bending radius which can reach about 0.5 m, so that the size of the winch can be effectively reduced.

Owner:DAQING CITY HUAYU PETROLEUM MASCH MFG CO LTD

Dual-hydraulic system of remote-control grab bucket

InactiveCN104141646AWill not affect the production scheduleImprove loading and unloading efficiencyServomotorsProduction scheduleRemote control

The invention relates to a dual-hydraulic system of a remote-control grab bucket. An oil tank and an operating cylinder are fixed to a transverse beam of the remote-control grab bucket. A working hydraulic valve is arranged in the oil tank and communicated with the oil tank. The operating cylinder is connected with the working hydraulic valve through a working hydraulic pipe. A standby hydraulic valve is arranged in the oil tank. A standby oil cylinder is fixed to the transverse beam of the remote-control grab bucket and connected with the standby hydraulic valve through a standby hydraulic pipe. By means of the dual-hydraulic system, it is guaranteed that in the use process of the remote-control grab bucket, one of hydraulic system bodies is kept used all the time, and the other one of the hydraulic system bodies is kept in the normally-standby condition all the time; once one of the hydraulic system bodies is damaged, the other one of the hydraulic system bodies can be immediately switched for use, the normal production schedule can not be influenced, and the loading-unloading efficiency is improved.

Owner:无锡市新华起重工具有限公司

Anti-clogging equipment used in pipe conveying, and using method of equipment

ActiveCN104310063ASave manpower and material resourcesShort blockage removal timeHollow article cleaningBulk conveyorsAutomatic processingMaterial resources

The invention relates to anti-clogging equipment used in pipe conveying. The equipment comprises a pipe conveying part, at least two detecting devices and at least one gas supplementing device, wherein the at least two detecting devices and the at least one gas supplementing device are arranged on the pipe conveying part; the pipe conveying part comprises a pipe, a conveying hopper, a conveying valve and a conveying fan connected with the conveying hopper; one end of the pipe is connected with a charging barrel through the conveying valve, and the other end of the pipe is connected with the conveying hopper; the at least two detecting devices and the at least one gas supplementing device are arranged on the pipe, and the gas supplementing device is positioned between the two detecting devices. By adopting the anti-clogging equipment, the clogging of pipes can be automatically detected, and automatic processing measure can be taken when the pipes are clogged, so that manpower and material resources are saved, and production schedules of clients cannot be influenced.

Owner:KAWATA MASCH MFG (SHANGHAI) CO LTD

A processing cleaning and disinfection device for fish and shrimp aquatic products

ActiveCN111084217BIncrease contact areaSimple production processFish washing/descalingShrimp/lobster processingFisheryAquatic product

The invention discloses a processing cleaning and disinfection device for fish and shrimp aquatic products, which comprises a horizontally distributed spiral washing pipe, a driving magnetic sleeve, a reverse magnetic cleaning cage, an ultraviolet disinfection pipe and a support frame. In the present invention, a drive magnetic sleeve is provided on the outside of the spiral flushing pipe, and the reverse magnetic cleaning cage includes a bearing sleeve, a punching cylinder that rotates and fits inside the bearing sleeve, and a reverse magnetic sleeve that is fixedly sleeved outside the bearing sleeve. The cylinder is used to place fish and shrimp aquatic products. After putting the entire reverse magnetic cleaning cage from the inlet end of the spiral flushing pipe, according to the "electromagnetic gun principle", the magnetic sleeve is driven to generate magnetic thrust on the reverse magnetic cleaning cage, and then pushes the reverse magnetic cleaning cage. The magnetic cleaning cage moves on a helical track. At the same time, a nozzle is installed in the spiral rinsing pipe. The cleaning liquid sprayed out by the nozzle rinses the fish and shrimp aquatic products in the punching cylinder, and blades are set on the outer periphery of the punching cylinder, so that the punching cylinder rolls Increase the contact area between flushing fluid and aquatic products, greatly improving the quality of cleaning and disinfection.

Owner:HUBEI JINLIYU FOOD

A differential pressure thermally coupled rectification device

ActiveCN106334328BHigh purityAchieve recyclingDistillation regulation/controlHalogenated hydrocarbon preparationDifferential pressureEvaporation

The invention discloses a differential pressure type thermal coupling rectification device. The device comprises an atmospheric tower equipment group and a vacuum tower equipment group, wherein the atmospheric tower equipment group comprises an atmospheric tower body and all atmospheric equipment which is connected with one another through pipelines; a plurality of extensible baffles are arranged on the inner wall of the atmospheric tower body; the expansion of the baffles is controlled through a flow meter arranged in the atmospheric tower body; the vacuum tower equipment group comprises a vacuum tower body and all vacuum equipment groups connected with the vacuum tower body; a liquid distributor is arranged on the inner wall of the vacuum tower body. The device adopting the structure can obtain high-purity products, cancels steam in the conventional sense, applies energy at the top of a prior tower to the evaporation of a second tower, can save the steam amount for a rectifying tower, and realizes energy saving, moreover, as an atmospheric tower and a vacuum tower are respectively provided with two sets of pipelines, when any one of the atmospheric tower or the vacuum tower breaks down, standby pipelines can be started, shutting down due to equipment failure cannot occur, and the production efficiency is effectively improved.

Owner:NINGBO JUHUA CHEM TECH CO LTD +1

An insect repellant suitable for feed and its raw materials and a feed factory insect repellent method

ActiveCN104824048BImprove the bactericidal effectImprove insect repellent effectBiocidePest repellentsBenzoic acidInsect repellent

The invention discloses a pest repellent suitable for feed and feed raw materials and a pest repelling method in a feed factory. The pest repellent is composed of the following components in parts by weight: 5 to 30 parts of cinnamon oil, 2 to 20 parts of eucalyptus oil, 2 to 8 parts of clove oil, 0.5 to 5 parts of lavender oil, 5 to 10 parts of benzoic acid, 20 to 50 parts of formic acid, and 0 to 40 parts of carrier. The pest repelling method comprises the following steps: mixing the pest repellent with a diluting material according to a mass ratio of 1:3-6 to obtain a diluted pest repellent, taking the diluted pest repellent as the production raw materials, running the normal feed production procedure, making the pest repellent go through each processing equipment in a feed factory, repeating the production procedure for 1 to 3 times, then cleaning the residual pest repellent in equipment, and carrying out feed production. The provided feed repellent and method are suitable for production units of all feeds and all feed raw materials, and have the advantages of no time limitation, good pest repelling effect, safety, no toxicity, small workload, and continuous production.

