Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

97results about How to "Vibration high" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

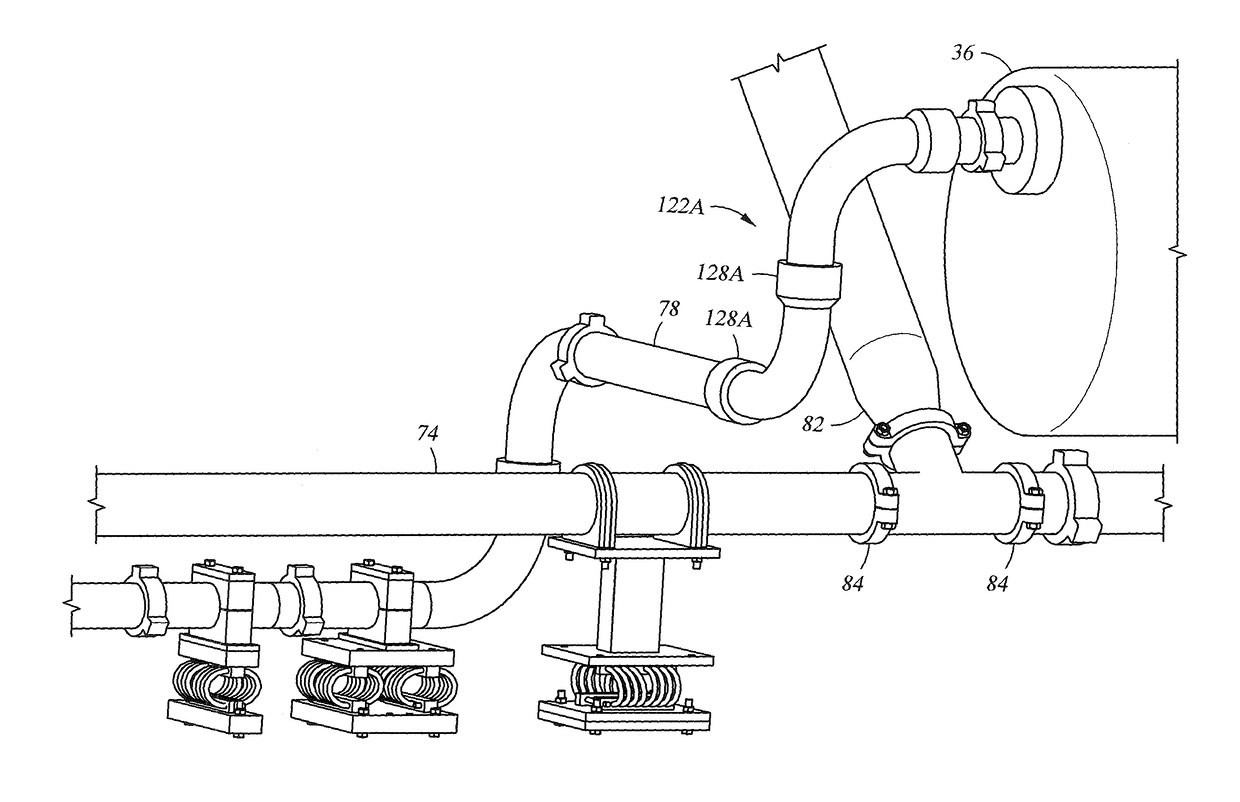

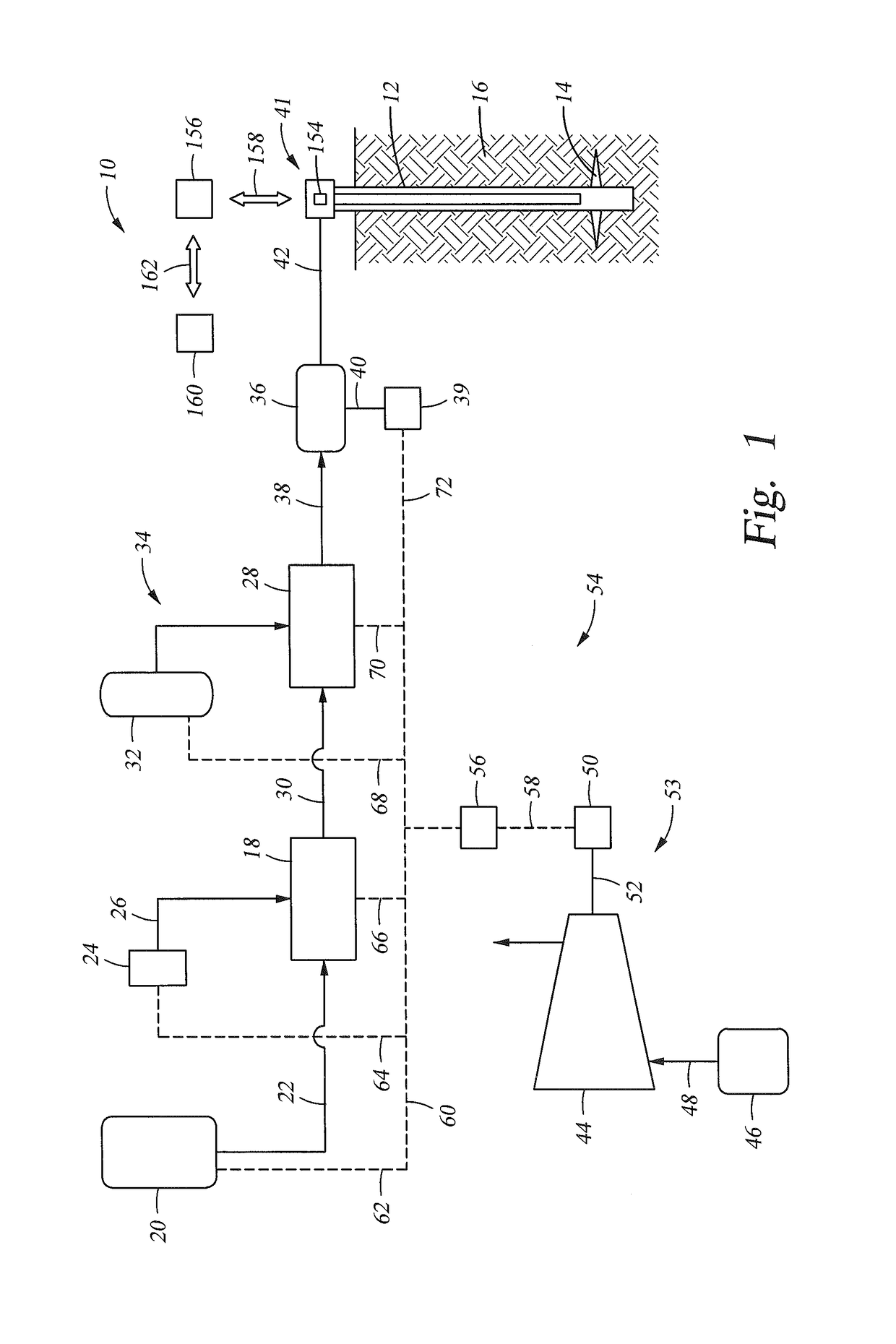

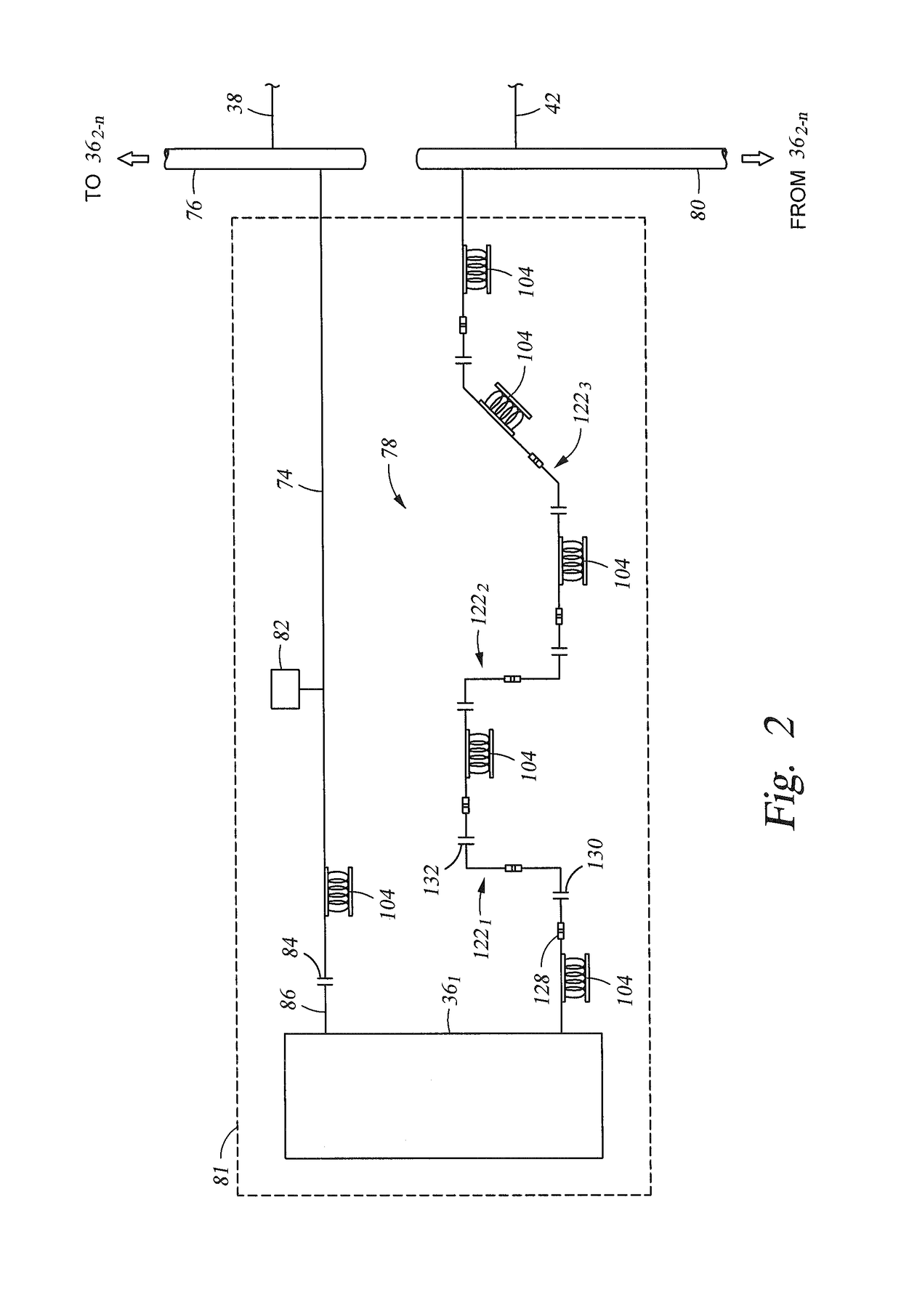

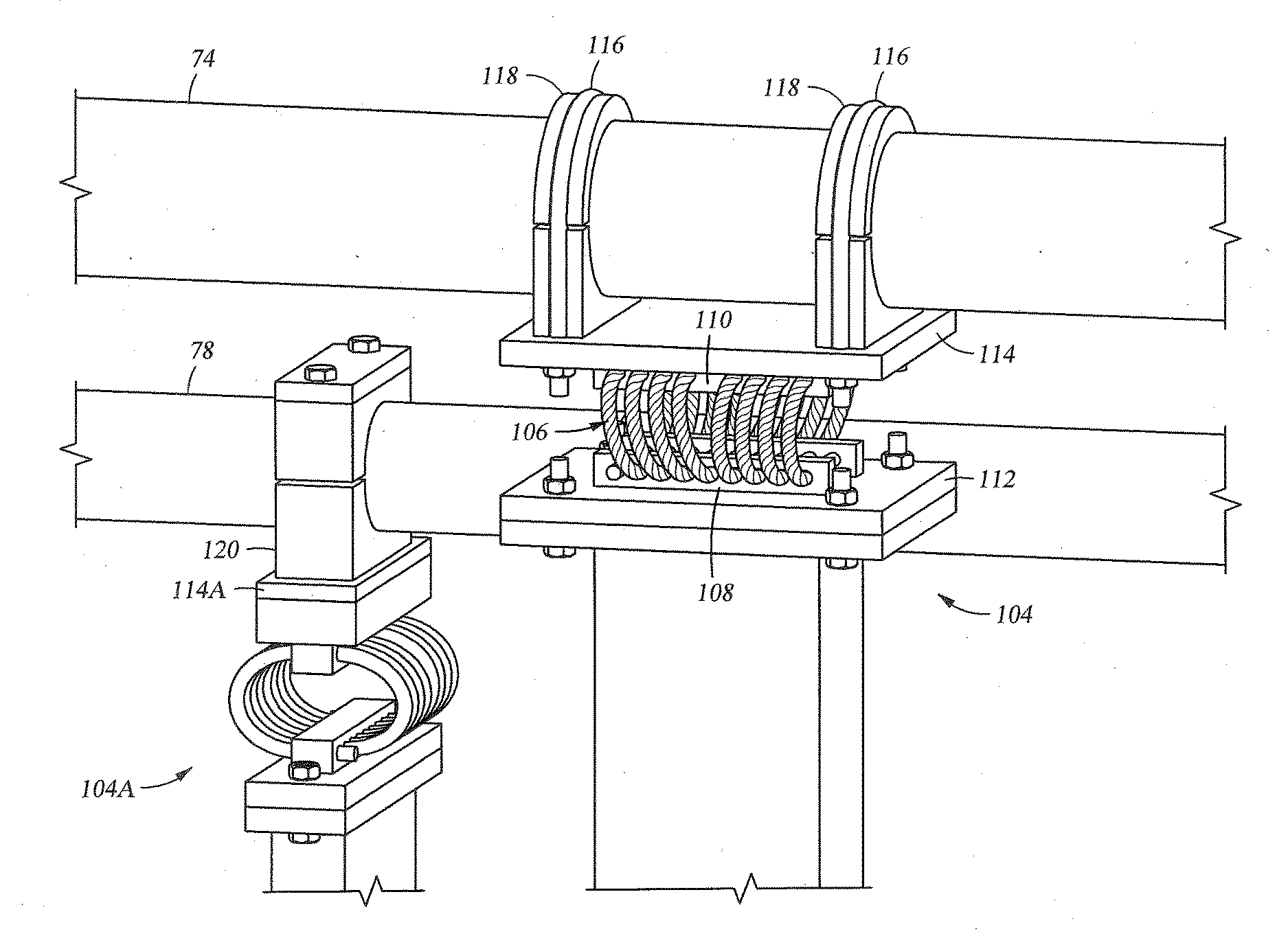

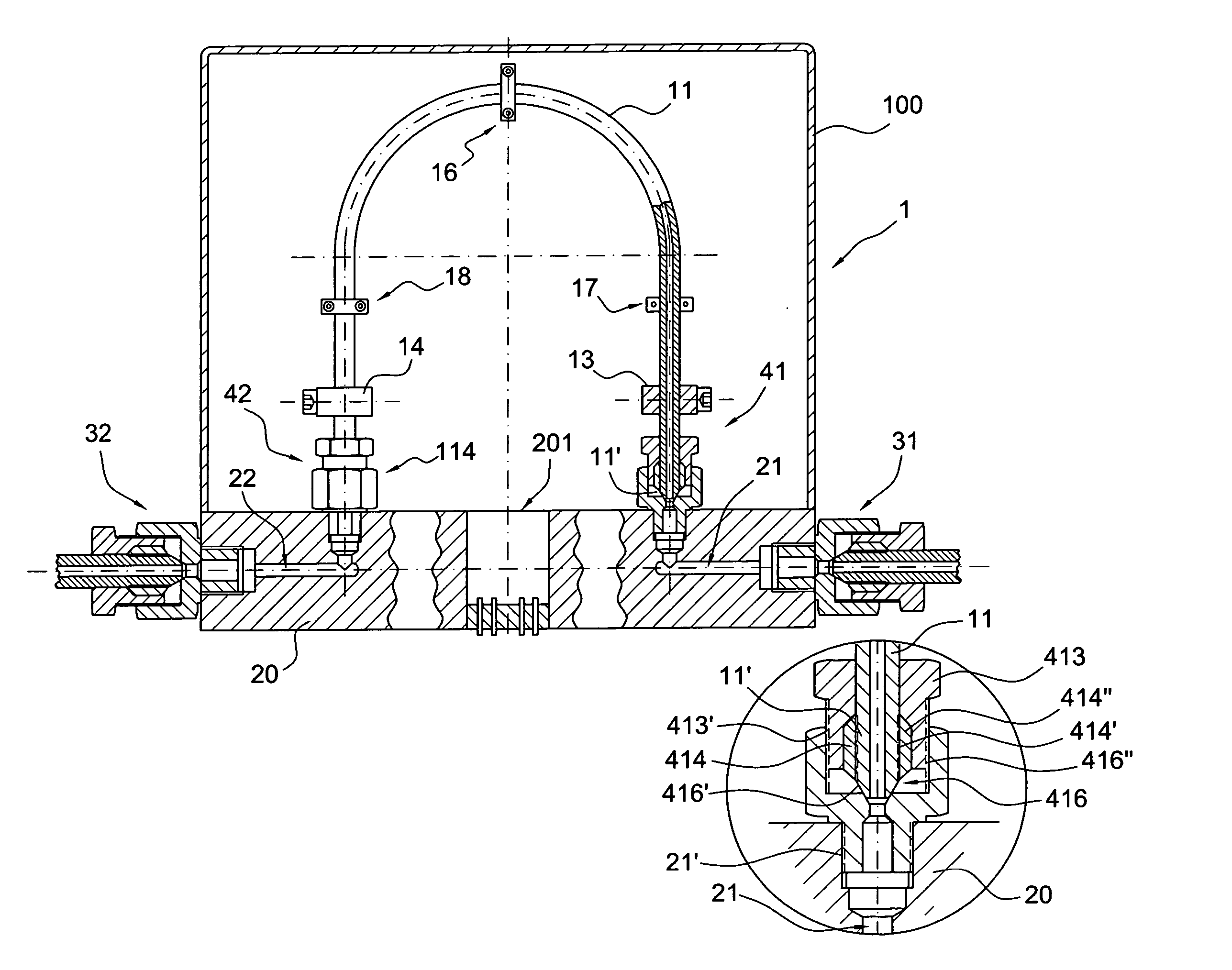

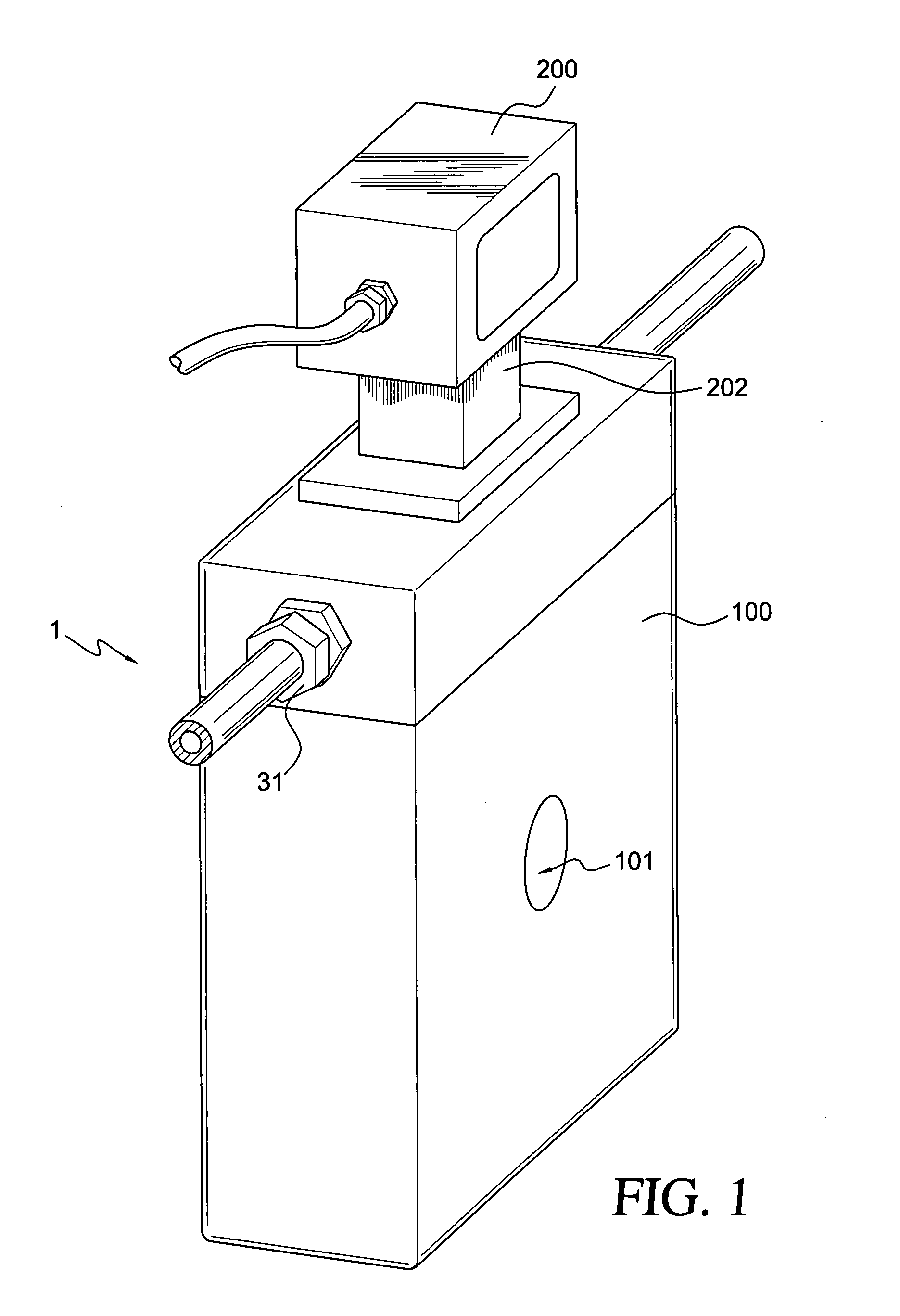

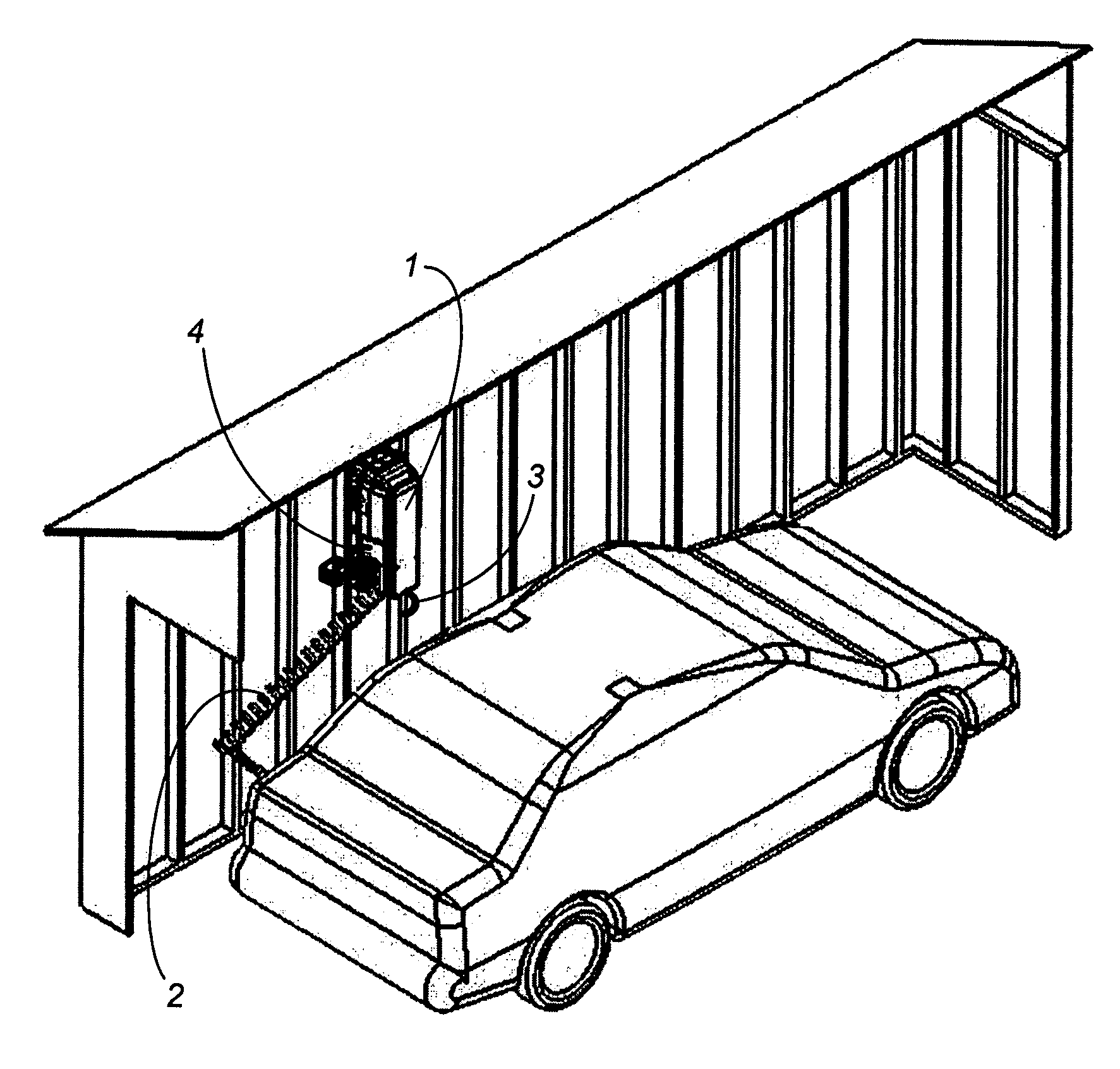

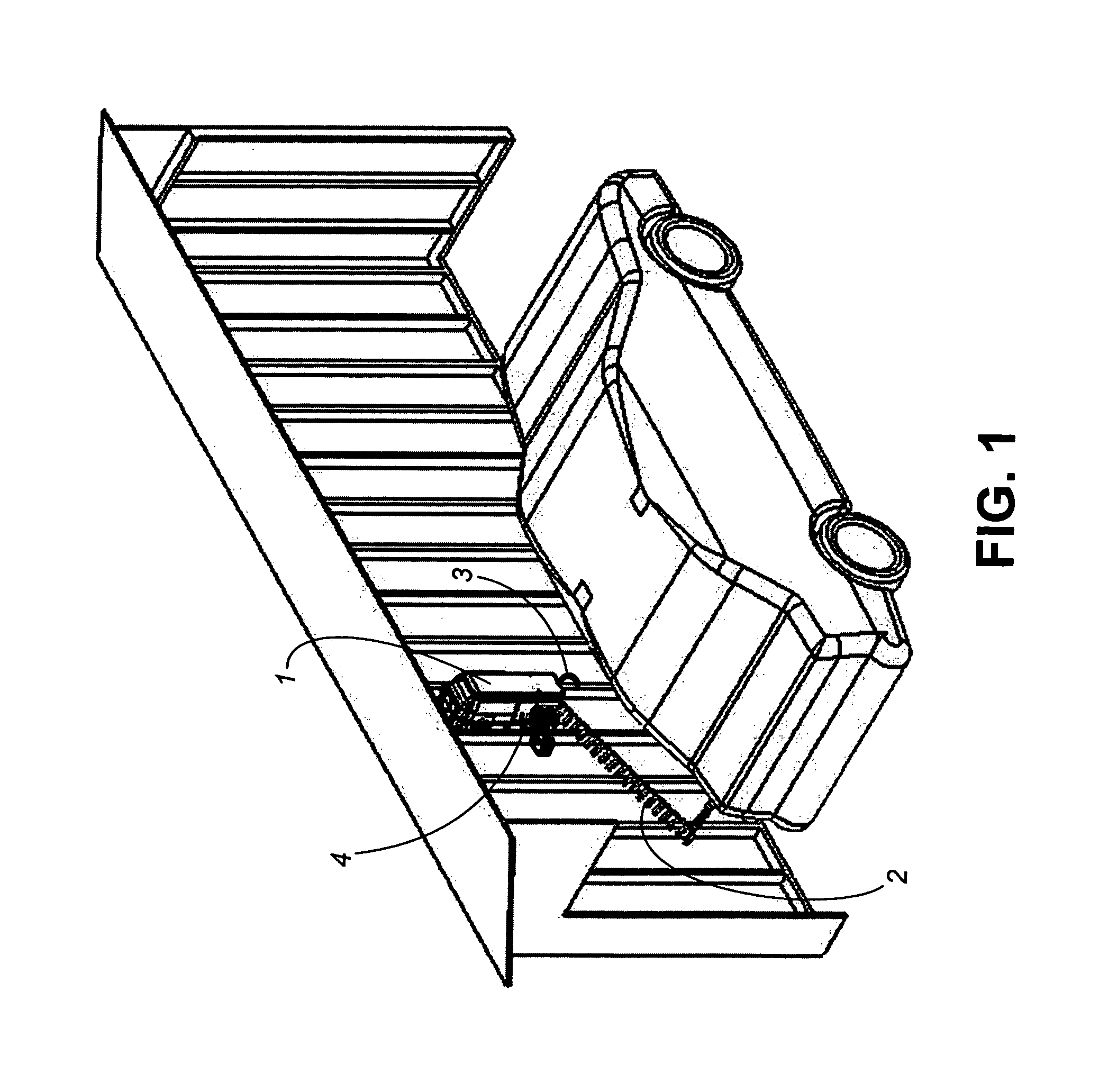

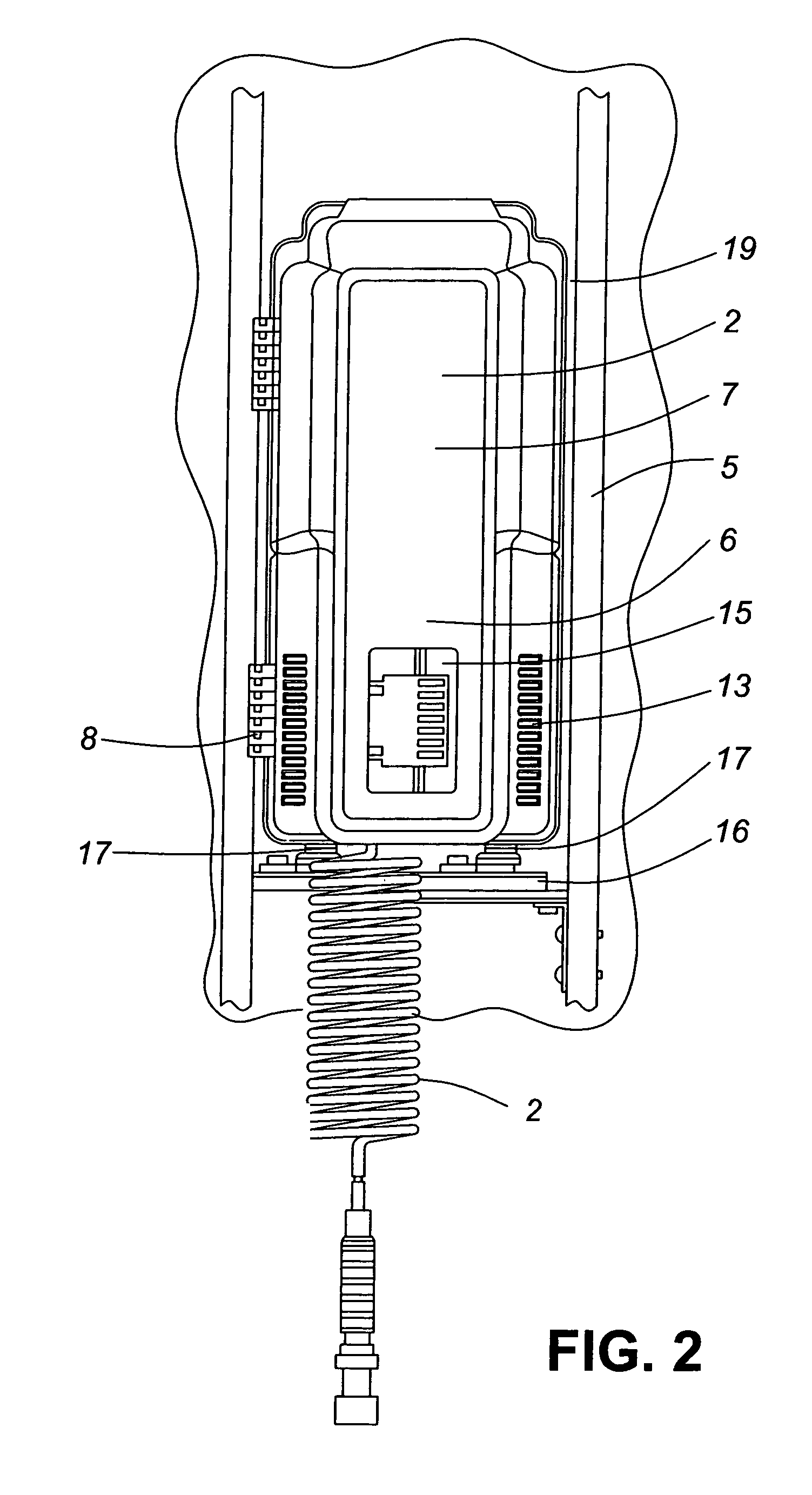

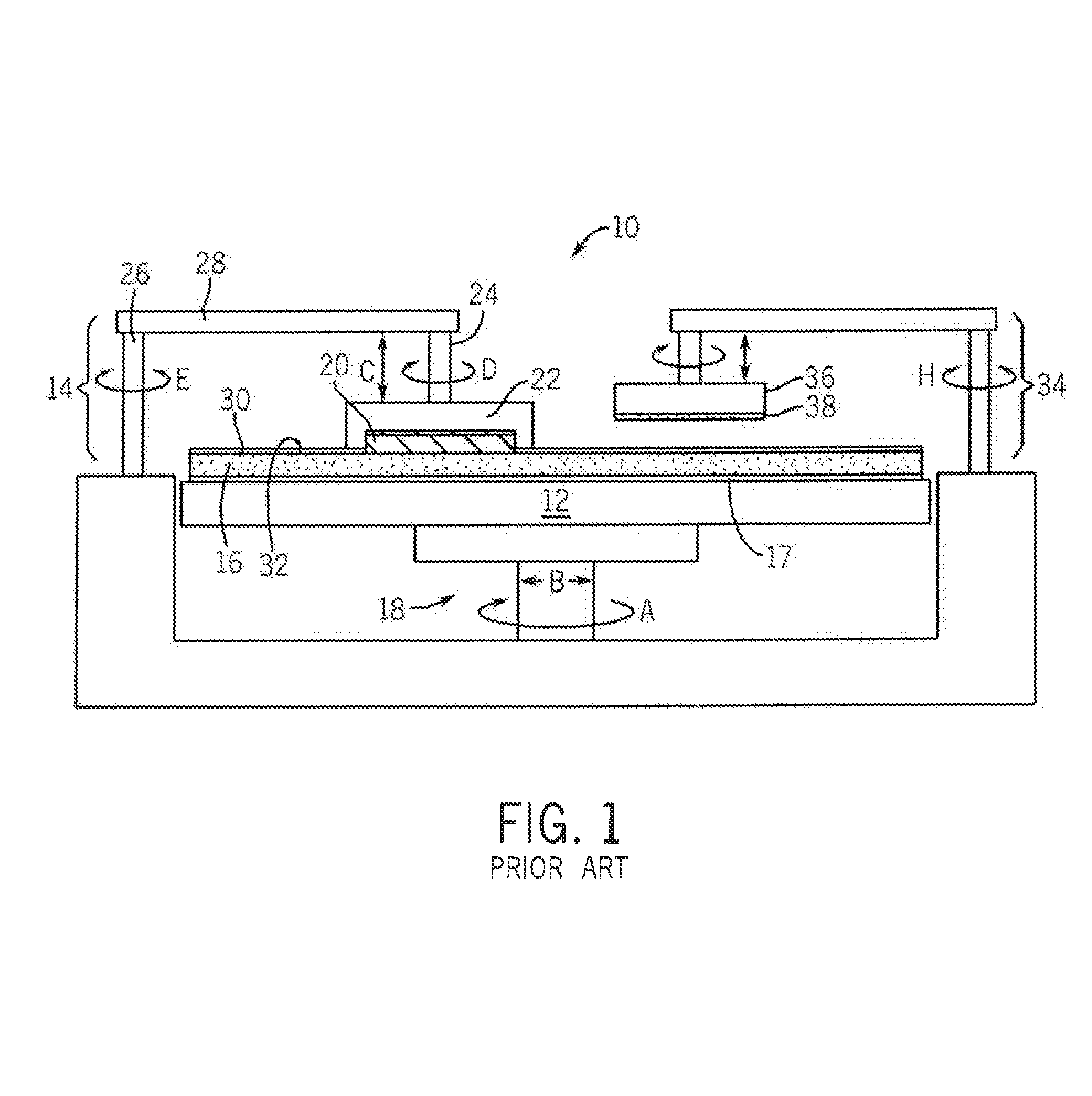

System for reducing vibrations in a pressure pumping fleet

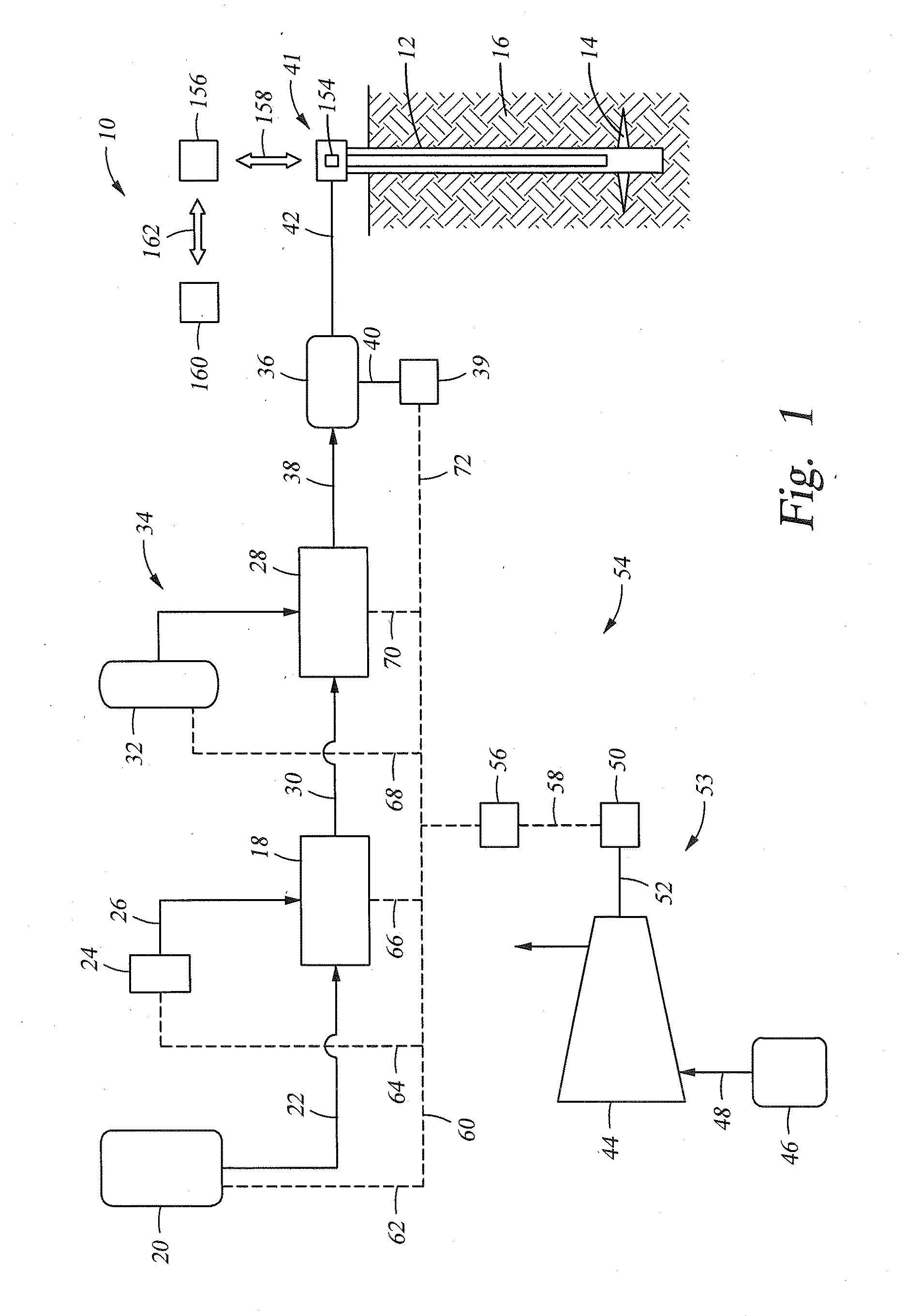

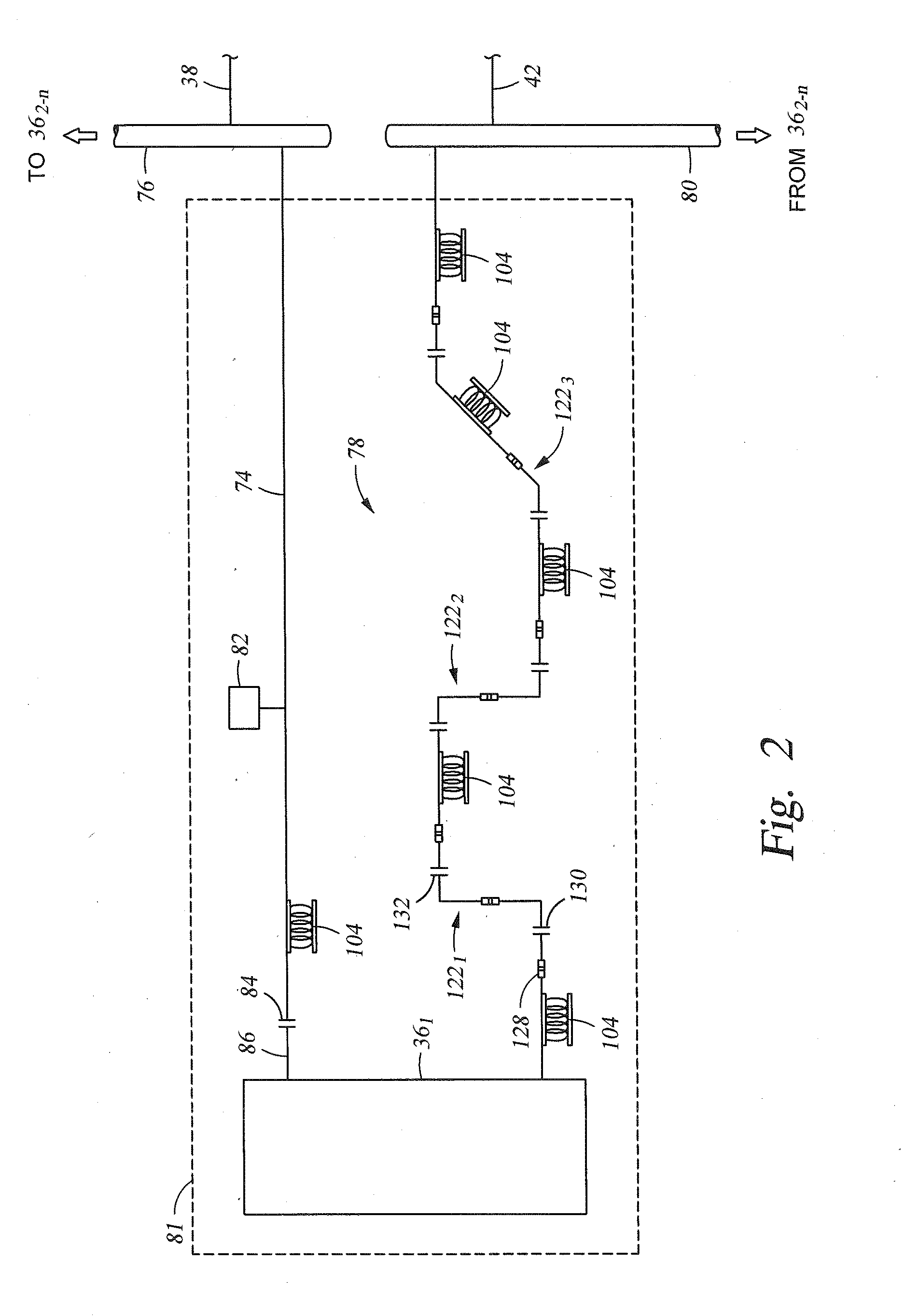

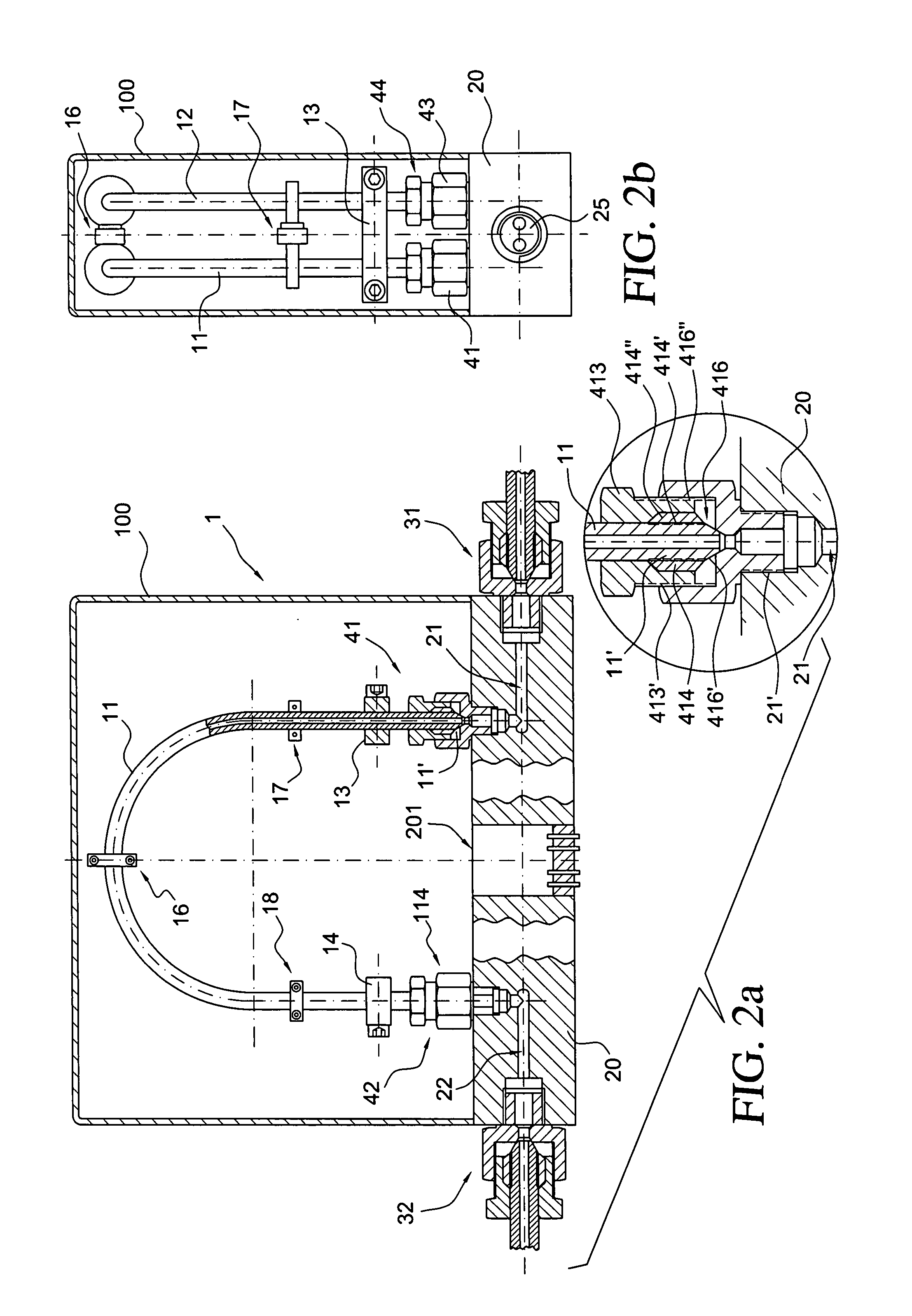

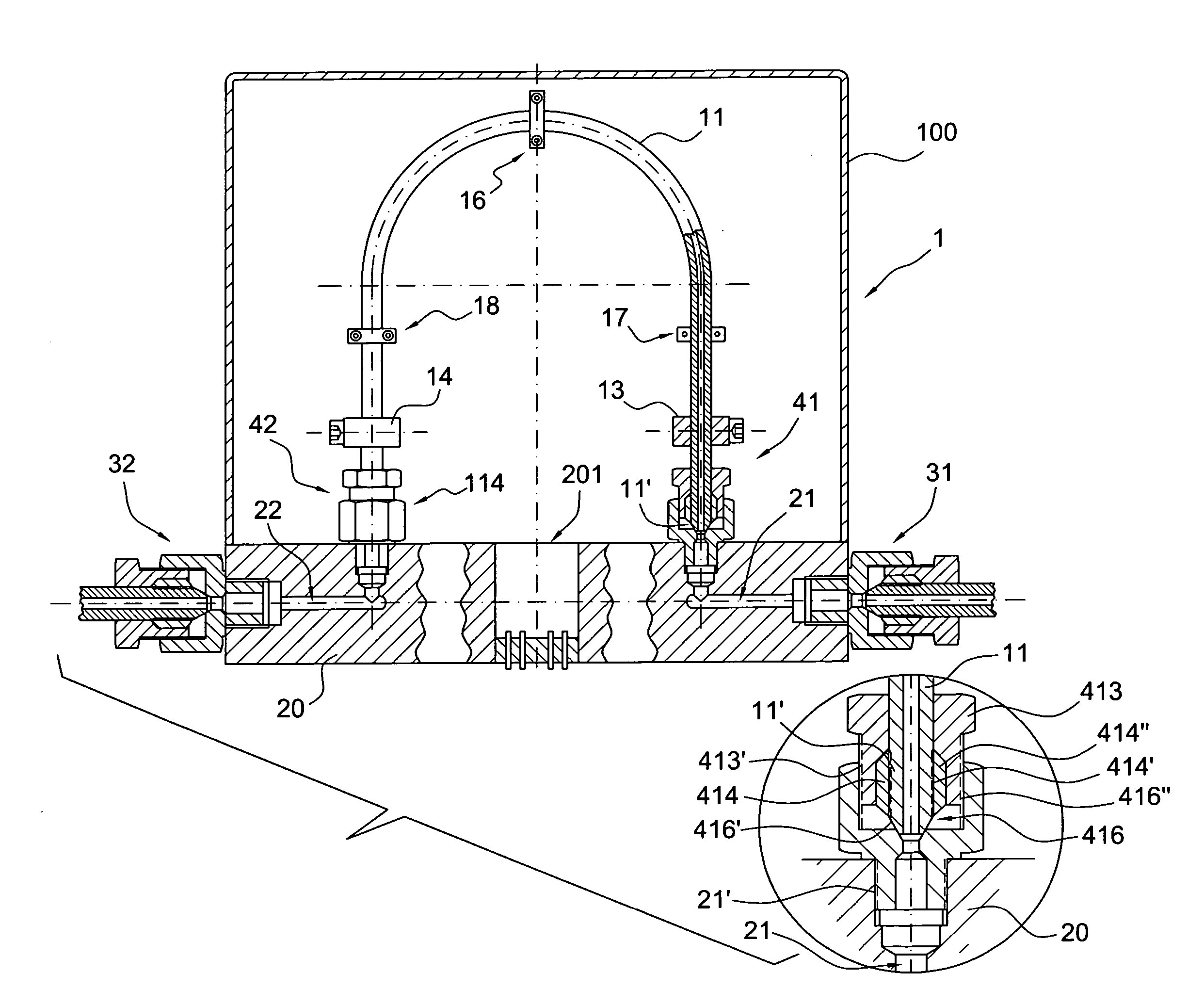

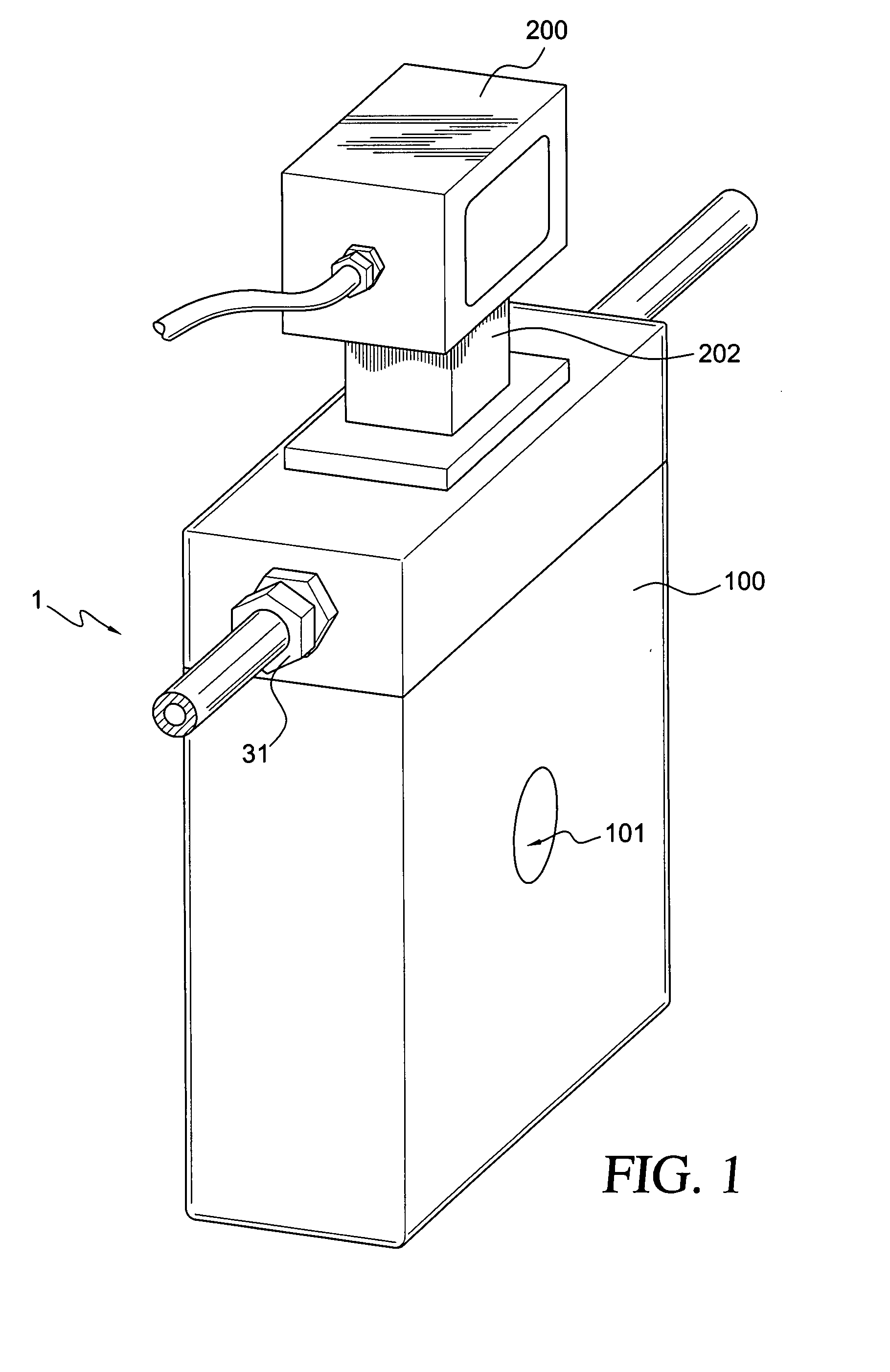

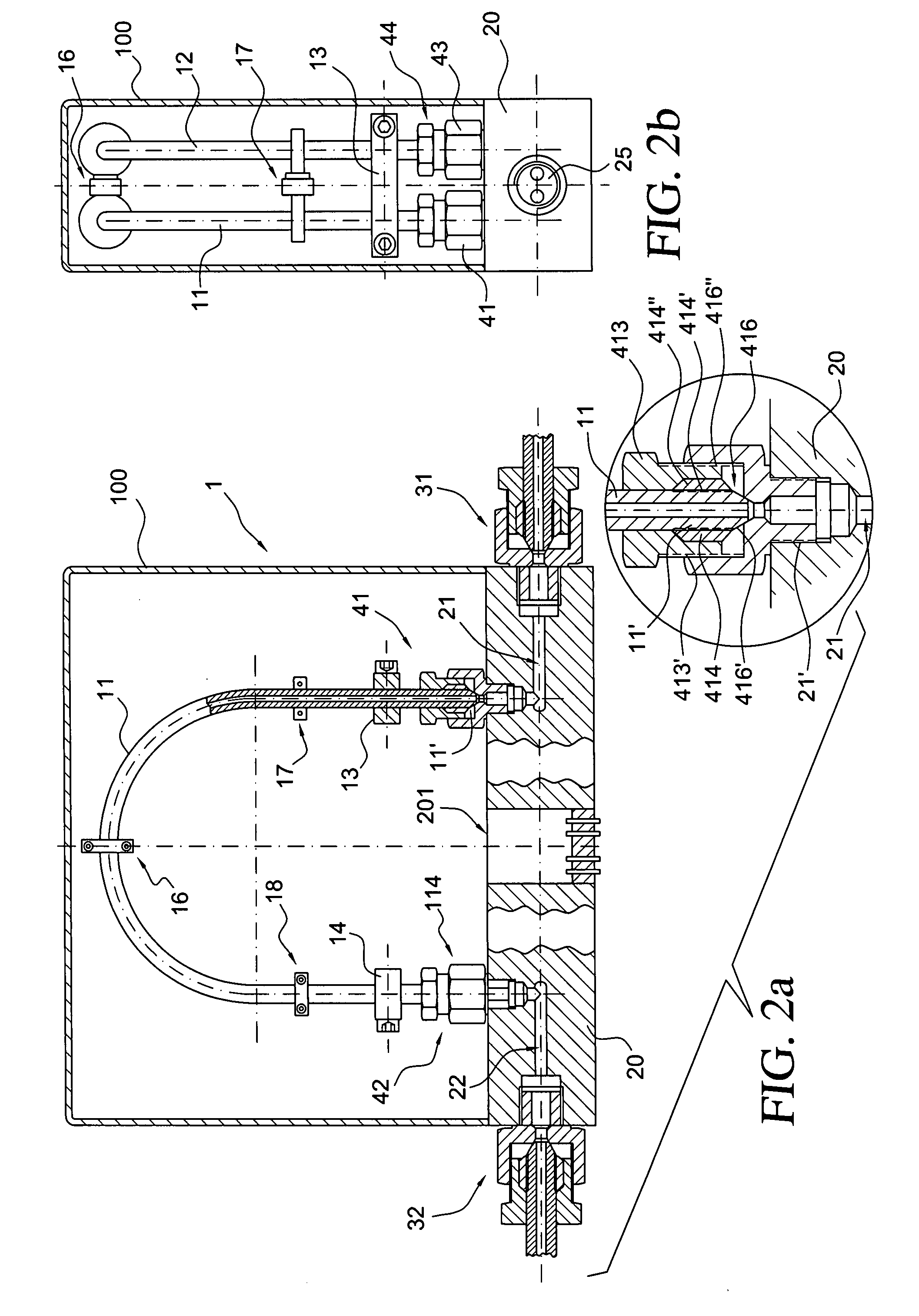

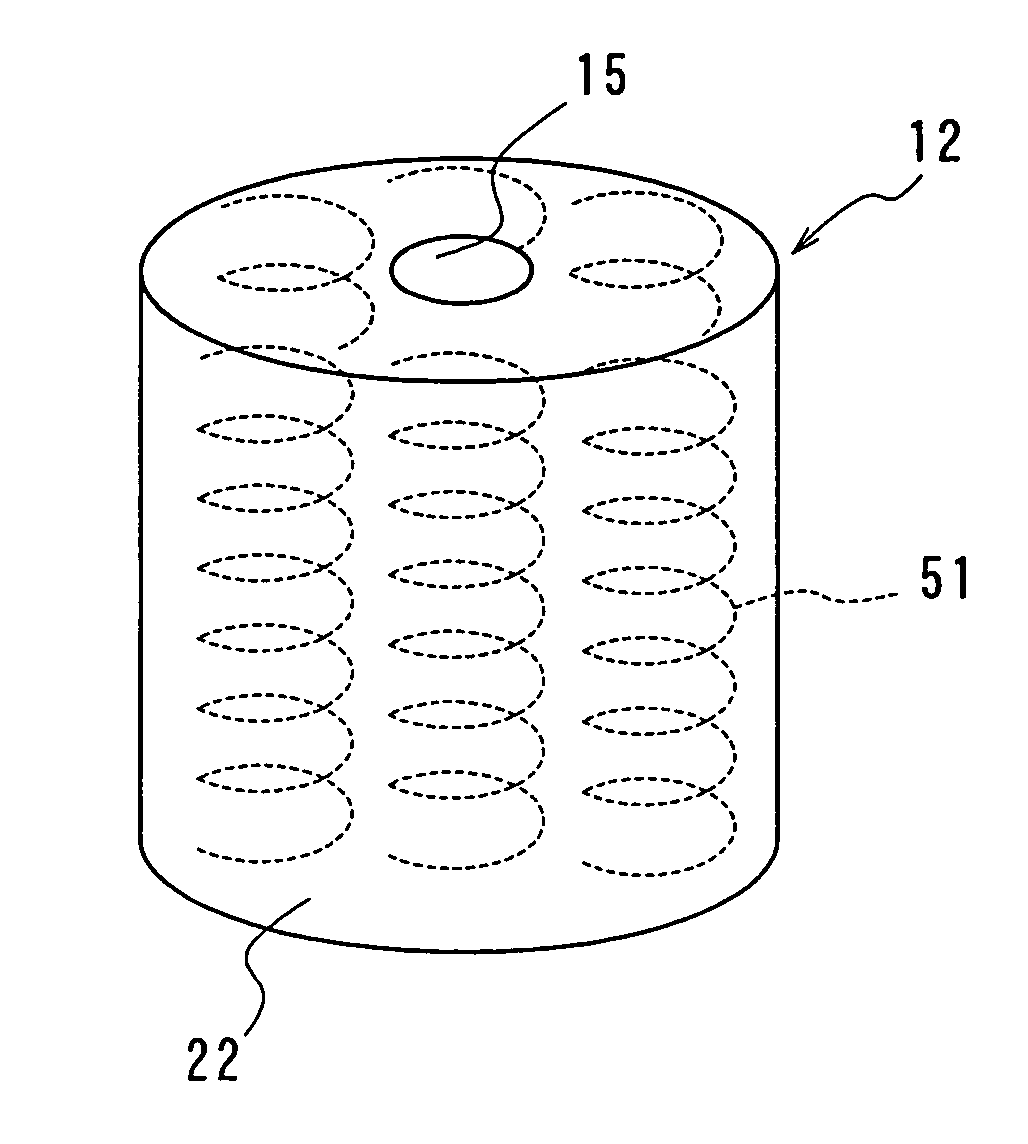

