Colored glass inspection device

An inspection device, colored glass technology, applied in the direction of measuring device, color/spectral characteristic measurement, material analysis through optical means, etc., can solve the problems of dust on the glass surface, a lot of time consumption, troublesome production process, etc., to achieve work Improve efficiency, save time and energy, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

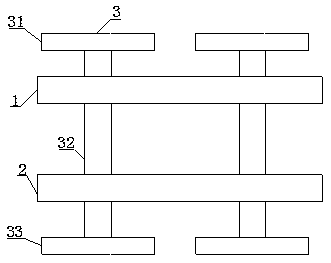

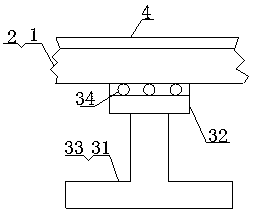

[0014] Such as figure 1 and figure 2 As shown, the colored glass inspection device includes support beam Ⅰ1, support beam Ⅱ2, support 3 and panel 4, support beam Ⅰ1 and support beam Ⅱ2 are placed on at least two supports 3, support beam Ⅰ1 and support beam Ⅱ2 are pasted on the surface A layer of panel 4, bracket 3 is composed of outrigger I31, rib plate 32, outrigger II33, bearing 34 and groove 35, outrigger I31 is fixedly connected to one end of rib plate 32, outrigger II33 is fixedly connected to the other end of rib plate 32, A groove 35 is formed on the surface of the rib plate 32, and several bearings 34 are arranged in the groove 35 evenly and equidistantly.

[0015] Described panel 4 is stainless steel plate, sponge and rubber successively from inside to outside.

[0016] The lengths of the supporting beam I1 and the supporting beam II2 are the same.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com