Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Strong cleaning function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intelligent glass wiping robot

InactiveCN105167704AEasy to cleanStrong cleaning functionWindow cleanersMagnetAutomotive engineering

The invention discloses an intelligent glass wiping robot which comprises a driving machine, a follower and a control device. The driving machine comprises a driving machine body, a driving traveling device and driving magnets, the driving traveling device and the driving magnets are located on the driving machine body, the driving magnets are connected with a lifting device and ascend and descend through the lifting device, and wiping elements are arranged below the driving machine body. The follower is driven by the driving machine to travel and comprises a follower body, a follower traveling device and follower magnets, the follower traveling device and the follower magnets are located in the follower body, the follower magnets and the driving magnets attract to each other, and wiping elements are arranged below the follower body. The control device is connected with the driving traveling device and controls traveling of the driving traveling device. The driving magnets and the follower magnets are arranged in the driving machine and in the follower, and the lifting device is arranged in the driving machine so that the robot can be suitable for being attached to glass with different thicknesses, the cleaning function is strong, the outer sides of windows exposed outsides for a long time can be well cleaned, and the problem that the inner sides of the windows are easy to wipe and the outer sides of the windows are difficult to wipe can be effectively solved.

Owner:HEBEI UNIV OF TECH +1

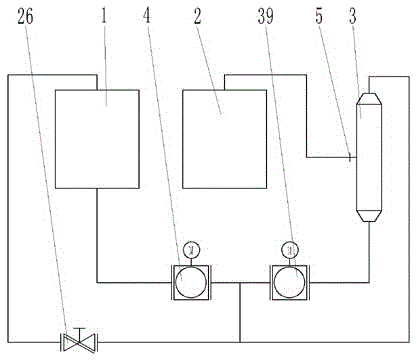

Washing and sweeping vehicle with double-circulation filter system

ActiveCN105464031AIncrease flow rateImprove filtration efficiencyWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentFilter systemWater resources

The invention discloses a washing and sweeping vehicle with a double-circulation filter system. The washing and sweeping vehicle comprises a vehicle chassis, a draught fan, a suction air duct, a suction pipe, a suction plate, a brush plate and a water spraying device. According to the double-circulation filter system, a sewage box is connected with a first-stage water pump through a pipeline, the first-stage water pump is connected with a second-stage water pump through a pipeline, the second-stage water pump is connected with one or more filters. The filter is connected with the sewage box through a pipeline. A pressure regulation valve is arranged on the connection pipeline between the filter and the sewage box. The connection pipeline between the first-stage water pump and the second-stage water pump is connected with the connection pipeline between the filter and the pressure regulation valve through a pipeline. The clear water outlet of the filter is connected with a clear water box through a pipeline. The filter is a ceramic membrane filter which comprises a ceramic membrane pipe arranged in a sealed shell. The two ends of the sealed shell are used as a sewage inlet and a sewage outlet respectively to be connected with pipelines. A clear water outlet is formed in the sealed shell. By means of the washing and sweeping vehicle, the effective working time of environmental sanitation devices can be greatly prolonged, the sewage discharge amount can be decreased, and the utilization rate of water resources is increased.