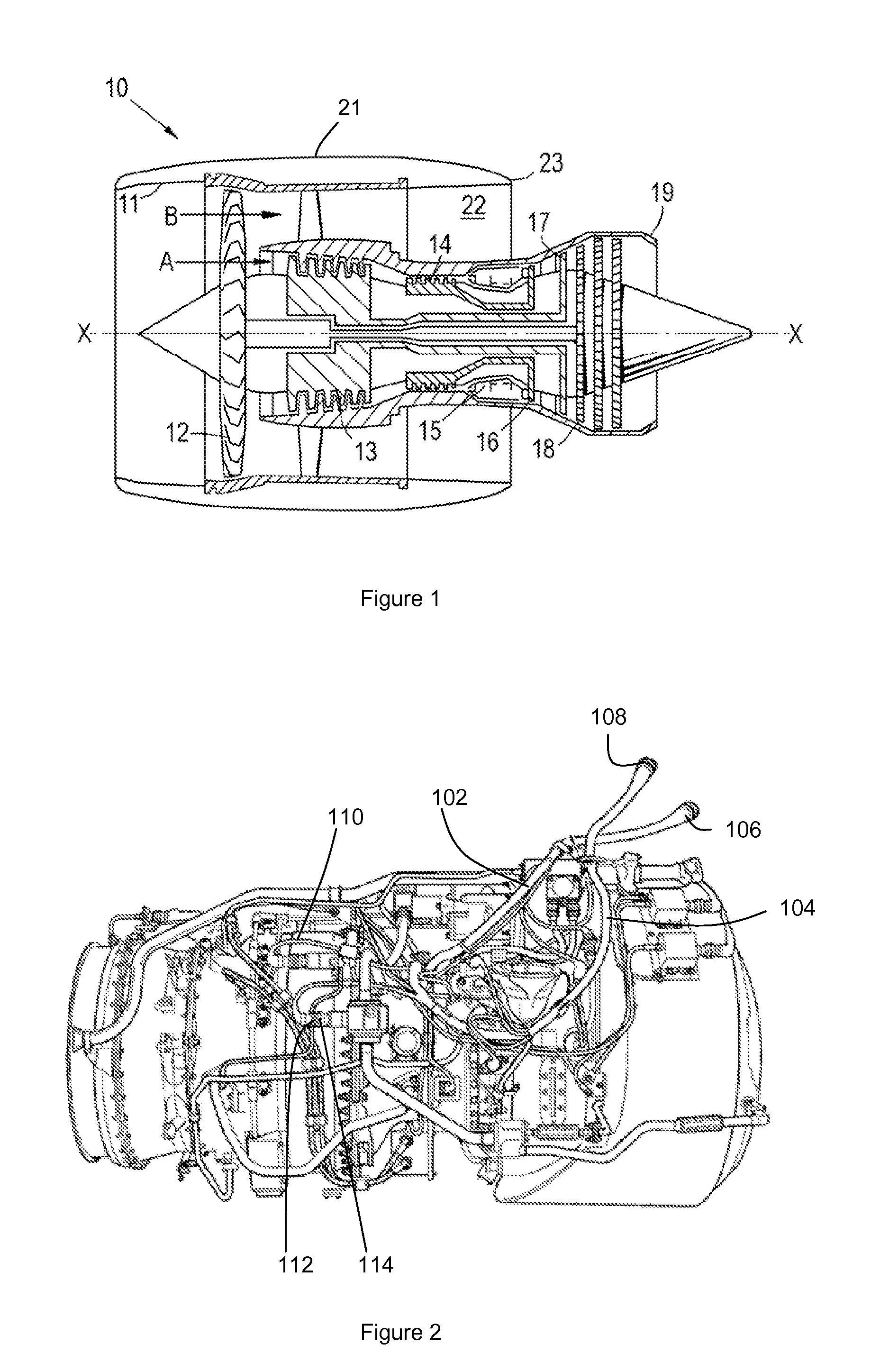

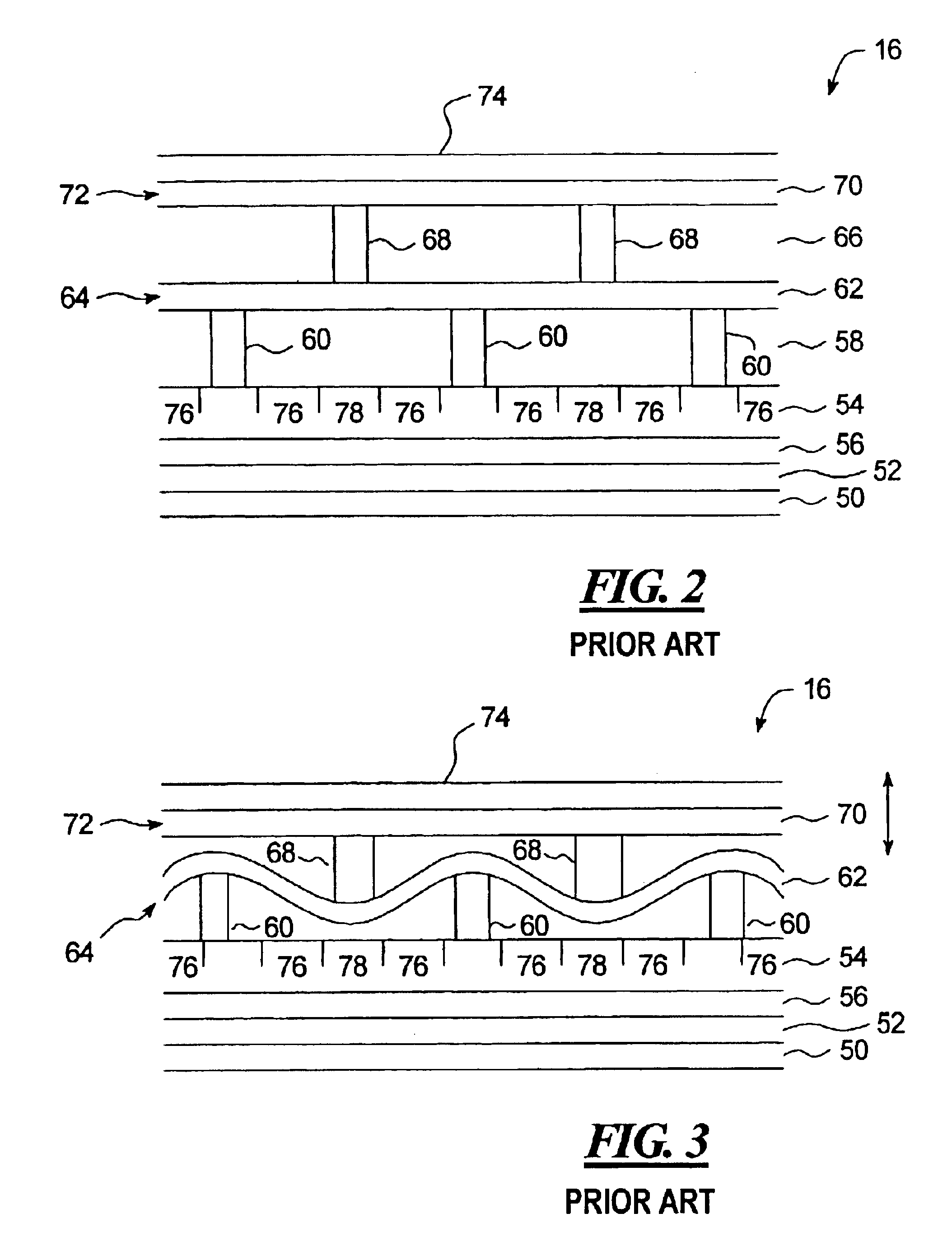

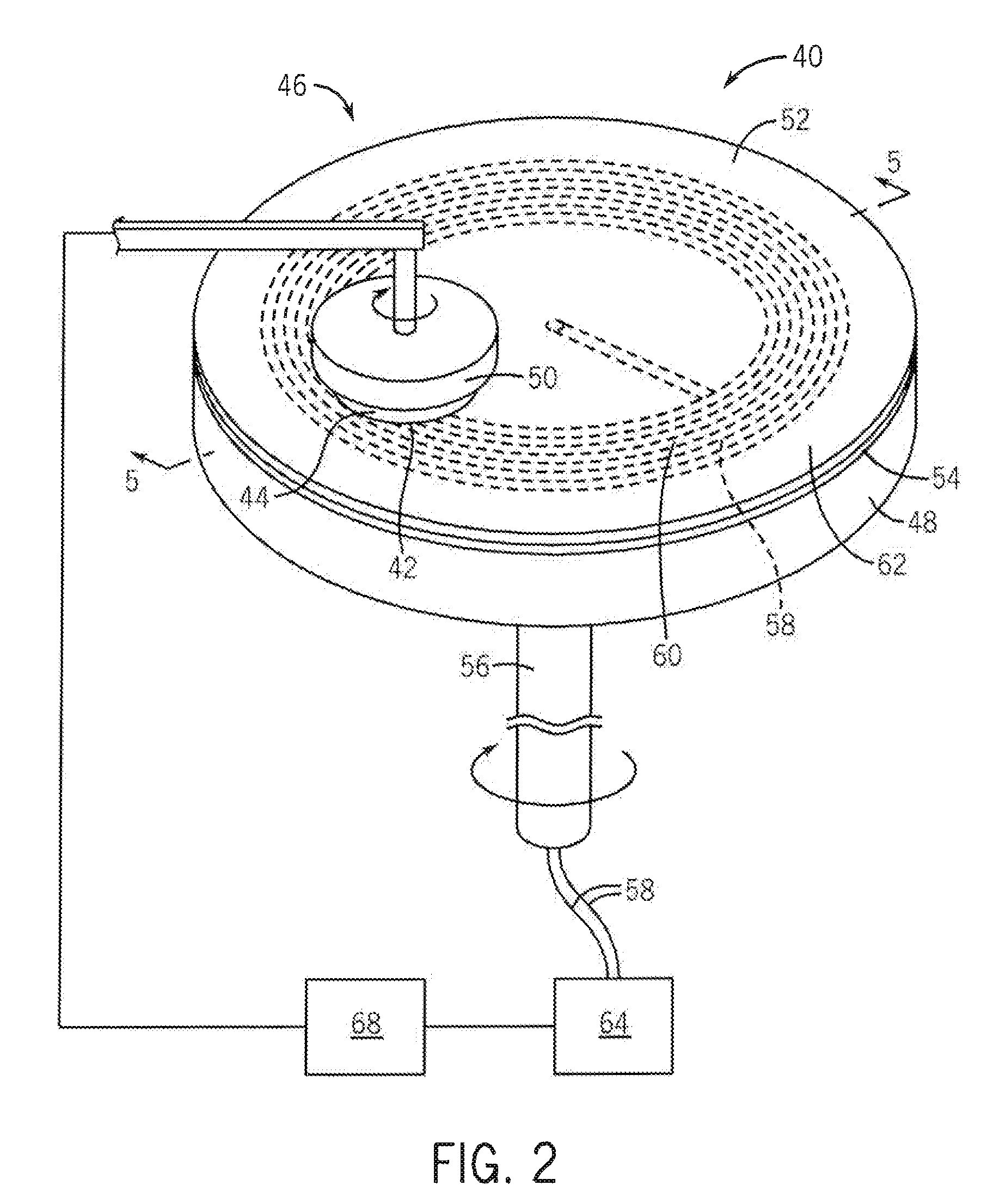

ActiveUS10119381B2Vibration highReduce turbulenceAC motor controlPositive displacement pump componentsFracturing fluidHelical coil

An electrically powered hydraulic fracturing system having pumps for pressurizing fracturing fluid, piping for carrying fracturing fluid, and vibration reducing equipment for use with the piping. The vibration reducing equipment includes helical coils that support the piping. The coils are made of a wire rope made of strands of steel cable twisted together. Grooved fittings are provided on some piping connections, and which allow pivoting between adjacent fluid conveyance members. Swivel joints are strategically located in the piping which allow rotational flexing between adjacent sections of the piping; thereby attenuating vibration in the piping but without stressing the piping.

