Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Suppress pressure pulsation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

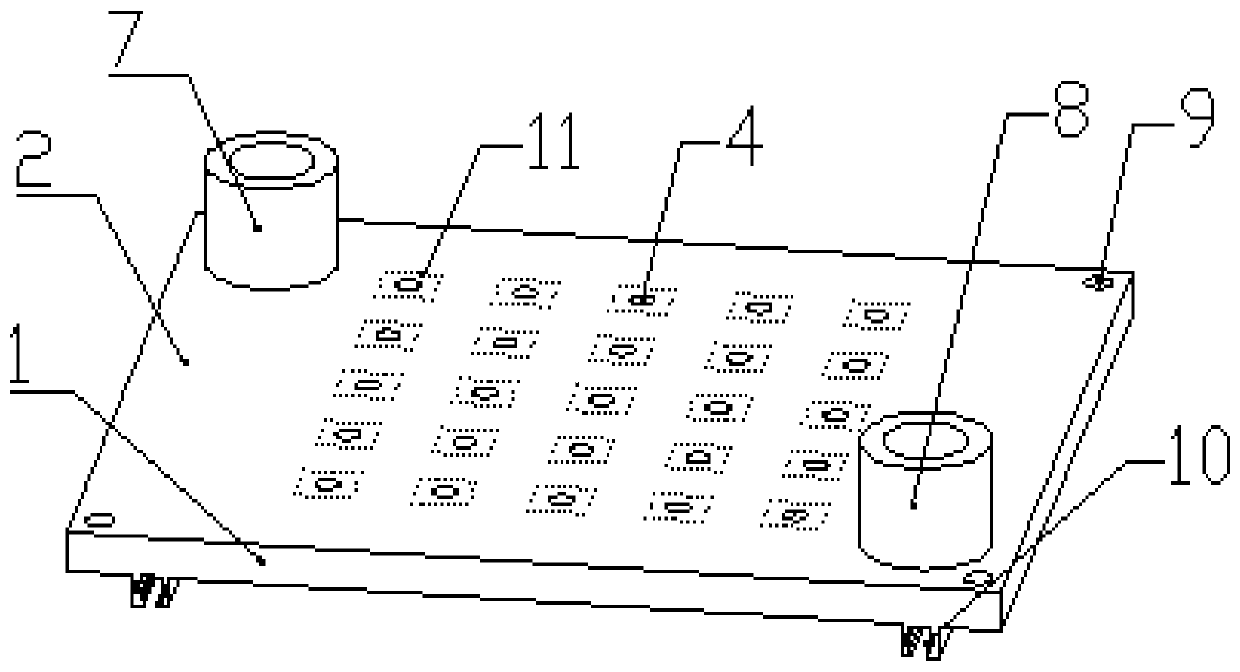

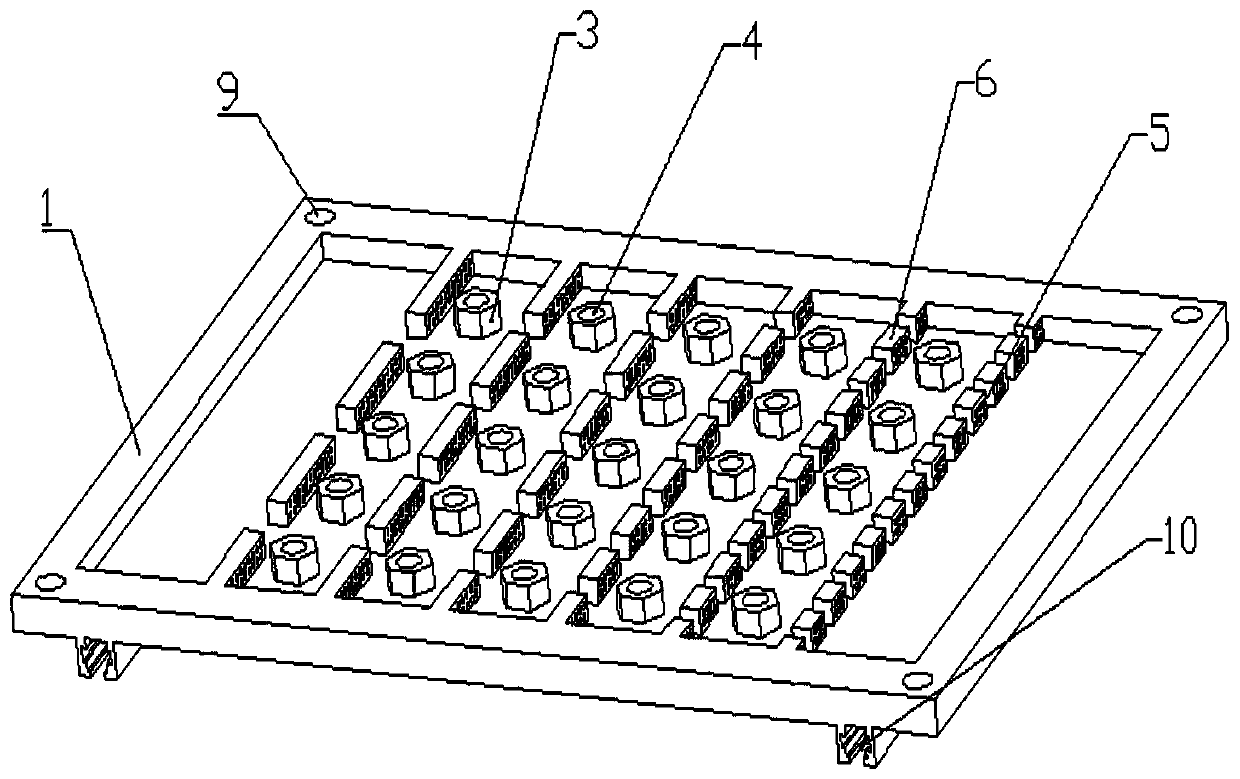

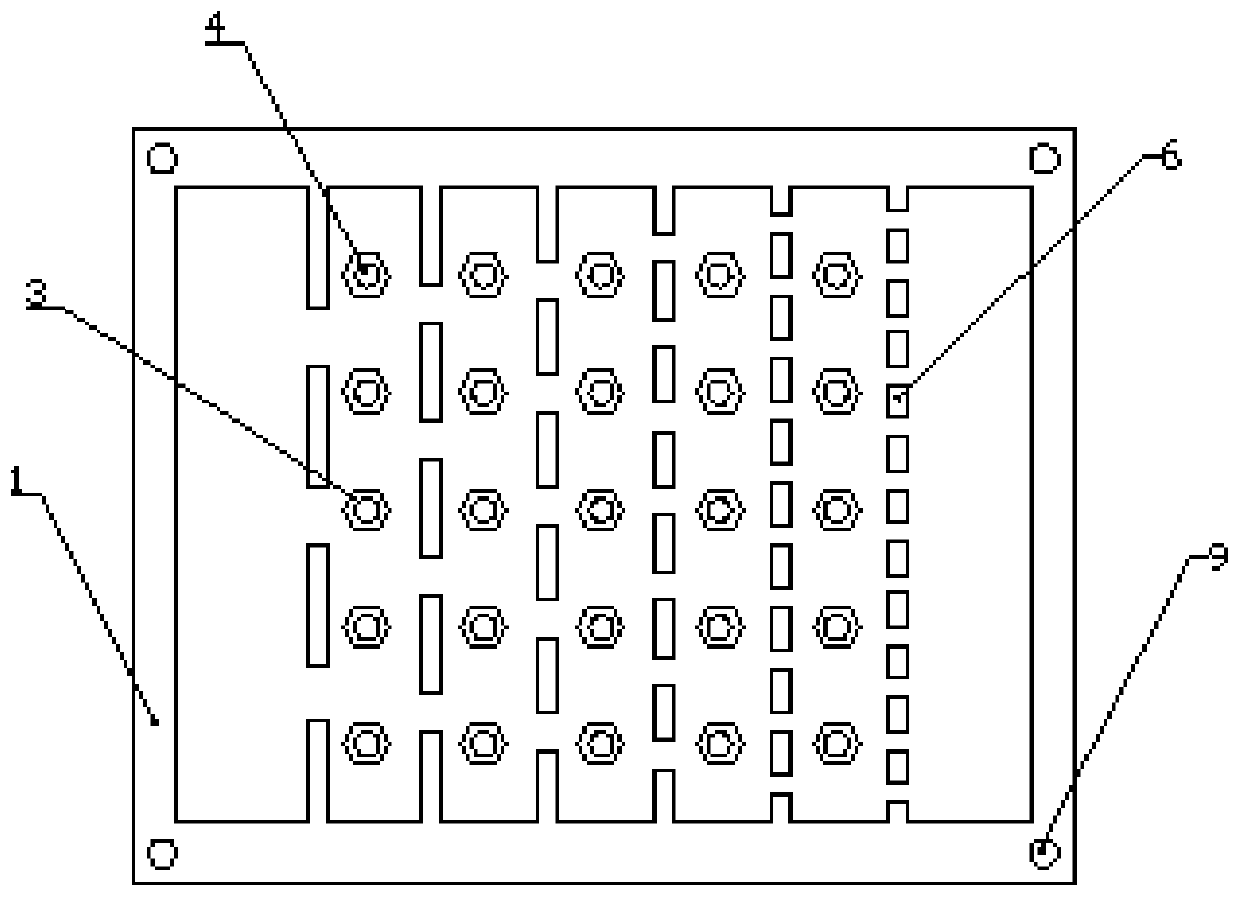

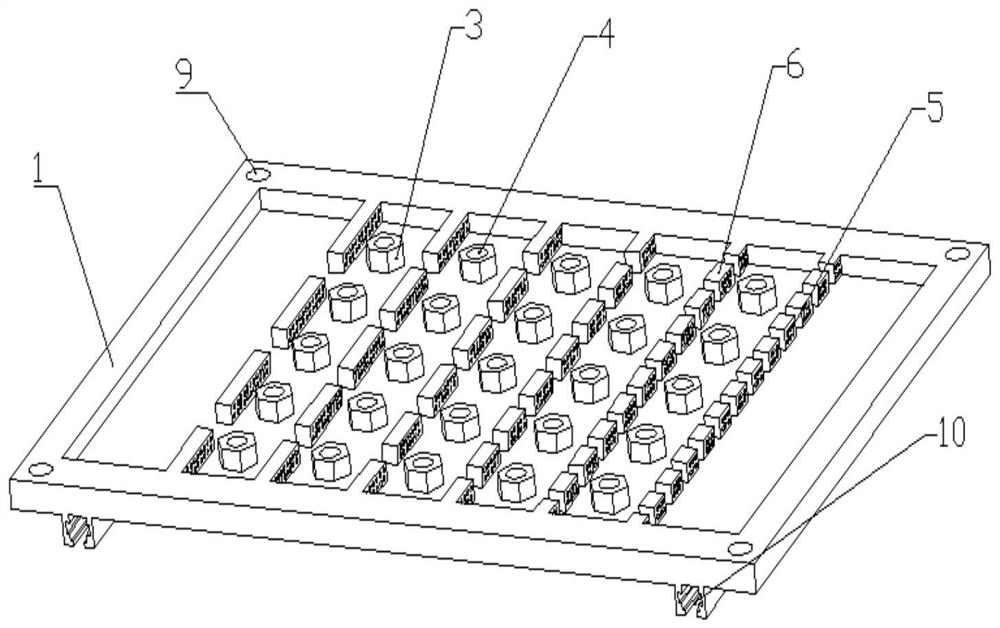

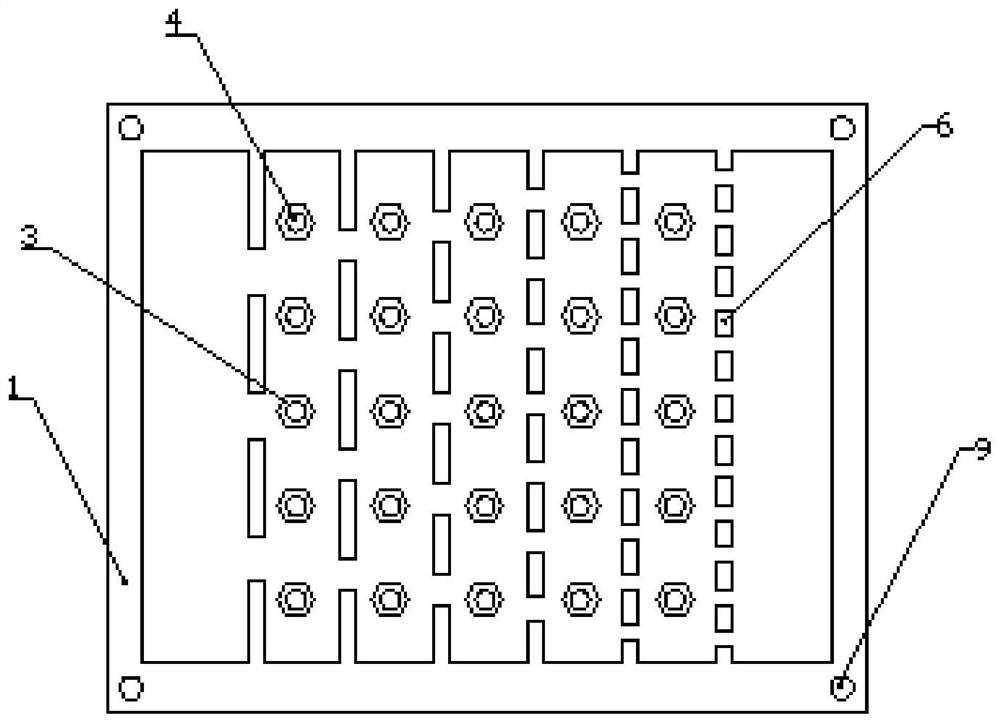

3D printing integrated radiator and application thereof in phased-array antenna

InactiveCN110165355ALowered byHelp passIndividually energised antenna arraysDe-icing/drying-out arrangementsEngineeringTemperature difference

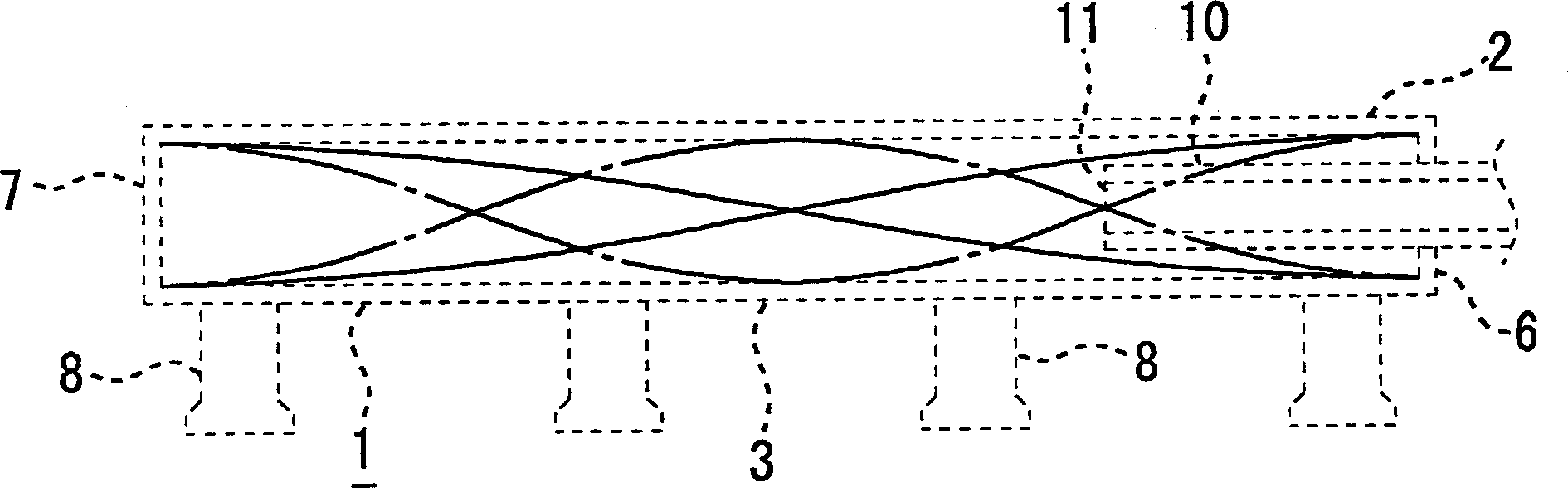

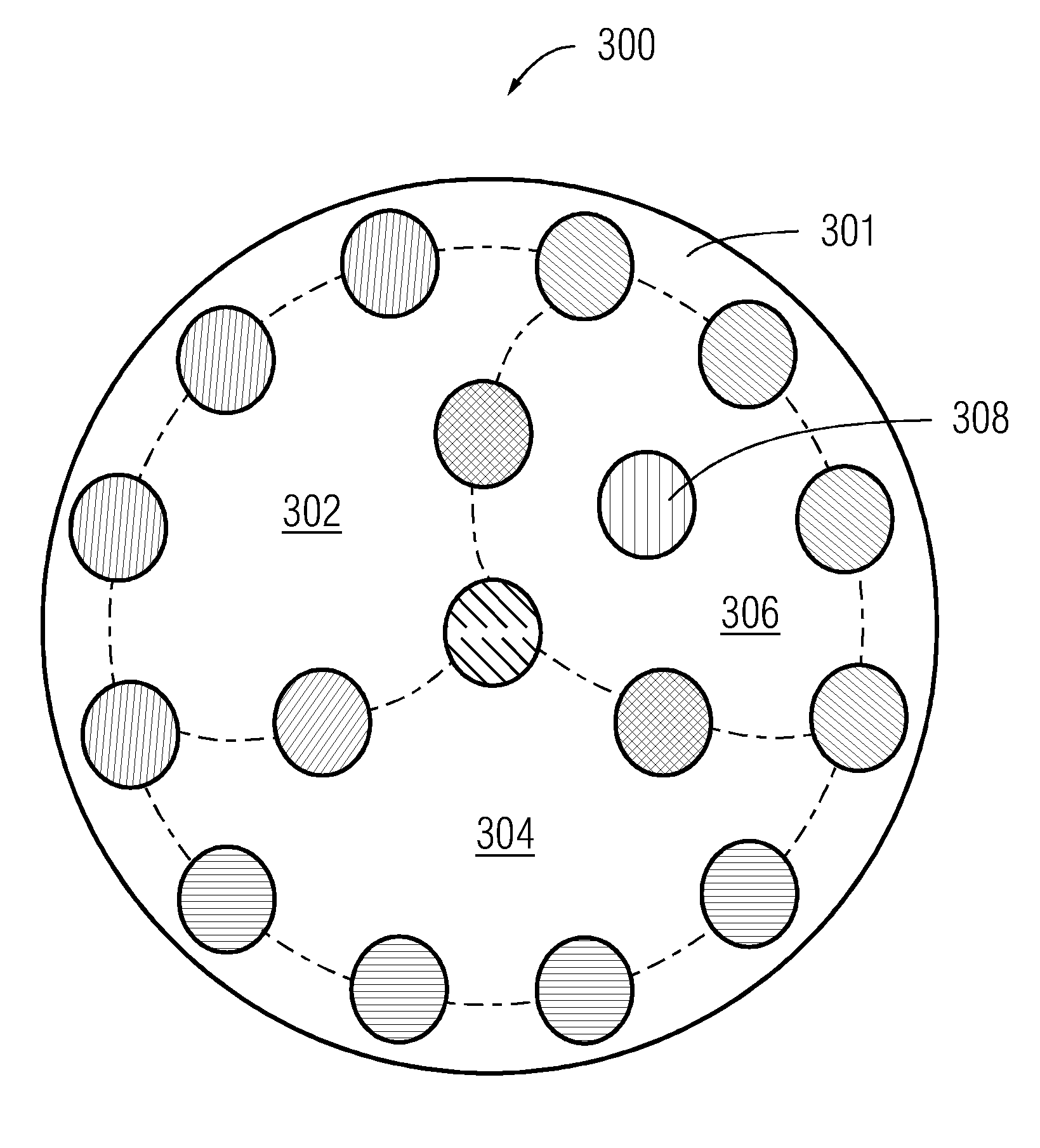

The invention relates to the field of heat dissipation, in particular to a micro-channel radiator, integrated manufacturing and an application of the micro-channel radiator in a control array antenna.The radiator is manufactured through 3D printing. Through a fluid channel which is distributed in a gradually changed manner and a liquid injection port and a liquid outlet which are respectively formed at the biggest end and the smallest end of the flow channel, cooling liquid uniformly passes through the whole fluid channel. When the radiator is in use, the highest temperature of the radiator is 298K, the lowest temperature of the radiator is 295K, and the temperature difference after heat dissipation is 3 DEG C. Compared with a pure runner structure, the radiator is stronger in heat dissipation capability and more uniform in temperature distribution after heat dissipation, and has the characteristics of good heat dissipation performance and temperature uniformity, one-time forming, noneed of using a nut sealing ring and the like for packaging.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

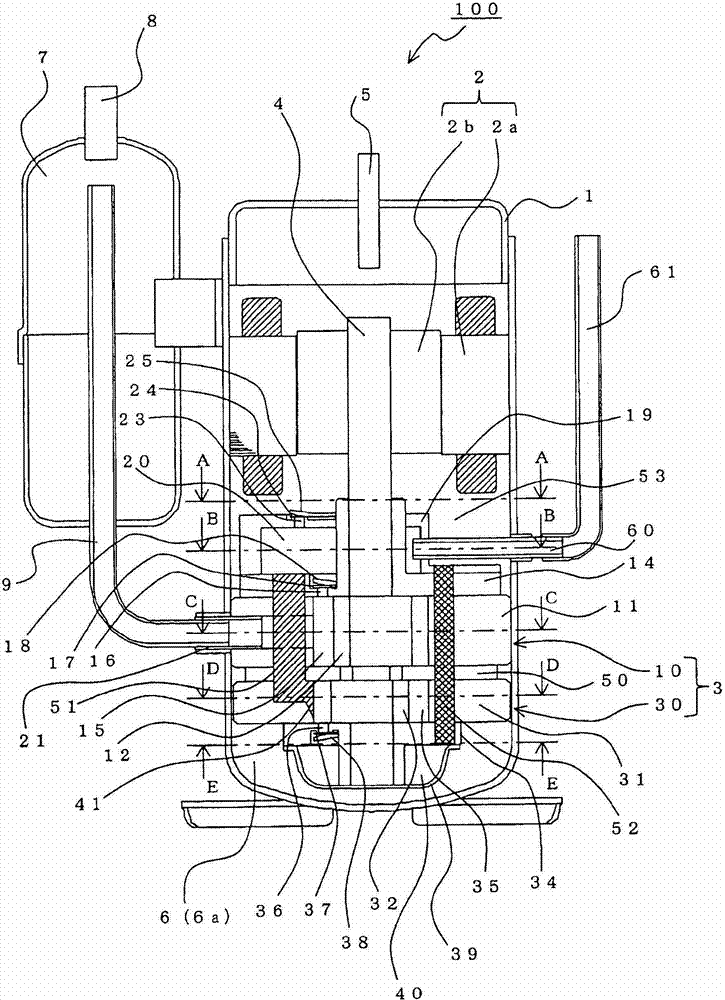

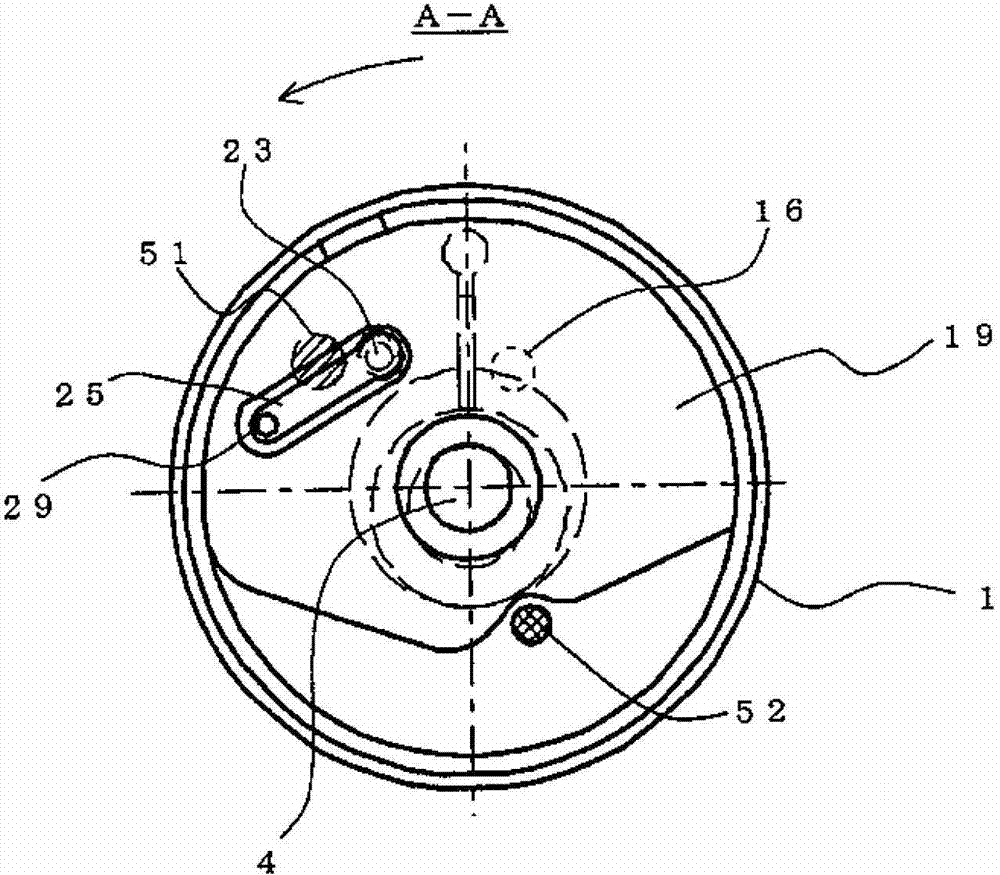

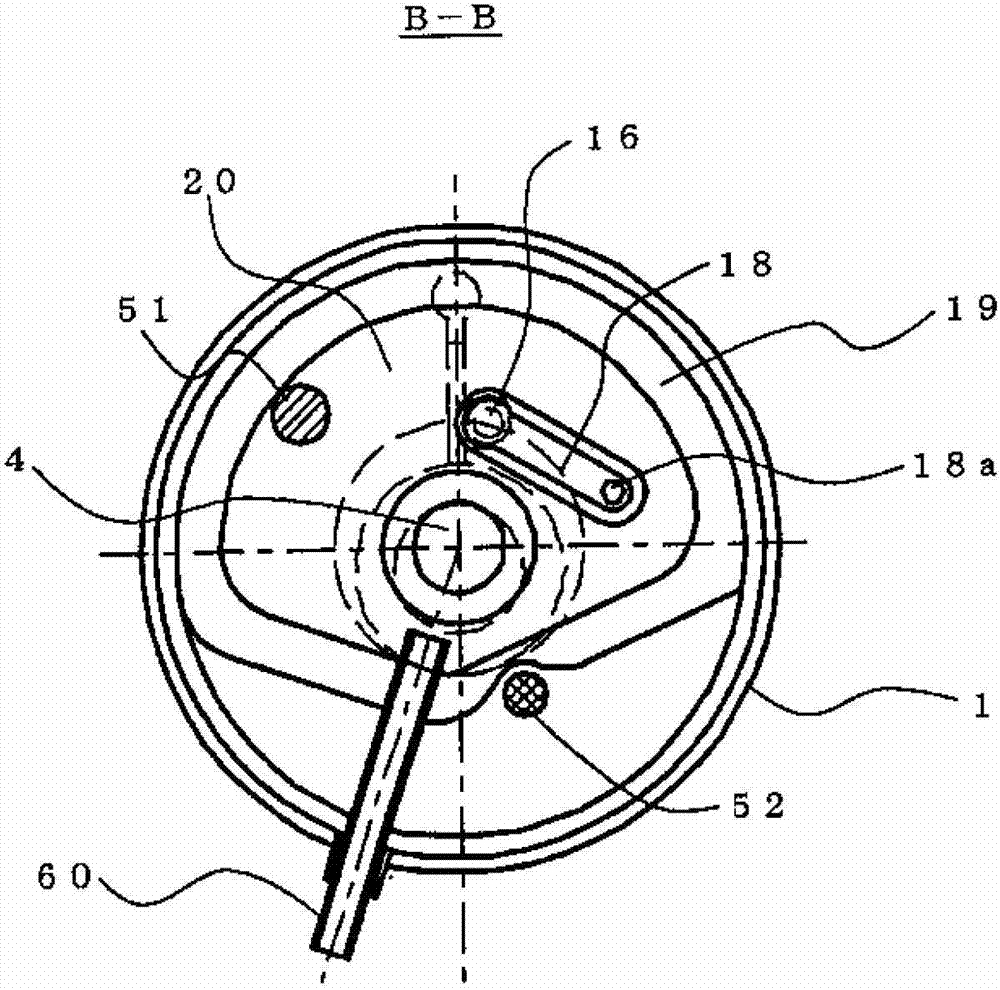

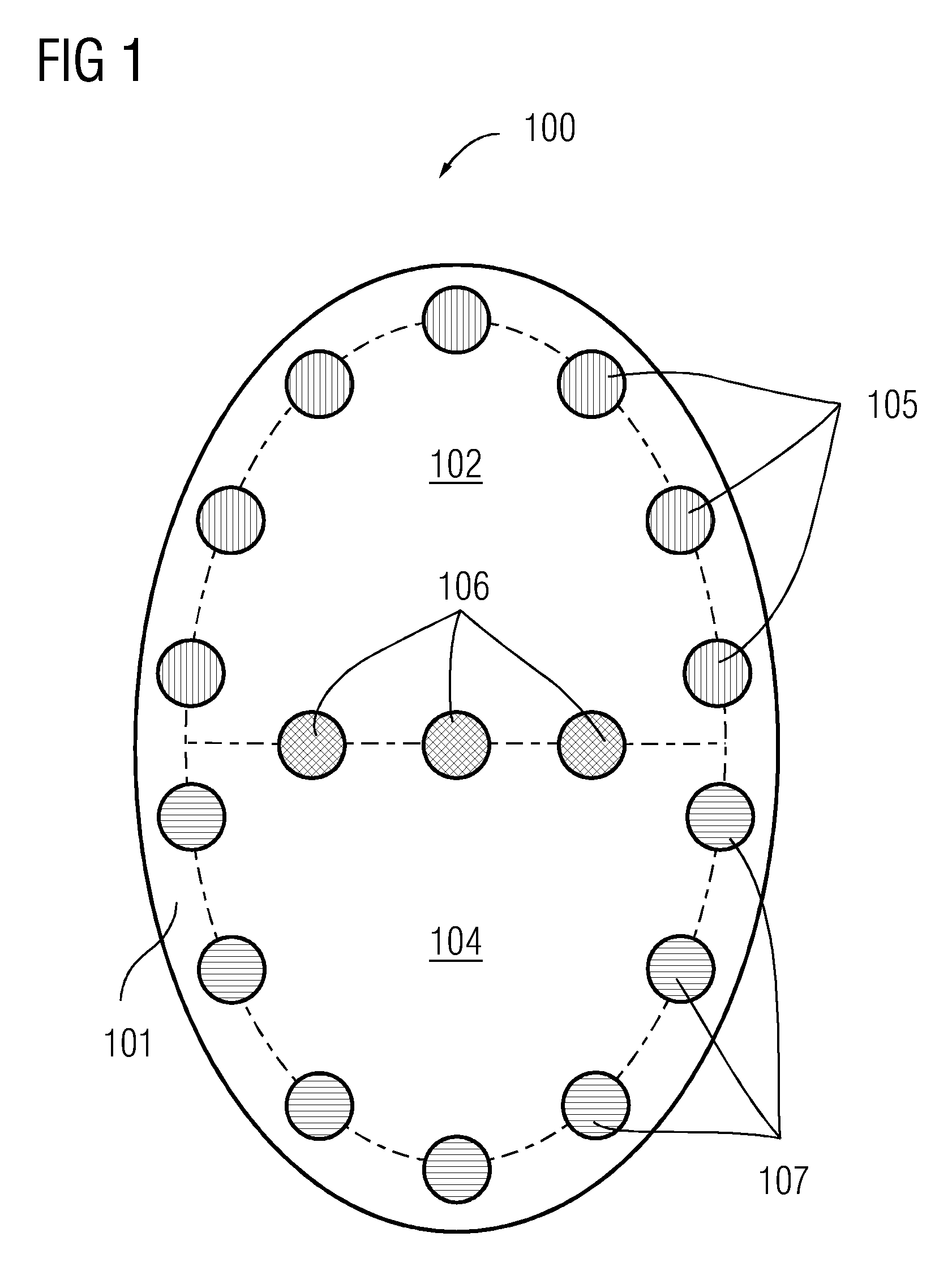

Two stage rotary compressor

ActiveCN102900669AGood followabilitySuppress pressure pulsationRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsDischarge pressureRefrigerant

The invention provides a two stage rotary compressor which can improve tracing ability of refrigerating fluid imported into an advanced compressing portion, restrain pressure fluctuation in intermediate flow paths, and prevent running efficiency from reducing in low load running. The two stage rotary compressor (100) of the internal high-pressure type includes a low stage cover (19) that covers a low stage outlet port (16) and forms a low stage discharge space (20) therein. Further, the two stage compressor (100) includes a compression mechanism (3) provided with an intermediate passage (51) that connects the low stage discharge space (20) and the high stage compression chamber (35) and a bypass mechanism (a bypass port (23), a bypass valve (24), and a bypass valve guard (25) in the low stage cover (19), in which the bypass mechanism opens when a load is smaller than a predetermined load and in which the bypass mechanism connects the low stage discharge space (20) and a discharge pressure space (53).