Owner:CHONGQING MINTAI NEW AGROTECH DEV GRP CO LTD

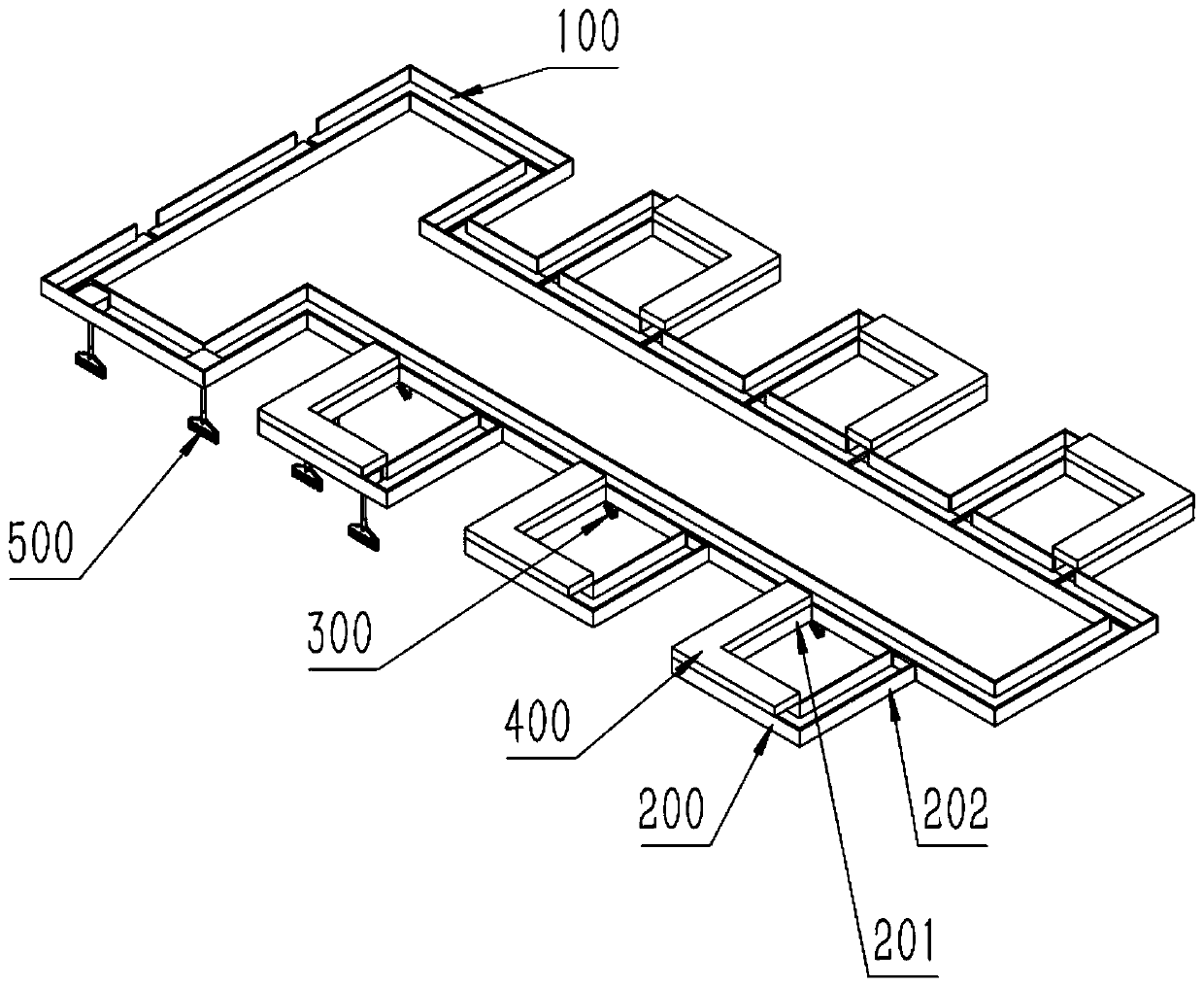

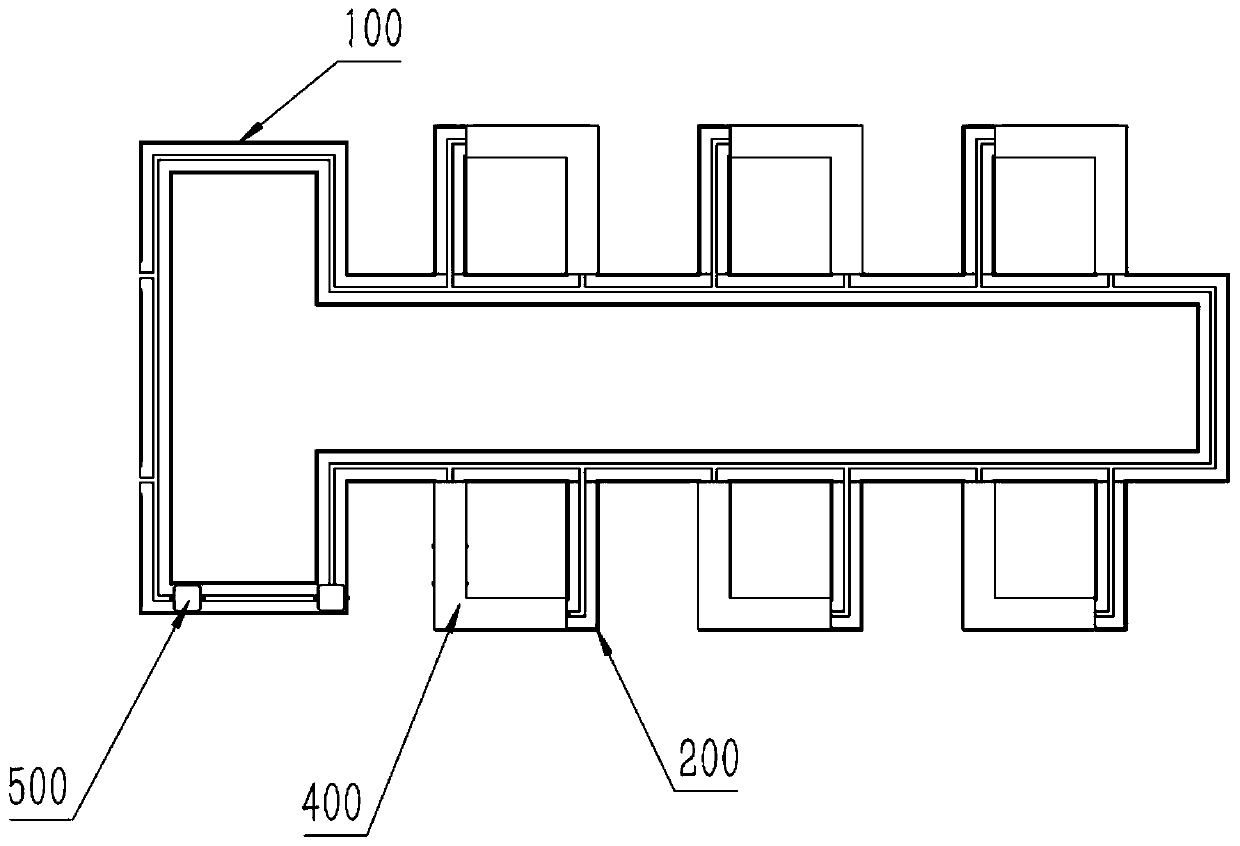

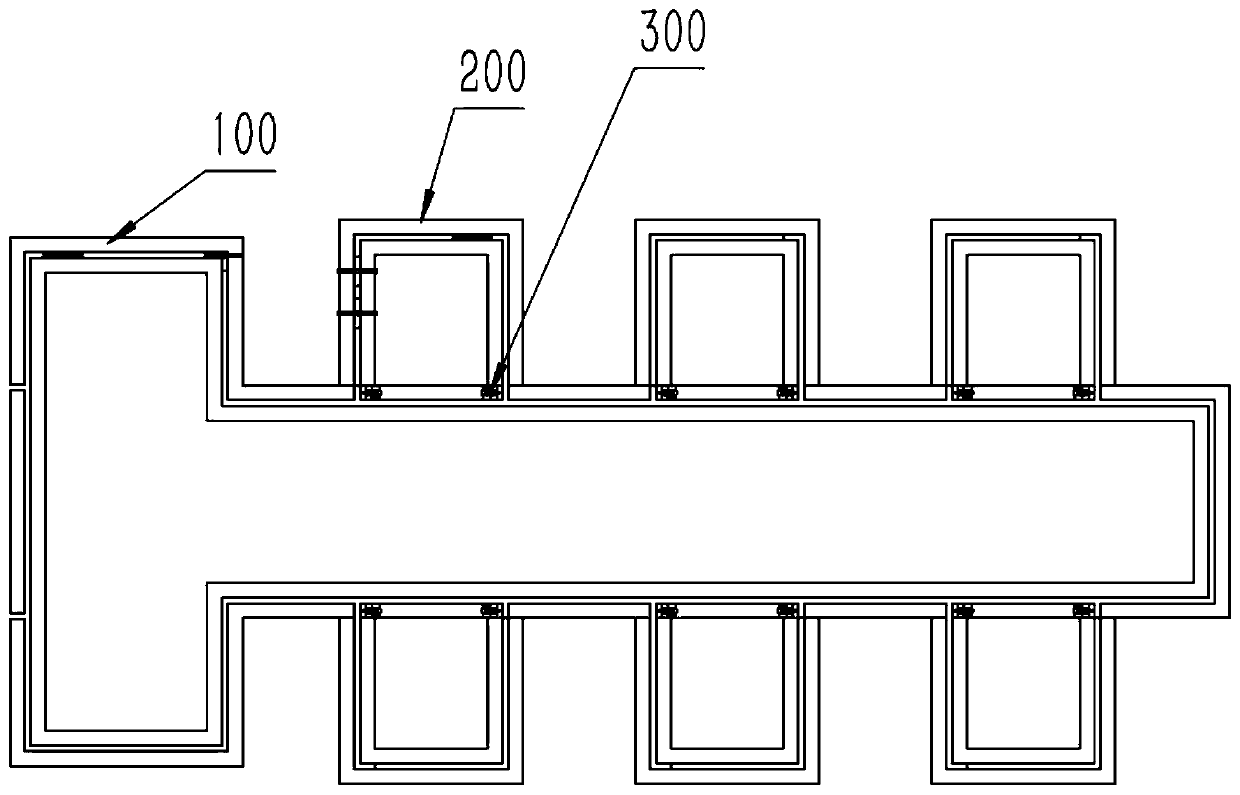

High-automation apparel production line

ActiveCN110937350AQuick adjustment of work progressWork schedule adjustmentCircuit arrangementsMechanical conveyorsPower apparatusClothes hanger

The invention relates to the technical field of garment processing, in particular to a high-automation apparel production line. The invention discloses the high-automation apparel production line which comprises a main rail, workstation rails, rail connecting devices, charging modules and apparel self-walking hangers. For the high-automation apparel production line disclosed by the invention, thearranged apparel self-walking hangers can flexibly move between the main rail and the corresponding workstation rails; as each apparel self-walking hanger has a power device, even if a certain apparelself-walking hanger has a fault, a system can send out a prompt to manually move the apparel self-walking hanger out of the corresponding workstation rail without affecting production of the whole production line; and meanwhile, when the condition of mismatched working progress between adjacent workstation rails occurs, the system can quickly adjust a moving speed of each apparel self-walking hanger, the station entrance amount of the apparel self-walking hangers and the working progress between the adjacent workstations. For the high-automation apparel production line disclosed by the invention, the charging modules arranged on the workstation rails respectively can charge the corresponding apparel self-walking hanger at the waiting stage thereof, and the production progress is not affected by charging the apparel self-walking hangers by using the residence time.

Owner:东莞市质品服饰有限公司

A cement kiln flue gas denitrification process

ActiveCN110585913BImprove denitrification effectExtension of timeGas treatmentDispersed particle separationBiomass carbonPtru catalyst

The invention belongs to the field of flue gas treatment, and specifically relates to a cement kiln flue gas denitrification process, comprising the following steps: step 1: pouring to form a denitrification cylinder, and forming pores on the wall of the denitrification cylinder; step 2: horizontally rotating the denitrification cylinder to set In the denitrification tower; Step 3: During the rotation of the denitrification cylinder, the flue gas enters the pores after contacting the denitrification cylinder, the vanadium and titanium in the slag act as a catalyst for the reduction of nitrogen oxides, and the biomass carbon powder oxidizes the nitrogen in the flue gas nitrogen oxides; step 4: In step 3, the flue gas entering the pores flows in the reverse direction under the barrier of the rotating tube, and the biomass carbon powder reduces the unreduced part of the nitrogen oxides in the flue gas to nitrogen, and reverses During the flow process, the denitrification cylinder continues to rotate with the rotating tube, and the nitrogen gas escapes from the pores and is discharged from the denitrification tower. When the technical solution is adopted, the denitrification effect of flue gas can be improved.

