Decolorization material filter in anhydrous dextrose production process

A technology of anhydrous glucose and filtration device, which is applied in the direction of glucose production, sugar derivatives, sugar production, etc. It can solve the problems of increased viscosity of the mixture, loss of enterprises, easy blockage of equipment and pipelines, etc., and achieve reduction of process steps , reduce the treatment process, and ensure the effect of the filtering effect

Active Publication Date: 2011-01-05

XIWANG GROUP

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the weak filtering capacity of the plate-and-frame filter, and the interior is often blocked by filter residues, it is necessary to frequently perform residue removal operations, especially once the plate-and-frame filter installed before entering the storage tank is blocked, the feeding must be stopped for maintenance Cleaning is not conducive to the continuous operation of the whole process; in order to ensure the continuous operation of the equipment, a buffer tank must be installed in front of the filter, so that the materials during maintenance can flow into the tank without being wasted, which increases the complexity of the process and the cost of equipment; at the same time, because the filter contains a large amount of glucose solution except containing activated carbon and impurities, it cannot be recycled in time when cleaning, thereby reducing the final yield of production and causing greater losses to the enterprise. The sugar liquid is mixed into the activated carbon and discharged, which will greatly increase the viscosity of the mixture, reduce the fluidity, make it easier to block equipment and pipelines, and increase the difficulty of maintenance and cleaning