Owner:US WELL SERVICS LLC

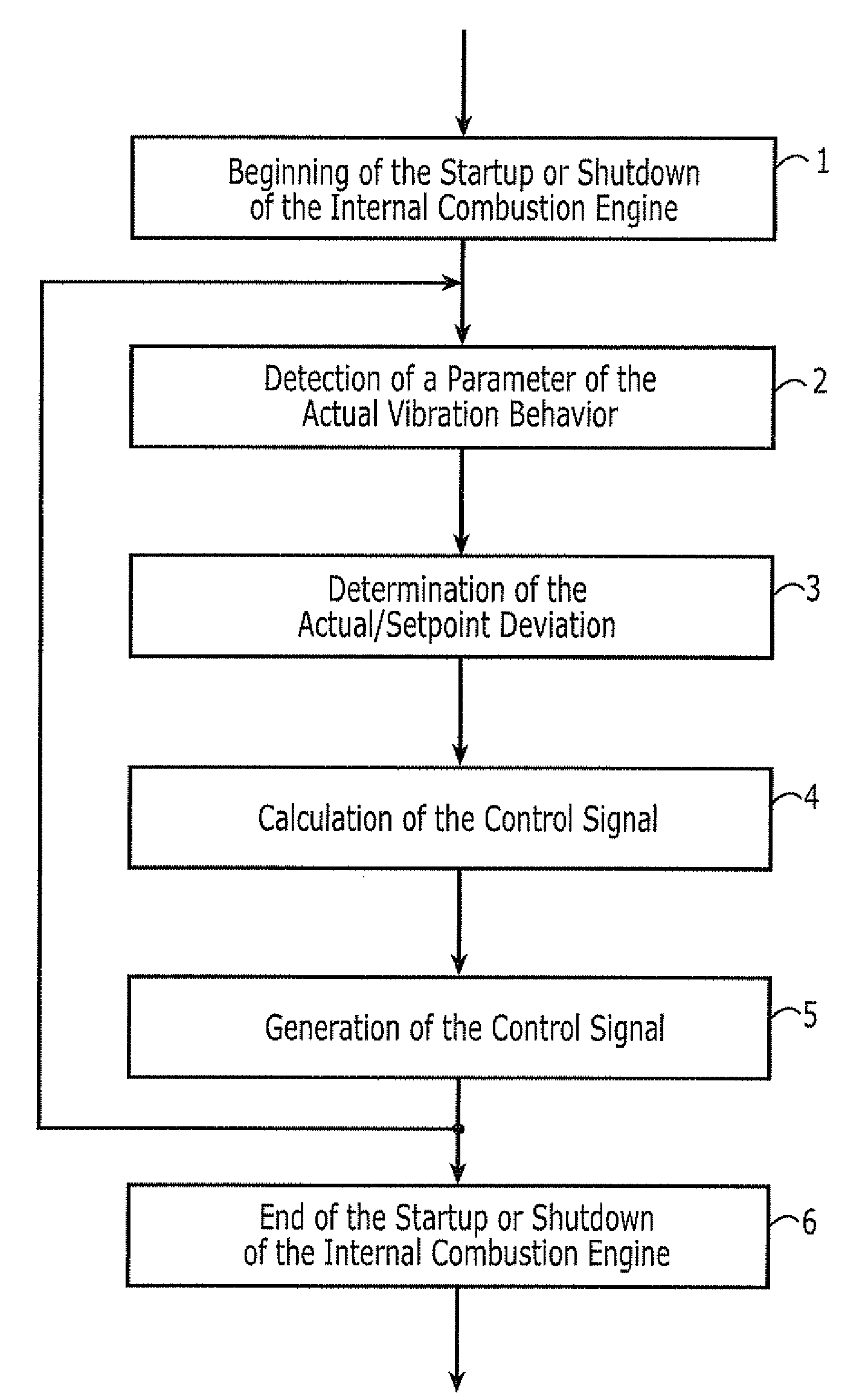

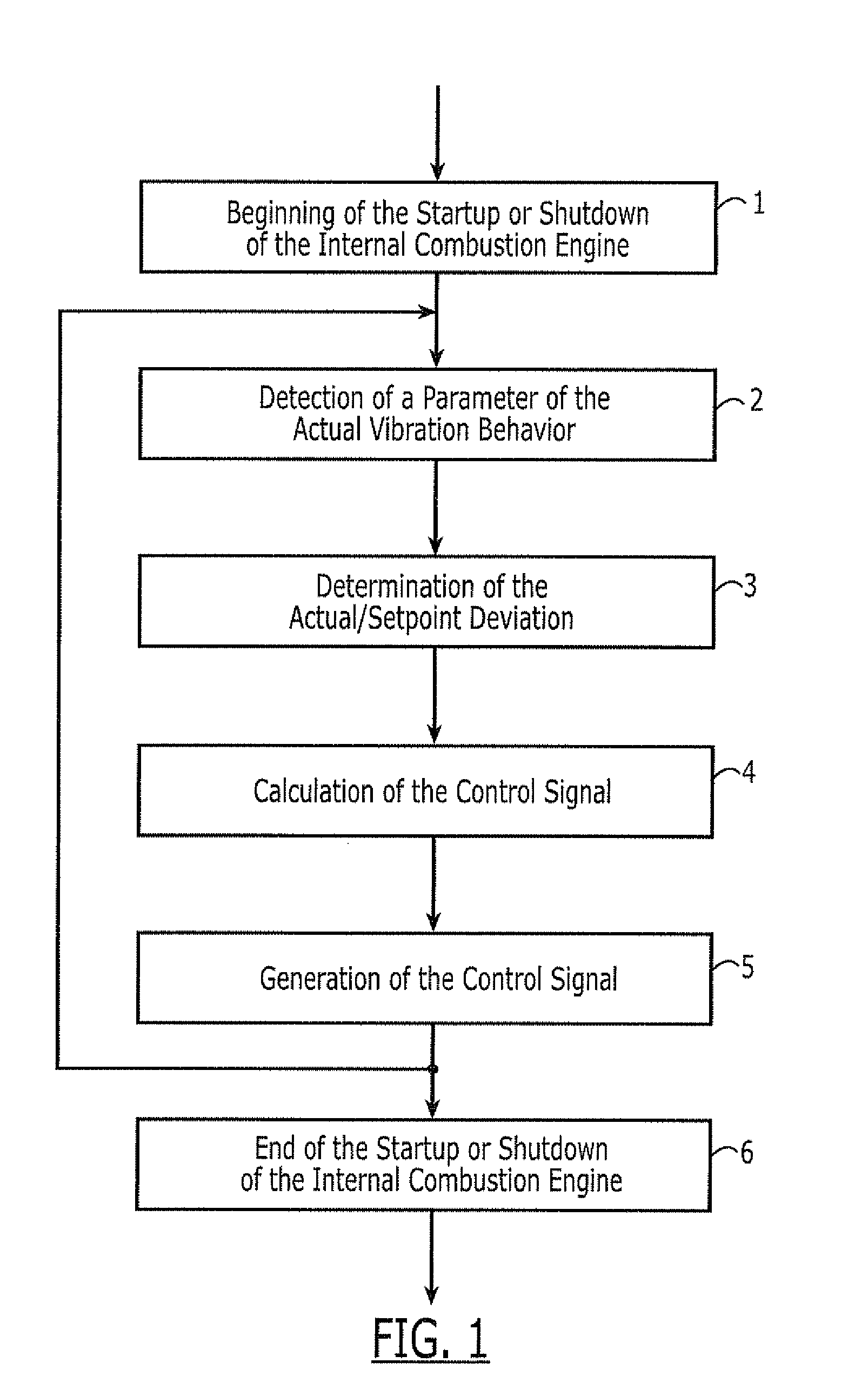

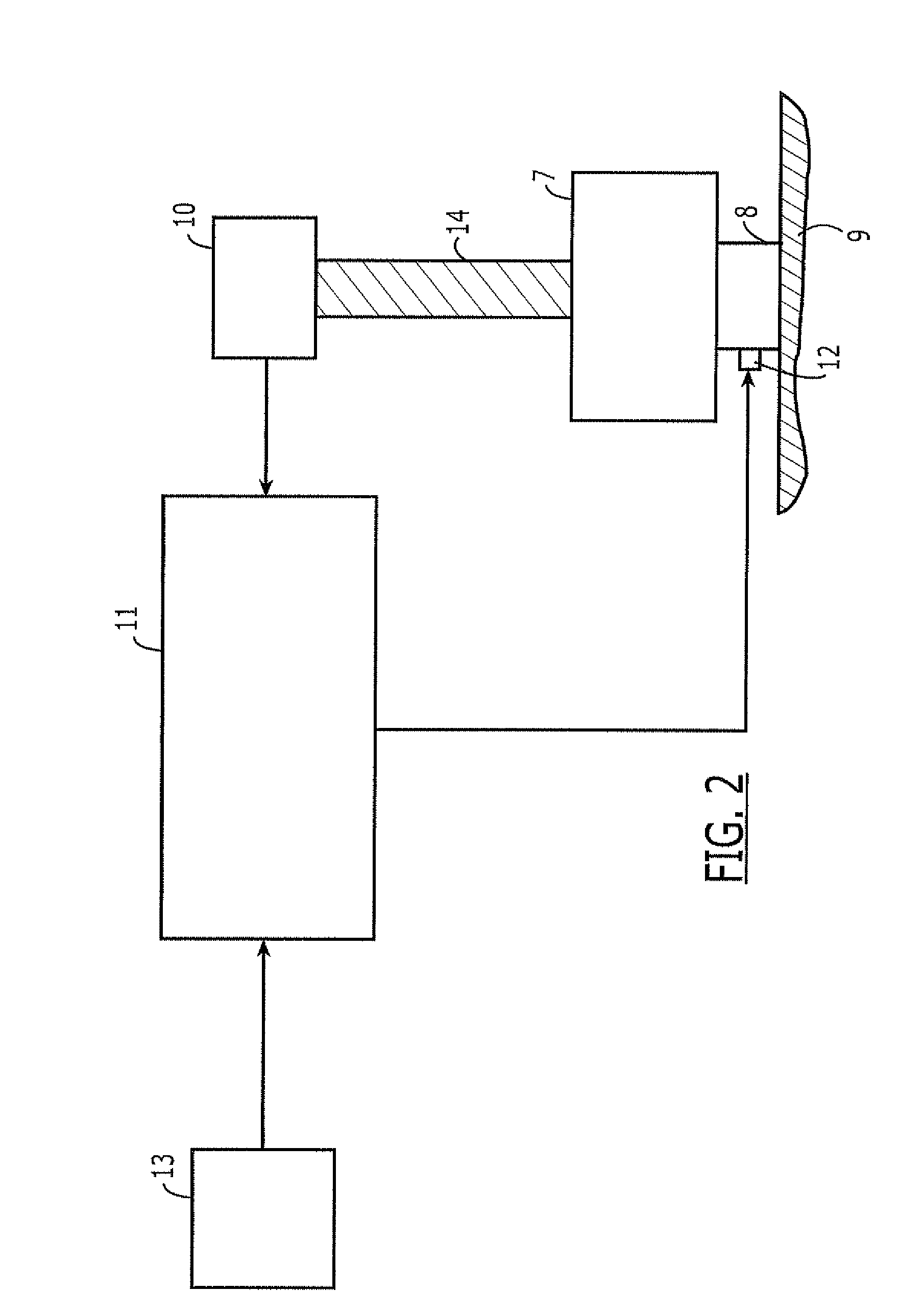

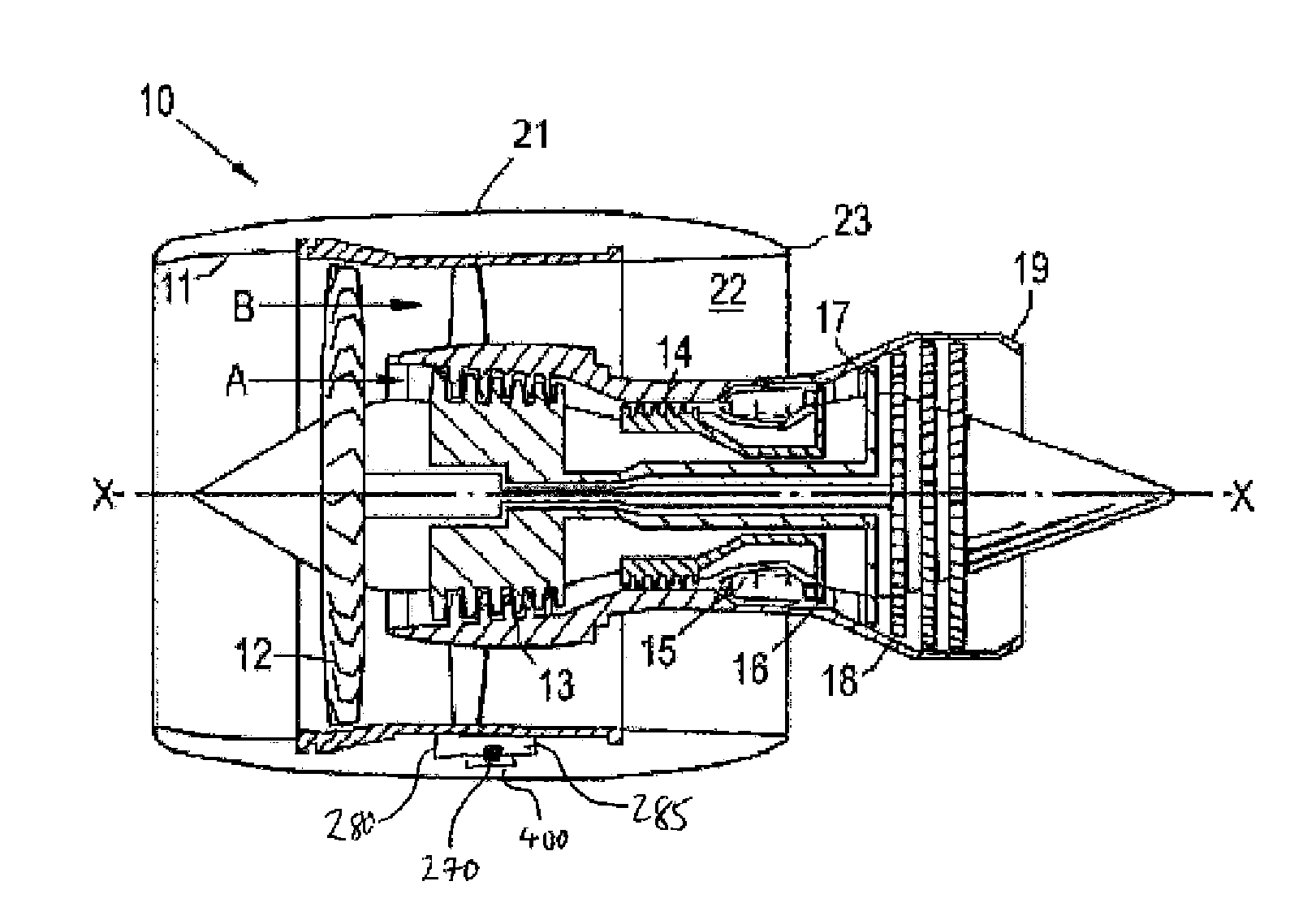

Method and device for reducing vibrations during the shutdown or startup of engines, in particular internal combustion engines

InactiveUS20090063026A1Advantageously adaptAdvantageously processAnalogue computers for vehiclesElectrical controlEngineeringExternal combustion engine

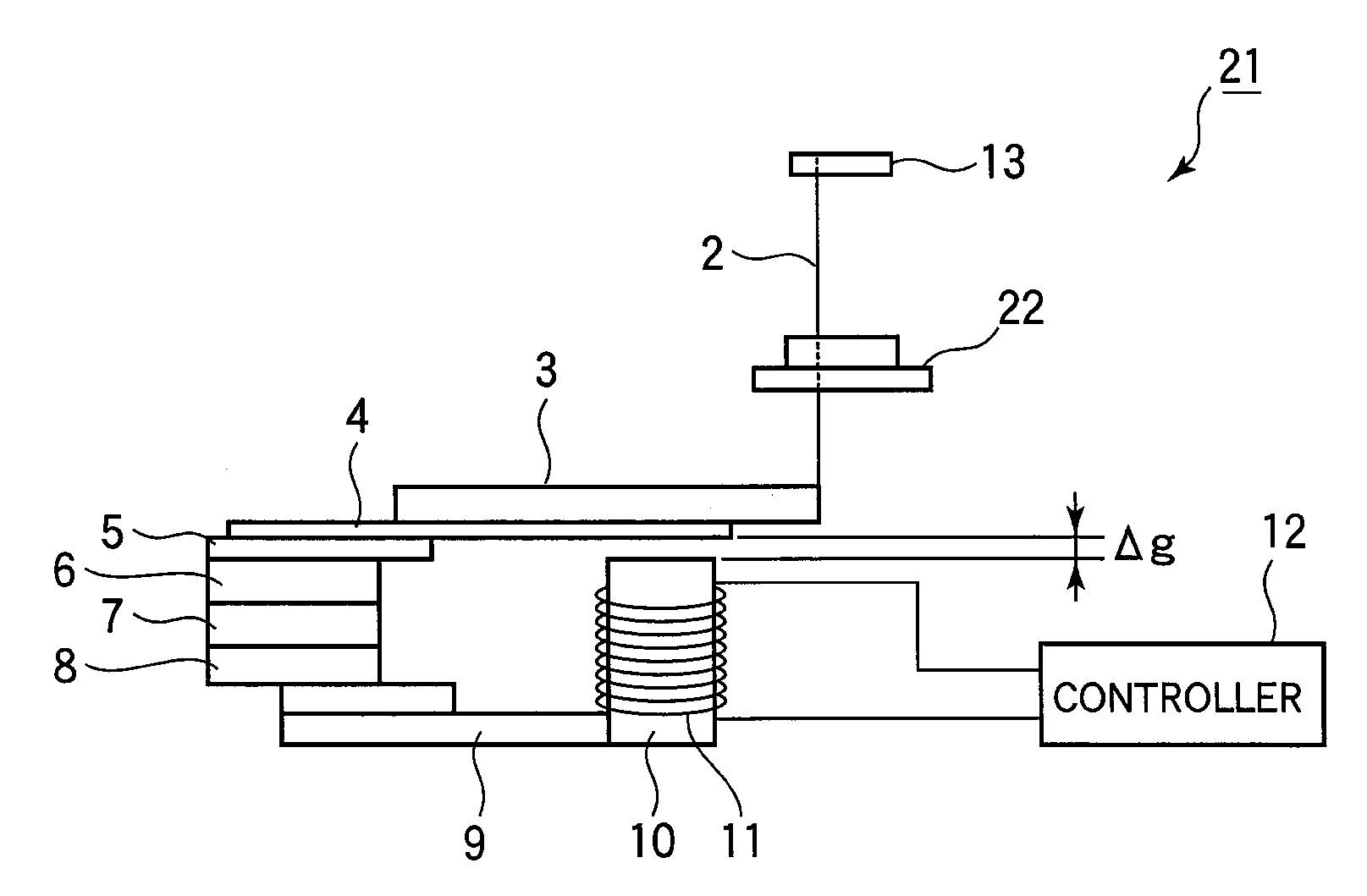

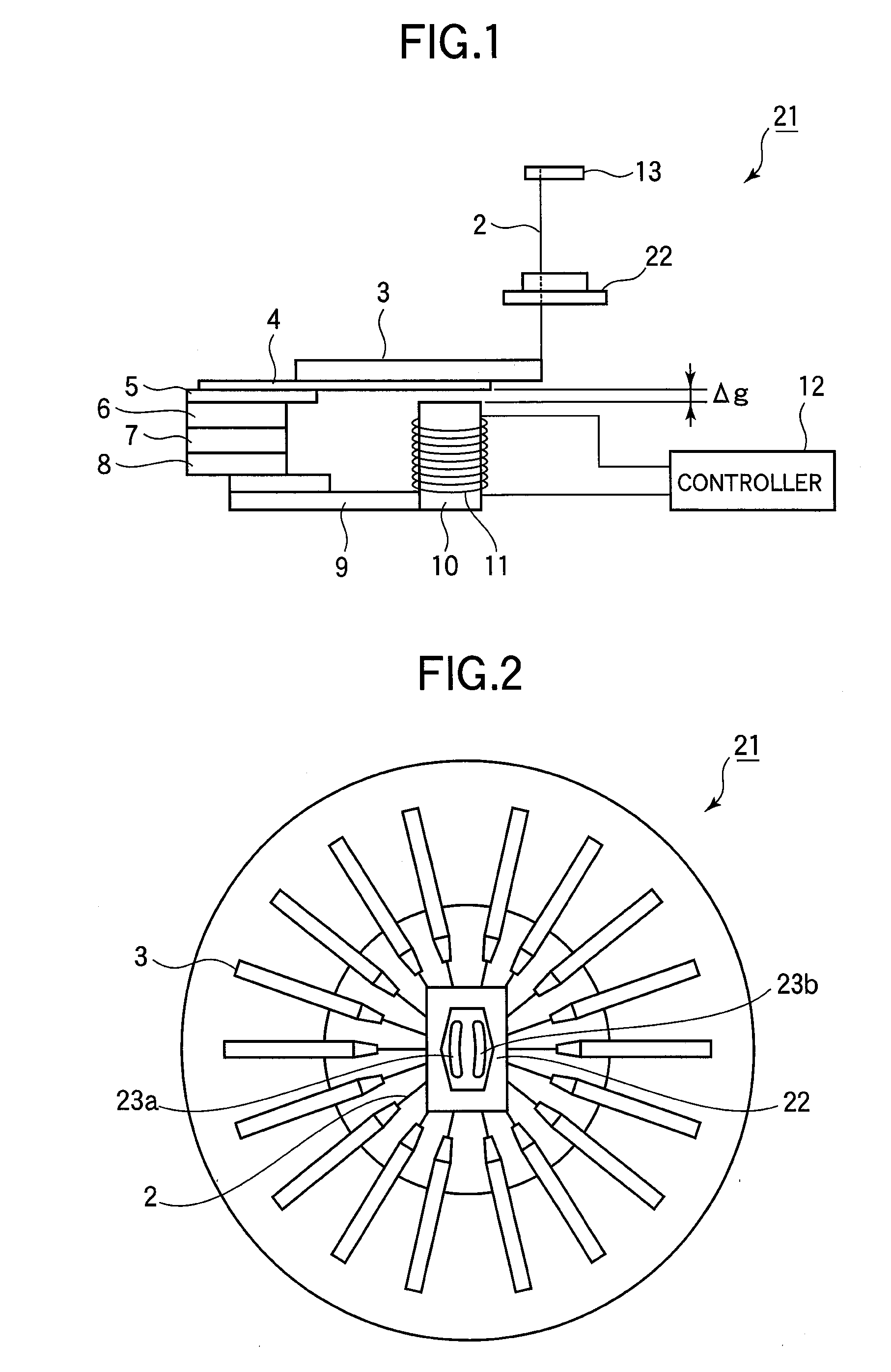

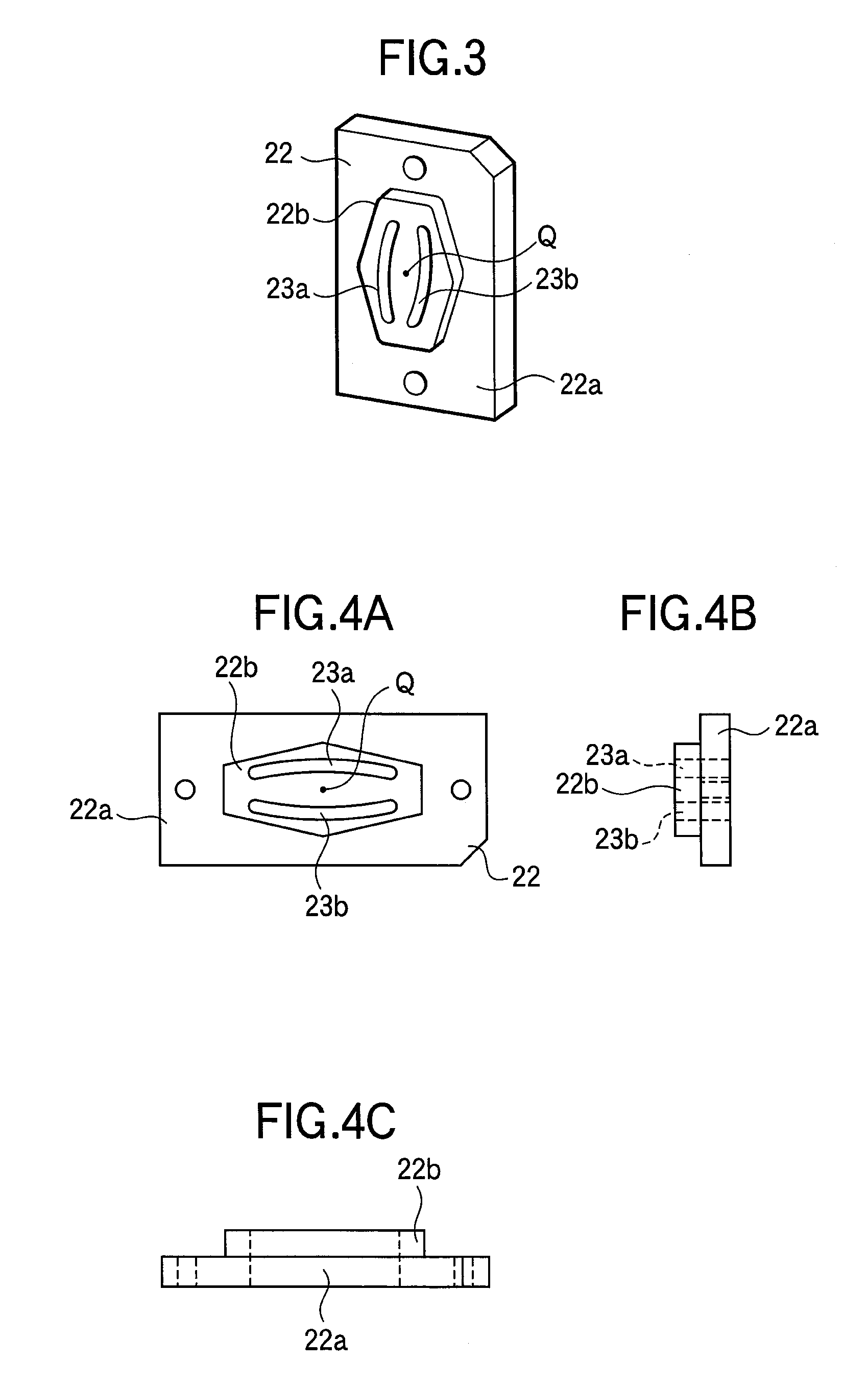

A method and a device for reducing vibrations during the shutdown or startup of an engine, in particular an internal combustion engine, in which the vibration behavior of the engine is determined at least during shutdown and / or startup, a control signal is applied to at least one engine mounting whose damping properties are settable via the control signal, and the control signal is calculated in such a way that a vibration behavior of the engine materializes according to a setpoint vibration behavior in which vibrations are introduced, for example into a passenger compartment, at a level which lies below a predefined threshold value.