Owner:冀东水泥重庆合川有限责任公司

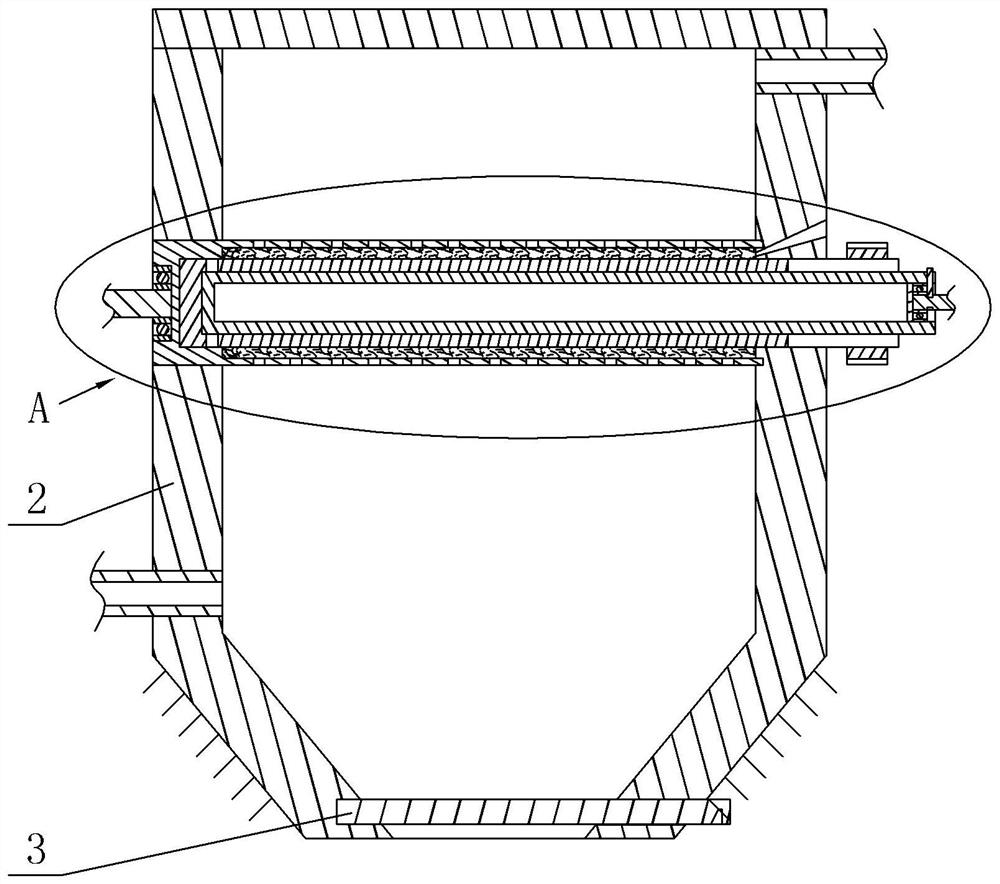

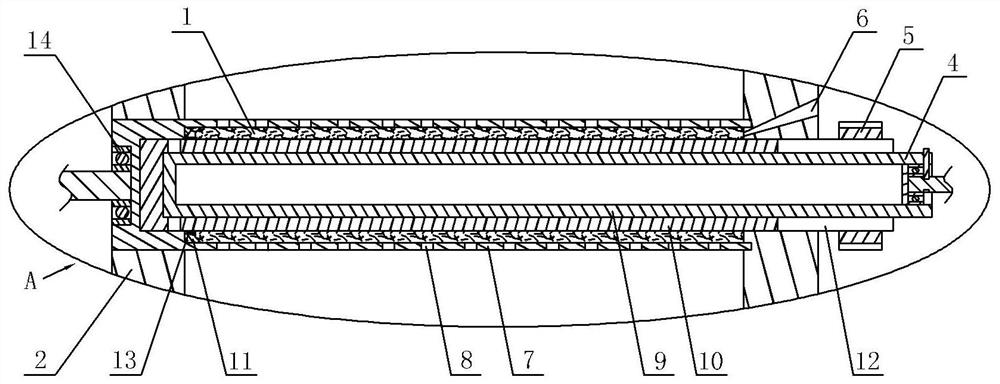

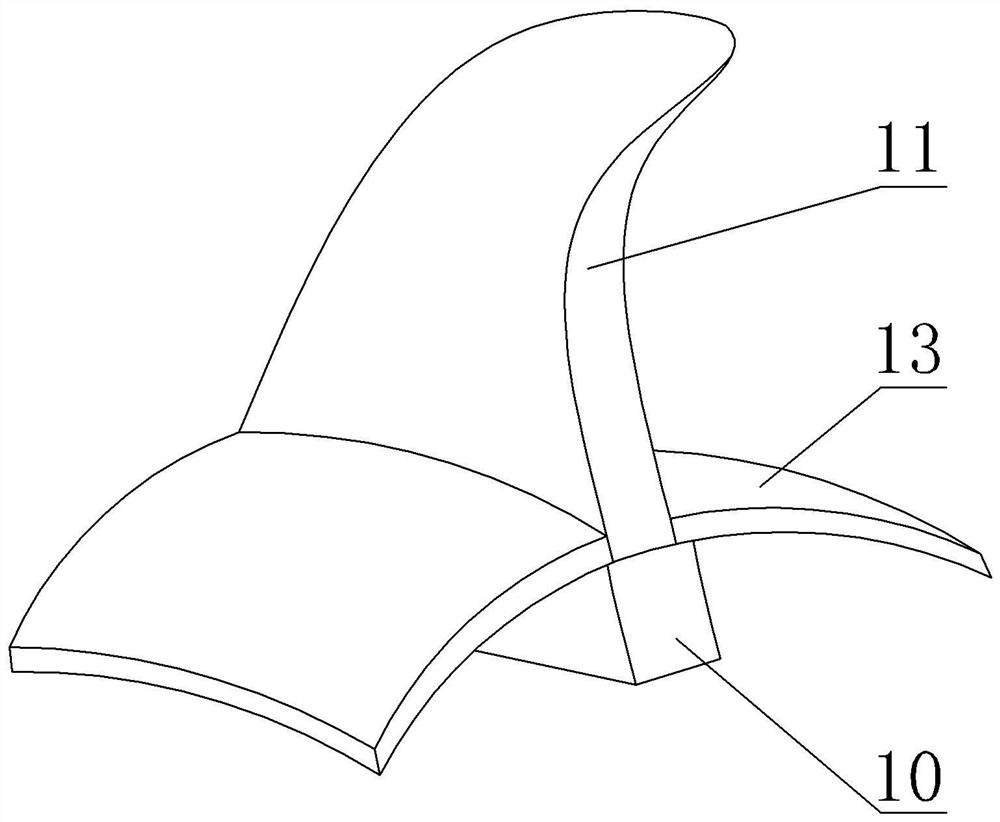

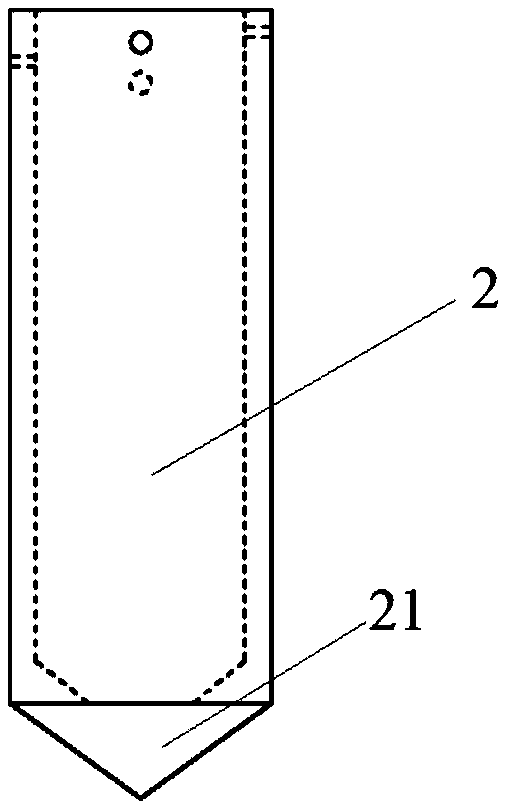

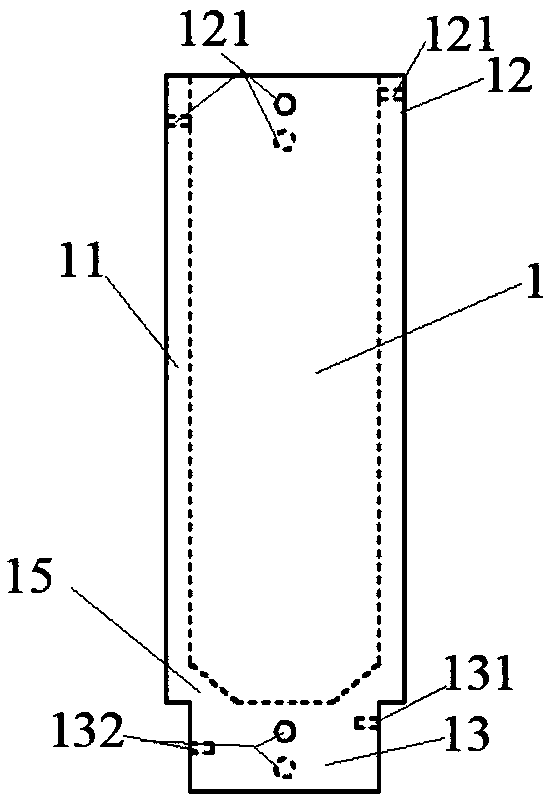

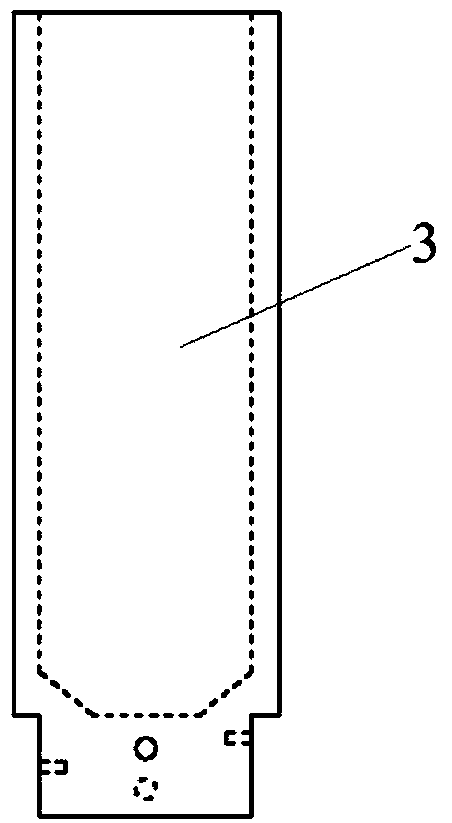

A mortise and tenon type internally connected prefabricated pile and its construction method

InactiveCN107190741BDoes not affect pile pressureWill not affect the production scheduleBulkheads/pilesStructural engineeringEngineering

The invention discloses a mortise and tenon type internally connected prefabricated pile and a construction method thereof. The prefabricated pile includes a pile tail mortise, a pile head mortise, a connecting bolt and a reinforced pile head block. The pile tail mortise is arranged at the tail of the prefabricated pile, and finally One section of prefabricated piles is not provided; pile tail sockets include pile tail connection steel cylinders, positioning chute and bolt notch, and a pile tail connection steel cylinder is arranged every 100mm along the length direction of prefabricated piles at a distance of 50mm from the tail of prefabricated piles. The installation angle of the last steel cylinder in the pile tail connection steel cylinder is that the direction of the previous steel cylinder is rotated 90 degrees around the center of the hole in the middle of the prefabricated pile; the two ends of the pile tail connection steel cylinder are sealed by rubber caps; the pile tail connection steel cylinder and A bolt notch is arranged at the joint of the outer wall of the prefabricated pile; a positioning chute is arranged at the position of the pile tail socket inside the prefabricated pile wall; the pile head tenon includes a positioning wedge and a pile head connection steel cylinder. The invention can realize the connection of two sections of prefabricated piles from the inside of the prefabricated piles.

Owner:SHAOXING UNIVERSITY

Movable steel strip brush

InactiveCN101905217BAvoid damagePrevent out of boundsWood working apparatusCleaning using toolsFiberEngineering

