Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Will not affect the feel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

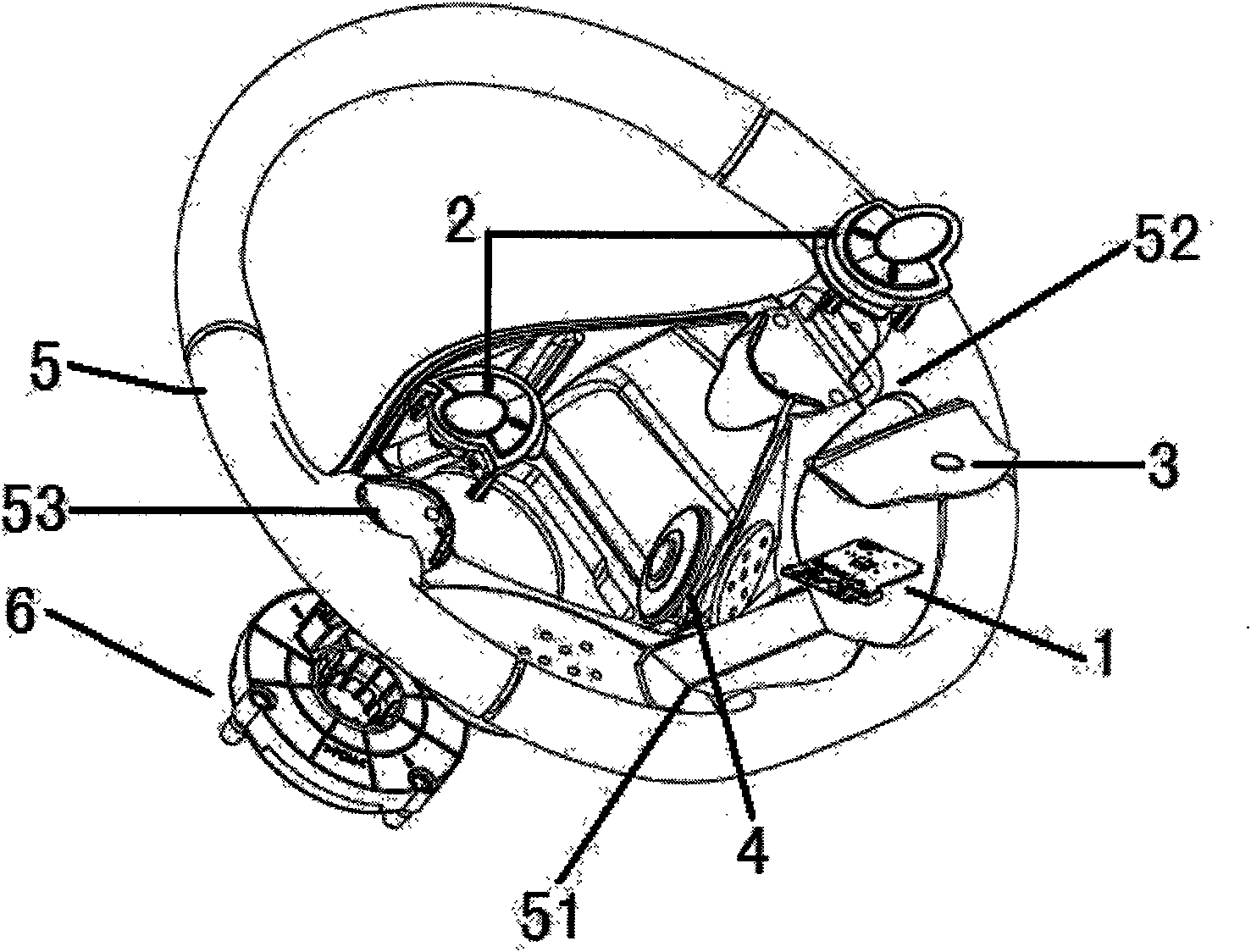

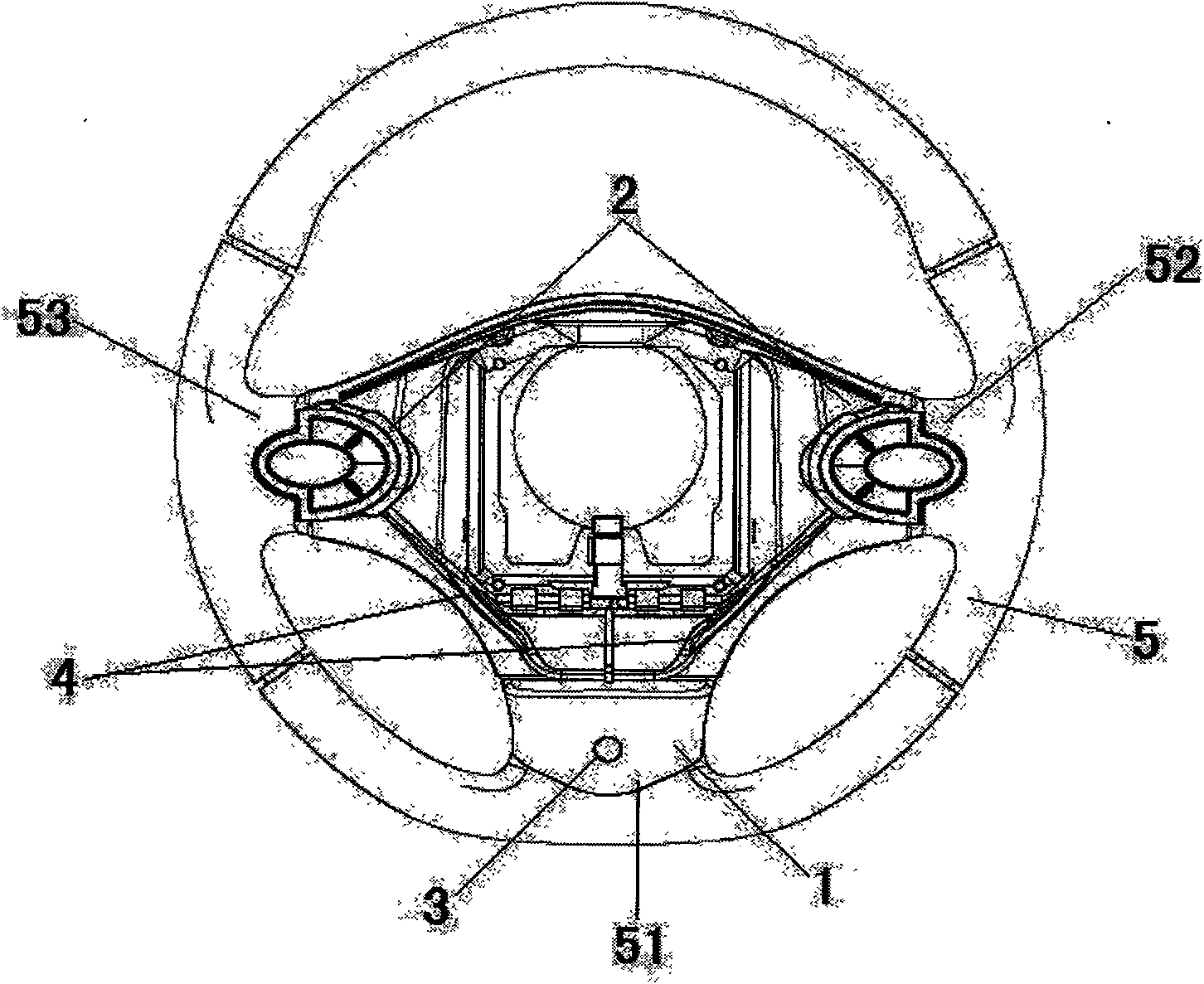

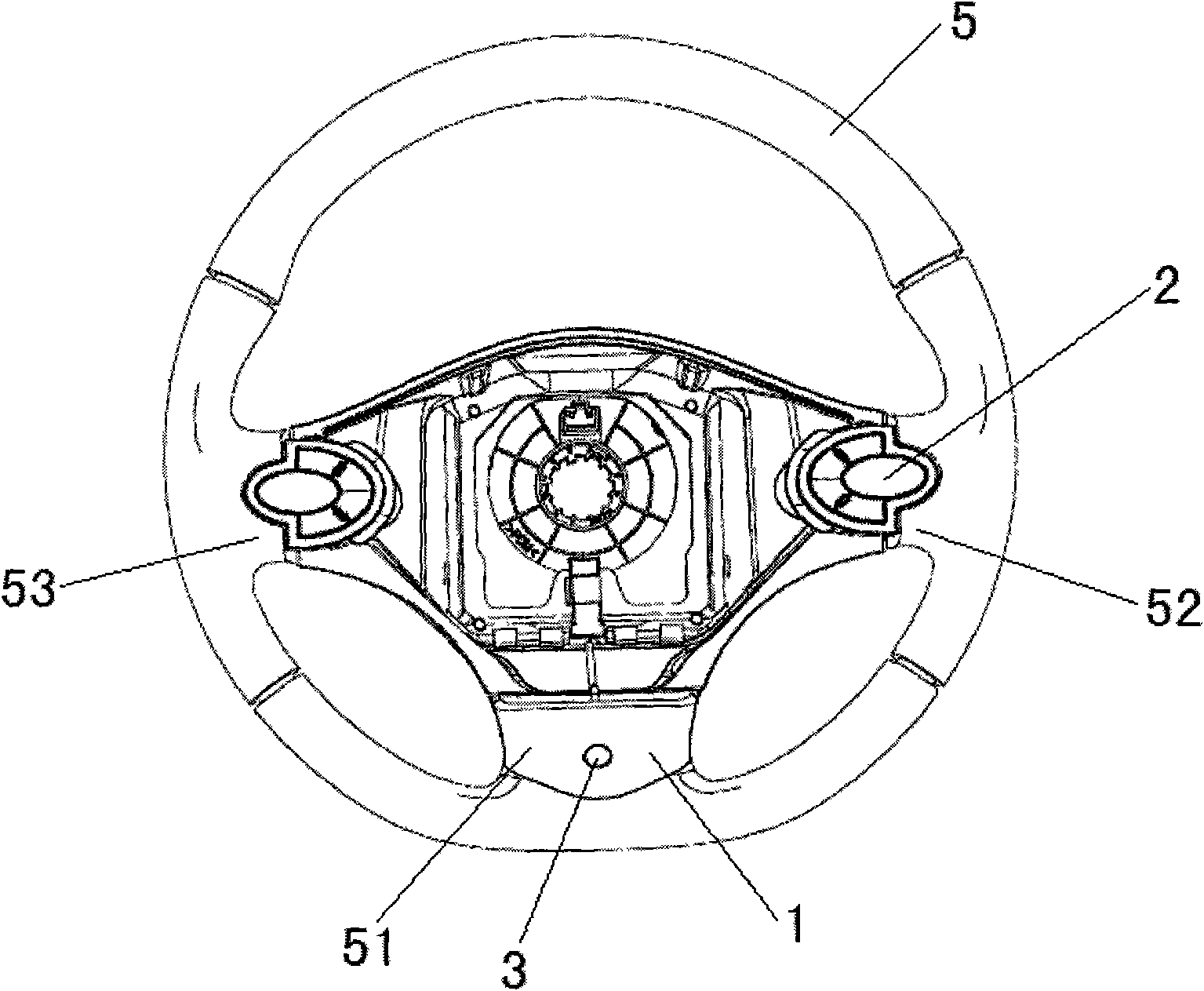

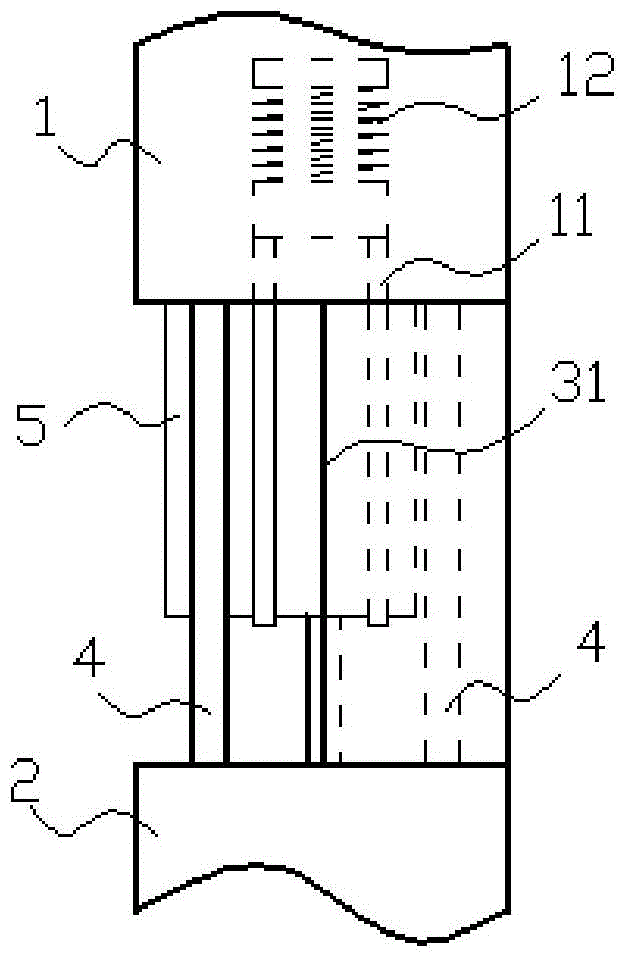

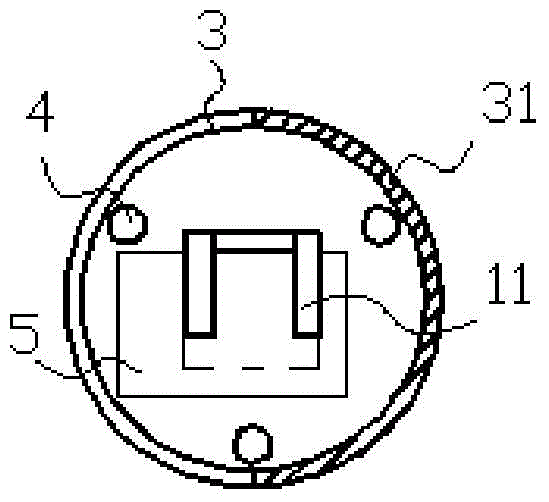

Steering wheel with voice acquisition system

ActiveCN101594409ALow costWill not affect the feelSubstation speech amplifiersHand wheelsShielded cableSteering wheel

The invention provides a steering wheel with a voice acquisition system, which comprises a steering wheel and the voice acquisition system, wherein the voice acquisition system can be a blue-tooth hands-free system comprising a blue-tooth hands-free control module, a microphone, control keys and a loudspeaker; the microphone is embedded in the steering wheel and positioned on a position which is close to the speaking direction of a driver and suitable for the mounting of the microphone; and the blue-tooth hands-free control module, the control keys and the loudspeaker can be also embedded in the steering wheel. The steering wheel solves the problems of poor received audio signals, bigger noise in sound effect and the like existing in the prior blue-tooth hands-free device, achieves the best speech quality, and simultaneously saves cost because an audio shield cable is not used; and because the voice acquisition system is completely integrated in the steering wheel, mounting places on other parts of a vehicle and special mounting devices are not needed.

Owner:YANFENG AUTOMOTIVE SAFETY SYST CO LTD +1

Molecular assembly type nanometer silver leather mildew inhibitor and method for preparing same

InactiveCN101543227ADoes not affect appearanceNot affected by colorBiocideFibre treatmentCrosslinked chitosanWater baths

The invention discloses a molecular assembly type nanometer silver leather mildew inhibitor and a method for preparing the same. The method is characterized by comprising the following steps: (1) reacting 2 to 5 portions of chitosan with the deacetylation degree more than 80 percent with 12 to 21 portions of benzaldehyde at room temperature to generate schiff alkali chitosan; (2) reacting 10 to 18 portions of the schiff alkali chitosan with 21 to 40 portions of bromization crown ether at a temperature of between 50 and 70 DEG C to generate crown ether crosslinking chitosan; (3) dissolving 28 to 41 portions of crown ether crosslinking chitosan in 5,000 to 7,000mL of distilled water, adding 400 to 1,200 portions of 0.05 to 0.3 percent hydrazine hydrate solution to the mixed solution, evenly mixing by shaking, adding 160 to 900 portions of 0.1 to 0.3mol / L silver nitrate solution to the mixed solution after 5 to 20 minutes; and (4) placing the mixed solution in a water bath at a temperature of between 40 and 60 DEG C, standing at the room temperature for 10 to 20 hours when the color of the mixed solution is stably changed, and obtaining the molecular assembly type nanometer silver leather mildew inhibitor.

