A processing cleaning and disinfection device for fish and shrimp aquatic products

A technology for cleaning and disinfecting aquatic products, which is applied in fish cleaning/descaler, shrimp/lobster processing, and crustacean processing, etc. It can solve problems such as low cleaning and disinfection efficiency, large production investment, and adaptability to easily damaged products. Ease of penetration, improve quality, and simplify the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

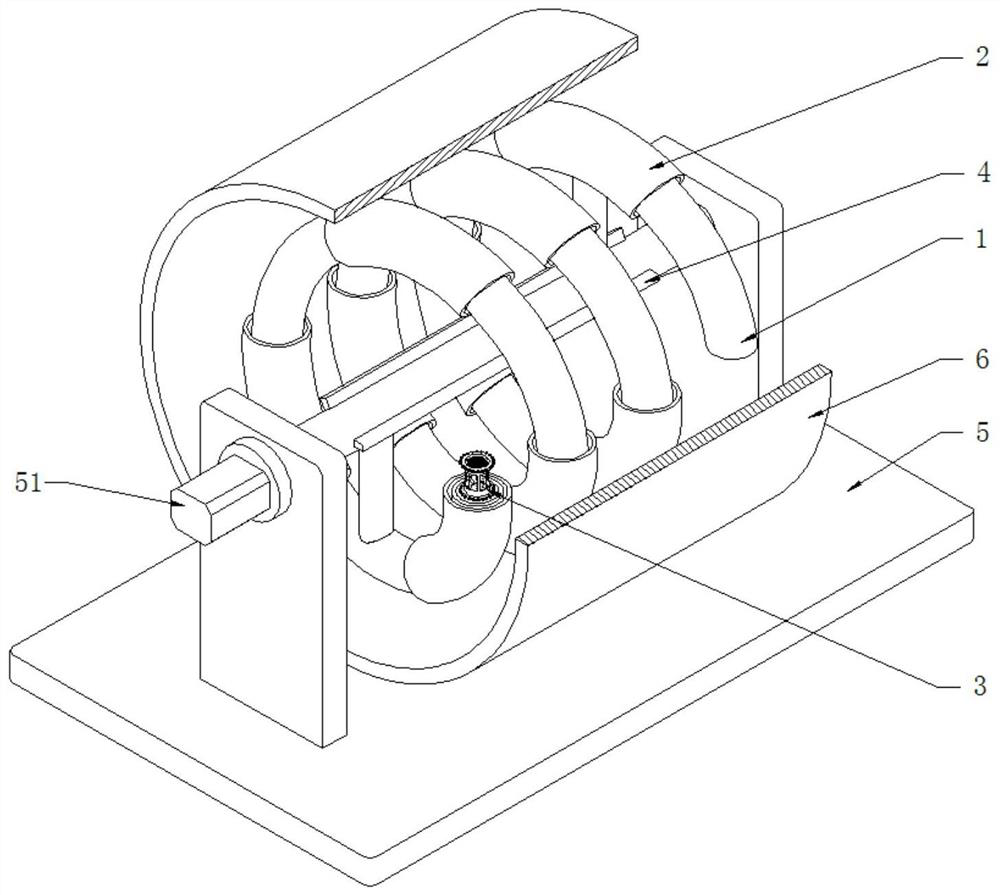

[0036] see Figure 1-6, a processing cleaning and disinfection device for fish and shrimp aquatic products, comprising a horizontally distributed spiral washing tube 1, a driving magnetic sleeve 2, a reverse magnetic cleaning cage 3, an ultraviolet disinfection tube 4 and a support frame 5, a reverse magnetic cleaning cage 3 and a spiral The inner hole of the flushing pipe 1 is used together, specifically, the entire reverse magnetic cleaning cage 3 is used to load fish and shrimp aquatic products, and then put into the spiral flushing pipe 1, and the driving magnetic sleeve 2 is fixedly sleeved on the spiral flushing pipe 1 Outside, the function of the driving magnetic sleeve 2 is to act as a magnetic thrust on the reverse magnetic cleaning cage 3 located in the spiral flushing tube 1, so that the reverse magnetic cleaning cage 3 "swimming" in one direction in the driving magnetic sleeve 2 , is further described as, the driving magnetic sleeve 2 is provided with an accelerati...