The invention relates to cleaning equipment of a continuous press, in particular to a movable steel strip brush used for cleaning a steel strip on the press, and aims to provide a movable steel strip brush with the advantages of reliable use and capacity of working on line. The movable steel strip brush is provided with a base, wherein a transverse guide rail is arranged on the base; a movable seat is connected to the transverse guide rail in a sliding mode; a longitudinal guide rail is arranged on the movable seat; a steel strip brush base is arranged on the longitudinal guide rail; a cylinder which is used for driving the steel strip brush base to slide longitudinally is arranged on the movable seat; a cleaning brush and a motor which is used for driving the cleaning brush to rotate arearranged on the steel strip brush base; and a variable frequency moving motor which is used for driving the movable seat to slide is arranged at the right end of the base. The movable steel strip brush can be arranged on one side of the continuous press to clean the steel strip on line, does not need to stop the work of the press, and cannot influence the production progress of fiber boards.

Owner:DIEFFENBACHER MACHINERY SERVICES BEIJING

Raw material detecting device for flour processing

InactiveCN110376340ASave time at workIncrease success rateTesting starch susbtancesProduction scheduleTerminal equipment

The invention relates to a raw material detecting device for flour processing. The raw material detecting device comprises a pouring hole, a panel, a box body, wheels, a handle, a control device, a screening board, a casing, an alarm device I, an alarm device II, a reinforcing rib I, a box body, a reinforcing rib II, a terminal device, an induction lamp, an external power supply, a terminal housing, a pulling handle and foot cups. The inverted-triangle-shaped pouring hole is fixedly installed on the box body; the panel is fixedly mounted on the surface of the box body; the handle is fixedly mounted on the panel surface; at least four wheels are fixedly installed under the bottom surface of the box body; the alarm device I and the alarm device II are fixedly mounted on the surface of the box body; the external power supply is fixedly mounted on the surface of the terminal housing; the pulling handle is fixed at one side of the surface of the terminal housing; and multiple foot cups arefixedly installed. Multi-times repeated manual detection work is avoided; the working time of the staff is shortened; the work efficiency is improved; and the completion of the production schedule isnot affected.