Owner:MITSUBISHI ELECTRIC CORP

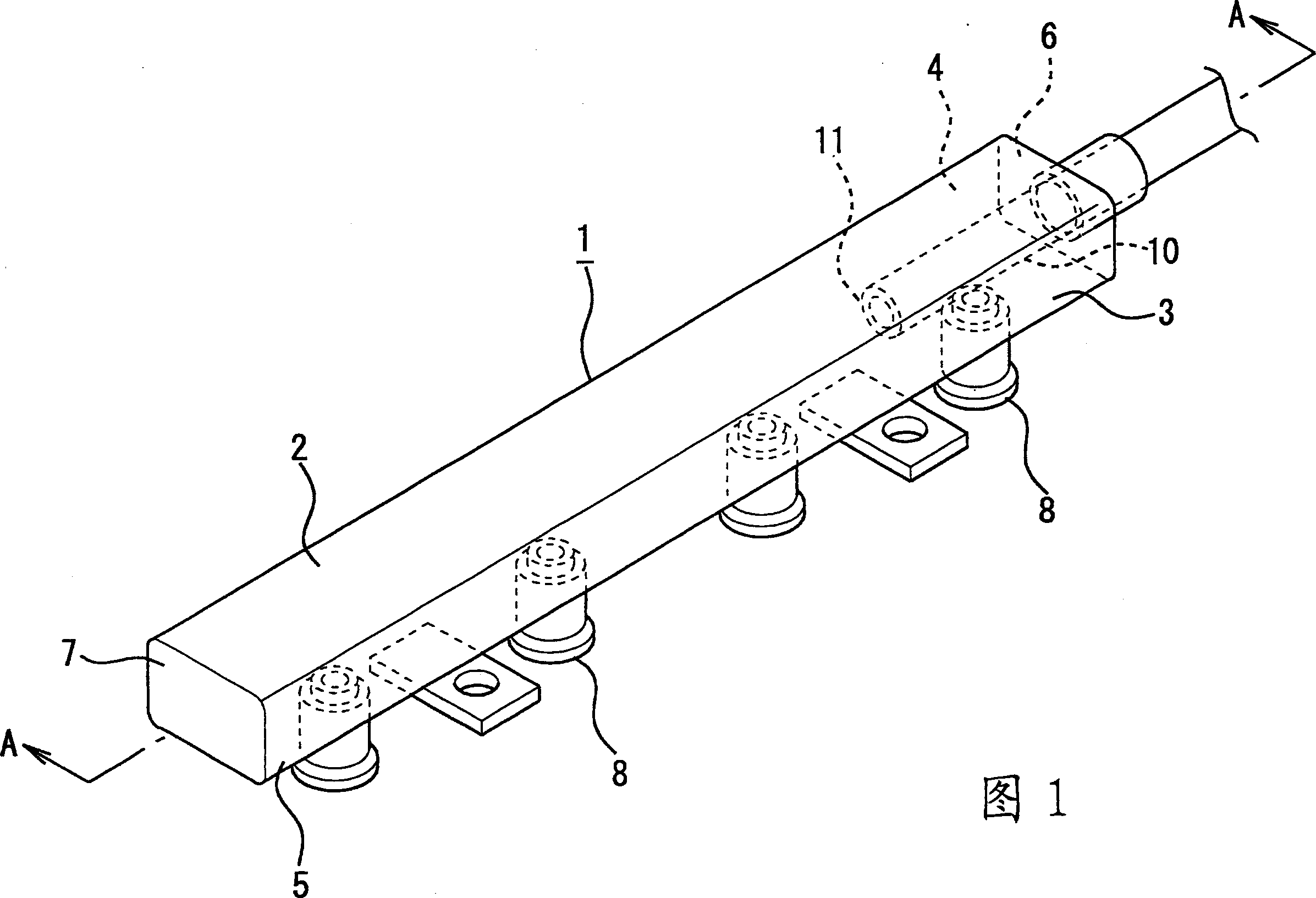

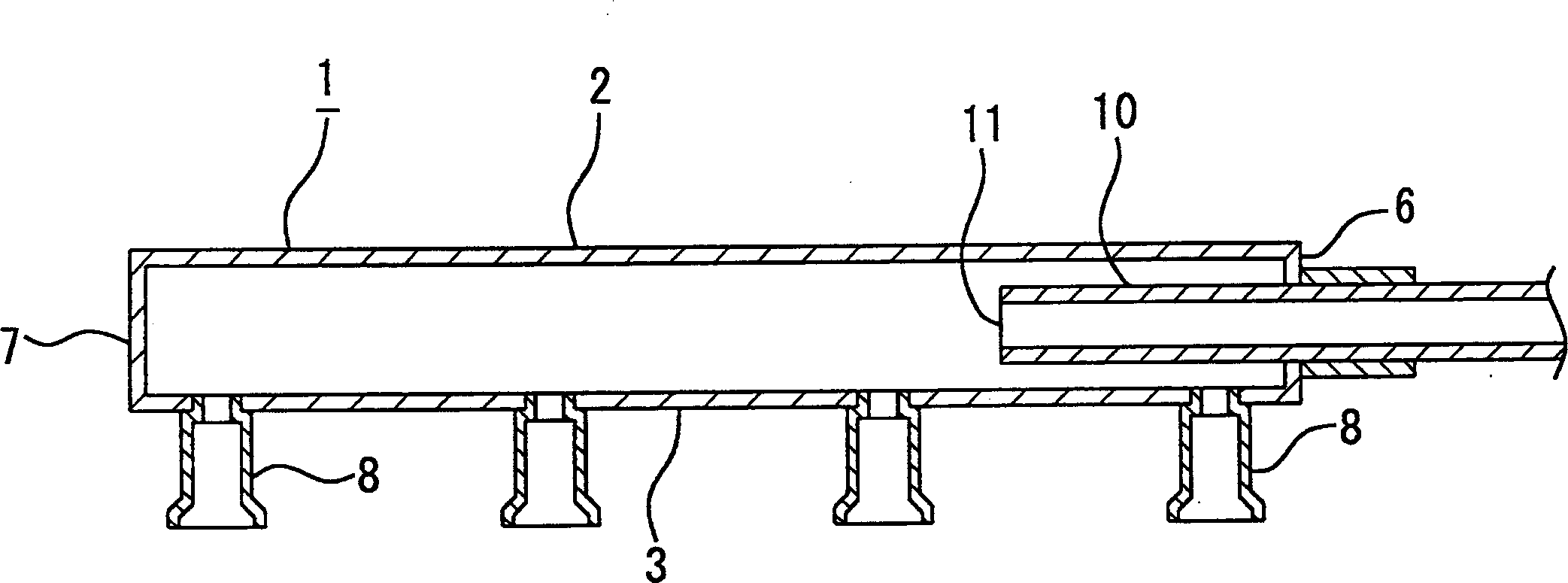

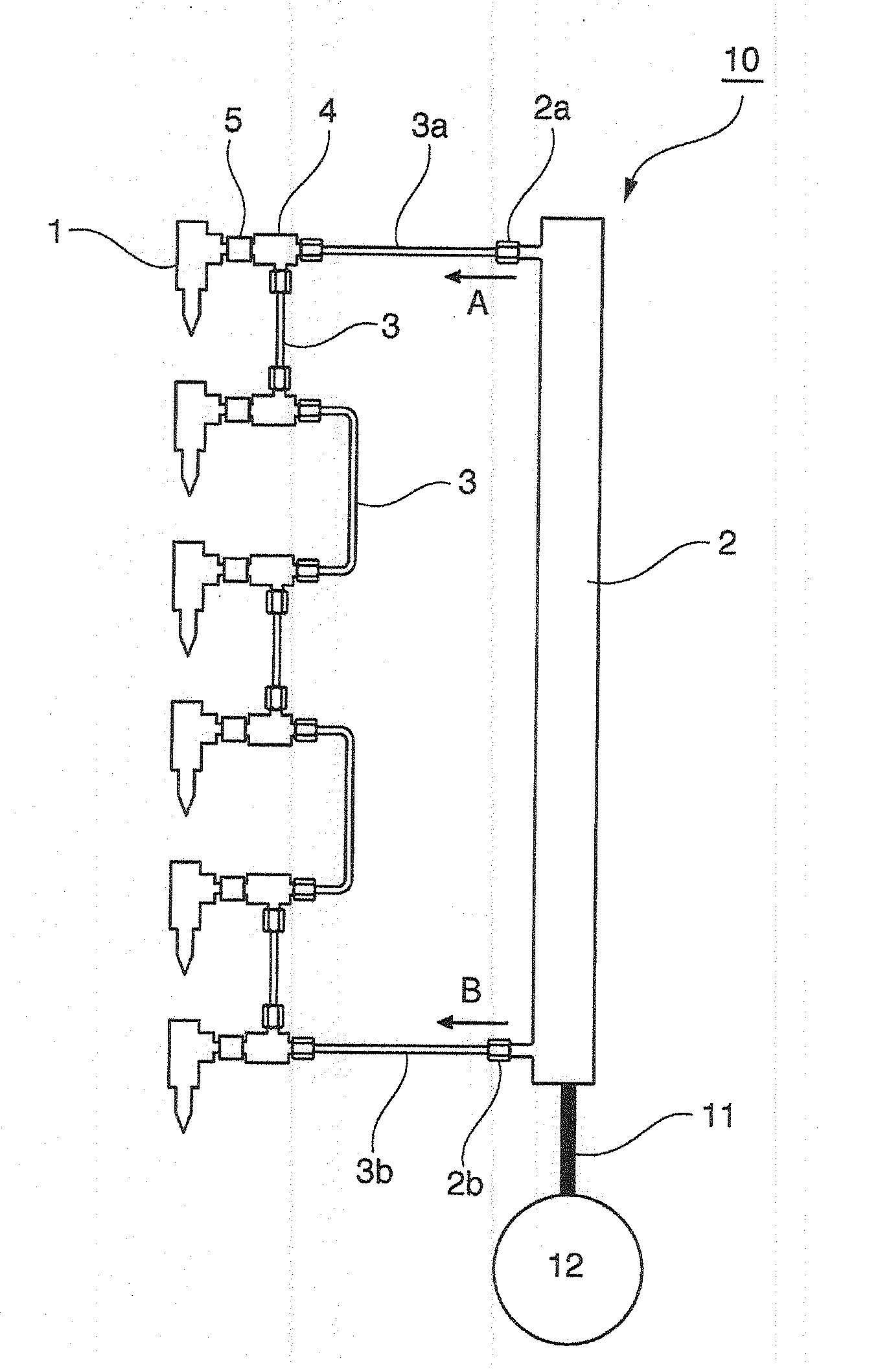

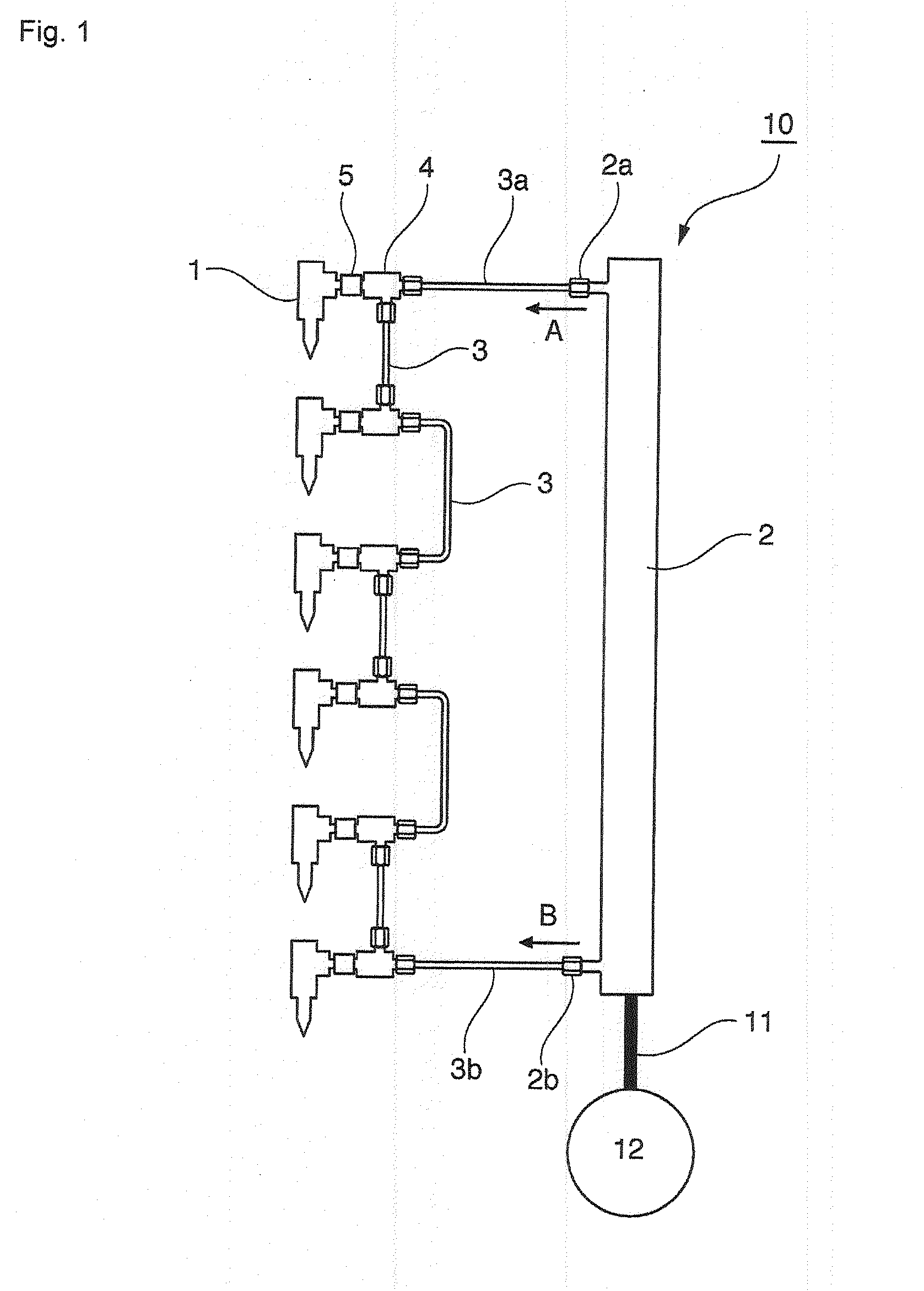

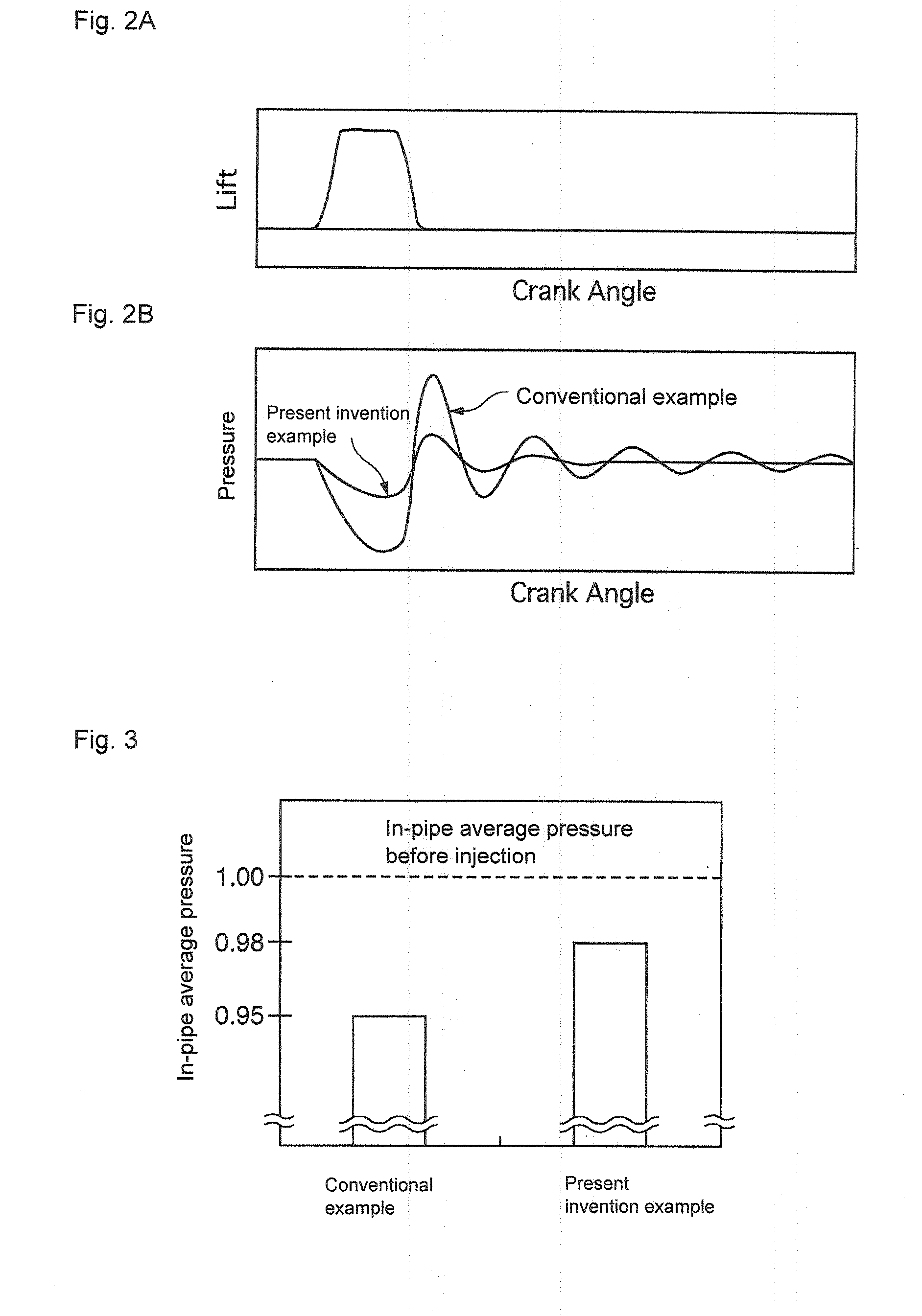

Fuel delivery pipe

InactiveCN1824941ASuppresses low frequency componentsLayout improvementPositive displacement pump componentsLow pressure fuel injectionManufacturing cost reductionFuel tank

The objective of the invention is to provide a fuel delivery pipe having high installation layout performance, and reducing manufacturing cost, while restraining propagation of a standing wave primary mode and a standing wave secondary mode, by connecting a fuel introducing pipe in the longitudinal direction to the inside from one end part of a fuel delivery body for forming a flexible absorbing wall surface on a wall surface. This fuel delivery pipe forms the flexible absorbing wall surface on the wall surface, has an injection nozzle, connects the fuel introducing pipe 10 to the one end part of the returnless type fuel delivery body 1 without a return circuit to a fuel tank, and connects this fuel introducing pipe 10 to the fuel tank via an underfloor pipe. When the total length in the longitudinal direction inside of the fuel delivery body 1 is set to 100, the fuel introducing pipe 10 is inserted inside the fuel delivery body 1 up to a position of 15 to 35 or 65 to 85, and is connected and fixed to the fuel delivery body 1.