Owner:成都塔拉生物科技有限公司

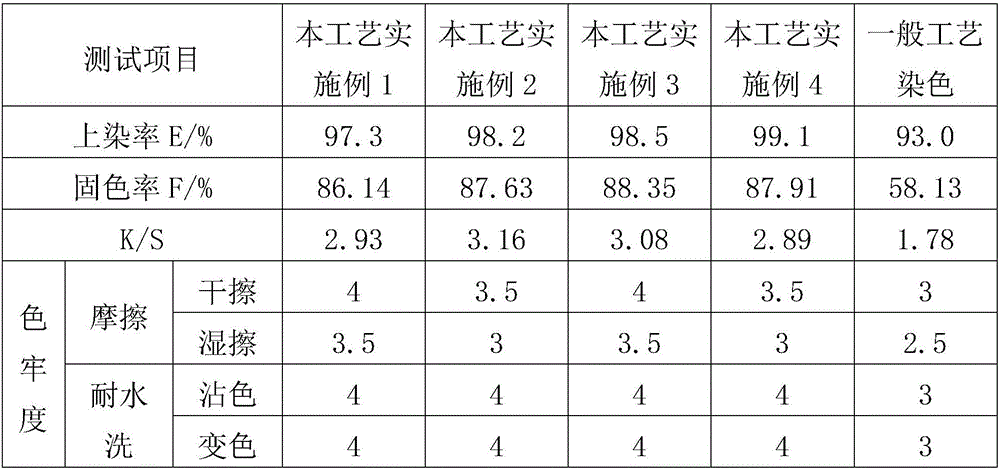

Dyeing method of reactive dye with high color fixation rate

ActiveCN106192470AImprove dye uptakeHigh color fixing rateDyeing processPhotochemistryChemical substance

The invention discloses a dyeing method of a reactive dye with a high color fixation rate. The dyeing method comprises the following steps: S1, pretreatment: padding a texture to be dyed in a finishing solution containing chitosan quaternary ammonium salt, dipping for two times, rolling for two times, prebaking at the temperature of 80 to 100DEG C, baking at the temperature of 110 to 130DEG C, washing with cold water and then drying; S2, reactive dyeing: immersing into a dyeing solution of the reactive dye, dyeing at the temperature of 20 to 30DEG C, raising the temperature to be 50 to 70DEG C, then adding an organic solvent B, and raising the temperature to be 80 to 100DEG C; adding sodium carbonate according to the volume of the dyeing solution of the reactive dye, insulating heat and reducing to room temperature; S3, performing after treatment, water washing, soaping, water washing and drying in air. The dyeing method of the reactive dye with the high color fixation rate, provided by the invention, has the advantages of high color fixation rate and good level-dyeing property; in addition, the process is simple, and industrial implementation is easily realized; meanwhile, chemical substances with high price and greater toxicity are prevented from being used.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

Ecological antimicrobial fabric and method for producing the same

InactiveCN101153460ANo growthGuaranteed antimicrobial propertiesFibre treatmentLiquid/gas/vapor textile treatmentAntibacterial agentChemistry

The invention discloses a preparation method of biological antibacterial fabric. The invention is characterized in that an antibacterial processing technology is provided based on the prior fabric preparation technology, and the antibacterial processing technology orderly comprises the following steps, the fabric is dipped in nano-silver ions antibacterial agent solution, stentered, preliminarily dried and baked. The method in the invention can be used to produce a biology antibacterial fabric.