Owner:江苏华升面粉有限公司

Colored glass inspection device

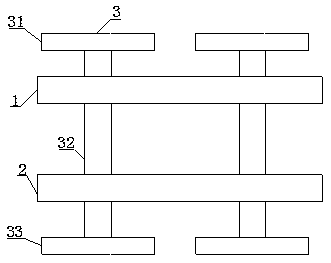

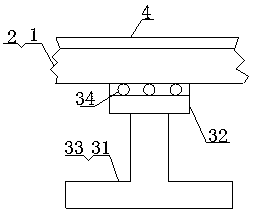

InactiveCN107764749AReduce labor intensityShort manufacturing cycleColor/spectral properties measurementsEngineering

The invention provides a colored glass inspection device which comprises a supporting beam I, a supporting beam II, brackets and panels, wherein the supporting beam I and the supporting beam II are placed on at least two brackets; a layer of panel is adhered to the surface of each of the supporting beam I and the supporting beam II; the brackets consist of supporting legs I, ribbed plates, supporting legs II, bearings and grooves; each supporting leg I is fixedly connected to one end of each ribbed plate; each supporting leg II is fixedly connected to the other end of each ribbed plate; the grooves are formed in the surfaces of the ribbed plates; the bearings are arrayed in the grooves in a uniformly spaced manner. The colored glass inspection device can quickly check glass; the time consumption is reduced, and the working efficiency is improved; cleaning the glass again is not needed.

Owner:徐州嘉恒玻璃制品有限公司

Method for controlling screen printing processing of liquid crystal display

InactiveCN102103285AImprove yieldReduce manufacturing costNon-linear opticsScreen printingManufacturing cost reduction

The invention relates to a method for controlling screen printing processing of a liquid crystal display. The method is characterized by comprising the following steps of: manufacturing a simulation orientation layer before a screen printing process of the orientation layer; judging whether the simulation orientation layer accords with the sample sealing standard; performing the screen printing process of the orientation layer under the condition that the simulation orientation layer accords with the sample sealing standard; comparing the simulation orientation layer with the sample sealing standard to determine whether to perform screen printing process of the orientation layer, so that the aim of controlling the screen printing degree of the orientation layer on line is fulfilled, the condition that the screen printing degree of the orientation layer does not meet the requirement can be detected in advance, the product yield is improved, and manufacturing cost is lowered; and whether the simulation orientation layer accords with the sample sealing standard is judged only once, and the subsequent screen printing process of the orientation layer is performed on a large scale, the time required by judging whether the simulation orientation layer accords with the sample sealing standard is short in the whole production process, so that the control method does not influence production progress.

