A differential pressure thermally coupled rectification device

A thermally coupled, differential pressure technology, applied in the field of rectification, can solve the problems of affecting production costs, large energy consumption in the rectification process, and large steam consumption, and achieve the effect of saving steam consumption, obvious energy saving effect and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

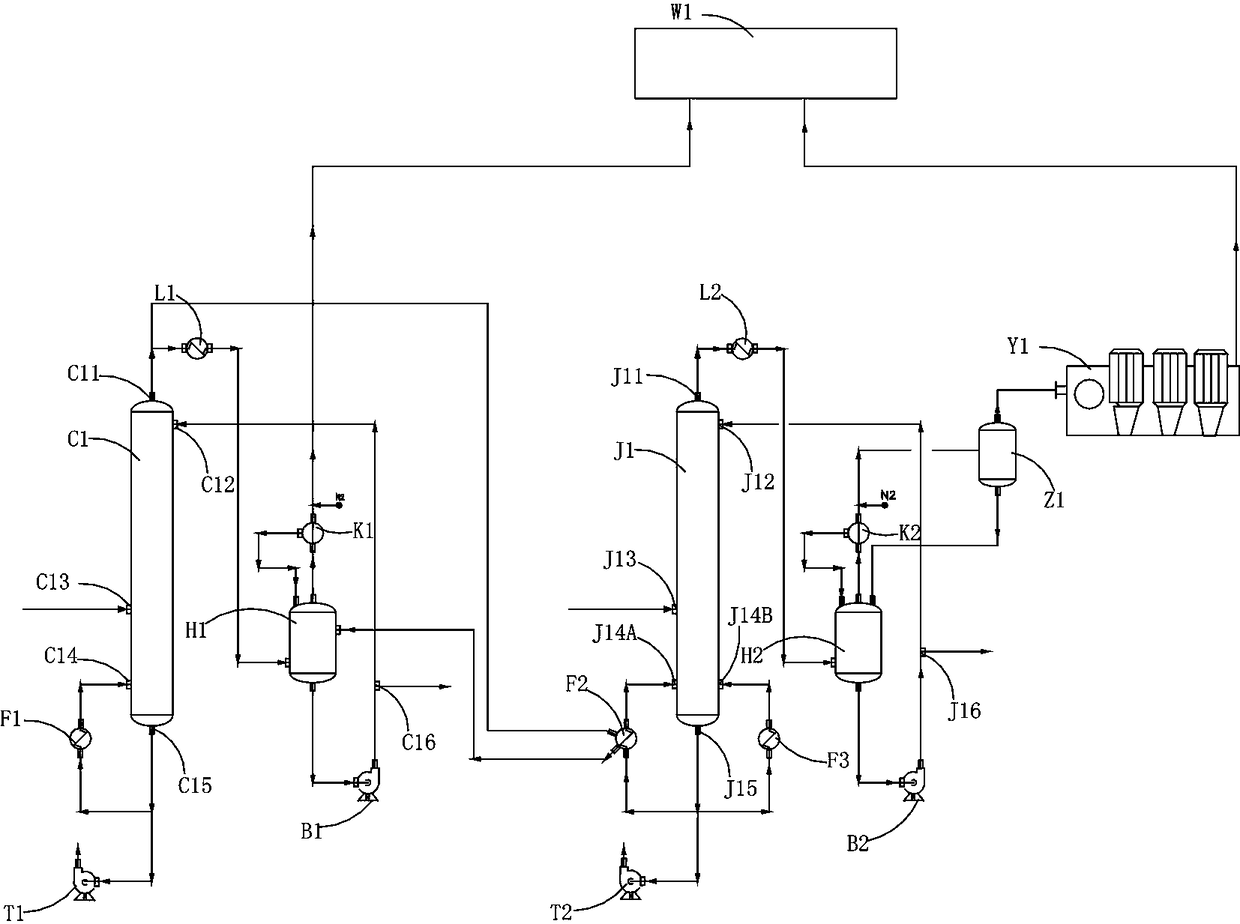

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, taking tetrachlorethylene rectification as an example.

[0017] see figure 1Shown, a kind of differential pressure type thermally coupled rectification device comprises atmospheric tower equipment group and vacuum tower equipment group, it is characterized in that, described atmospheric tower equipment group comprises atmospheric tower tower body C1) and is connected by pipeline Each atmospheric equipment group, the inner wall of the atmospheric tower body C1 is provided with a plurality of scalable baffles, and the expansion and contraction of the baffles is controlled by a flow meter arranged in the atmospheric tower body, and the atmospheric tower body C1 is provided with a first material inlet C13, a first material outlet C16, a first liquid inlet C12, a first liquid outlet C15, a first air inlet C14, and a first gas outlet C11. The atmospher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com