Preparation method for anticorrosive antibacterial wood fiber composite

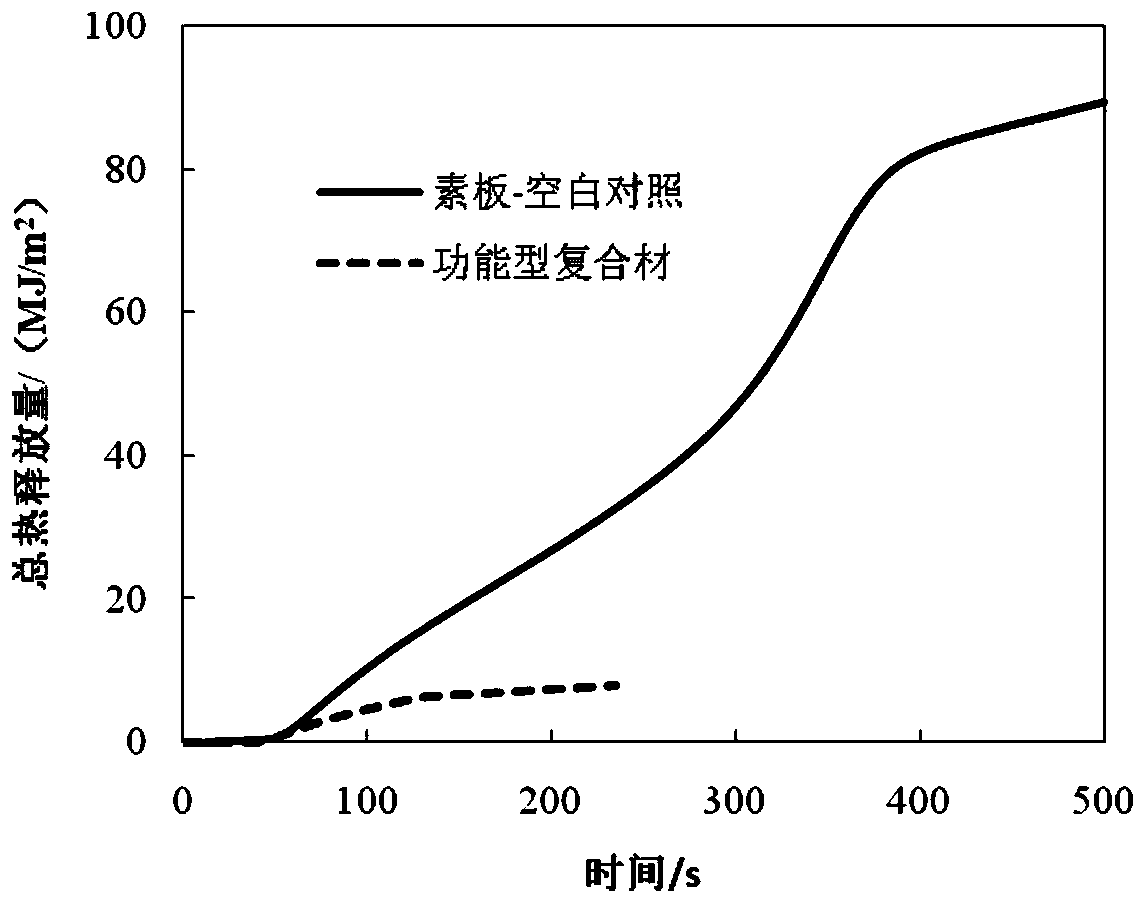

A wood fiber, anti-corrosion and anti-bacterial technology, which is applied to the device, coating, special surface and other directions of coating liquid on the surface. , Improve the effect of anti-corrosion and antibacterial durability, and widely promote the application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of antiseptic and antibacterial wood fiber composite material of the present invention, comprises the following steps:

[0031] (1) Fully mix the camphor wood fiber with 3% calcium silicate and 3% magnesium sulfate, then apply 5% modified urea-formaldehyde resin adhesive and 1% paraffin, and carry out hot-press molding (hot-press temperature is 170 ℃, the hot pressing time is 0.3min / mm, and the hot pressing pressure is 5MPa), and the wood fiber composite material is prepared;

[0032] (2) adding the nano-alumina to absolute ethanol, ultrasonic treatment for 50min, and preparing a suspension of nano-alumina with a mass concentration of 0.5%;

[0033] Weigh 5g polydimethylsiloxane and 500mL hexane and mix it as solution A, weigh 1g polyamide and 500mL hexane and mix it as solution B, keep stirring solution A and solution B for 20min respectively, then mix solution A and solution B mixed and kept stirring for 20 minutes to prepare a polydimethylsiloxa...

Embodiment 2

[0039] A preparation method of antiseptic and antibacterial wood fiber composite material of the present invention, comprises the following steps:

[0040] (1) Fully mix the ginkgo wood fiber with 5% calcium phosphate and 5% zinc borate, apply 7% modified urea-formaldehyde resin adhesive and 1% paraffin, and carry out hot-press molding (hot-press temperature is 160 ° C, heat The pressing time is 0.5min / mm, and the hot pressing pressure is 5MPa), and the wood fiber composite material is prepared;

[0041] (2) Weigh nano-titanium dioxide and place it in a large beaker, add absolute ethanol, and ultrasonically treat it for 50 minutes to prepare a nano-titanium dioxide suspension with a mass concentration of 1.0%;

[0042] Weigh 10g of polydimethylsiloxane and 500mL of hexane and mix it into solution A, weigh 2g of aminoethylpiperazine and 500mL of hexane and mix it into solution B, keep stirring solution A and solution B for 20min respectively, and then dissolve the solution A i...

Embodiment 3

[0048] A preparation method of antiseptic and antibacterial wood fiber composite material of the present invention, comprises the following steps:

[0049] (1) Fully mix cinnamon wood fiber with 7% calcium carbonate and 7% calcium phosphomolybdate, apply 9% modified urea-formaldehyde resin adhesive and 1% paraffin, and carry out hot-press molding (hot-press temperature is 170°C , the hot-pressing time is 0.2min / mm, and the hot-pressing pressure is 5MPa), and it is prepared into a wood fiber composite material;

[0050] (2) Take nano-zinc oxide and place it in a large beaker, add absolute ethanol, and ultrasonically treat it for 50 minutes to prepare a nano-zinc oxide suspension with a mass concentration of 1.5%;

[0051] Weigh 15g of polydimethylsiloxane and 500mL of hexane and mix it as solution A, weigh 3g of trimethylhexamethylenediamine and 500mL of hexane and mix it as solution B, and keep stirring solution A and solution B for 20min respectively , and then mixed solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com