Owner:USUI CO LTD

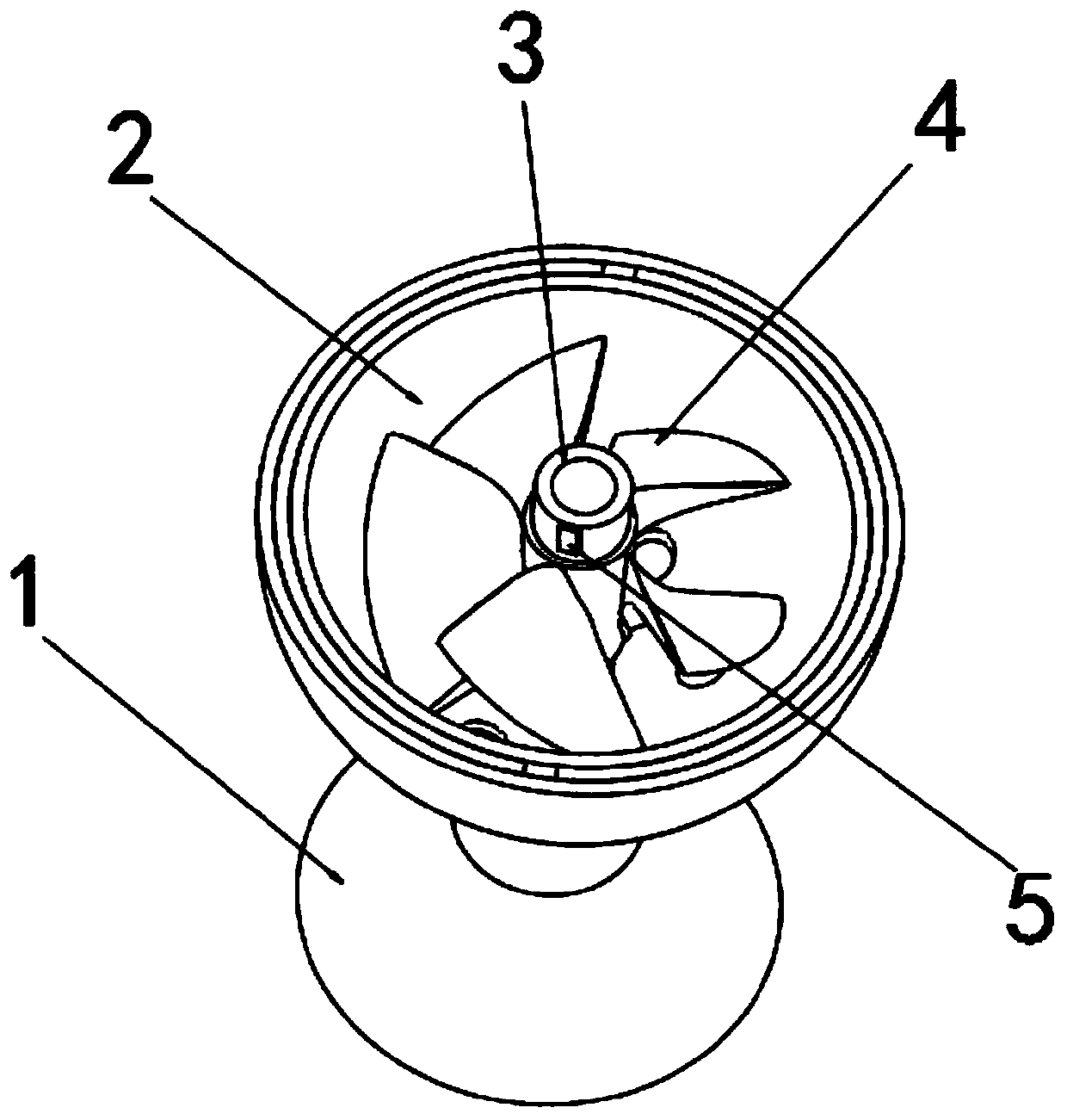

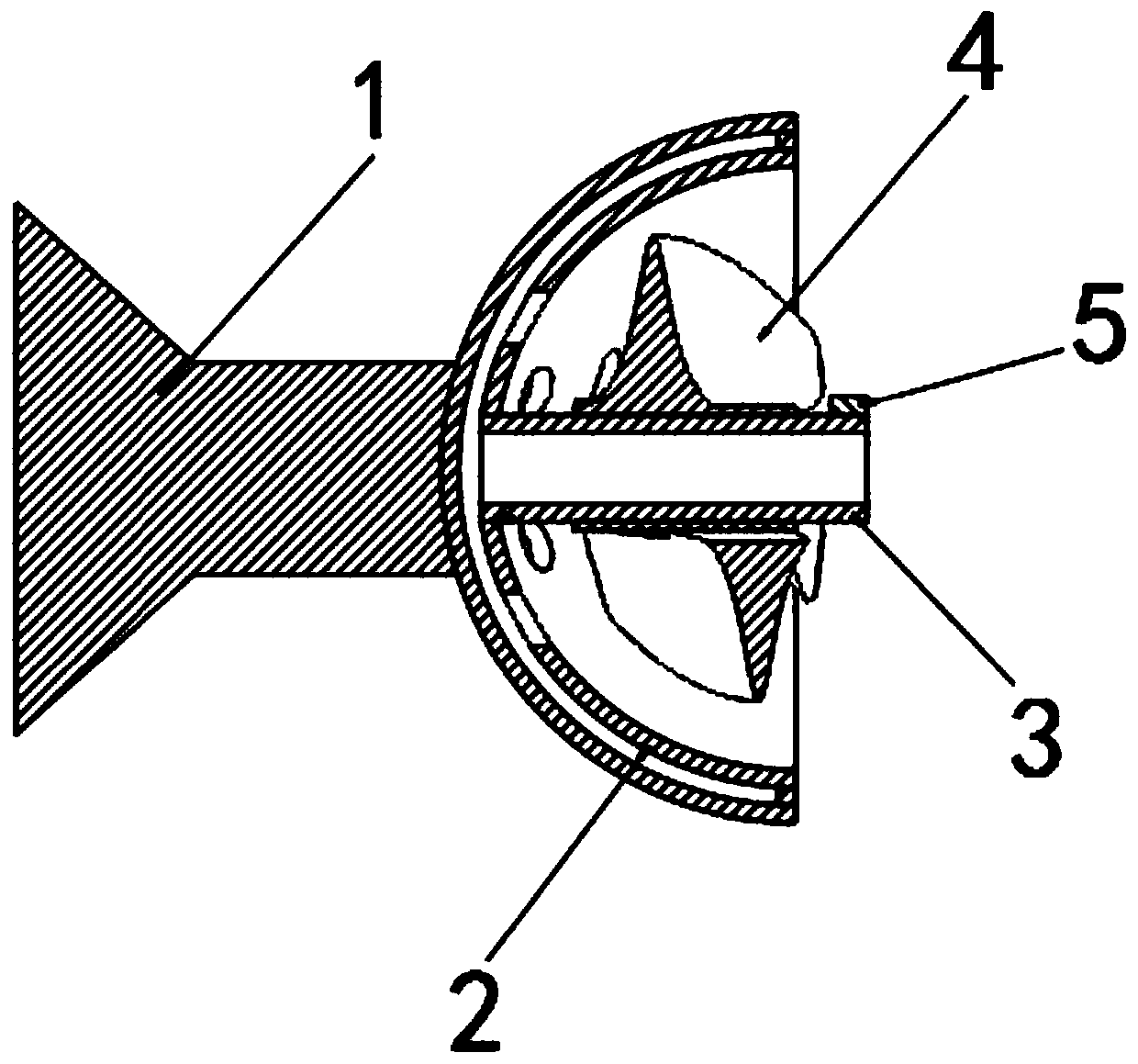

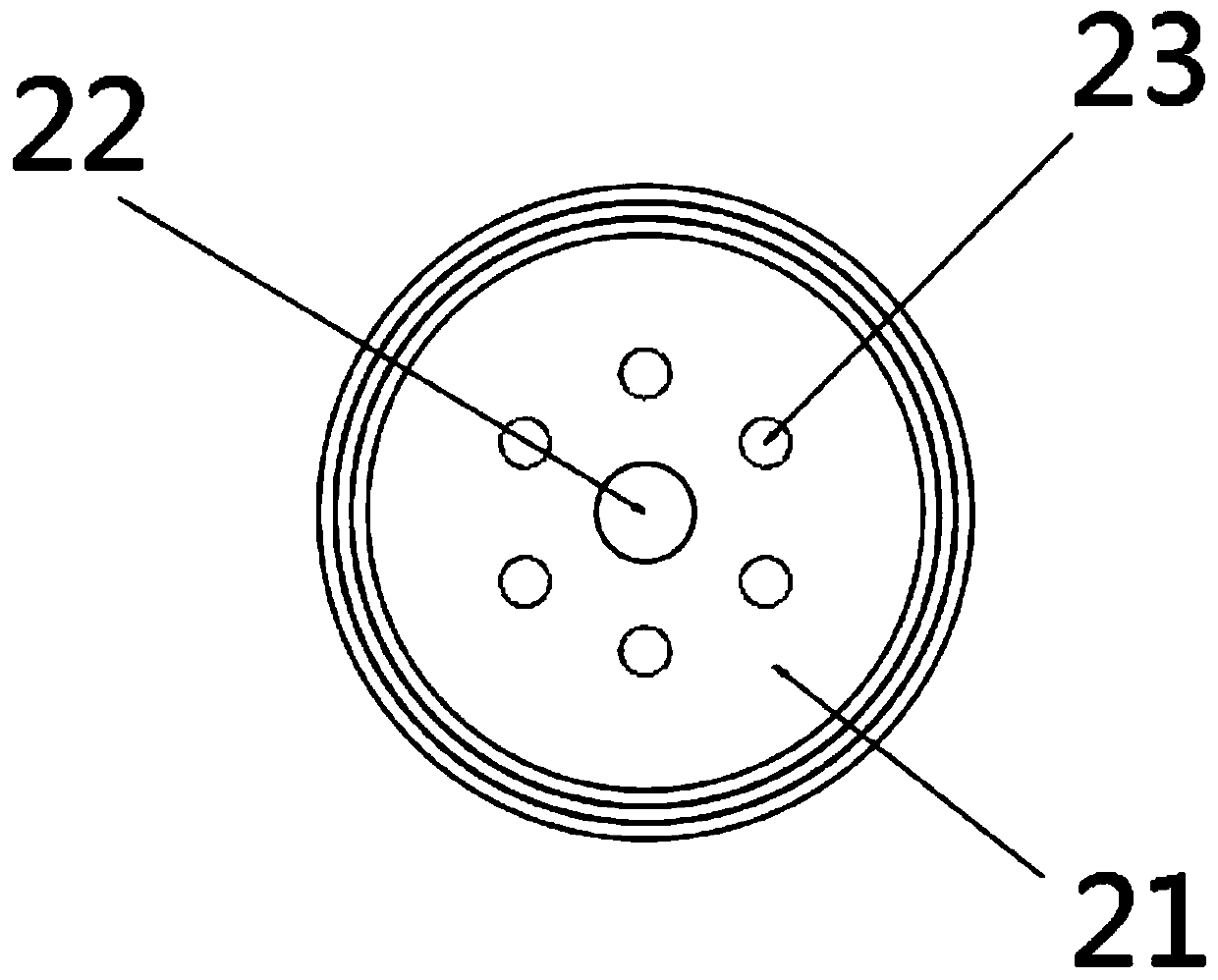

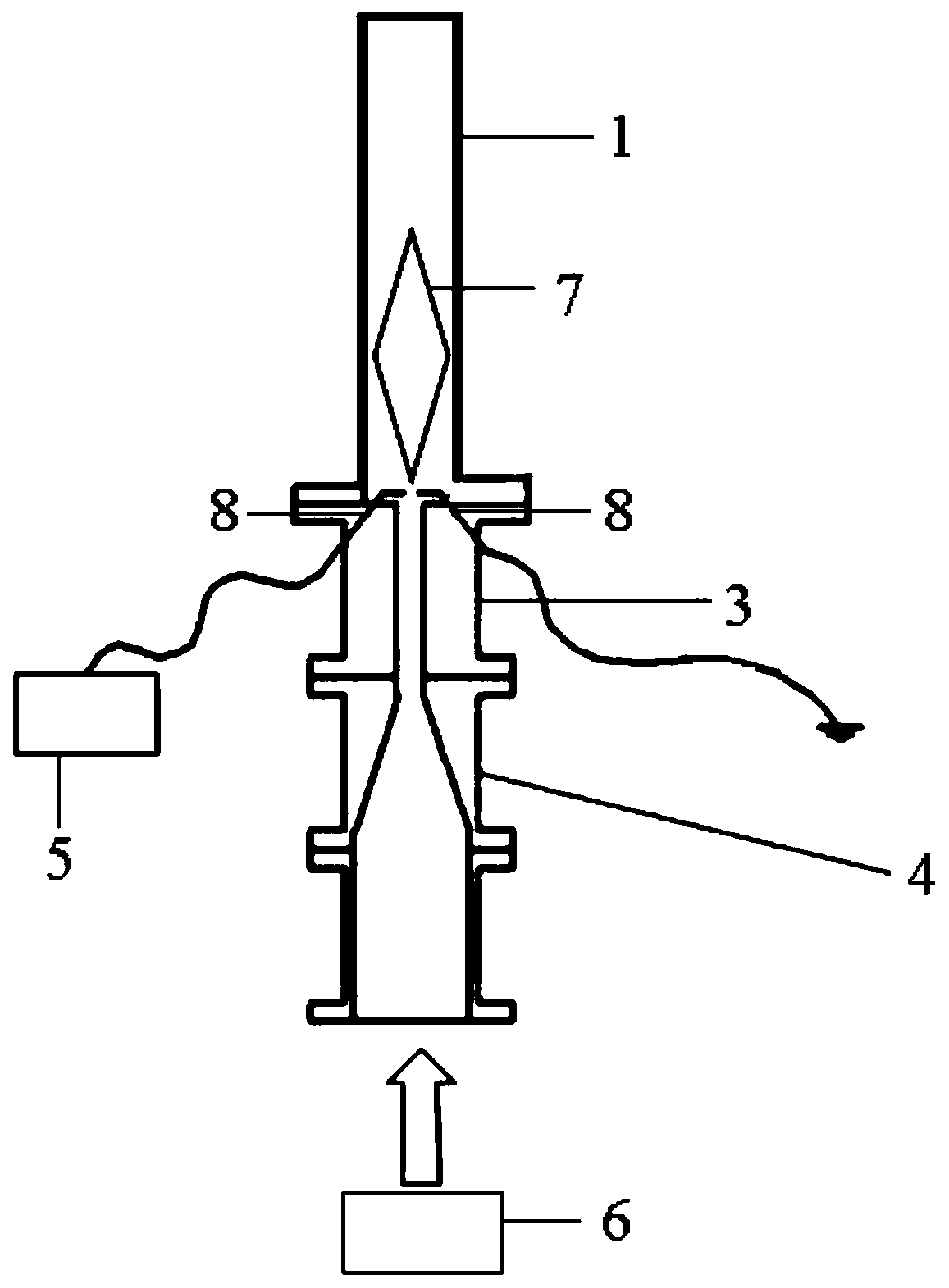

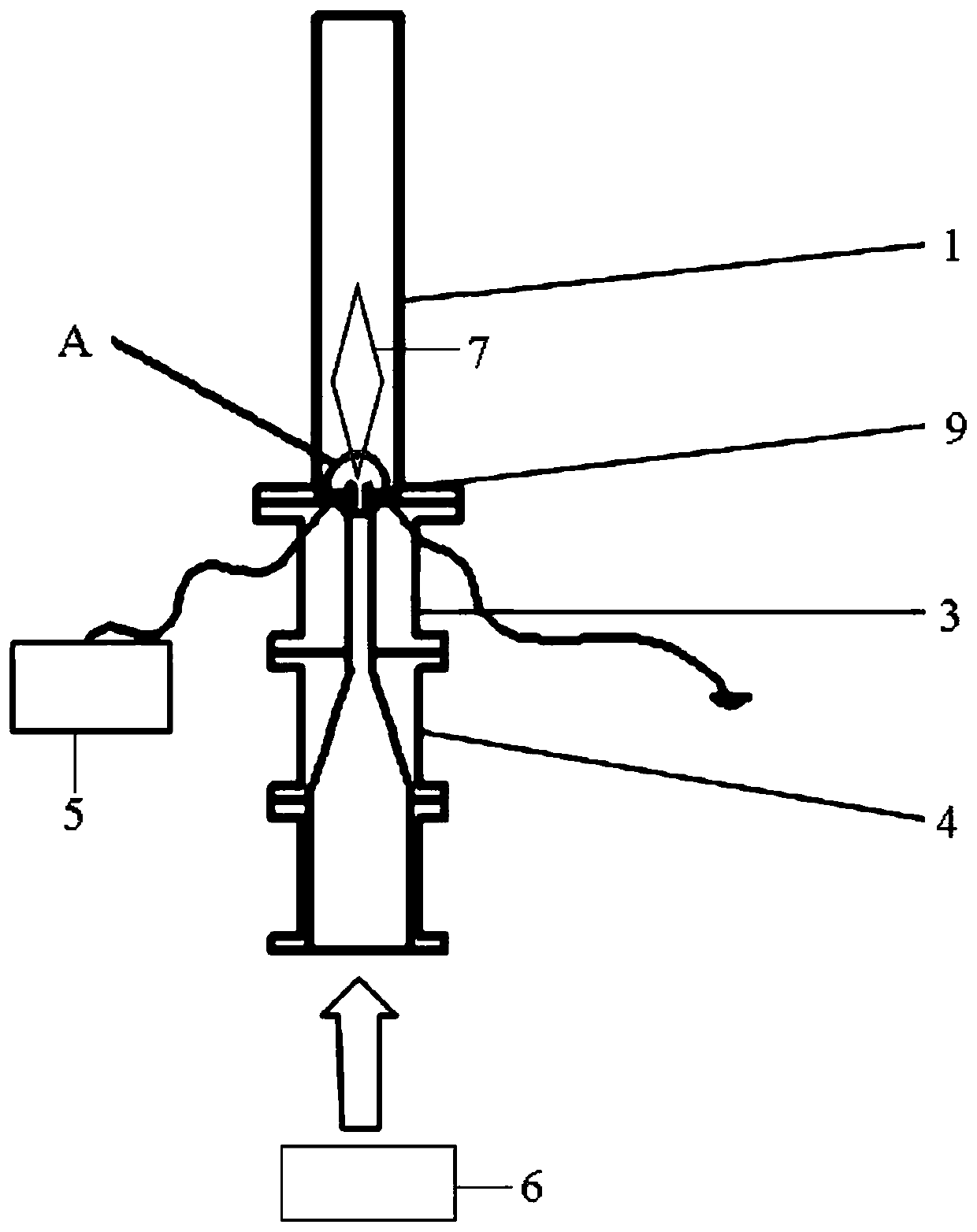

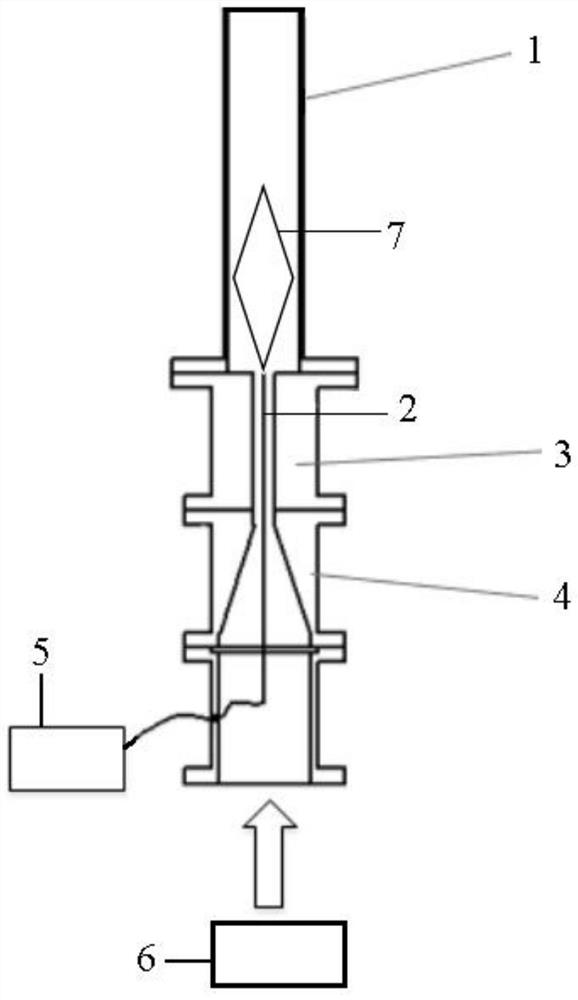

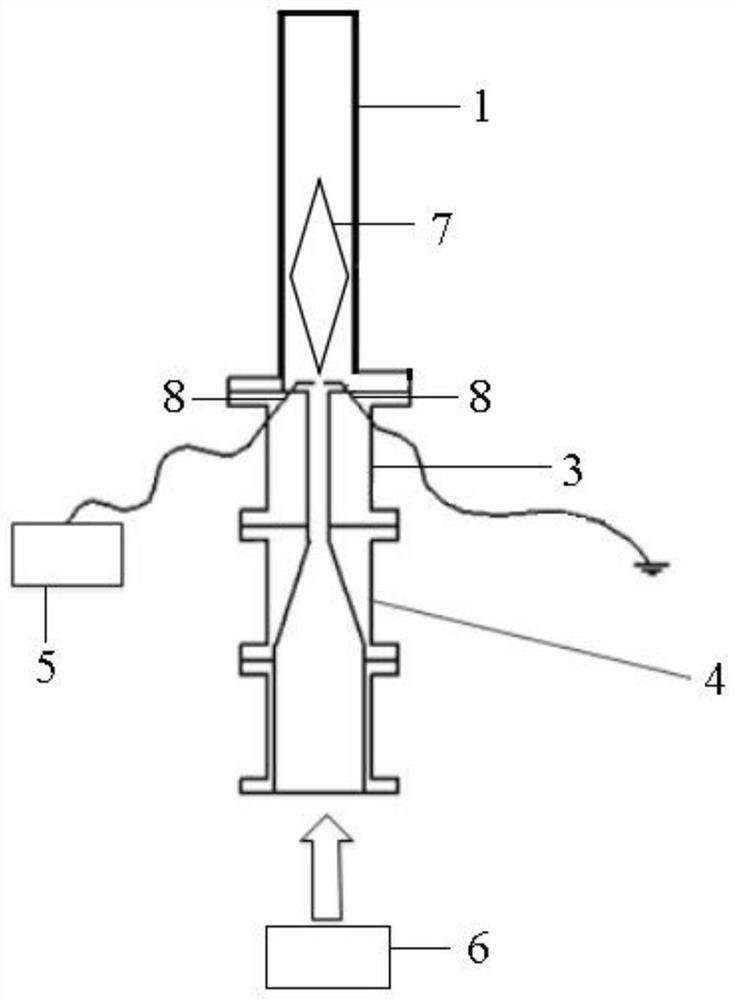

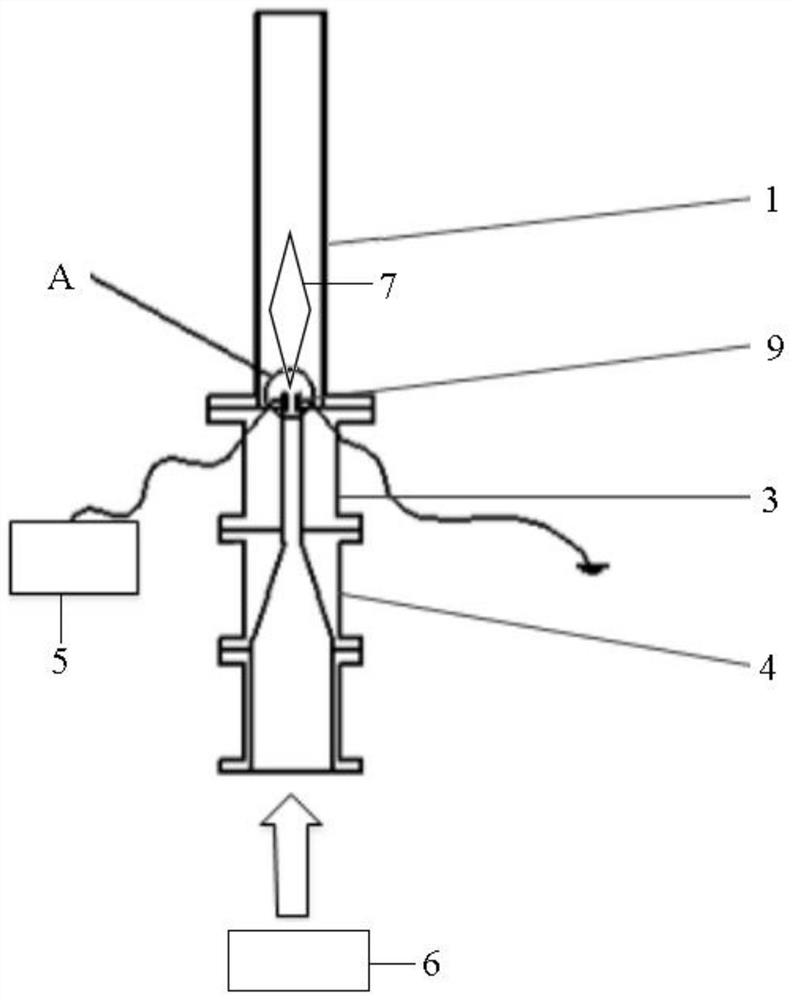

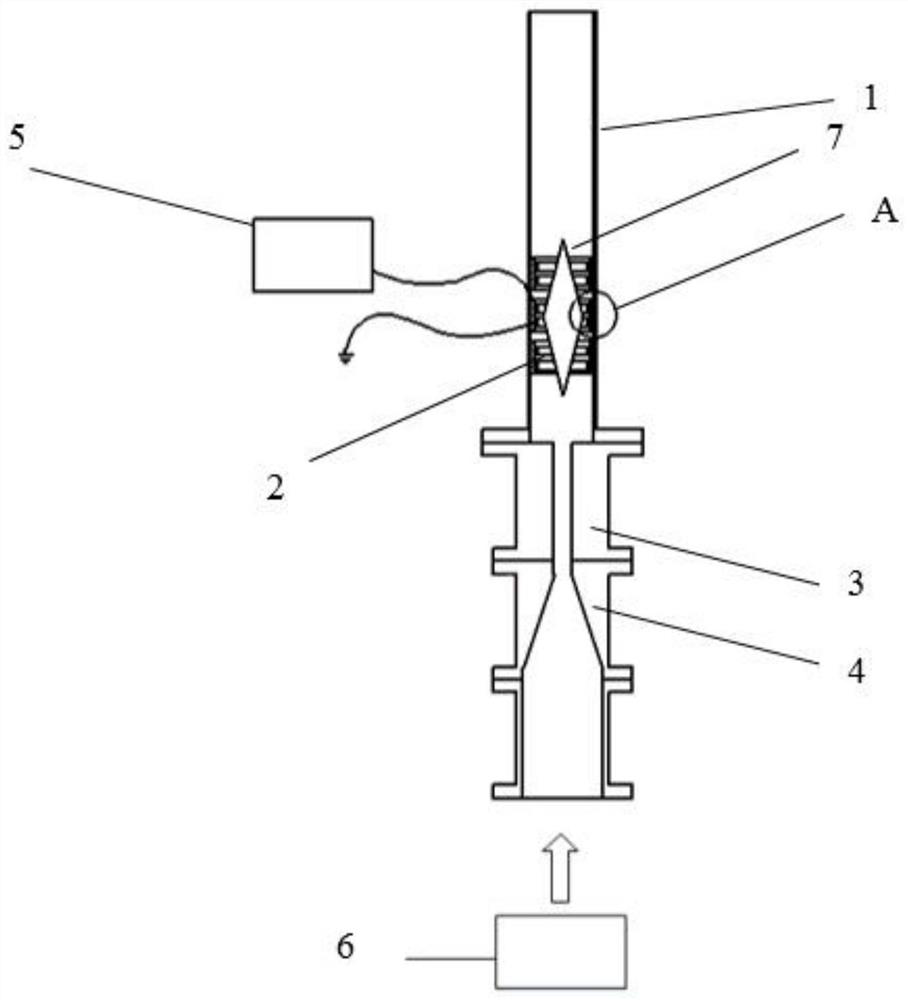

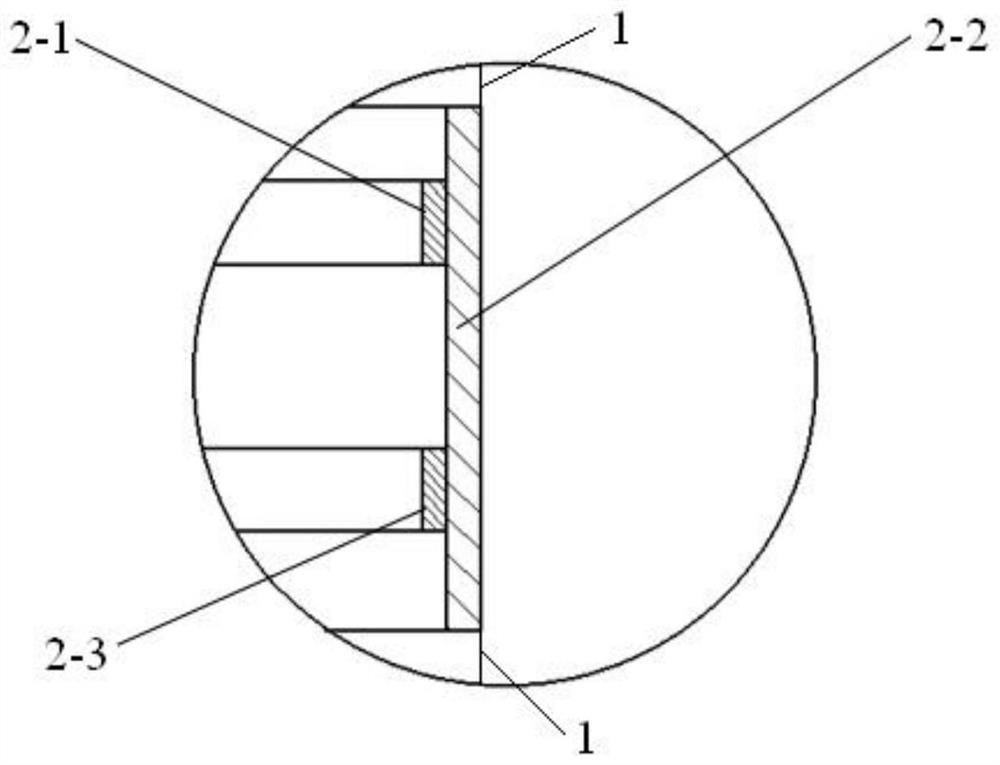

Flow control device and method for improving stability of ventilation cavitation bubbles

PendingCN111098973ASuppress pressure pulsationImprove stabilityWatercraft hull designHydrodynamic/hydrostatic featuresUnderwater navigationEngineering

The invention discloses a flow control device and method for improving ventilation cavitation stability. The flow control device comprises a cavitator, an air guide bowl, a ventilation pipeline, a spiral assembly, a flow controller and the like. High-pressure airflow enters an interlayer through an air inlet hole along a ventilation pipeline, is finally exhausted from an exhaust hole to form swirling airflow and impacts a spiral assembly to make the spiral assembly rotate around a super air bubble underwater vehicle, the flow controller is additionally arranged on a traditional cavitation device, the air in the cavitation device is made to rotate, internal energy of the high-pressure airflow is converted into axial and tangential kinetic energy, and thereby active control over the cavitation form is achieved. The flow control method for improving stability of the ventilation cavitation bubbles is advantaged in that the generation rate of the ventilation cavitation bubbles can be increased, generation of liquid backflow flow in the cavitation bubbles is inhibited, the cavitation bubbles are rapidly generated till the cavitation bubbles wrap the whole underwater navigation body to form a supercavitation state, and thereby frictional resistance of the surface of the underwater navigation body is greatly reduced.

Owner:NAT UNIV OF DEFENSE TECH

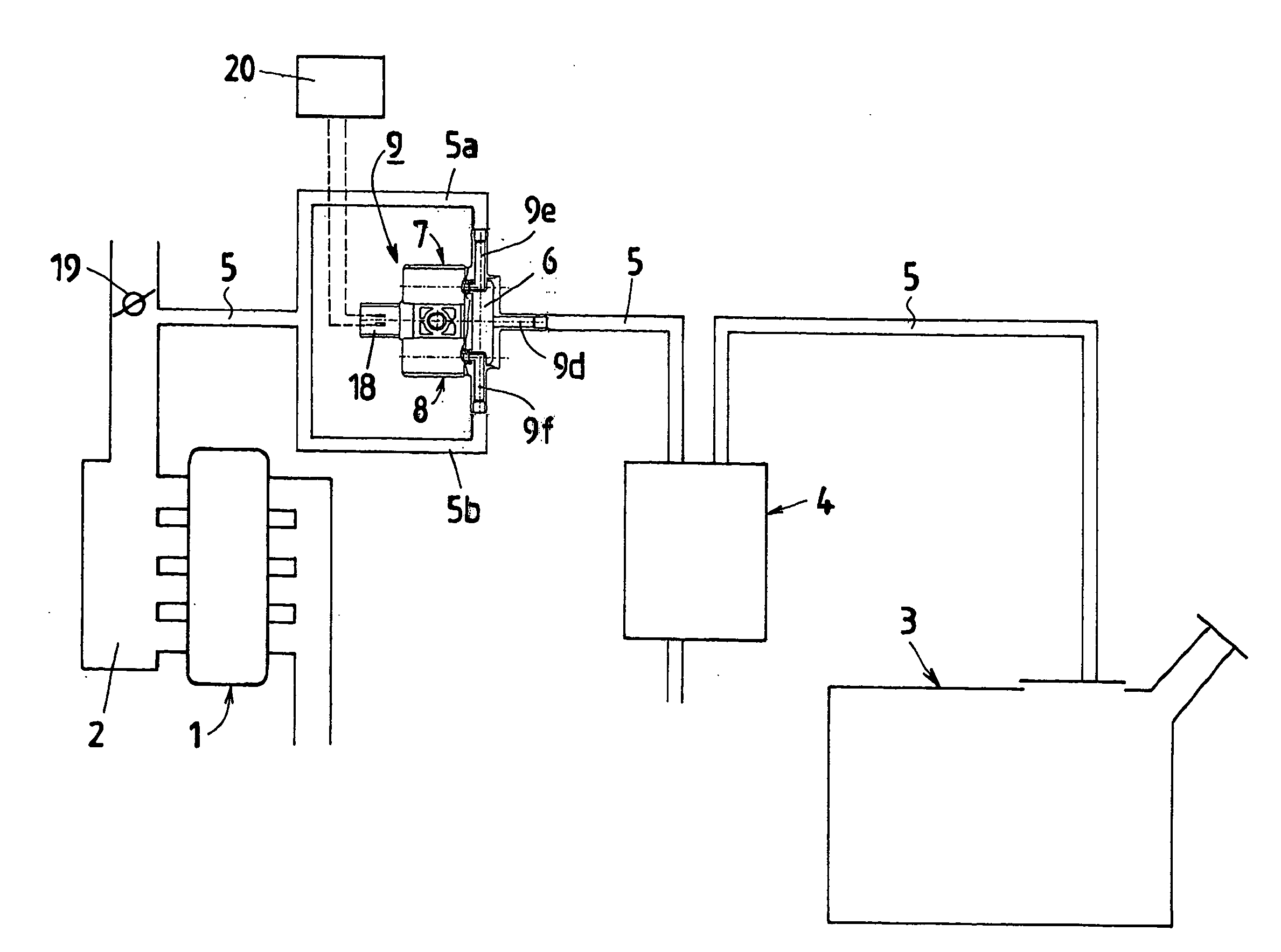

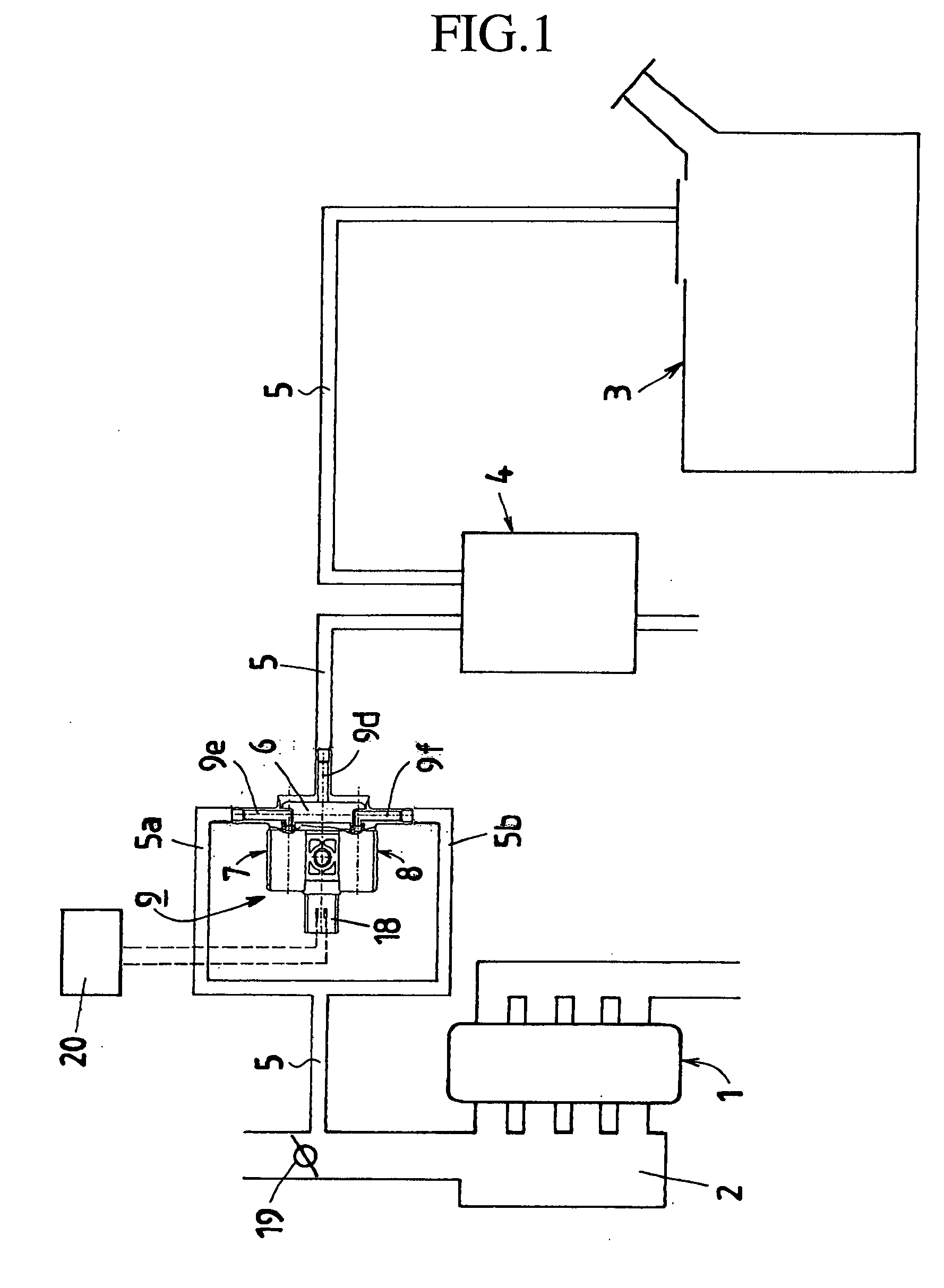

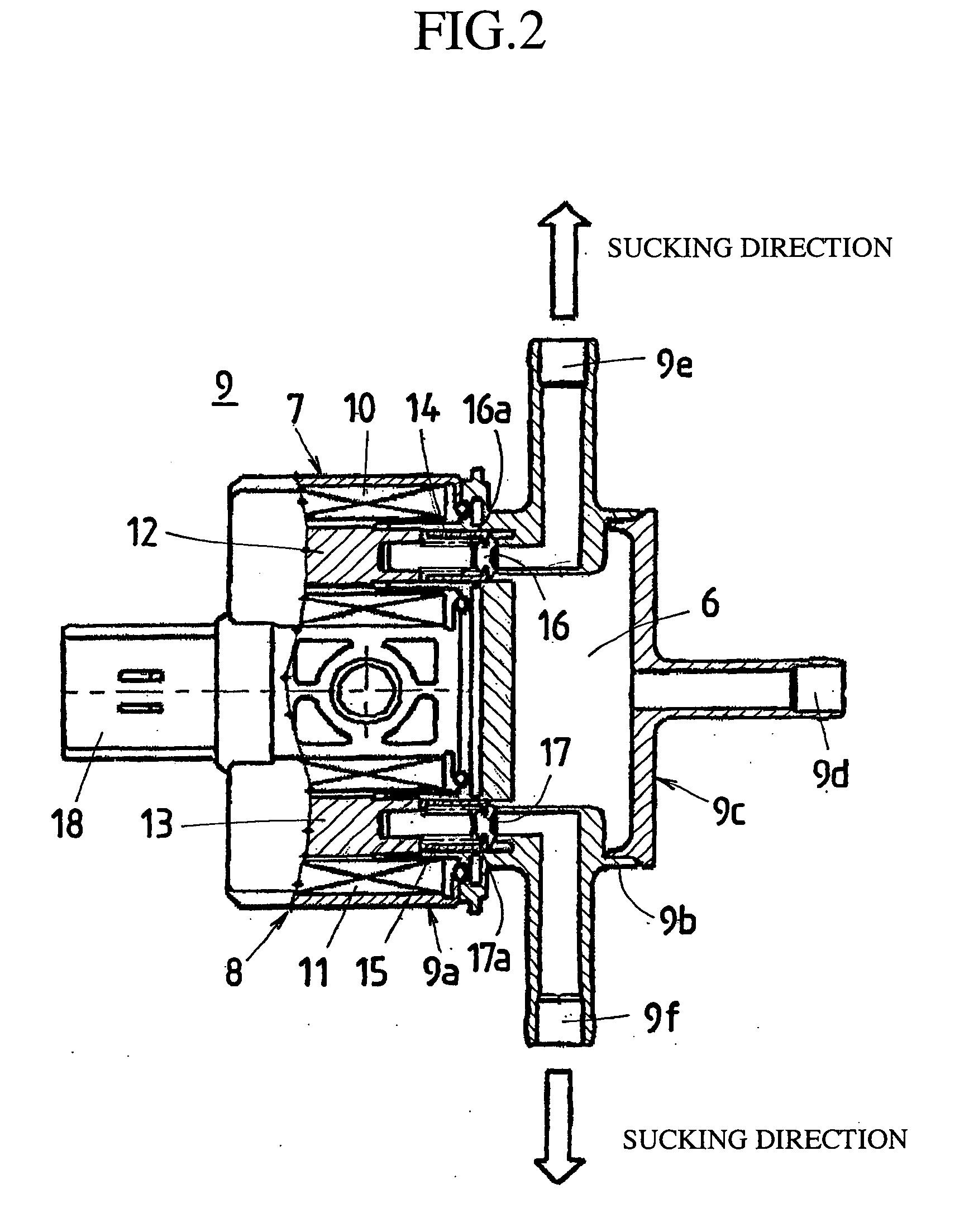

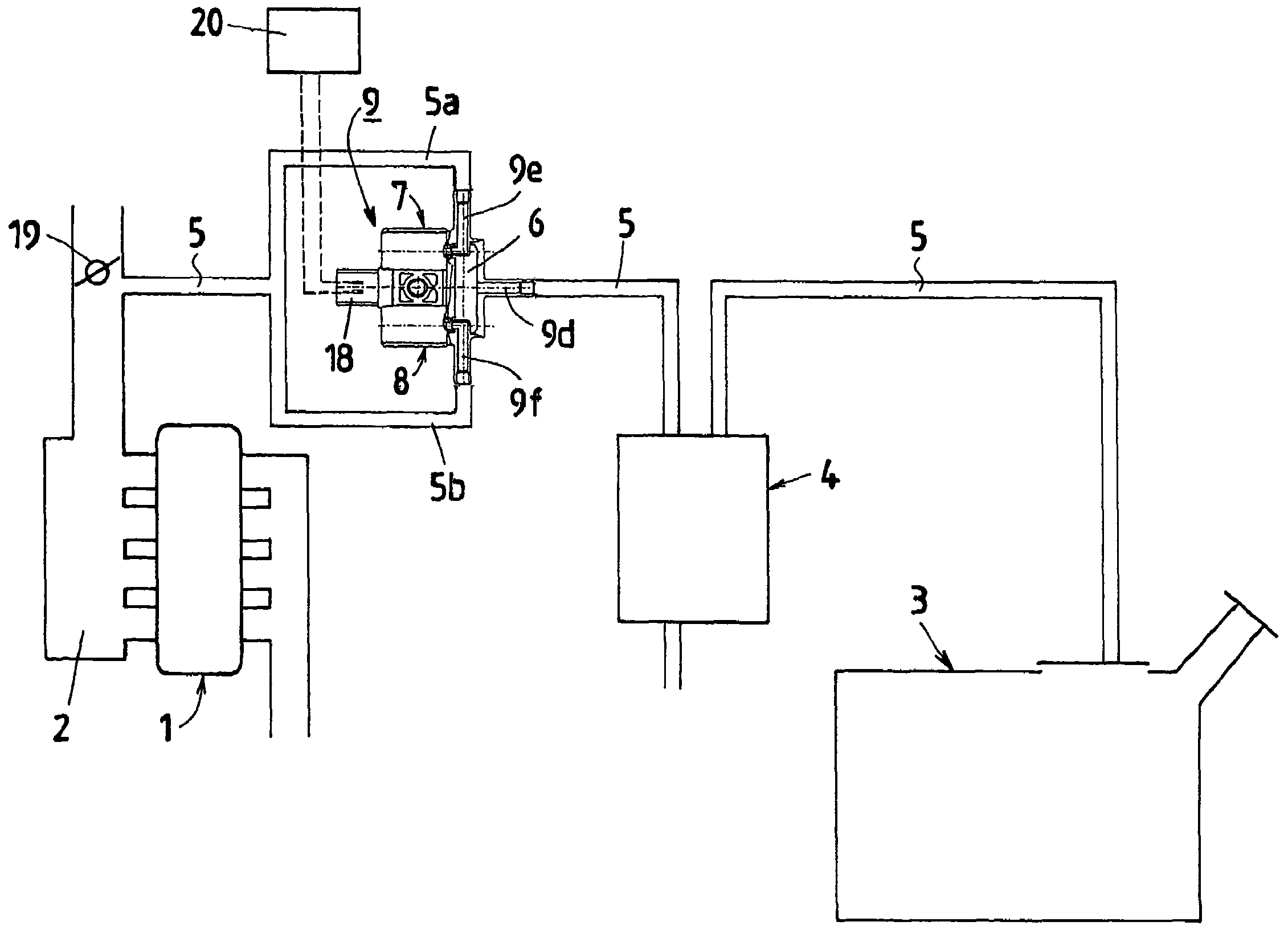

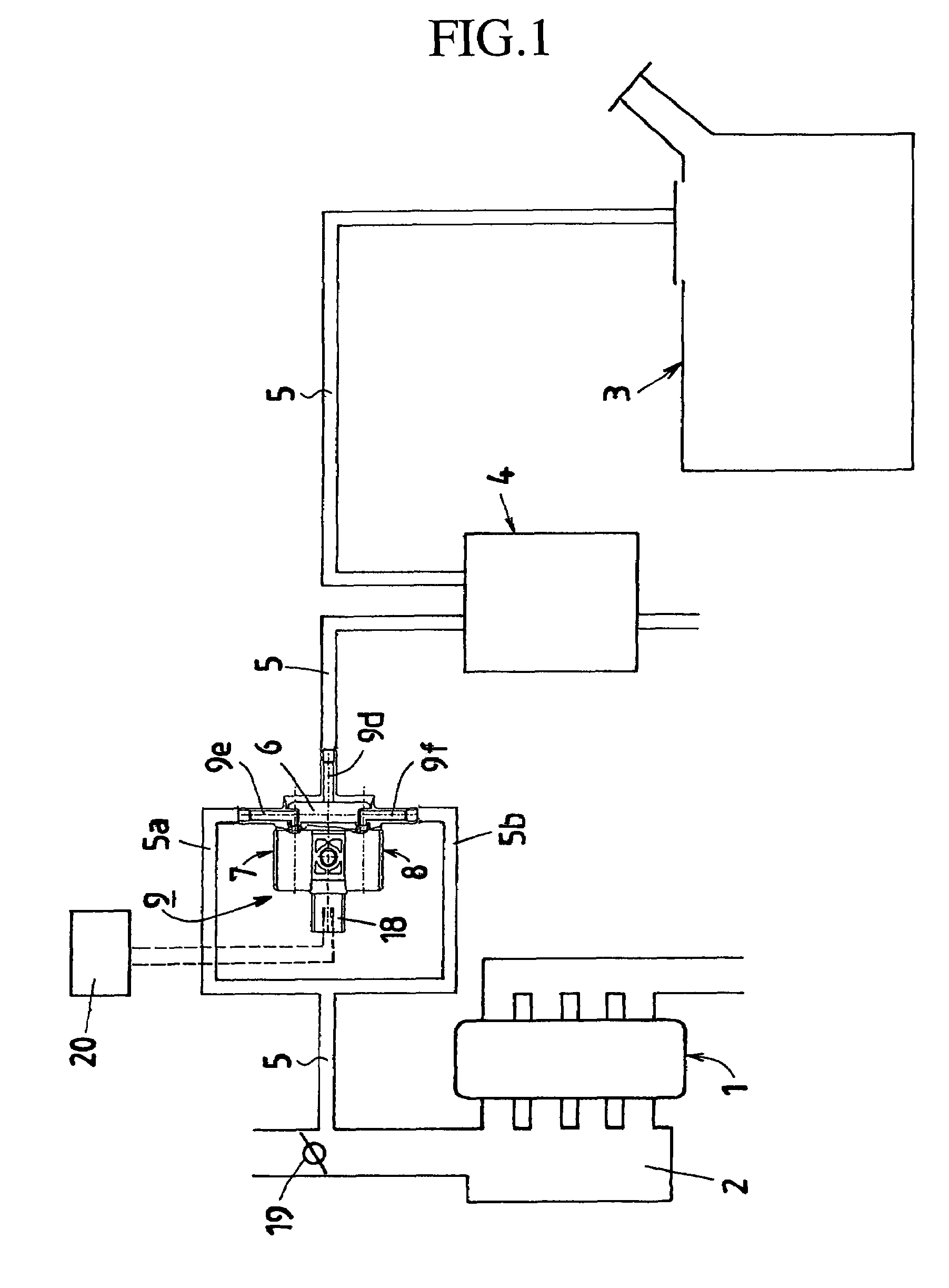

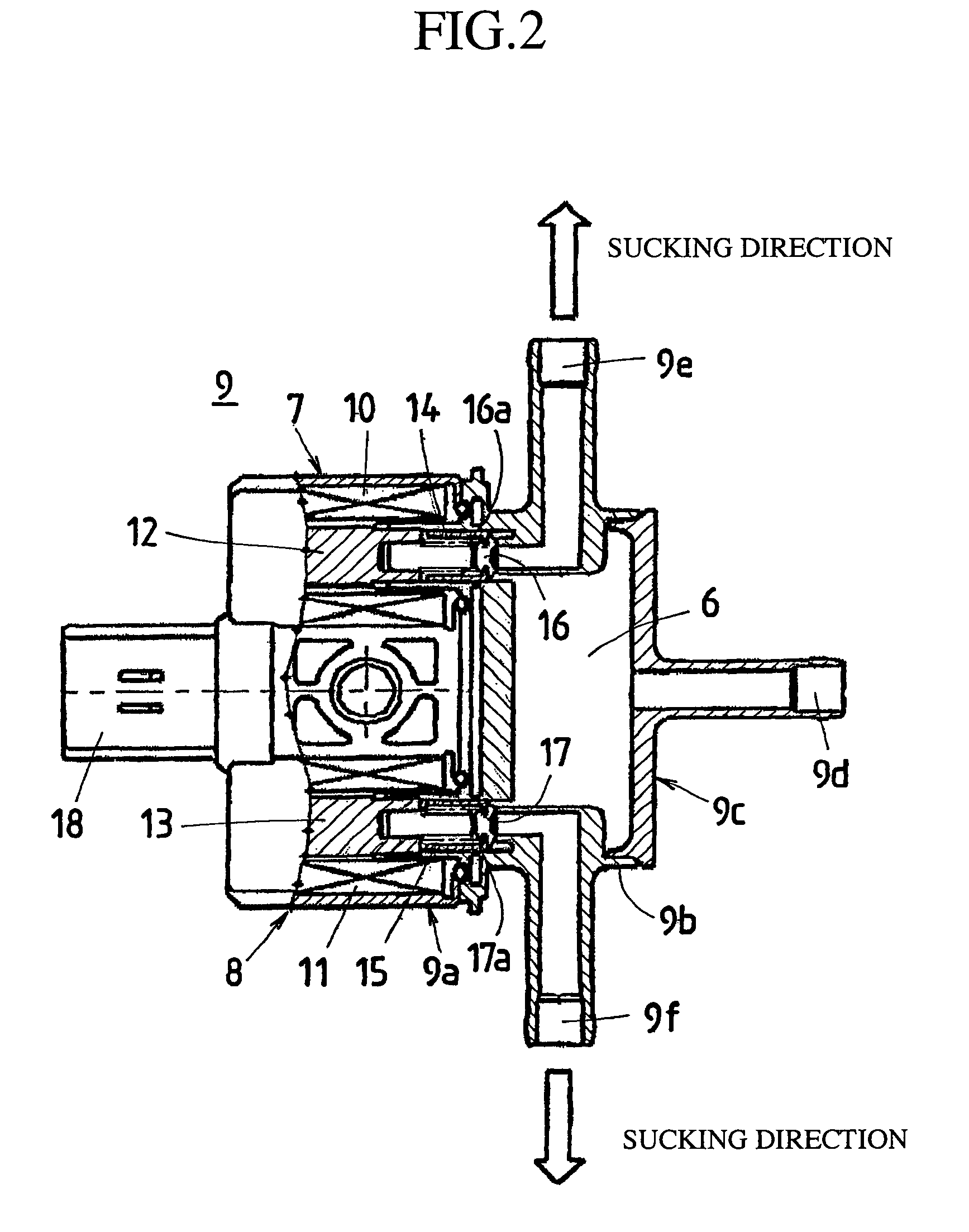

Fuel-Evaporated Gas Processing System and Electromagnetic Valve Device

ActiveUS20090078238A1Suppress pressure pulsationEfficient degradationNon-fuel substance addition to fuelMachines/enginesFuel tankEngineering

A fuel-evaporated gas processing system includes an input port taking in evaporated gas evaporated in a fuel tank; output ports supplying the evaporated gas taken in through the input port to an intake system of an engine; a chamber interposed between the input port and the output ports; an electromagnetic valve device including at least first and second electromagnetic valves disposed in the connection between the input port or the output ports and the chamber, either of the input port or the output ports being branched off into a plurality of sections, and perform opening and closing operations in response to a driving signal; and a valve control means driving the first and the second electromagnetic valves of the electromagnetic valve device.