Owner:上海龙头家纺有限公司

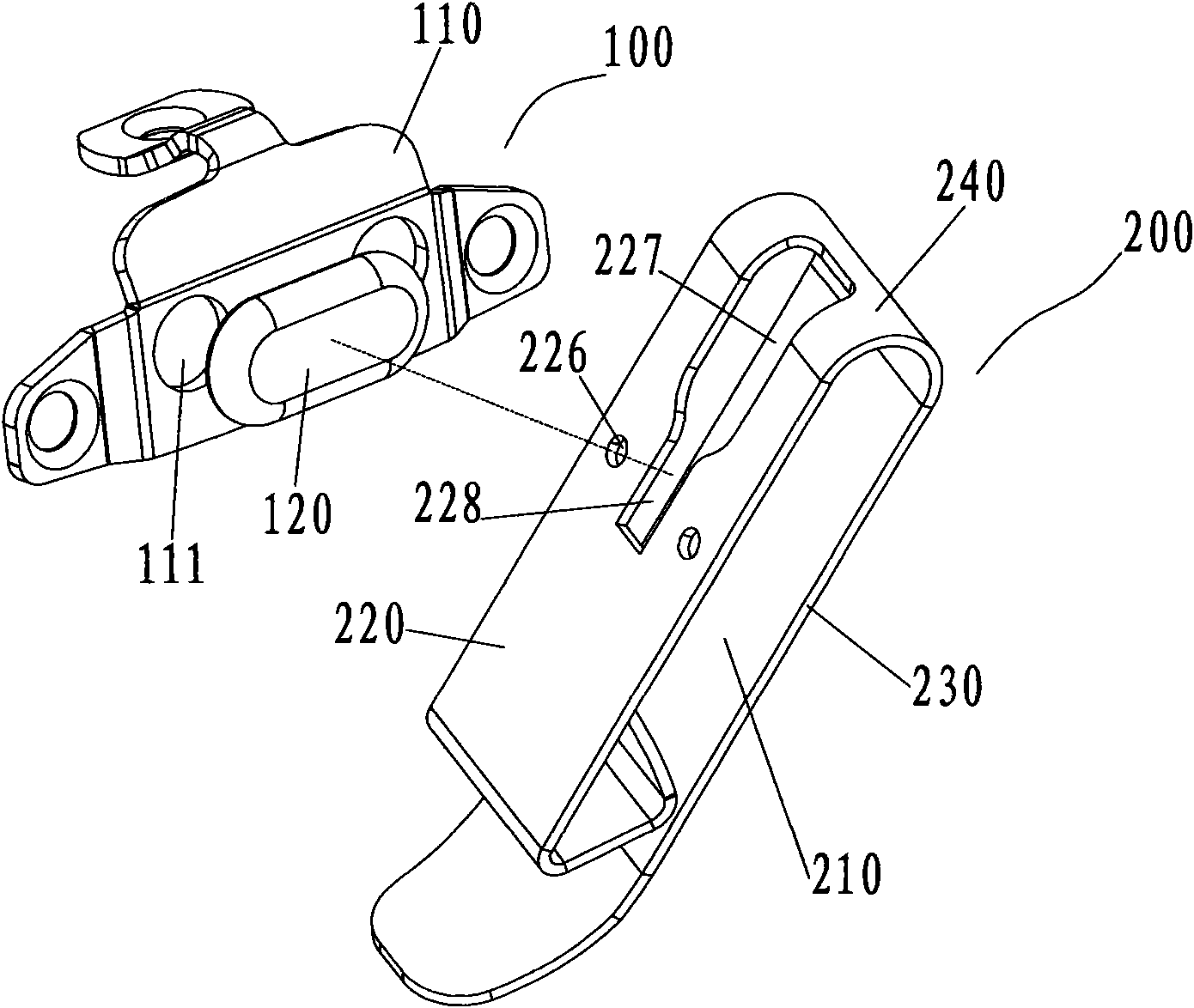

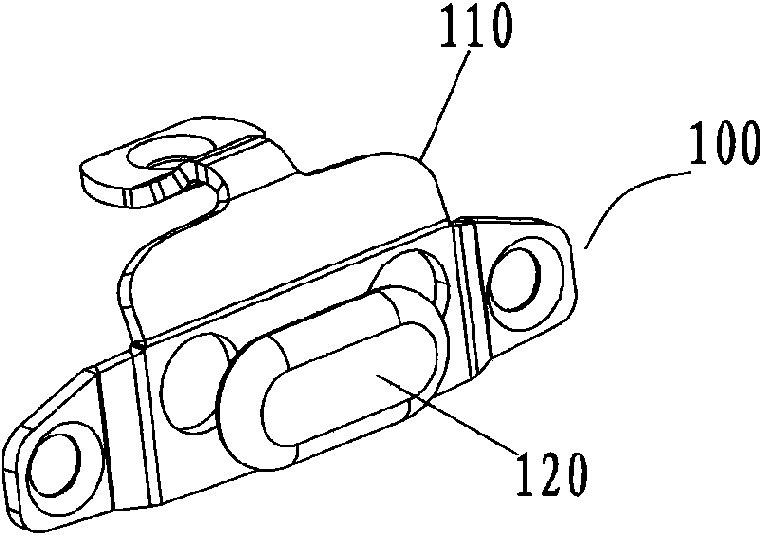

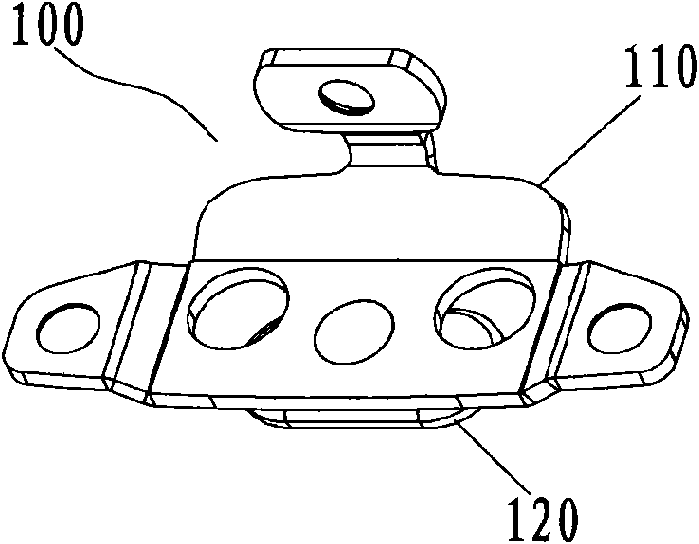

Hanging buckle structure for carrying articles and interphone provided with hanging buckle structure

InactiveCN101574194AWill not affect the feelReduce volumeTravelling carriersHoldersNeck partsLeather belt

The invention relates to a hanging buckle structure for carrying articles, which comprises a belt clip base and a belt clip. The belt clip base comprises a belt clip base main body and a hanging buckle; the hanging buckle comprises a connecting part, a neck part and a limitation part; a front panel of the belt clip is provided with a notch and a spacing notch; the notch is communicated with the spacing notch; and after the belt clip is arranged on a belt on the waist of a user, a limit part of the hanging buckle on the belt clip base is embedded into the spacing notch of the front panel of the belt clip from the notch of the front panel of the belt clip, so that the neck part of the hanging buckle is clamped at the spacing notch. The hanging buckle structure has the advantages of long service life, simple structure, attractiveness, elegance, firmness and convenient loading and unloading. The invention also relates to an interphone provided with the hanging buckle structure, which can be conveniently taken out from the belt on the waist of the user at any time, while the belt still can stay on the belt so as to be separated from the interphone, so the problem that the handfeel is influenced due to the belt clip when the interphone is used is solved; and meanwhile, the buckle structure also ensures the safety of the interphone.

Owner:深圳市欧标实业发展有限公司

Paper for daily use

ActiveCN103284647AMeet strength requirementsWill not affect the feelSpecial paperPaper/cardboardPulp and paper industryMono layer

Paper for daily use comprises a piece of surface paper and a piece of core paper, wherein the surface paper comprises a piece of upper paper and a piece of a lower paper; the core paper is arranged between the upper paper and the lower paper; the upper paper and the lower paper are composite fiber layers formed by native wood pulp fiber layers, native non-wood pulp fiber layers or native wood pulp fiber and non-native wood pulp fiber; the core paper adopts a single layer or multilayer structure; and at least one layer of the core paper is a composite fiber layer contains non-plant pulp fiber and plant pulp fiber. The paper for daily use can not only meet use requirements, but also can effectively reduce the production cost.

Owner:GOLD HONG YE PAPER

High-temperature-resistant textile dye

InactiveCN104862997AImprove high temperature resistanceImprove dyeing effectDyeing processCellulosePolymer science

High-temperature-resistant textile dye is prepared from raw materials in parts by weight as follows: 6-14 parts of epichlorohydrin, 2-8 parts of acetic acid, 7-9 parts of rosin, 4-10 parts of polyvinyl alcohol, 4-10 parts of an acetic acid aqueous solution, 4-8 parts of methyl silicone oil, 4.2-8 parts of propylene glycol, 5-11 parts of ethylene glycol monobutyl ether, 3-10 parts of ethyl cellulose, 2.5-6 parts of palmitic acid, 5-11 parts of anhydrous sodium sulfite, 4-9 parts of acrylamide and 1-4 parts of an aid. The textile dye has the benefits as follows: the textile dye has the good high temperature resistance and the good dyeing effect and cannot affect hand feeling of cloth.

Owner:QINGDAO BAOLIKANG NEW MATERIALS

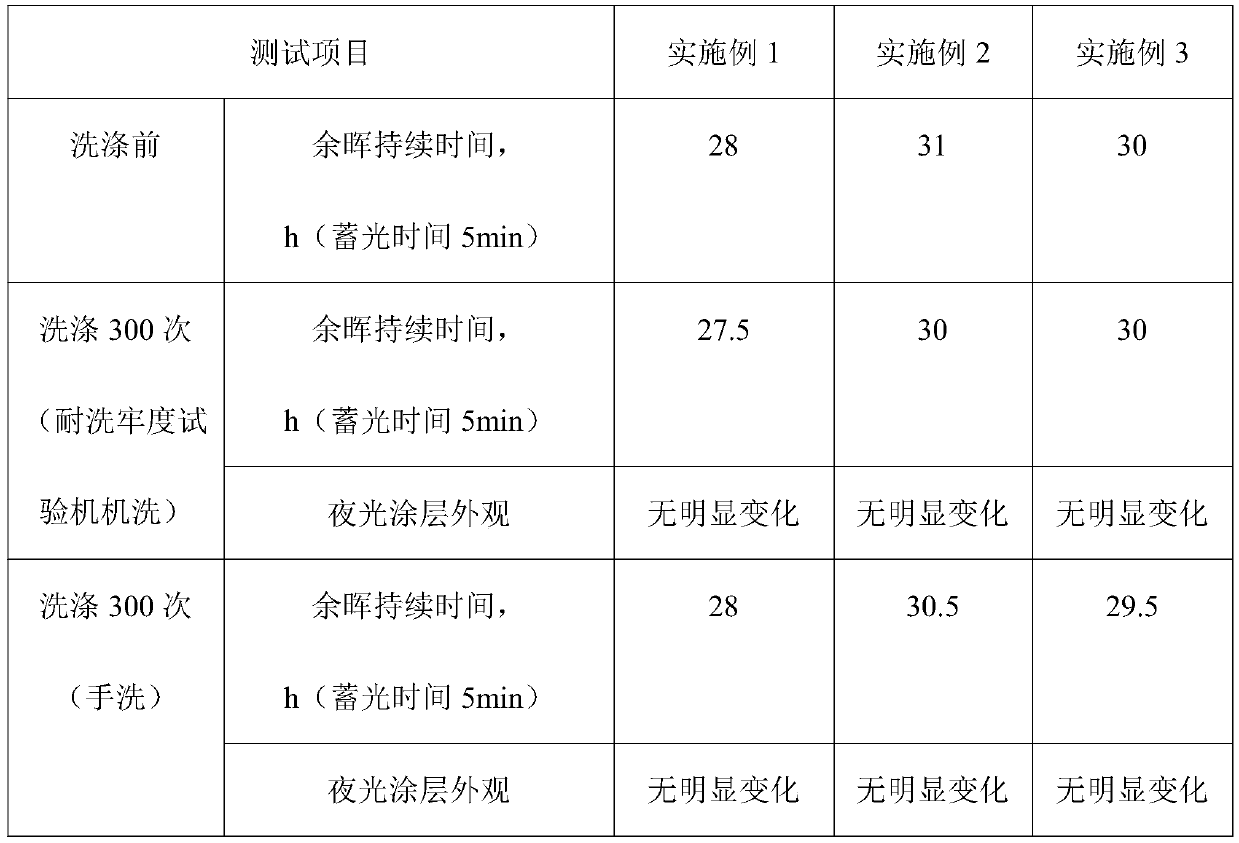

Post-finishing technology of aluminous water-repellent polyester fabric

InactiveCN109853225AImprove hydrophobic propertiesGood compound performanceFibre typesPolyesterPre treatment

The invention provides a post-finishing technology of a luminous water-repellent polyester fabric, and belongs to the technical field of textiles. The post-finishing technology of the luminous water-repellent polyester fabric comprises the steps of pretreatment, water-repellent finishing, luminous coating preparation, coating, dipping, rolling, drying and the like. The technology further comprisesthe step of coating under the action of ultrasonic waves after a luminous coating is prepared. The finally prepared fabric has a good luminous function and good water-repellent performance; meanwhile, the technology is environmentally friendly, so that the prepared fabric has relatively good market prospects.

