Finishing agents capable of improving radiation resistance of weft-knitted fabric, and application thereof

A weft-knitted fabric and finishing agent technology, which is applied in the field of fabric processing technology, can solve the problems of not being able to meet the needs of daily wear, poor air permeability of knitted fabrics, and not very good effect, so as to enhance the radiation resistance and durability, increase Long-lasting, comfortable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

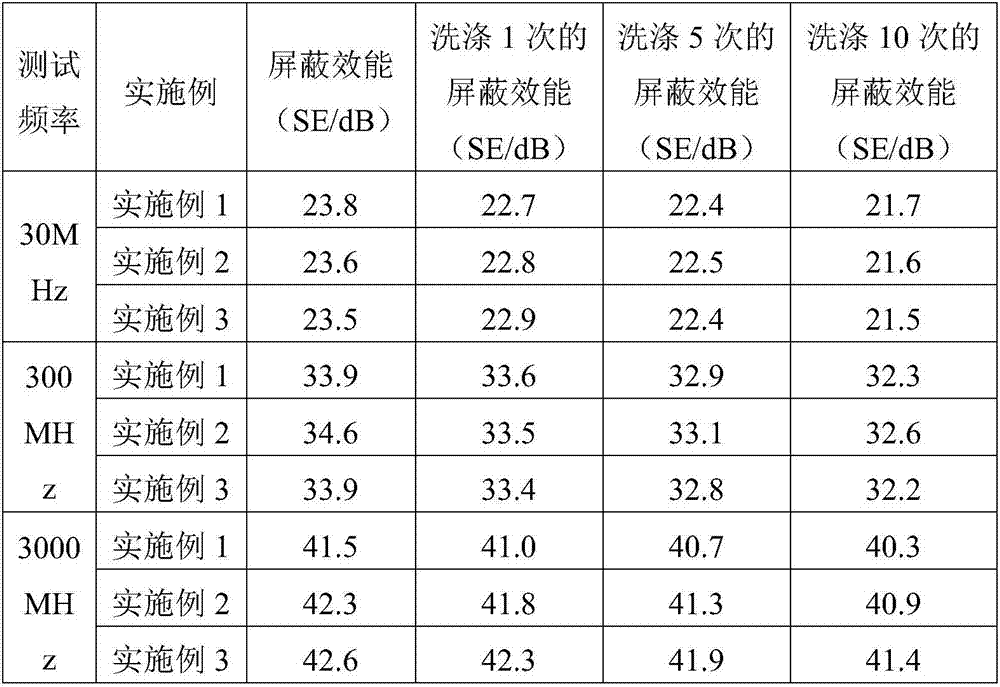

Embodiment 1

[0021] The finishing agent for improving the anti-radiation ability of weft-knitted fabrics includes two kinds of finishing agents used in two different stages in the weft-knitted fabric processing technology, one of which is the antistatic and anti-ultraviolet finishing agent used before the dyeing and finishing process, and the other is Anti-radiation finishing agents used in the finishing process;

[0022] Wherein, the antistatic and anti-ultraviolet finishing agent includes the following components in terms of mass: 8 parts of ultraviolet absorbers, 5 parts of ultraviolet shielding agents, 2 parts of fatty acid amides, 3 parts of chitin fibers, 3 parts of dehydroacetic acid, 1 part of penetrant, 1.8 parts of hydrophilic surfactants;

[0023] The anti-radiation finishing agent includes the following components calculated by mass: 13 parts of radiation-resistant plant leaf fiber extract, 12 parts of radiation-resistant plant bast fiber extract, 3 parts of wood powder carbon,...

Embodiment 2

[0027] The finishing agent for improving the anti-radiation ability of weft-knitted fabrics includes two kinds of finishing agents used in two different stages in the weft-knitted fabric processing technology, one of which is the antistatic and anti-ultraviolet finishing agent used before the dyeing and finishing process, and the other is Anti-radiation finishing agents used in the finishing process;

[0028] Wherein, the antistatic and anti-ultraviolet finishing agent includes the following components in terms of mass: 14 parts of ultraviolet absorbers, 8 parts of ultraviolet shielding agents, 4 parts of fatty acid amides, 6 parts of chitin fibers, 6 parts of dehydroacetic acid, 2 parts of penetrants, 2.5 parts of hydrophilic surfactants;

[0029] The anti-radiation finishing agent includes the following components calculated by mass: 20 parts of anti-radiation plant leaf fiber extract, 15 parts of anti-radiation plant bast fiber extract, 8 parts of wood powder carbon, 1.2 pa...

Embodiment 3

[0033] The finishing agent for improving the anti-radiation ability of weft-knitted fabrics includes two kinds of finishing agents used in two different stages in the weft-knitted fabric processing technology, one of which is the antistatic and anti-ultraviolet finishing agent used before the dyeing and finishing process, and the other is Anti-radiation finishing agents used in the finishing process;

[0034] Wherein the antistatic and anti-ultraviolet finishing agent includes the following components by mass: 10 parts of ultraviolet absorber, 7 parts of ultraviolet shielding agent, 3 parts of fatty acid amide, 5 parts of chitin fiber, 4 parts of dehydroacetic acid, 1.5 parts of penetrating agent, 25 parts of hydrophilic surfactants;

[0035] The anti-radiation finishing agent includes the following components in terms of mass: 17 parts of radiation-resistant plant leaf fiber extract, 13 parts of radiation-resistant plant bast fiber extract, 5 parts of wood powder carbon, 0.9 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com