Owner:MITSUBISHI ELECTRIC CORP

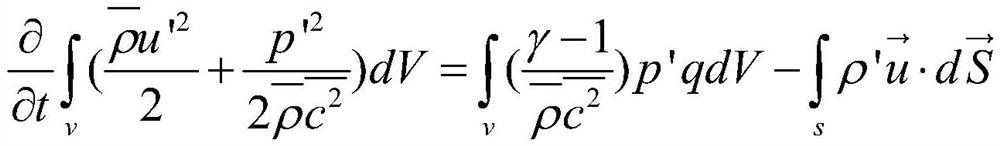

Method for synergistically suppressing combustion pressure pulsation by using high-frequency excitation discharge center plasma and side plasma

ActiveCN109462928AResolution frequencyResolution timePlasma techniqueCombustion chamberPhase difference

The present invention provides a method for synergistically suppressing combustion pressure pulsation by using a high-frequency excitation discharge center plasma and a side plasma, and relates to a method for suppressing pressure pulsation in a thermoacoustic oscillation phenomenon. In the present invention, synergy of a center plasma and a side plasma is taken as a dynamic and active way to regulate the pressure pulsation state of the combustion chamber during combustion. The method provided by the present invention is characterized in that plasmas are generated at the root and side of the flame in the combustion chamber, and the root plasma dynamically affects the frequency and the phase law of the flame heat release, so that the response degree of the pulsating flame to the airflow disturbance changes; the plasma applied on the side of the flame is input to the main body for absorbing the flame through certain energy to change the distance between the main flame heat release zone and the outlet of the combustion chamber, that is, the length of the return path reflected by the pressure pulsation in the combustion chamber from the outlet of the combustion chamber is changed, andthe phase difference between the pressure pulsation and the flame heat release rate changes; and at the same time, the synergy and adjustment of the plasmas at the two positions can achieve the slowing or suppression of the combustion pressure pulsation.

Owner:HARBIN INST OF TECH

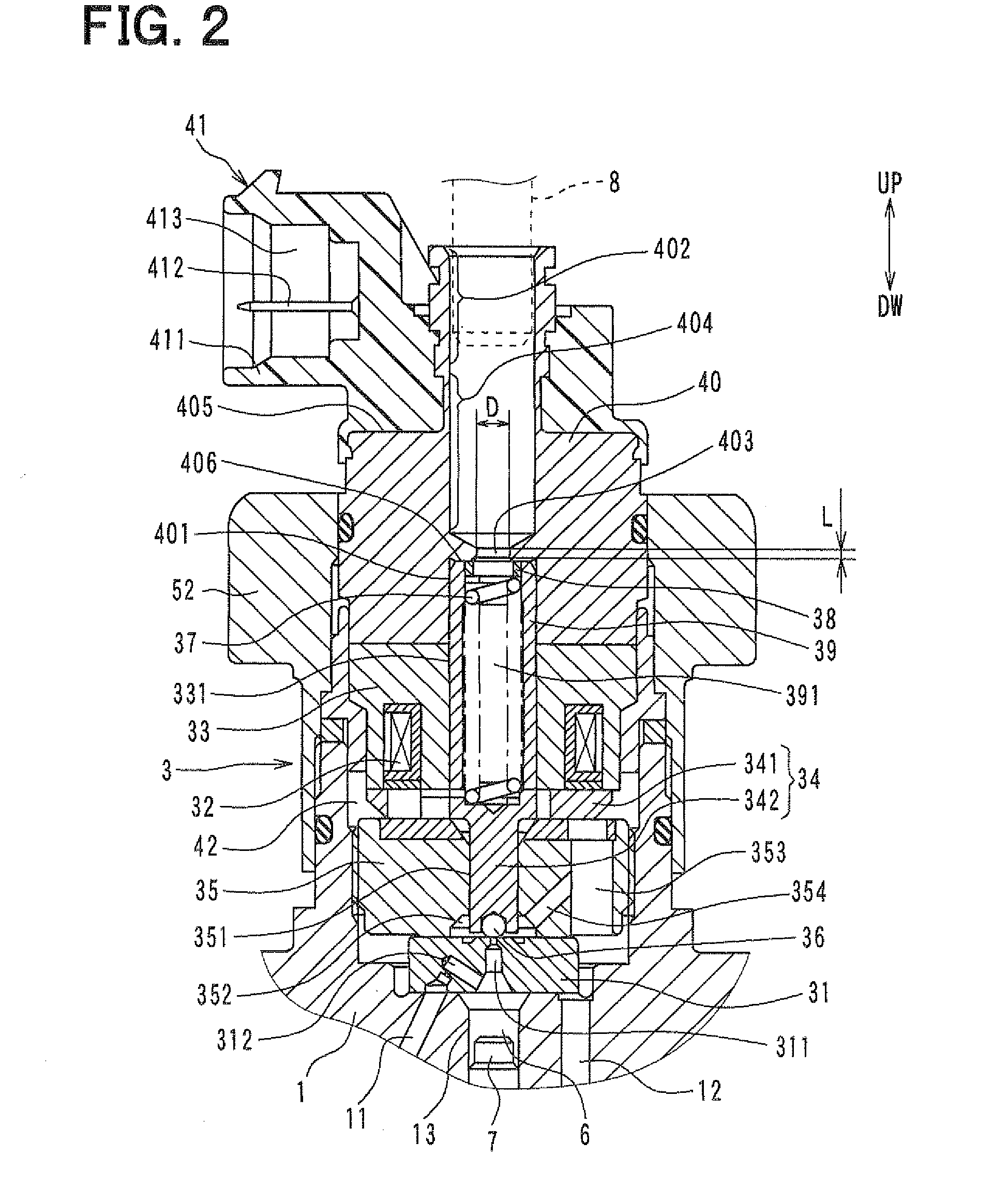

Hermetically sealed scroll compressor

ActiveUS20120156068A1Low efficiencyReduce internal leakageRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringMechanical engineering

In the hermetically sealed scroll compressor, an injection pipe for injecting a fluid to a compression chamber is connected to an injecting port of a fixed scroll. The injecting port includes a first injecting port which is provided in the vicinity of a fixed scroll inner curve and injects the fluid to an orbiting outer compression chamber, and a second injecting port 22b which is provided in the vicinity of a fixed scroll outer curve and injects the fluid to a orbiting inner compression chamber 8b. The second injecting port is placed in parallel in a radius direction with respect to the first injecting port and is placed so that an orbiting scroll wrap does not practically communicate with the orbiting outer compression chamber in the state in which the orbiting scroll wrap is in contact with the outer side of a fixed scroll wrap.

Owner:HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

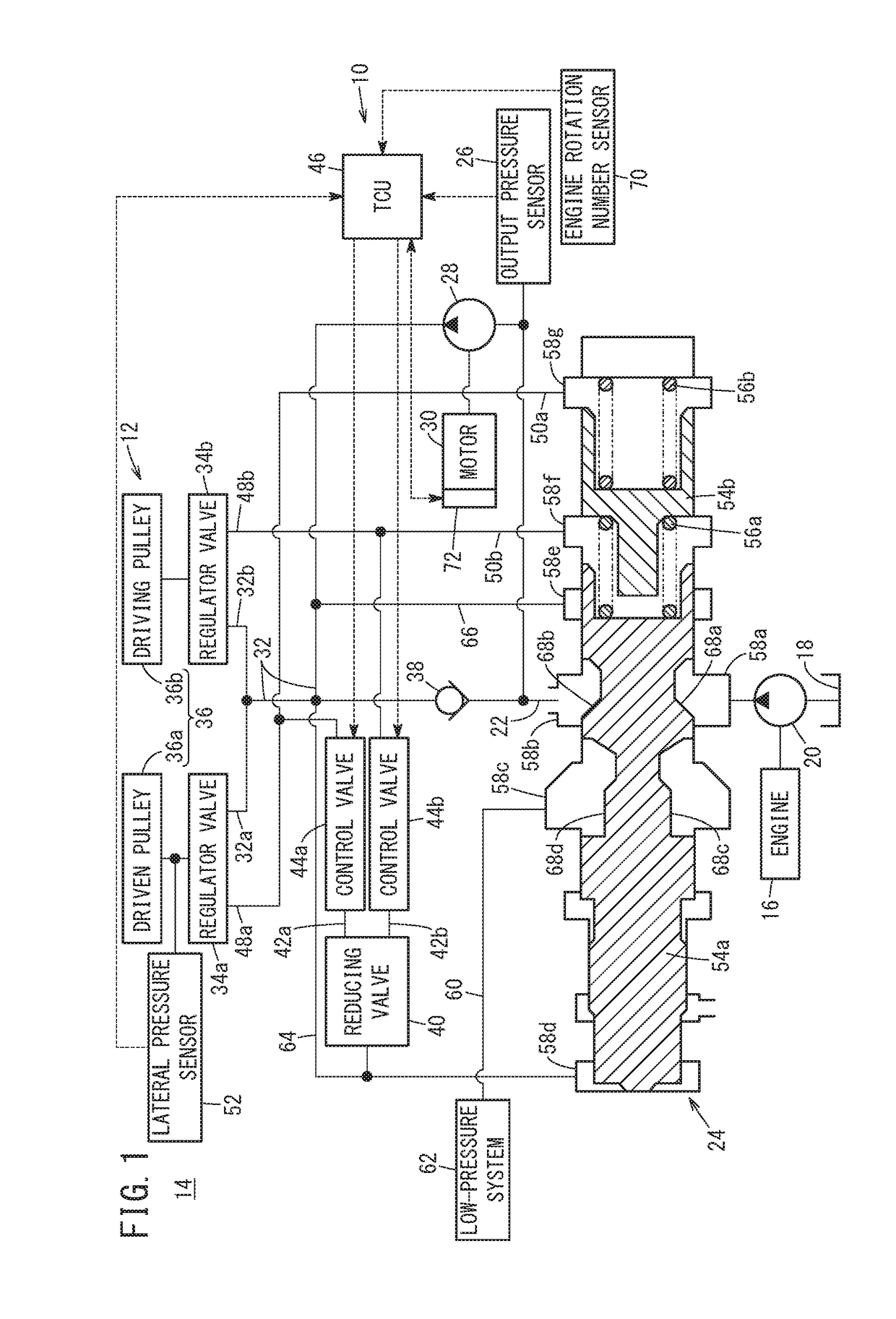

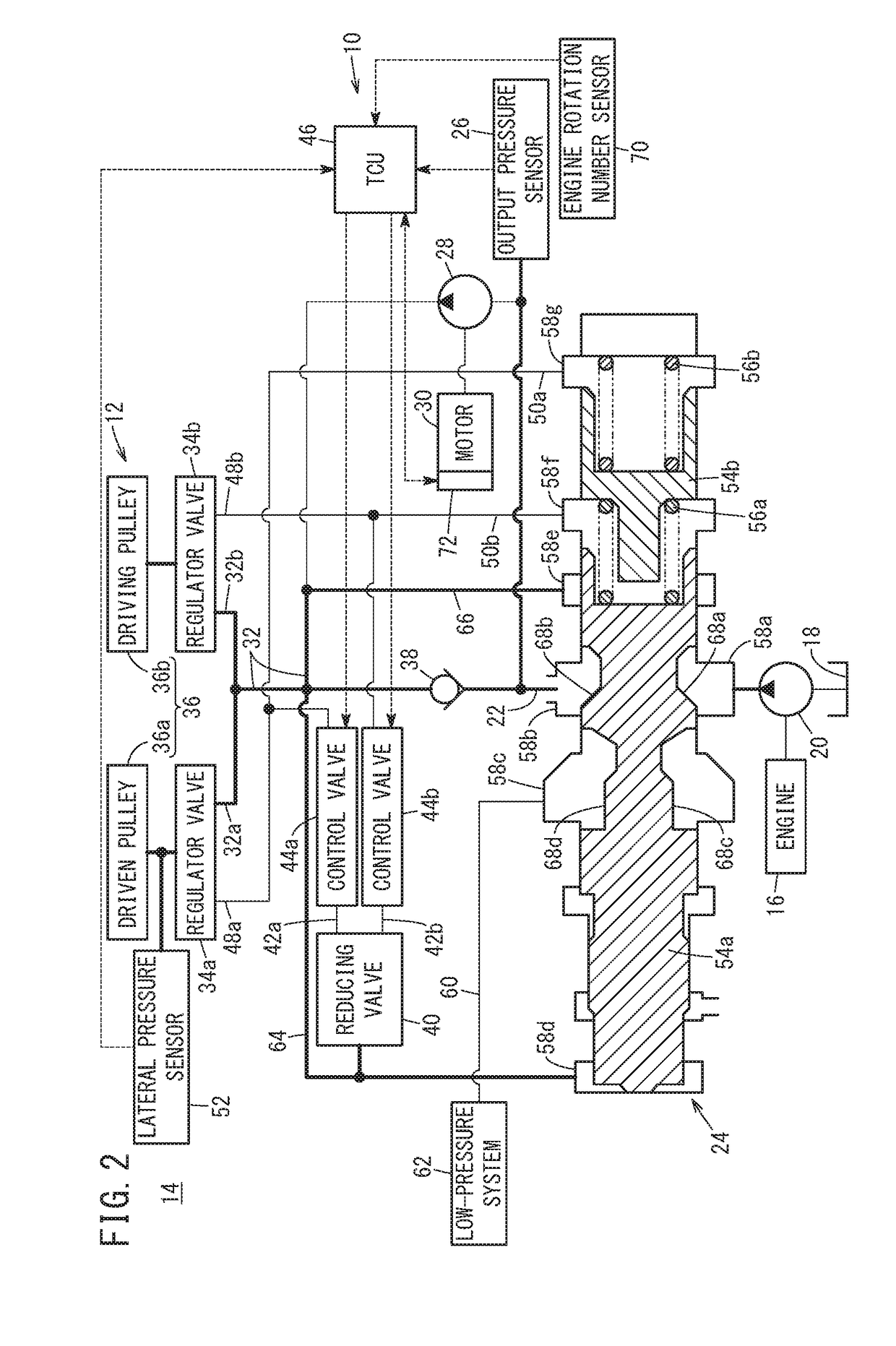

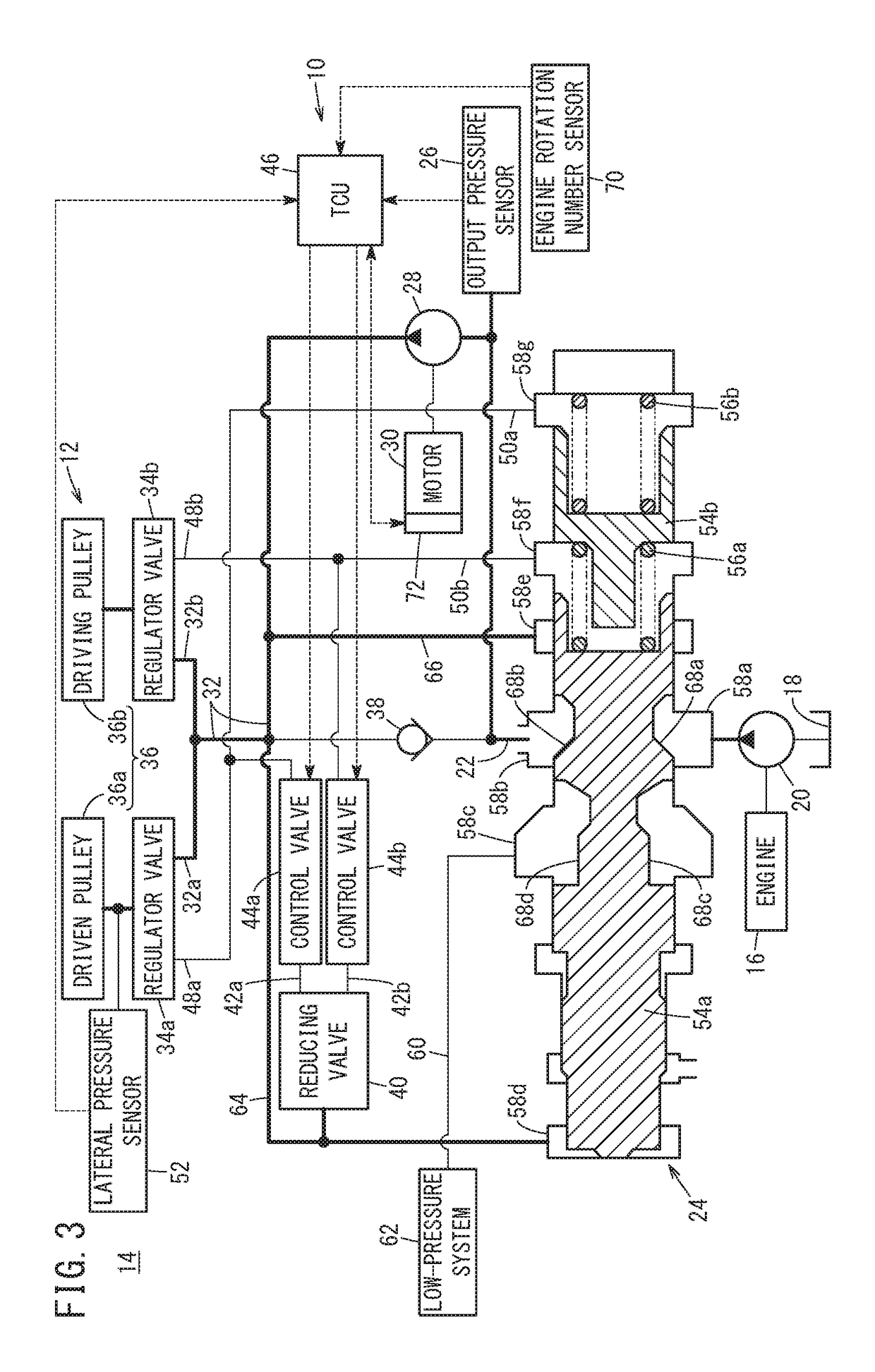

Hydraulic control device

ActiveUS20190048899A1Pressure of second can be preventedRelieve stressFluid parameterServomotorsControl theoryPressure sensor

In a hydraulic control device, when it is detected that a pressure of first oil (output pressure) detected by an output pressure sensor pulsates, a transmission control unit as a TCU stops driving of a second pump or decreases a rotation number of the second pump as a first operation. Alternatively, when it is detected that the output pressure pulsates, the TCU increases the rotation number of the second pump to a rotation number (for example, maximum rotation number) that is higher than a target rotation number as a second operation.

Owner:HONDA MOTOR CO LTD

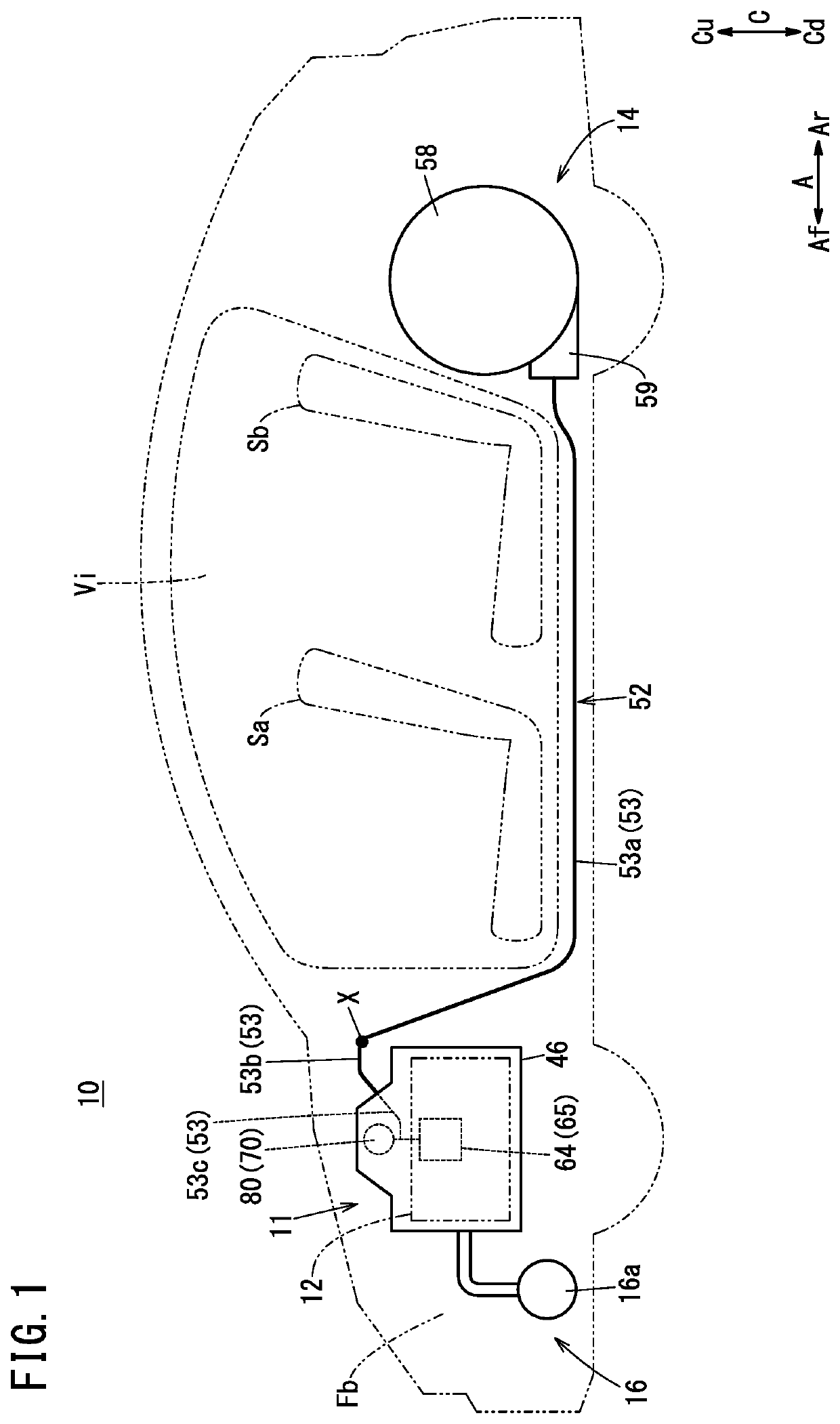

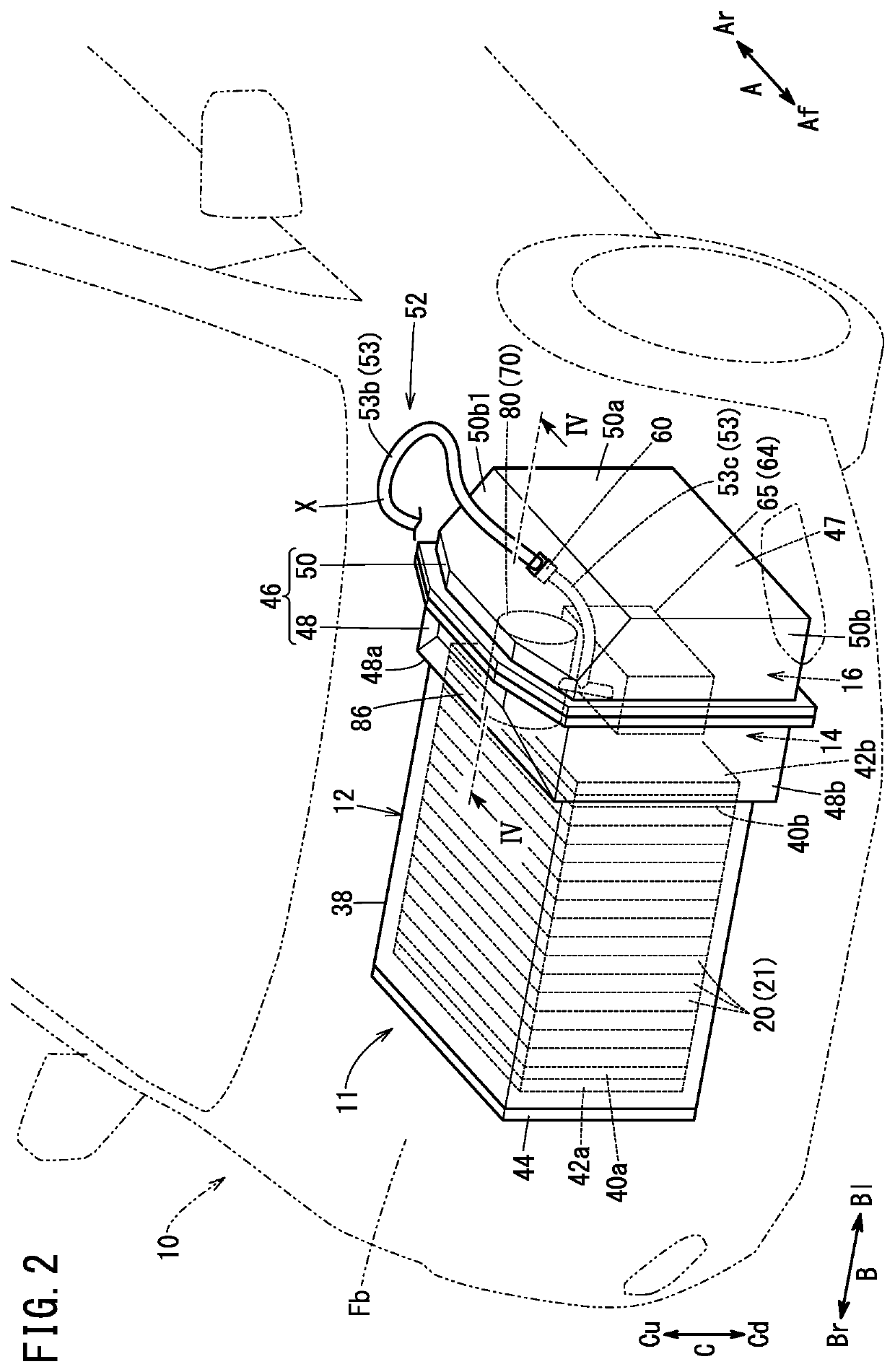

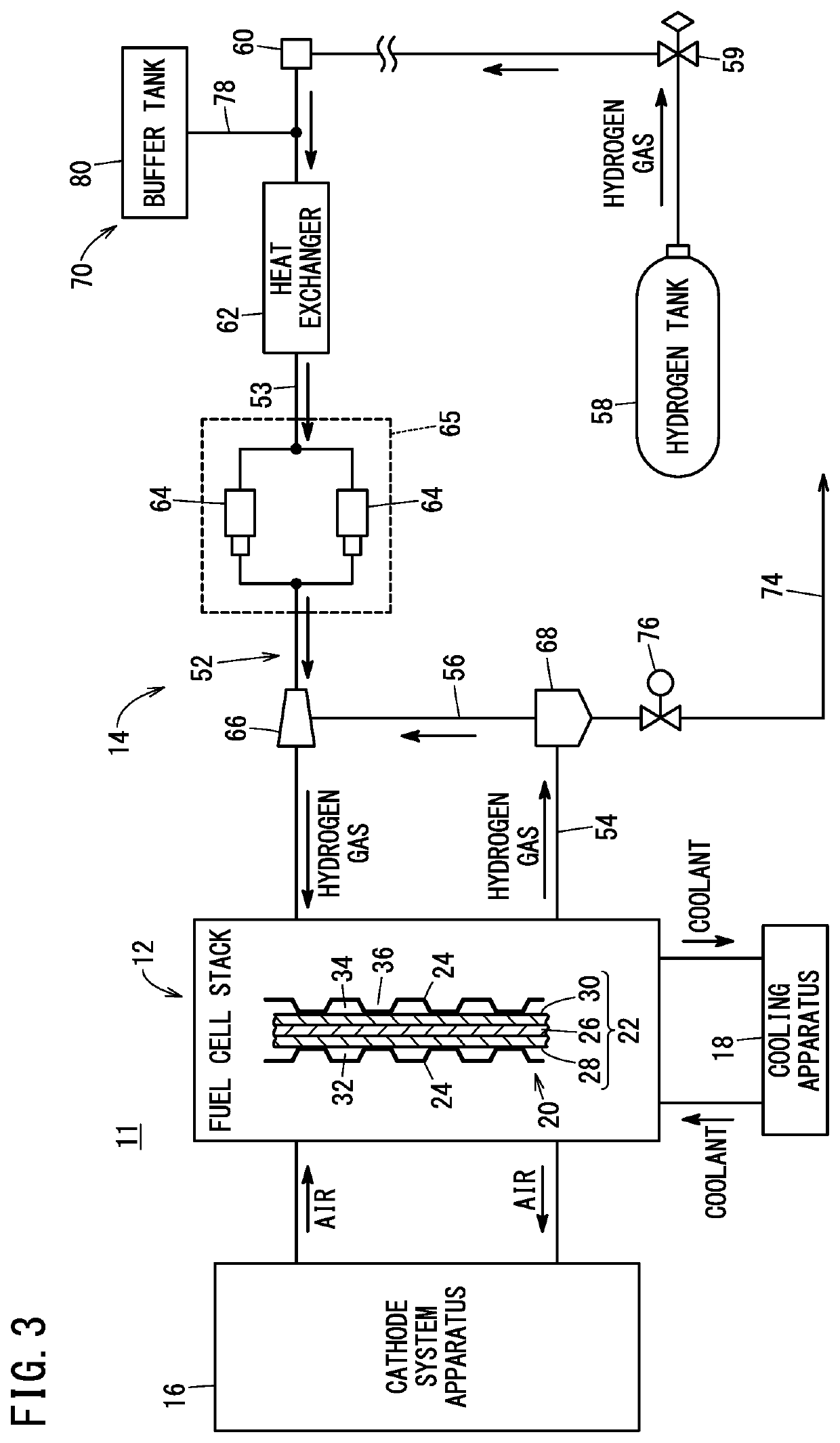

Fuel cell vehicle

PendingUS20210104756A1Reducing noise producedSimplifies accommodationFuel cell heat exchangeReactant parameters controlAutomotive engineeringInjector

A fuel cell vehicle includes a fuel cell stack, a hydrogen gas supply pipe for supplying a hydrogen gas to the fuel cell stack, and injectors provided at positions along the hydrogen gas supply pipe, for injecting the hydrogen gas to the fuel cell stack. The hydrogen gas supply pipe includes a buffer, provided on the upstream side of the injectors, and the hydrogen gas can flow through the buffer. The buffer includes a branch pipe branched from the hydrogen gas supply pipe, and the buffer tank coupled to the branch pipe so as to allow the hydrogen gas to flow through the buffer tank.

Owner:HONDA MOTOR CO LTD

Common rail fuel injection system

InactiveUS20140283790A1Reduce exhaustIncrease valueLow-pressure fuel injectionMachines/enginesCommon railInternal combustion engine

A common rail fuel injection system includes injectors having a fuel intake port and being provided for respective cylinders of a multi-cylinder diesel internal combustion engine, a common rail accumulating pressurized fuel, a high-pressure supply pump supplying high-pressure fuel, a fuel supply pipe causing the common rail and the high-pressure supply pump to communicate with each other. The fuel injection pipes communicating with pressure supply ports provided in the common rail and causing the injectors and the pressure supply ports to communicating with each other. The fuel injection pipes cause at least three injectors to communicate with one another in series. The number NP of pressure supply ports is less than the number PI of injectors, and supply of high-pressure fuel to the respective injectors for the cylinders is performed through fuel injection pipes of two lines.