Owner:吉祥三宝高科纺织有限公司

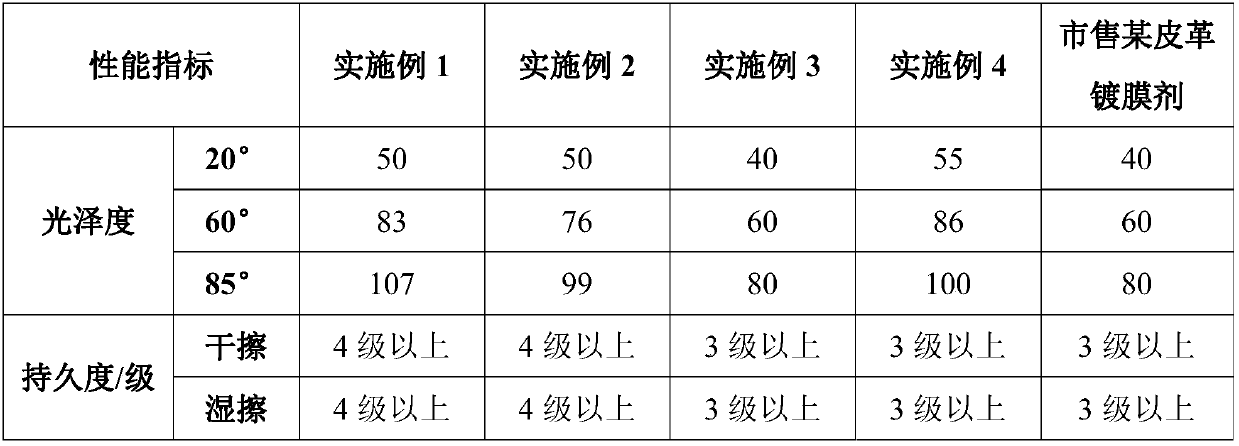

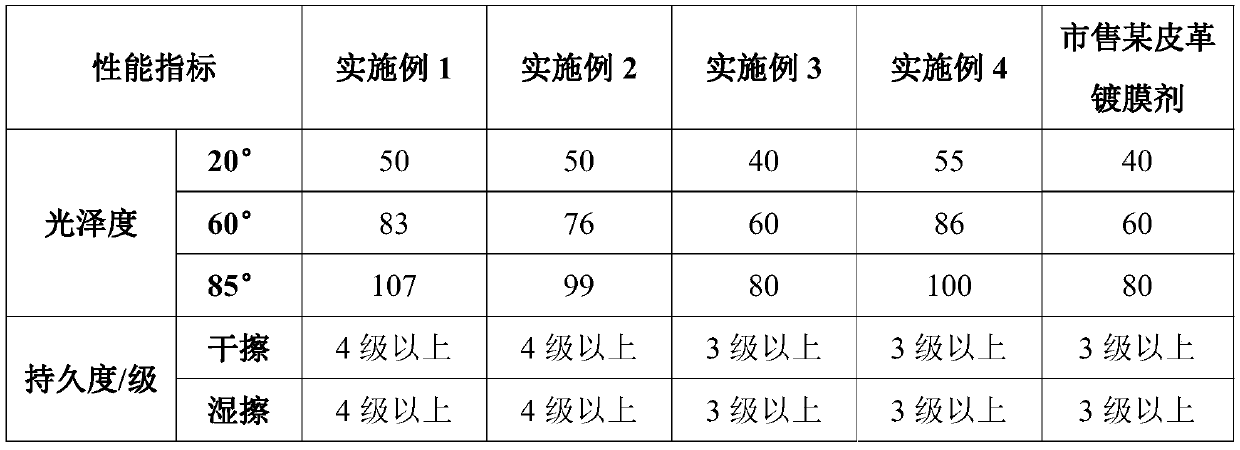

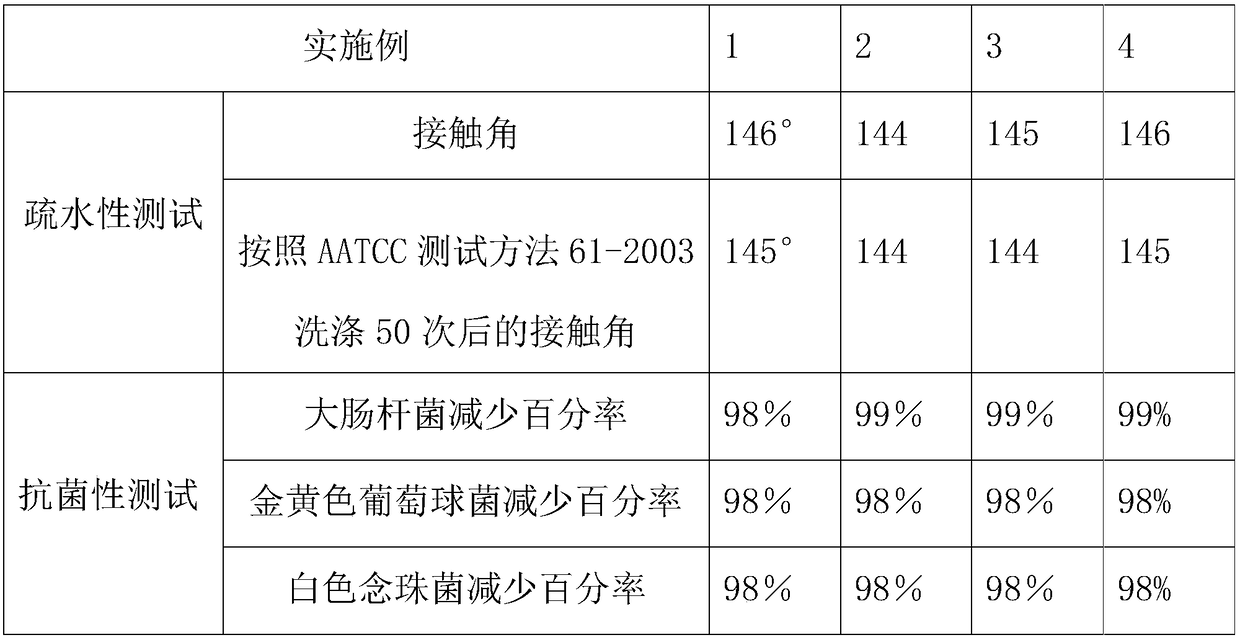

Leather coating and lustering agent and preparation method thereof

ActiveCN107556924AWill not affect the feelImprove durabilityPolishing compositionsLeather surface finishingAcrylic resinAnti ageing

The invention discloses a leather coating and lustering agent and a preparation method thereof. The leather coating and lustering agent is prepared from raw materials in percentage by mass as follows:0.1%-2% of organosilicone modified acrylic resin, 1%-10% of a lustering component, 1%-3% of a hydrophobic component, 3%-7% of a volatile component, 1%-2% of a wetting agent, 0.1%-1% of a thickening agent, 0.3%-0.7% of a corrosion remover and the balance of water. The components are mixed uniformly in batches, and the leather coating and lustering agent can be obtained. The formula of the leathercoating and lustering agent is safe and environmentally friendly, the preparation method is simple and low in production cost, the leather coating and lustering agent has no corrosion effect on leather, a transparent flexible coating layer can be formed on the leather surface after the agent is sprayed on the leather surface and the leather is slightly wiped by a towel, the hand feeling of the leather surface cannot be affected by the coating layer, the coating layer is high in stability and good in durability, and the leather coating and lustering agent can realize lustering, waterproof, anti-pollution and anti-aging functions for a long time.

Owner:广州市拓新化工科技有限公司

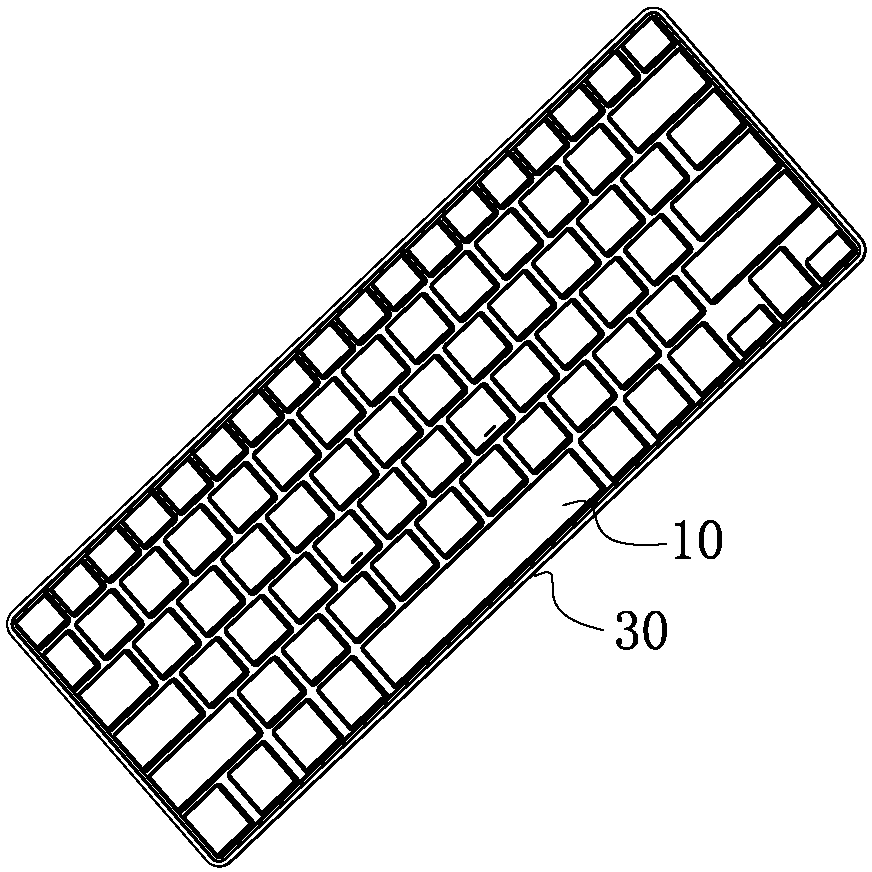

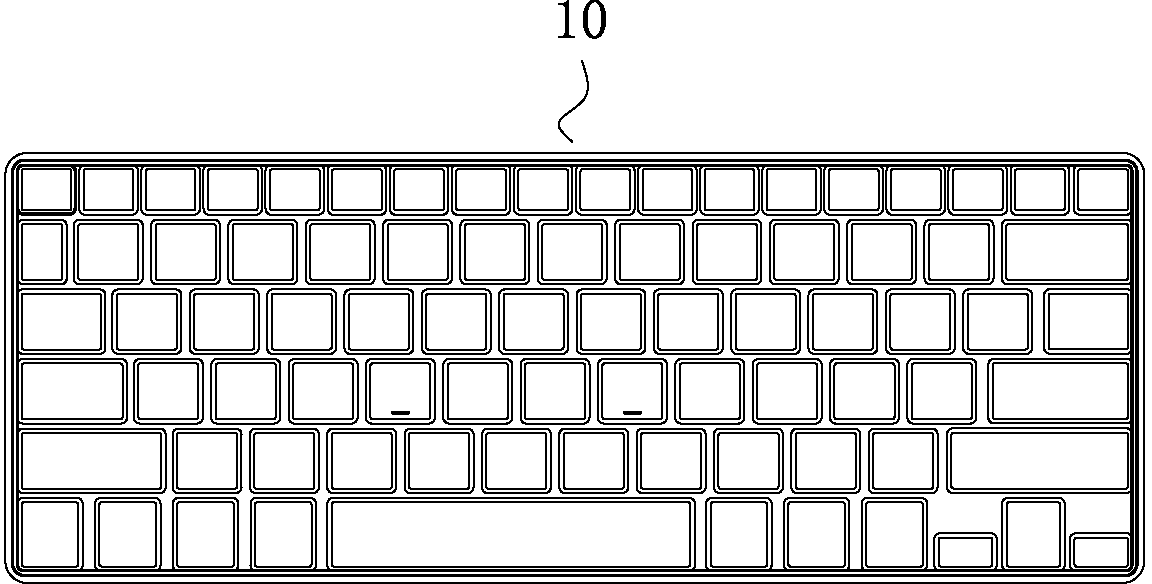

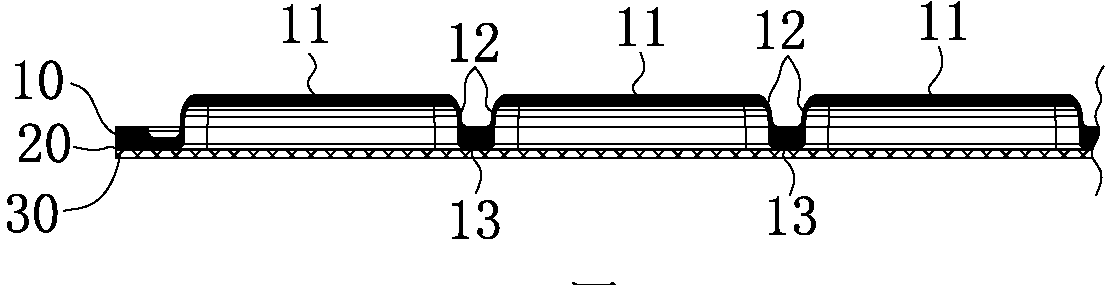

Thin-type computer keyboard with nonelastic silica gel body and scissor-kick support

ActiveCN103219182AAvoid deformationWill not affect the feelInput/output for user-computer interactionElectric switchesHigh intensityInjection moulding

The invention relates to a computer keyboard with a nonelastic silica gel body and a scissor-kick support. The computer keyboard is formed only by combining a key base board, a printed circuit film covering the lower side of the key base board and a film support bottom board arranged under the printed circuit film; the key base board is subjected to integral molding forming by using high-strength hard plastics and comprises a plurality of key units with same cross structures, wherein each key unit consists of a key surface body, an elastic connection body and a key base body, each key base body is distributed at the bottom position between every two adjacent key surface bodies, each elastic connection body is connected between the edge of each key surface body and each key base to form a cap-shape structure, and the cross section of each elastic connection body is a thin-type cambered surface, so that each elastic connection body has elasticity with cambered deformation after being stressed. The thin-type computer keyboard has the characteristics of low cost, ultrathin-type property, firm structure, good handfeel and simple waterproof and dustproof structure; and the cost of labor is saved.