Owner:ROBERT BOSCH GMBH

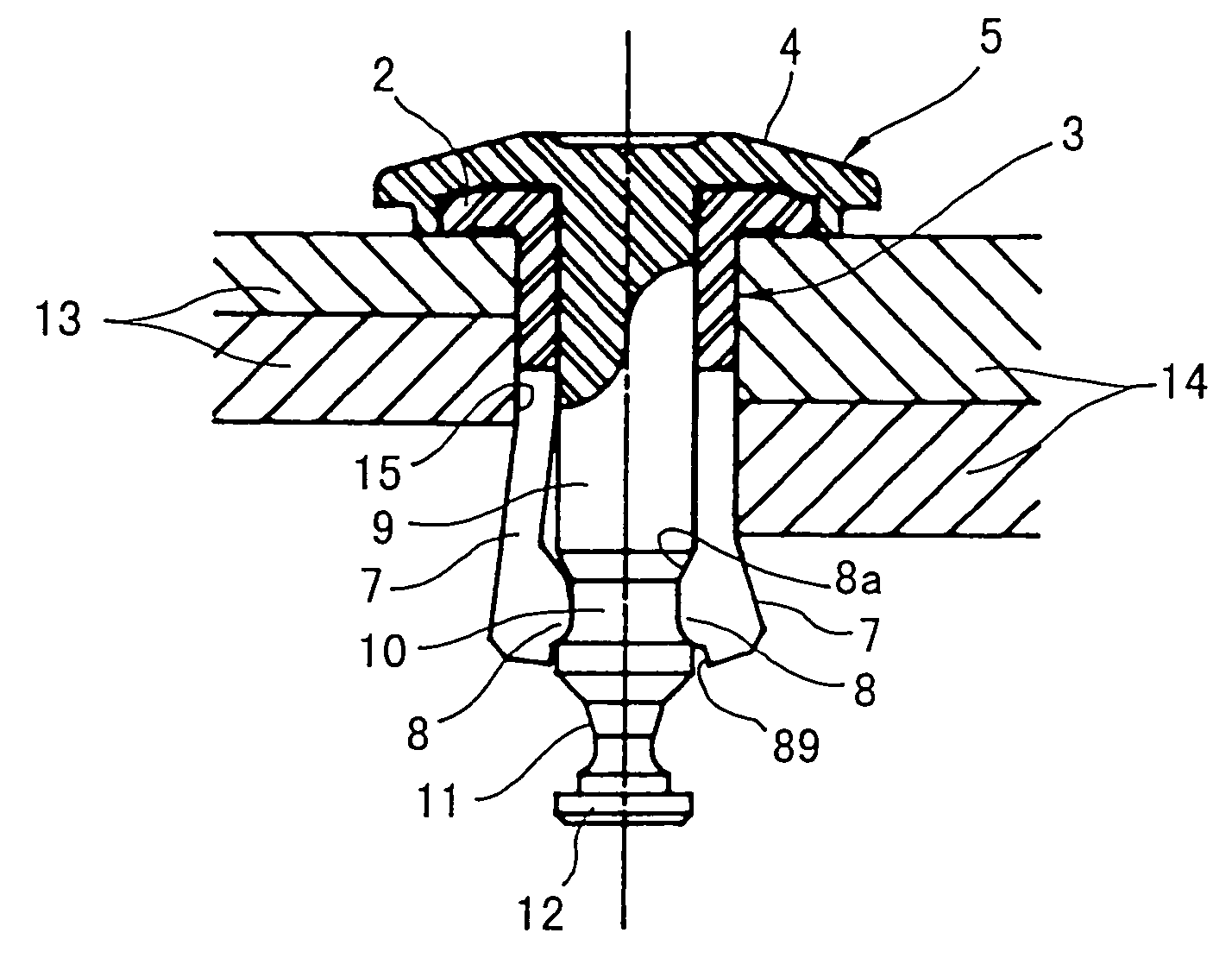

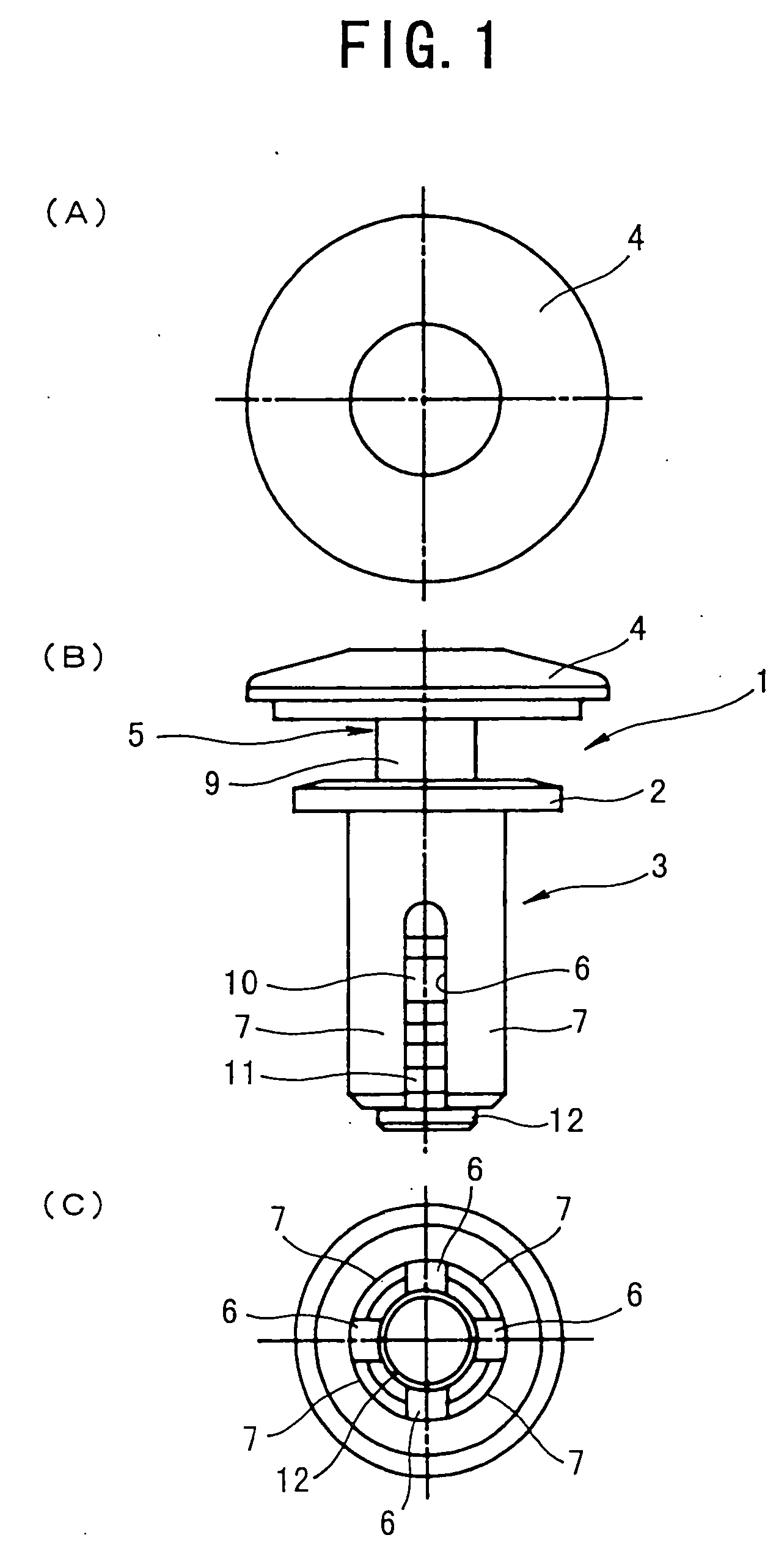

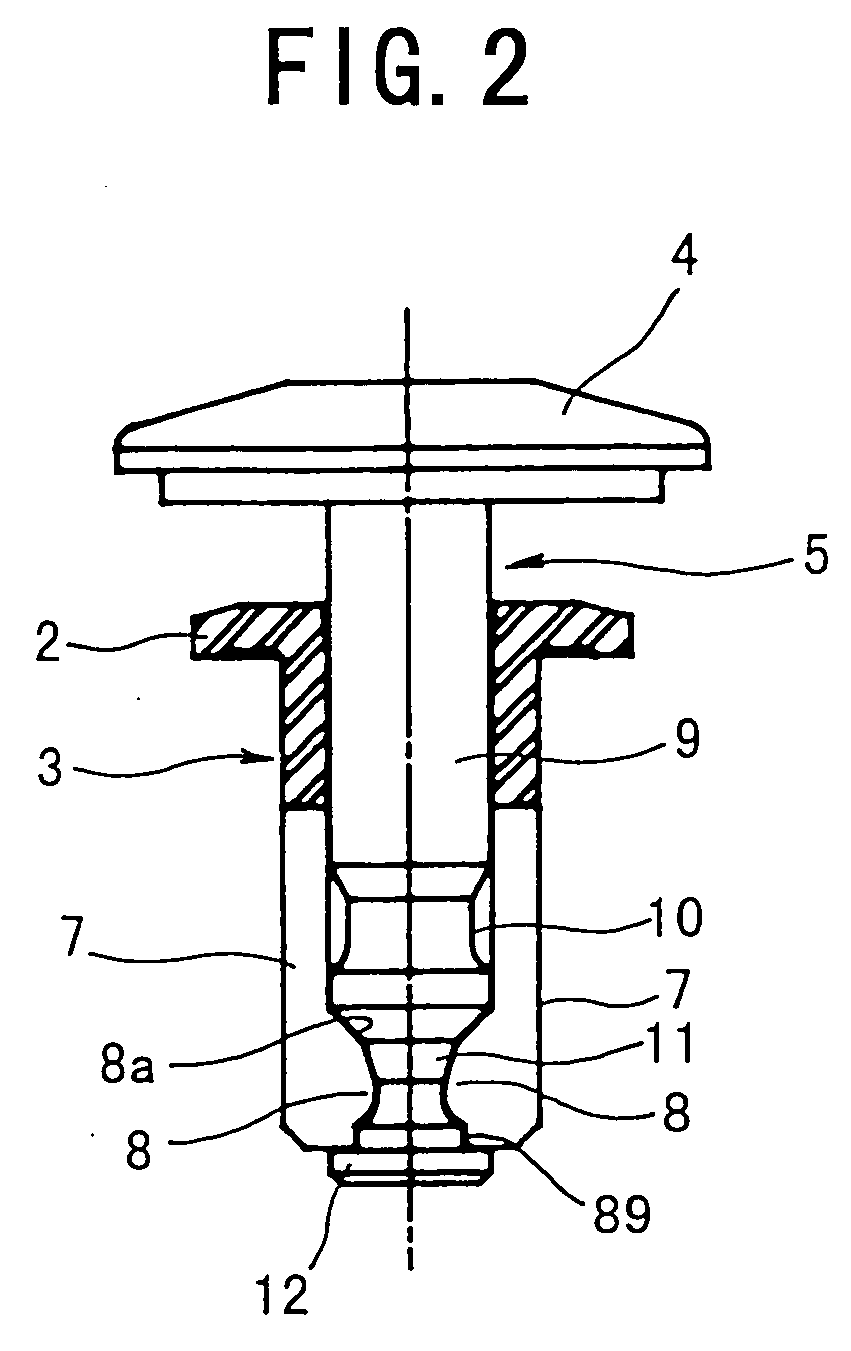

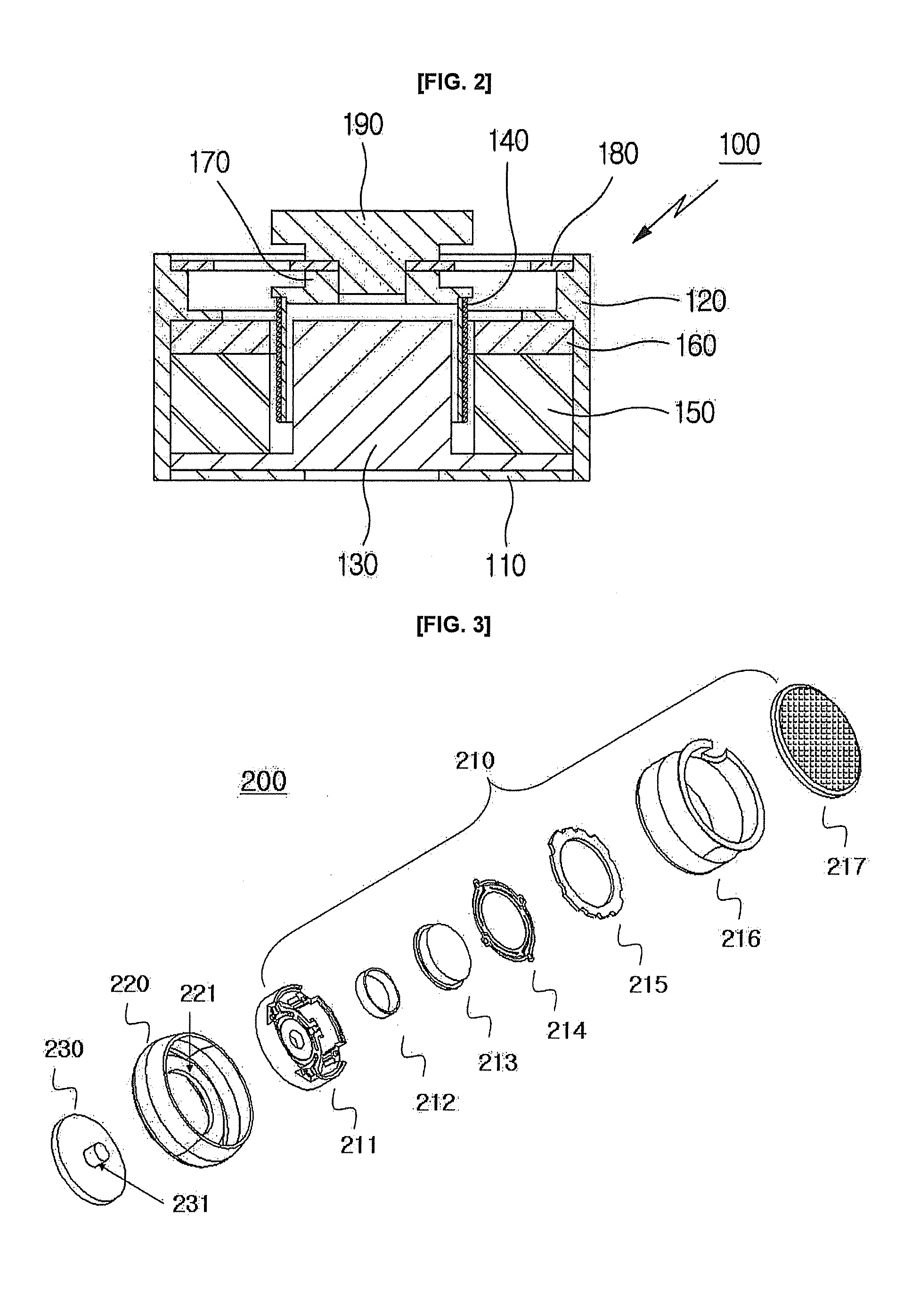

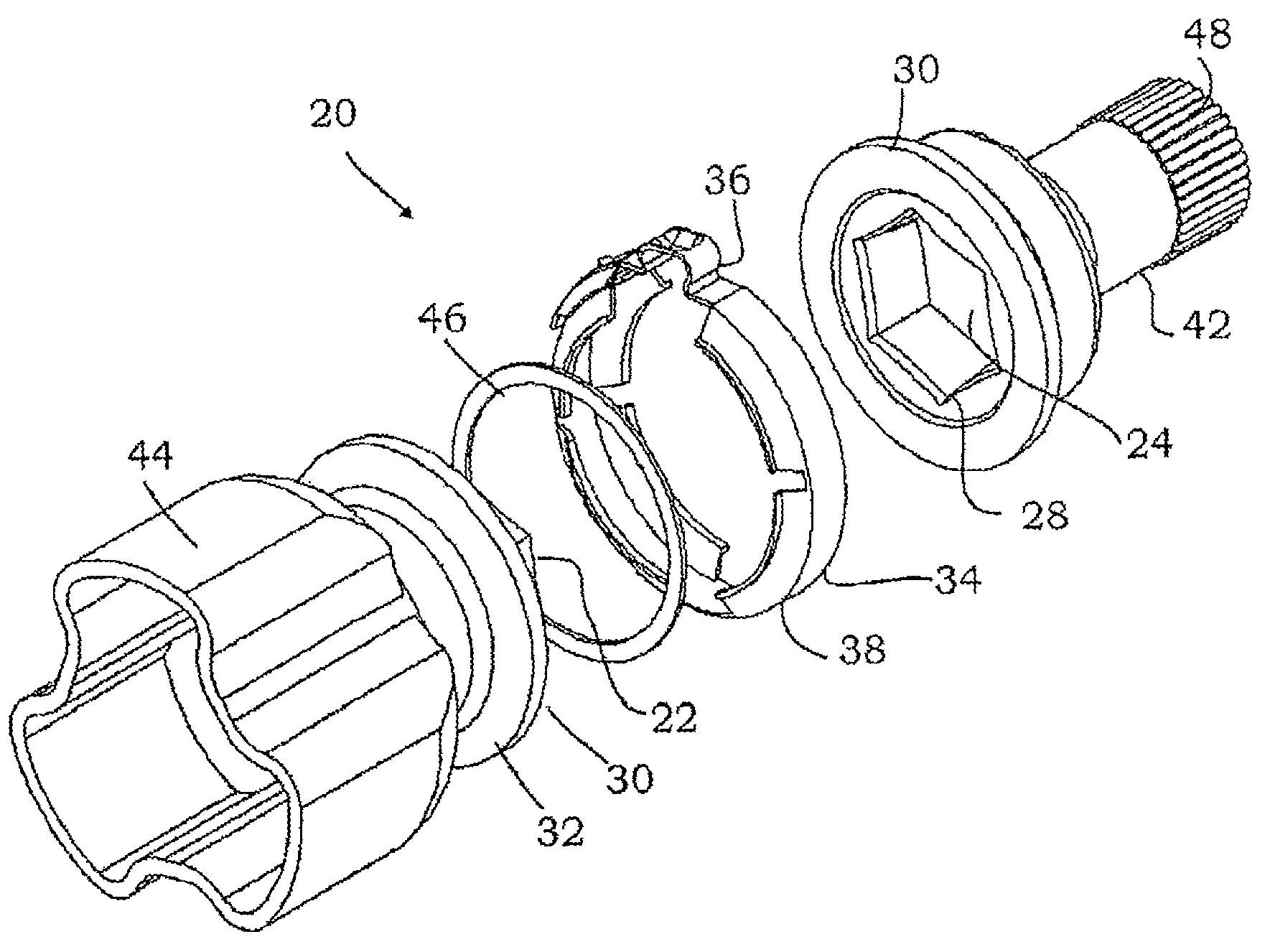

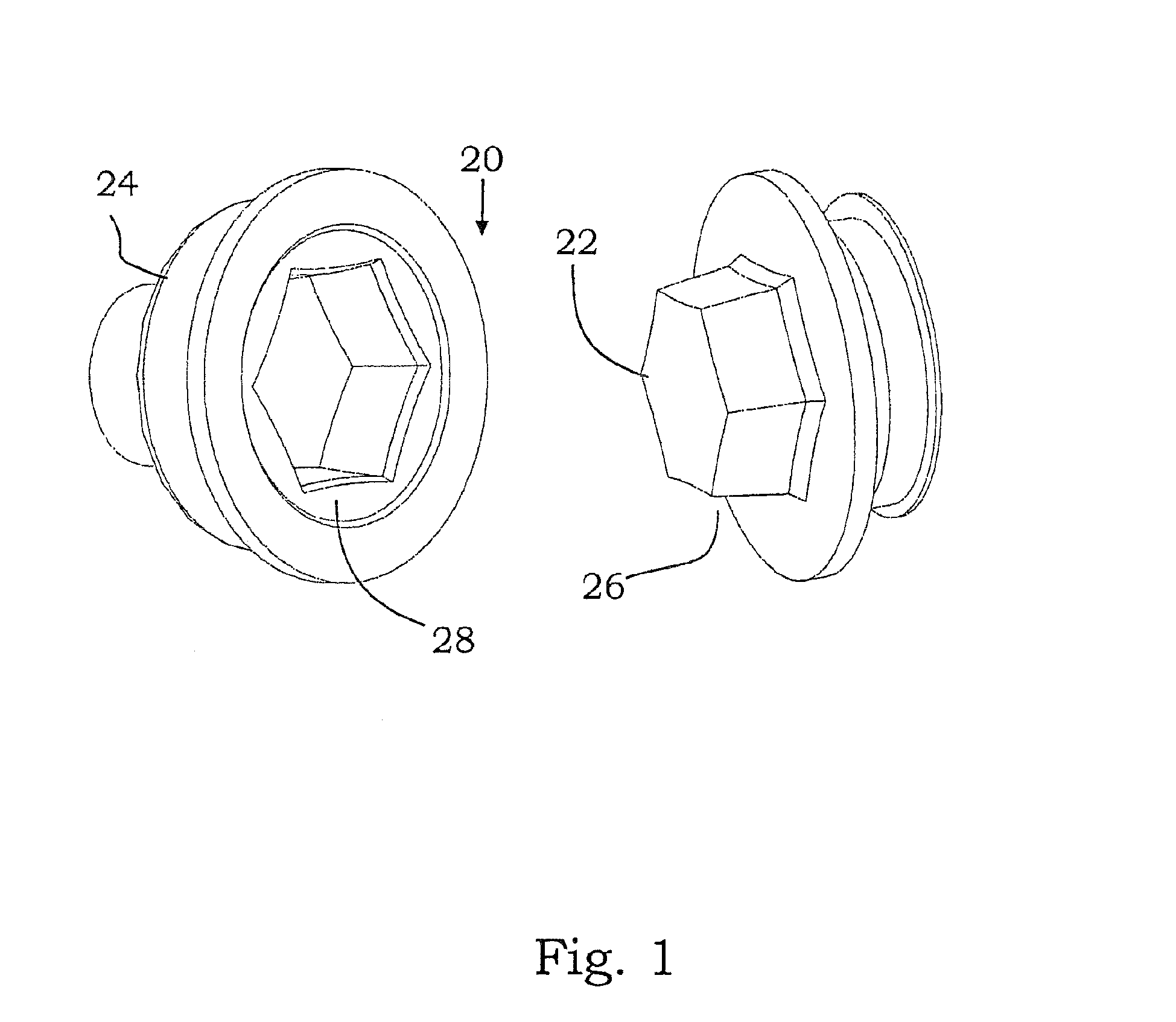

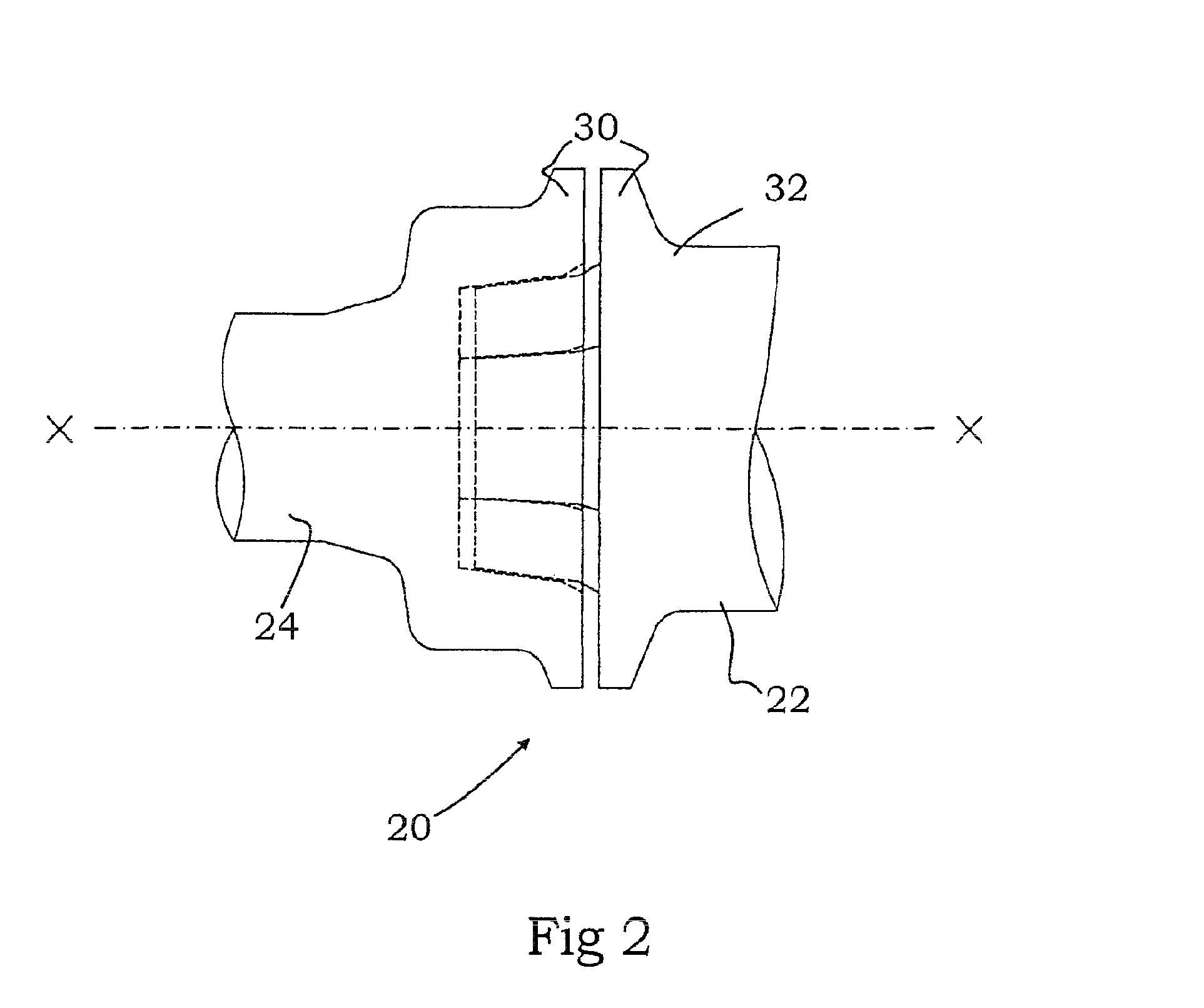

Fastener

InactiveUS20050123372A1Avoid serious impactImprove vibration resistanceRivetsNutsFastenerEngineering

A fastener in which a sleeve 3 and a plug 4 are put into concavo-convex engagement both before and after execution to exert an effect of preventing separation between the two and an effect of preventing loosening therebetween after execution and which can be released by a single action during disassembling. Before execution, the sleeve 3 and the plug 4 press fitted therein are positioned by concavo-convex engagement between a fitting protrusion 8 on the inner periphery of an expanding portion 7 and a neck portion 11 of the plug 4. After execution, the fitting protrusion 8 on the inner periphery of the expanding portion 7 as expanded put into concavo-convex engagement with a neck portion 10 of the plug 4 again, thereby exerting an effect of stopping loosening between the two with respect to vibration, etc. During disassembling, a striking force is given to an end of the plug 4 to release the expanded state by a single action, allowing immediate pulling-away of the fastener 1.

Owner:ZEN KENCHIKU SEKKEI JIMUSHO TOKIOTOKYO

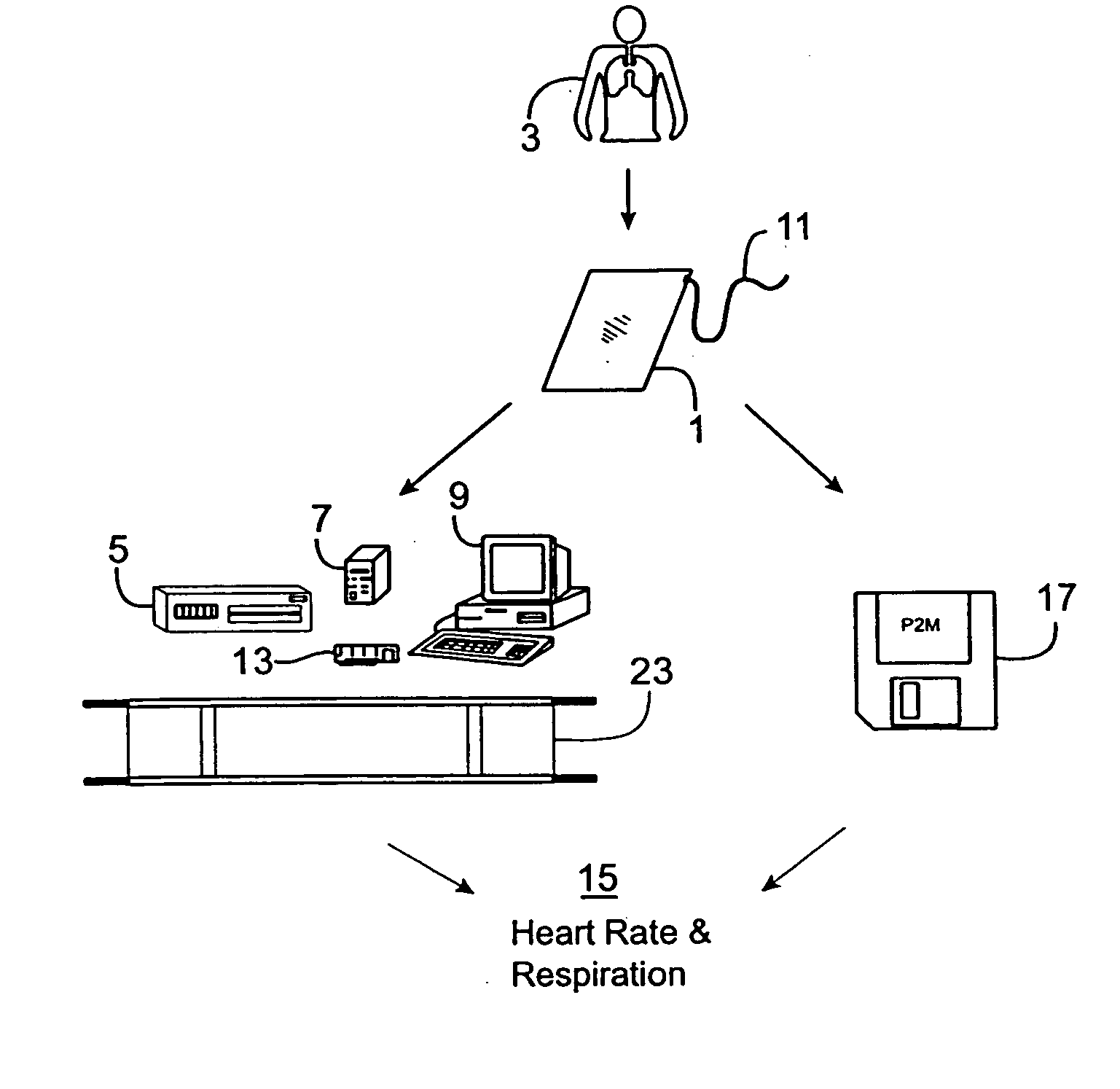

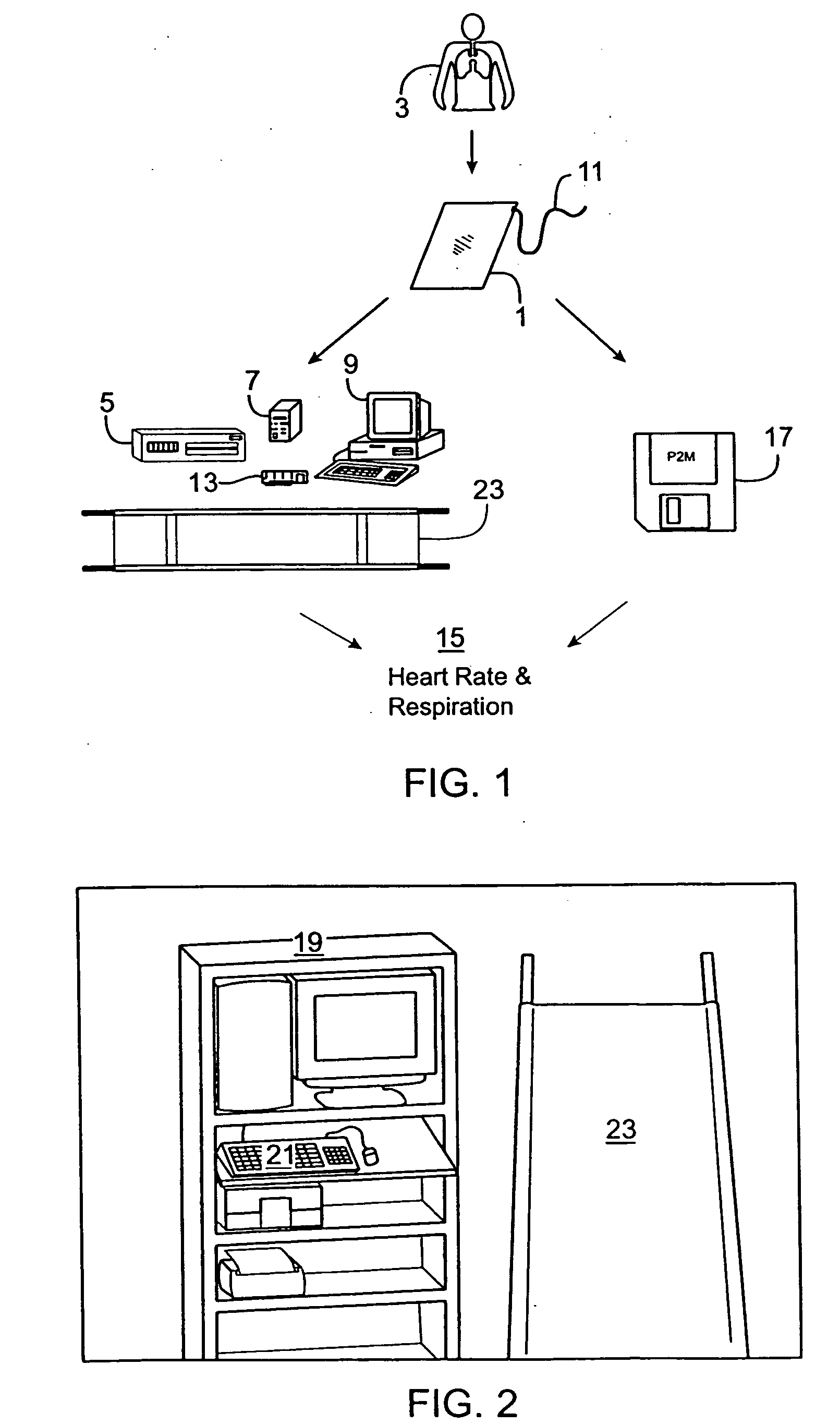

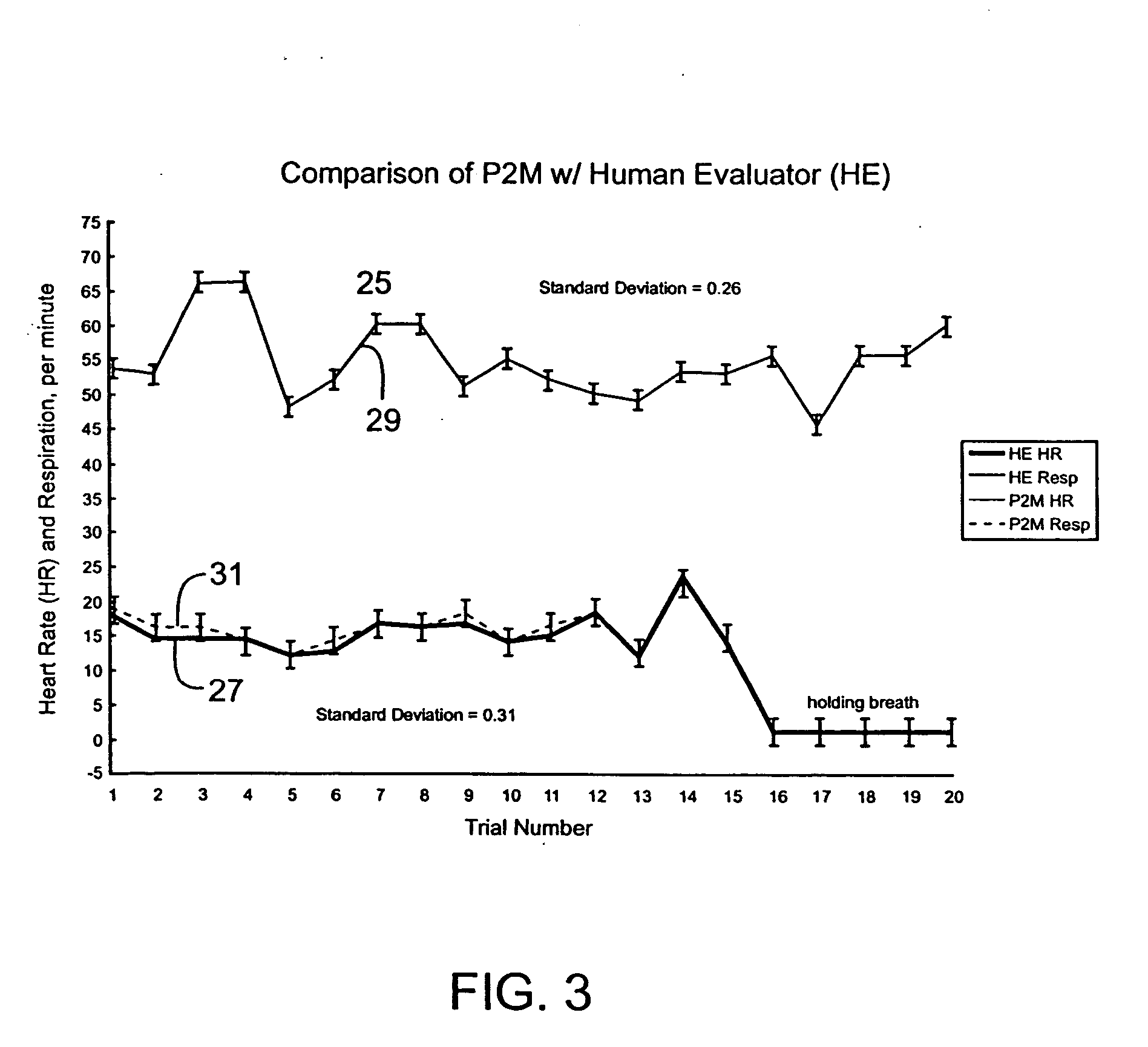

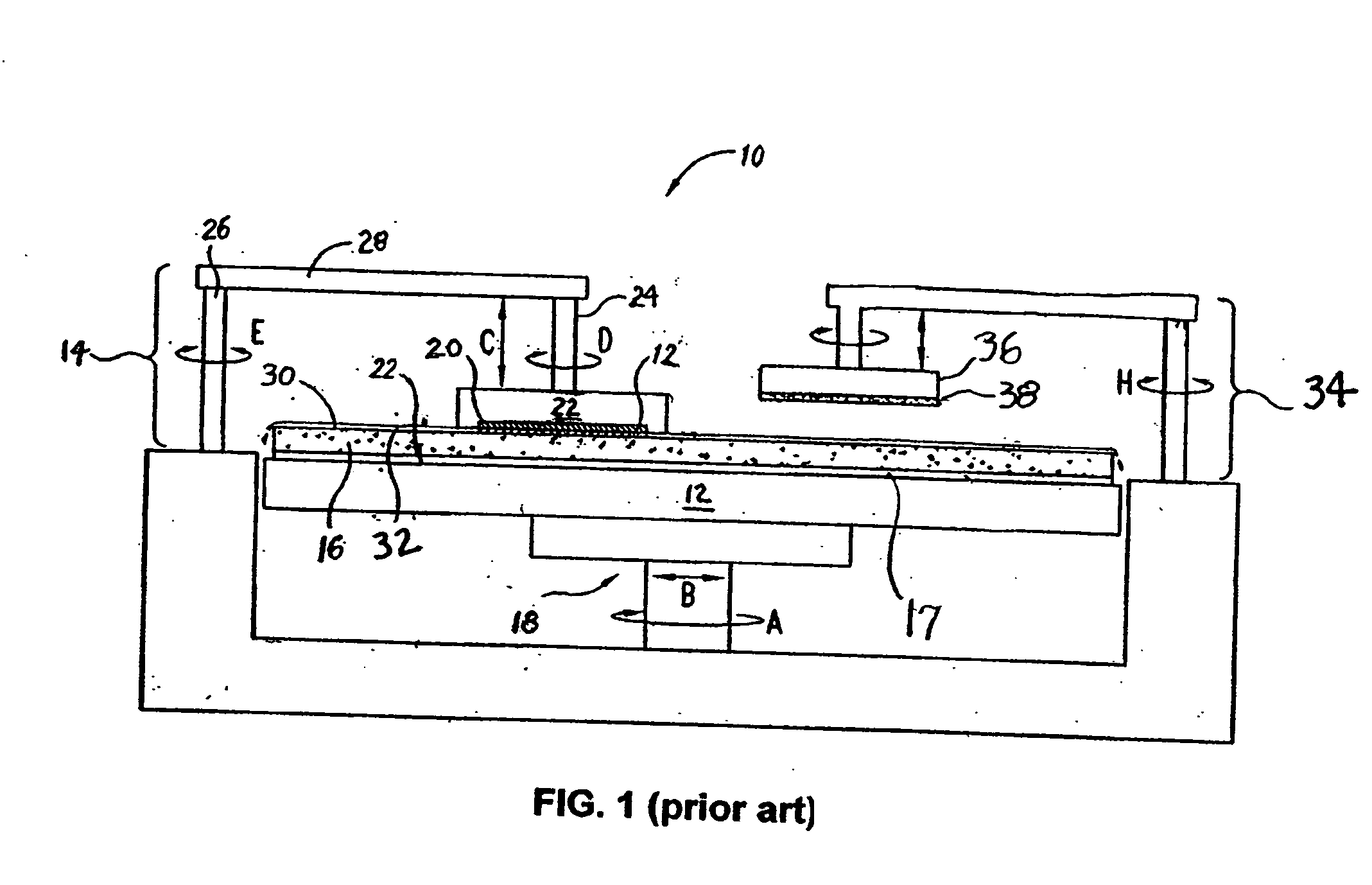

Passive physiological monitoring (P2M) system

InactiveUS20060063982A1Easy to deployAccurate measurementEvaluation of blood vesselsCatheterInternal bleedingBand-pass filter

Passive physiological monitoring apparatus and method has a sensor for sensing physiological phenomenon. A converter converts sensed data into electrical signals and a computer receives and computes the signals and outputs computed data for real-time interactive display. The sensor is a piezoelectric film of polyvinylidene fluoride. A band-pass filter filters out noise and isolates the signals to reflect data from the body. A pre-amplifier amplifies signals. Signals detected include mechanical, thermal and acoustic signatures reflecting cardiac output, cardiac function, internal bleeding, respiratory, pulse, apnea, and temperature. A pad may incorporate the PVDF film and may be fluid-filled. The film converts mechanical energy into analog voltage signals. Analog signals are fed through the band-pass filter and the amplifier. A converter converts the analog signals to digital signals. A Fourier transform routine is used to transform into the frequency domain. A microcomputer is used for recording, analyzing and displaying data for on-line assessment and for providing realtime response. A radio-frequency filter may be connected to a cable and the film for transferring signals from the film through the cable. The sensor may be an array provided in a MEDEVAC litter or other device for measuring acoustic and hydraulic signals from the body of a patient for field monitoring, hospital monitoring, transport monitoring, home, remote monitoring.