Owner:SHANTOU GOWORLD DISPLAY (PLANT II) CO LTD

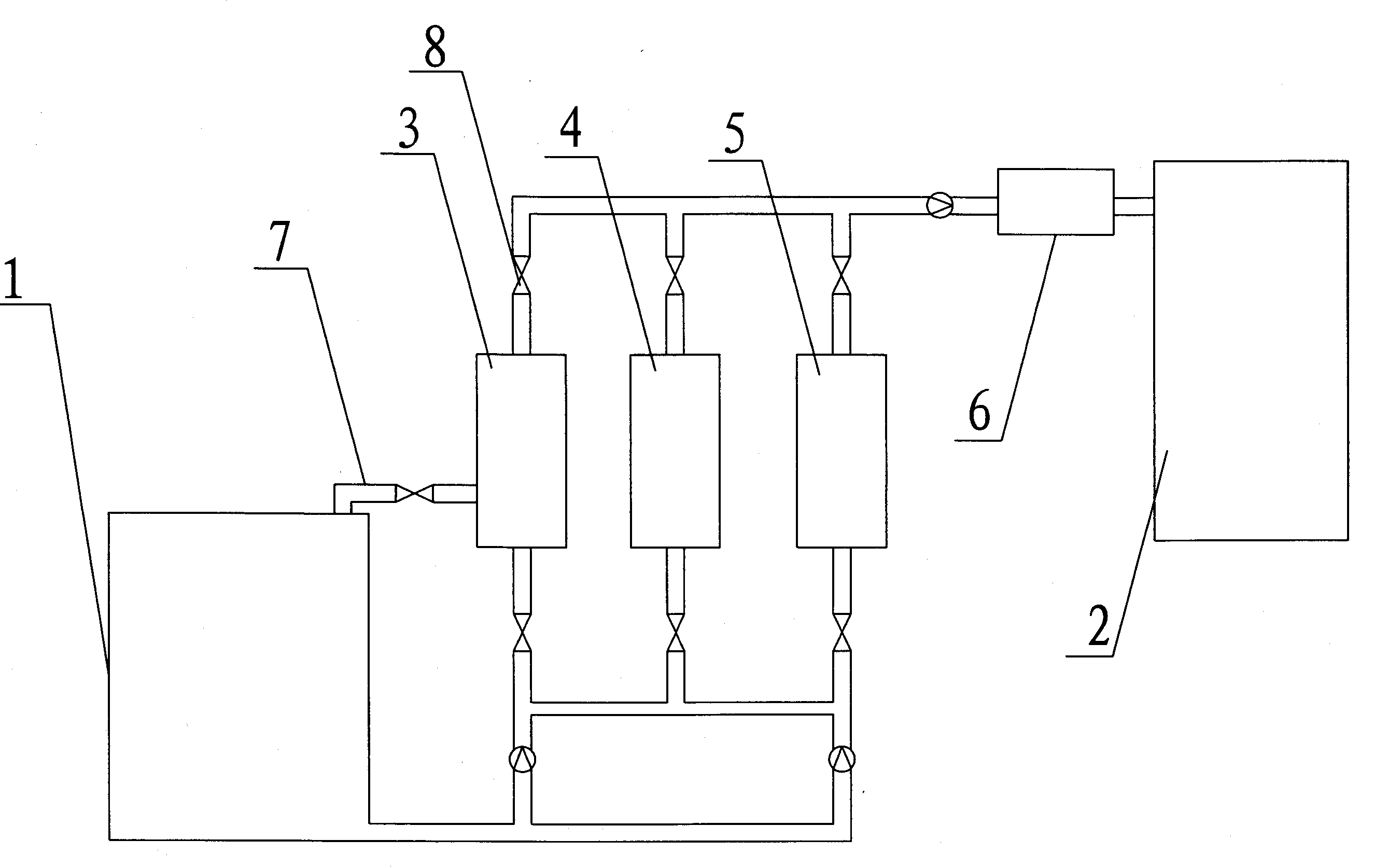

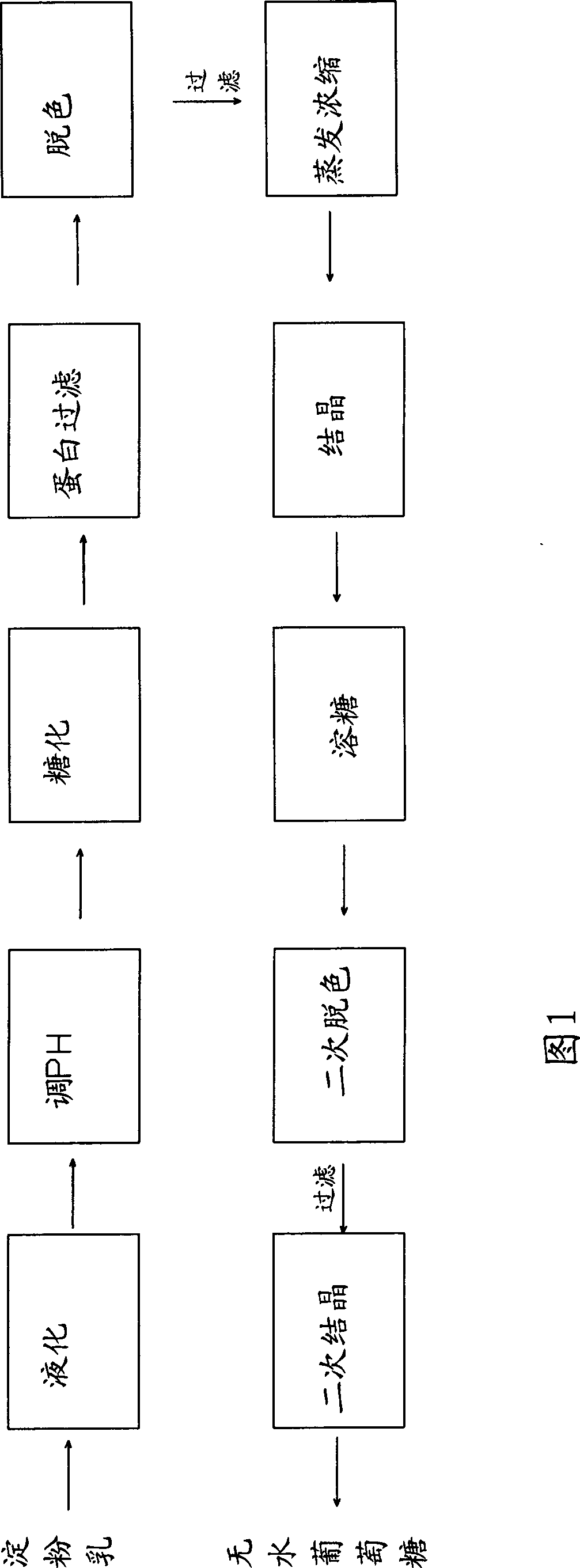

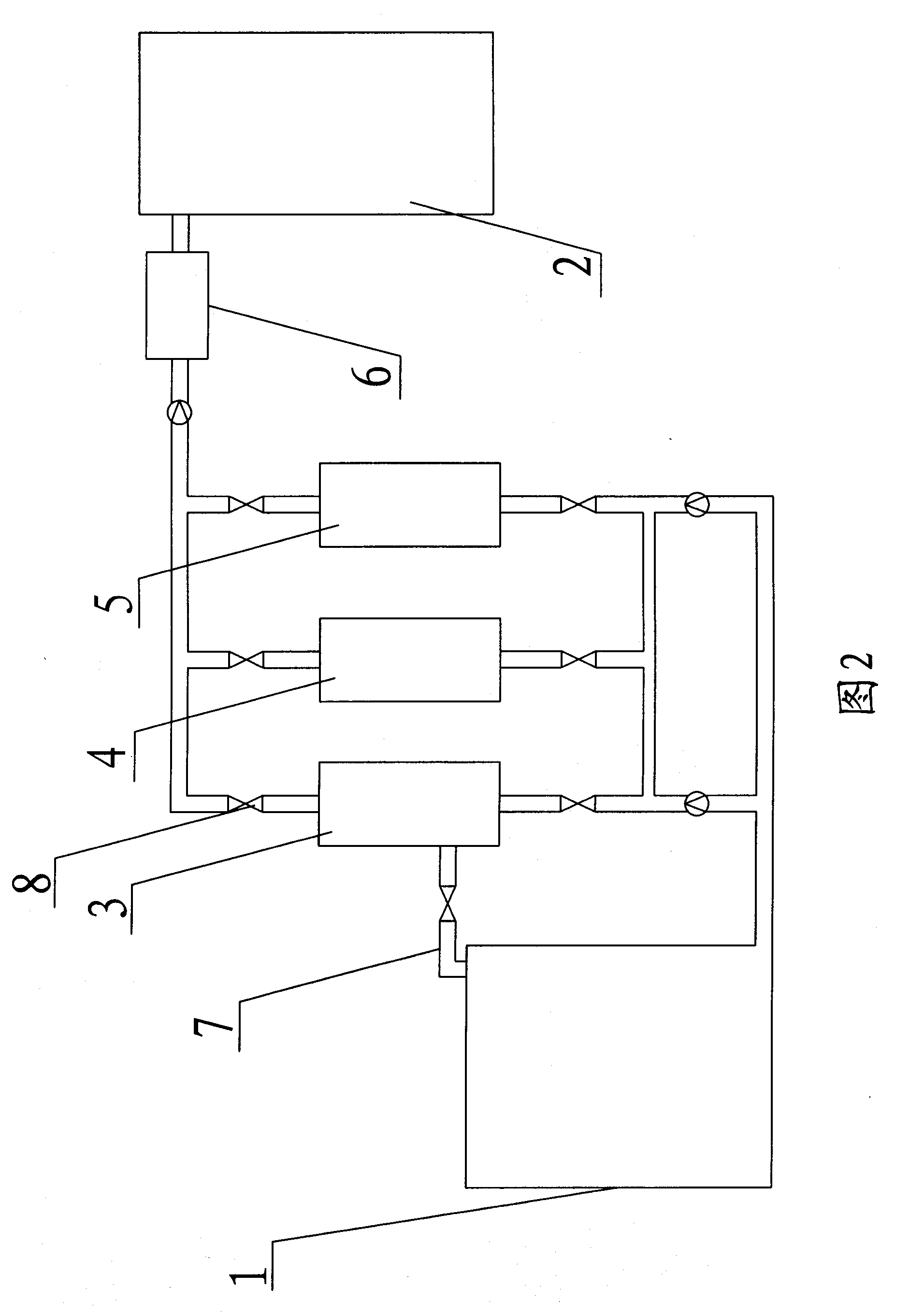

Decolorization material filter in anhydrous dextrose production process

ActiveCN101381383BReduce processing stepsReduce dosageSugar derivativesSugar derivatives preparationSlagProcess engineering

The invention provides a device for filtering decoloration materials for use in the production of anhydrous glucose, which comprises a plate-frame shape filtering machine, a flat filtering machine as well as a micron filter, wherein the plate-frame shape filtering machine and the flat filtering machine are connected parallelly and then the micron filter is connected with the plate-frame shape filtering machine and the flat filtering machine in series; a feeding / discharging pipe of each filtering equipment is provided with a valve; and the flat filtering machine is connected with a decoloration tank through a discharging pipe with a valve. With the combined filtering device, the filtering process can be performed continuously, thereby avoiding shutdown caused by cleaning the blockage in the filtering machine, reducing the loss of glucose liquid during cleaning and maintenance and facilitating the operation of slag throwing.