Owner:深圳源创塑胶电子科技有限公司

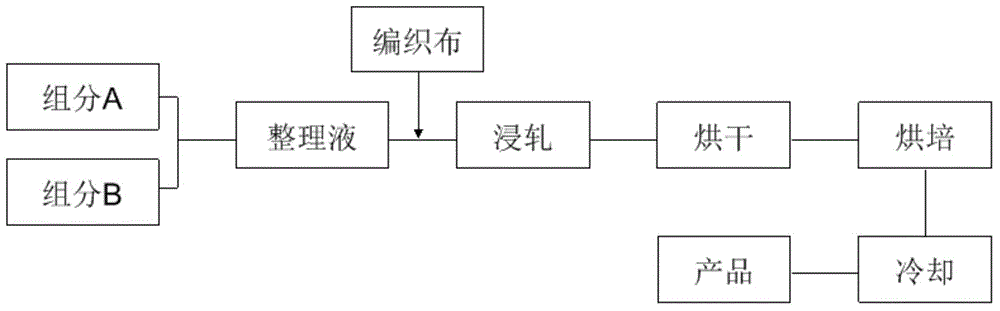

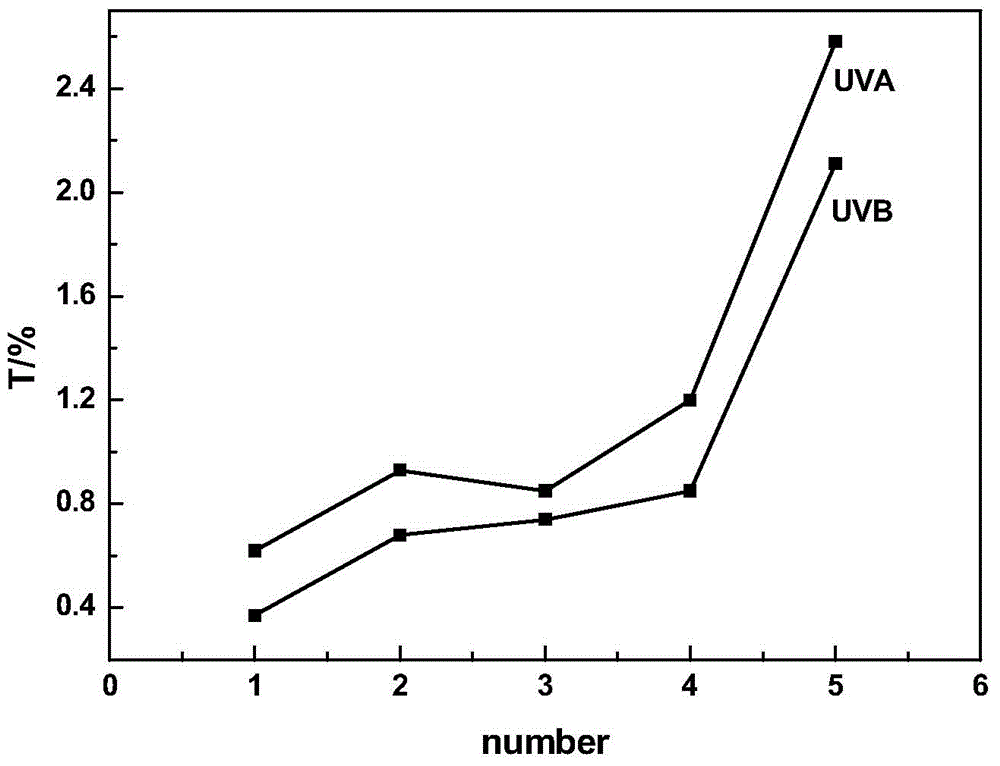

Composite ultraviolet-proof finishing liquid and preparation method and application thereof

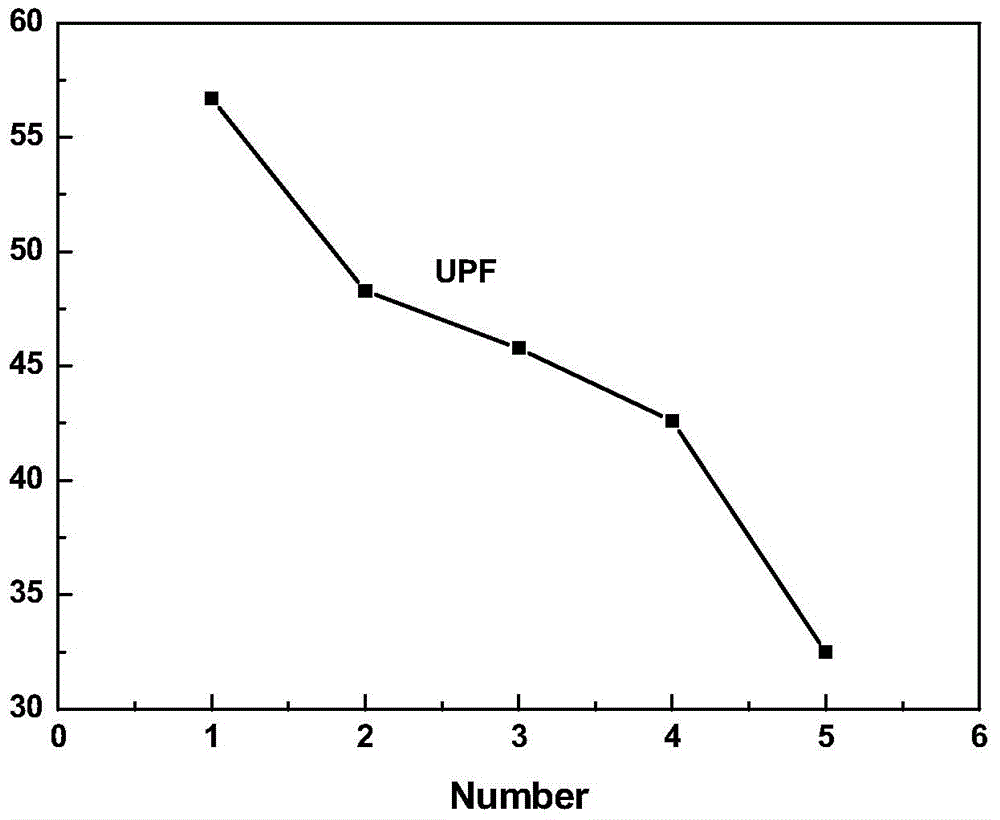

The invention relates to composite ultraviolet-proof finishing liquid. The composite ultraviolet-proof finishing liquid comprises 25-30 g / L of nanometer oxide, 15-30 g / L of metallo chelate, 20-30 g / L of synergist, 15-20 g / L of ethyl alcohol, 10-15 g / L of methyl alcohol, 10-15 g / L of urea, 2-4 g / L of glycerinum, 0.5-1 g / L of polyoxyethylene ether, 0.5-1 g / L of azodiisobutyronitrile, 0.3-1 g / L of flatting agent, 0.2-1 g / L of antifoaming agent, and 1-2 g / L of curing agent, water serves as the solvent, the nanometer oxide is the powder mixture of ZnO, TiO2 and SiO2. Woven cloth treated through the finishing liquid has the excellent ultraviolet-proof function, the shading coefficient reaches to over 70%, the ultraviolet light shielding rate reaches to over 98%, and the ultraviolet protection factor (UPF) is higher than 40.

Owner:NINGBO SANDO KNITTING

Flame-retardant finishing agent for pure cotton fabric and preparation method thereof

ActiveCN108951164AGood cross-linking performanceGood flame retardant effectHeat resistant fibresVegetal fibresChemistryEmulsion

The invention discloses a flame-retardant finishing agent for a pure cotton fabric and a preparation method thereof, and the preparation method comprises the following steps: after prepared polyurethane emulsion is diluted with water, adding a flame retardant synergist, a surfactant and a hydroxymethyl cellulose, controlling the temperature at 50 to 60 DEG C, stirring for 1 to 2 hours, and removing air bubbles to obtain the flame-retardant finishing agent for the pure cotton fabric. After being finished by the environmentally-friendly flame-retardant finishing agent, the cotton fabric has goodflameproofness, and the hand feeling of the fabric does not become stiff, and the cotton fabric can maintain good flameproof performance after long-term use and washing.

Owner:SUZHOU INSILK CO LTD

Wood facing and wood facing manufacturing method

InactiveCN109910492ALow priceWill not affect the feelStarch dervative coatingsNatural patternsDigital printingCoating

The invention discloses wood facing, the decoration effect is achieved through the digital jet printing technology, and accordingly traditional facing paper is replaced. The wood facing comprises veneer or wood, cured slurry is arranged on the surface of the veneer or wood, and a pattern layer formed through digital jet printing is arranged on the cured slurry. A wood facing manufacturing method comprises following sequentially-conducted several steps that in the veneer or wood pretreatment step, the veneer or wood is subjected to bleaching treatment; in the glue dipping or coating step, the veneer obtained after veneer or wood pretreatment is dipped in the slurry to be subjected to glue dipping treatment, or the surface of the veneer or wood is coated with the slurry through the coating technology; in the drying step, the product obtained through the glue dipping or coating step is dried; in the digital printing step, digital printing equipment is used for jet printing of the ink to the product obtained after the drying step; and in the drying color fixing step, the product obtained after the digital printing step is dried.

Owner:嘉兴市科富喷绘材料有限公司

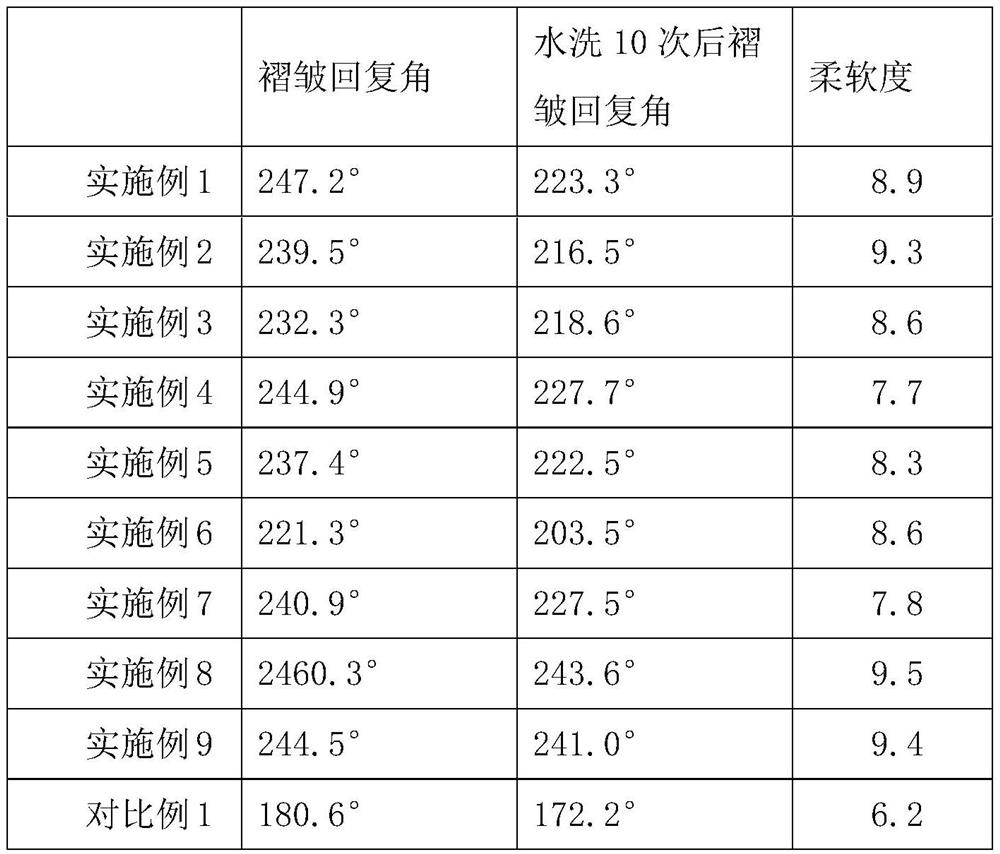

Antibacterial and anti-wrinkle cotton and linen fabric and preparation method thereof

PendingCN113914104APlay a protective effectLess prone to wrinklesBiochemical fibre treatmentWrinkle resistant fibresCelluloseFiber

The invention provides an antibacterial and anti-wrinkle cotton and linen fabric and a preparation method thereof. Antibacterial and anti-wrinkle finishing liquid prepared through reaction of modified vinyl silicone oil, silver ions and organic amine is used for performing an antibacterial and anti-wrinkle finishing process, and rich amino groups and carboxyl groups on the modified vinyl silicone oil and cellulose macromolecules form a covalent cross-linked structure, so that the fabric has the advantage that wrinkles are not prone to being generated; and on the other hand, the high viscosity, the adhesivity and the dispersity of the vinyl silicone oil structure are utilized, so that sulfydryl groups and silver ions can be fully and uniformly contacted with the cotton and linen fibers. The fabric can be subjected to antibacterial and crease-resistant finishing at the same time, and the technological process is simplified. The preparation process does not generate formaldehyde and has good environmental protection property.

