Anode material of lithium ion cell and preparation method thereof

A technology for lithium ion batteries and positive electrode materials, applied in the field of lithium cobalt oxide materials and their preparation, can solve the problems of unfavorable industrialized production, high cost of lithium cobalt oxide materials, difficulty in realizing large-scale production, etc., so as to improve the compaction density and volume. Effects of specific capacity, improved long-term cycle performance, and increased structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

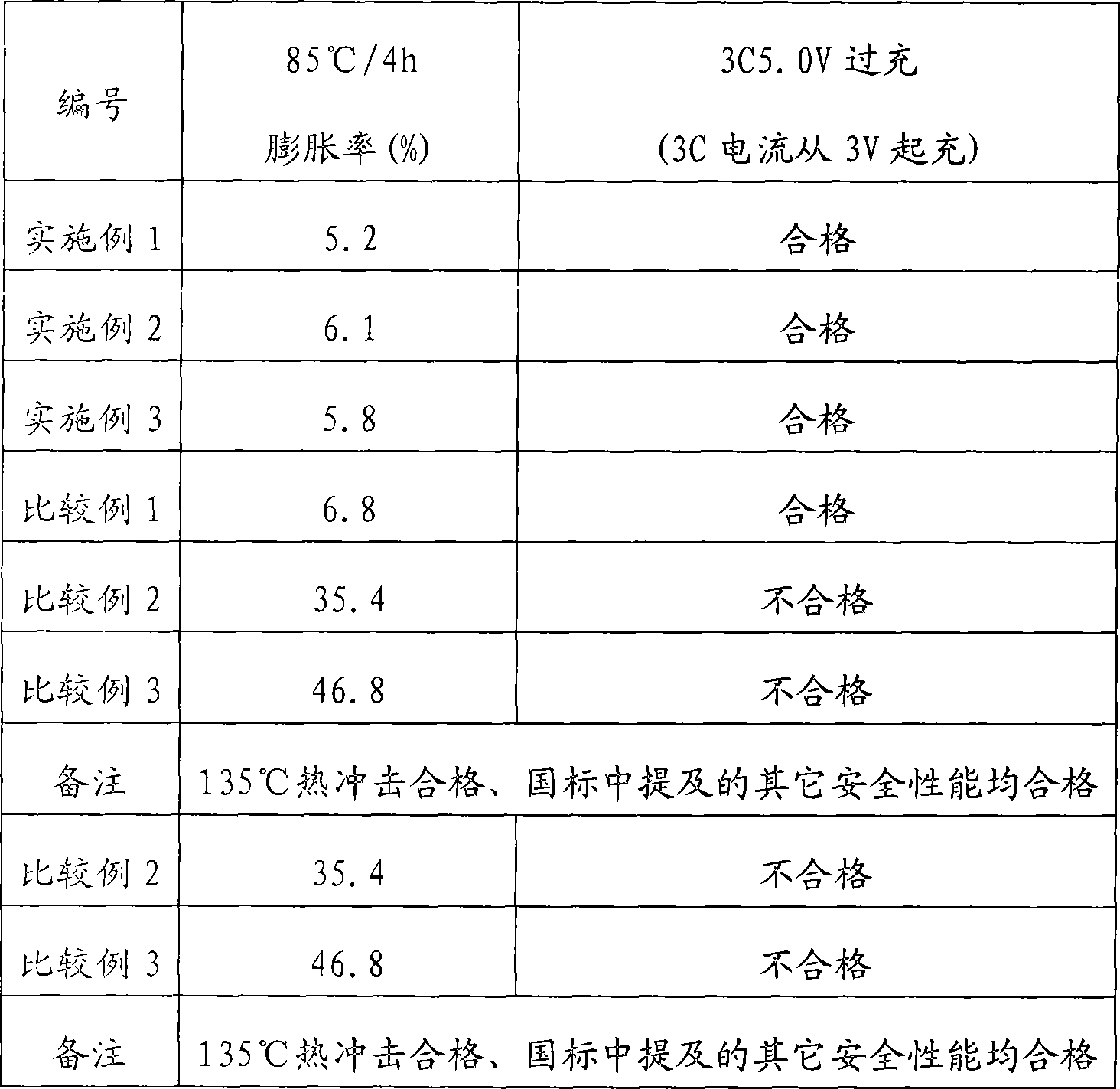

Examples

preparation example Construction

[0032] Step 1, preparation of doped tricobalt tetroxide:

[0033] 1) Select high-purity cobalt carbonate or cobalt oxalate as raw material, Sb 2 o 3 As a dopant, it is prepared at a molar ratio of Co:Sb=1:(0.002-0.02);

[0034] 2) Mix the cobalt raw material and the dopant according to a certain ratio, use a planetary ball mill or other mixing methods to mix the raw materials evenly, and put them in a bowl;

[0035] 3) Put the material at 300-500°C for 2-10 hours, and put it in a bowl;

[0036] 4) Put the material at 750-920°C for 1-2 hours, and then sieve to obtain the required raw material of tricobalt tetroxide;

[0037] Step 2, A material production:

[0038] 1) Select cobalt tetroxide and lithium carbonate (purity ≥ 99.5%) prepared in step 1 as raw materials, and carry out ingredients according to the lithium-cobalt ratio of 1.05-1.20;

[0039] 2) Use planetary ball mill or other forms of ball milling to mix the dry powder evenly, then loosely pack it in a bowl and put...

Embodiment 1

[0054] Prepare lithium cobalt oxide cathode material according to the above-mentioned scheme:

[0055] 1.1 Using cobalt oxalate as raw material, Sb 2 o 3 As a dopant, the ingredients are mixed according to the molar ratio of Co:Sb=1:0.005, treated at 400°C for 3h, sieved into a bowl, and treated at 900°C / 2h to obtain tricobalt tetroxide;

[0056] 1.2 Select lithium carbonate and cobalt tetroxide prepared in step 1.1 as raw materials, mix the ingredients according to the lithium-cobalt ratio of 1.08:1, put in a bowl, treat at 900°C / 8h, and obtain material A after crushing and grading;

[0057] 1.3 Lithium carbonate, small particles of highly active cobalt carbonate (0.1μm≤D50≤1.0μm), dopant Sb 2 o 3 , according to the stoichiometric ratio Li 1.0 co 0.99 Sb 0.01 o 2 Carry out batching, after the dry powder is mixed evenly, obtain B material;

[0058] 1.4 Select material A prepared in step 1.2 and material B prepared in step 1.3, mix according to the weight ratio of 90:10...

Embodiment 2

[0062] Prepare lithium cobaltate positive electrode material by the method for above-mentioned embodiment 1, but different from above-mentioned embodiment 1 is:

[0063] 2.1 The dopant Sb in step 1.1 of embodiment 1 2 o 3 The doping amount of the improved, by the molar ratio of Co:Sb=1:0.01 batching;

[0064] 2.2 Adjust the lithium-cobalt ratio in Step 1.2 of Example 1 to 1.10:1;

[0065] 2.3 Adjust the stoichiometric ratio to Li in step 1.3 of Example 1 1.0 co 0.995 Sb 0.005 o 2 ;

[0066] 2.4 Adjust the weight ratio of material A to material B in step 1.4 of Example 1 to 80:20;

[0067] 2.5 Carry out secondary synthesis of the material prepared in step 1.4, raise the temperature to 750°C for 4 hours and keep it for 4 hours, then increase the temperature to 940°C at a rate of 35°C / h, keep it for 12 hours, and then cool down naturally;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com