Owner:USUI KOKUSAI SANGYO KAISHA LTD +1

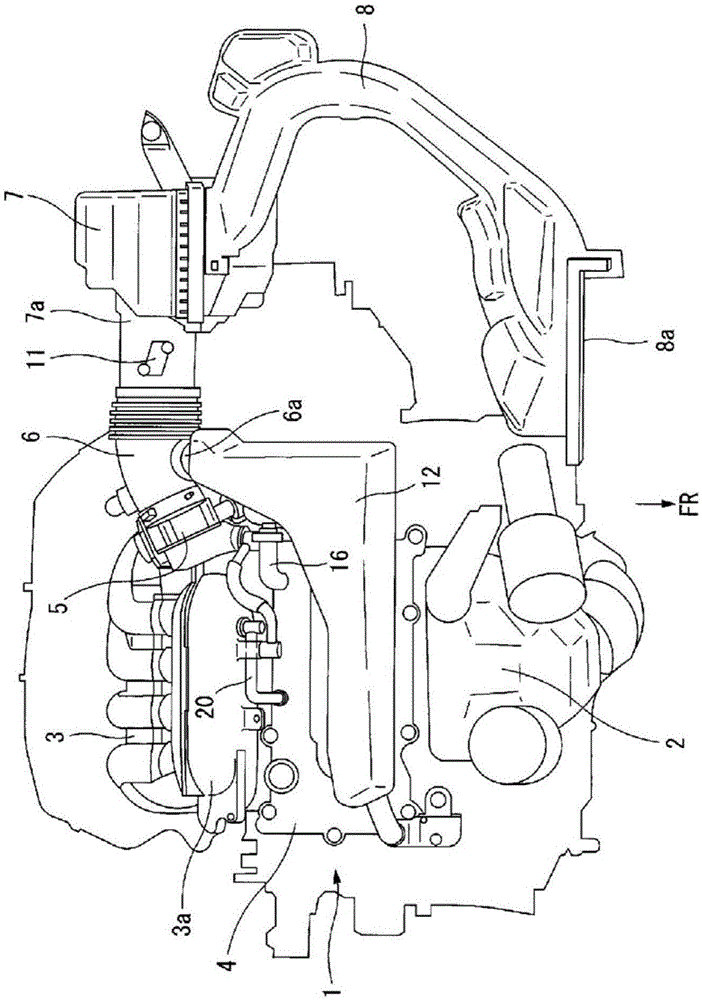

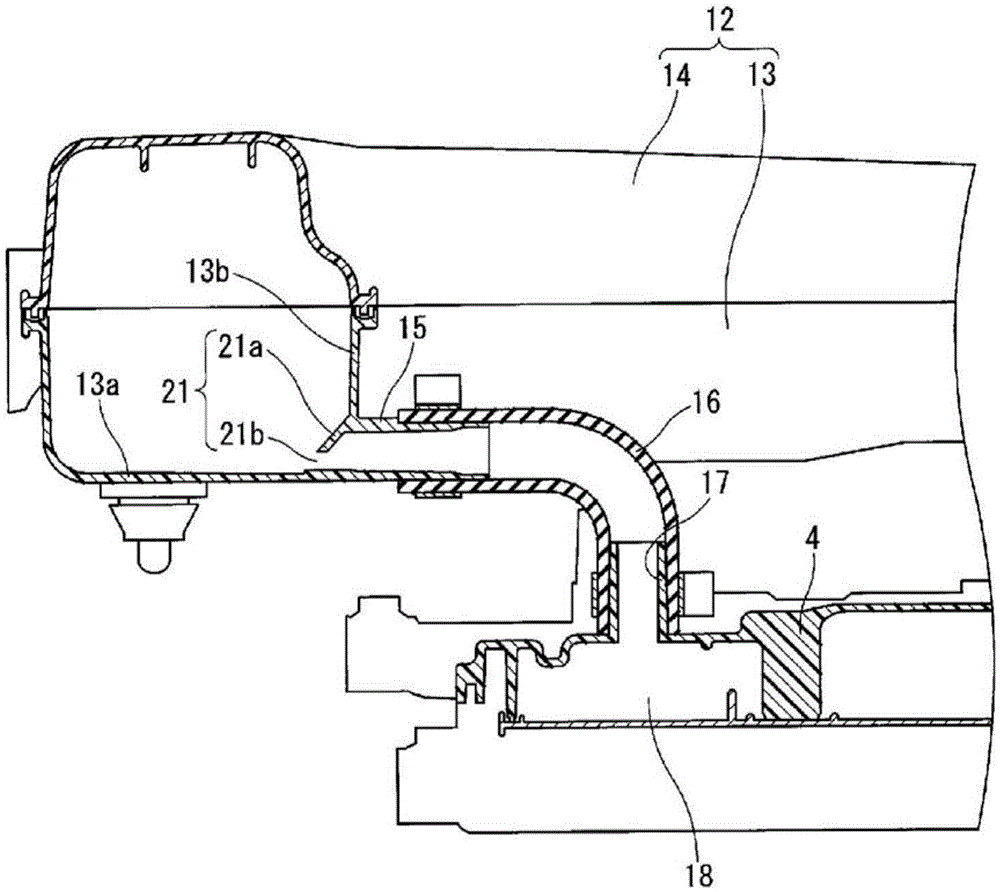

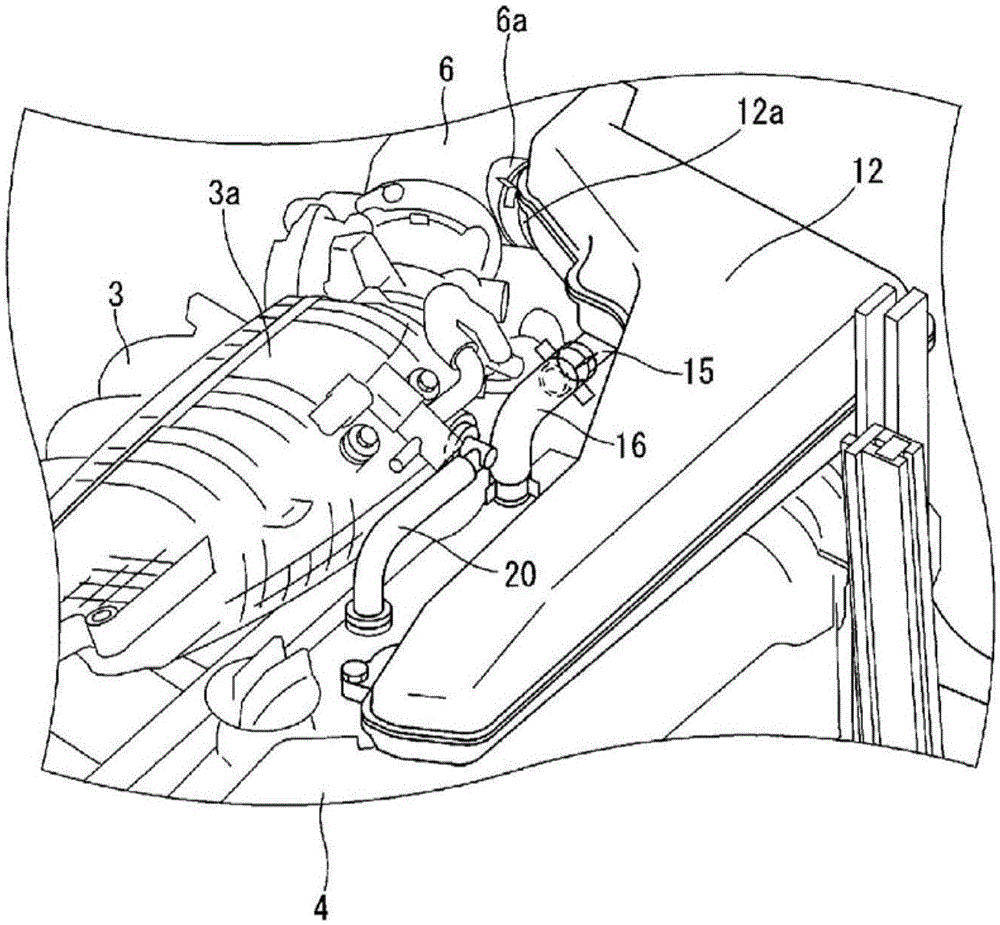

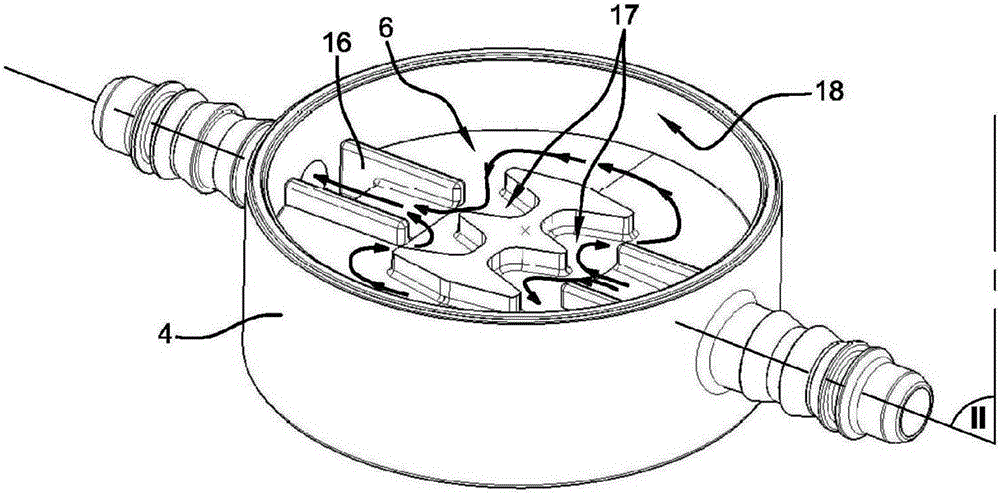

Blow-by gas treatment device for internal combustion engine

ActiveCN105612318AReduce measurement errorSuppress pressure pulsationInternal combustion piston enginesNon-fuel substance addition to fuelCylinder headExternal combustion engine

A resonator (12) for reducing intake air noise is connected to an intake air duct (6) connecting a throttle chamber (5) and an air cleaner case (7). This blow-by gas treatment device is equipped with a fresh air introduction passage comprising a fresh air introduction hose (16), and a blow-by gas passage comprising a blow-by gas hose (20), with the fresh air introduction hose (16) connecting the cylinder head (4) and the resonator (12). A connector part (15) of the resonator (12) to which the fresh air introduction hose (16) is connected is equipped with an orifice (21), which is formed integrally as a part of a synthetic resin lower body (13). Pulsation is effectively reduced by the throttling effect of the orifice (21) and the expansion effect of the resonator (12).

Owner:NISSAN MOTOR CO LTD

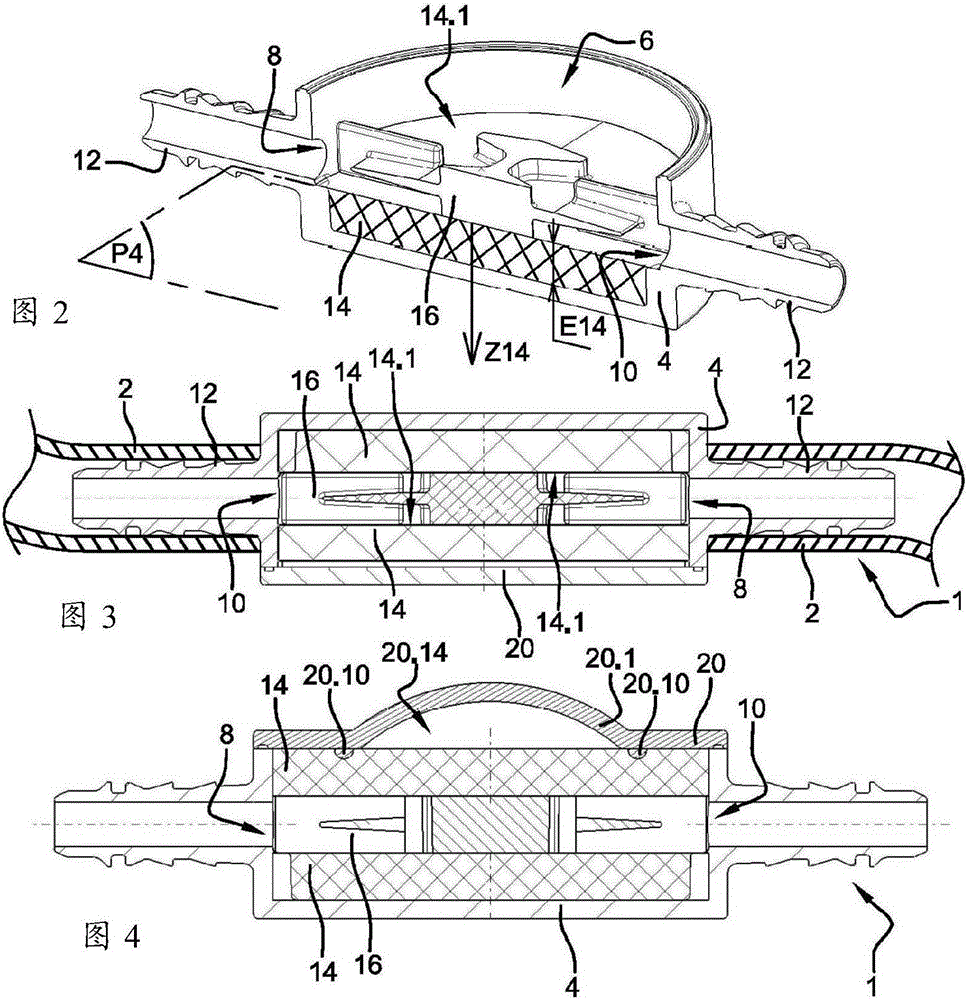

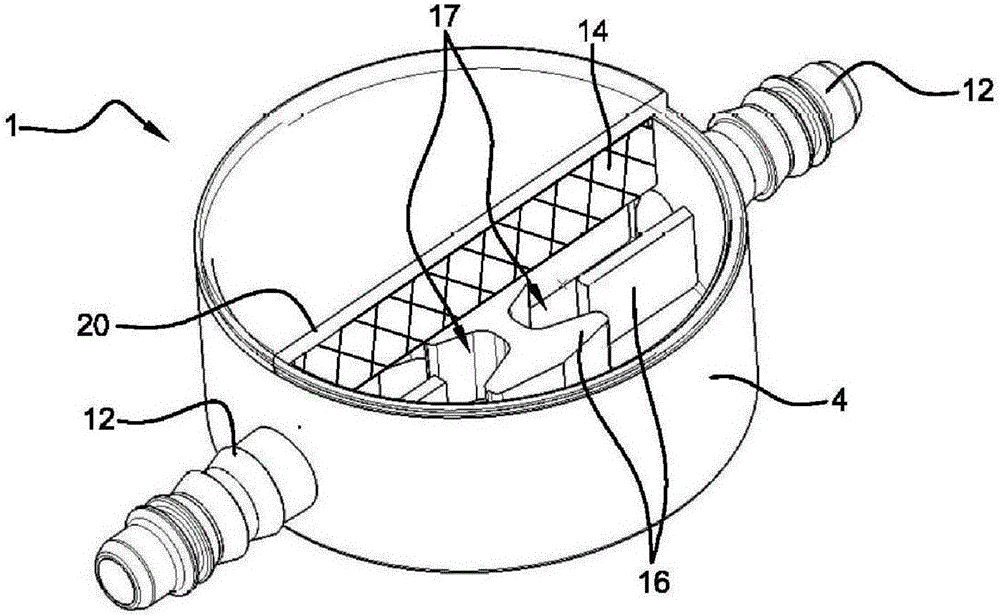

Dampening device

InactiveCN106224678ARestricted movementRestricted mobilityPipe elementsMachines/enginesPorosityBiomedical engineering

This dampening device comprises a body defining a chamber and presenting at least one orifice intended for the inlet and the outlet of the fluid in the chamber. The dampening device further comprises i) a dampening member located in the chamber and comprising at least one foam with closed cells, and ii) a holding member configured to hold the dampening member in place. The dampening device being characterized in that at least one foam has a porosity comprised between 50% and 98%.

Owner:AKWEL SA

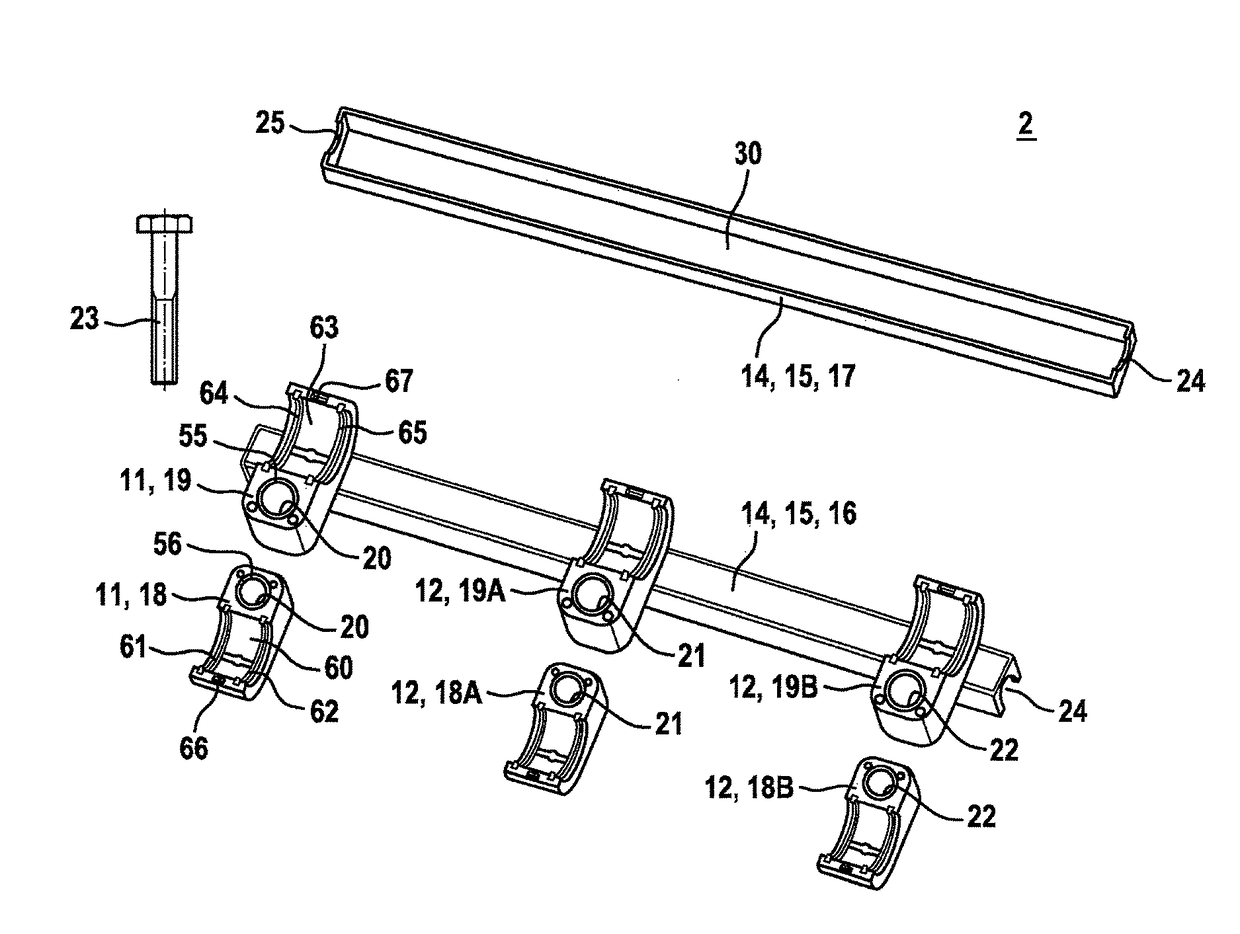

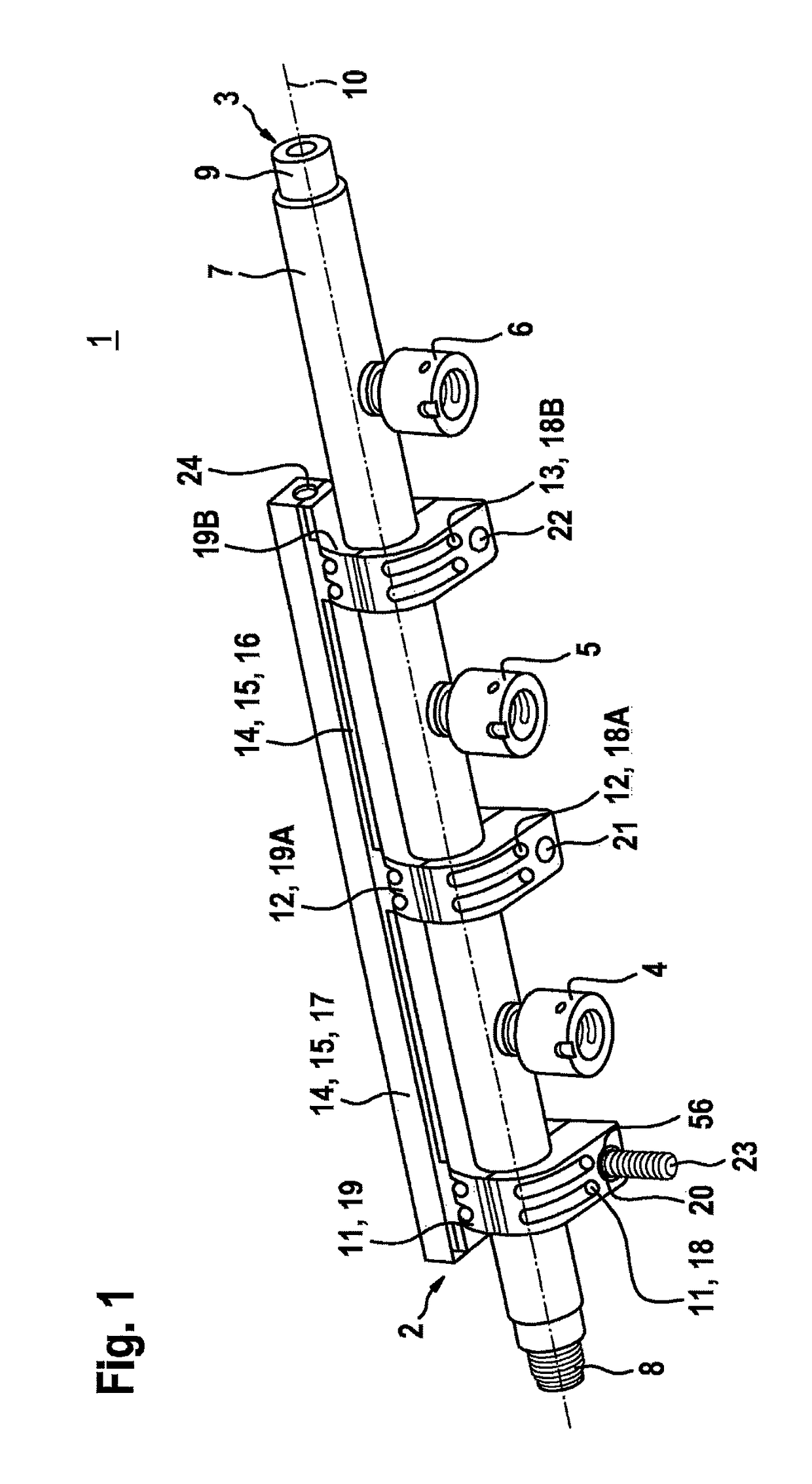

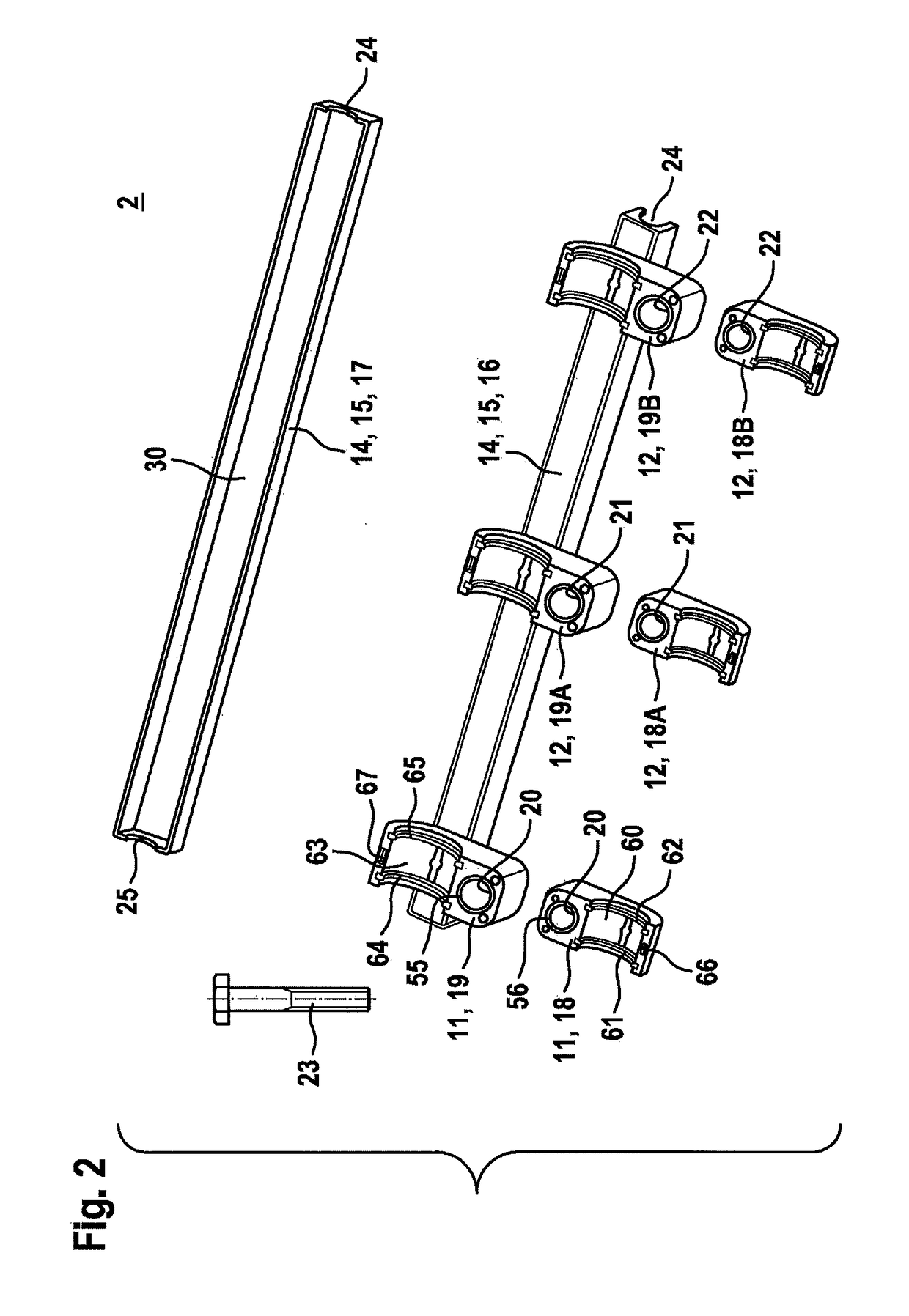

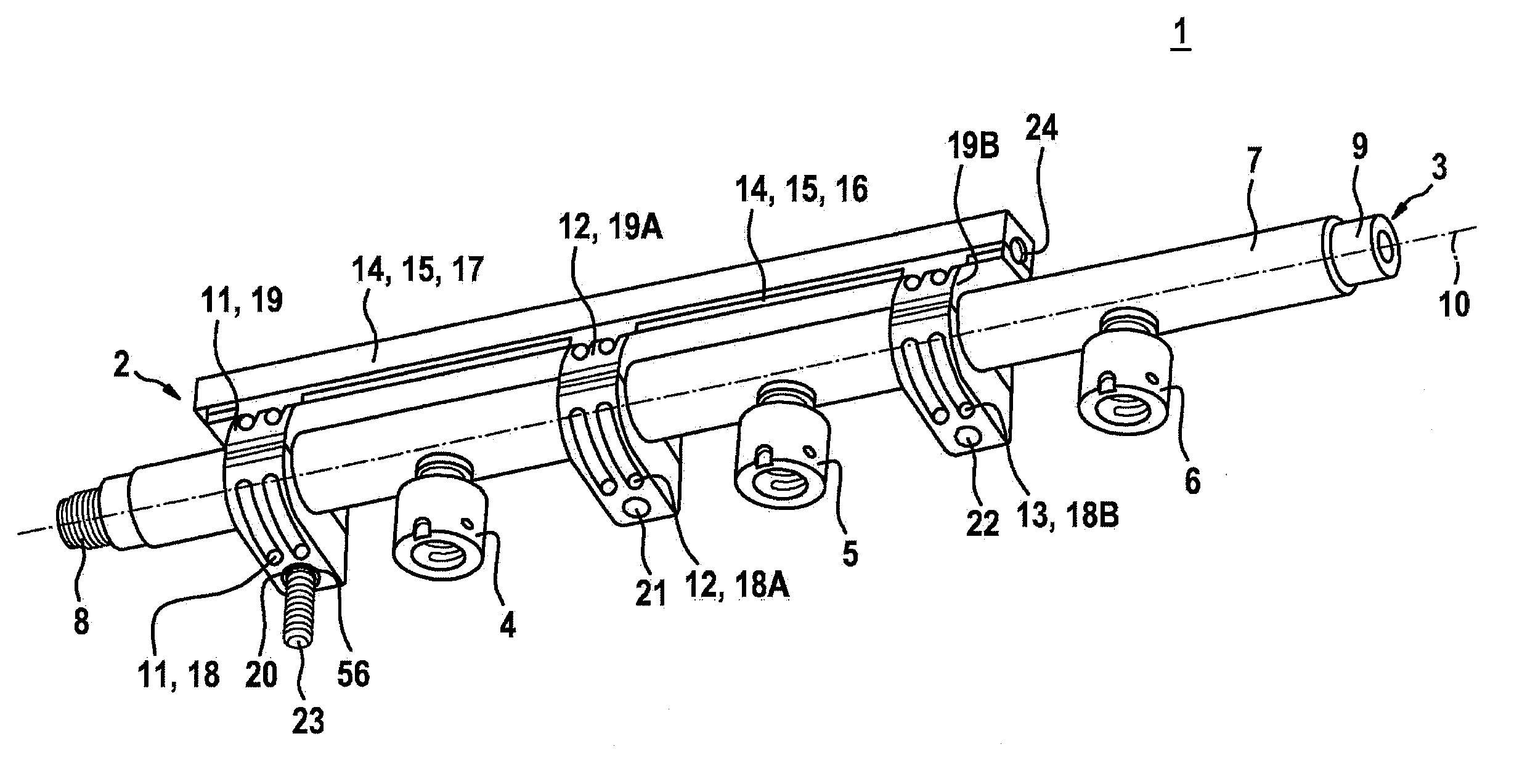

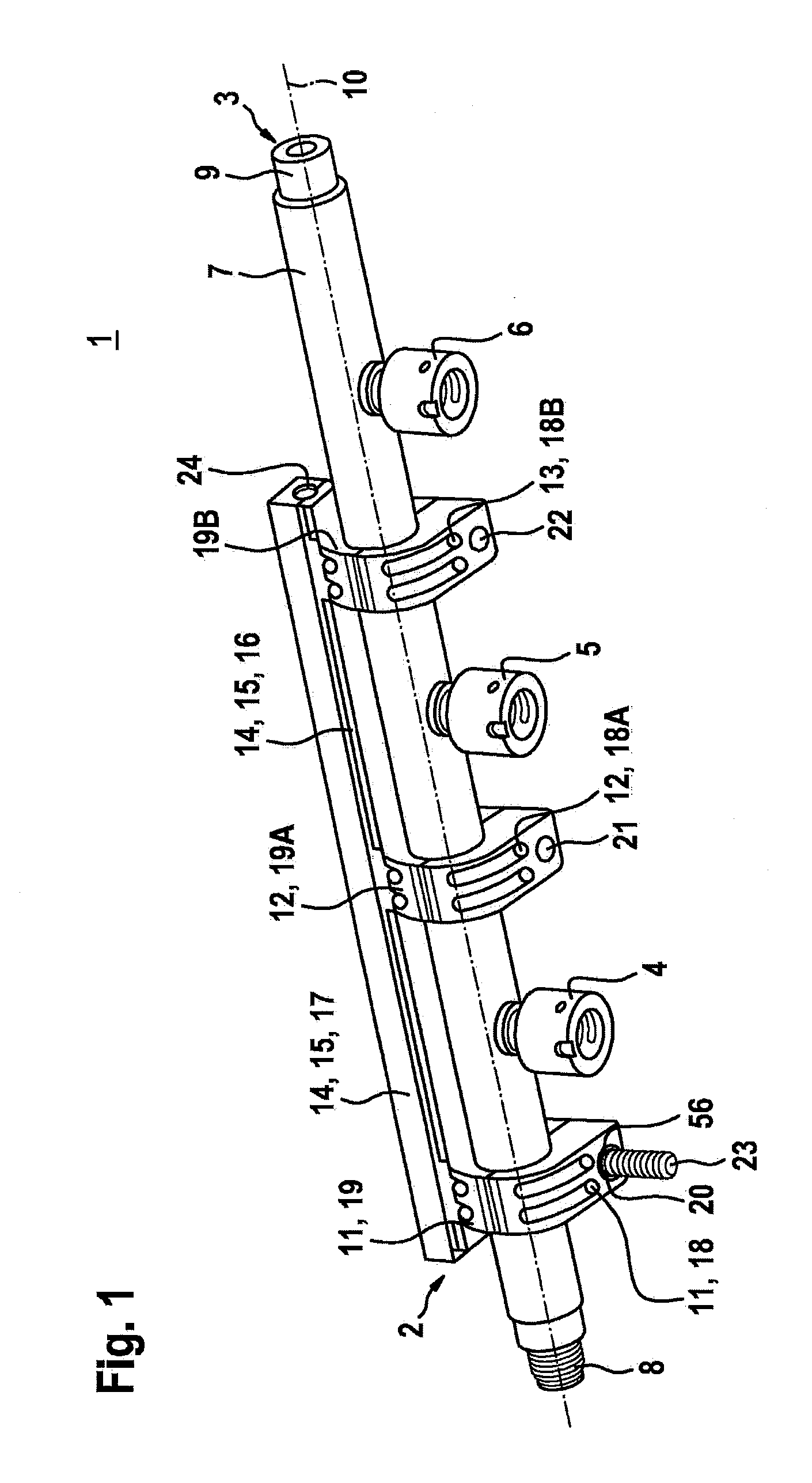

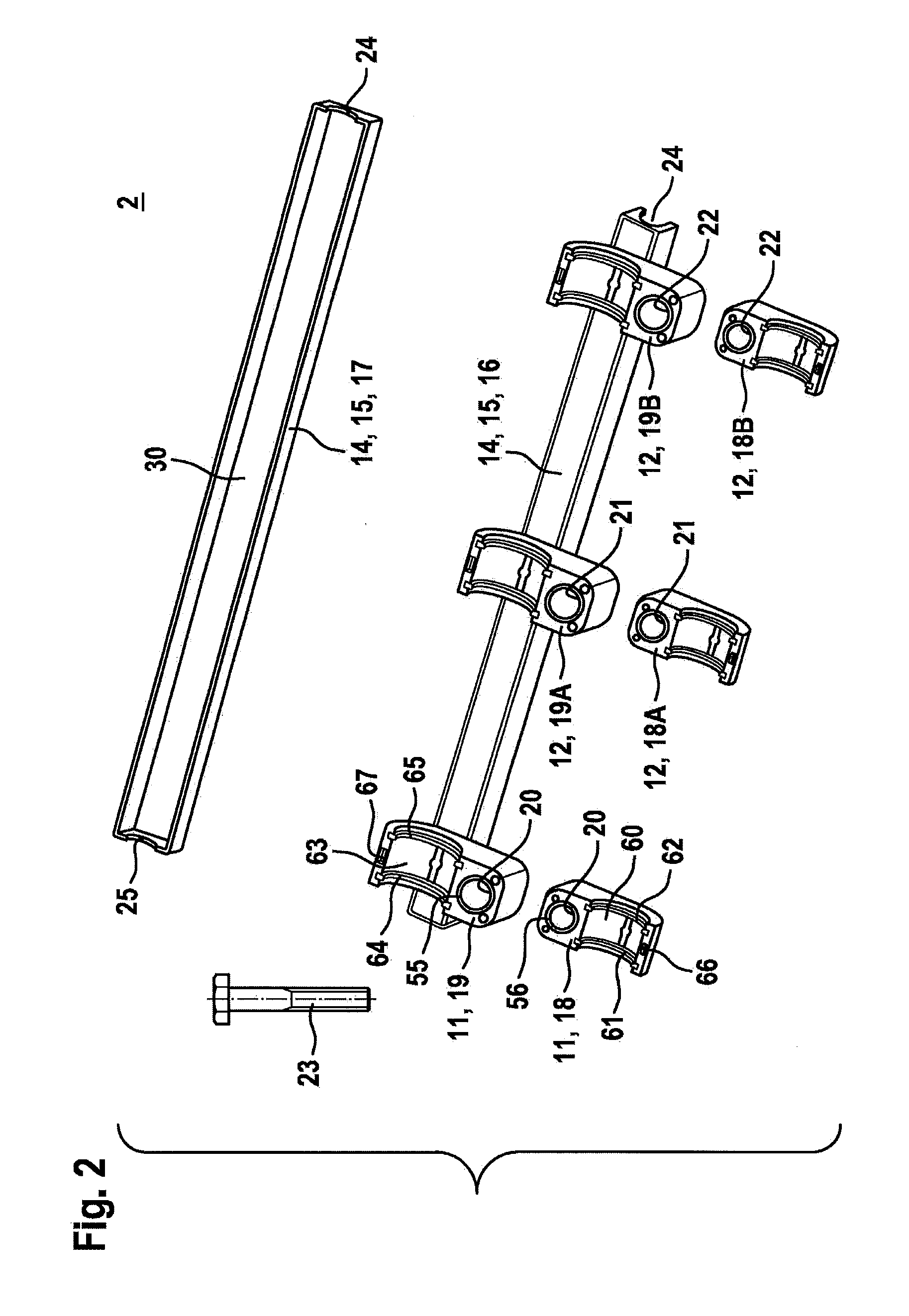

Holding device for fastening a fuel distributor to an internal combustion engine

ActiveUS9863388B2Increase fuel injectionProtection from damageLow pressure fuel injectionMachines/enginesExternal combustion engineEngineering

Owner:ROBERT BOSCH GMBH

Method for suppressing combustion pressure pulsation by high-frequency excitation discharge center plasma

ActiveCN109729634AReduce magnificationImproved heat release stabilityPlasma techniqueCombustion chamberThermoacoustics

A method for suppressing combustion pressure pulsation by a high-frequency excitation discharge center plasma relates to a method for suppressing pressure pulsation in a thermoacoustic oscillation phenomenon. The method uses plasma as a dynamic and active way to regulate the pressure pulsation state of a combustion chamber which occurs during combustion under a certain working condition. The plasma is generated at the flame root of the combustion chamber, so that the flame is dynamically affected by the plasma and is less affected by the disturbance of an air flow. Thus, the heat release stability is correspondingly improved, and the phase and frequency of the flame heat release are adjusted, so that the degree of amplification of the pulsating energy of the combustion chamber is reduced,and the condition of the thermoacoustic oscillation is destroyed, thereby realizing the reduction or even disappearance of the pressure pulsation in the combustion chamber.