Owner:ZHEJIANG KINGSAFE INTERLINING

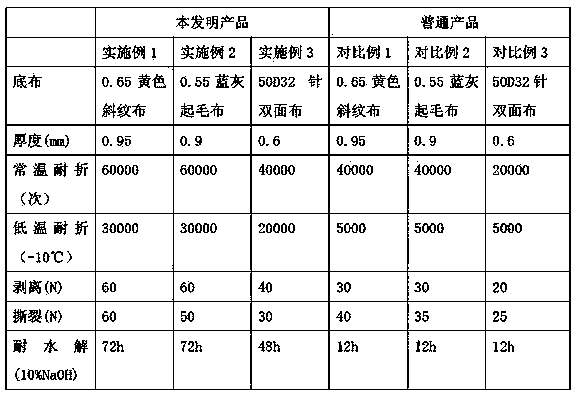

Preparation method of waterborne polyurethane synthetic leather Bayse and applications thereof

ActiveCN102787510BNo pollutionObvious cloth seamLamination ancillary operationsPolyureas/polyurethane adhesivesPolymer sciencePolymer chemistry

Owner:浙江昶丰新材料有限公司

Preparation method of ultraviolet-proof coating

The invention provides a preparation method of an ultraviolet-proof coating. The preparation method comprises the following steps of: (1) adding 4 to 12% of nanometer titania, 0.5 to 2% of talcum powder and 2 to 6% of benzotriazole to a stirrer, and uniformly stirring; (2) adding proper acetone to the mixture in step (1), and uniformly dispersing; (3) adding 5 to 15% of polyethylene glycol to the mixture in step (2); and (4) compensating the acetone until reaching 100%, and uniformly stirring so as to obtain the finished product of the ultraviolet-proof coating. By adopting the ultraviolet-proof coating prepared by the preparation method provided by the invention, the fabric can be processed without greatly changing the original hand feel, and the ultraviolet transmittance of the fabric is below 8%.

Owner:陈小康

High-temperature-resistant textile dye

The invention provides a high-temperature-resistant textile dye. The high-temperature-resistant textile dye is prepared from raw materials in parts by weight as follows: 20-40 parts of polyamide resin, 6-10 parts of polyvinyl alcohol, 4-7 parts of ethyl cellulose, 5-6 parts of methylsilicone oil, 5-8 parts of alkyl polyglucoside, 1-2 parts of tannic acid, 1-1.5 parts of aminopropyltriethoxysilane, 0.5-0.8 parts of polypyrrolidone, 3-8 parts of urea, 5-10 parts of turmeric, 2-5 parts of sodium fatty acid, 3-8 parts of sodium alginate, 1-3 parts of nano-titania, 5-8 parts of an antioxidant and 100-120 parts of deionized water. The high-temperature-resistant textile dye has excellent high-temperature-resistant capacity, can meet the dyeing requirements of high-temperature and acid-base environments and other environments, is good in dyeing uniformity, cannot affect the handfeel of textiles and cannot produce fading easily.

Owner:NANTONG RICHISLAND BEDDING DEV CO LTD

Ball rod with chalk box

The invention relates to a ball rod with a chalk box. The ball rod with the chalk box mainly comprises a ball hitting rod and a holding rod, wherein the bottom surface of the ball hitting rod is opposite to the top surface of the holding rod and the radii of the ball hitting rod and the holding rod are the same; the ball hitting rod and the holding rod are fixedly connected by hard connection columns; the hard connection columns are parallel to the axis of the ball rod and the hard connection columns are uniformly distributed in the peripheral direction by taking the axis of the ball rod as the axis center; a limiting clip is mounted on the bottom surface of the ball hitting rod; the limiting clip is connected into the ball hitting rod through a tension spring; the limiting clip can slide along the axis of the ball hitting rod; the chalk box can be stored in the ball rod so that a chalk is effectively prevented from falling off to pollute clothes; and meanwhile, the normal utilization of the ball rod is not influenced.

Owner:廊坊秋睿工程技术有限公司

A kind of leather coating polish and preparation method thereof

ActiveCN107556924BWill not affect the feelImprove durabilityCoatingsLeather surface finishingAcrylic resinOrganosilicon

The invention discloses a leather coating and lustering agent and a preparation method thereof. The leather coating and lustering agent is prepared from raw materials in percentage by mass as follows:0.1%-2% of organosilicone modified acrylic resin, 1%-10% of a lustering component, 1%-3% of a hydrophobic component, 3%-7% of a volatile component, 1%-2% of a wetting agent, 0.1%-1% of a thickening agent, 0.3%-0.7% of a corrosion remover and the balance of water. The components are mixed uniformly in batches, and the leather coating and lustering agent can be obtained. The formula of the leathercoating and lustering agent is safe and environmentally friendly, the preparation method is simple and low in production cost, the leather coating and lustering agent has no corrosion effect on leather, a transparent flexible coating layer can be formed on the leather surface after the agent is sprayed on the leather surface and the leather is slightly wiped by a towel, the hand feeling of the leather surface cannot be affected by the coating layer, the coating layer is high in stability and good in durability, and the leather coating and lustering agent can realize lustering, waterproof, anti-pollution and anti-aging functions for a long time.

Owner:广州市拓新化工科技有限公司

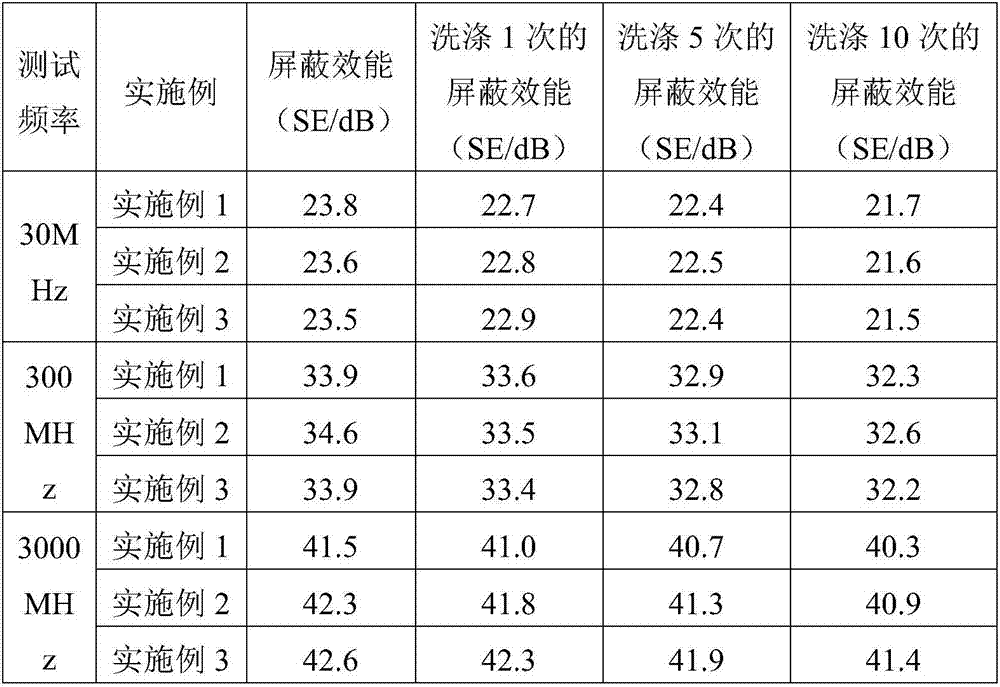

Antibacterial hydrophobic finishing method for linen rayon interwoven fabric

InactiveCN109295701AImprove antibacterial propertiesWill not affect the feelBiochemical fibre treatmentLiquid repellent fibresSodium Hypophosphite MonohydratePropyl ether

The invention discloses an antibacterial hydrophobic finishing method for linen rayon interwoven fabric. The method comprises the following steps: S1, pretreating the linen rayon interwoven fabric, then performing dip padding in an aqueous solution containing polycarboxylic acid and sodium hypophosphite, and predrying the material to obtain the linen rayon interwoven fabric with a surface containing a -COOH group; and S2, performing dip padding on the linen rayon interwoven fabric with the surface containing the -COOH group obtained in the step S1) in an aqueous solution containing an organicantibacterial hectorite, cyclodextrin modified glycidyl 3-(trimethoxysilyl)propyl ether, nano zinc oxide and nano silica sol, and then performing drying treatment to obtain the antibacterial hydrophobic linen rayon interwoven fabric. According to the antibacterial hydrophobic finishing method of the linen rayon interwoven fabric proposed by the invention, the linen rayon interwoven fabric has theexcellent antibacterial and hydrophobic properties.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

Ultraviolet-proof coating

InactiveCN103015182AWill not affect the feelUV protectionFibre treatmentPolyethylene glycolUltraviolet

The invention discloses an ultraviolet-proof coating. The ultraviolet-proof coating comprises the following components in percentage by weight: 4-12% of nanometer titanium dioxide, 0.5-2% of talcum powder, 5-15% of polyethylene glycol, 2-6% of benzotriazole and the balance of acetone. The ultraviolet-proof coating provided by the invention does not remarkably change the hand feeling of the fabric when being used for treating the fabric, and enables the ultraviolet transmission rate to be lower than 8%.

Owner:陈小康

High-temperature-resistant dye for light-shading curtain fabric

InactiveCN108166280AImprove high temperature resistanceWill not affect the feelDyeing processIonChemistry

The invention discloses a high-temperature-resistant dye for light-shading curtain fabric. The high-temperature-resistant dye for the light-shading curtain fabric comprises the following raw materialsin parts by weight: 4-6 parts of polyvinyl chloride, 4-6 parts of an acrylate copolymer, 6-8 parts of didecyl phthalate, 5-7 parts of trioctyl phosphate, 6-8 parts of calcium carbonate, 3-6 parts ofantimony trioxide, 8-10 parts of dibasic lead stearate, 5-8 parts of polyethylene wax, 4-6 parts of glyceryl monostearate, 6-8 parts of carbon black, 6-10 parts of polyvinyl alcohol, 4-7 parts of ethyecellulose, 5-6 parts of methylsilicone oil, 5-8 parts of alkyl glycoside and 80-150 parts of deionized water. Compared with the prior art, through interaction of the raw materials, the dye is excellent in high temperature resistance, can be adapted to dyeing requirements in high-temperature, acid and alkali environments and the like, has good dyeing uniformity, does not affect the hand feel of atextile, is unlikely to cause a fading phenomenon, guarantees a light-shading effect during using of multiple curtains, brings a better market prospect and helps to increase the demand on materials inthe market.

