Method for controlling screen printing processing of liquid crystal display

A liquid crystal display and control method technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve problems such as difficult judgment and determination, reduced product yield, unqualified, etc., to achieve the effect of reducing manufacturing costs and improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Further description will be given below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

[0020] The specific method of controlling the screen printing process of this liquid crystal display is as follows:

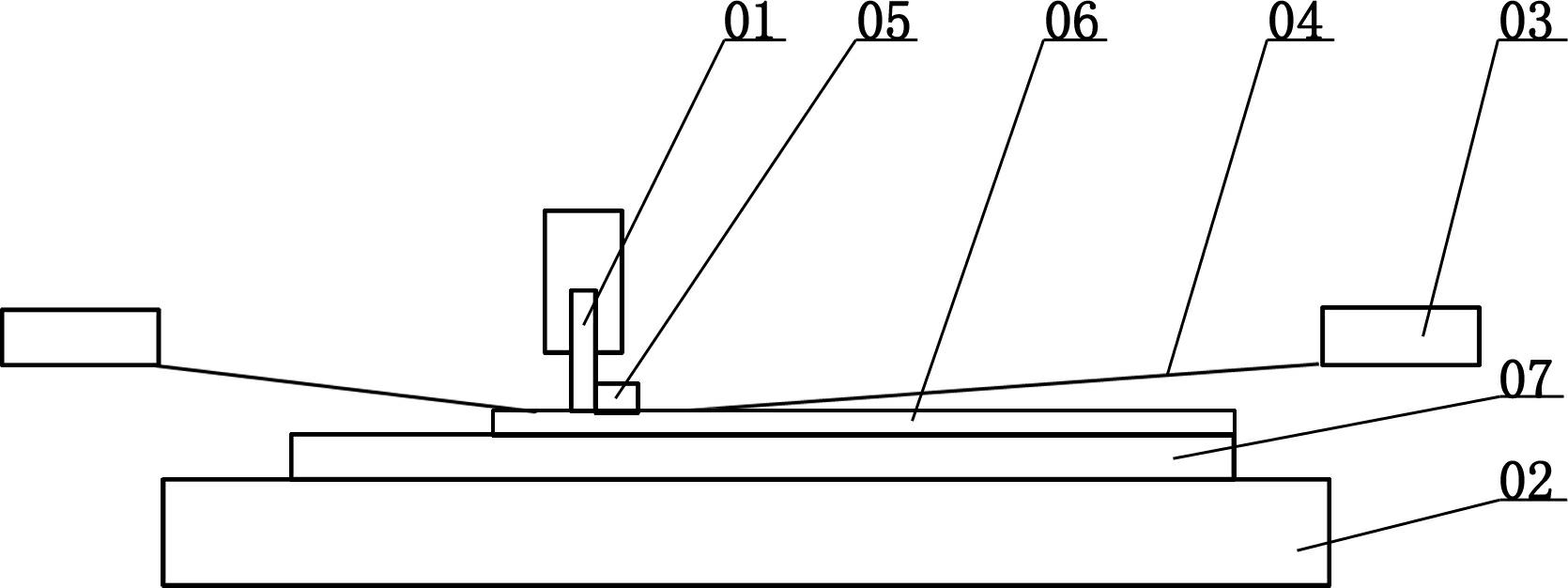

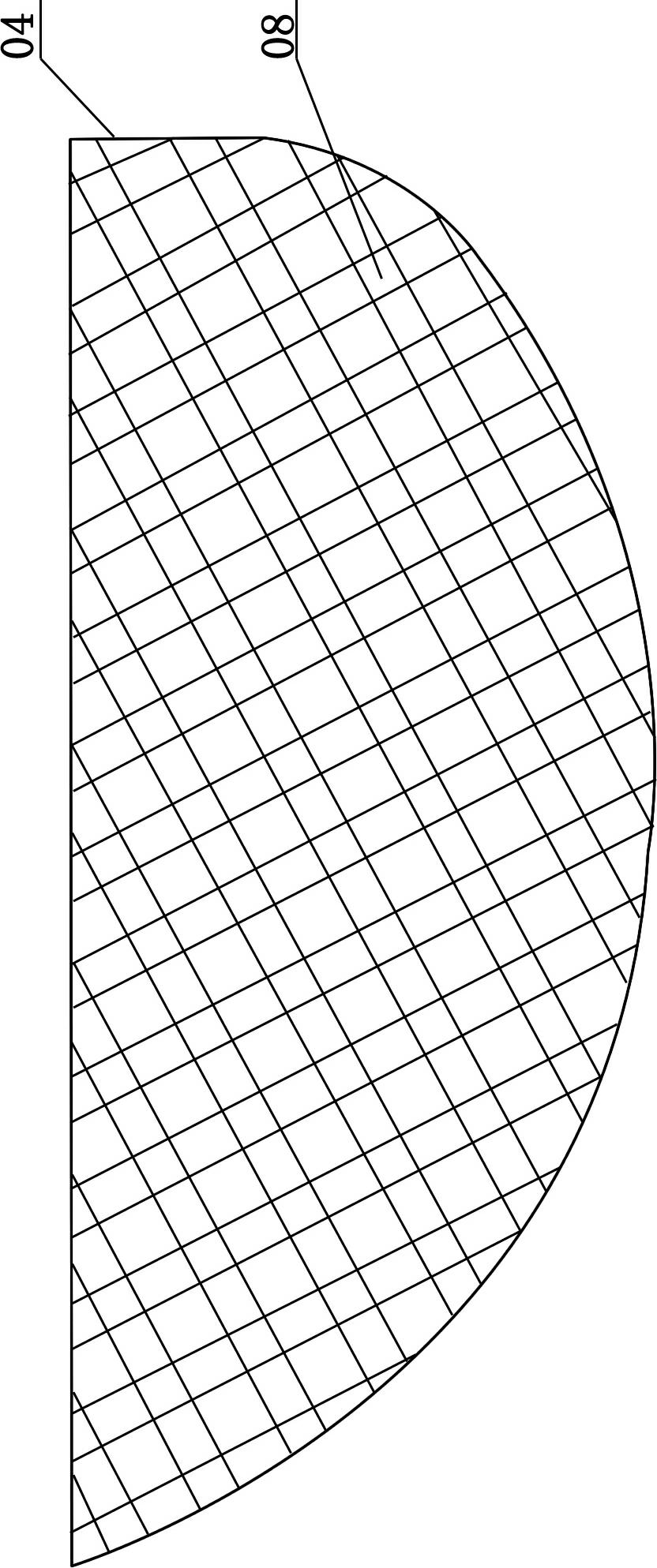

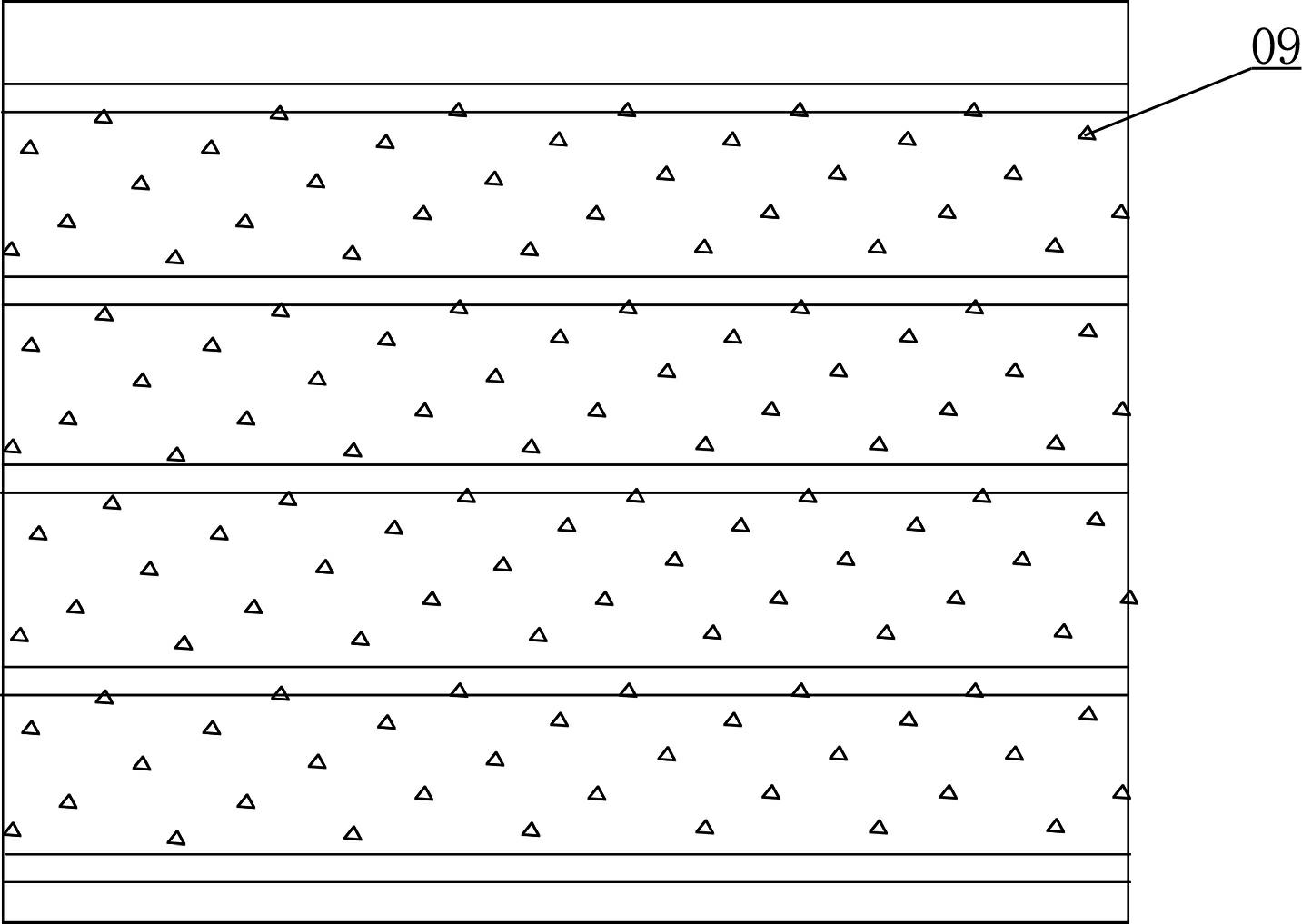

[0021] Such as Figure 4 As shown, before the screen printing process of the alignment layer, the glass plate 1 is first used in the figure 1 Screen printing is carried out on the screen printing equipment shown, and the simulated orientation layer 2 is produced, and there is a display defect 3 on the simulated orientation layer 2; then, according to the simulated orientation layer 2, the following Figure 5 The simulated liquid crystal cell 4 shown; Figure 6 As shown, the polarizing device that generates the polarizing field includes an upper polarizing plate 5 and a lower polarizing plate 6, the simulated liquid crystal cell 4 is placed in the polarizing field, and the degree of screen printing of the simulated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com