Owner:HARBIN INST OF TECH

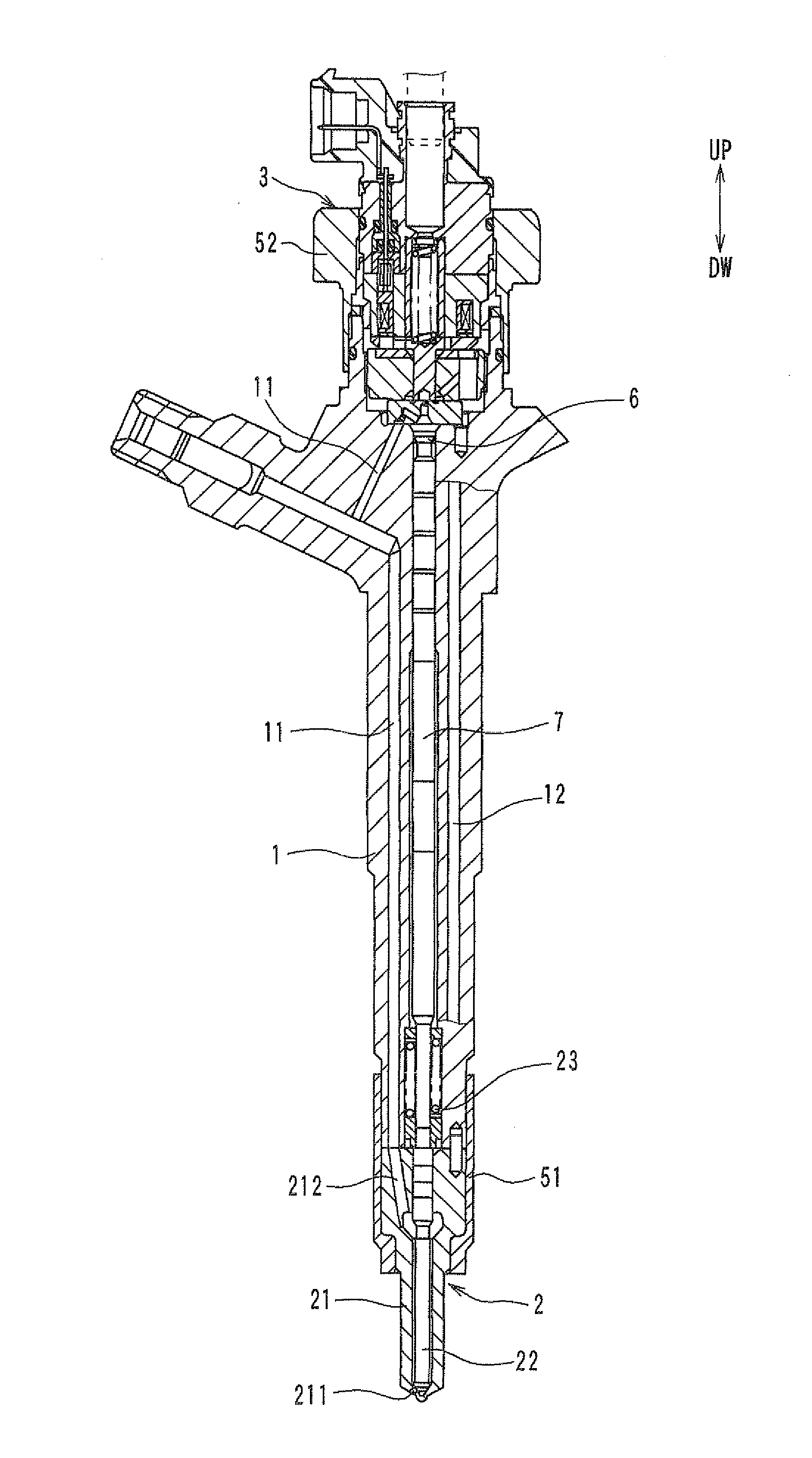

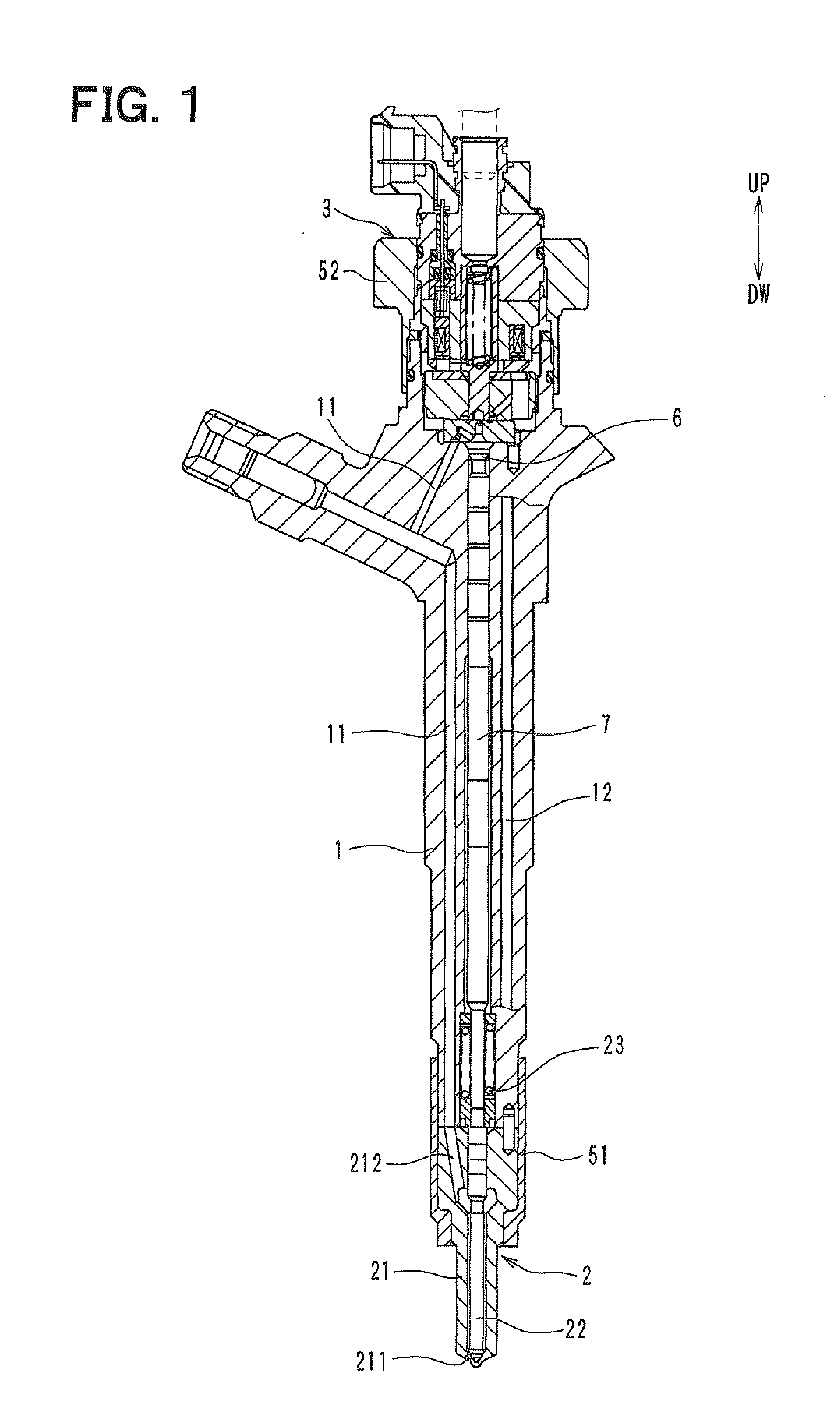

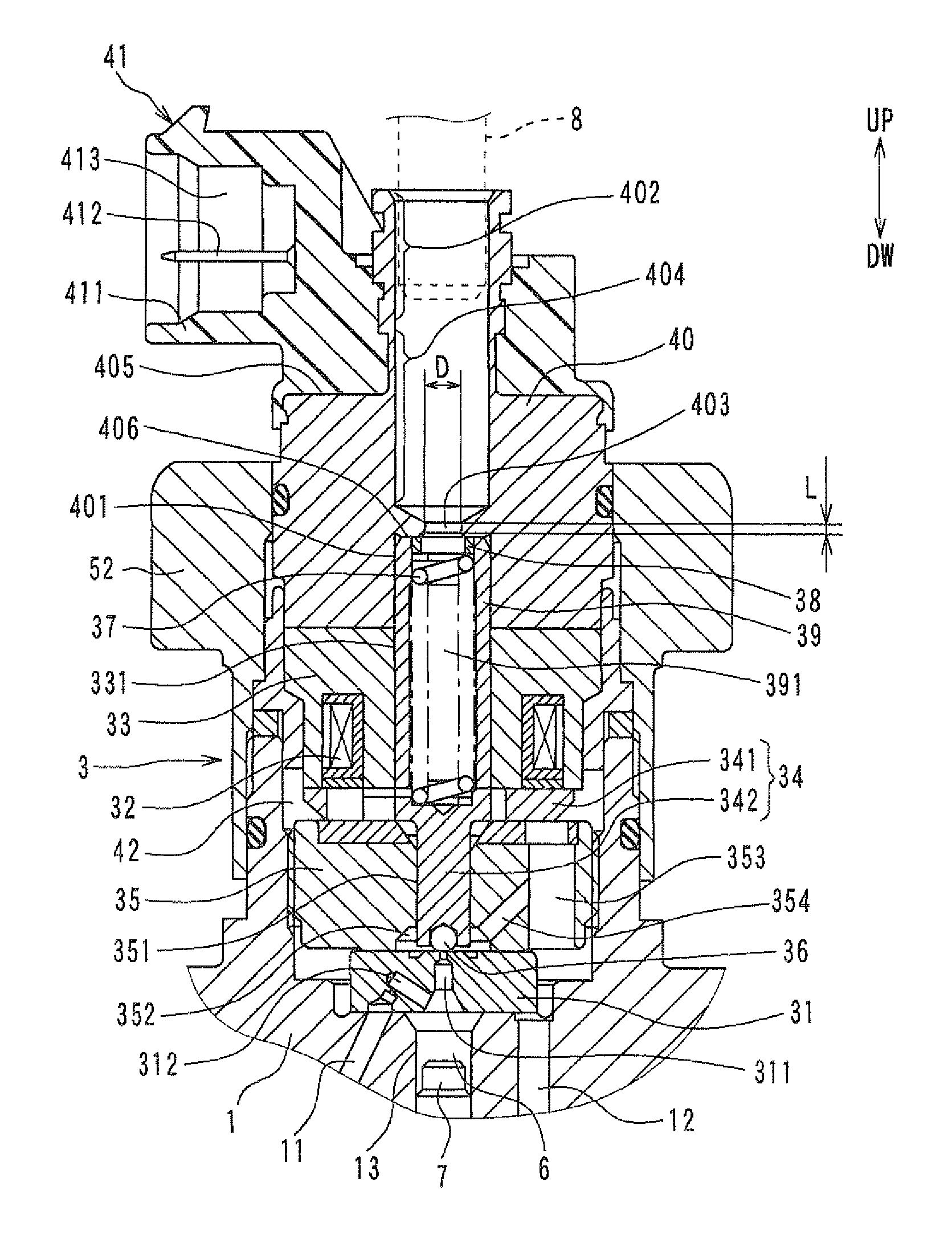

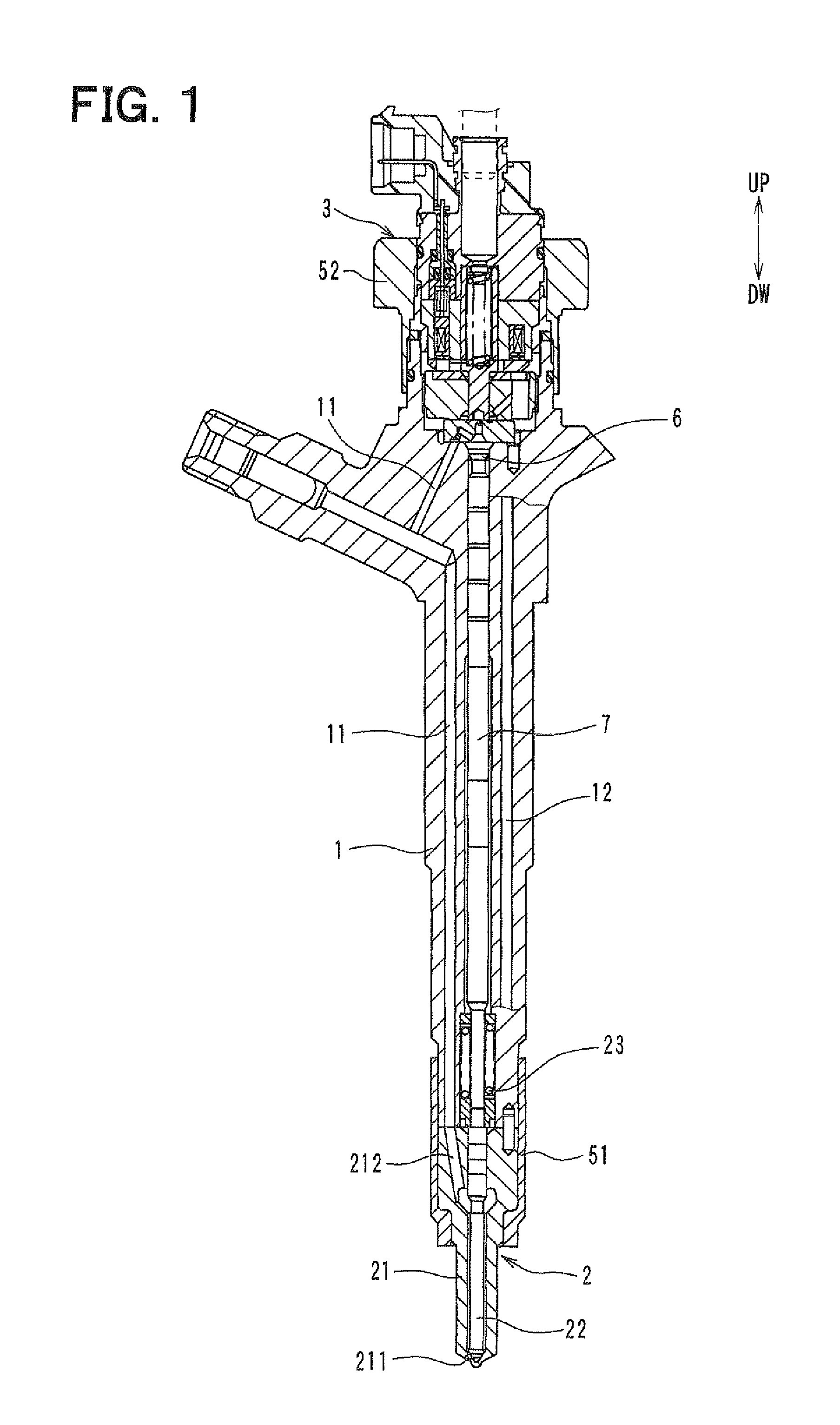

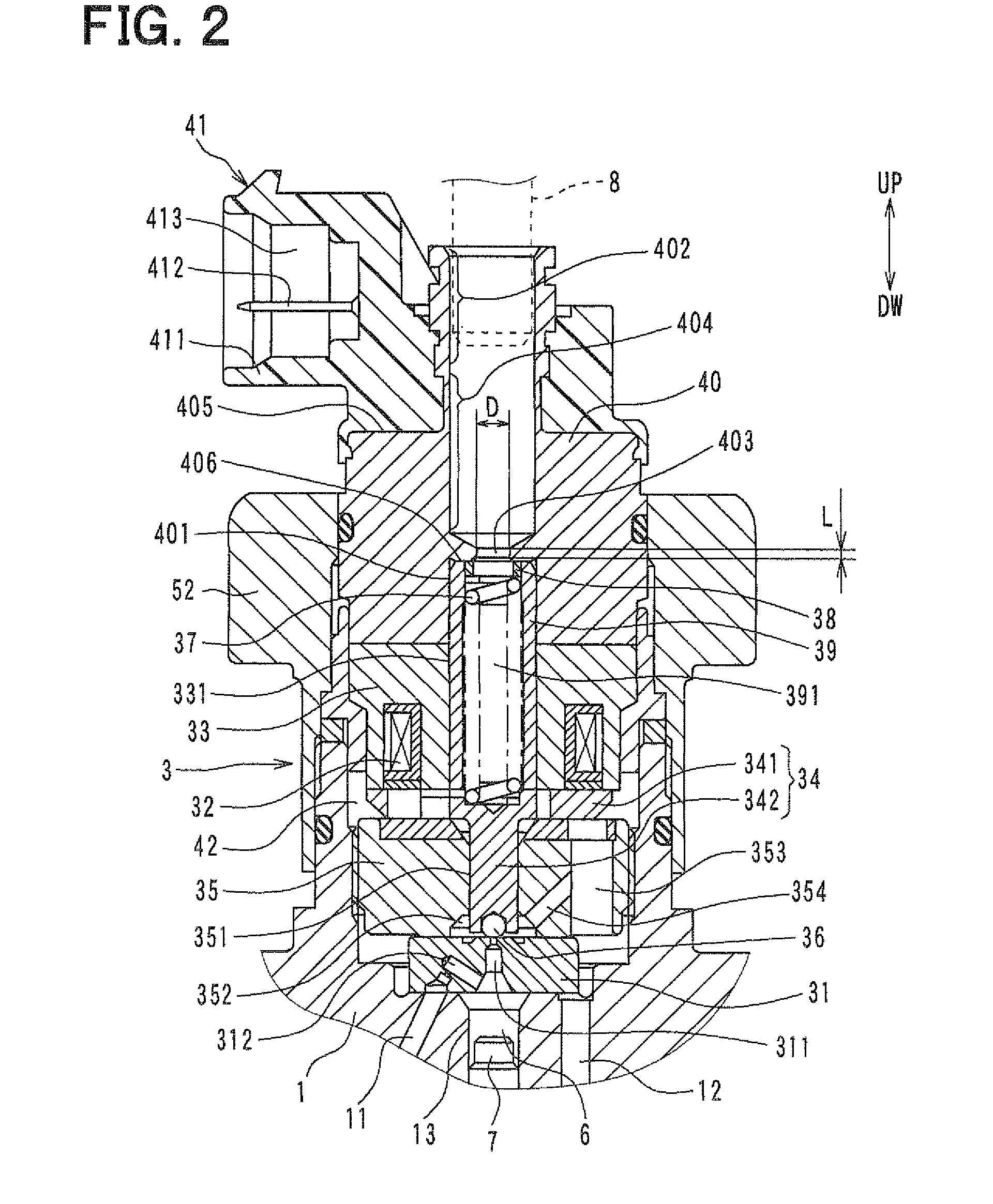

Fuel injection valve

ActiveUS20110095102A1Shorten the lengthPrecise control of injection volumeSpray nozzlesFuel injection apparatusSolenoid valveEngineering

A fuel injection valve includes a needle for opening or closing an injection hole. The needle moves in response to a fuel pressure in a control chamber. The fuel injection valve includes an electromagnetic valve which opens or closes a discharge passage for changing pressure in the control chamber to actuate the needle. A narrow part is provided in the discharge passage. The narrow part is formed to shorten a length along a flow direction. The shortened narrow part can suppress pulsations. Therefore, it is possible to accurately control injection quantity, since a variation of closing speed of the armature caused by the pulsations can be suppressed.

Owner:DENSO CORP

Fuel-evaporated gas processing system and electromagnetic valve device

ActiveUS7607420B2Reduce degradationSuppress pressure pulsationNon-fuel substance addition to fuelMachines/enginesSolenoid valveFuel tank

A fuel-evaporated gas processing system includes an input port taking in evaporated gas evaporated in a fuel tank; output ports supplying the evaporated gas taken in through the input port to an intake system of an engine; a chamber interposed between the input port and the output ports; an electromagnetic valve device including at least first and second electromagnetic valves disposed in the connection between the input port or the output ports and the chamber, either of the input port or the output ports being branched off into a plurality of sections, and perform opening and closing operations in response to a driving signal; and a valve control means driving the first and the second electromagnetic valves of the electromagnetic valve device.

Owner:MITSUBISHI ELECTRIC CORP

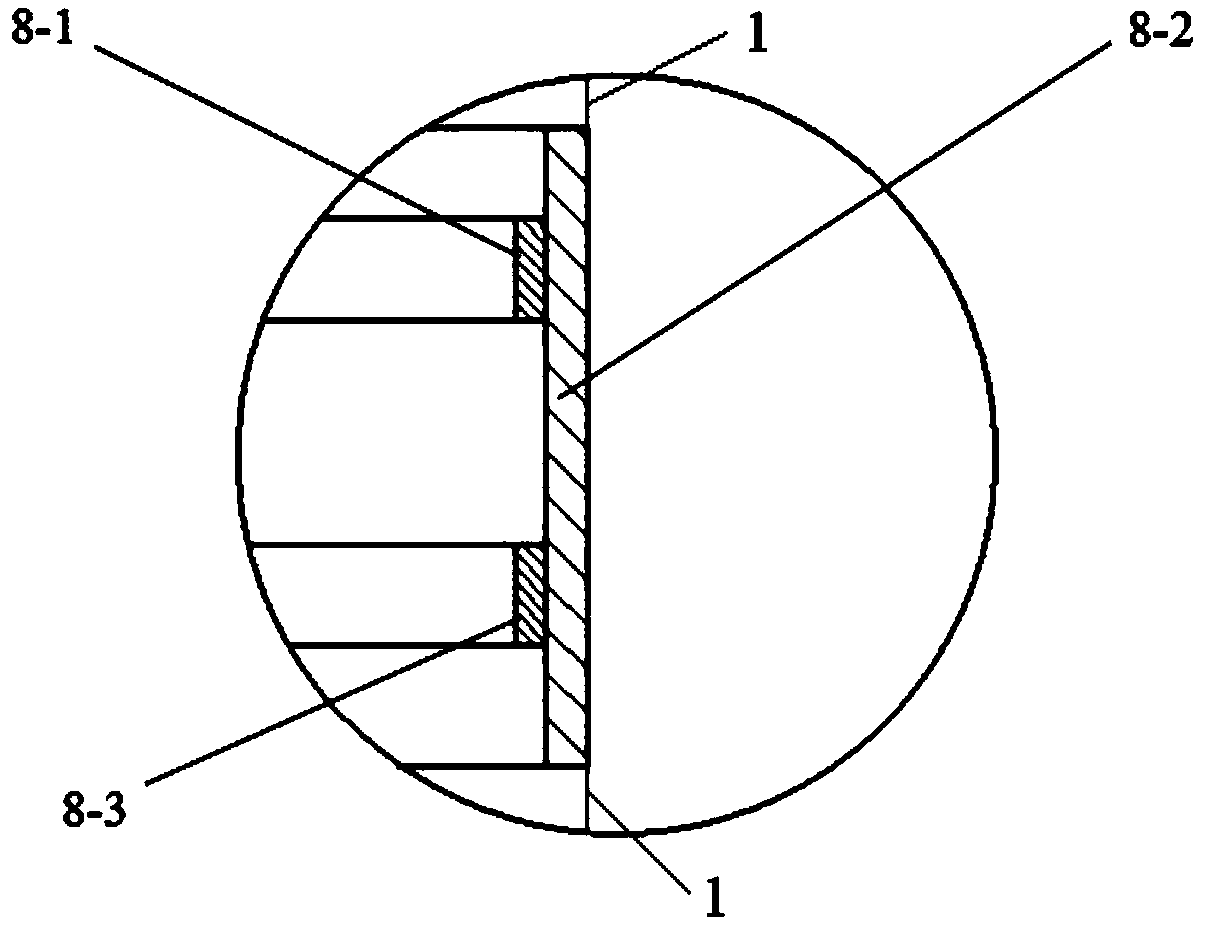

Oil filter capable of controlling pressure fluctuation

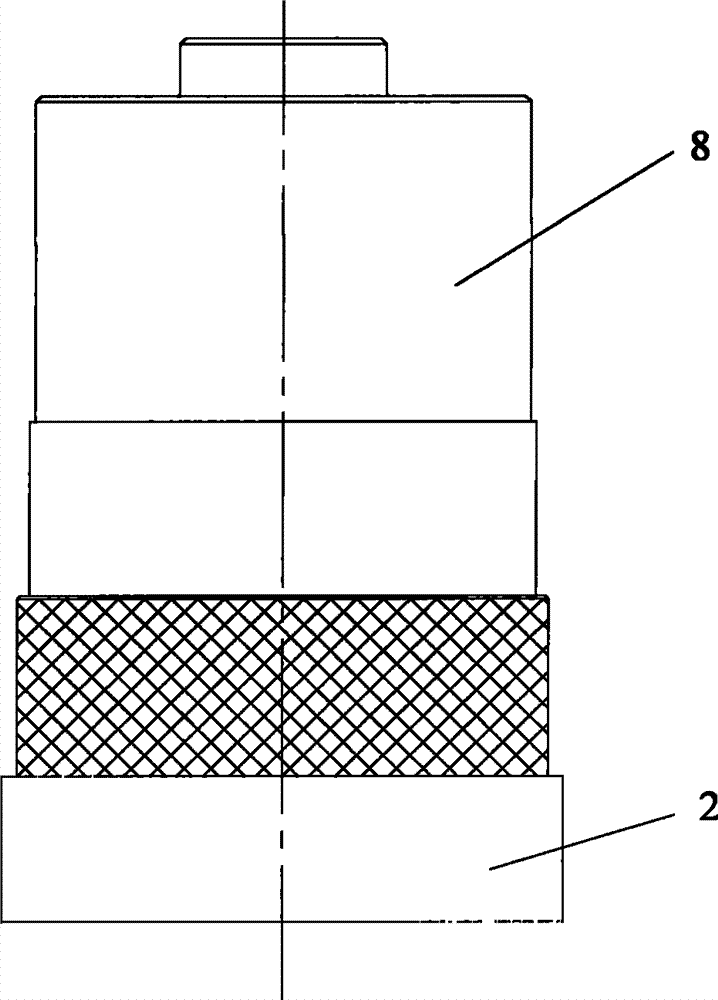

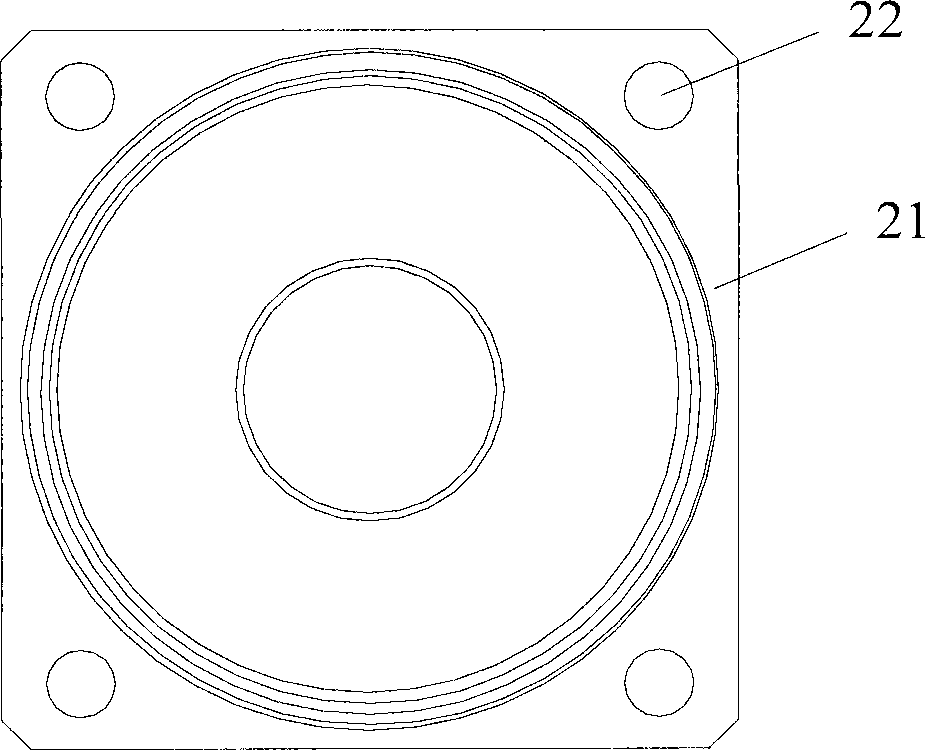

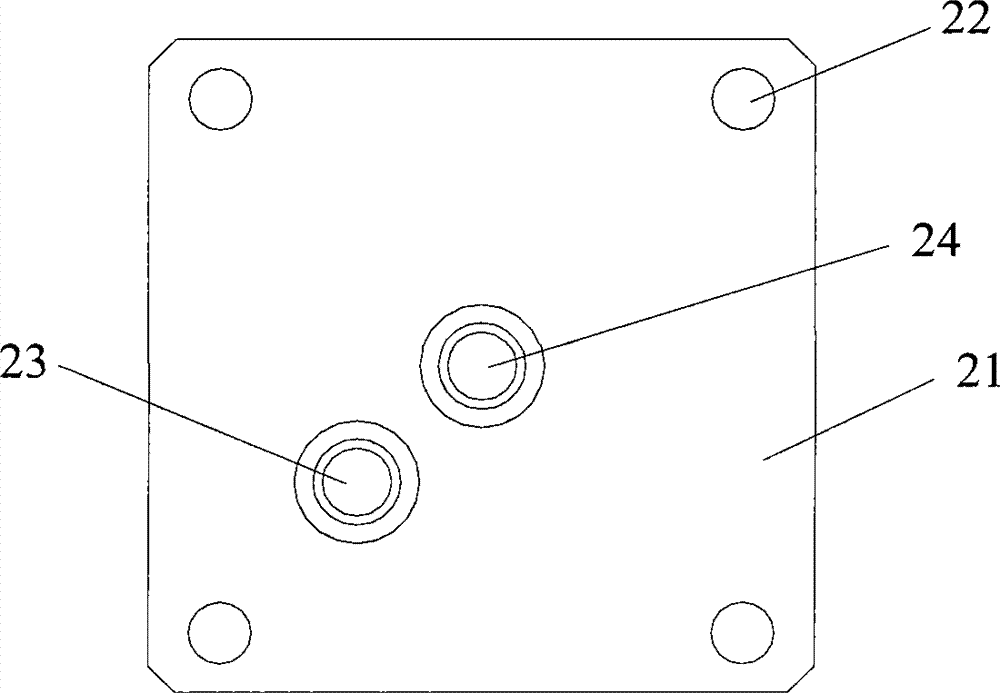

ActiveCN102235401BChange the pulsation frequencySuppress pressure pulsationFluid-pressure actuator componentsCopper wireBiochemical engineering

The invention discloses an oil filter capable of controlling pressure fluctuation. The oil filter comprises a base, a filter core mounting sleeve, a filter core and a filter cartridge, wherein the filter core mounting sleeve and the filter cartridge are arranged on the base; the filter core is sleeved on the filter core mounting sleeve; and the filter cartridge is sleeved on the filter core and is used for tightly compressing the filter core. The oil filter is characterized in that: a certain gap is formed between the filter core and the filter cartridge; a copper wire is filled in the gap; and oil which flows into the oil filter flows through the copper wire and the filter core and then flows out of the oil filter. The oil filter capable of controlling the pressure fluctuation can eliminate pollutants in the oil, keep the cleanness of the oil and effectively control the pressure fluctuation, so that the reliability of the whole hydraulic system is improved; in addition, the oil filter has a simple structure, is convenient to machine and is easy to realize.