Owner:XIWANG GROUP

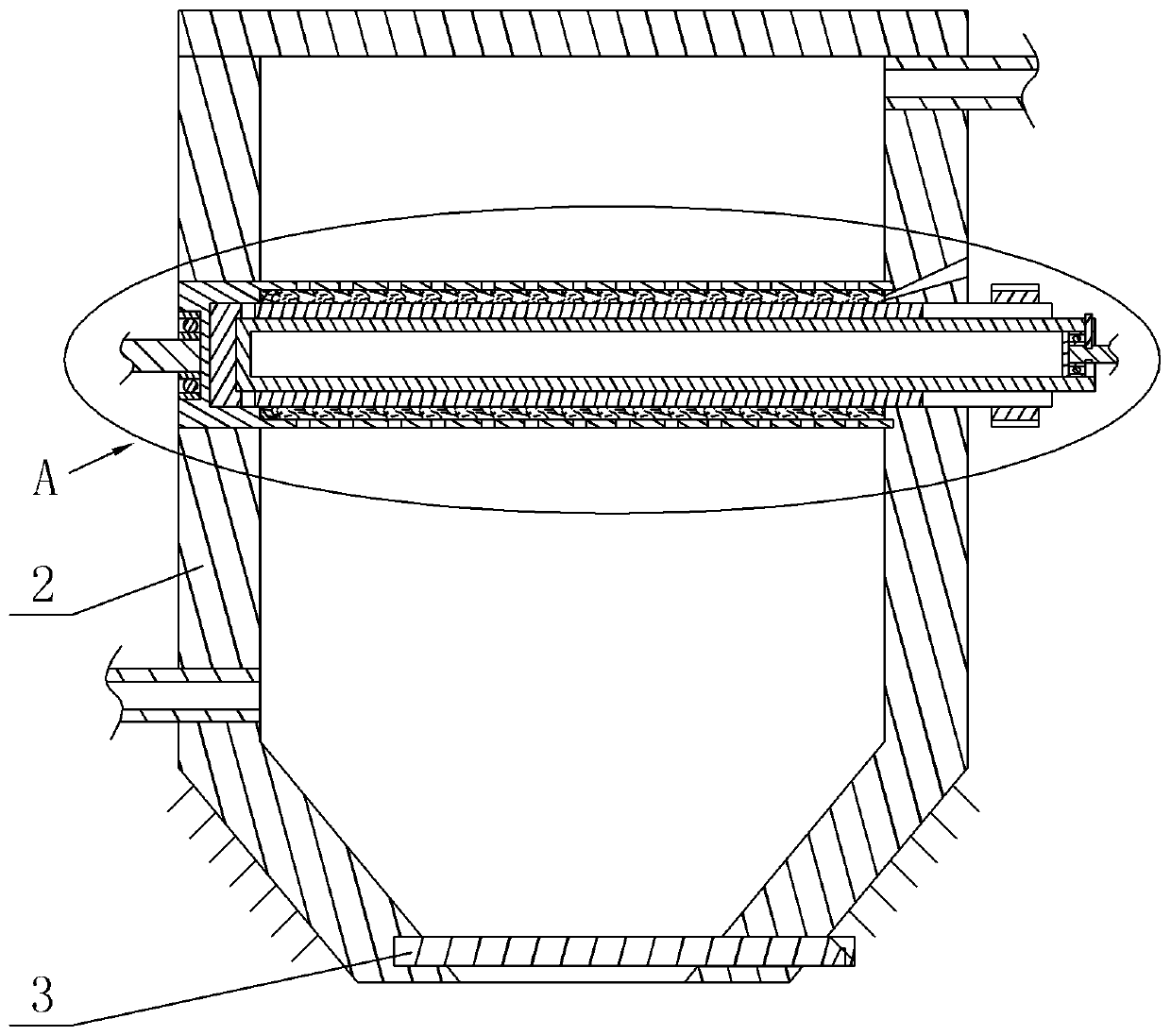

A countersink tool with quick adjustment and positioning

ActiveCN106583807BEasy to assemble and disassembleReduce maintenance costsTransportation and packagingTrepanning drillsEngineeringMachining

The invention relates to the field of machining knife tools and discloses a novel countersink tool. The novel countersink tool comprises knife-containing blocks, knife tools used for machining are removably mounted on the knife-containing blocks correspondingly, and the knife-containing blocks are removably mounted on a main drilling shaft and rotate with the main drilling shaft. Each knife-containing block is designed in a briefs shape, a knife-containing block installing hole is formed in the central position of each knife-containing block, the knife-containing blocks are mounted on the main drilling shaft through the knife-containing block installing holes, two knife tool installing holes are formed in the two ends of each knife-containing block symmetrically, and knife tools are mounted in the knife-containing blocks through the knife tool installing holes correspondingly. Installation and operation are easy, maintenance, dismounting and assembly are convenient, cost is low, universality is good, and the labor strength of a worker is greatly reduced.

Owner:SICHUAN CHUANGUO BOILER

Cement kiln flue gas denitration process

ActiveCN110585913AImprove denitrification effectExtension of timeGas treatmentDispersed particle separationSlagEngineering

Belonging to the field of flue gas treatment, the invention particularly relates to a cement kiln flue gas denitration process. The process includes the steps of: S1. conducting pouring to form a denitration barrel, and forming pores on the barrel wall of the denitration barrel; S2. horizontally and rotatably arranging the denitration barrel in a denitration tower; S3. in the rotating process of the denitration barrel, letting flue gas contact the denitration barrel and then enter the pores, adopting vanadium-titanium in the slag as a catalyst for nitrogen oxide reduction, and reducing the nitrogen oxide in the flue gas into nitrogen by biomass charcoal powder; and S4. letting the flue gas entering the pores flows in the step 3 flow reversely under the blocking of a rotating pipe, reducingpart of the unreduced nitrogen oxide in the flue gas into nitrogen by biomass charcoal powder, and further enabling the denitration barrel to rotate along with the rotating pipe in the reverse flow process, and discharging the nitrogen out of the denitration tower after escape from the pores. The technical scheme adopted by the invention can improve the flue gas denitration effect.

Owner:冀东水泥重庆合川有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com