Scissor of sampling sheet metal

A metal sheet and sampling machine technology, applied in sampling devices and other directions, can solve the problems of chemical composition and mechanical property damage, affecting the accuracy of assays and tests, wasting man-hours and labor, and saving shearing time, man-hours and labor. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

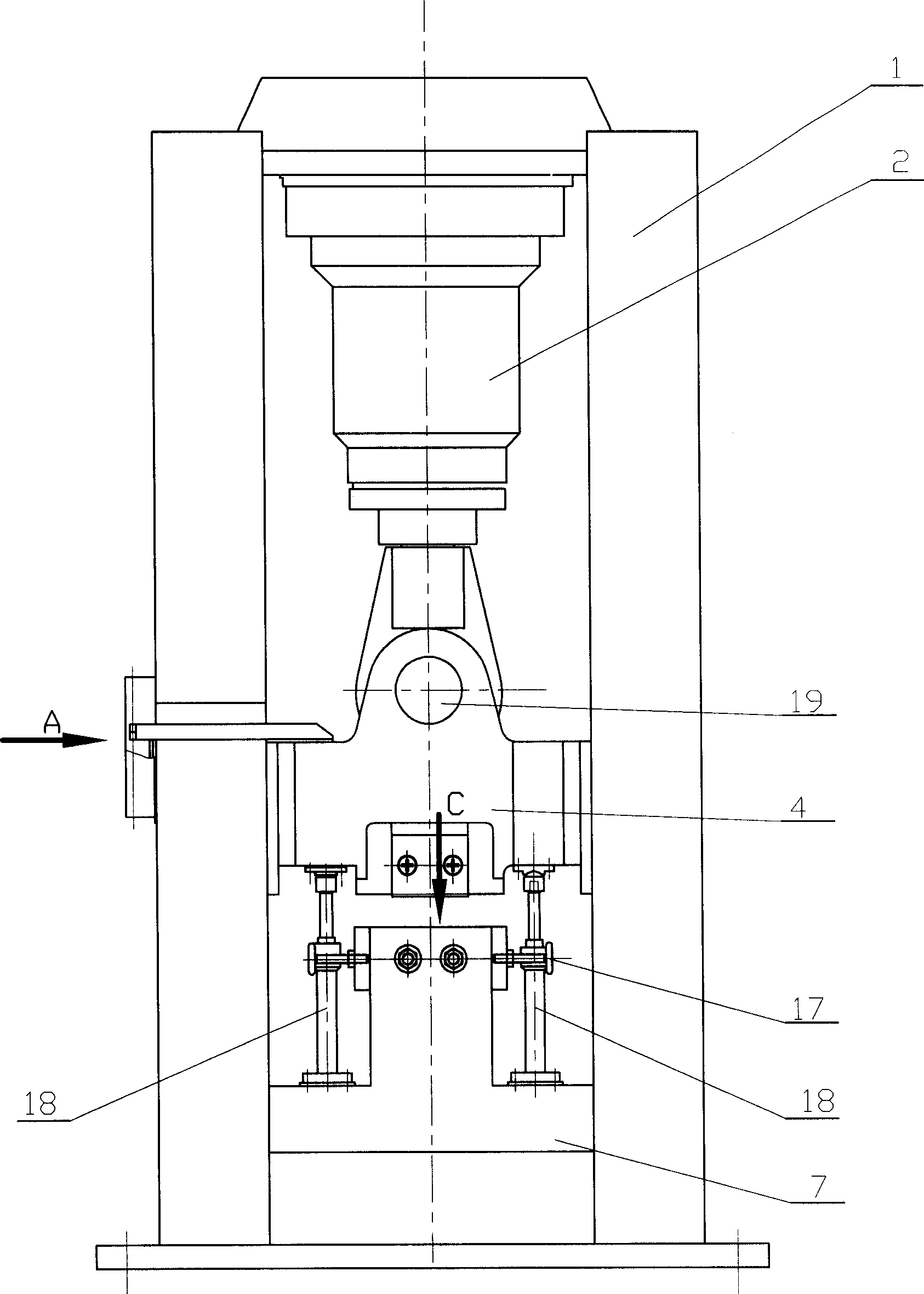

[0034] Such as figure 1 As shown, the feature of the present invention is that the main hydraulic cylinder 2 that can drive the upper cutting edge device 4 is mounted on the upper part of the frame 1. It is connected to the upper cutting edge device 4 through a pin 19, and the lower cutting edge device 7 is mounted on The lower part of the frame 1 corresponds to the upper cutting blade device 4, and is located in front of the upper and lower cutting blade devices. A compression hydraulic pressure which can compress the sheet metal is installed through the pin 20 and installed on the frame 1. The material pressing device 6 connected to the cylinder 3 is installed on the frame 1 at the rear of the upper and lower cutting blade devices, and is equipped with a sizing mechanism 15 and upper and lower cutting blade gap adjustment mechanisms 14 and 17, which are installed at the front feeding position of the frame 1. There are a feeding roller table device 8 and a feeding roller table r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com