Owner:COMAC +1

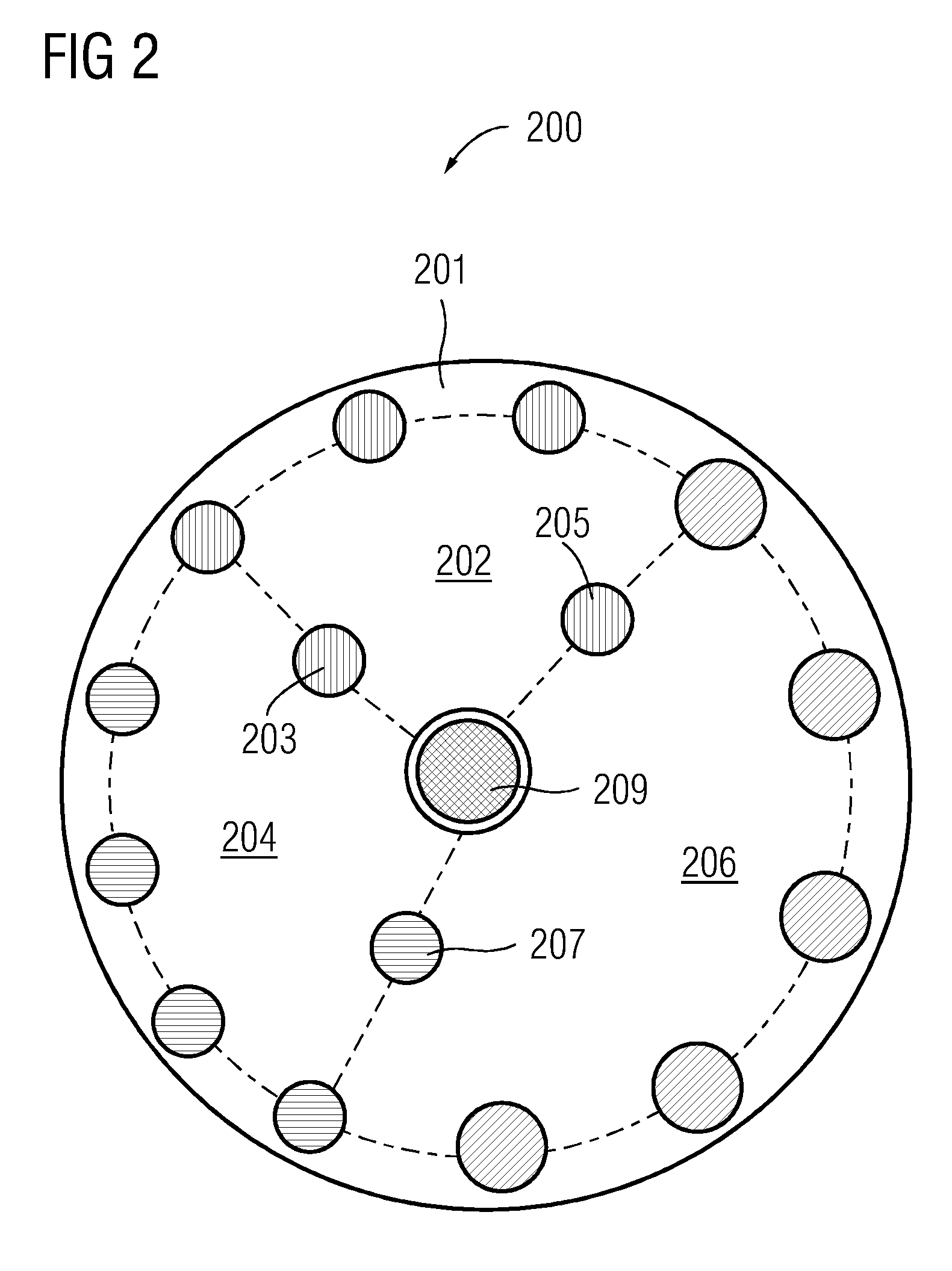

Burner for a gas combustor and a method of operating the burner thereof

InactiveUS20130232988A1Maintain temperatureProvide stabilityFuel supply regulationContinuous combustion chamberCombustorProcess engineering

A burner for a gas combustor and a method of operating the burner are disclosed. The burner includes a front surface area divided into a plurality of subareas and inlets arranged on the front surface area such that each subarea is encircled by at least four inlets and such that during operation of the burner, a gas recirculation in the combustor is facilitated corresponding to each subarea.

Owner:SIEMENS AG

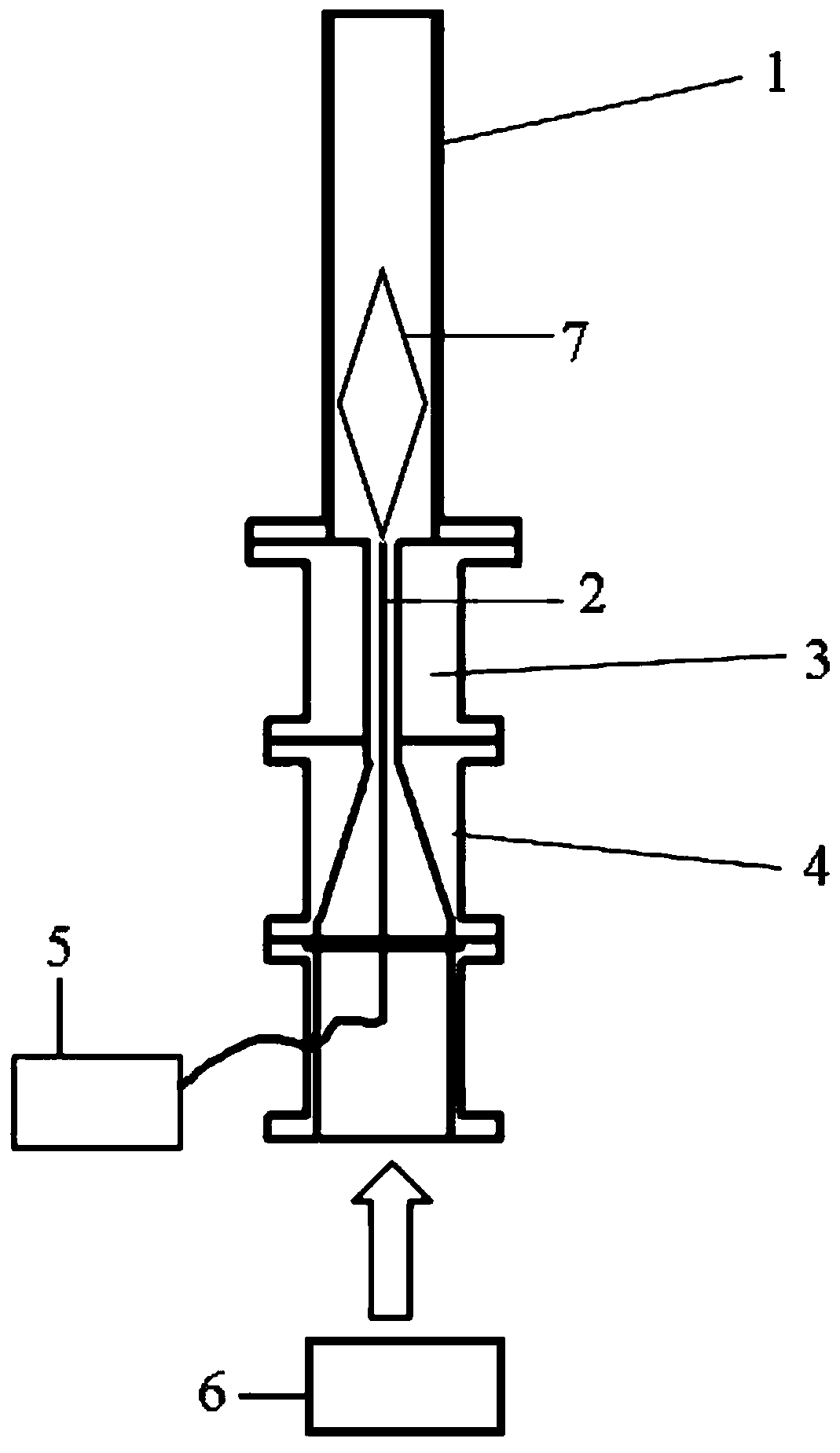

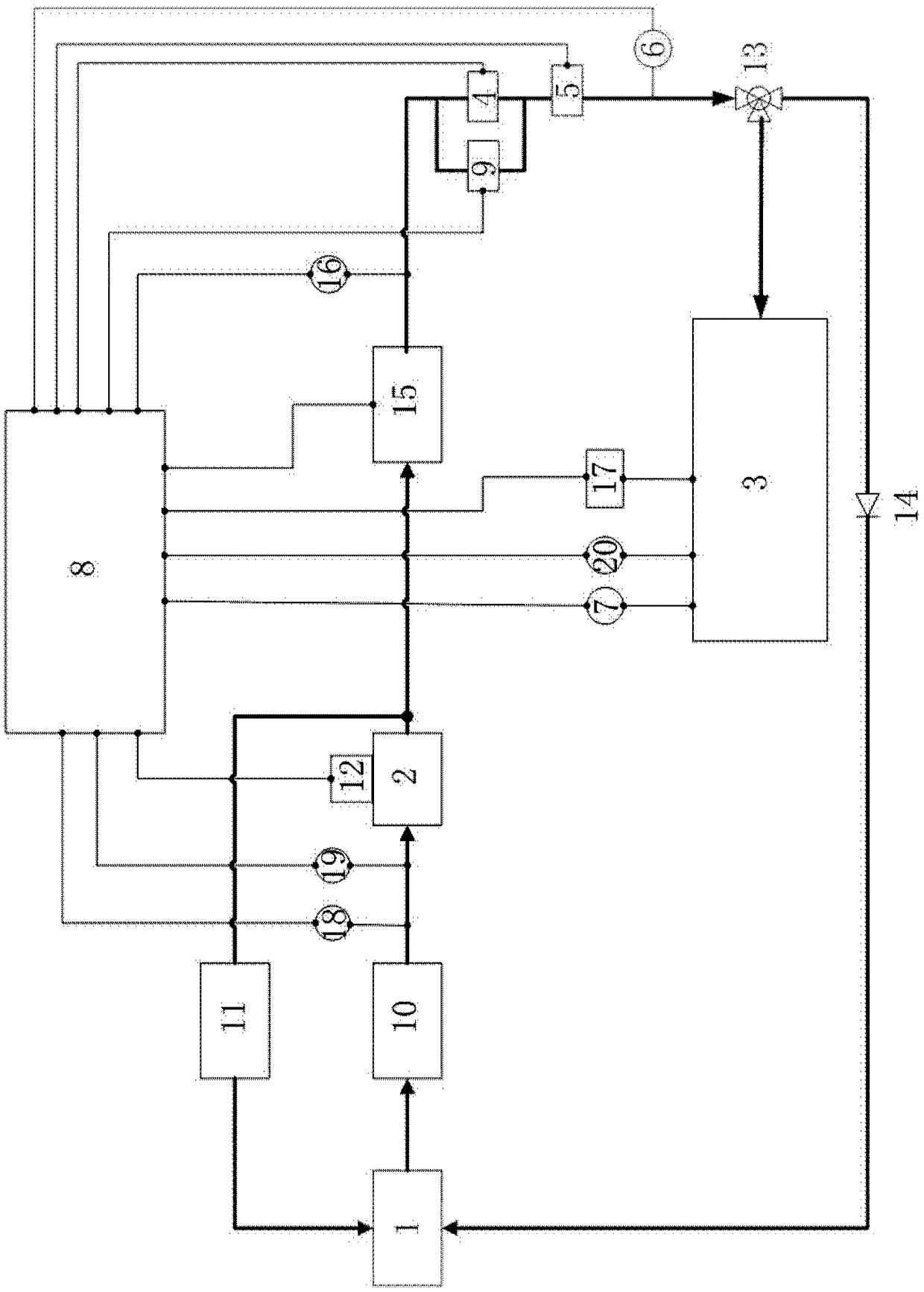

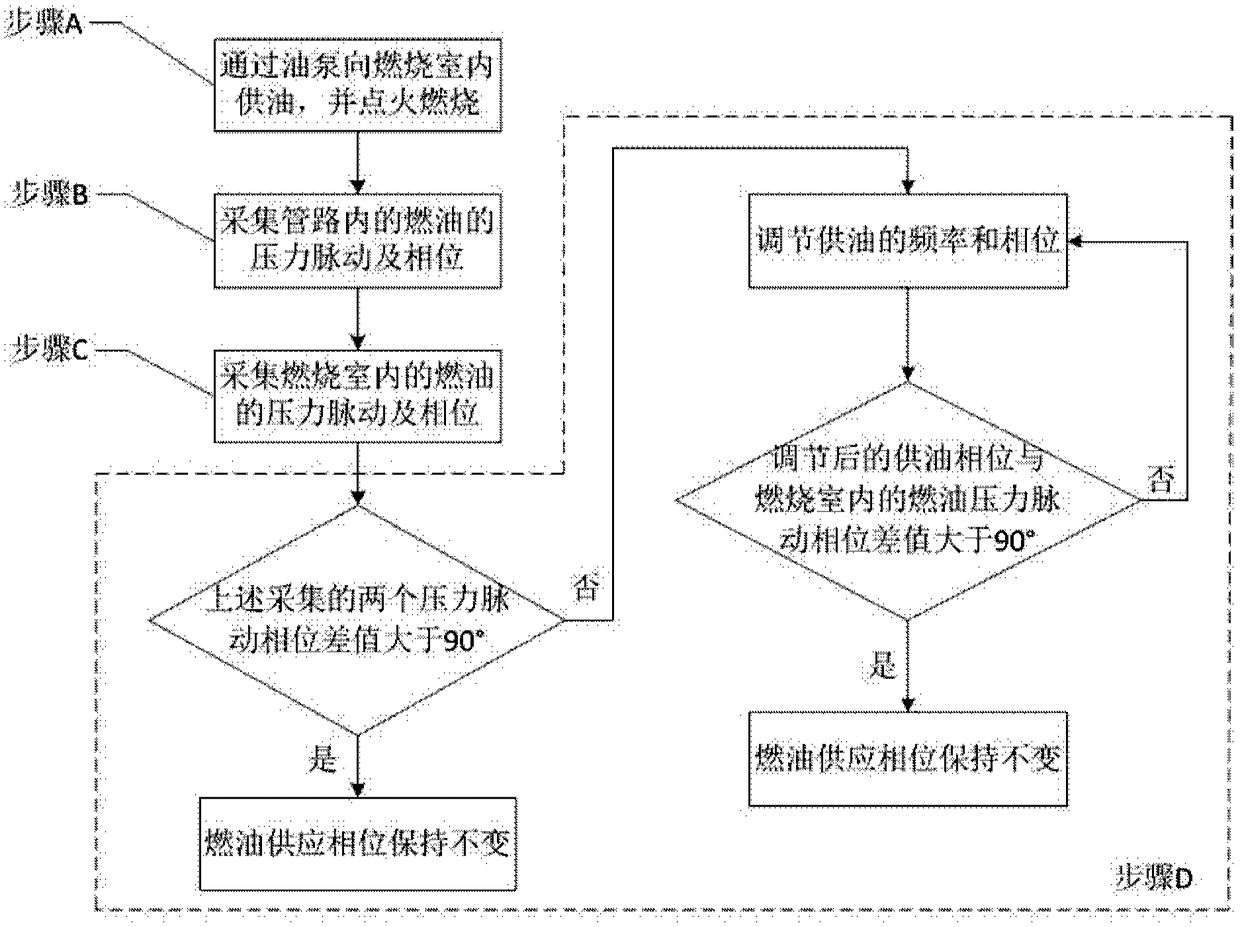

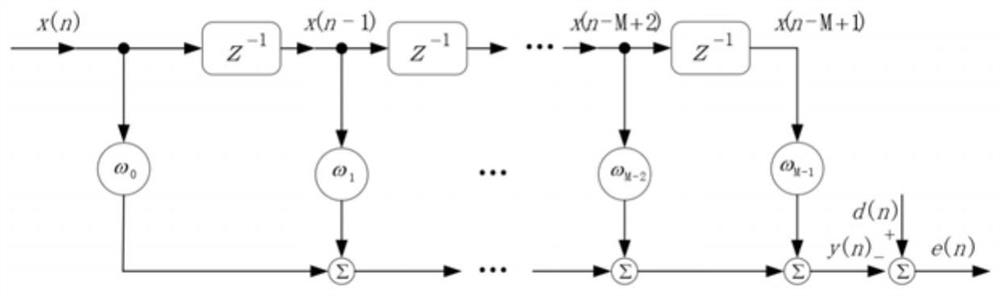

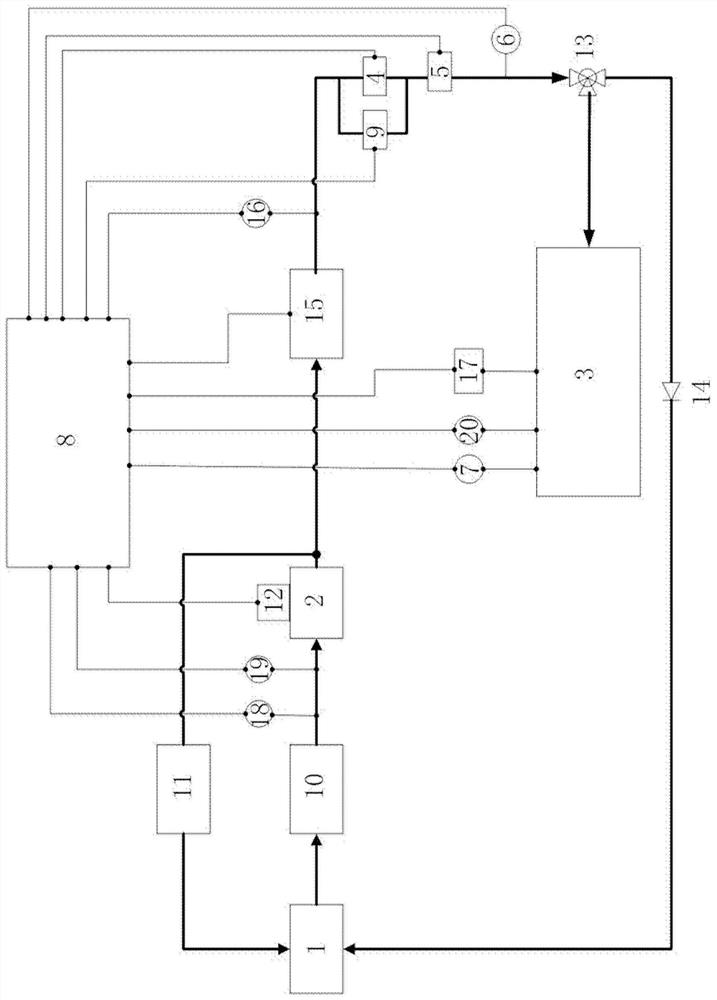

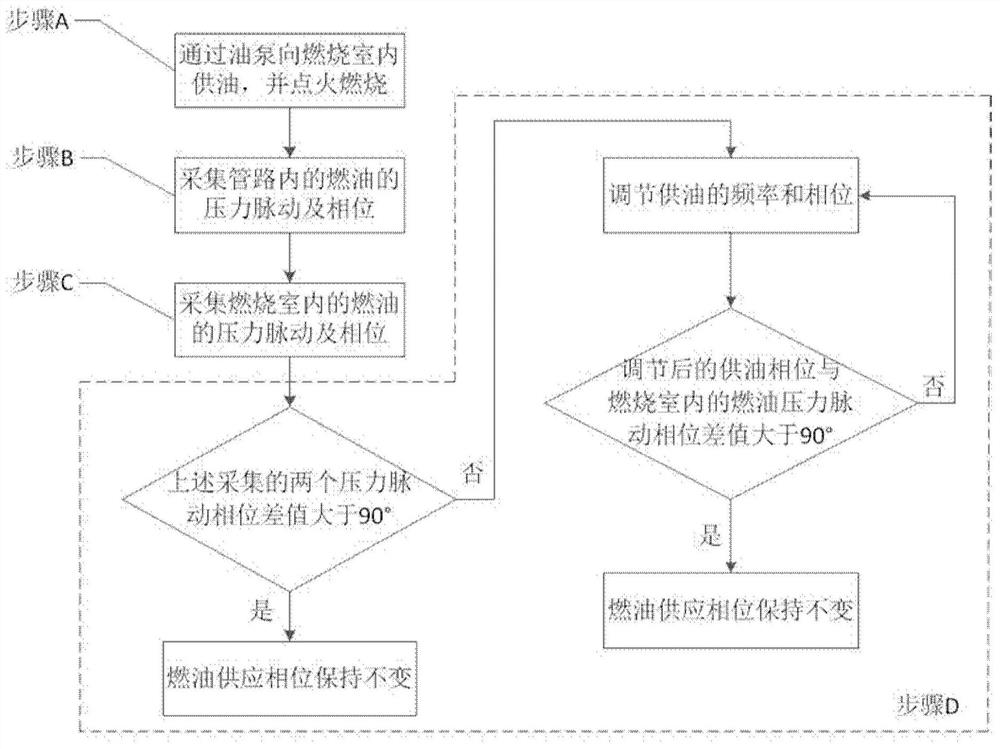

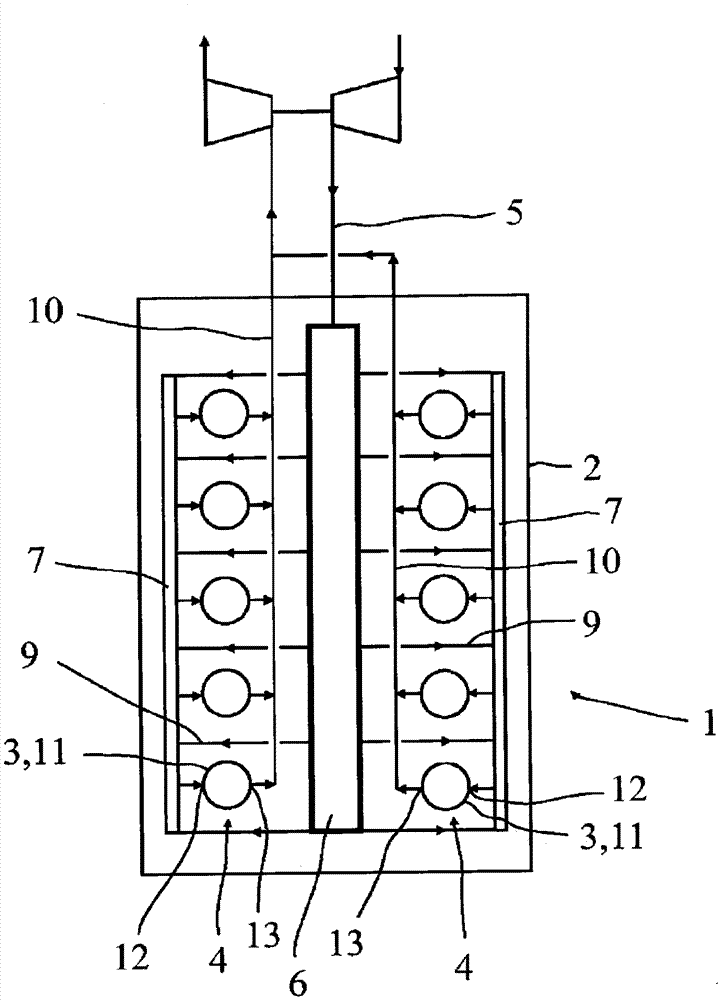

Fuel supply device for inhibiting combustion instability, combustion equipment and control method

ActiveCN109028143ASuppress pressure pulsationContinuous combustion chamberCombustion instabilityCombustion chamber

The invention provides a fuel supply device for inhibiting combustion instability, combustion equipment and a control method, The fuel supply device for inhibiting the combustion instability comprisesan oil tank, a booster pump and a phase frequency adjusting device, wherein the oil tank is used for storing fuel oil, and is used for increasing the pressure of the fuel oil in a pipeline; the phasefrequency adjusting device is used for adjusting the frequency of the fuel oil sprayed in a combustion chamber and a phase in real time according to the difference value of the fuel oil phase in thepipeline and the combustion chamber, so that pressure pulsation in the combustion chamber is inhibited. The fuel supply device for inhibiting the combustion instability is used for measuring the phaseof the fuel oil in the pipeline and the phase of the combustion chamber in real time by arranging a first dynamic pressure sensor and a high-frequency dynamic pressure sensor; and the frequency and the phase of the oil supply are adjusted in real time by arranging a high-frequency electromagnetic valve and a phase shifter, so that when the phase difference value of the fuel oil in the pipeline and the phase difference value of the fuel oil in the combustion chamber are smaller than 90 degrees, the frequency and the phase of the oil supply can be timely adjusted, and the pressure pulsation generated by combustion in the combustion chamber can be effectively inhibited.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

A 3D printing integrated heat sink and its application in phased array antenna

InactiveCN110165355BLowered byHelp passIndividually energised antenna arraysDe-icing/drying-out arrangementsEngineering3d printed

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

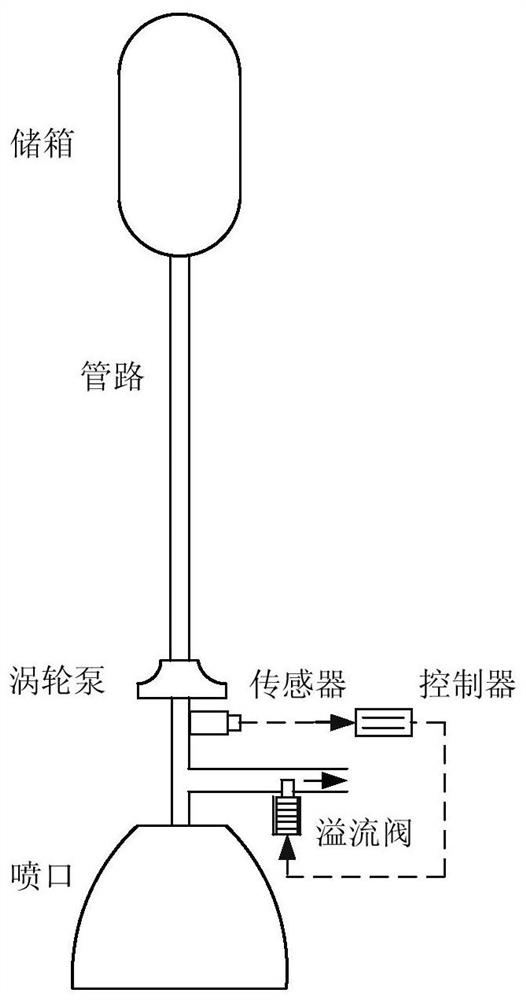

POGO active suppression method and system based on overflow valve

ActiveCN113944571AReduce vibrationSuppression technology is multi-passive vibration suppressionRocket engine plantsControl theoryStress sensors

The invention relates to a POGO active suppression method and system based on an overflow valve. The system comprises a pressure sensor, a controller and the overflow valve. The pressure sensor is installed on a high-pressure pipeline behind an engine pump and used for sensing the pressure pulsation condition of fluid in the high-pressure pipeline behind the pump, and a sensed pressure signal is sent to the controller. The controller generates an excitation signal according to the pressure signal and is used for controlling the opening degree of the overflow valve; and the overflow valve is used for adjusting the opening degree and the overflow amount according to the excitation signal sent by the controller, and then the pressure pulsation of the high-pressure pipeline behind the engine pump is reduced.

Owner:BEIJING INST OF ASTRONAUTICAL SYST ENG

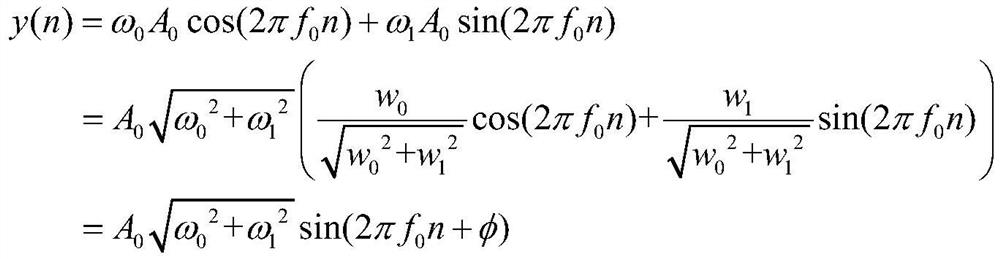

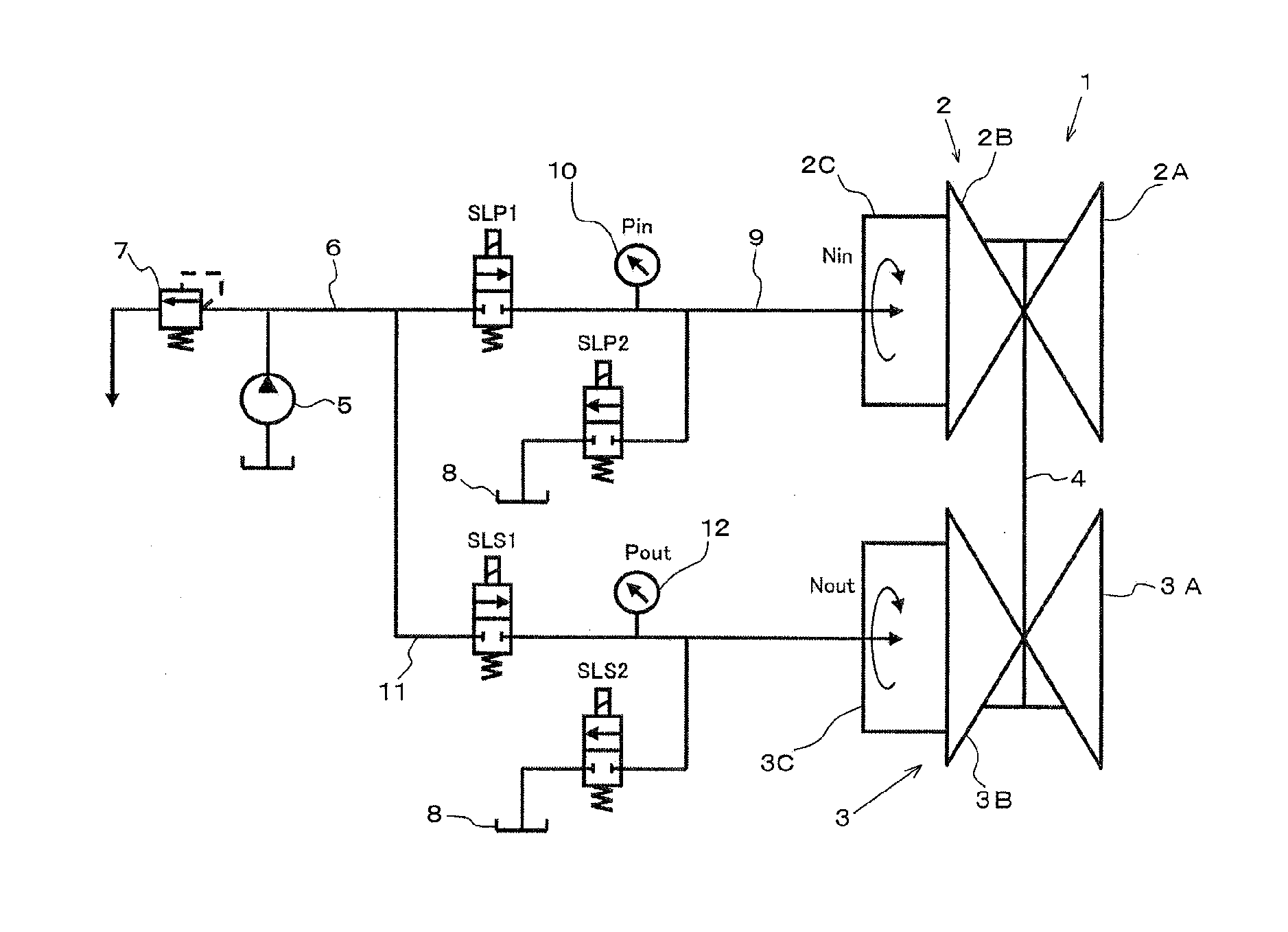

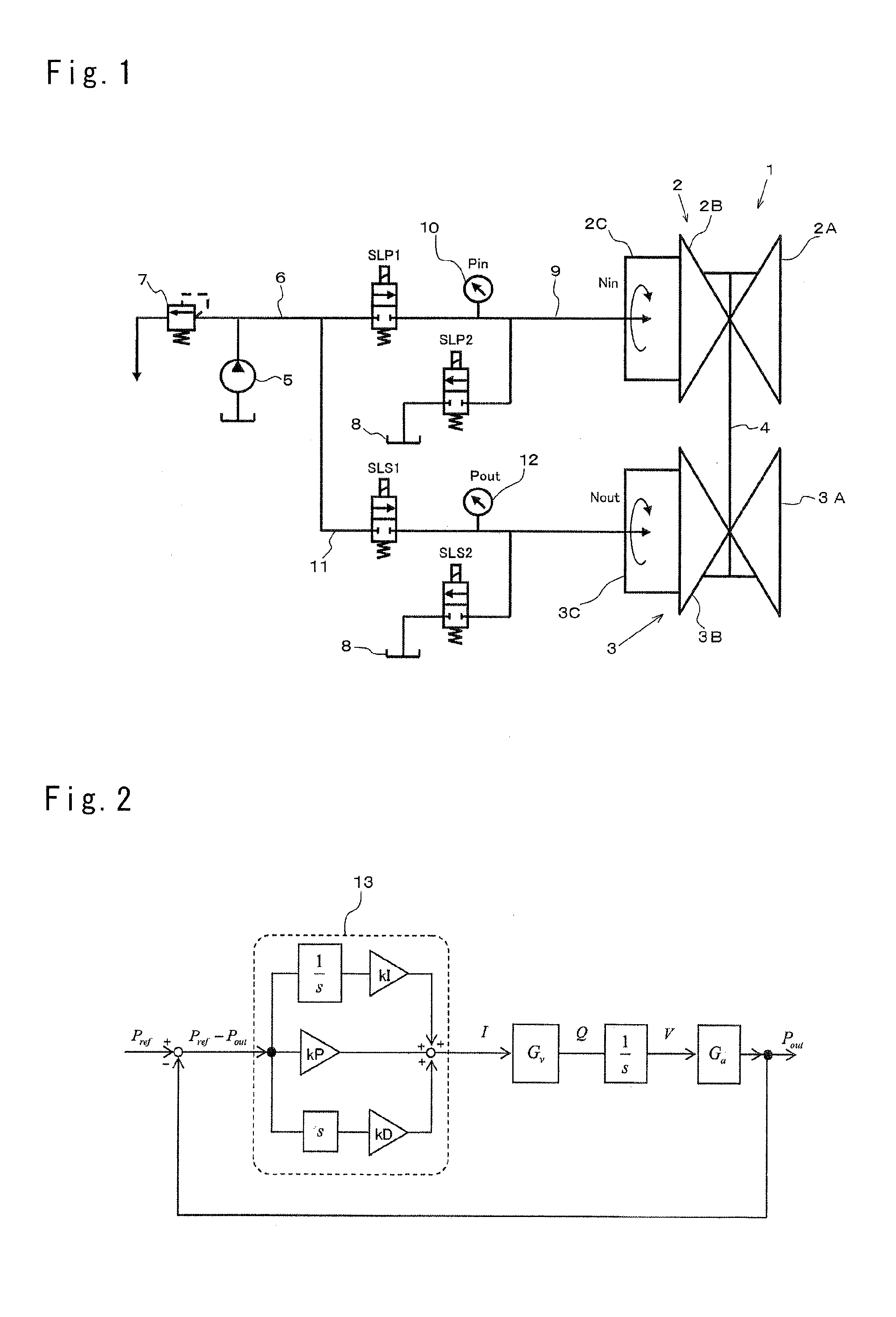

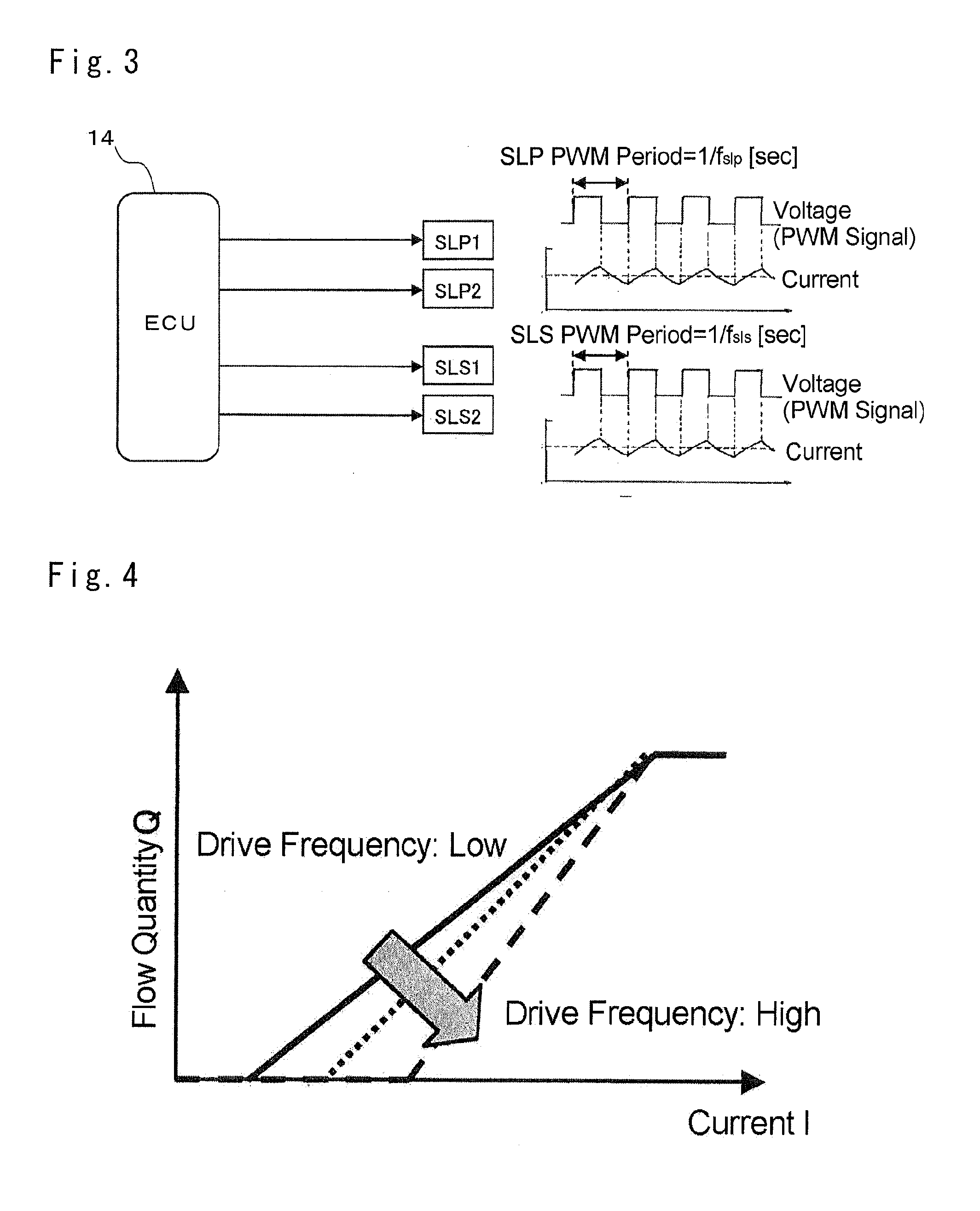

Hydraulic control system for automatic transmission

InactiveUS20140329628A1Suppress pulsationAvoid changeGear vibration/noise dampingGearing controlAutomatic transmissionControl system

A hydraulic control system for an automatic transmission, in which a belt is applied to at least one pair of pulleys, and in which widths of belt grooves of the pulleys, or pressures to clamp the belt by the pulleys are controlled by hydraulic pressures applied to hydraulic chambers of the pulleys. The hydraulic control system is comprised of: a control valve that controls a delivery and a drainage of hydraulic fluid to / from the hydraulic chamber; and a drive frequency setting means that determines a drive frequency of a drive signal for actuating the control valves in such a manner that a phase of a local maximum value of amplitude of the drive signal is shifted from a phase of a local maximum value of amplitude of vibrations resulting from rotating the pulleys.