Owner:HOANA MEDICAL

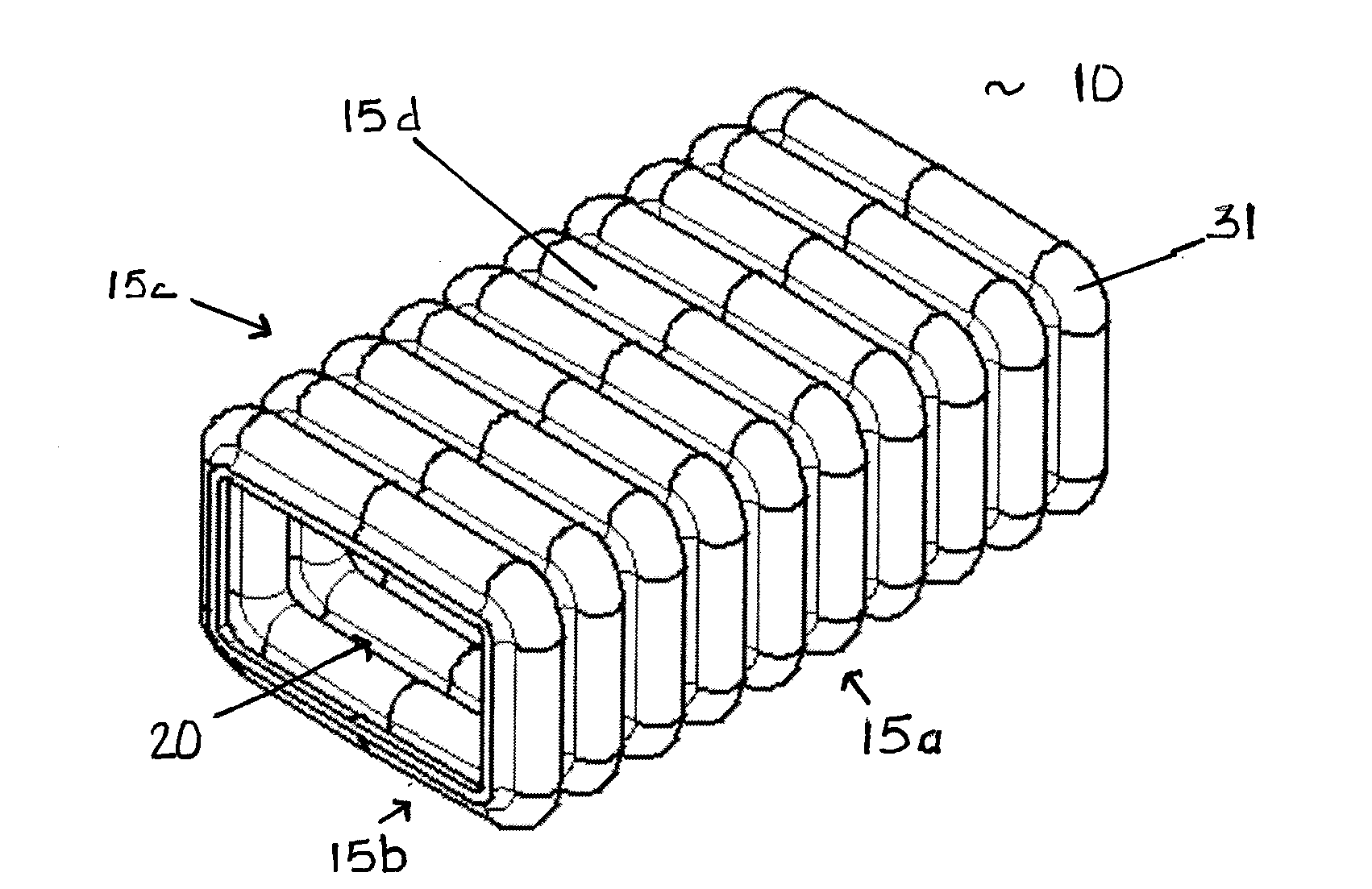

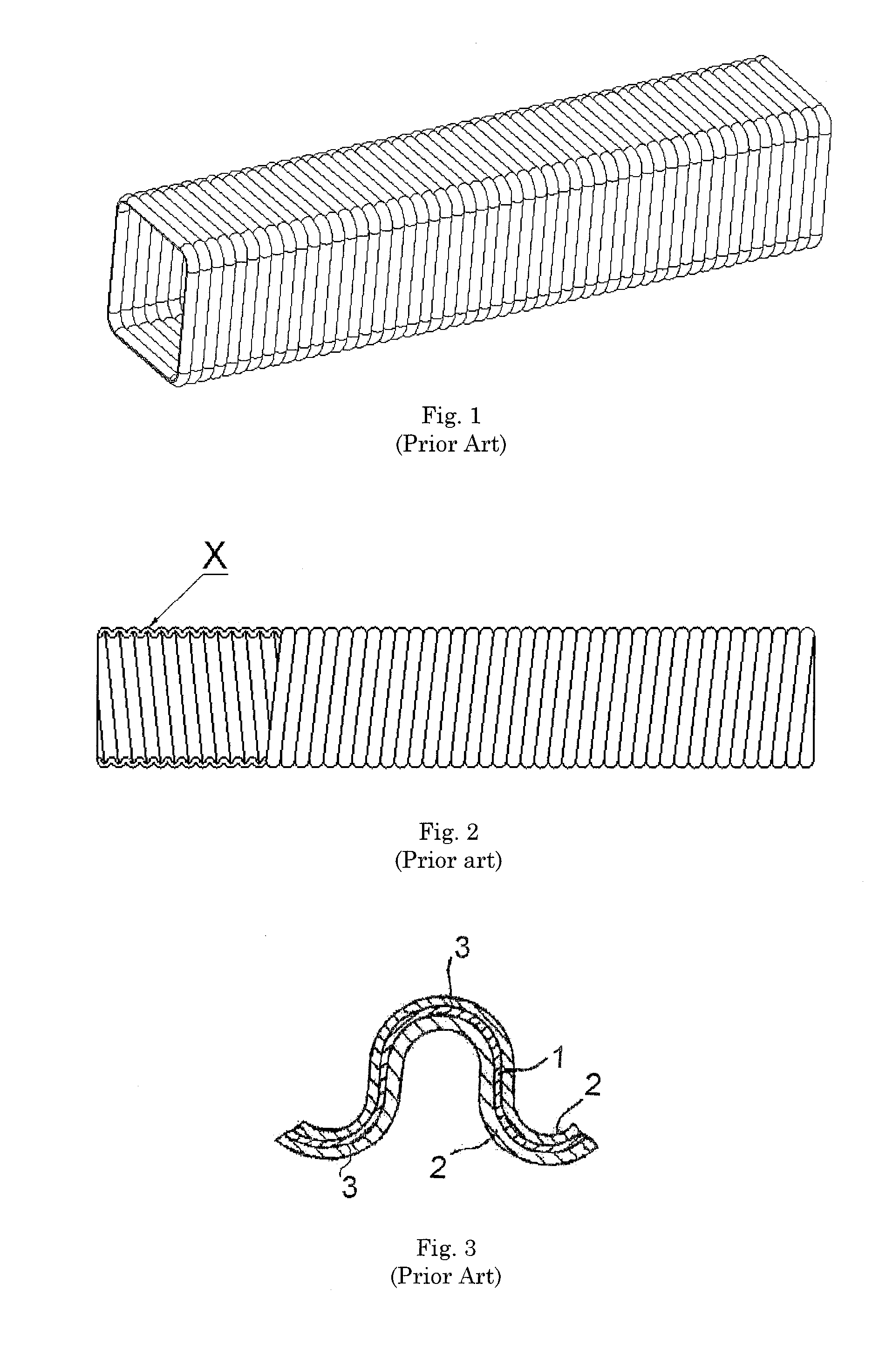

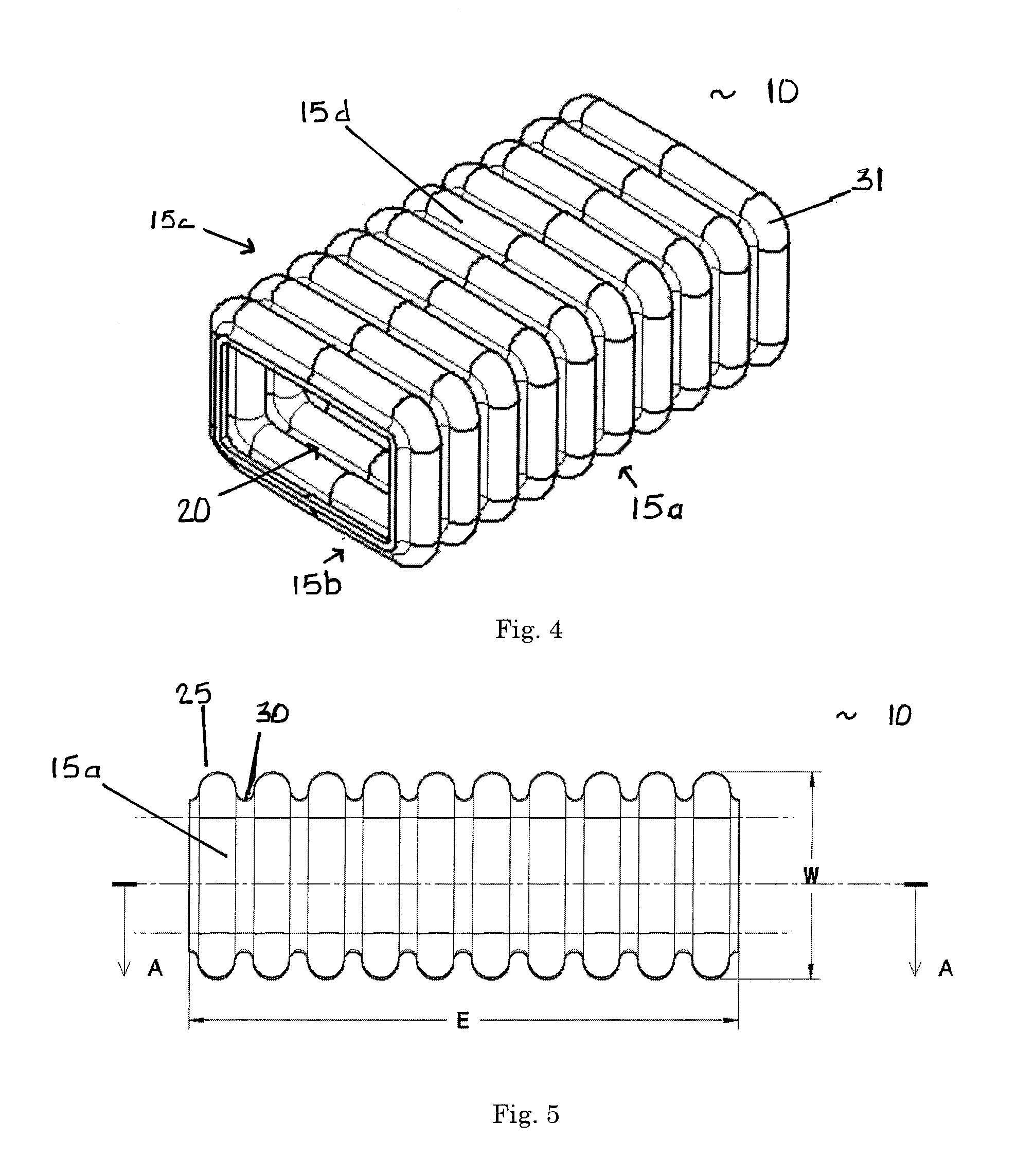

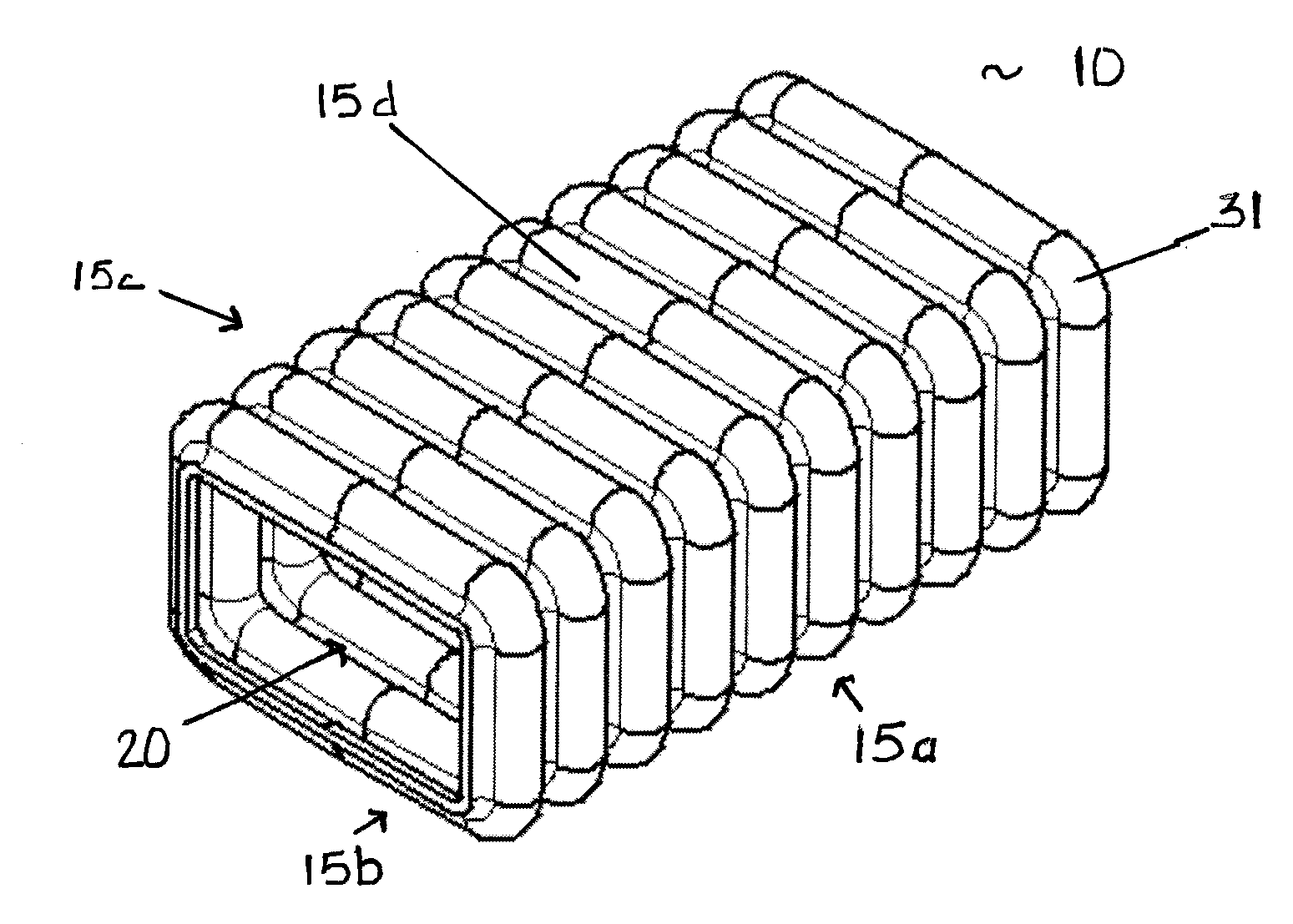

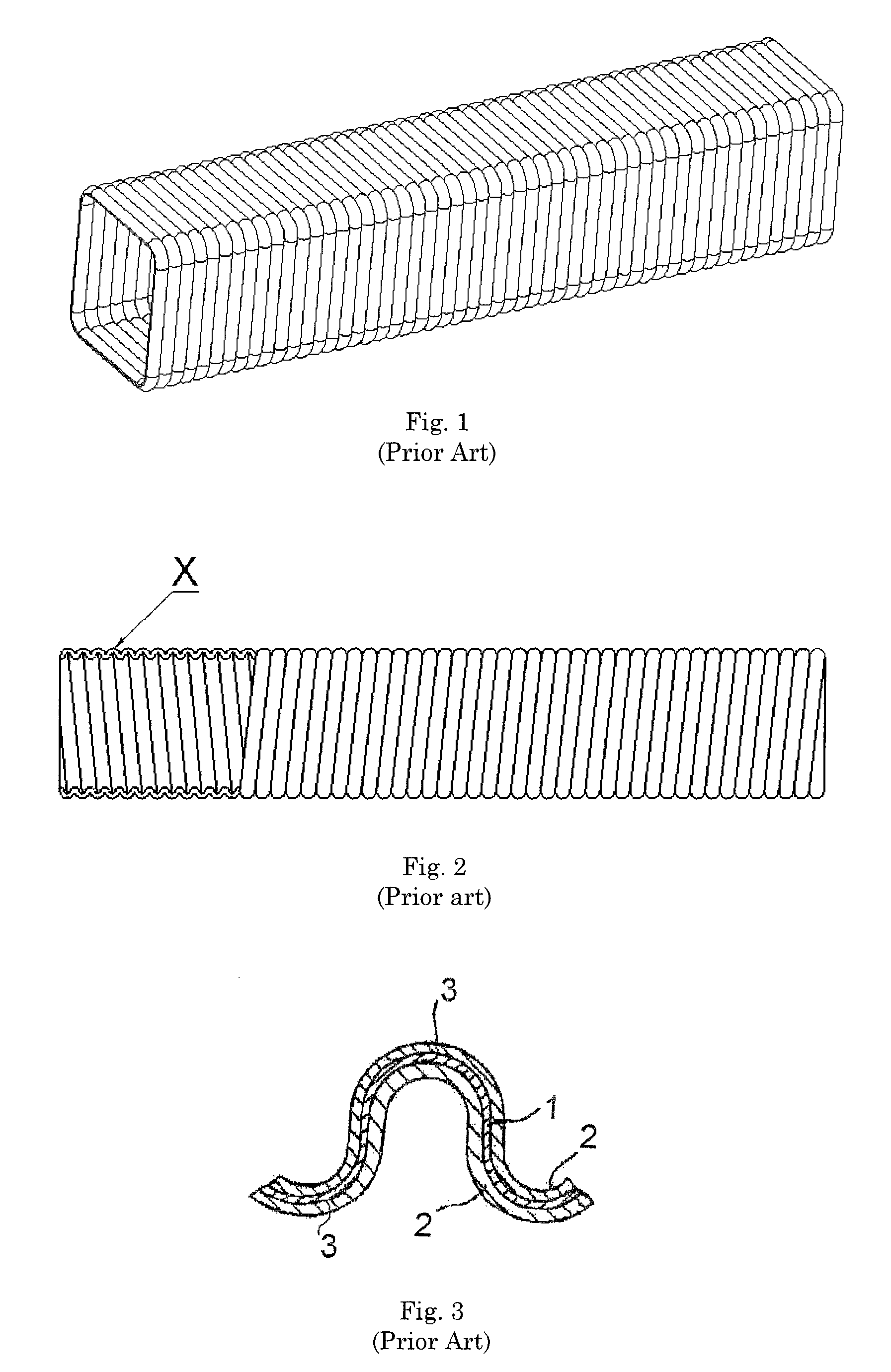

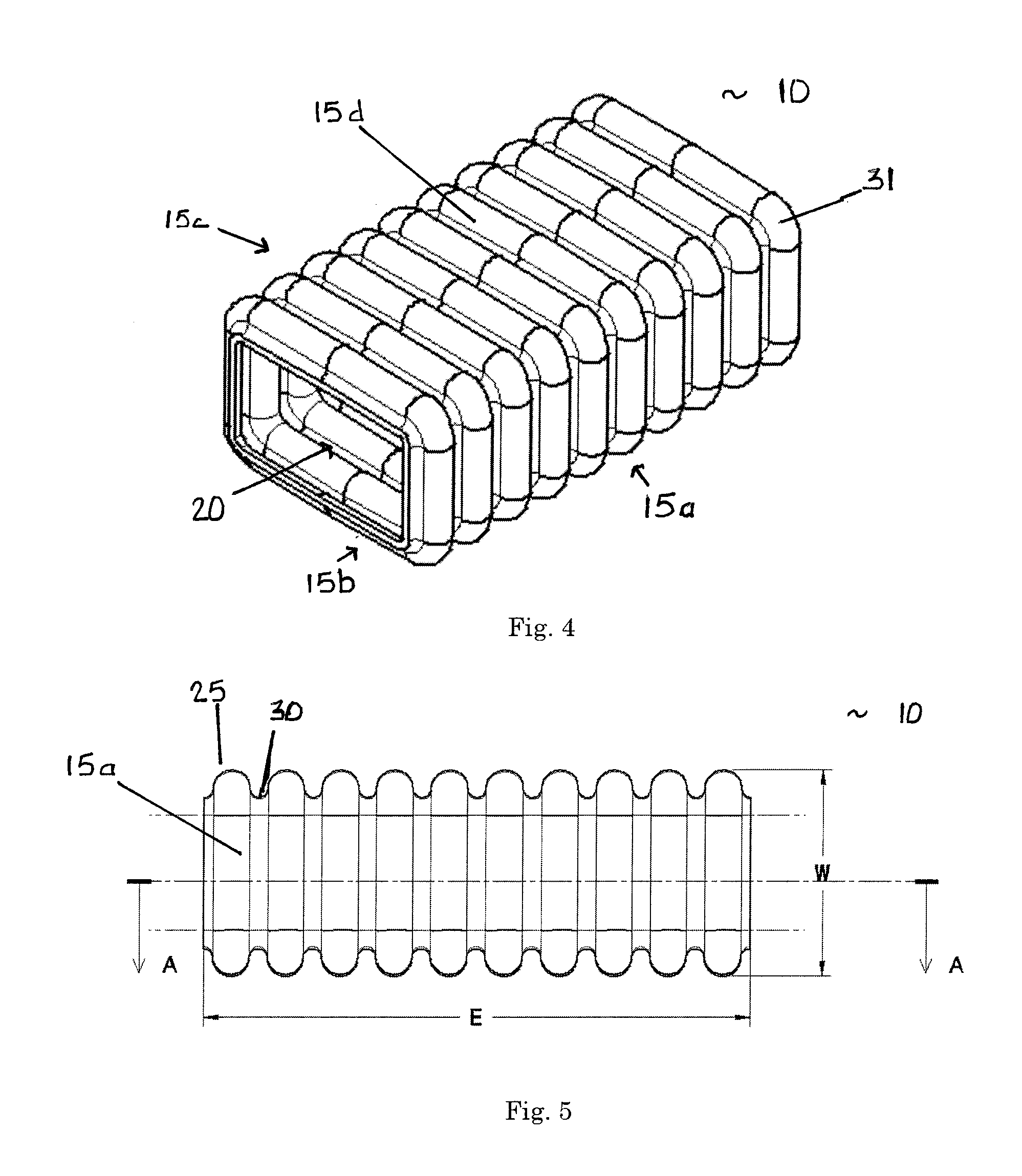

Corrugated tubular energy absorbing structure

ActiveUS20080036242A1Efficiently absorb impact energyLow costVehicle seatsPedestrian/occupant safety arrangementEnergy absorbingEngineering

An energy absorbing tubular structure is formed of a molded or extruded polymer. The tube has a quadrangular cross-section with rounded corners. The walls of tube are corrugated with alternating convex and concave corrugations surfaces having a continuous constant radius, preferably with no flat spots. The corrugated walls have a constant thickness. The corrugations progressively deform during impact thereby providing a near perfect square wave force vs. deflection energy absorption curve at any predetermined nearly constant force level. The tube may be filled with polymer foam to vary the impact performance of the structure.

Owner:O FLEX GRP

System for Reducing Vibrations in a Pressure Pumping Fleet

ActiveUS20170037717A1Reduce turbulenceSimple flowAC motor controlFlexible member pumpsPipingEngineering

Owner:US WELL SERVICS LLC

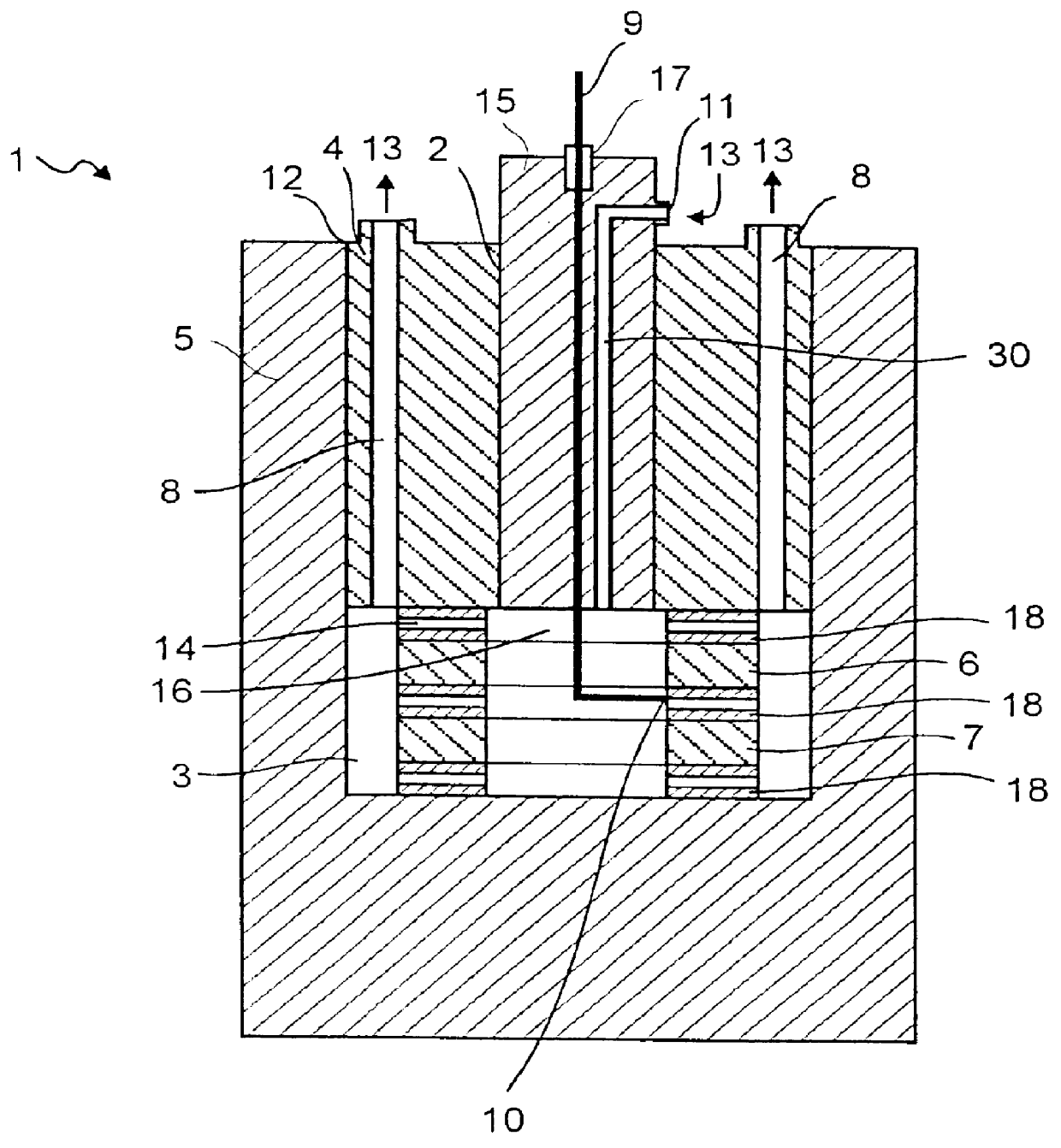

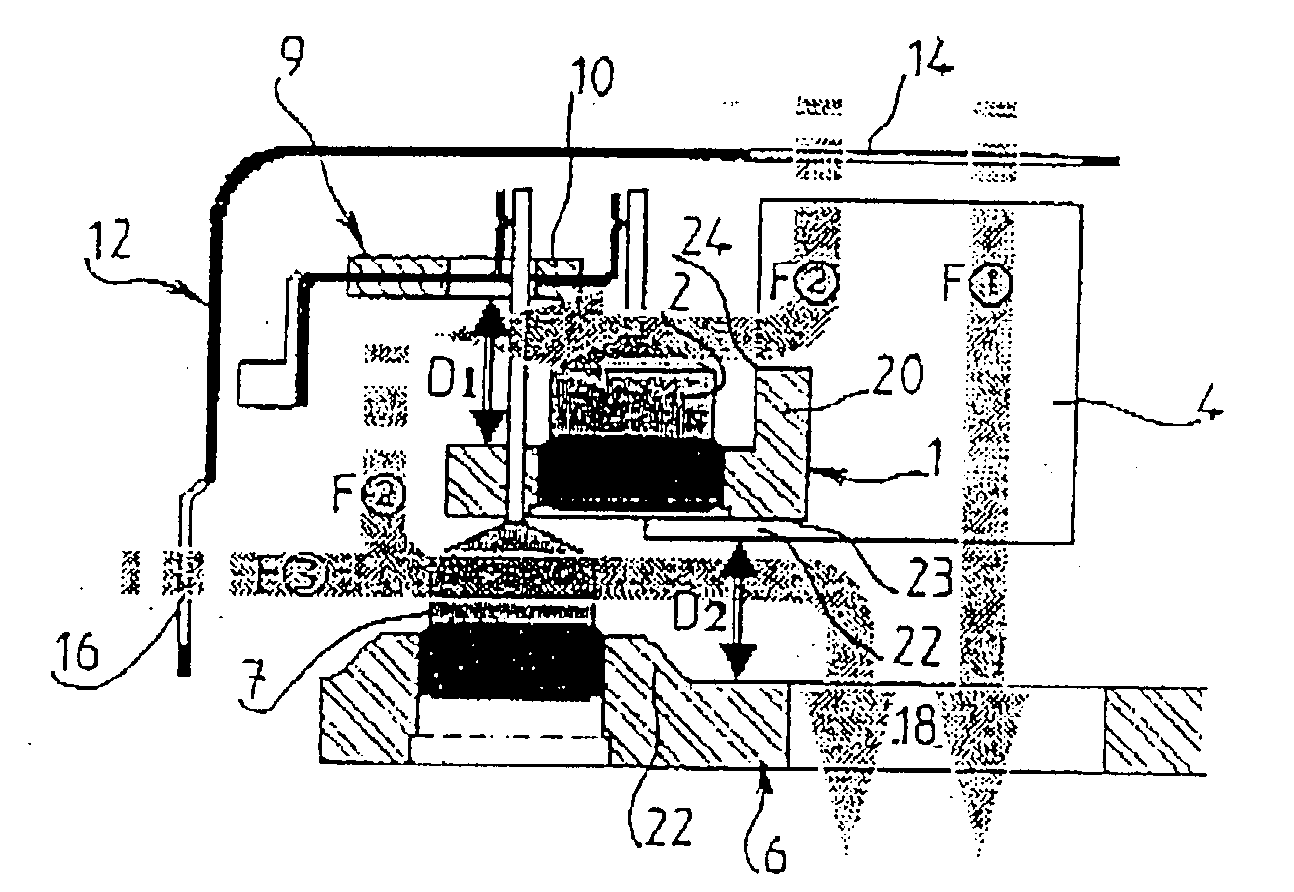

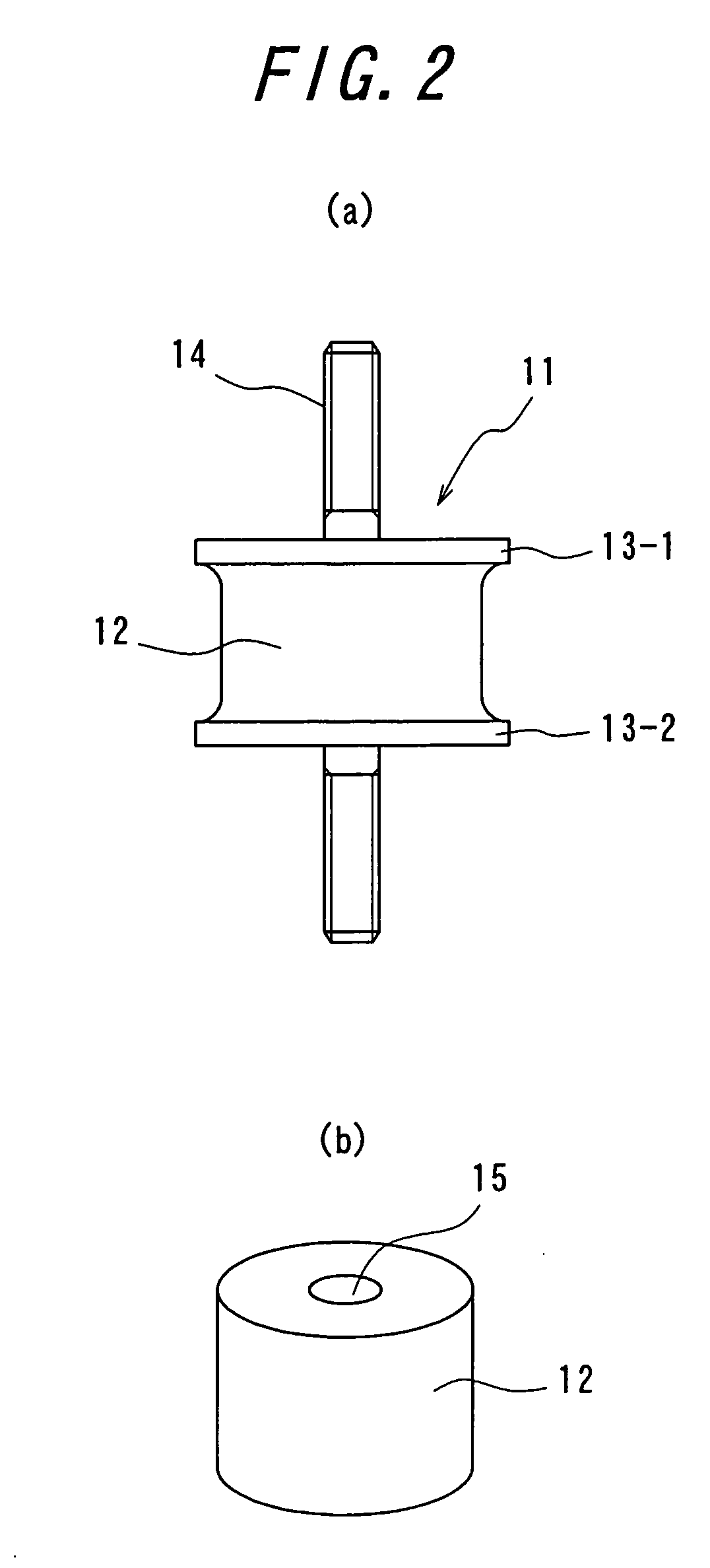

High power ultrasonic transducer

InactiveUS6137209AImprove efficiencyVibration highUltrasonic/sonic/infrasonic diagnosticsPiezoelectric/electrostriction/magnetostriction machinesElectricityUltrasonic sensor

A method to improve the high output characteristics of a ultrasonic transducer 1 by urging a cooling gas 13 to flow through the transducer, thereby passing a cooling member 18 between at least one pair of adjacent piezoelectric elements 6, 7. In a preferred embodiment sulfurhexafluoride (SF6) is used as cooling gas.

Owner:ULTRASONUS

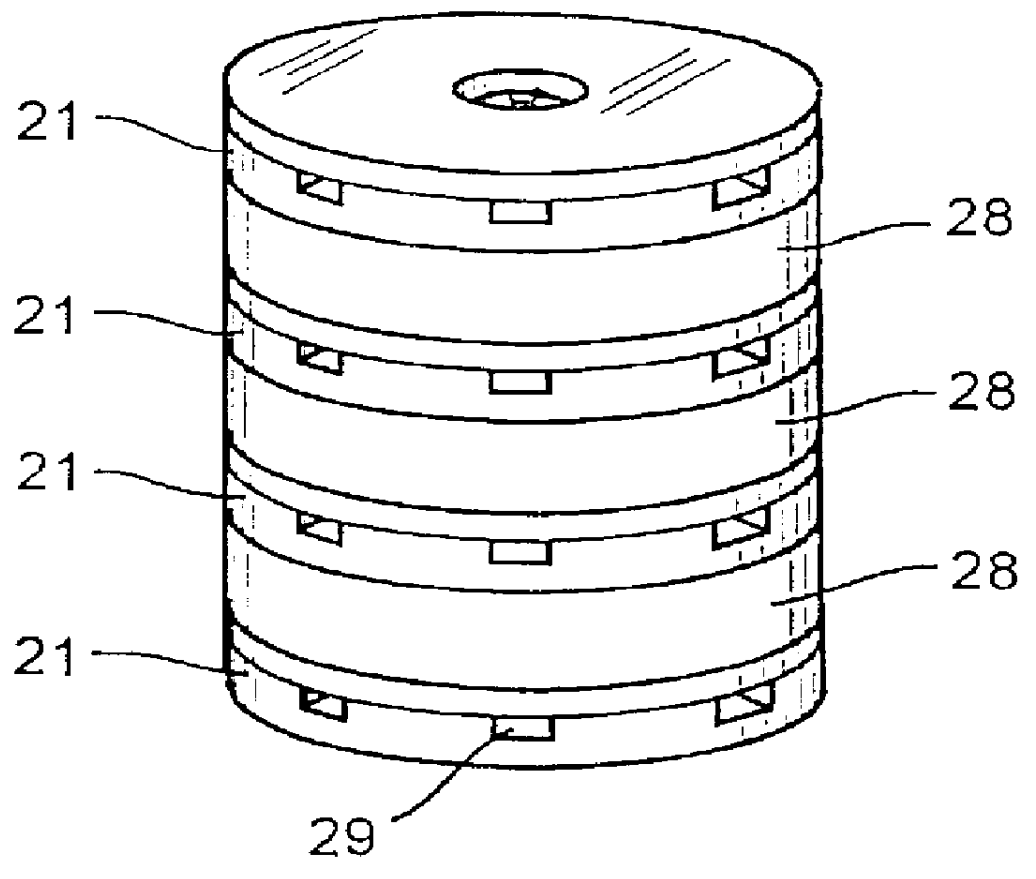

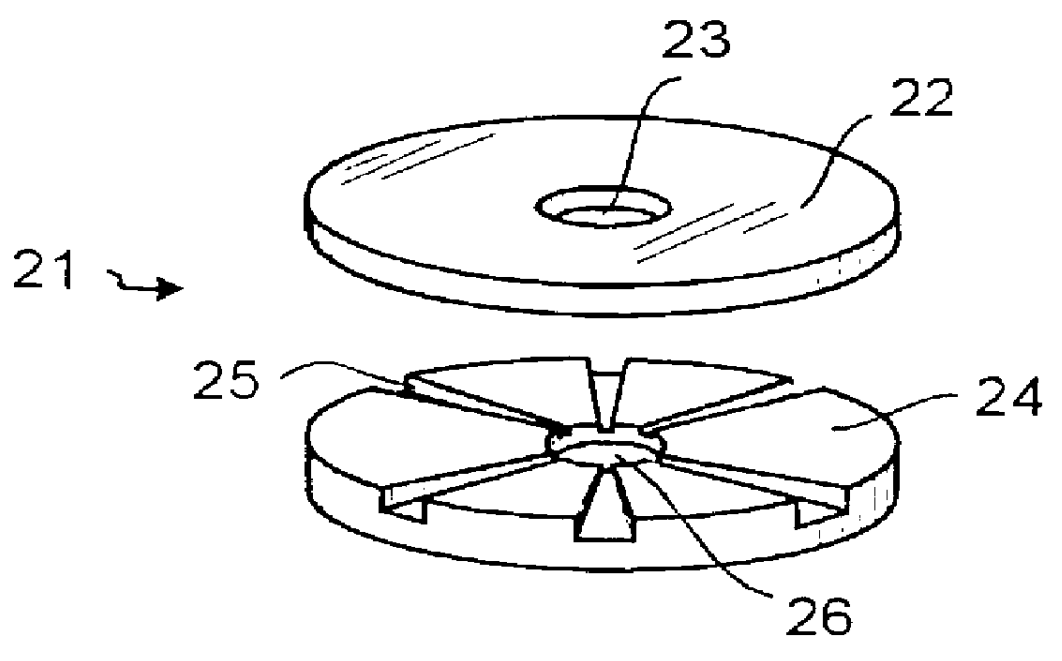

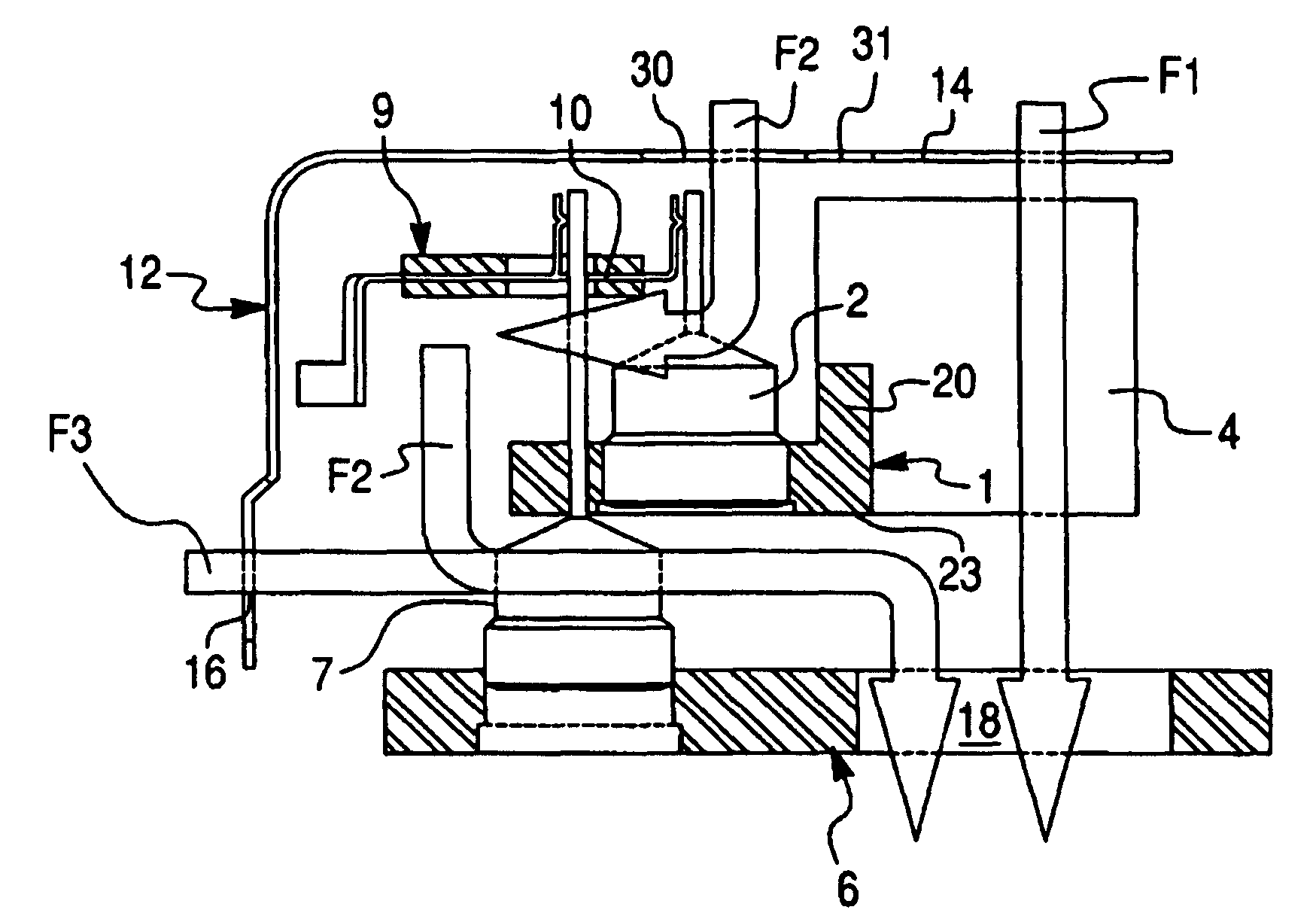

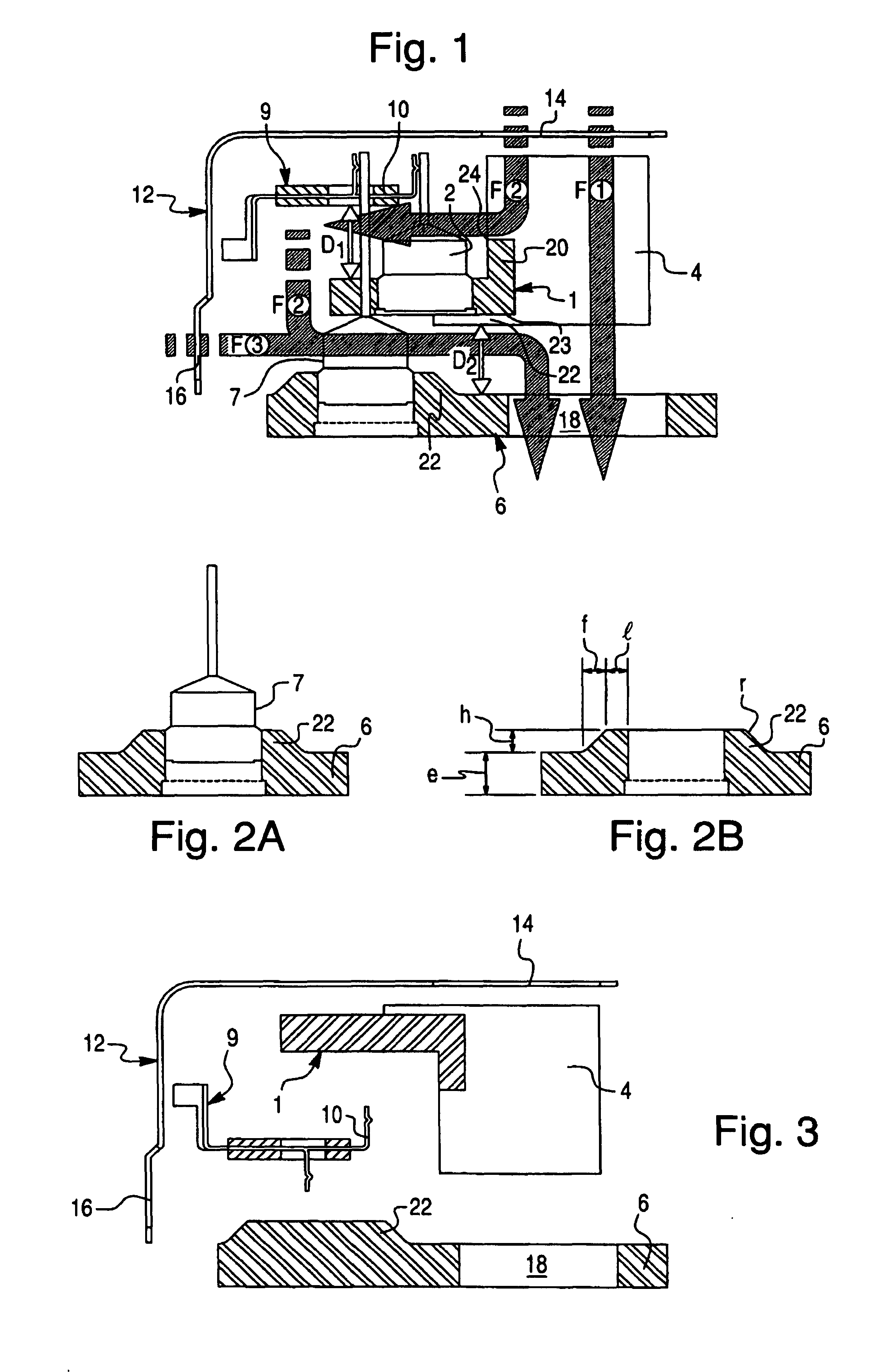

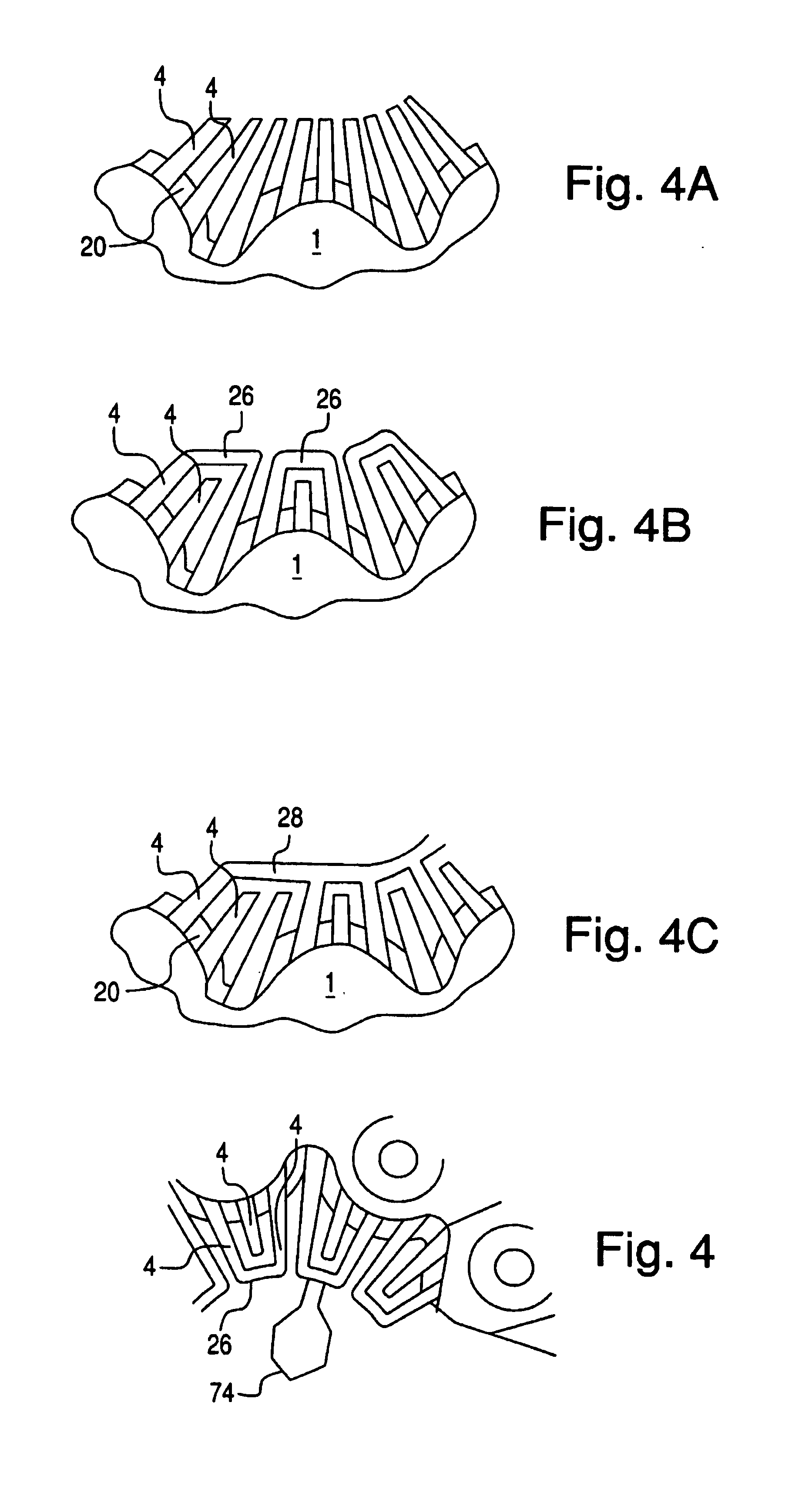

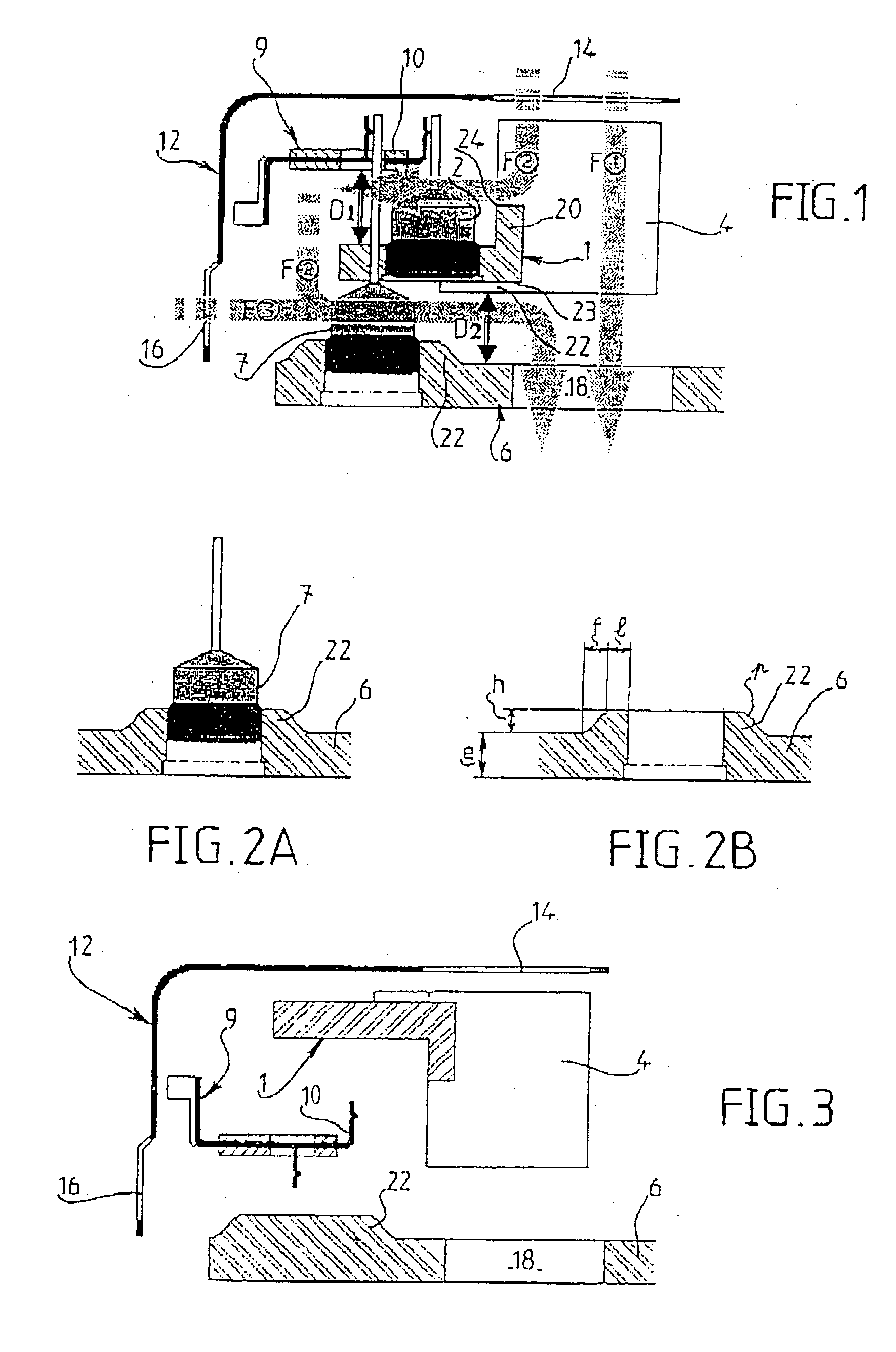

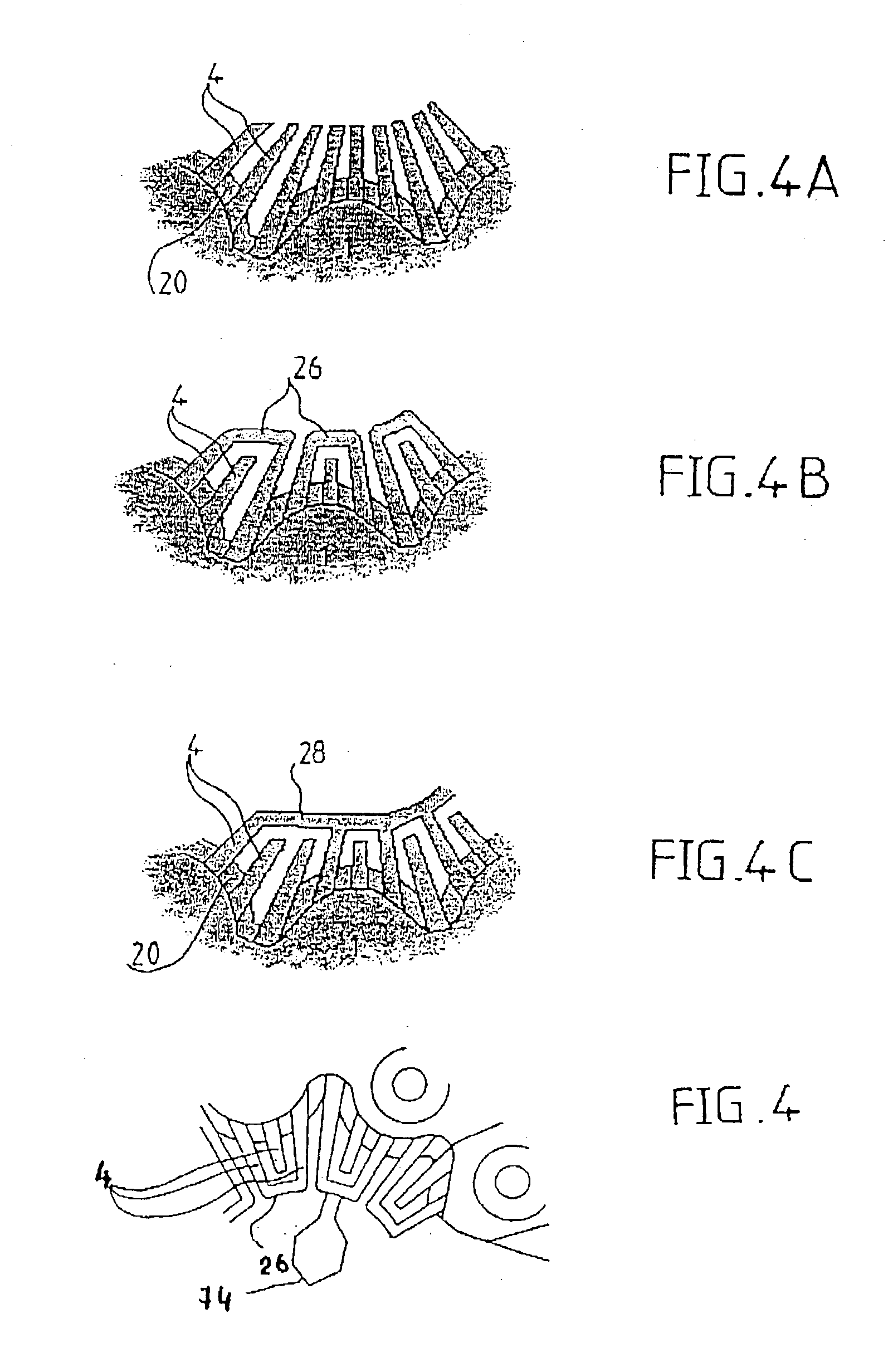

Current rectifier assembly for rotating electrical machines, in particular motor vehicle alternator

InactiveUS7019424B2Easy to assembleEliminates transferSynchronous generatorsMagnetic circuit rotating partsAlternatorMotor vehicle part

Current rectifying equipment for rotary electrical machines has a rear bearing, of the type comprising a plurality of positive diodes (2) supported by a support (1) in the form of a plate, a plurality of negative diodes (7) supported by the rear bearing (6) of the machine, a device (9) for connecting the positive and negative diodes together, and structure for generating a forced axial stream of a coolant fluid, the support (1) for the diodes carrying cooling fins (4) which extend in the axial stream (F1) of the coolant fluid in the radial direction of the machine. The equipment includes means for effecting mixed cooling of the support for the negative diodes by convection and conduction. The invention can be used for alternators for motor vehicles.