Owner:海宁市金雅特纺织有限公司

Coating and decoration method for solving crust leather cross color

ActiveCN107524027AWill not affect the feelFeel comfortableDyeing processLeather surface finishingWaxEmulsion

The invention relates to the technical field of leather making chemistry and engineering, and provides a coating and decoration method for solving crust leather cross color. Oxidized polyethlene wax emulsion is introduced into a coating and decoration agent, and the coating and decoration agent is used for coating the surface of crust leather to show a natural fog luster state; during high-temperature ironing, the wax agent migrates to the surface layer of a coating film along with the moisture volatilization; a waxed surface layer is formed with other ingredients in the coating and decoration agent; a good shielding effect is achieved; the crust leather with the uniform and consistent surface color is obtained; meanwhile, the dispersion degree of the pigment paste in the coating and decoration agent can be increased through the oxidized polyethlene wax emulsion; the coloring intensity is improved. By using the coating and decoration method for solving crust leather cross color, a crust leather product with the advantages of uniform particle surface color, comfortable hand feeling, exquisite surface and aniline coating and decoration effects can be obtained; in addition, the operability is very high; the production efficiency is high; the crust leather accumulation is avoided; the economic loss is reduced; the practicability is high.

Owner:XINGYE LEATHER TECH CO LTD

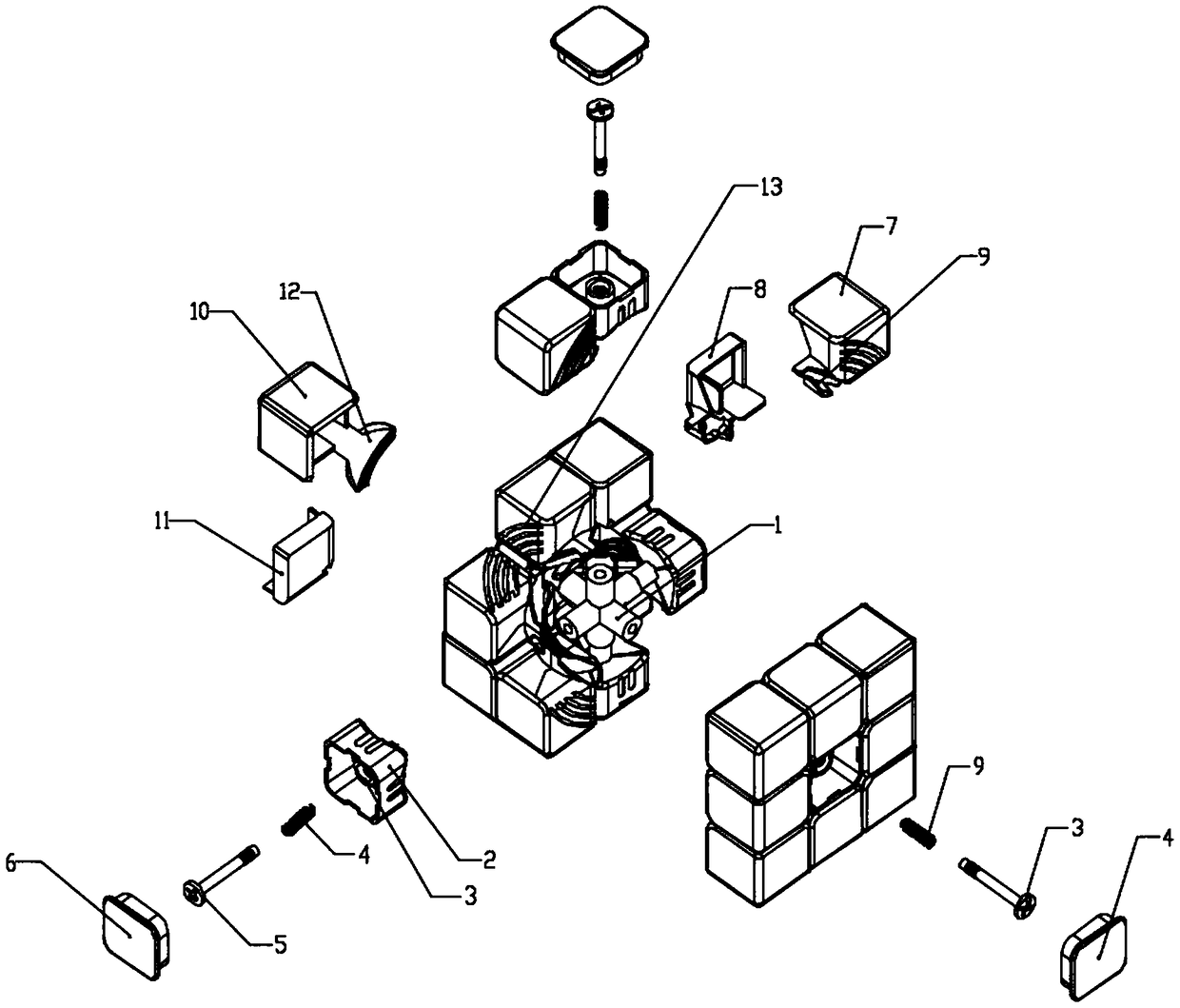

Magic cube with rotatable corners

The invention discloses a magic cube with rotatable corners. The magic cube with rotatable corners comprises a center shaft, magic cube blocks and the rotatable corners, wherein the center shaft is connected with the magic cube blocks; the magic cube blocks are divided into middle shaft blocks, edge blocks and corner blocks; the bottom of the middle shaft blocks is connected with a pedestal; a mounting hole is formed in the pedestal; the mounting hole is in cooperative connection with the center shaft; a movable spring and an elastic screw are arranged on the pedestal; the elastic screw is insleeving connection with the spring; the end part of the elastic screw is in threaded connection with a shaft hole of the center shaft; a top cover is arranged on the pedestal in a matched way; the edge blocks are arranged at the periphery of the middle shaft in a matched way; a connecting clamping buckle is connected with the part between the two middle shaft blocks; the corner blocks are dividedinto corner block connecting blocks and corner block covers; connecting heads are arranged on the corner blocks. Compared with the prior art, the magic cube has the following advantages: the normal playing method is the same as that of the traditional magic cube, the rotatable corner blocks are increased, the playability is improved, the recovery difficulty is enhanced, the playability is improved, and smooth rotation at the combined position is realized.

Owner:程有良

High-temperature-resistant antibacterial dye

InactiveCN106120383ABroad antimicrobial effectAvoid breedingDyeing processTemperature resistanceDimethyl siloxane

The invention discloses a high-temperature resistant antibacterial dye, which comprises the following raw materials in parts by weight: 25-30 parts of dye extract, 3-5 parts of polyvinyl alcohol, 5-8 parts of sodium propionate, and 2-5 parts of benzophenone , 10-15 parts of antibacterial agent, 2-4 parts of microcrystalline cellulose, 1-3 parts of butyl acrylate, 1-3 parts of polydimethylsiloxane, 60-80 parts of deionized water. The dye formula includes antibacterial agents, which have wide antibacterial properties, can effectively prevent the growth and reproduction of various bacteria, effectively inhibit and sterilize bacteria, and have good high temperature resistance, good dyeing effect, and will not affect the fabric feel. The raw material of the dye is easy to obtain and has no toxic effect on the human body. It also makes the fabric have a delicate fragrance and can be widely used in the field of fabric printing and dyeing.

Owner:NANTONG RICHISLAND BEDDING DEV CO LTD

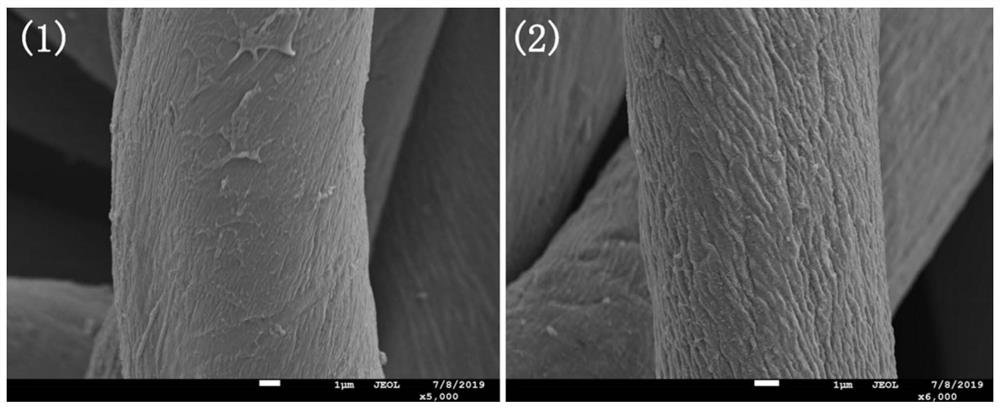

Production method of antibacterial woolen cashmere yarn

ActiveCN114657665AUniform adsorptionImprove antibacterial propertiesDrying solid materials with heatDrying solid materials without heatYarnPolymer science

The invention relates to a production method of antibacterial woolen cashmere yarn. The production method comprises the following steps of A, cashmere selection, wherein cashmere loose fibers with the fineness being 16-16.5 micrometers and the length being 34-36 mm are selected; b, dyeing: dyeing, drying and opening the cashmere loose fibers to obtain colored cashmere loose fibers; c, antibacterial treatment; d, dehydration: carrying out dehydration treatment on the wet antibacterial cashmere loose fibers through a centrifugal machine, and controlling the moisture content of the dehydrated antibacterial cashmere loose fibers to be 23-25%; e, high-temperature drying and permeation: putting the antibacterial cashmere loose fibers with the water content of 23-25% into a radio frequency dryer for drying at the drying temperature of 125-130 DEG C, and enabling the high temperature to open hair cuticles on the surfaces of the cashmere loose fibers and enable the nano-antibacterial additive to deeply permeate into the cashmere loose fibers; f, opening; g, wool blending; and H, spinning the antibacterial cashmere loose fibers subjected to the health maintenance treatment through a traditional roving process including carding, wobbling, spooling, doubling and two-for-one twisting to obtain antibacterial cashmere yarns, so that cashmere garments made of the antibacterial cashmere yarns have better and long-term antibacterial performance.

Owner:JIANGSU LIANHONG TEXTILE

Preparation method of heat-conducting textile material

PendingCN112553885AWill not affect the feelReduce dosageAbrasion resistant fibresVegetal fibresHeat conductingEngineering

The invention relates to a preparation method of a high-thermal-conductivity textile. The preparation method comprises the following steps of (1) soaking a textile in a dopamine solution, taking out,and drying; and (2) generating a uniform and compact heat-conducting material coating on the surface of the textile obtained in the step (1) by adopting atomic layer deposition equipment so as to obtain the heat-conducting textile material. The method is suitable for processing various textile materials, has the characteristics of uniformity, controllable thickness and high precision, and does notinfluence the original hand feeling, smoothness and luster of the textile; and the method has the advantages of extremely low raw material consumption, no generation of an aqueous solution in the deposition process, small environmental pollution in production, few technological processes and convenient and easily-controlled operation process.

Owner:WUHAN UNIV OF TECH

Ultraviolet-proof coating

InactiveCN103015182BWill not affect the feelUV protectionFibre treatmentPolyethylene glycolUltraviolet

Owner:陈小康

Finishing agents capable of improving radiation resistance of weft-knitted fabric, and application thereof

ActiveCN106930105ADoes not affect the colorWill not affect the feelFibre treatmentEngineeringMoisture

The invention discloses finishing agents capable of improving radiation resistance of weft-knitted fabric, and application thereof. The finishing agents include two finishing agents for two different stages in a weft-knitted fabric processing process, wherein one agent is an anti-static anti-ultraviolet finishing agent used before a dyeing and finishing process, and the finishing agent is used before the dyeing and finishing process, does not influence the original color and cluster, hand feeling, moisture absorbility and color fastness of the fabric and enhances the durability of the anti-static and anti-ultraviolet properties; the other agent is an anti-radiation finishing agent used in an after-finishing process; and the final consolidated finishing is formed for the anti-radiation capability of the weft-knitted fabric, so that the anti-radiation property and the durability are enhanced maximally on the premise of guaranteeing the comfort level.