Owner:TOYOTA JIDOSHA KK

A method of high-frequency exciting discharge center plasma to suppress combustion pressure pulsation

ActiveCN109729634BReduce magnificationImproved heat release stabilityPlasma techniqueCombustion chamberThermoacoustics

A method for suppressing combustion pressure pulsation by high-frequency exciting discharge center plasma relates to a method for suppressing pressure pulsation in thermoacoustic oscillation phenomenon. The invention uses the plasma as a dynamic and active way to regulate the pressure pulsation state in the combustion process of the combustion chamber under certain working conditions. The present invention generates plasma at the root of the flame in the combustion chamber, so that the flame is dynamically affected by the plasma and less affected by air flow disturbance, the stability of heat release is correspondingly improved, and the phase and frequency of flame heat release are adjusted, so that The amplification degree of the pulsation energy in the combustion chamber is reduced, and the condition of thermoacoustic oscillation is destroyed, thereby realizing the reduction or even disappearance of the pressure pulsation in the combustion chamber.

Owner:HARBIN INST OF TECH

Fuel supply device, combustion equipment and control method for suppressing combustion instability

ActiveCN109028143BSuppress pressure pulsationContinuous combustion chamberCombustion instabilityCombustion chamber

The disclosure provides a fuel supply device for suppressing combustion instability, combustion equipment and a control method. The fuel supply device for suppressing combustion instability includes: a fuel tank, a booster pump, and a phase frequency adjustment device; the fuel tank is used to store fuel, and is used to To pressurize the fuel in the pipeline, the phase frequency adjustment device adjusts the frequency and phase of the fuel injected into the combustion chamber in real time according to the phase difference between the fuel in the pipeline and the combustion chamber, and suppresses the pressure pulsation in the combustion chamber. The fuel supply device for suppressing combustion instability provided by the present disclosure measures the phase of the fuel in the pipeline and the combustion chamber in real time by setting the first dynamic pressure sensor and the high-frequency dynamic pressure sensor, and by setting the high-frequency solenoid valve and the phase shifter Adjust the frequency and phase of the fuel supply in real time, so that when the phase difference between the fuel in the pipeline and the combustion chamber is less than 90°, the frequency and phase of the fuel supply can be adjusted in time to effectively suppress the pressure pulsation generated by the combustion in the combustion chamber.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Fuel injection valve

ActiveUS8382007B2Control quantityReduce adverse effectsSpray nozzlesFuel injection apparatusSolenoid valveEngineering

A fuel injection valve includes a needle for opening or closing an injection hole. The needle moves in response to a fuel pressure in a control chamber. The fuel injection valve includes an electromagnetic valve which opens or closes a discharge passage for changing pressure in the control chamber to actuate the needle. A narrow part is provided in the discharge passage. The narrow part is formed to shorten a length along a flow direction. The shortened narrow part can suppress pulsations. Therefore, it is possible to accurately control injection quantity, since a variation of closing speed of the armature caused by the pulsations can be suppressed.

Owner:DENSO CORP

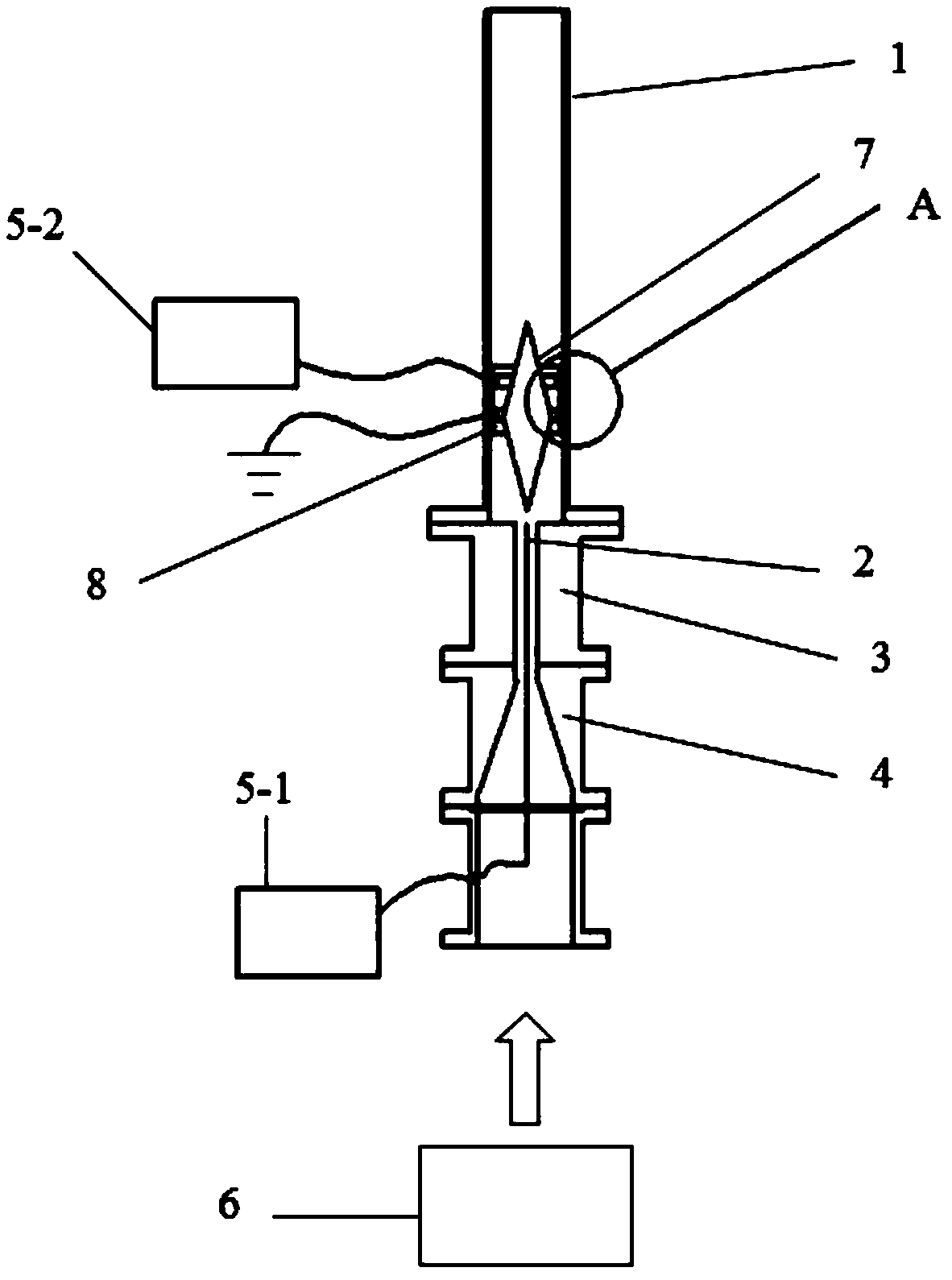

A method for suppressing combustion pressure pulsation by using high-frequency excitation discharge side plasma

ActiveCN109724107BAchieve inhibitionReduce the impact of disturbanceContinuous combustion chamberPlasma techniqueThermodynamicsCombustion chamber

A method for suppressing combustion pressure pulsation by high-frequency excitation discharge side plasma relates to a method for suppressing pressure pulsation in thermoacoustic oscillation phenomenon. The present invention uses side plasma as a dynamic and active way to regulate the pressure pulsation state that occurs during the combustion process of the combustion chamber under certain working conditions. This invention uses dielectric barrier (DBD) discharge to generate plasma on the flame side of the combustion chamber. By adjusting the flame concentration area and changing the distance of the flame main heat release area relative to the combustion chamber outlet, the pressure pulsation in the combustion chamber is reflected from the combustion chamber outlet. The length of the return path changes, and the phase difference between the pressure pulsation and the flame heat release rate changes, which destroys the original conditions for thermoacoustic oscillation, thereby reducing or even disappearing the pressure pulsation in the combustion chamber.

Owner:HARBIN INST OF TECH

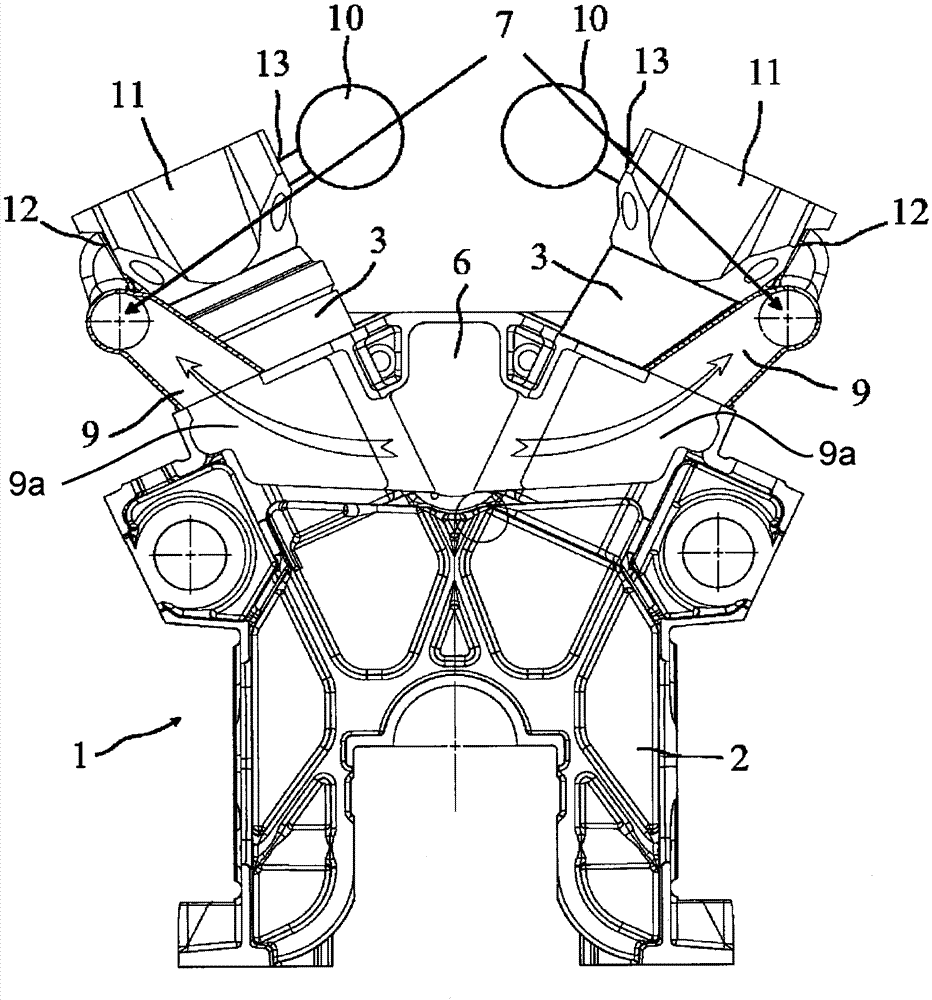

Reciprocating Engines and Engine Blocks

A reciprocating engine (1) comprising an engine block (2) with cylinders (3) and inlet passages (5) for guiding intake air into the cylinders (3). The inlet passage (5) is provided with a main intake receiver (6) and at least one auxiliary intake receiver (7), and the auxiliary intake receiver (7) is arranged on the main intake receiver (6) ) and upstream of the cylinder (3).

Owner:WARTSILA FINLAND OY

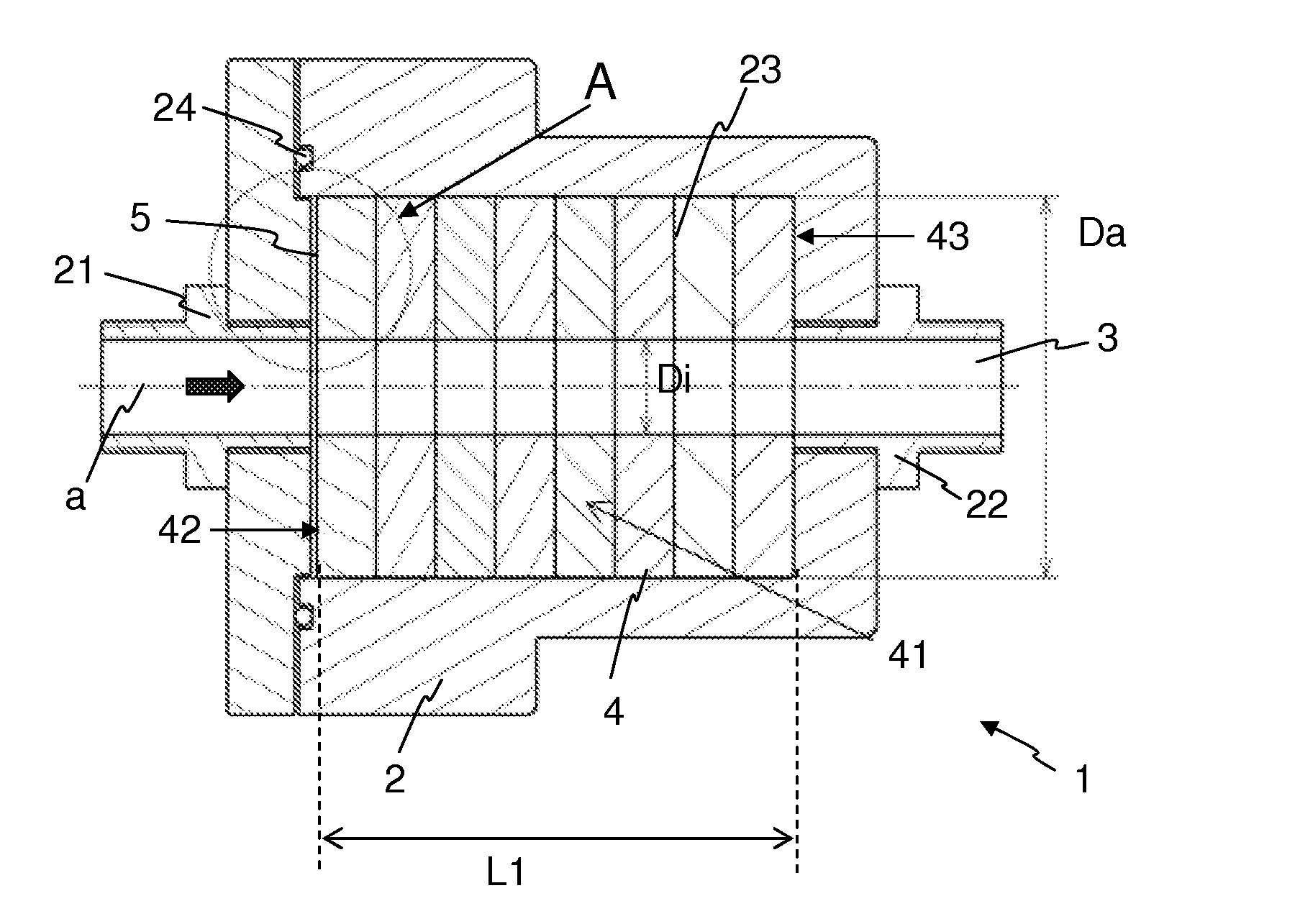

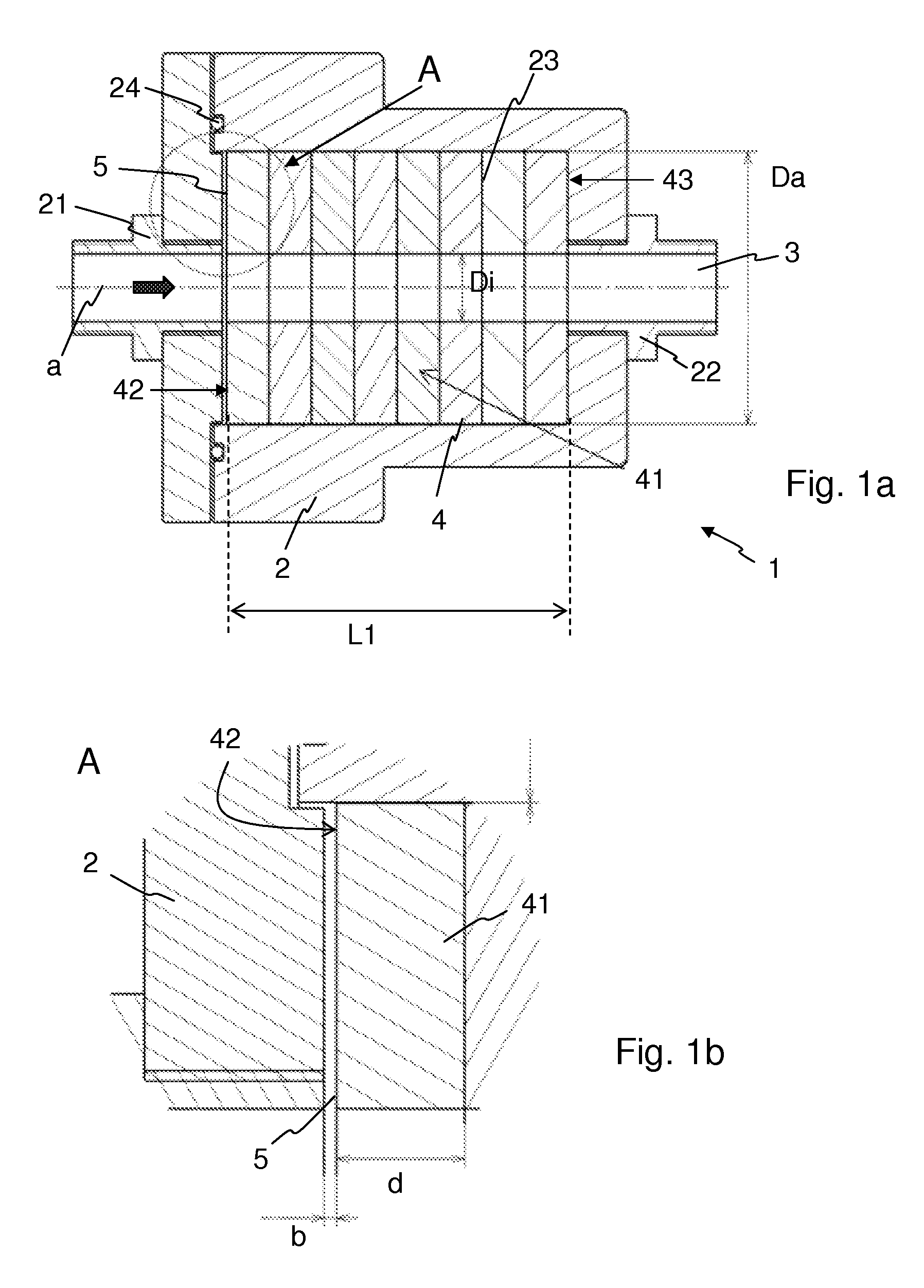

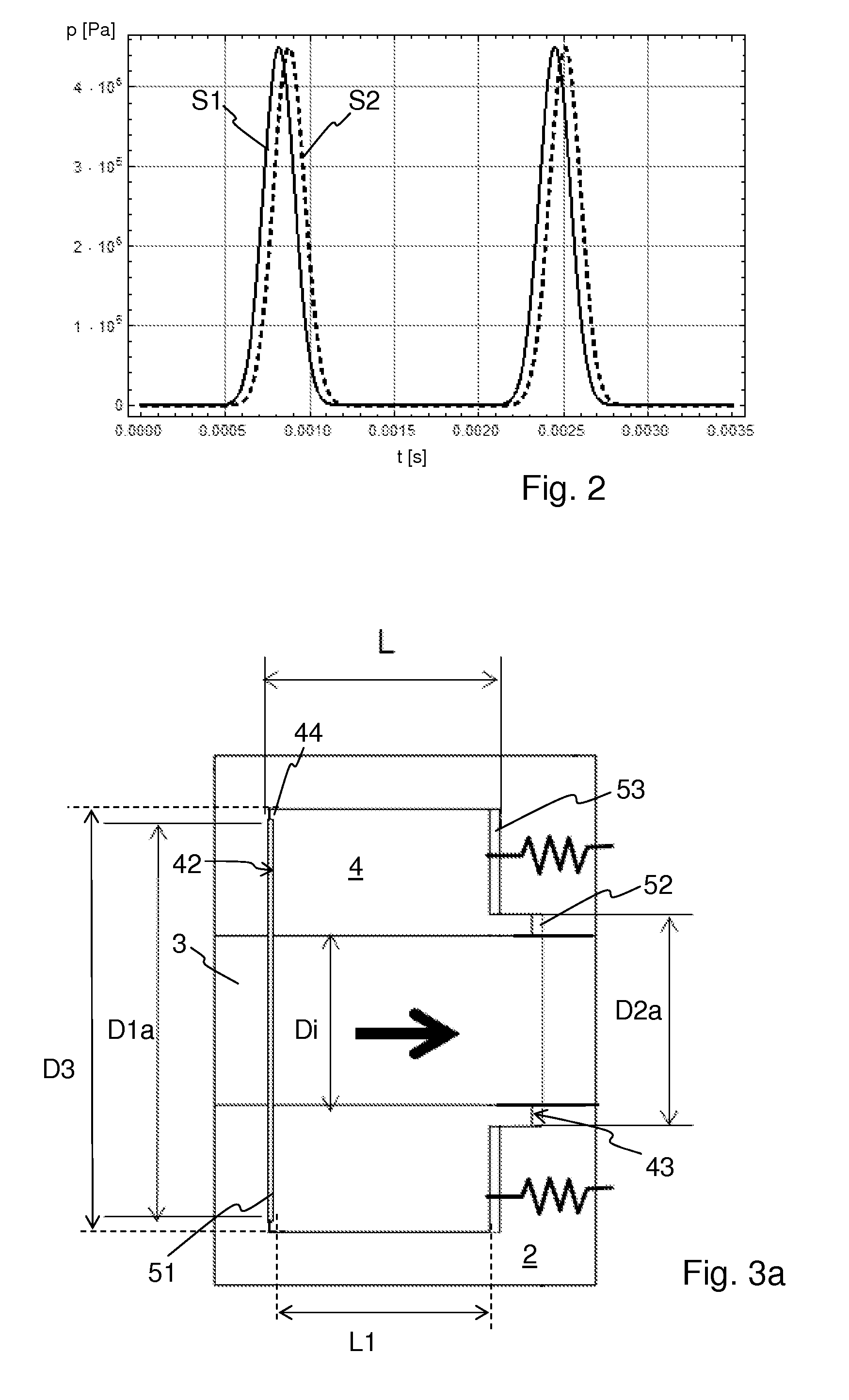

Pulsation damper

A pulsation damper (1) for damping pressure pulsations of a fluid is insertable into the fluid line as intermediate piece by forming an axial flow channel (3), and the pulsation damper (1) featuring a housing (2). The pulsation damper (1) is characterized by the fact that the housing (2) has at least one hollow space (23) communicating with the flow channel (3) and in which at least one attenuator (4) is disposed movably in axial direction.

Owner:MANN HUMMEL GMBH

Holding device for fastening a fuel distributor to an internal combustion engine

ActiveUS20160208760A1Improve developmentImprove protectionCasingsMachine framesEngineeringInternal combustion engine

A holding device is used for fastening a fuel distributor to an internal combustion engine. A plurality of holding elements is provided, which are able to be fixed in place on the internal combustion engine via a fastener. A cable guide is provided in addition. The holding elements are connected to the cable guide. In addition, a system having such a holding device and a fuel distributor for conveying fuel are provided.

Owner:ROBERT BOSCH GMBH

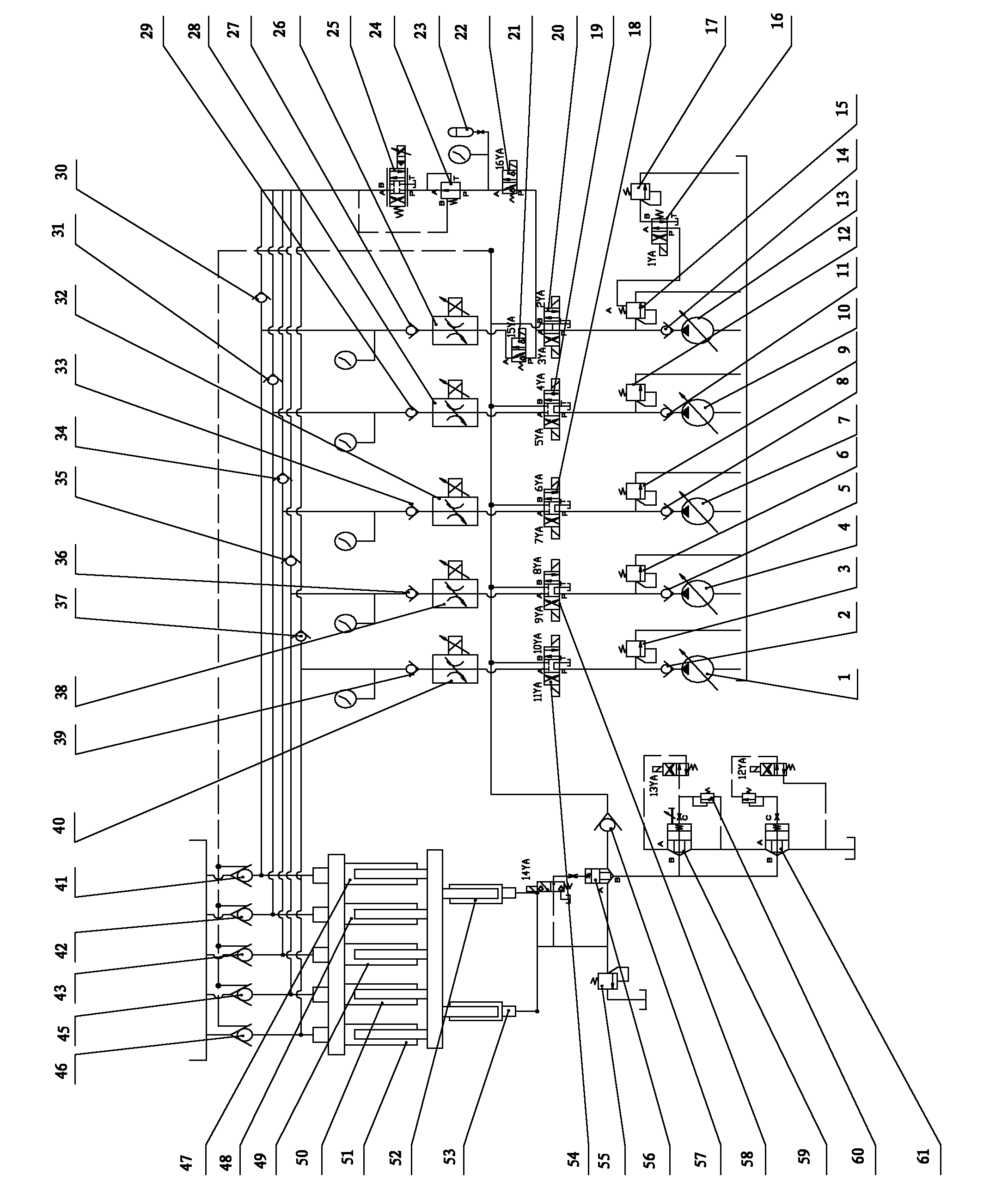

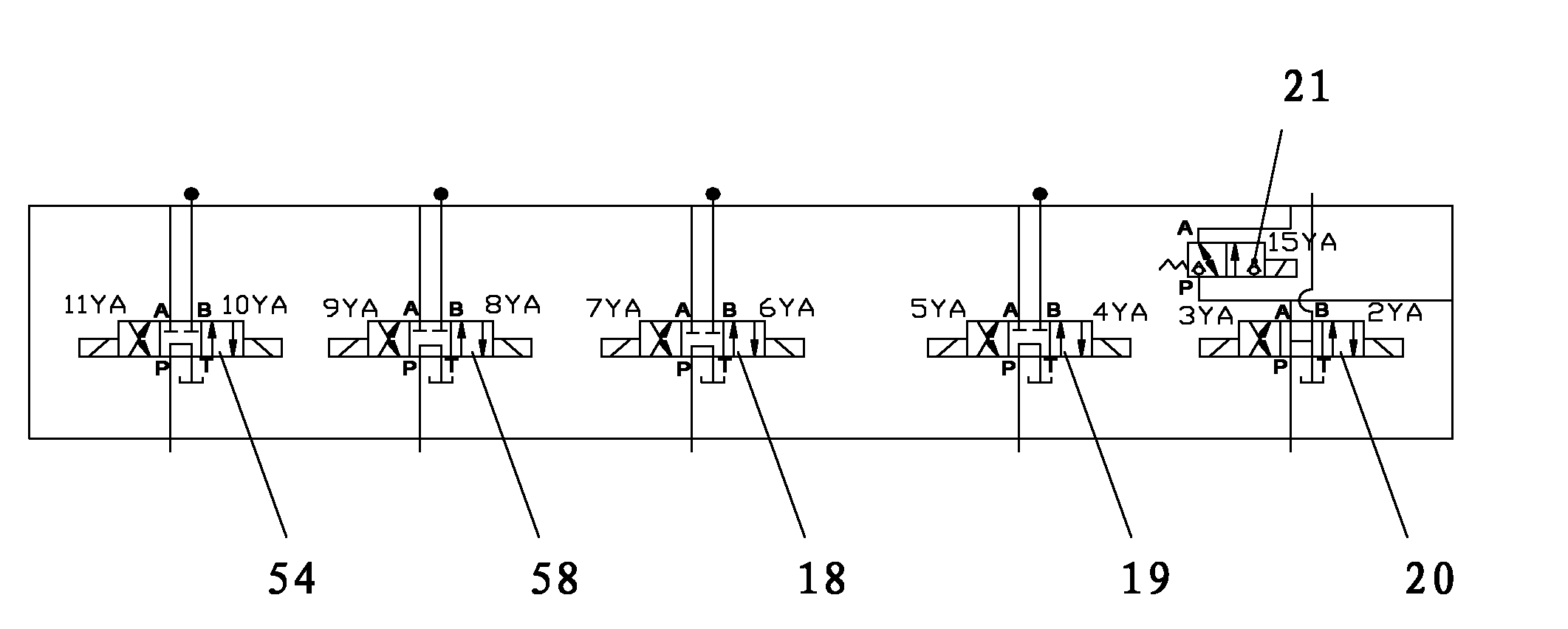

Super-slow hydraulic system for synchro-driven die-forging hydraulic press

ActiveCN102430680BRunning speed is stableSuppress pressure pulsationForging press drivesInlet channelSynchro

The invention discloses a super-slow hydraulic system for a synchro-driven die-forging hydraulic press, mainly consisting of five synchro-driven channels of a driving cylinder, a super-slow driving channel of the driving cylinder, a releasing channel of the driving cylinder, a liquid drainage channel of a return cylinder and a liquid inlet channel of the return cylinder. In the invention, an independent oil source is arranged for each driving channel of the driving cylinder to realize self-adaptive compensation of load pressure of the driving cylinder and flows of different channels are changed according to the openness of a proportional flow control valve for adjusting the position and signal of a plunger of the driving cylinder. The descending speed of a moveable beam is adjusted by controlling start and stop of a fast descending valve set and a slow t descending valve set to realize real time synchronous movement control of the driving cylinder. During super-low driving, the constant front and back pressure difference of a proportional flow valve is ensured by arranging a pressure maintaining valve to output stable flow under super-low working condition. Pressure impact of the oil source is eliminated by arranging an accumulator. The working position of a change valve is changed to realize rapid load removal for the driving cylinder and rapid return of the moving beam.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com