Post-finishing technology of aluminous water-repellent polyester fabric

A technology for water-repellent finishing and post-finishing, applied in fiber processing, fiber types, textiles and papermaking, etc., can solve the problems of difficult biodegradation of fluorine-containing chemicals, environmental and human health hazards, and the water-repellent functional effect of fabrics. Achieve the effect of short luminous duration, enhanced hydrophobicity, and good water repellency of fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

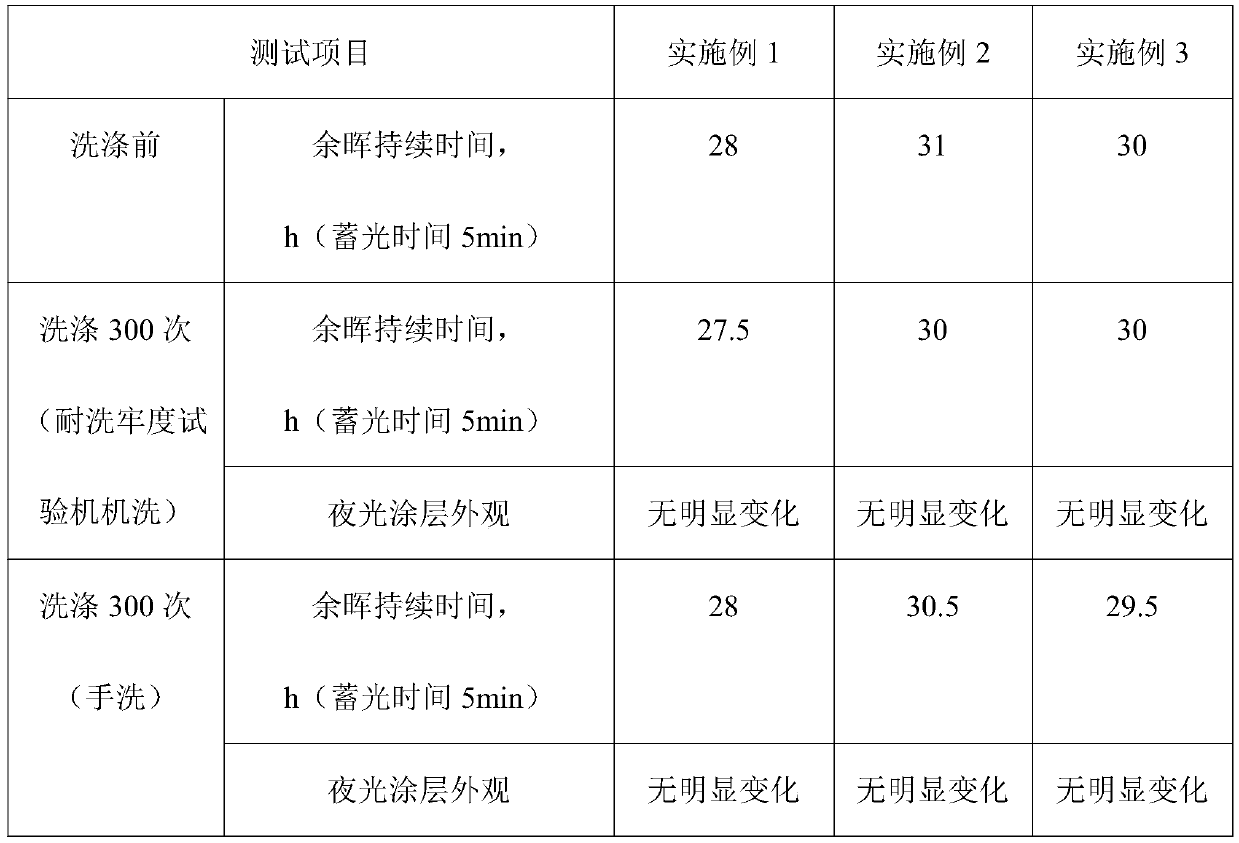

Embodiment 1

[0026] A post-finishing process for luminous water-repellent polyester fabrics, comprising the following steps:

[0027] Step 1. Fabric pretreatment: put the polyester fabric in a 8g / L sodium bicarbonate solution in a water bath at 80°C for 30 minutes;

[0028] Step 2. Water-repellent finishing: use 40g / L water-repellent finishing agent and 8g / L cross-linking agent to carry out water-repellent finishing on the polyester fabric by dipping and rolling. The bath ratio is 1:32, the soaking time is 10min, and the rolling ratio is 75%. %, and then dried at 90°C for 5 minutes;

[0029] Step 3, preparation of luminous coating: take 20 parts of zinc sulfide type luminous powder, 2 parts of acrylate adhesive, 6 parts of polyethylene glycol, 2 parts of soybean protein glue, 1 part of guar gum and 2 parts of sodium sulfate in parts by weight 1. Mix 2 parts of sodium hexametaphosphate and 200 parts of water, add sodium bicarbonate solution to adjust the pH of the solution to 7.0, stir at ...

Embodiment 2

[0036] A post-finishing process for luminous water-repellent polyester fabrics, comprising the following steps:

[0037] Step 1. Fabric pretreatment: put the polyester fabric in a 9g / L sodium bicarbonate solution in a water bath at 83°C for 36 minutes;

[0038] Step 2. Water-repellent finishing: Use 45g / L water-repellent finishing agent and 9g / L cross-linking agent to carry out one-dipping and one-rolling water-repellent finishing on the polyester fabric. The bath ratio is 1:31, the soaking time is 13min, and the rolling ratio is 77%. %, and then dried at 95°C for 8 minutes;

[0039] Step 3, preparation of luminous coating: take 30 parts of zinc sulfide type luminous powder, 4 parts of acrylate adhesive, 8 parts of polyethylene glycol, 4 parts of soybean protein glue, 3 parts of guar gum and 6 parts of sodium sulfate in parts by weight 1. Mix 5 parts of sodium hexametaphosphate and 100 parts of water, add sodium bicarbonate solution to adjust the pH of the solution to 7.2, st...

Embodiment 3

[0046] A post-finishing process for luminous water-repellent polyester fabrics, comprising the following steps:

[0047] Step 1. Fabric pretreatment: put the polyester fabric in a 10g / L sodium bicarbonate solution in a water bath at 95°C for 40 minutes;

[0048] Step 2. Water-repellent finishing: Use 50g / L of water-repellent finishing agent and 10g / L of cross-linking agent to carry out one-dipping and one-rolling water-repellent finishing on the polyester fabric. The liquor ratio is 1:30, the soaking time is 15min, and the rolling ratio is 80% %, and then dried at 100°C for 10 minutes;

[0049] Step 3, preparation of luminous coating: take 22 parts of zinc sulfide type luminous powder, 3 parts of acrylate adhesive, 7 parts of polyethylene glycol, 3 parts of soybean protein glue, 2 parts of guar gum and 3 parts of sodium sulfate in parts by weight 1. Mix 3 parts of sodium hexametaphosphate and 180 parts of water, add sodium bicarbonate solution to adjust the pH of the solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com