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

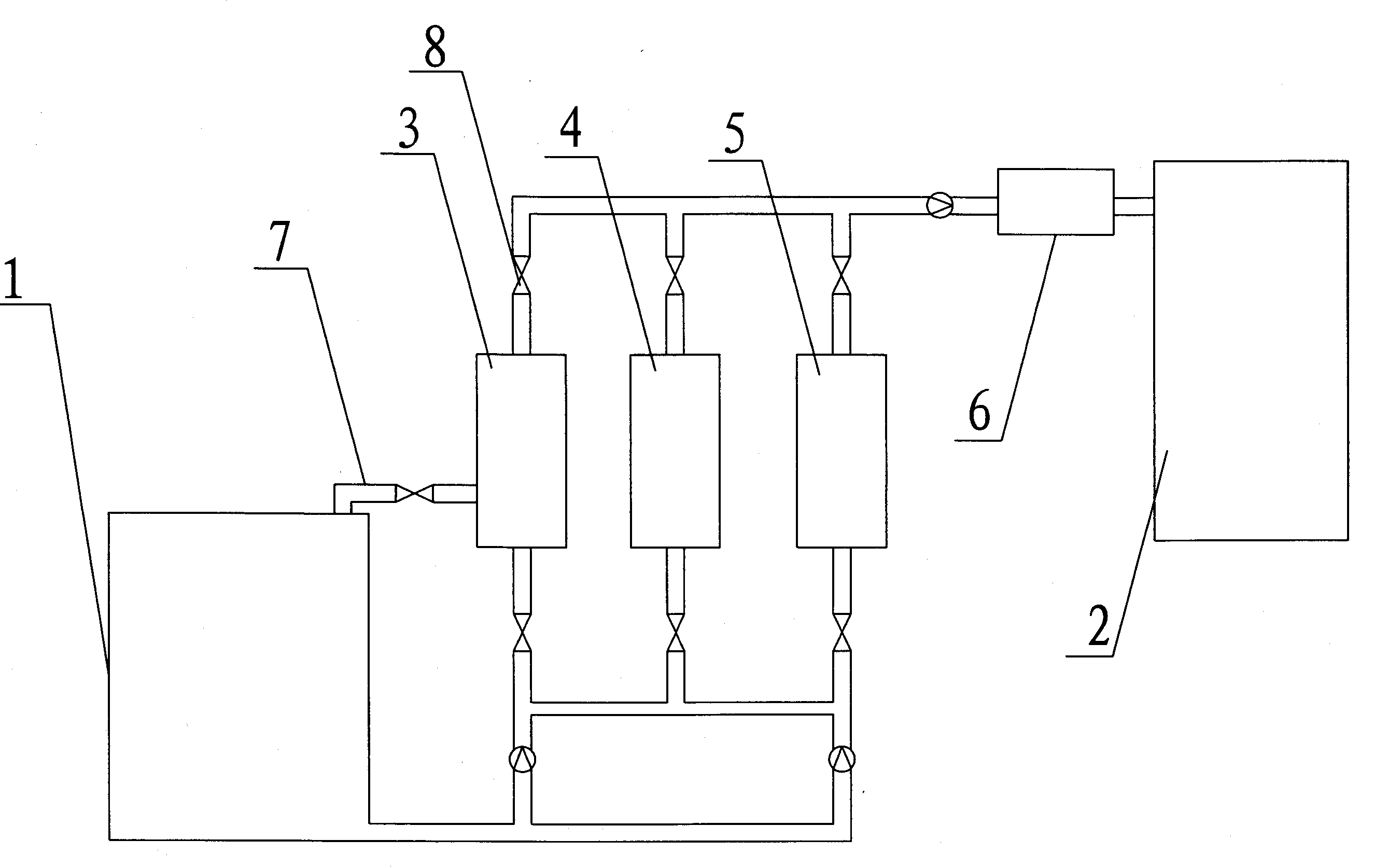

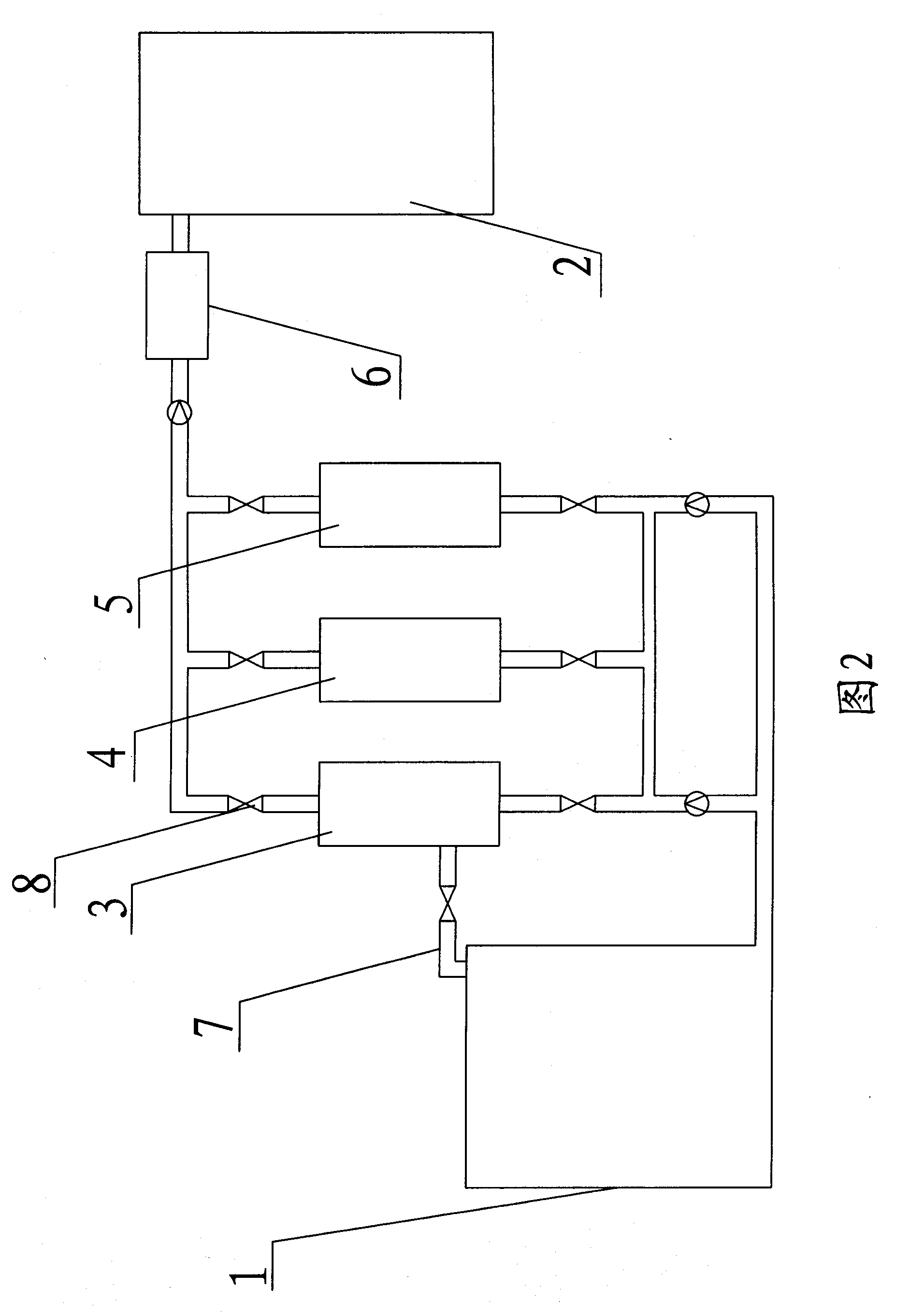

The invention provides a device for filtering decoloration materials for use in the production of anhydrous glucose, which comprises a plate-frame shape filtering machine, a flat filtering machine as well as a micron filter, wherein the plate-frame shape filtering machine and the flat filtering machine are connected parallelly and then the micron filter is connected with the plate-frame shape filtering machine and the flat filtering machine in series; a feeding / discharging pipe of each filtering equipment is provided with a valve; and the flat filtering machine is connected with a decoloration tank through a discharging pipe with a valve. With the combined filtering device, the filtering process can be performed continuously, thereby avoiding shutdown caused by cleaning the blockage in the filtering machine, reducing the loss of glucose liquid during cleaning and maintenance and facilitating the operation of slag throwing.

Description

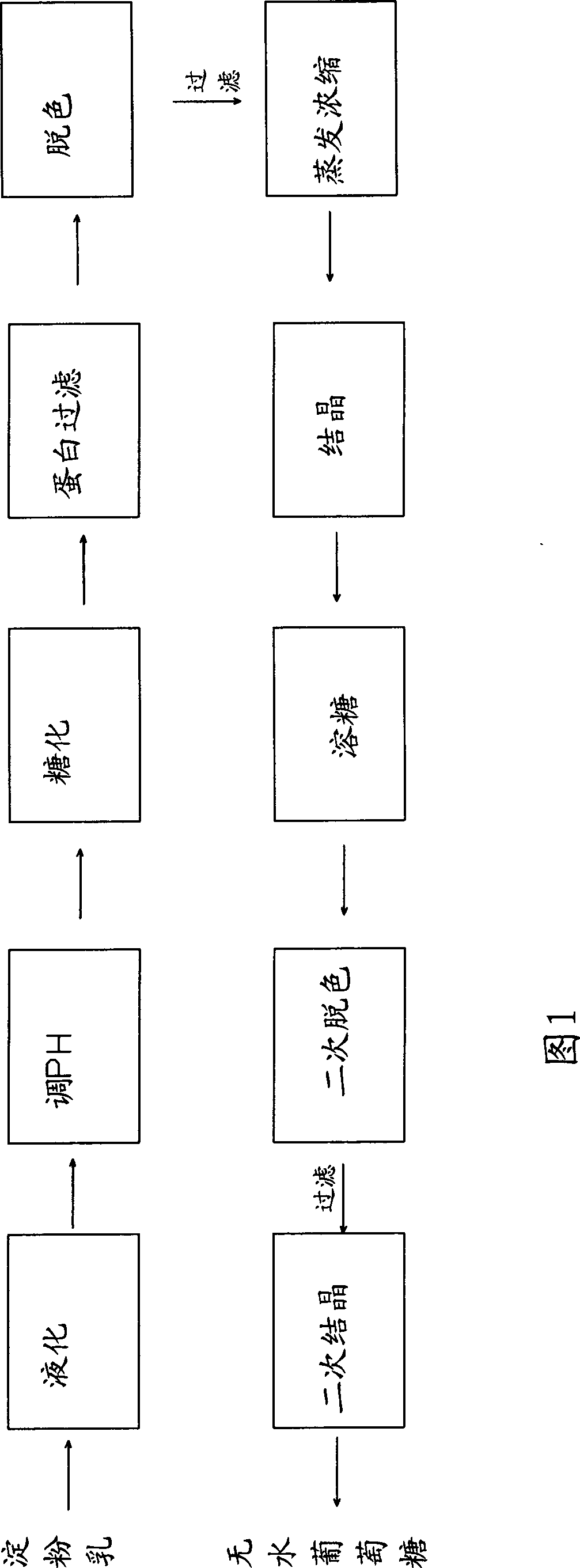

Decolorization material filtration device in the production process of anhydrous glucose technical field The invention relates to the production of anhydrous glucose, in particular to a filter device after the decolorization process in the production process of anhydrous glucose. Background technique In the production process of anhydrous glucose, the material will have a certain color and be mixed with other impurities due to saccharification and other steps. In order to ensure the quality of the final anhydrous glucose, it is necessary to decolorize the material. The decolorization process is as follows: Activated carbon is added to the material in a certain proportion to absorb pigments and other impurities. After the activated carbon is stirred evenly in the material, it is pumped into the filter to form a filter cake. When the filtered material meets the process requirements, it is sent to the next step. In the existing process, a plate and frame filter is generally...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C07H3/02C07H1/06C13K1/10B01D36/02

Inventor 王勇王岩刘剑侠张全刚程平王非何玉梅

Owner XIWANG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com