Carbon brush grinding chamfering machine

A technology of chamfering machine and carbon brush, which is applied to the parts of grinding machine tools, machine tools suitable for grinding workpiece edges, and grinding feed movement, etc. It can solve the problems of small carbon brush structure size, danger to operators, and production efficiency. Low quality and other problems, to achieve the effect of good product quality, low labor intensity and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

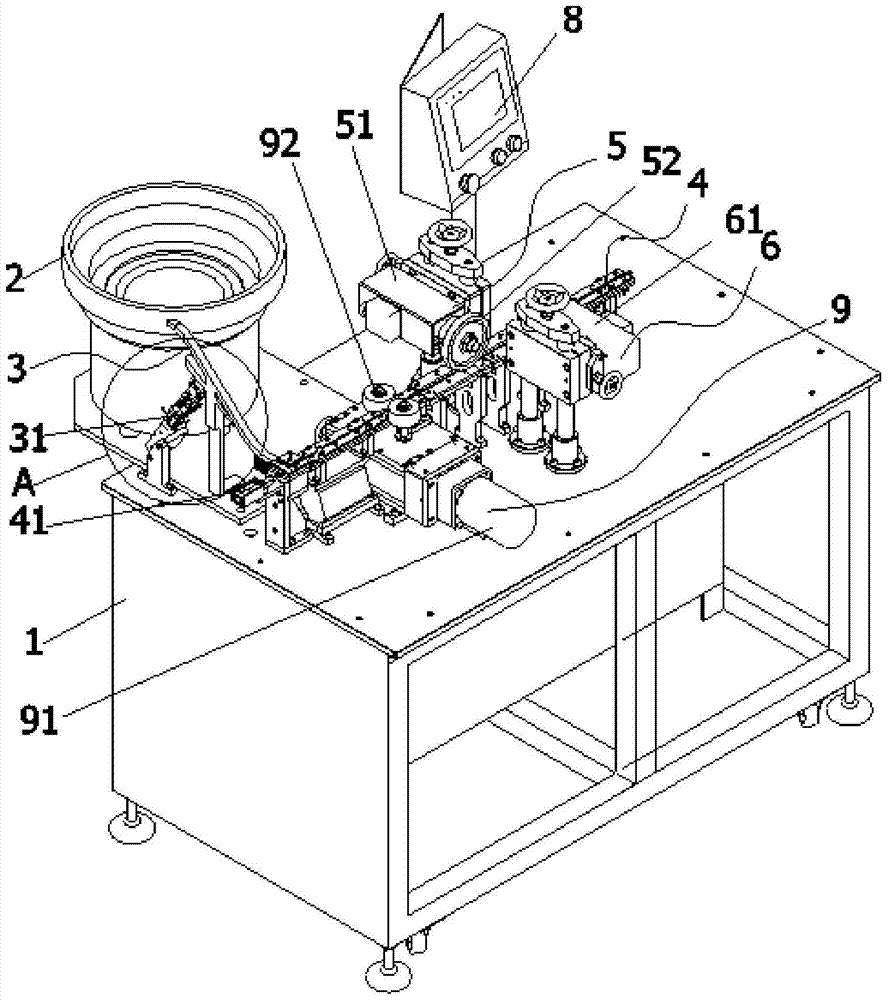

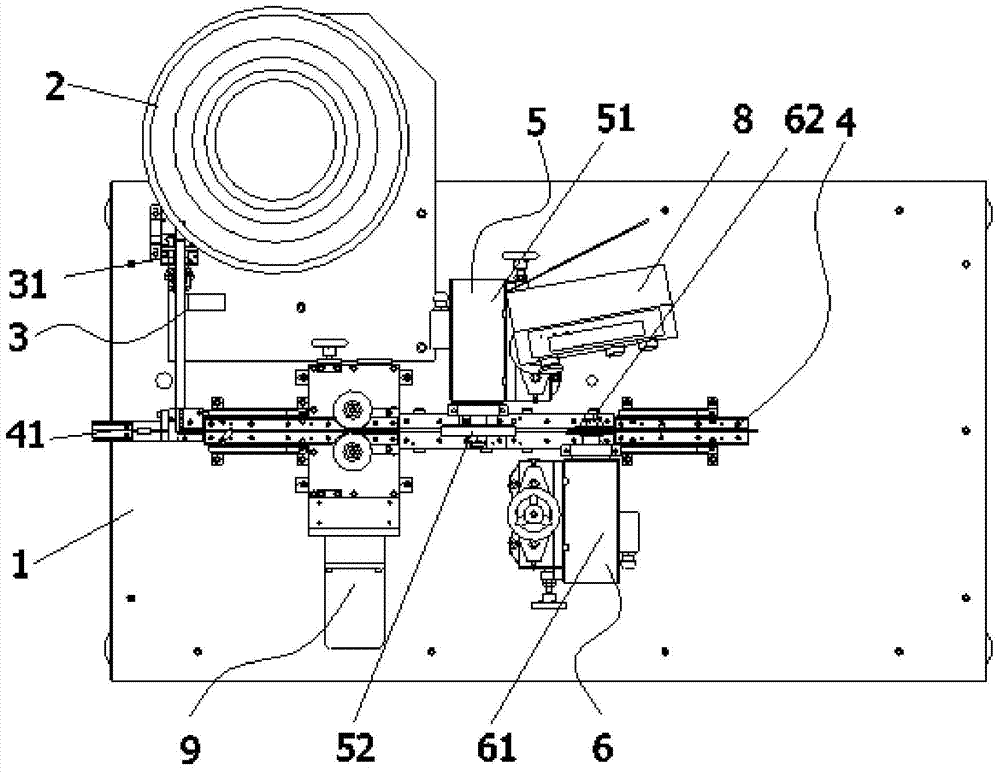

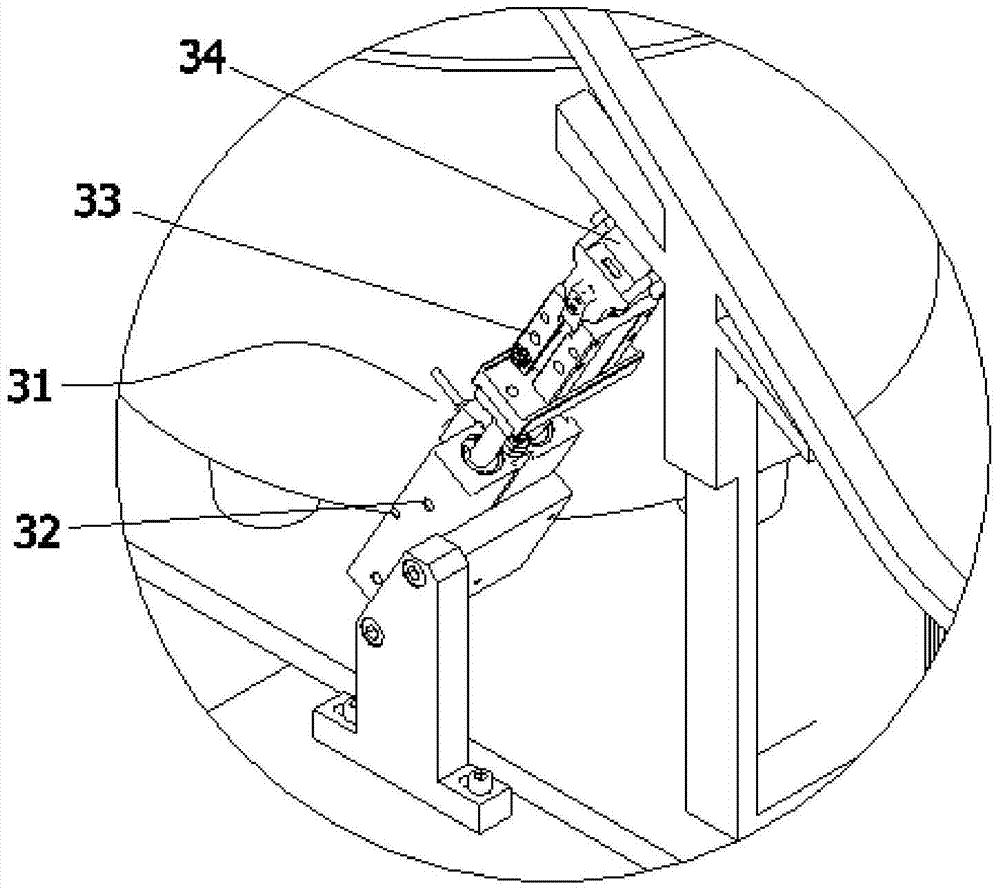

[0027] Such as figure 1 Shown is the three-dimensional structural diagram of the carbon brush grinding and chamfering machine of the present invention. As can be seen from the figure, it includes: a plurality of carbon brushes installed on the workbench 1 are used to automatically orientate and sort a plurality of carbon brushes and transport them to the processing workers in turn. The conveying device has a linear guide rail 4 for transporting multiple carbon brushes; a grinding plane device 5 arranged on the workbench 1 for grinding the upper end surface of the carbon brushes conveyed on the linear guide rail 4; arranged on the workbench The chamfering device 6 on the 1 is used for chamfering the carbon brushes that have been ground on the upper end surface. In addition, there is also a control device for controlling the work of the conveying device, the grinding device 5 and the chamfering device 6, and the control device has a display device 8, which is a touch screen, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com