Raw material detecting device for flour processing

A detection device and a technology for raw materials, which are used in material inspection products, food testing, starch contamination testing, etc., can solve the problems of increasing the working time of the staff, reducing the working efficiency, affecting the production progress, etc., so as to achieve a small occupied space and save production. cost, the effect of improving the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

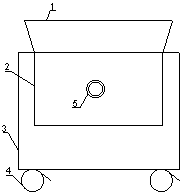

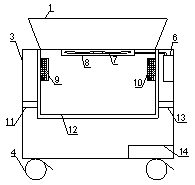

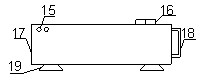

[0016] Such as Figure 1 to Figure 3 As shown, a raw material detection device suitable for flour processing includes a pouring port 1, a panel 2, a box body 3, wheels 4, a handle 5, a control device 6, a screening plate 7, a casing 8, an alarm device I9, and an alarm device II10 , reinforcement rib I11, box body 12, reinforcement rib II13, terminal device 14, sensor lamp 15, external power supply 16, terminal casing 17, handle 18 and foot cup 19, and the inverted triangular pouring spout 1 is fixedly installed on the box body 3 , the panel 2 is fixedly installed on the surface of the box body 3, the handle 5 is fixedly installed on the surface of the panel 2, the number of at least four wheels 4 is fixedly installed on the bottom surface of the box body 3, the control device 6 is fixedly installed inside the box body 3, and the reinforcing rib One end of I11 and one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com