Embodiment 2

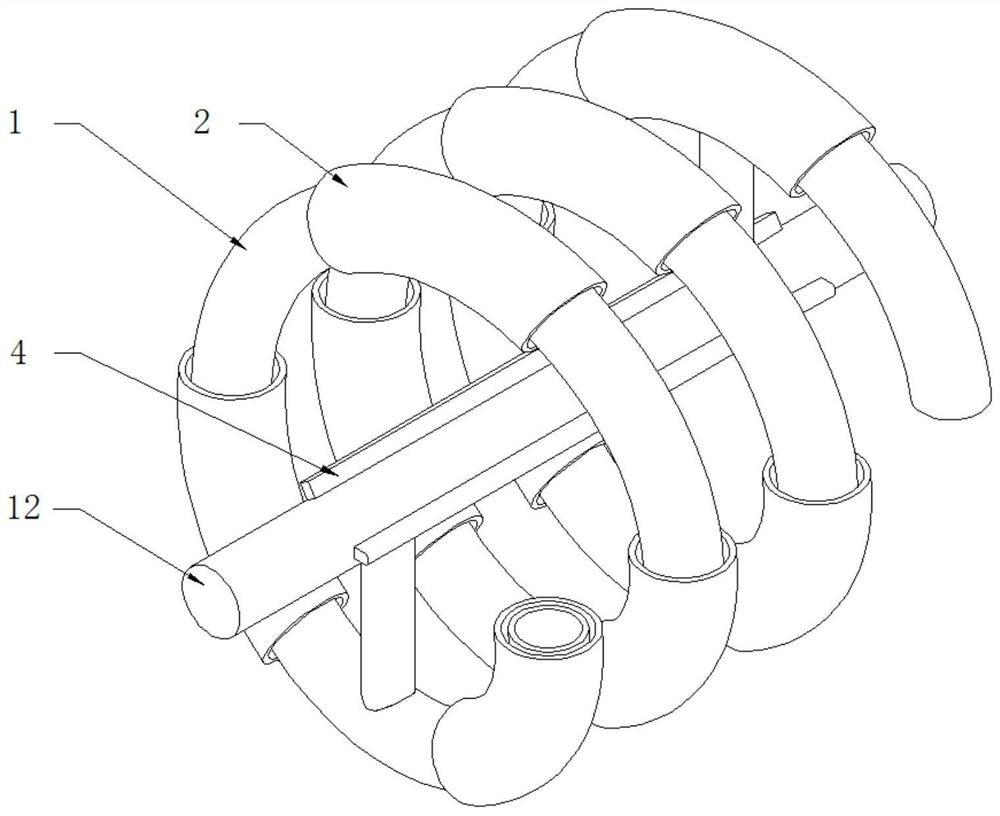

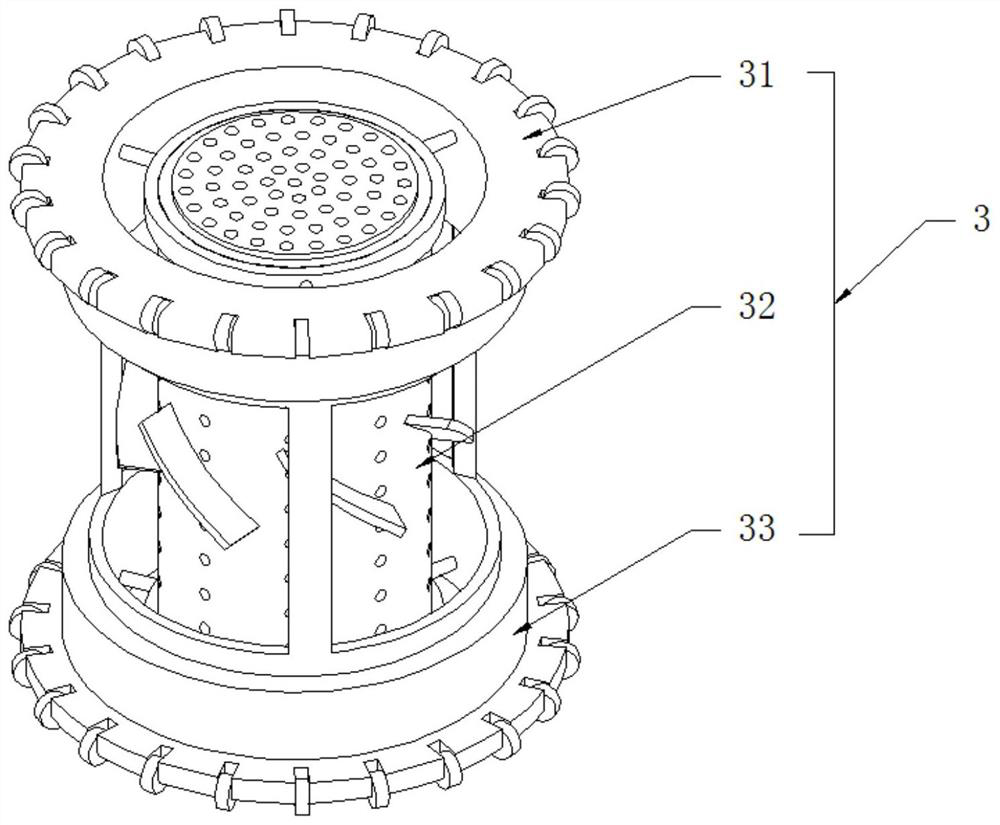

[0038] see Figure 2-6 , and the difference from Embodiment 1 is that the ultraviolet disinfection tube 4 is fixedly arranged on the outer wall of the support shaft 12, and three ultraviolet disinfection tubes 4 can be arranged and evenly distributed in the circumferential direction, so that the ultraviolet rays emitted by the ultraviolet disinfection tube 4 cover the entire spiral washing In the cylindrical space formed by the tube 1, the outer wall of the bearing sleeve 31 is provided with light-transmitting openings 312 evenly distributed in the circumferential direction, the number of driving magnetic sleeves 2 is at least three and distributed at equal intervals, and the number of reverse magnetic sleeves 33 is two group and located on both sides of the light-transmitting port 312, wherein the punching cylinder 32 and the spiral flushing tube 1 can be made of quartz glass to facilitate the penetration of ultraviolet rays, so that the ultraviolet rays pass through the space...

Embodiment 3

[0040] see figure 1 and figure 2 , and the difference of embodiment 1 is that the inlet end and the outlet end of the spiral flushing pipe 1 are on the same horizontal plane. It is discharged by its own weight, and the loading and unloading operation is convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com