Pipeline conveying block preventing equipment under pressure feed state and using method thereof

An anti-clogging equipment and pipeline transportation technology, applied in the field of pipelines, can solve problems such as troublesome disassembly, cleaning and installation, limited effect of purging methods, and threats to product quality, so as to achieve high practical value, avoid unsafe conditions, and eliminate blockages short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] In order to understand the technical content of the present invention more clearly, the specific implementation method of the present invention will be further described below in conjunction with the accompanying drawings.

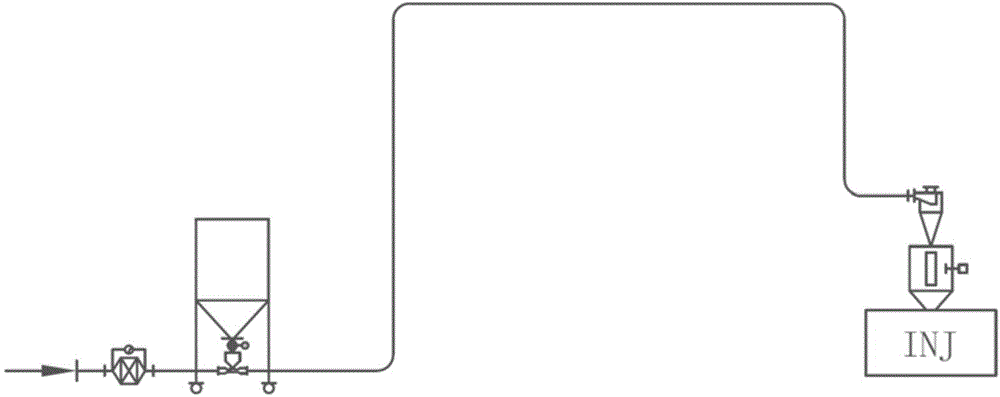

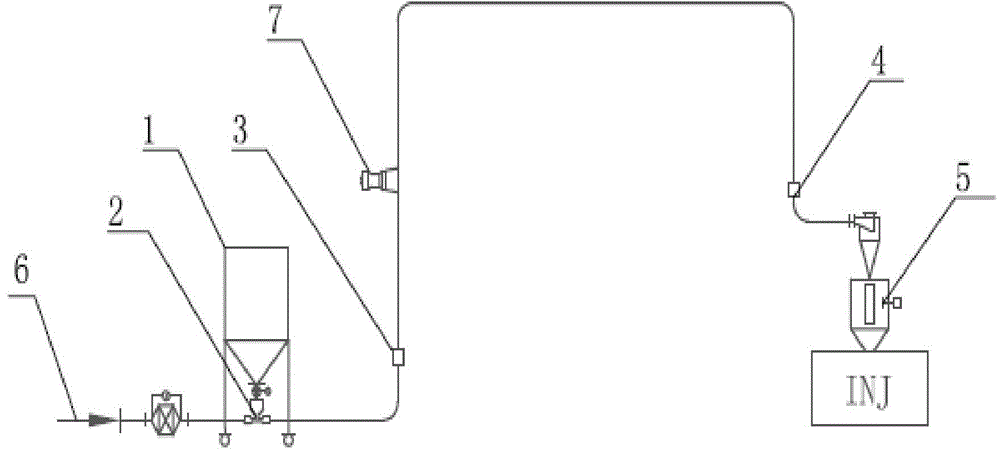

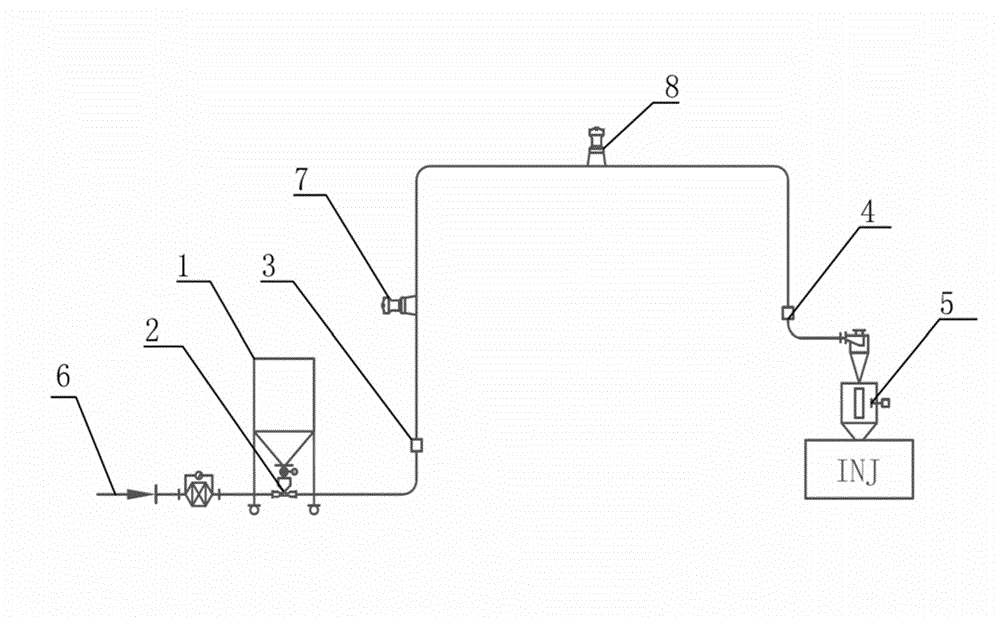

[0065] Figure 2a-2c They are the schematic diagrams of the anti-clogging equipment for pipeline transportation under the pressure feeding state of the three embodiments of the present invention, wherein, the first embodiment has one vibrator, the second embodiment has two vibrators, and the third embodiment The example has three vibrators. Such as Figure 2a-2c As shown, the anti-clogging equipment for pipeline transportation under the pressure feeding state includes:

[0066] The conveying pipeline part, at least two detection devices and at least one vibrating device both arranged on the conveying pipeline part;

[0067] Wherein, the conveying pipeline part includes a pipeline, a conveying hopper 5, a conveying valve 2 and an air inlet 6 conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com