Owner:VALEO EQUIP ELECTRIC MOTEUR

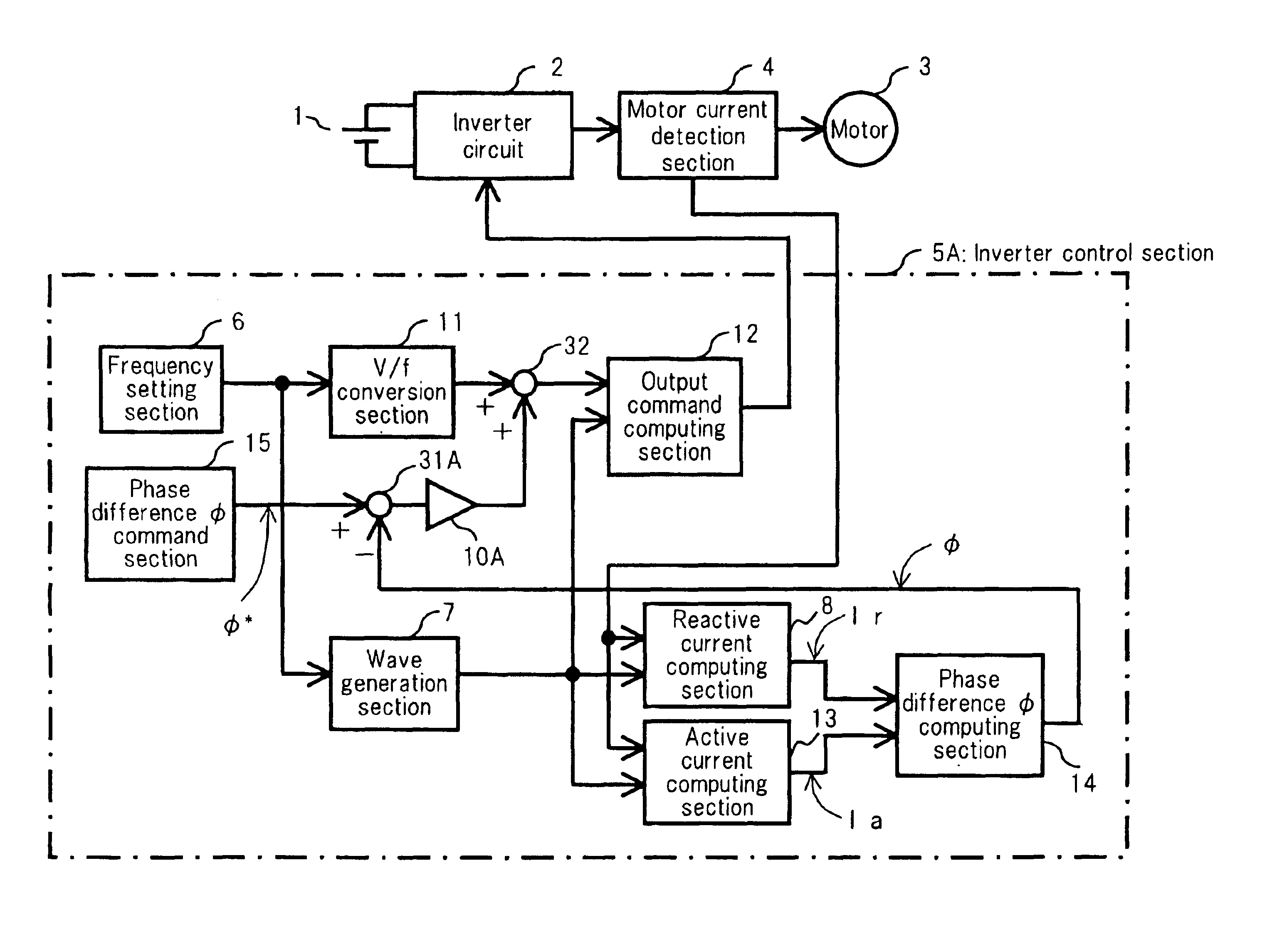

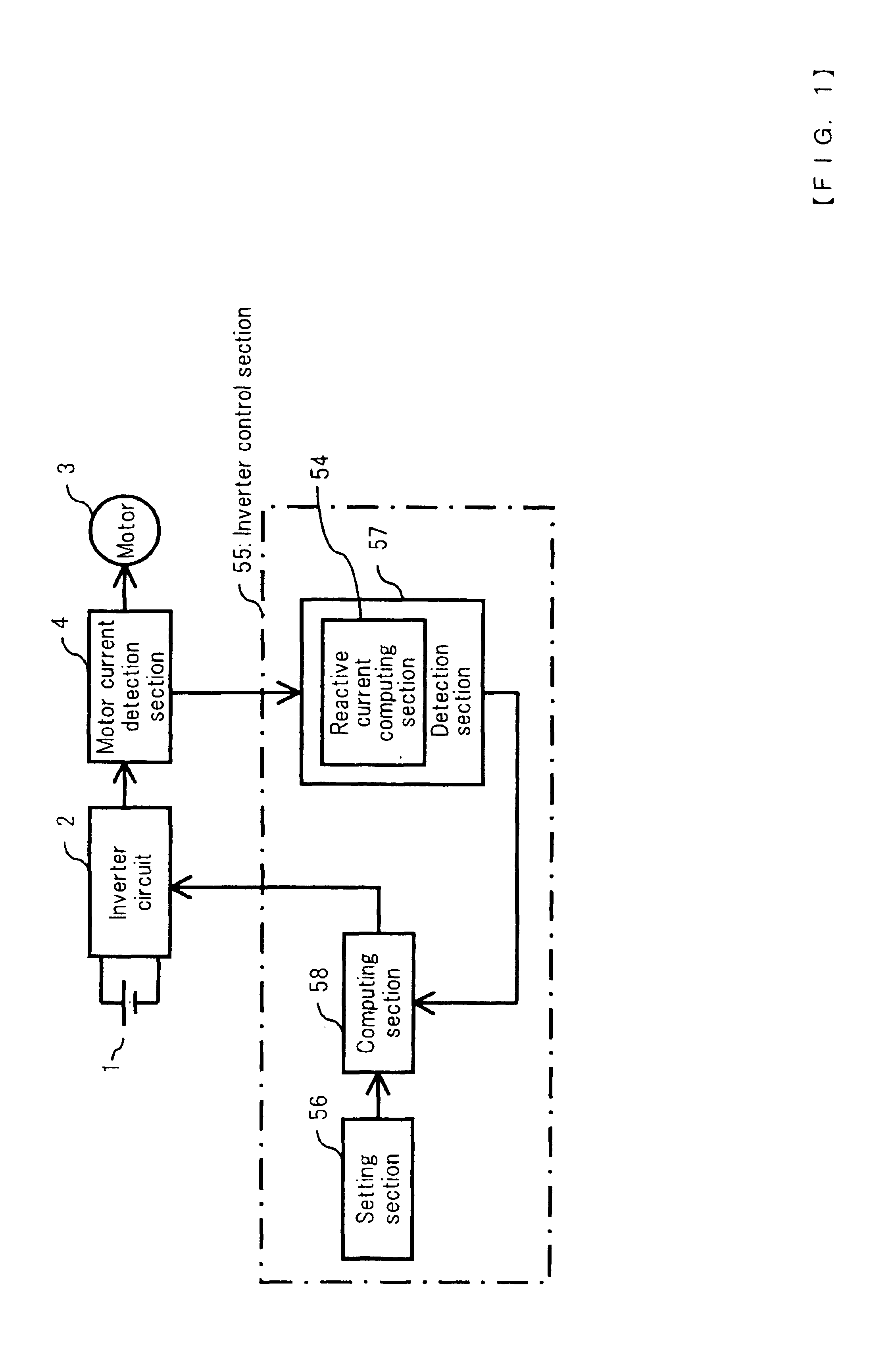

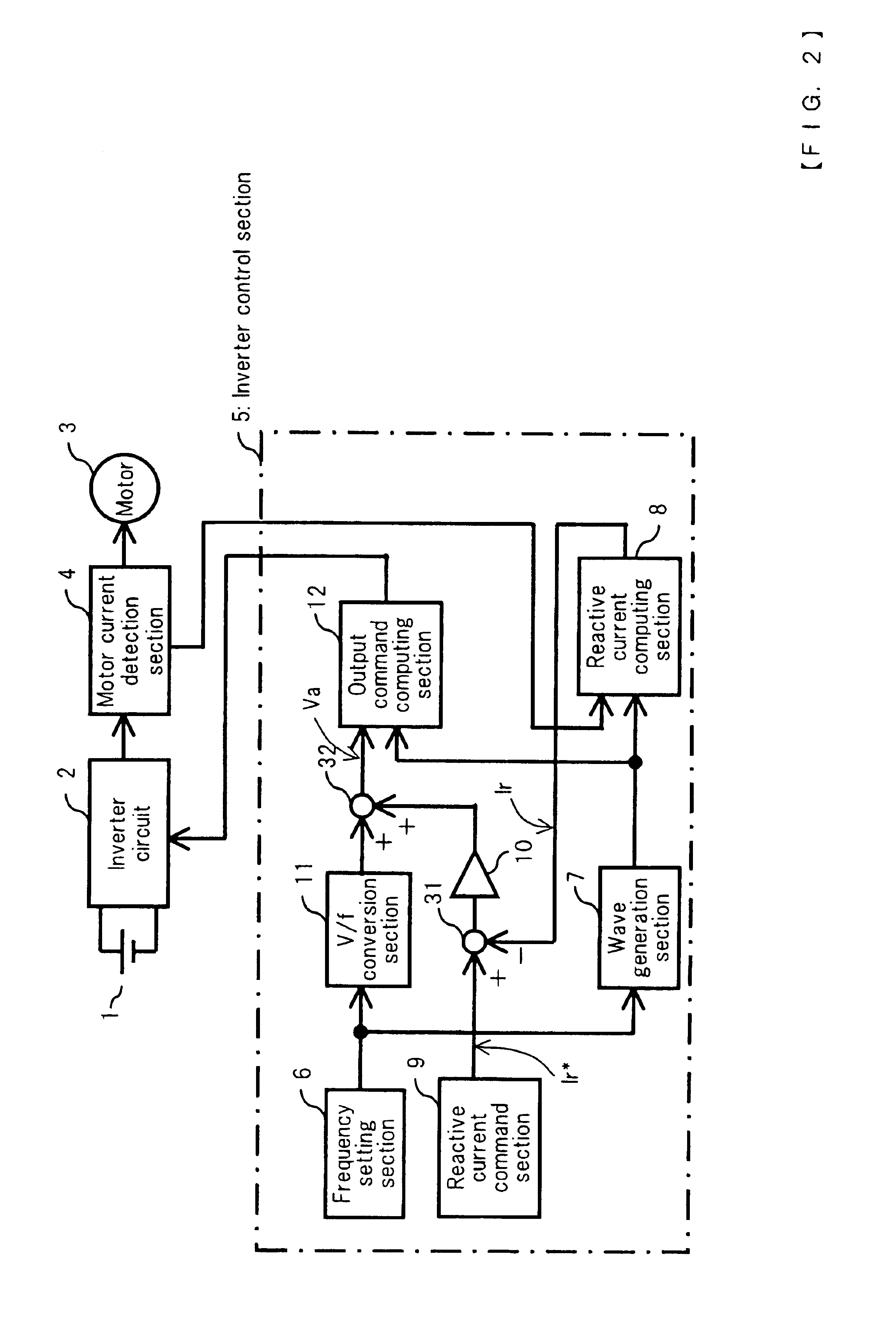

Electric motor controller

InactiveUS6850031B2Improve efficiencyReduce noiseAC motor controlDC motor speed/torque controlSynchronous motorElectric machine

The present invention provides a motor controller capable of driving a synchronous motor having no position sensor stably at high efficiency by carrying out simple control. In order to attain this purpose, a reactive current is obtained from a motor current and a rotation phase, an error voltage is obtained from the reactive current and the command value of the reactive current, thereby obtaining a motor applied voltage command value Va that is used to compensate for the V / f characteristic of the motor. Furthermore, the motor applied voltage command value Va is applied to an output command computing section, and computed with the rotation phase signal of a wave generation section, thereby obtaining a signal for PWM driving the switching devices of an inverter circuit.

Owner:PANASONIC CORP

Current rectifier assembly for rotating electrical machines, in particular motor vehicle alternator

InactiveUS20030178899A1Easy to assembleEliminates transferSynchronous generatorsDynamo-electric brakes/clutchesMobile vehicleAlternator

The invention relates to current rectifying equipment for rotary electrical machines having a rear bearing, of the type comprising a plurality of positive diodes (2) supported by a support (1) in the form of a plate, a plurality of negative diodes (7) supported by the rear bearing (6) of the machine, a device (9) for connecting the positive and negative diodes together, and means for generating a forced axial stream of a coolant fluid, the support (1) for the diodes carrying cooling fins (4) which extend in the said axial stream (F1) of the coolant fluid in the radial direction of the machine. The equipment is characterised in that it includes means for effecting mixed cooling of the support for the negative diodes by convection and conduction. The invention can be used for alternators for motor vehicles.

Owner:VALEO EQUIP ELECTRIC MOTEUR

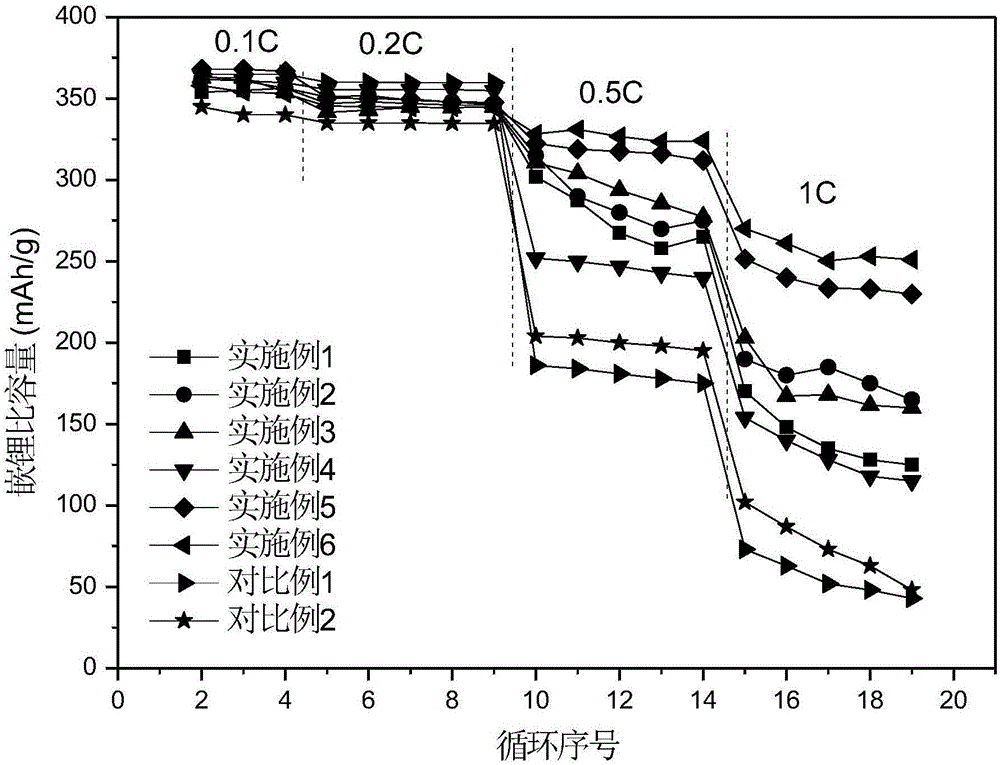

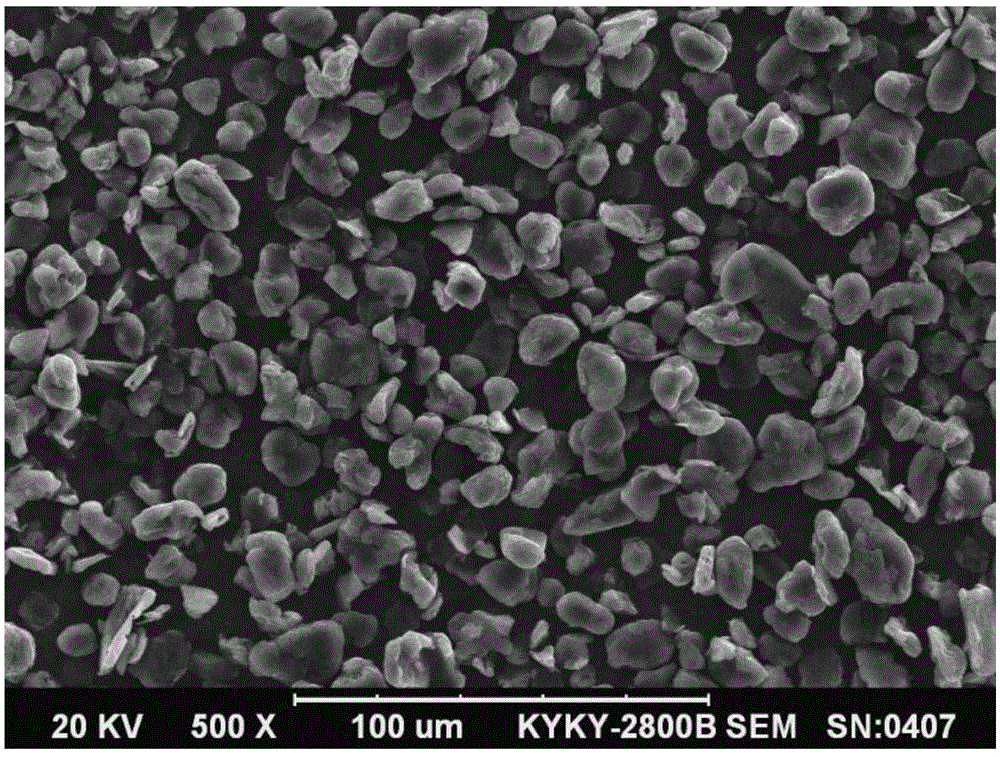

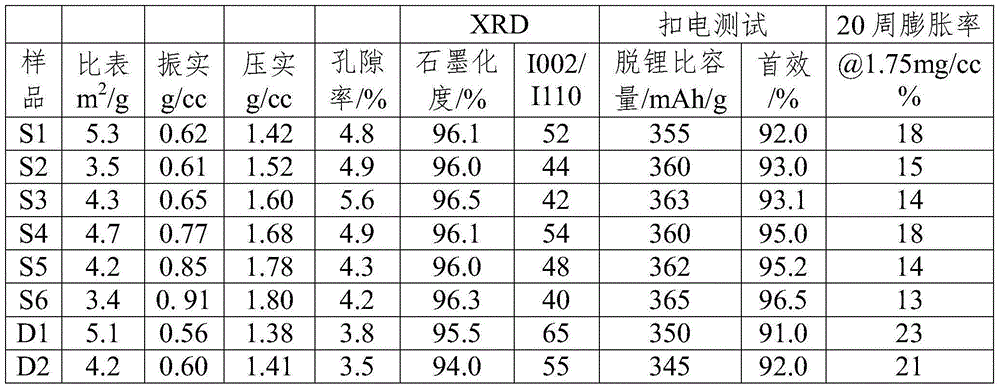

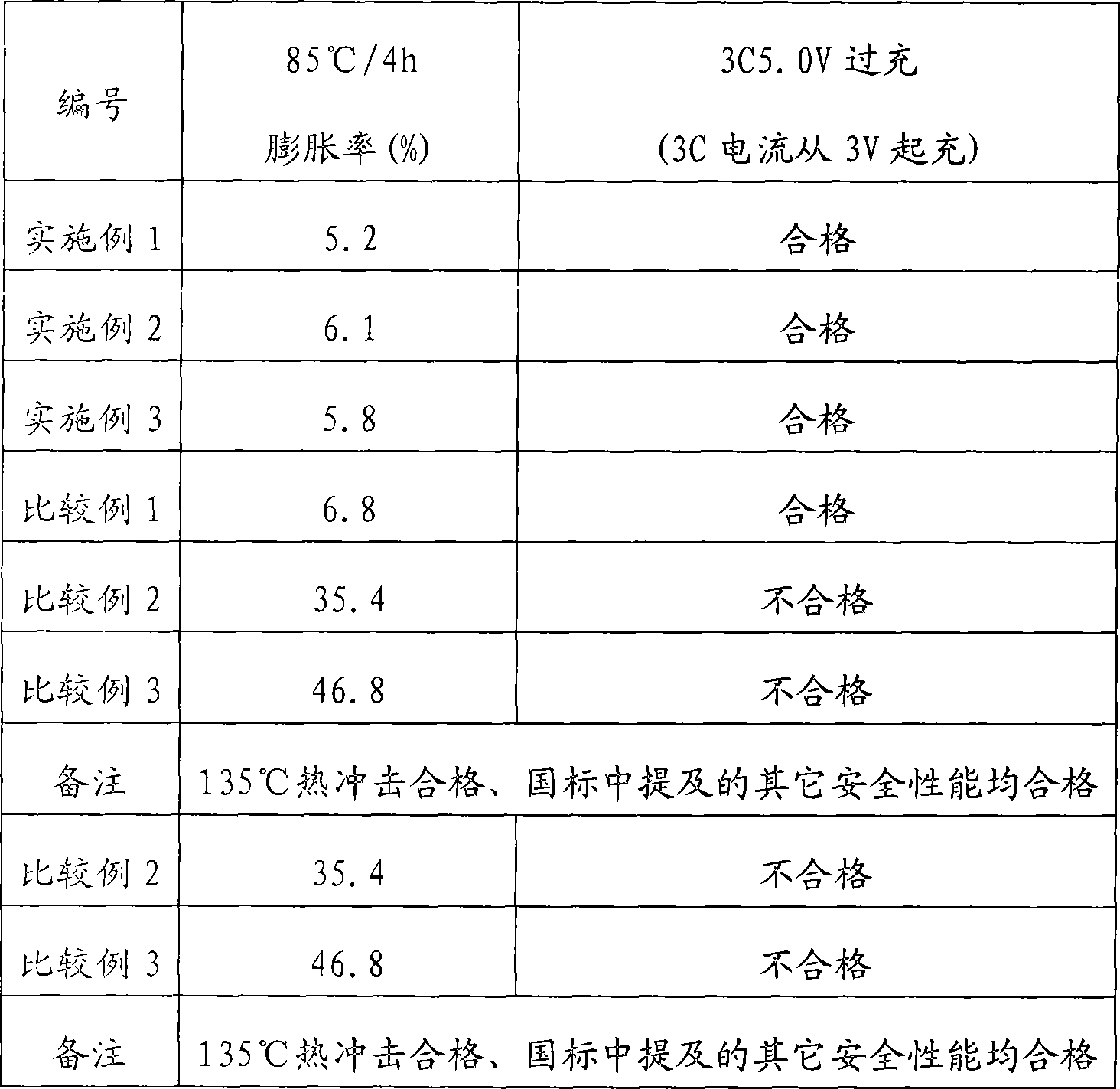

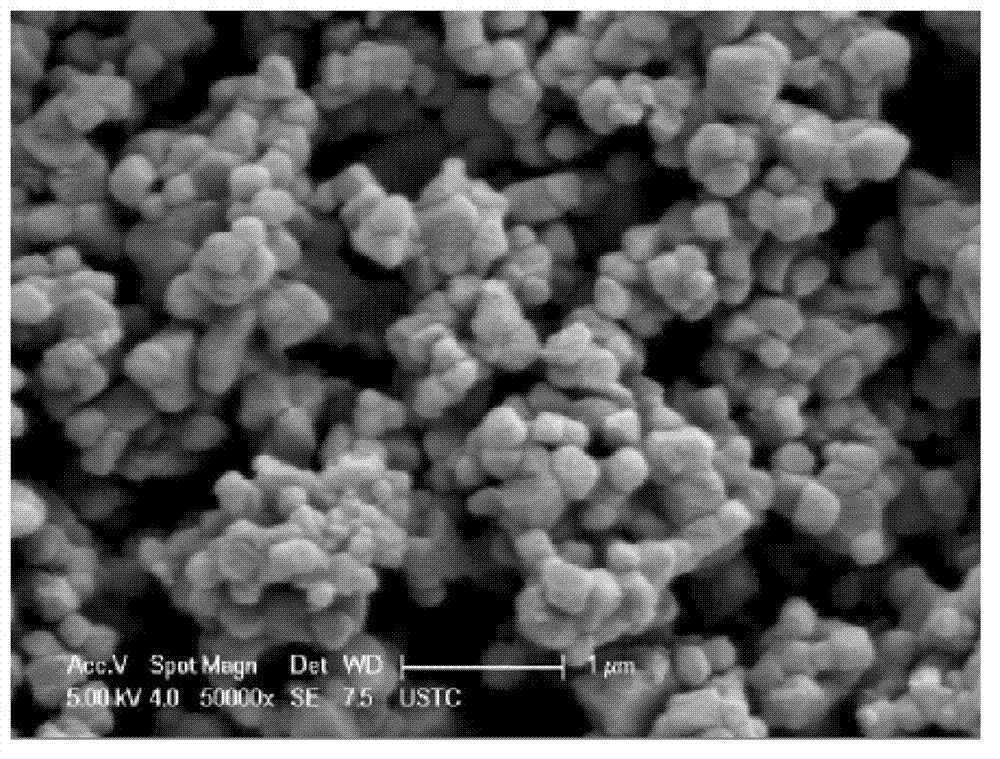

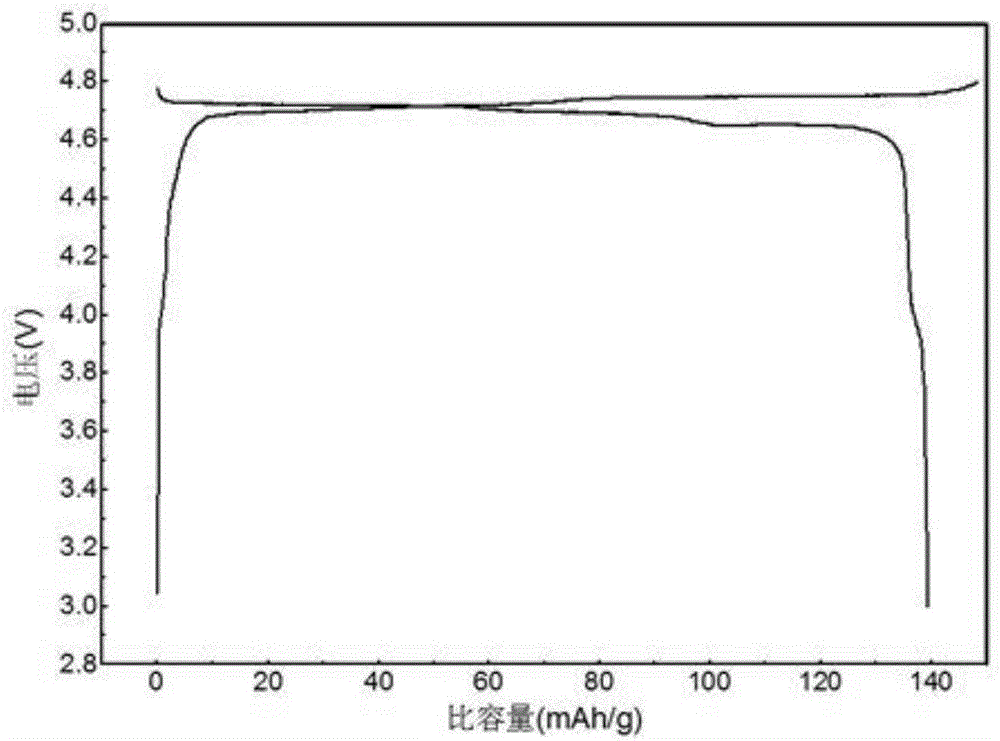

Preparation method of composite graphite, composite graphite and lithium ion battery

InactiveCN105098184ALow costHomogeneous catalytic effectCell electrodesSecondary cellsLithium electrodeGraphite

The invention provides a preparation method of composite graphite to overcome the problems that the composite graphite prepared by the method in the prior art is low in energy density, poor in high-rate charge and discharge properties and high in expansion rate in the charging and discharging processes. The preparation method comprises the following steps: (S1) providing ultrafine carbon powder, wherein the ultrafine carbon powder comprises green coke and / or mesophase carbon green microspheres; (S2) mixing the ultrafine carbon powder with a binder to obtain a mixture A, mixing the mixture A with a catalyst to obtain a mixture B, and then carrying out combined treatment on the mixture B to obtain a precursor; (S3) carrying out graphitizing treatment on the precursor to obtain a semi-finished product; and (S4) crushing, spheroidizing, wrapping and sieving the semi-finished product to obtain the composite graphite. Meanwhile, the invention further discloses the composite graphite prepared by the method and a lithium ion battery. The composite graphite provided by the invention is high in energy density, good in liquid absorption and retention properties, good in isotropic property, good in high-rate charge and discharge properties and low expansion rate in the charging and discharging processes.

Owner:BTR NEW MATERIAL GRP CO LTD

Anode material of lithium ion cell and preparation method thereof

ActiveCN101436666AImprove distributionEvenly distributedElectrode manufacturing processesCobalt compoundsLithium carbonatePhysical chemistry

The invention discloses a method for preparing lithium cobaltate positive pole material for a lithium ion cell and the obtained lithium cobaltate positive pole material. The method comprises the following steps: adopting a multiple-step synthesizing process; in a first synthesis, adopting excessive lithium so as to obtain larger lithium cobaltate particles at lower temperature; and before a second synthesis, adhering mixed powder of cobalt carbonate and lithium carbonate with small particle size and larger specific surface area to the one-step synthesized lithium cobaltate large particles through a mechanical granulation mode. The method can effectively improve the particle size and the tap density of the lithium cobaltate positive pole material so as to improve the compacted density and the volume specific capacity of the positive pole material.

Owner:广东风华新能源股份有限公司

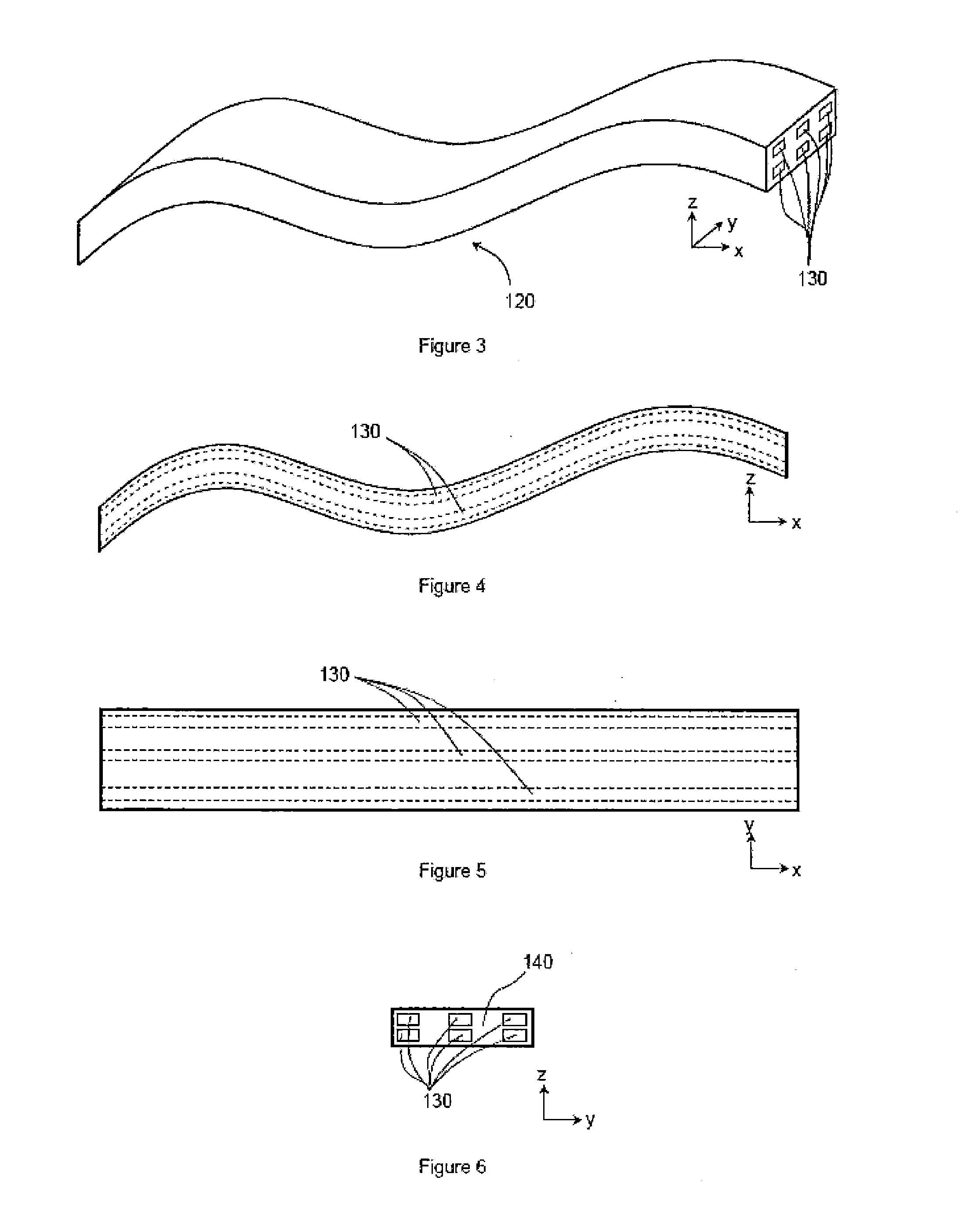

Measuring transducer of vibration-type

ActiveUS20070234824A1High sensitivityEasy constructionVolume meteringDirect mass flowmetersTransducerDistributor

The measuring transducer includes at least one measuring tube communicating with a line connected during operation for conveying a medium to be measured, and a support element oscillatably holding the at least one measuring tube. Additionally, it is provided that the support element contains at least two passageways, via which the at least one measuring tube communicates with the line, and that the at least one measuring tube is affixed, especially releasably, at at least one end to the support element by means of a screwed-fitting at one of the passageways. Alternatively or in supplementation thereof, it is further provided that the at least one measuring tube is, at least in part, made of cold-strengthened, for instance cold-stretched or autofrettaged, material. As required, the measuring transducer can further include at least two measuring tubes communicating with the line for conveying the medium; each of these two measuring tubes is to be connected to an inlet-side distributor element and an outlet-side distributor element. In such case, at least one of the two distributor elements can be embodied as an integral component of the support element, so that the support element can be kept, at least in the area of this at least one distributor element, free of materially bonded, joined locations, especially free of solder, braze or weld connections. The measuring transducer of the invention is especially provided also for applications in which the medium to be measured acts with a pressure of more than 500 bar, especially over 700 bar, on the measuring tube.

