Movable steel strip brush

A mobile, steel-belt technology, applied in the direction of household components, flat products, household appliances, etc., can solve the problems of fiberboard quality impact, time-consuming and labor-intensive, and affect the surface finish of the board, so as to ensure smooth progress and keep clean.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

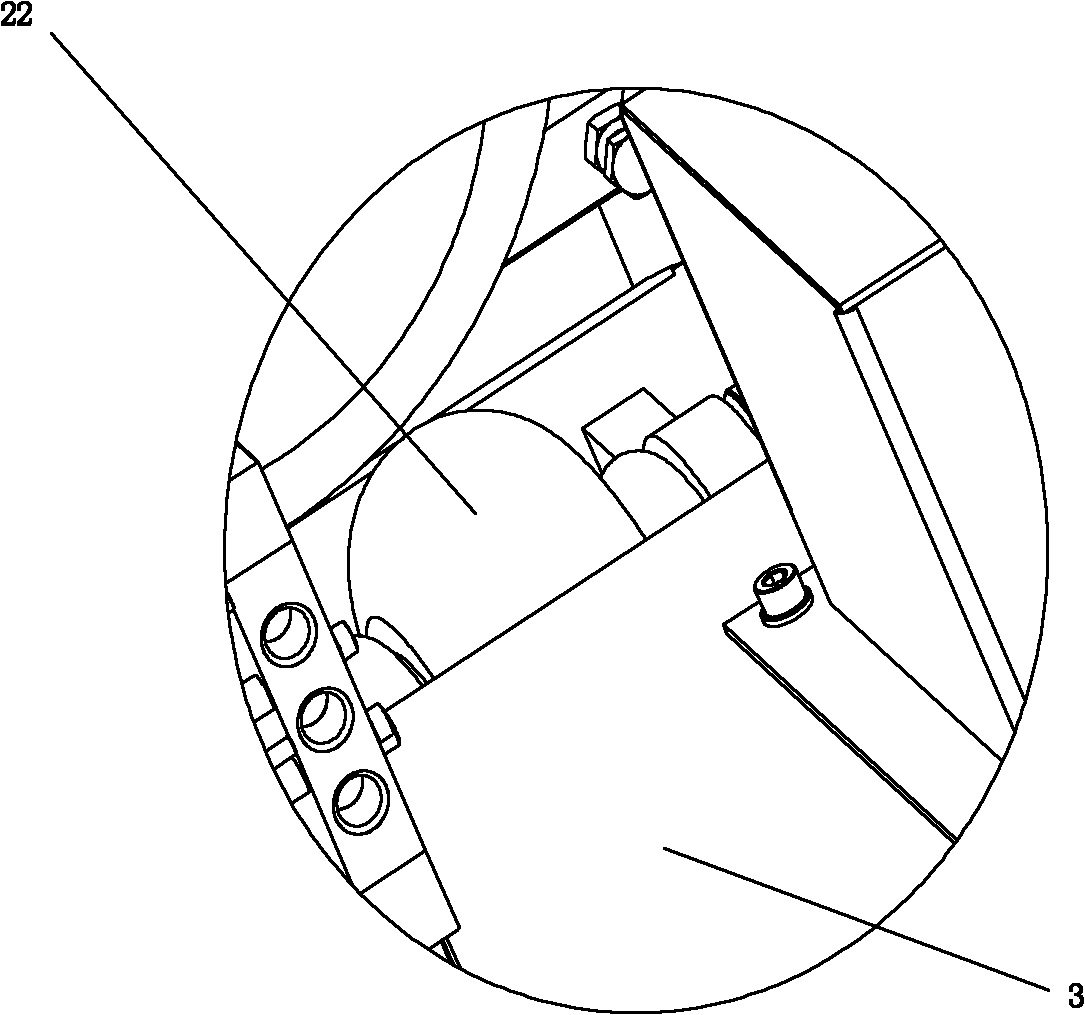

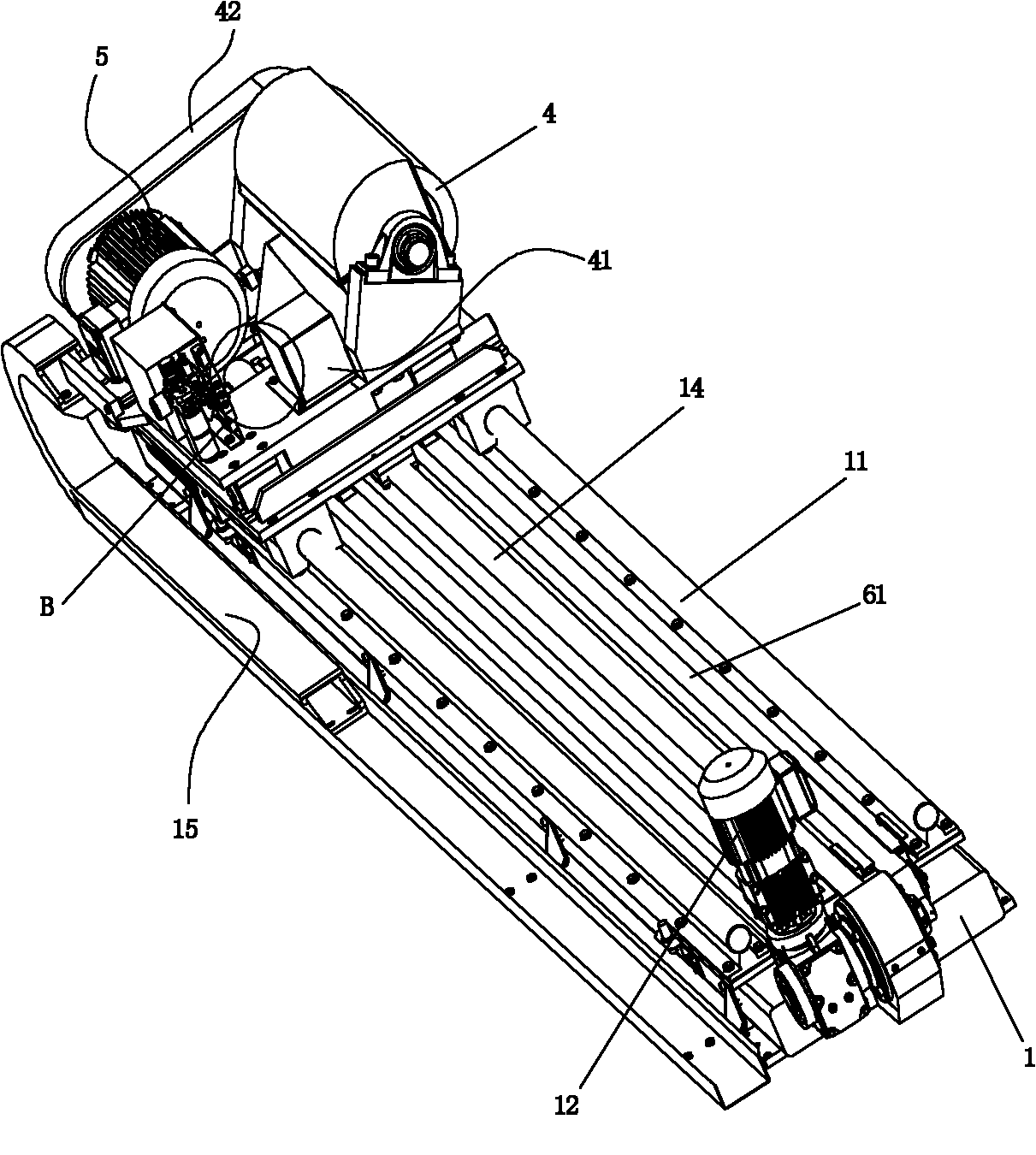

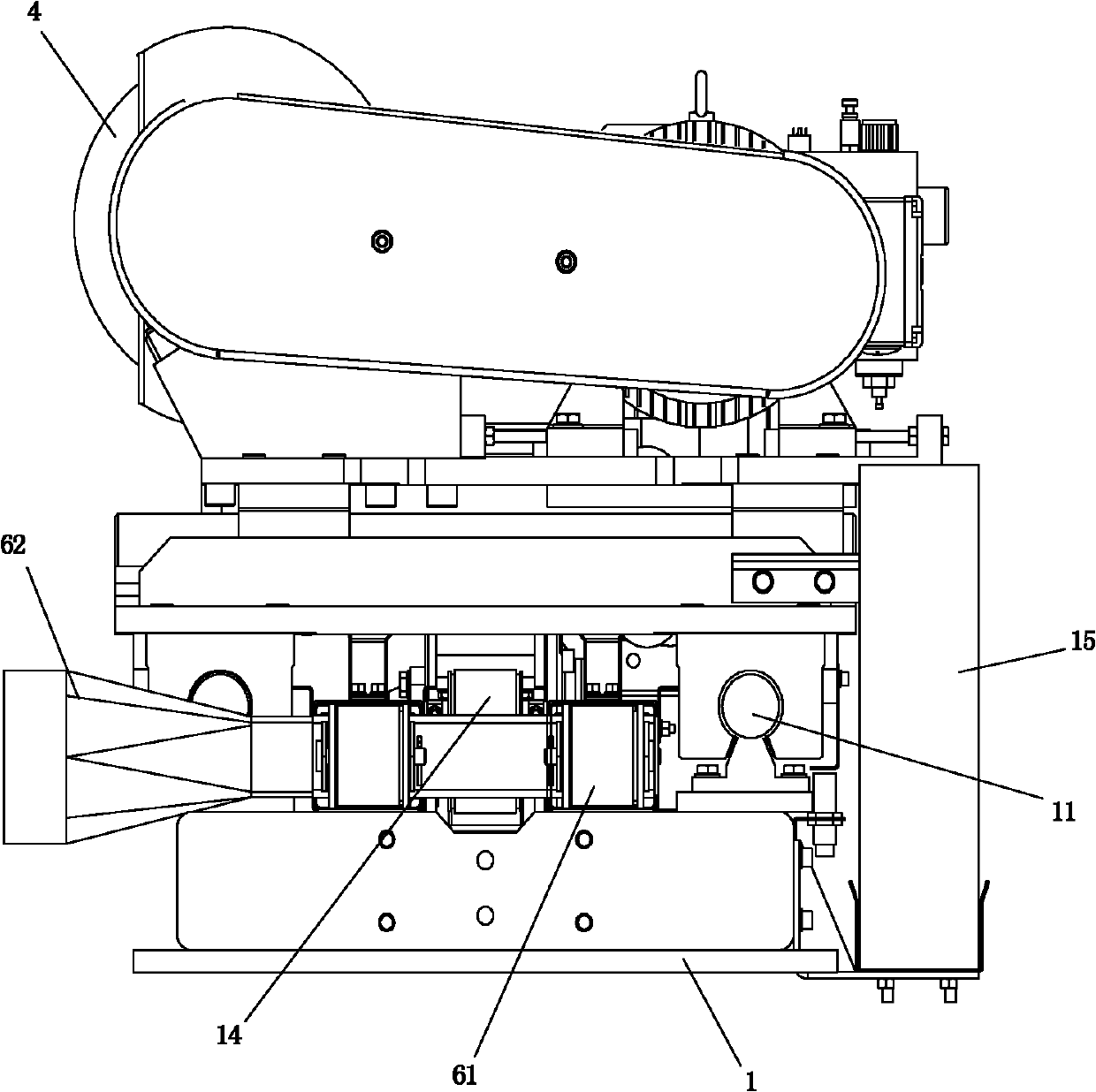

[0019] See figure 1 , figure 2 , image 3 and Figure 4 , The mobile steel belt brush of the present invention is an online cleaning equipment for the steel belt of a continuous press, and has a base 1 , a moving seat 2 and a steel belt brush seat 3 .

[0020] Above-mentioned base 1 is provided with transverse guide rail 11, and base right end is equipped with mobile motor 12, and above-mentioned mobile seat 2 is slidably connected on the transverse guide rail, and transverse guide rail is cylindrical, and mobile seat is provided with sliding block and transverse guide rail to cooperate. The sliding of the moving seat on the horizontal guide rail is driven by the moving motor. There is a gear at the bottom of the moving seat. The output end of the moving motor and the gear of the moving seat are connected and driven by a toothed belt 14. When the moving motor is working, the moving seat 2 is in the tooth shape Under the action of the belt, it slides along the transverse gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com