Dual-hydraulic system of remote-control grab bucket

A dual-hydraulic and grab technology, applied in the field of hydraulic systems, can solve the problems of affecting loading and unloading progress, reducing production efficiency, and long maintenance cycle, so as to achieve the effect of improving loading and unloading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with specific examples.

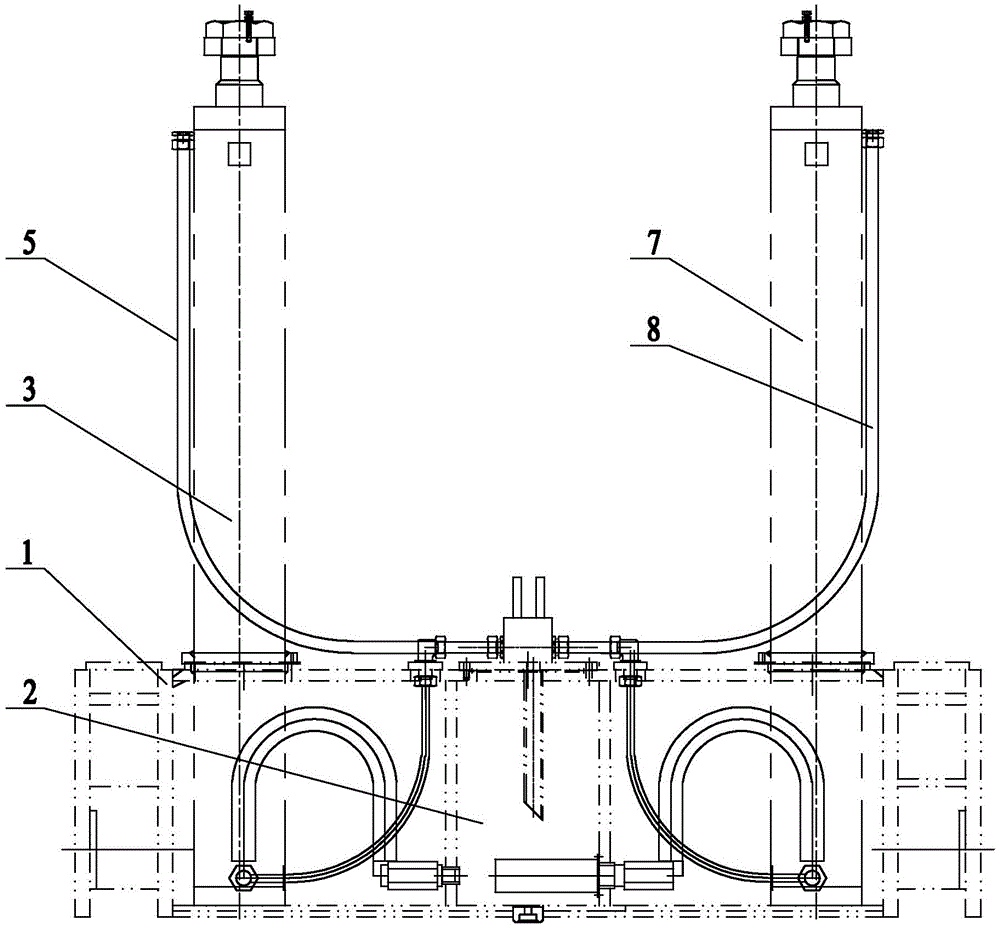

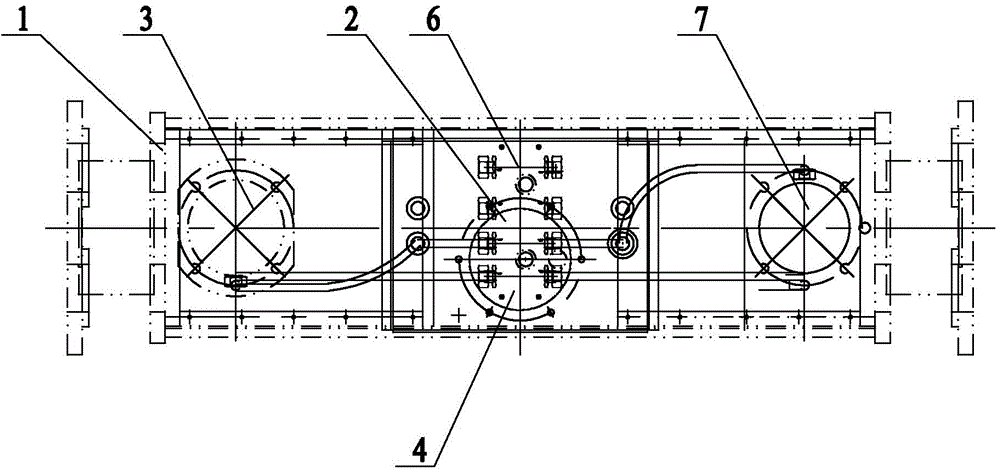

[0010] The dual hydraulic system of the remote control grab has a fuel tank 2 and a working cylinder 3 fixed on the beam 1 of the remote control grab, and a working hydraulic valve block 4 is arranged in the fuel tank 2. The working hydraulic valve block 4 is connected to the fuel tank 2, and the working cylinder 3 and the working The hydraulic valve block 4 is connected through the working hydraulic pipeline 5. There is a spare hydraulic valve block 6 in the fuel tank 2. A spare oil cylinder 7 is fixed on the remote control grab beam 1. The spare oil cylinder 7 and the spare hydraulic valve block (6) pass through the spare hydraulic valve block (6). The hydraulic pipeline 8 is connected.

[0011] On the remote control grab beam 1, the working oil cylinder 3 and the spare oil cylinder 7 are left and right symmetrically arranged.

[0012] During normal use of the remote contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com