Owner:ENDRESS HAUSER FLOWTEC AG

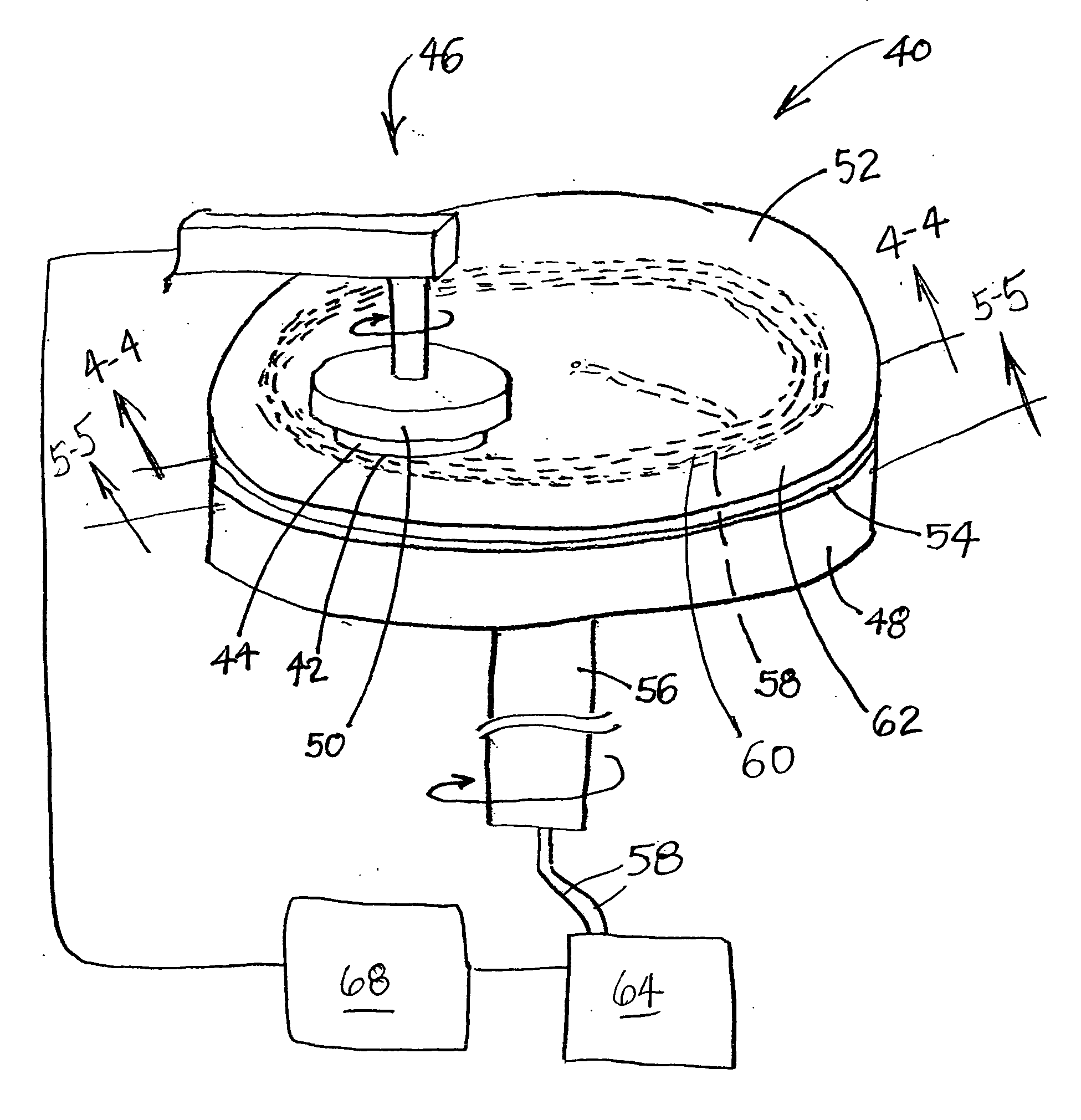

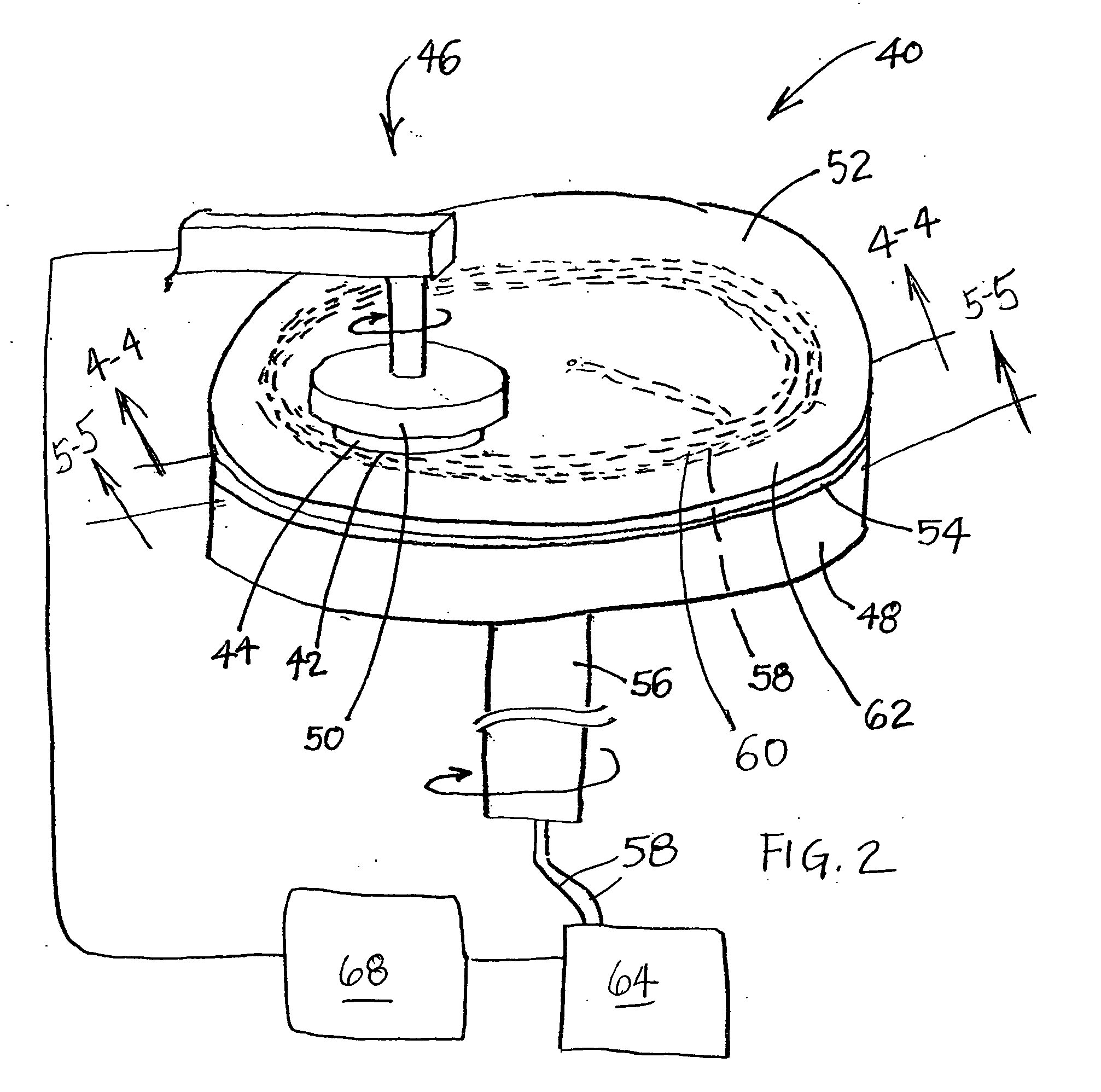

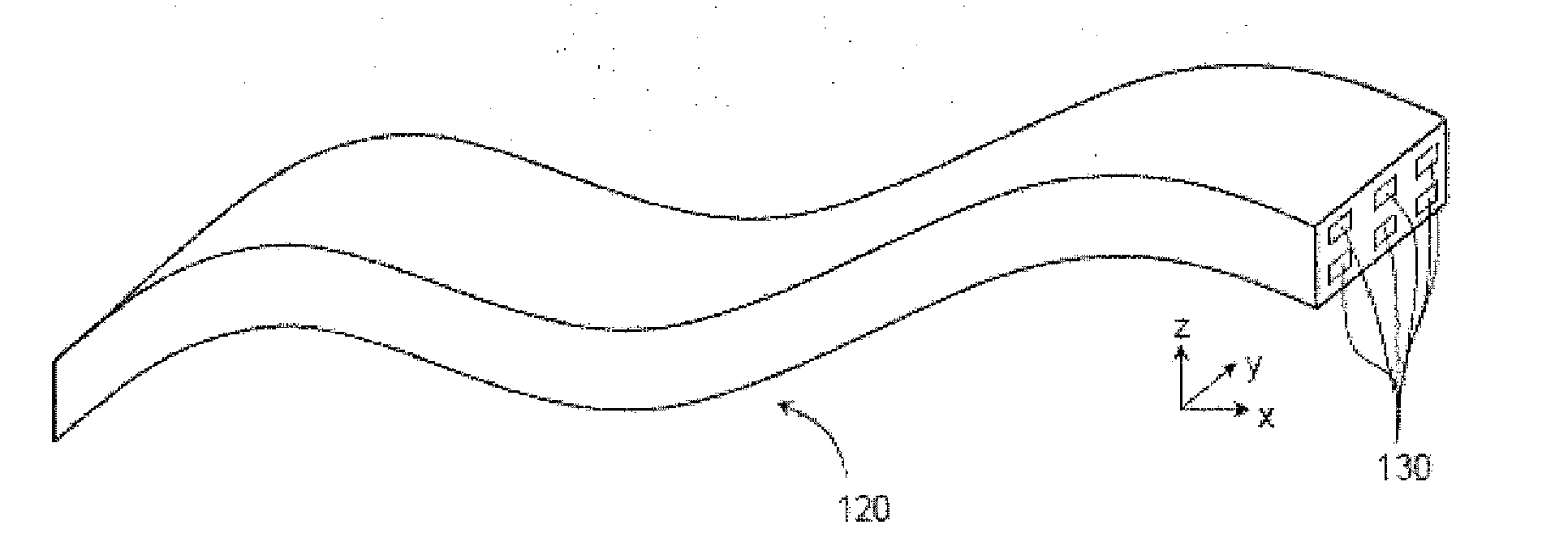

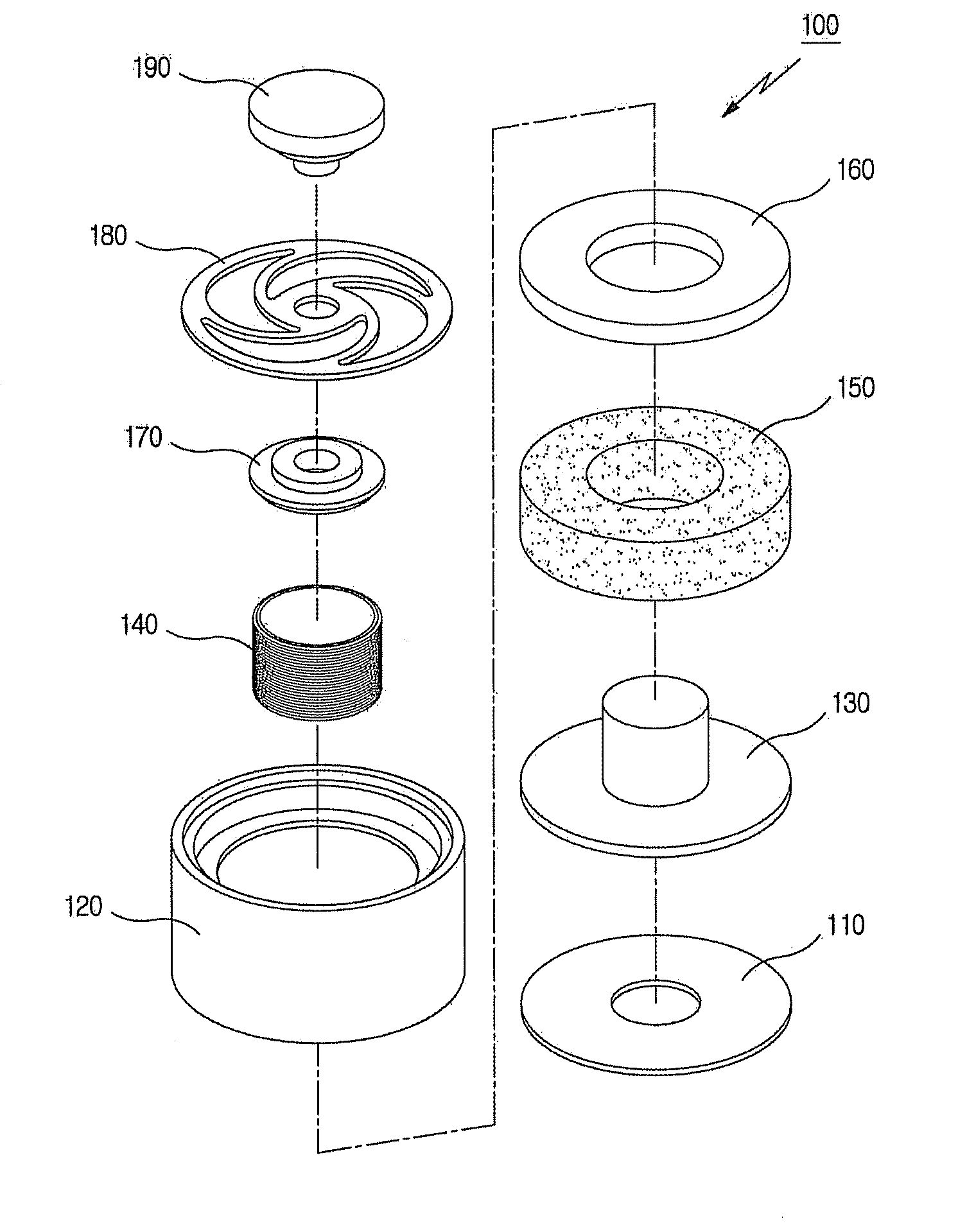

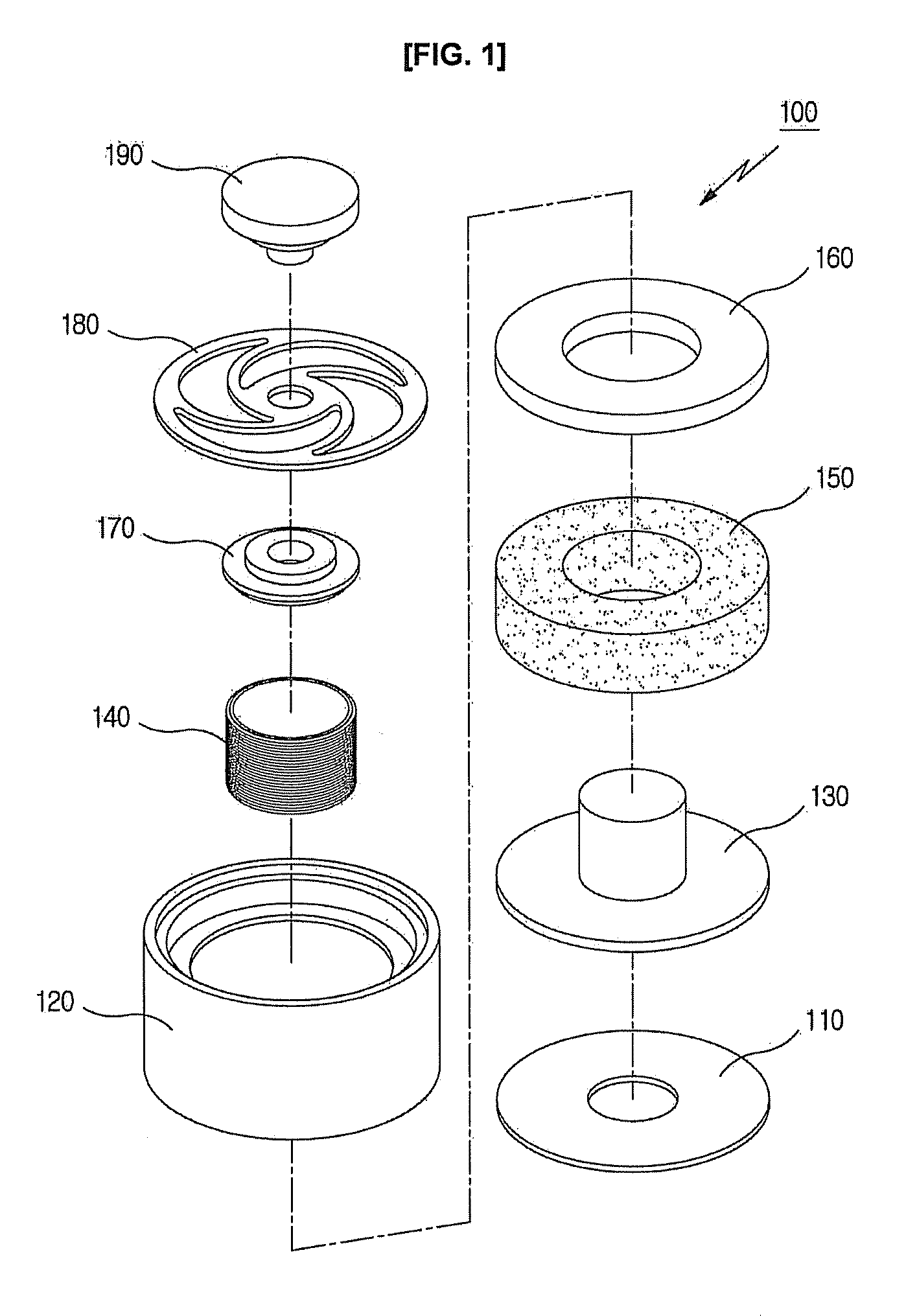

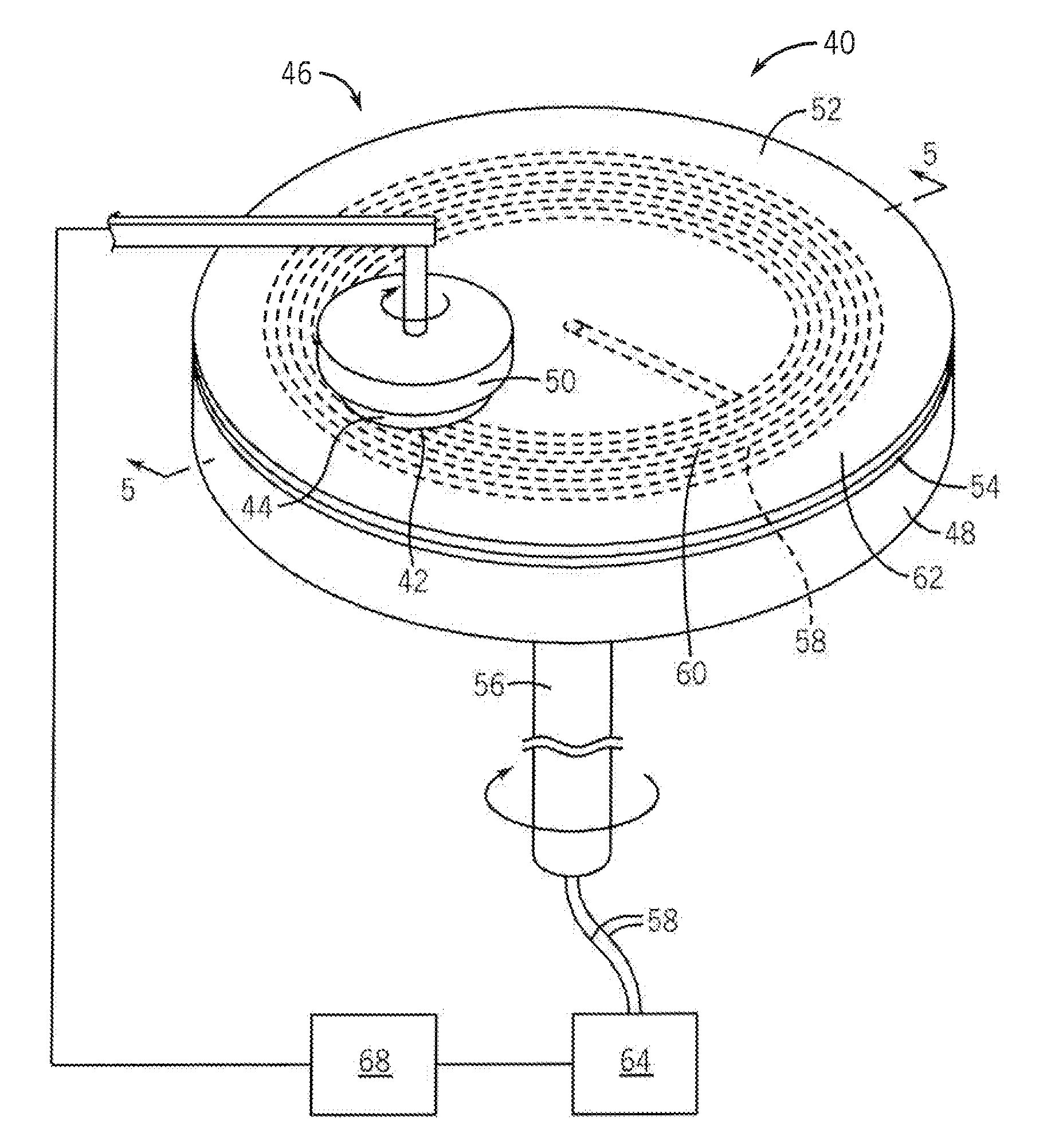

Embedded fiber acoustic sensor for CMP process endpoint

ActiveUS20070218806A1High sensitivityEasy to mergePolishing machinesRevolution surface grinding machinesMechanical energyEngineering

Devices, systems and methods for monitoring characteristics of semiconductor substrates and workpieces during planarization and for endpointing planarization processes are provided. The invention utilizes a fiber optic contact sensor incorporated into a planarizing pad or pad-subpad assembly for process monitoring of mechanical energy (e.g., mechanical vibration) and acoustical energy (e.g., ultrasonic vibration) that allows an operator to determine status and / or an endpoint of a planarizing or polishing process. In another embodiment, the invention utilizes a fiber optic contact sensor incorporated into a table support for a planarizing pad.

Owner:MICRON TECH INC

Measuring transducer of vibration-type

ActiveUS20070234822A1High sensitivityEasy constructionVolume meteringDirect mass flowmetersTransducerEngineering

The measuring transducer includes at least one measuring tube communicating with a line connected during operation for conveying a medium to be measured, and a support element oscillatably holding the at least one measuring tube. Additionally, it is provided that the support element contains at least two passageways, via which the at least one measuring tube communicates with the line, and that the at least one measuring tube is affixed, especially releasably, at at least one end to the support element by means of a screwed-fitting at one of the passageways. Alternatively or in supplementation thereof, it is further provided that the at least one measuring tube is, at least in part, made of cold-strengthened, for instance cold-stretched or autofrettaged, material. As required, the measuring transducer can further include at least two measuring tubes communicating with the line for conveying the medium; each of these two measuring tubes is to be connected to an inlet-side distributor element and an outlet-side distributor element. In such case, at least one of the two distributor elements can be embodied as an integral component of the support element, so that the support element can be kept, at least in the area of this at least one distributor element, free of materially bonded, joined locations, especially free of solder, braze or weld connections. The measuring transducer of the invention is especially provided also for applications in which the medium to be measured acts with a pressure of more than 500 bar, especially over 700 bar, on the measuring tube.

Owner:ENDRESS HAUSER FLOWTEC AG

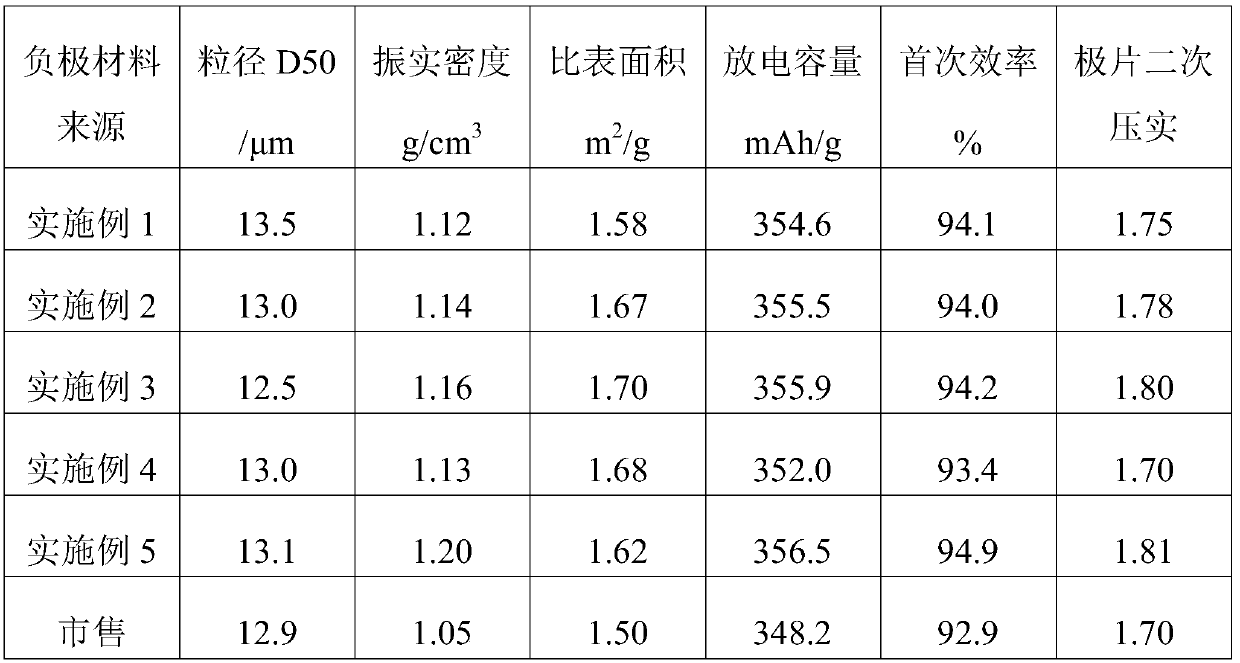

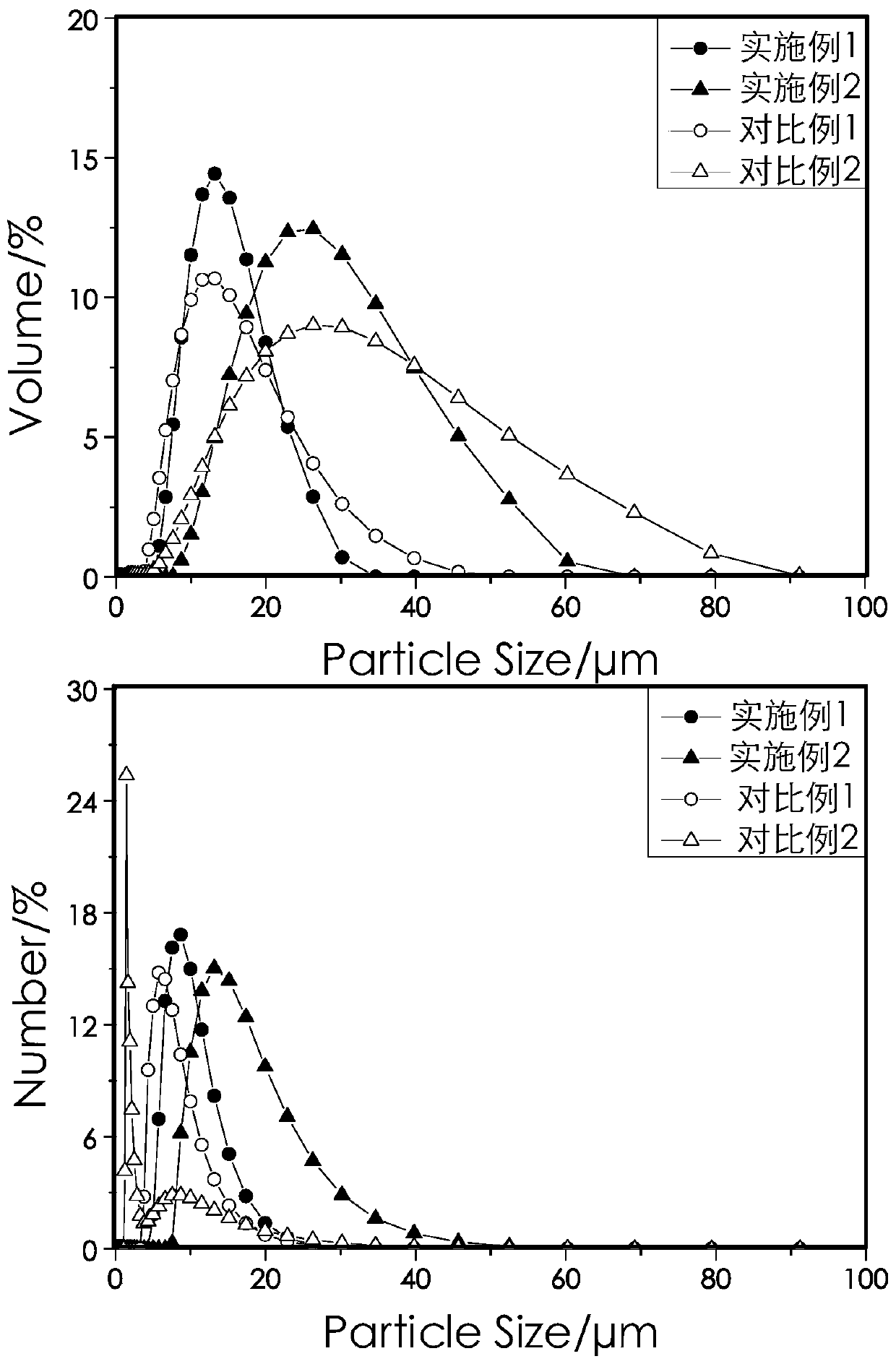

Single-particle and secondary-particle mixed high-energy-density graphite negative electrode material and preparation method thereof

ActiveCN110649256ASmall particle sizeLarge particle sizeCell electrodesHigh energyPhysical chemistry

The invention relates to a single-particle and secondary-particle mixed high-energy-density graphite negative electrode material and a preparation method thereof.The preparation method comprises the steps of crushing and drying an artificial graphite raw material to obtain coarse powder, finely grinding and shaping the coarse powder to obtain fine powder, performing high-temperature graphitizationtreatment on the fine powder to obtain a single-particle graphitized material, mixing the fine powder with a binder carrying out surface modification treatment under the protection of an inert gas toobtain secondary particles, carrying out fusion granulation treatment on the secondary particles to obtain a fusion material and then carrying out high-temperature graphitization treatment to obtaina secondary particle graphitized material, and mixing the single-particle graphitized material with the secondary-particle graphitized material to obtain a lithium ion battery negative electrode material. Through measurement, the high-energy-density graphite negative electrode material has excellent performances in the aspects of tap density, discharge capacity, first efficiency, secondary compaction of a pole piece and other indexes.

Owner:石家庄尚太科技股份有限公司 +1

Impact printhead

An impact printhead includes impact wires loosely held in a guide and driven to print. The printhead includes individual holes through which corresponding wires extend, and elongated holes formed in the guide for guiding the wires. The elongated hole includes a concave wall and a convex wall opposing each other. The wires are slidable on the convex wall. When the wires are not driven to print, the wires are at rest in pressure contact with the convex wall. Grooves may be formed in place of the elongated holes, and have second walls. The second wall lies substantially in a curved plane in which a first wall lies to define the individual hole. The wire is guided by the hole and groove. When the wire is not driven to print, the wire is at rest in pressure contact with the first and second walls.

Owner:OKI ELECTRIC IND CO LTD

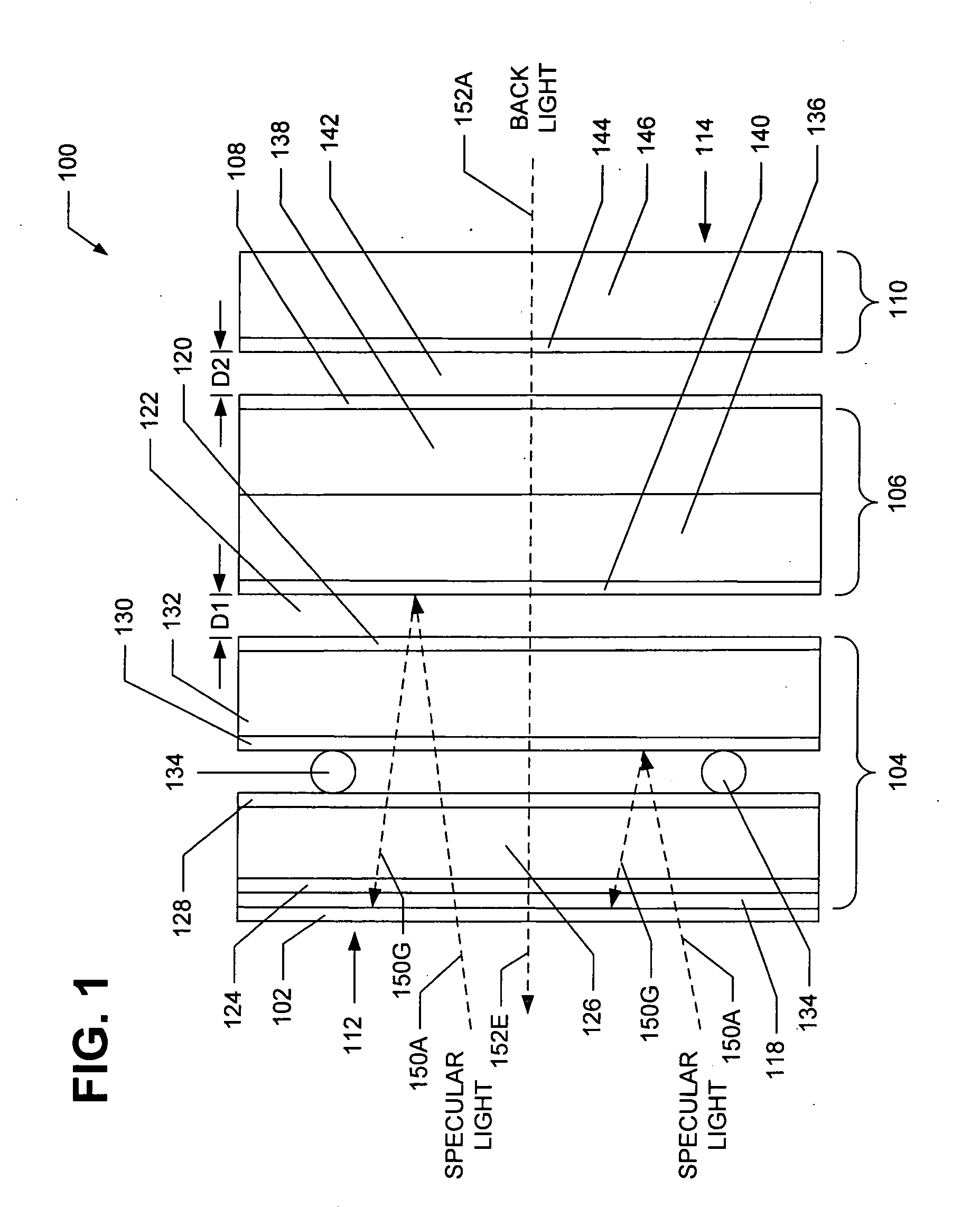

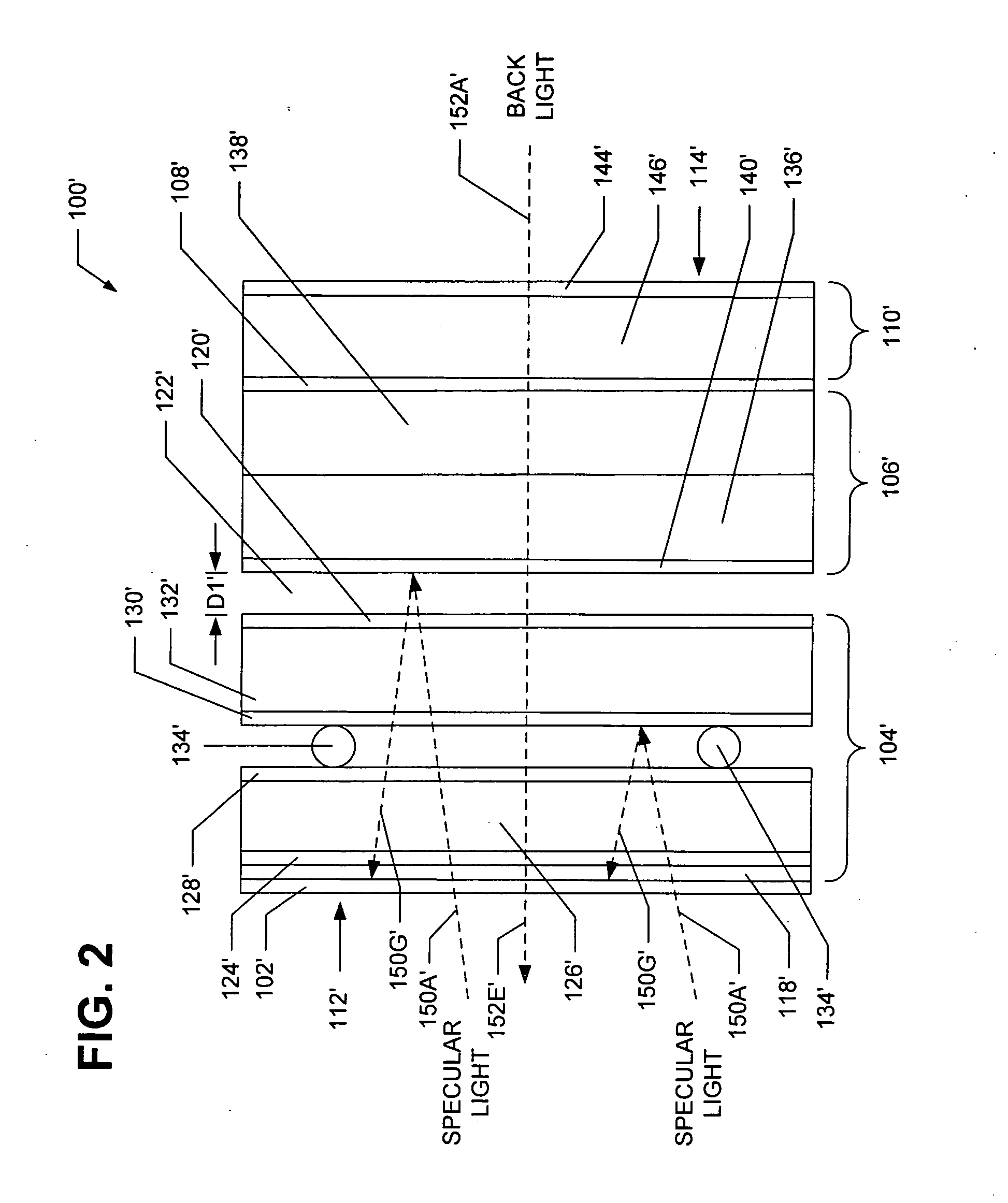

Optically enhanced flat panel display system having integral touch screen

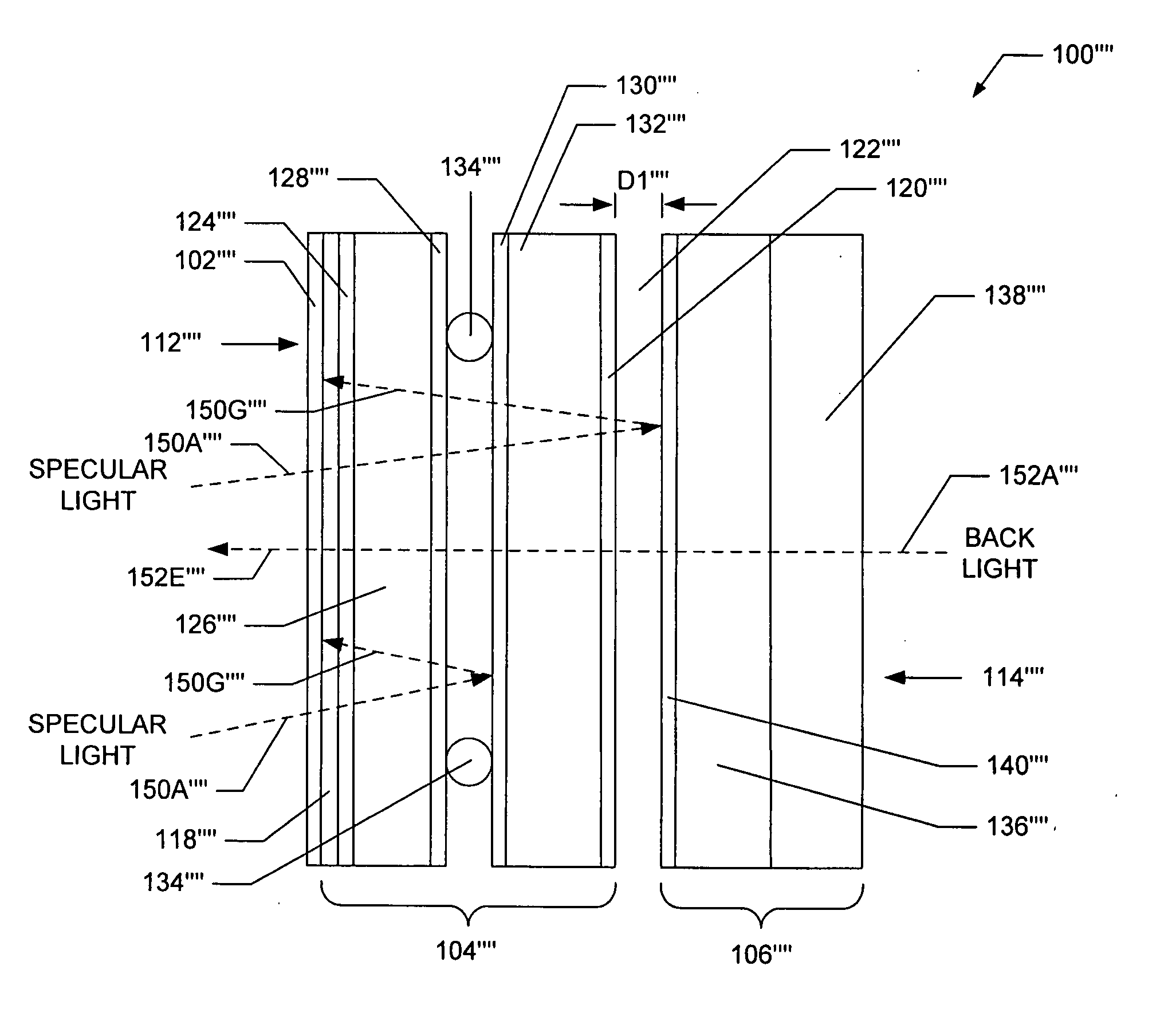

InactiveUS20100020045A1Increase brightnessReduce reflectivityStatic indicating devicesInput/output processes for data processingUltrasound attenuationLiquid-crystal display

An optically enhanced flat panel display system, including apparatuses and methods for assembling same, for displaying images generated by a computer or electronic device with increased luminance and reduced reflectance, and for receiving user input for a computer or electronic device via a touch screen portion thereof. The flat panel display system comprises a touch screen portion integrally incorporated with and forward of a display portion. The display system has only one front polarizer such that the touch screen and display portions are generally positioned rearward thereof. In exemplary embodiments, the touch screen portion employs resistive touch screen technology and the display portion employs liquid crystal display technology. By including only one front polarizer, attenuation of display image light is minimized and an increase in net luminance is achieved over other flat panel display systems.

