Antibacterial and anti-wrinkle cotton and linen fabric and preparation method thereof

A cotton and linen, anti-wrinkle finishing agent technology, used in textiles, biochemical fiber treatment, fabrics and other directions, can solve the problem of cotton and linen linings prone to wrinkles and other problems, achieve excellent antibacterial and anti-wrinkle properties, improve antibacterial and anti-wrinkle properties, and simplify the process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

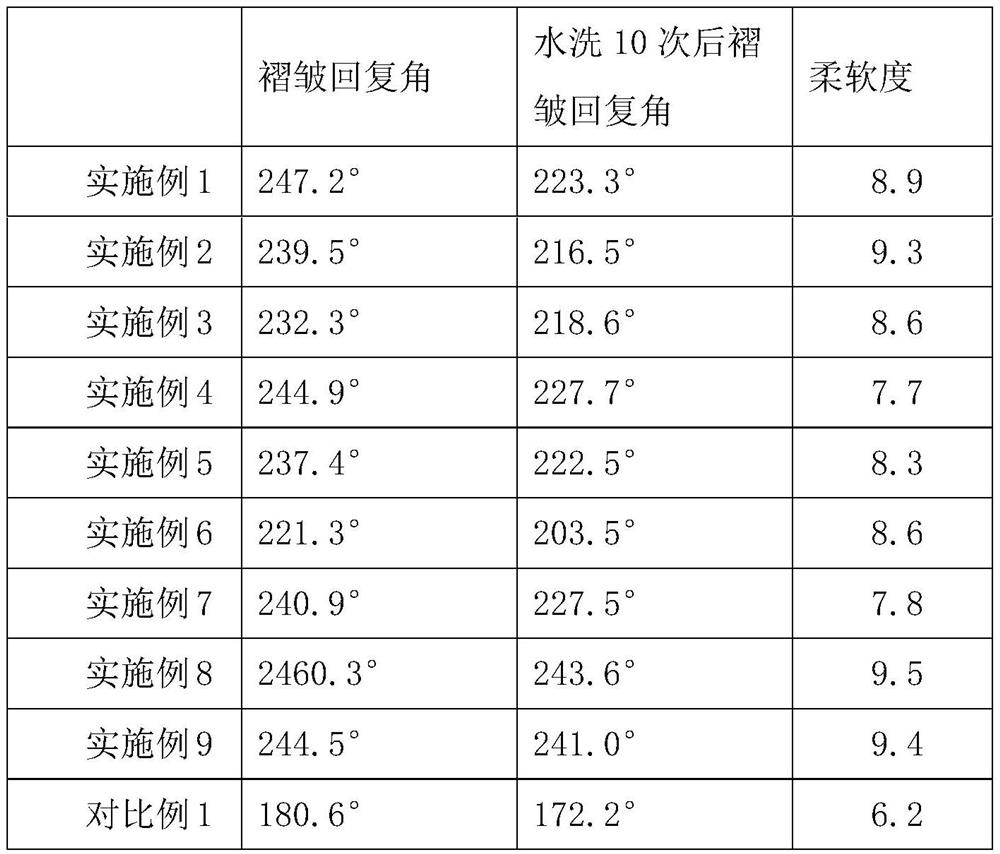

Examples

Embodiment 1

[0039] Preparation of Antibacterial Anti-Wrinkle Cotton Lining:

[0040] (1) Base fabric weaving: Warp yarn (30D / 24F polyester low-elastic yarn) and weft yarn (30D / 24F polyester low-elastic yarn) are formed into base fabric through twill weaving on a water-jet loom.

[0041] (2) Preparation of antibacterial anti-wrinkle finishing agent:

[0042] Add 2g of mercaptoethanol and 2g of glutathione to 10g of terminal vinyl silicone oil, stir evenly, adjust the pH value to 8, keep the temperature at 30°C, and react for 1-2h under the protection of an inert gas to obtain mercapto-modified vinyl Silicone oil solution.

[0043] Take 100g of mercapto-modified vinyl silicone oil solution, add 5g of silver oxide and 3.5g of ethylenediamine, adjust the temperature to 50°C, stir well, and let stand for 0.5h to obtain the antibacterial and anti-wrinkle finishing agent.

[0044] (3) Antibacterial and anti-wrinkle finishing: After the antibacterial and anti-wrinkle finishing agent prepared in...

Embodiment 2

[0048] Other conditions and operations were the same as in Example 1, except that the amount of glutathione was changed to 1 g.

Embodiment 3

[0050] Other conditions and operations were the same as in Example 1, except that the amount of glutathione was changed to 0.7g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com