Owner:JURONG SHENTU TECH KNITTING FACTORY

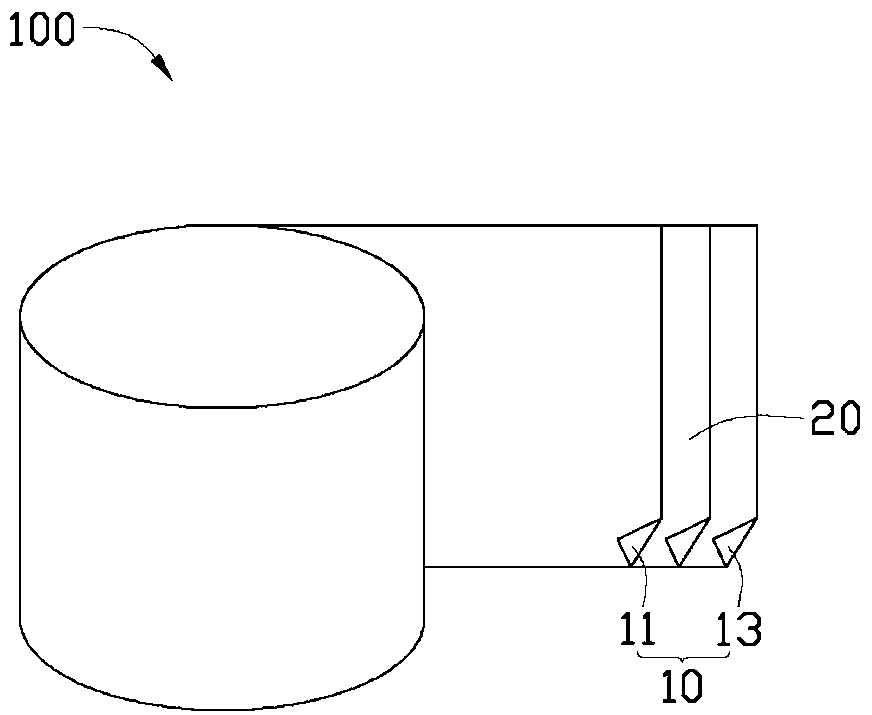

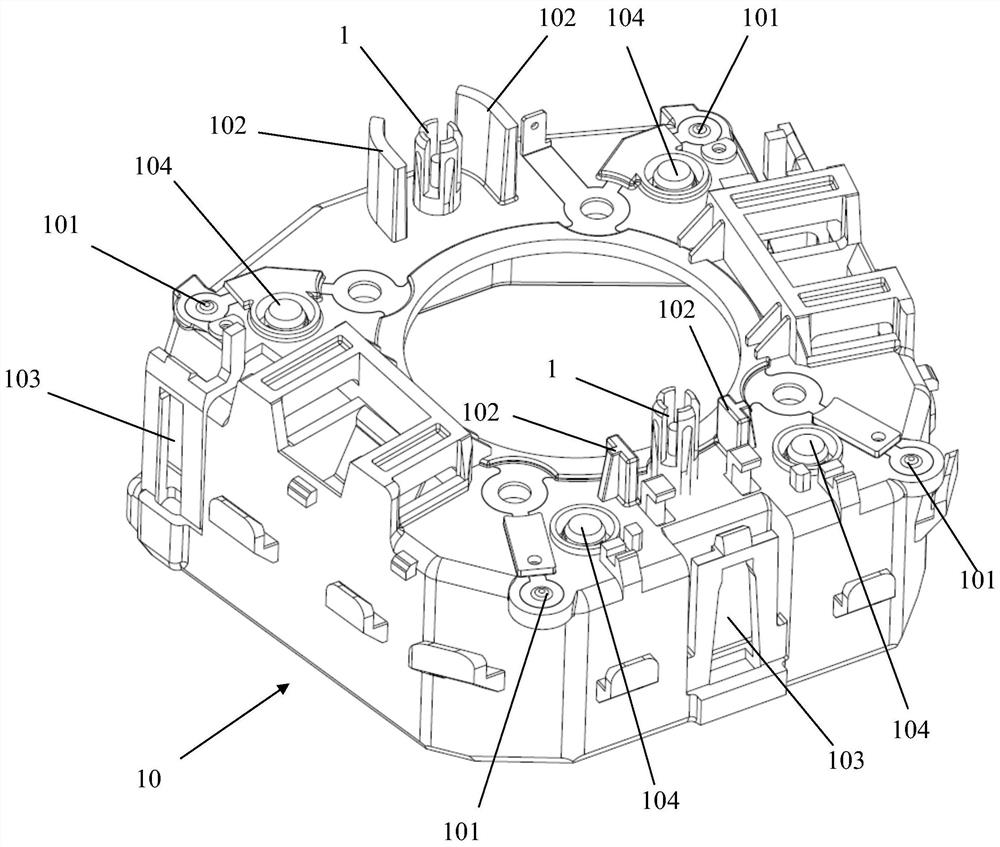

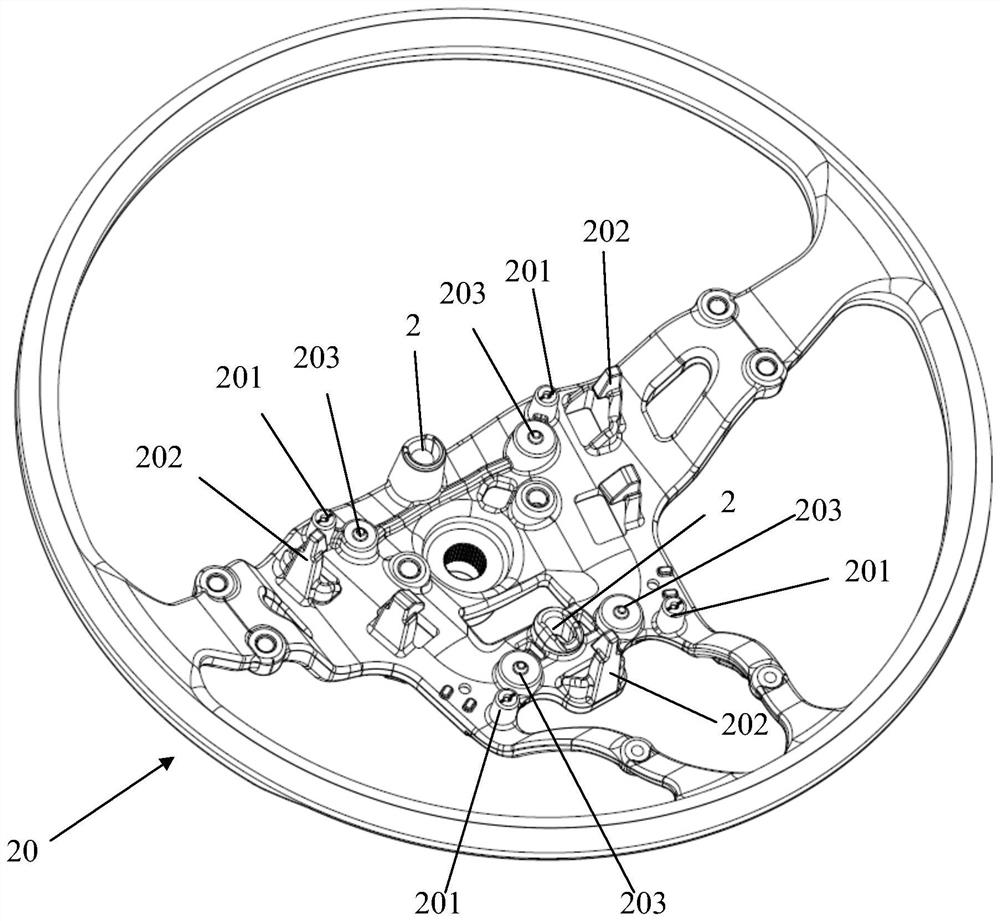

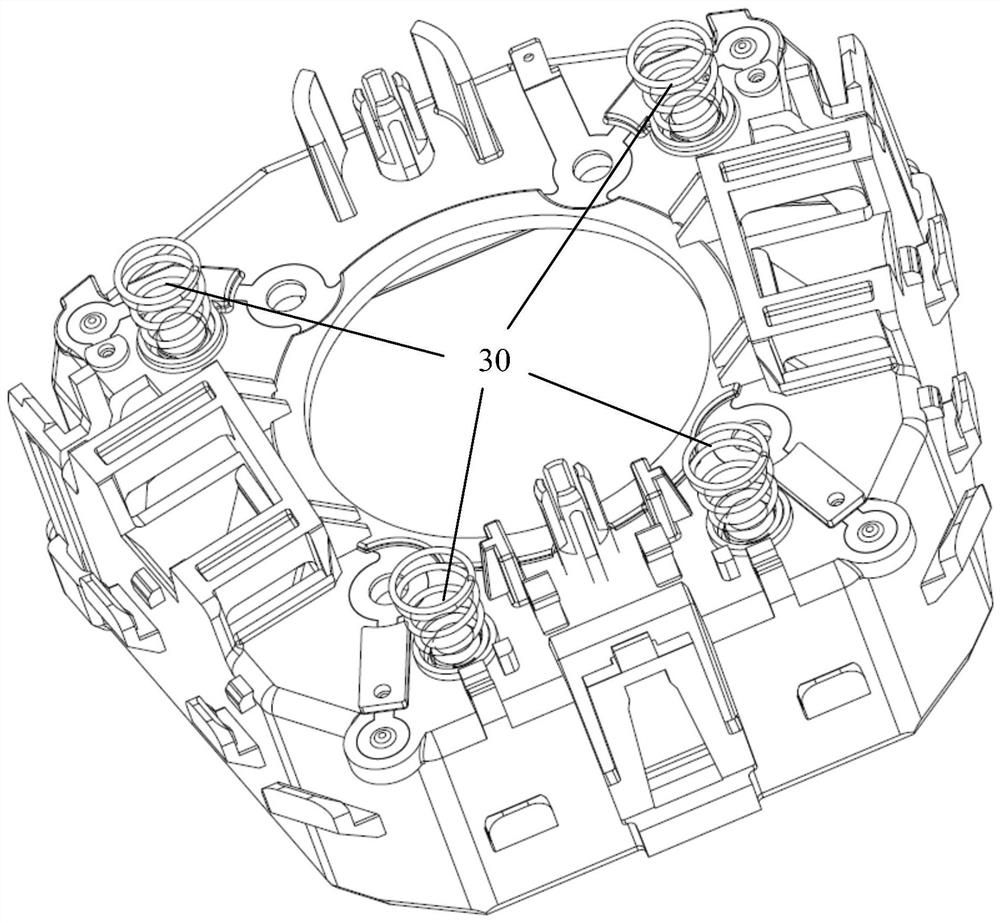

Positioning assembly for steering wheel and steering wheel

PendingCN113320590AWill not affect the feelAvoid interferenceHand wheelsSteering wheelDriver/operator

The invention discloses a positioning assembly for a steering wheel. The positioning assembly comprises a first positioning piece and a second positioning piece; the first positioning piece is inserted into the second positioning piece; the first positioning piece comprises a first positioning part and a receding part; the second positioning piece comprises a second positioning part; before pressing, the first positioning part and the second positioning part are in close contact and are positioned; after the first positioning piece is pressed to rotate, the first positioning part is separated from the second positioning part, and the receding part is in clearance fit with the second positioning part. The invention further discloses the steering wheel. Through the arrangement of the receding part, when a driver safety airbag module is pushed to activate a horn function, an airbag shell drives the first positioning piece to rotate, the receding part avoids interference between the positioning function of the airbag shell and a steering wheel framework, the hand feeling of a horn cannot be affected, and more pre-tightening force can be designed to avoid the noise problem.

Owner:AUTOLIV DEV AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com