Owner:L 3 COMM CORP

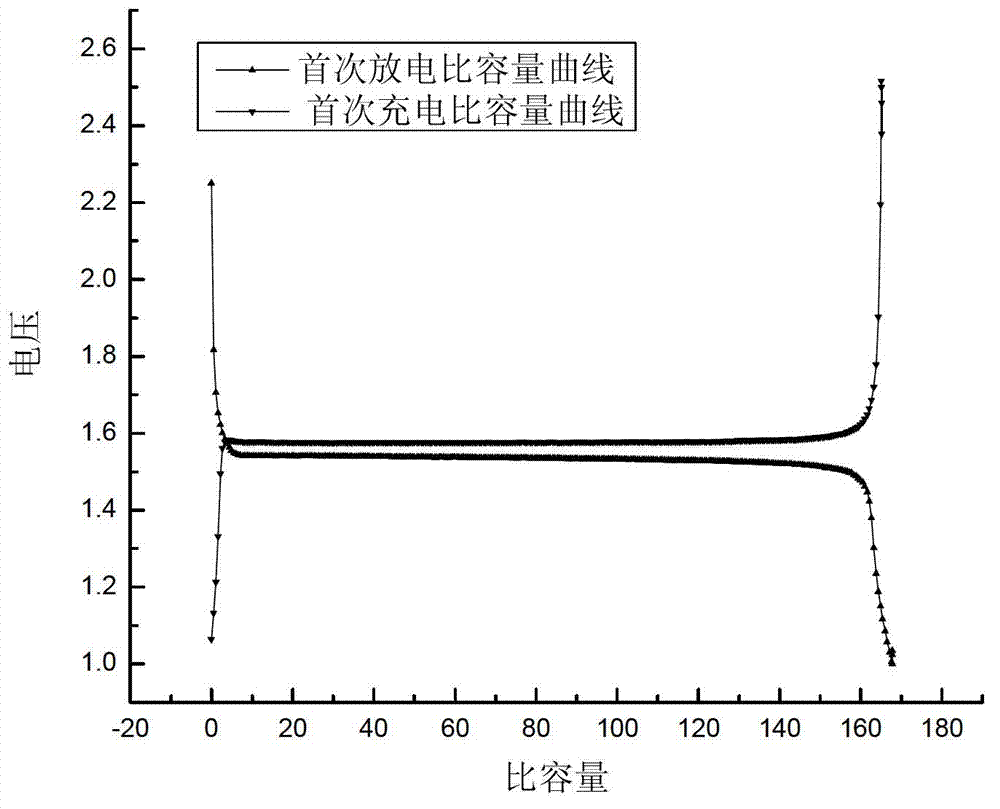

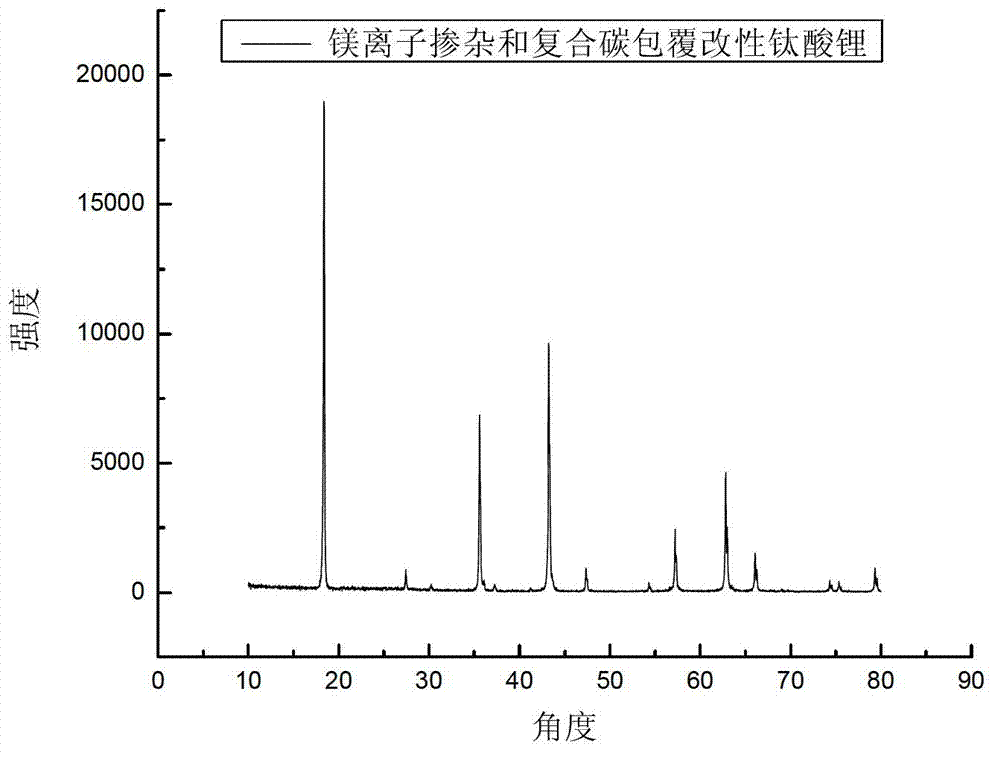

Briquetting and sintering method for synthesizing lithium titanate negative electrode material

InactiveCN103326008AClose contactCloser contact is conducive to closer reactionCell electrodesTitanium compoundsPhysical chemistryTitanium oxide

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Corrugated tubular energy absorbing structure

InactiveUS7963378B2Effectively absorb impact energyLow costPedestrian/occupant safety arrangementUnderstructuresConstant forceEnergy absorption

An energy absorbing tubular structure is formed of a molded or extruded polymer. The tube has a quadrangular cross-section with rounded corners. The walls of tube are corrugated with alternating convex and concave corrugations surfaces having a continuous constant radius, preferably with no flat spots. The corrugated walls have a constant thickness. The corrugations progressively deform during impact thereby providing a near perfect square wave force vs. deflection energy absorption curve at any predetermined nearly constant force level. The tube may be filled with polymer foam to vary the impact performance of the structure.

Owner:O FLEX GRP

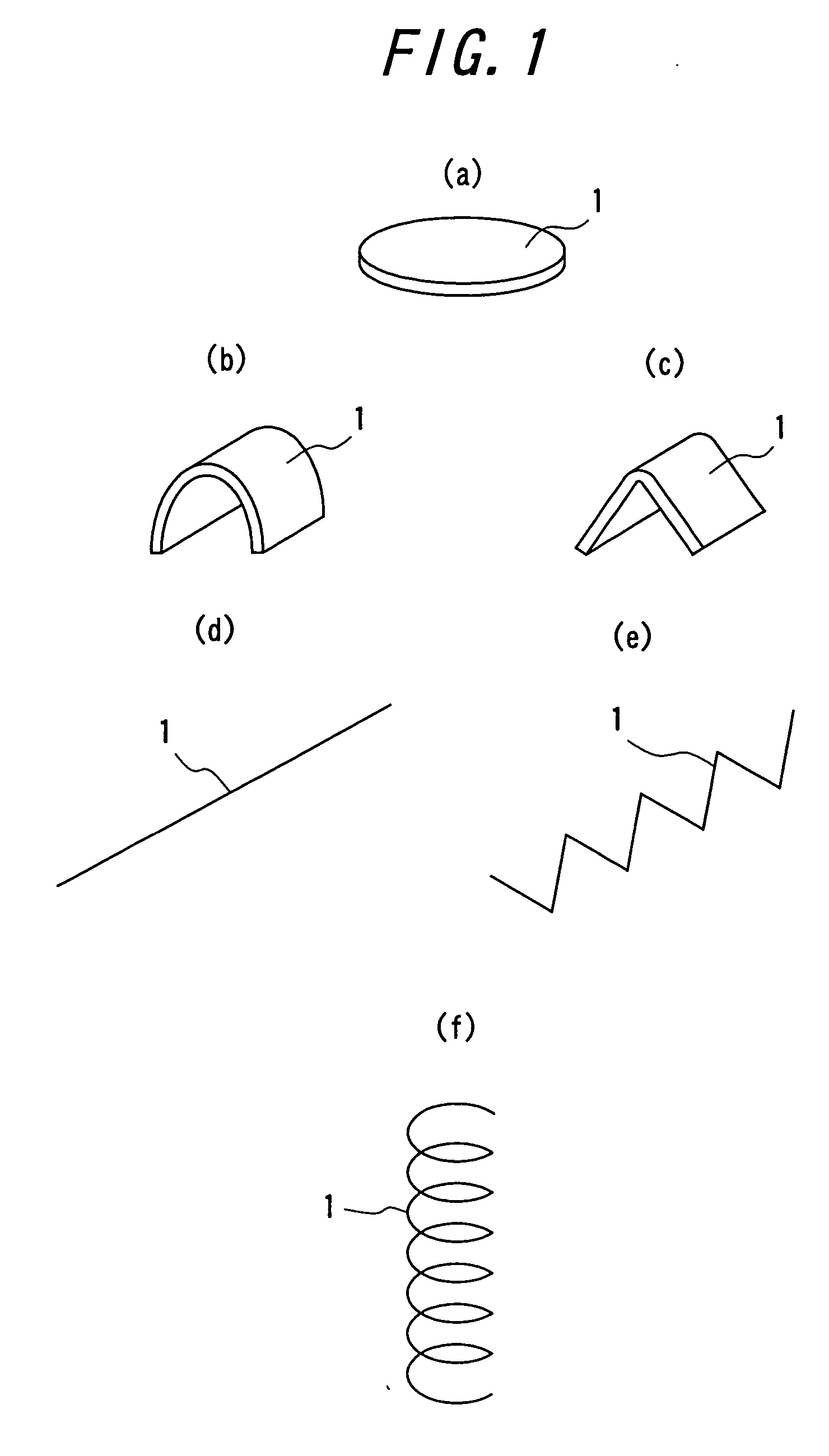

Vibration absorbing alloy member, and rubber vibration isolator, floor vibration damping apparatus, tires, steel cord and rubber sesmic isolator using the same

InactiveUS20070085251A1High damping performanceReduce noise and vibrationNon-rotating vibration suppressionMultiple spring combinationsMn alloyMaterials science

A damping alloy member 1 is constructed in such a manner that the improvement consists of a twin crystal type damping alloy made of Cu—Al—Mn alloy, Mg—Zr alloy, Mn—Cu alloy, Mn—Cu—Ni—Fe alloy, Cu—Al—Ni alloy, Ti—Ni alloy, Al—Zn alloy, Cu—Zn—Al alloy, Mg alloy, Cu—Si alloy, Fe—Mn—Si alloy, Fe—Ni—Co—Ti alloy, Fe—Ni—C alloy, Fe—Cr—Ni—Mn—Si—Co alloy and Ni—Al alloy, and has a shape of a flake, a wire or a spring for optimizing a deformation of the alloy. Moreover, a rubber vibration isolator, a floor vibration damping apparatus, a tire, a steel cord and a quake-absorbing rubber are constructed by using the damping apply member.

Owner:BRIDGESTONE CORP

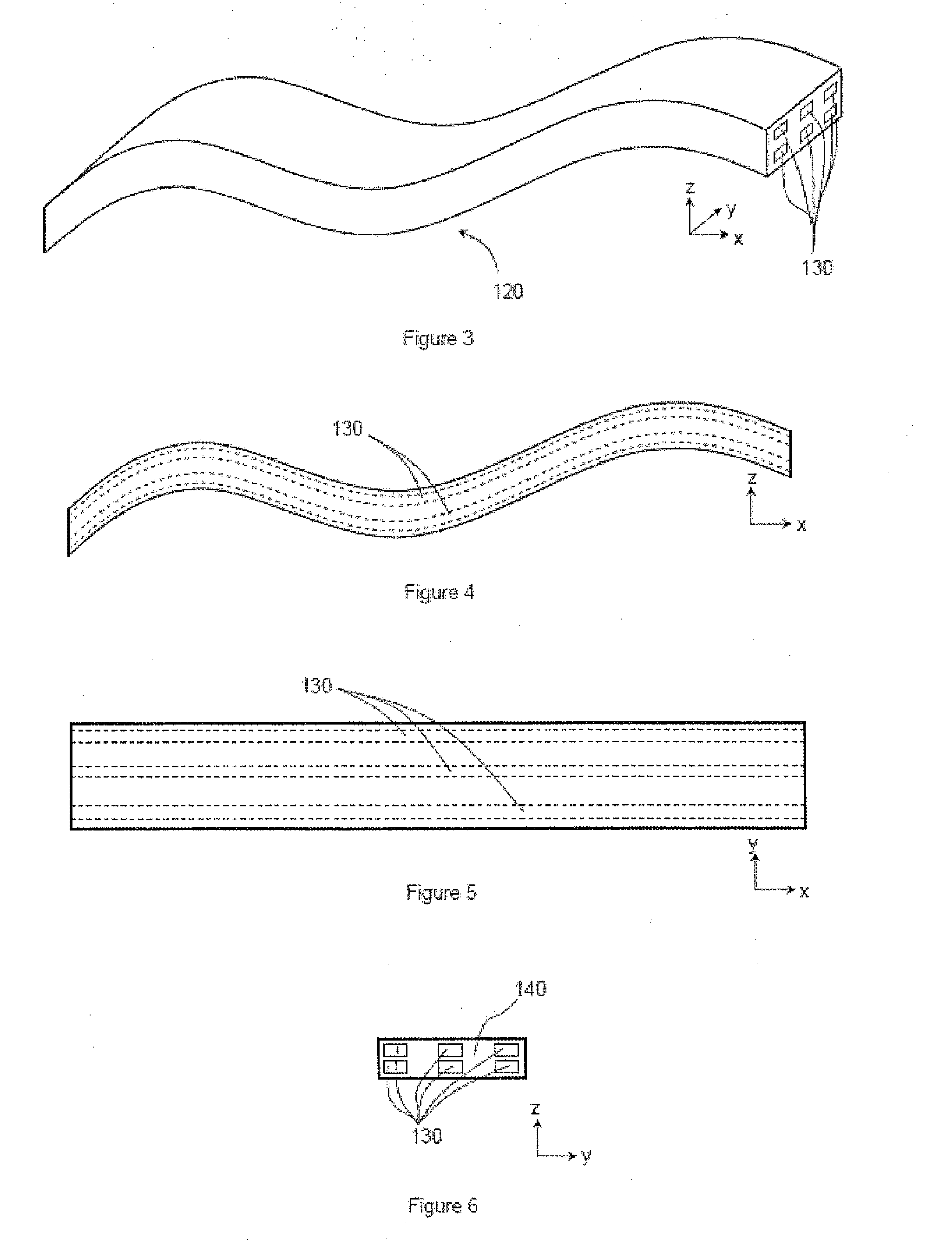

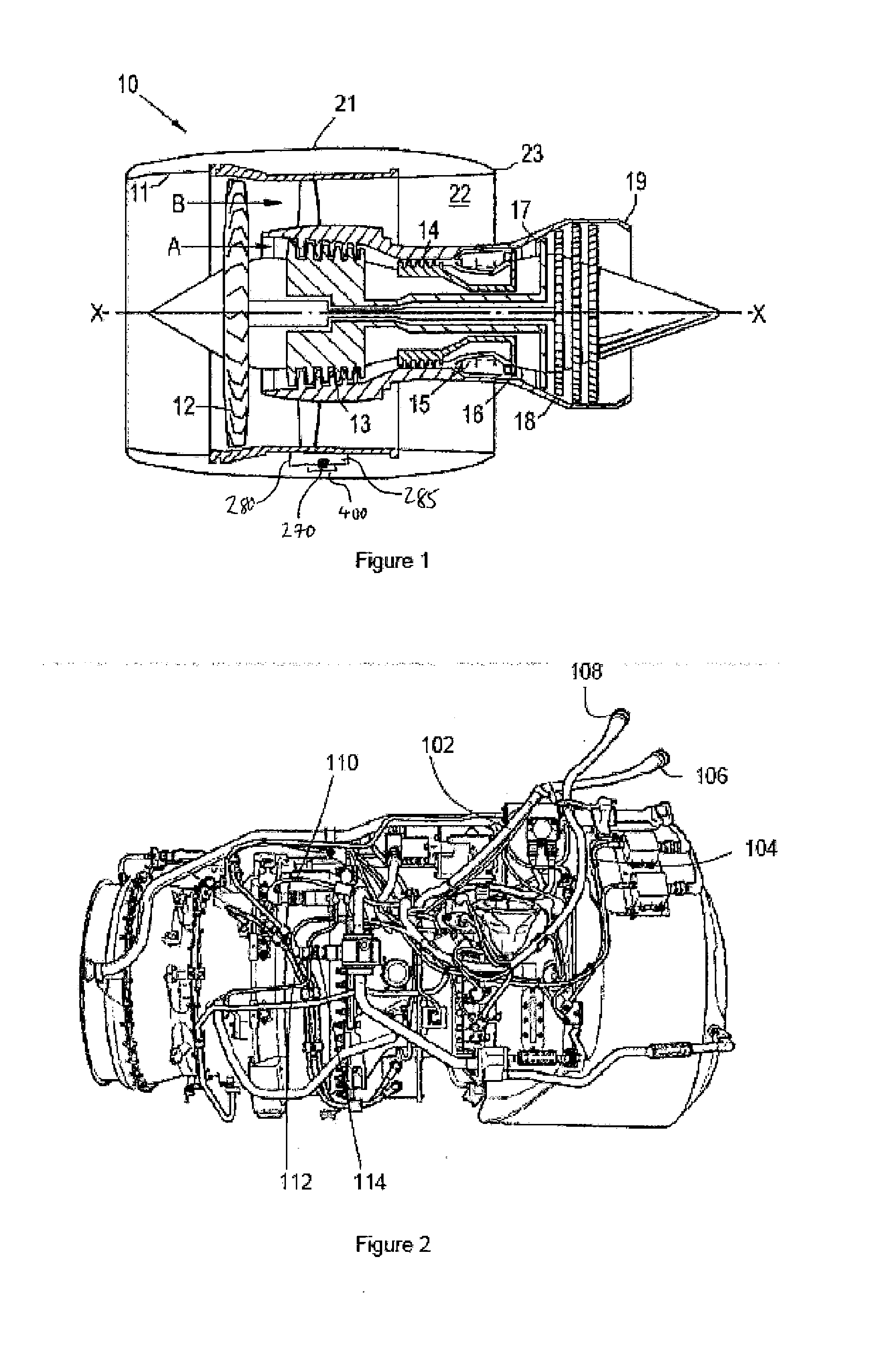

Electrical harness connector

ActiveUS20140328030A1Reduce the amount requiredProlong lifePrinted circuit assemblingEngine fuctionsElectrical connectionElectric wire

An electrical connection between two electrical harnesses is provided. The electrical harnesses include flexible printed circuits with embedded conductive tracks, each of which terminates in a receiving hole in a respective terminating region The terminating regions are connected together using conductive pins. The connection formation is then encapsulated by an encapsulating body formed of an insulating. The encapsulating body seals and protects the electrical connection, which is thus reliable and robust.

Owner:ROLLS ROYCE PLC

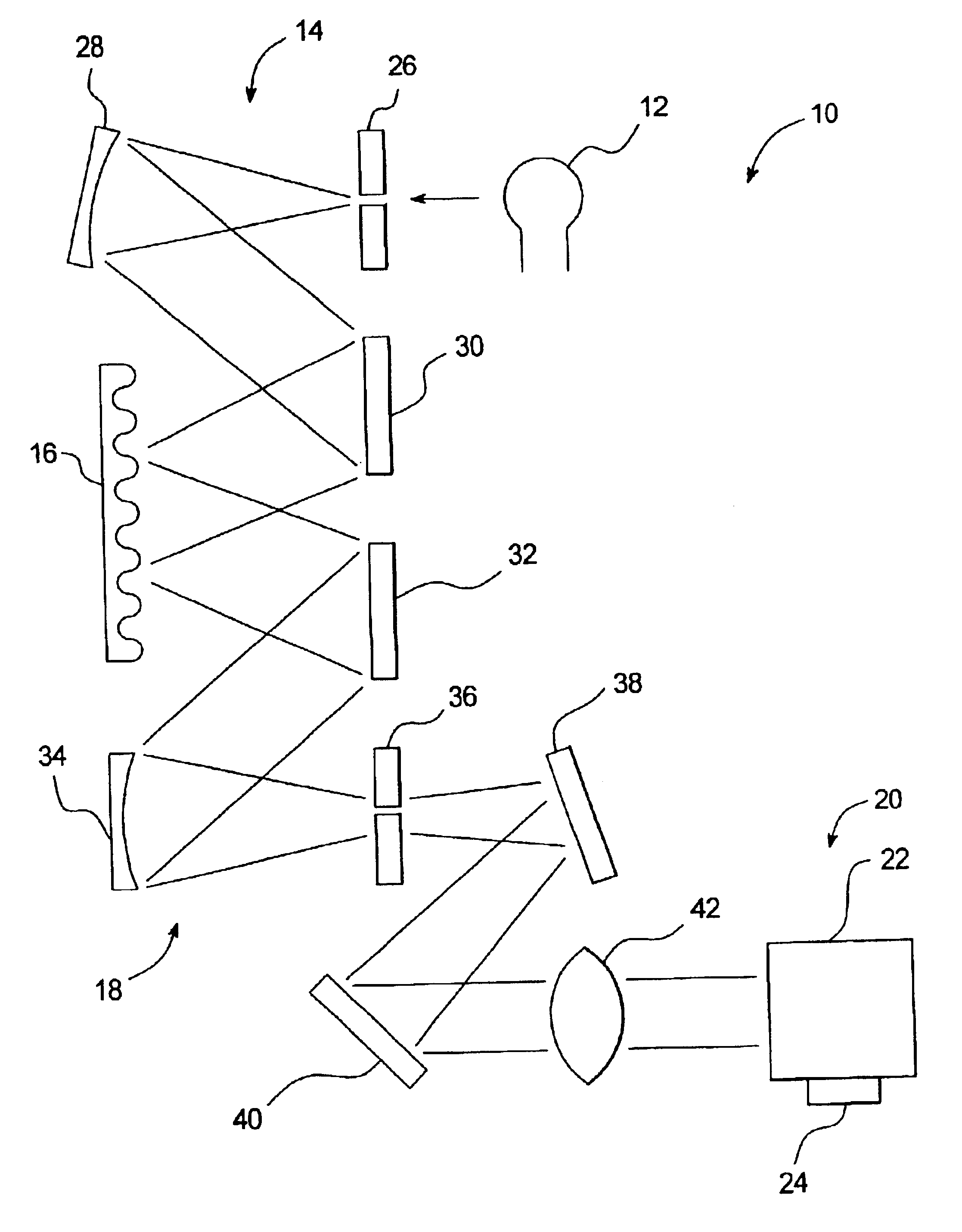

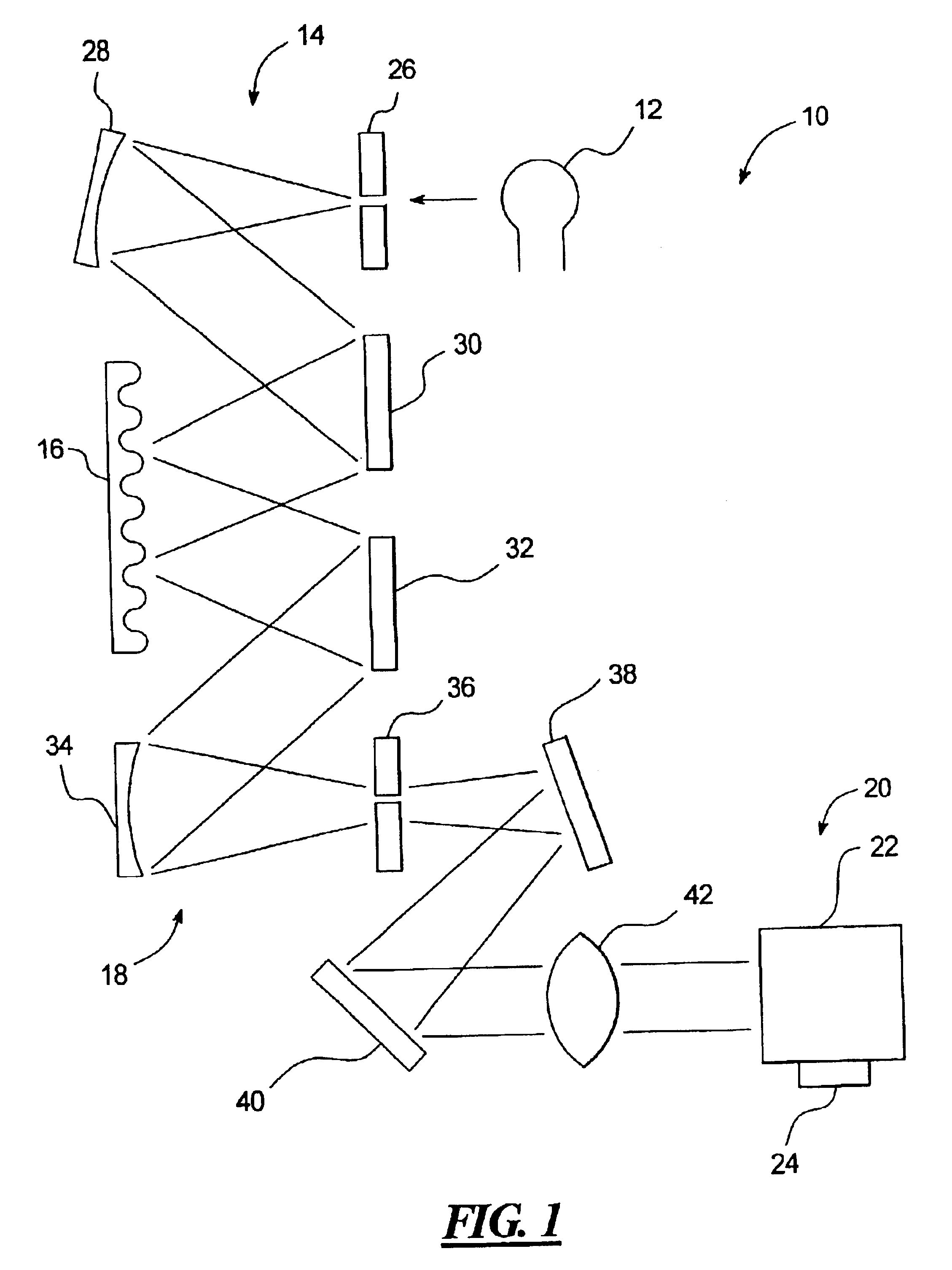

Programmable diffraction grating sensor

InactiveUS6853449B2Simple and sensitive photoacoustic detectionImprove pressure resistanceMaterial analysis using sonic/ultrasonic/infrasonic wavesRadiation pyrometryLight sourceDiffraction grating

A programmable substance detector includes a light source, a sample cell, a programmable diffraction grating positioned to receive light from the light source and to direct diffracted light to the sample cell, and a detector associated with the cell to detect a match between a characteristic of the diffracted light and a corresponding characteristic of a substance within the cell.

Owner:HONEYWELL INT INC

Preparation method of lithium nickel manganese oxide serving as high-voltage positive electrode material

ActiveCN106684350AHigh tap densityBuffer precipitation processCell electrodesSecondary cellsLithium hydroxideManganese oxide

The invention relates to a preparation method of lithium nickel manganese oxide serving as a high-voltage positive electrode material. The preparation method comprises the following steps of using oxalate and carbonate as precipitants; preparing an oxalic acid / nickel manganese carbonate composite precursor by a co-precipitation method; pre-burning, dispersing into a lithium hydroxide water solution, spraying and drying; calcining at high temperature, so as to obtain the lithium nickel manganese oxide serving as the high-voltage positive electrode material. Compared with the traditional method using the hydroxide as the precipitant, the protection by inert gas is not needed, the strong alkaline is not needed, the requirement on equipment is low, and the production cost is reduced; compared with the traditional method using single oxalate or carbonate as the precipitant, the oxalate and carbonate are used as double precipitants, so that the compaction density of the material is effectively improved. The prepared high-voltage positive electrode material has the advantages that the material is in a sphere shape, the voltage is high, the compaction degree is high, the capacity is high, the doubling property is excellent, the material cost is low, and the like.

Owner:SOUNDON NEW ENERGY TECH CO LTD

Vibration earphone

InactiveUS20120082324A1Improve efficiencyIncrease productionBone conduction transducer hearing devicesEarpiece/earphone attachmentsAcoustic transmissionEngineering

The present invention relates to a vibration earphone that improves the efficiency of sound output from the earphone by outputting vibrations for the high sound frequency range through a mastoid and by simultaneously outputting vibrations for the low frequency range through a cylindrical low sound transmitting member. The vibration earphone comprises a vibration member for outputting sound through vibrations and including a face plate, a voice coil, a basket with a magnet coupled thereto, and a cover; the low sound transmitting member housing the vibration member therein, for outputting vibrations for low sound through an external wall inside an ear; and a mastoid for outputting vibrations for the high sound frequency range generated from the face plate through a projection passing through the low sound transmitting member and inserted in and coupled to a hole defined in a central portion of the face plate of the vibration member.

Owner:ECOSHELL

Electrical harness connector

ActiveUS20140325993A1High levelVibration highContact member assembly/disassemblyFlexible printed circuitsElectrical conductorEngineering

An electrical harness assembly is provided that comprises a flexible printed circuit electrically connected to one end of an electrical connector. The other end of the electrical connector is presented for connection to another electrical component. Electrical tracks or conductors in the flexible printed circuit terminate in receiving holes. The electrical connector comprises terminals, each of which has a first end that is received in one of the receiving holes to form a connection formation, and a second end which is present for connection to the other electrical device. The connection formation is encapsulated so as to be sealed, thereby providing a reliable and robust connection between the connector and the flexible printed circuit.

Owner:ROLLS ROYCE PLC

Residential compressor for refueling motor vehicles that operate on gaseous fuels

InactiveUS7011118B2Improve noiseIncrease vibrationLiquid fillingInternal combustion piston enginesAir cycleMotor speed

A compressor for natural gas is made in a format suitable for mounting on a wall or upright support at a residential location to permit refilling of the gas reservoir of a gaseous-fueled motor vehicle parked at the residence. The wall-mounted appliance has vibration isolation supports to minimize transmission of noise into the residence. It has a ventilation and air circulation system that allows it to test for the presence of flammable gas both leaking from the appliance and present in the adjacent ambient environment, e.g. a garage. A motor speed control system permits operation of the appliance at speeds which are reduced when approaching the final pressure for the motor vehicle reservoir and at speeds which avoid the natural resonant frequencies of the system.

Owner:MTM

Prestressed shaft and hub connection having a perfect cone shape

ActiveUS8075218B2Spend lessAvoid disadvantagesYielding couplingFlanged jointsEngineeringMechanical engineering

Owner:NEAPCO INTPROP HLDG LLC

Embedded fiber acoustic sensor for CMP process endpoint

ActiveUS7537511B2Easy to mergeHigh energyPolishing machinesRevolution surface grinding machinesMechanical energyUltrasonic vibration

Devices, systems and methods for monitoring characteristics of semiconductor substrates and workpieces during planarization and for endpointing planarization processes are provided. The invention utilizes a fiber optic contact sensor incorporated into a planarizing pad or pad-subpad assembly for process monitoring of mechanical energy (e.g., mechanical vibration) and acoustical energy (e.g., ultrasonic vibration) that allows an operator to determine status and / or an endpoint of a planarizing or polishing process. In another embodiment, the invention utilizes a fiber optic contact sensor incorporated into a table support for a planarizing pad.

Owner:MICRON TECH INC

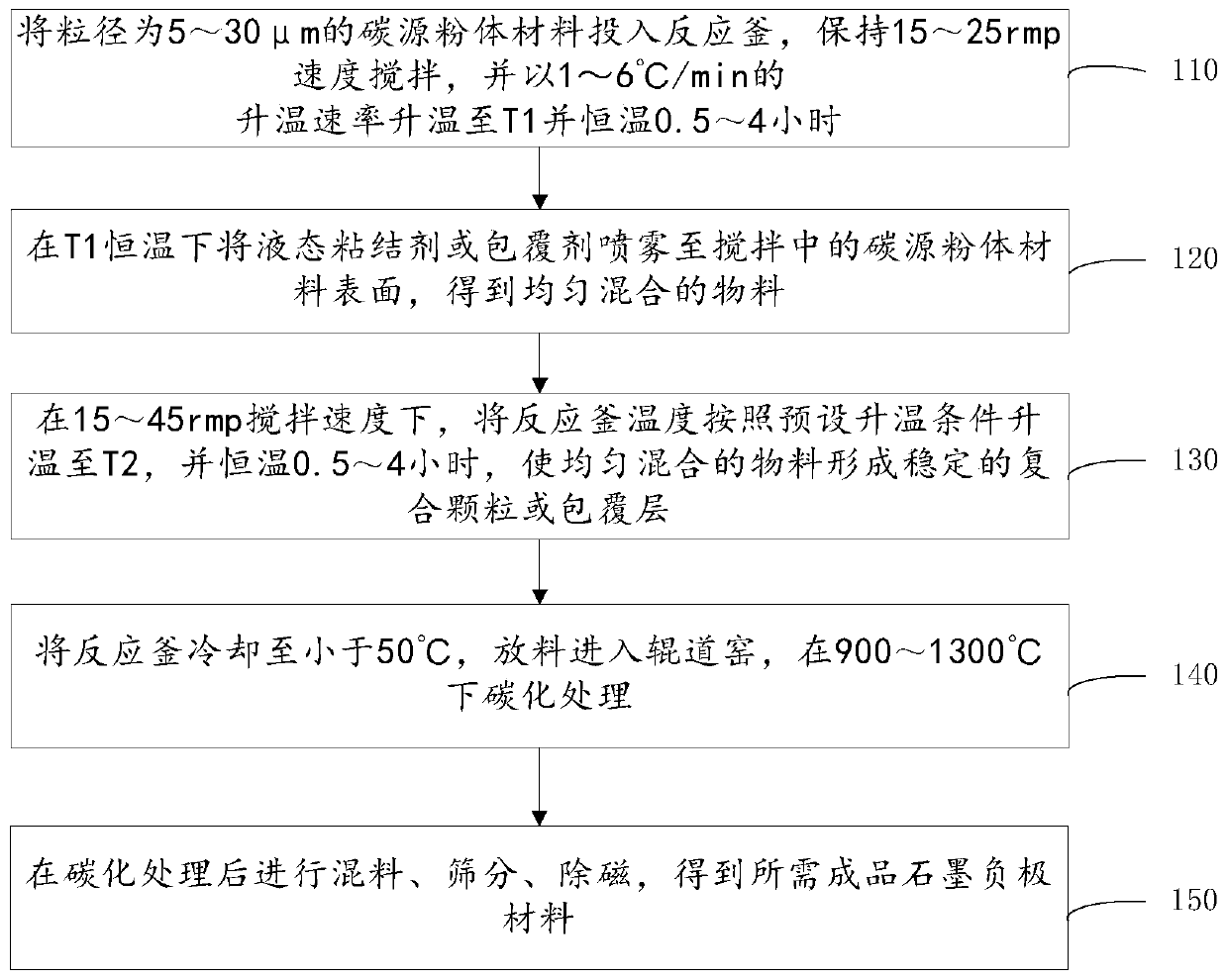

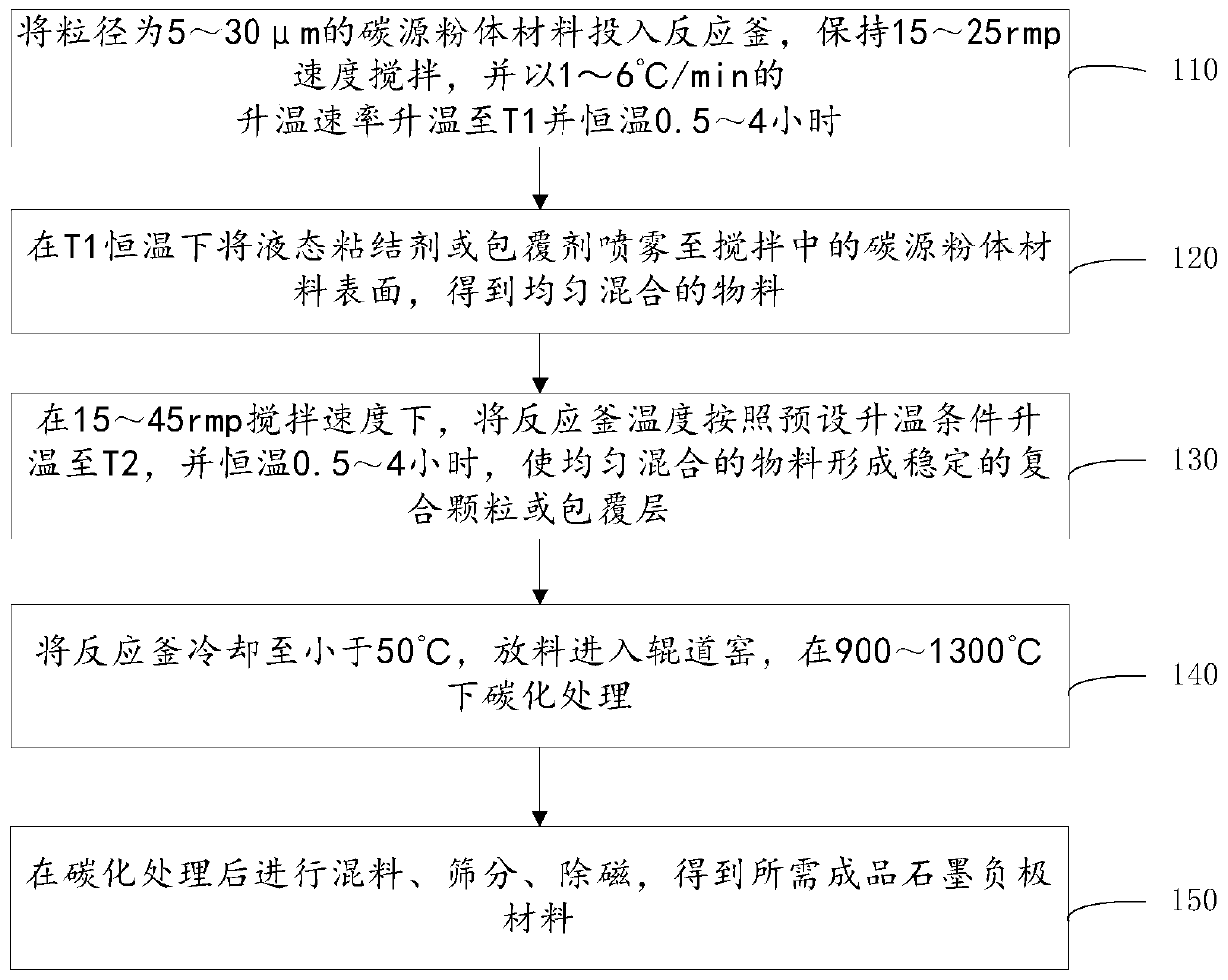

Process method for granulating or coating graphite negative electrode material

ActiveCN109956471AImprove cycle lifeIncrease charging rateGraphiteCell electrodesCarbonizationRoom temperature

The invention discloses a process method for granulating or coating a graphite negative electrode material. The method comprises the following steps: 1) adding a carbon source powder material of 5-30[mu]m into a reaction kettle, stirring the material at a speed of 15-25 rpm, heating the material to T1 at a heating rate of 1-6 DEG C / min, and carrying out constant temperature treatment for 0.5-4 hours, T1 ranging from room temperature to 300 DEG C; 2) at the constant temperature T1, spraying a liquid binder or a coating agent to the surface of the carbon source powder material under stirring toobtain a uniformly mixed material; 3) increasing the temperature of the reaction kettle to T2 according to a preset temperature rise condition at a stirring speed of 15-45 rpm, and performing constant-temperature treatment for 0.5-4 hours to enable the uniformly mixed materials to form stable composite particles or coatings, T2 ranging from T1 to 900 DEG C; 4) cooling the reaction kettle to be lower than 50 DEG C, feeding the reaction kettle into a roller kiln, and carbonizing the raw materials at 900-1300 DEG C, and 5) mixing, screening and demagnetizing the product after carbonization to obtain the required finished product, namely, the graphite negative electrode material.

Owner:溧阳紫宸新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com