Owner:YANTAI HAIDE SPECIAL VEHICLE

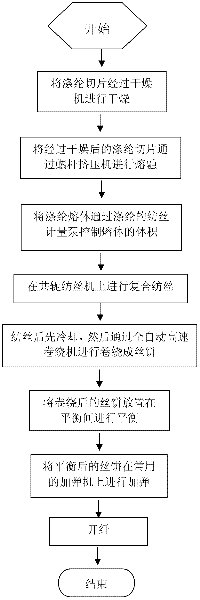

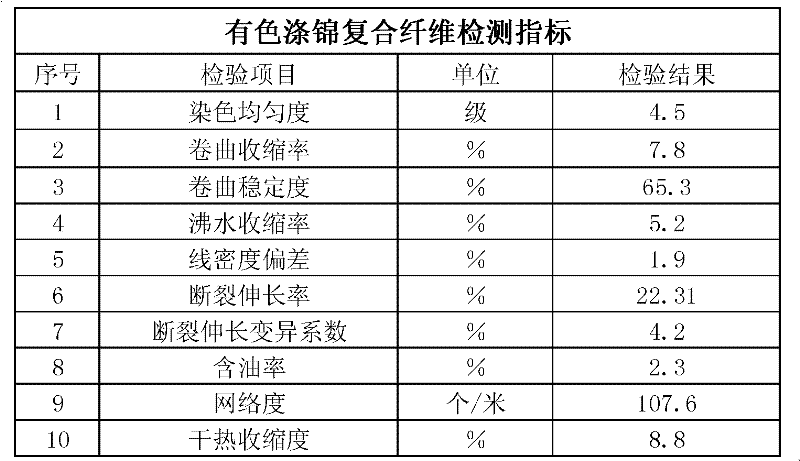

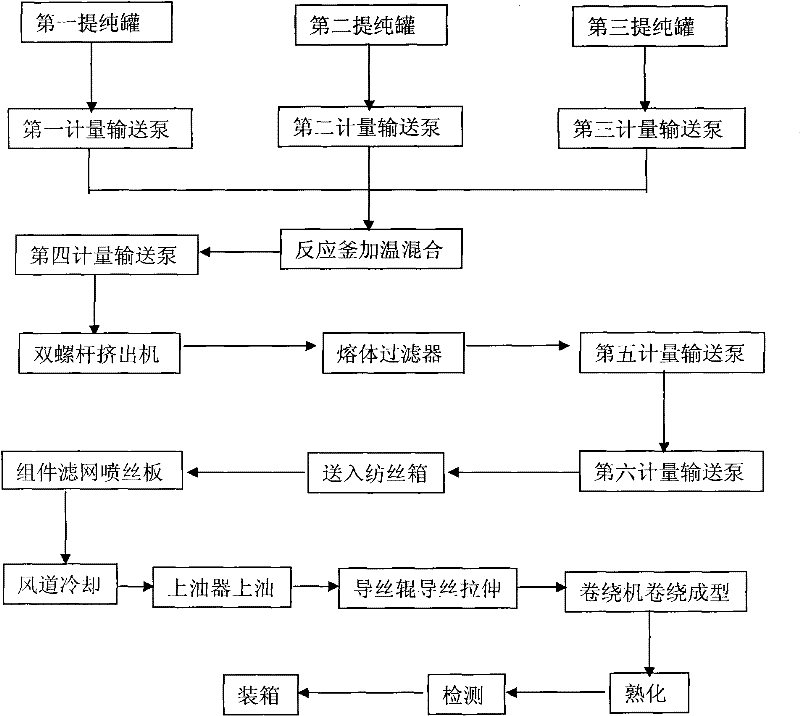

Method for manufacturing hollow micro-fine terylene denier fiber

ActiveCN102517719AHigh hollownessIncrease coverageHollow filament manufactureFilament/thread formingState of artFiber

The invention discloses a manufacturing process for a hollow micro-fine terylene denier fiber. The process is characterized by comprising the following steps of: a) preparing a raw material, i.e. sliced terylene; b) drying the sliced terylene through a cystallization dryer; c) injecting the dried sliced terylene into a screw extruder to be fused; d) controlling the volume of a melt through a spinning oil metering pump and a spinning metering pump; e) spinning on a spinning machine, and after spinning, coiling the silk into silk cakes through a fully-automatic high-speed coiler; f) balancing the silk cakes in a balance room to be balanced; and g) elasticizing the silk cakes on an elasticizer. Compared with the prior art, the process realizes the fiber of which the denier per filament is less than 0.5dpf.

Owner:NINGBO SANBANG MICROFIBER

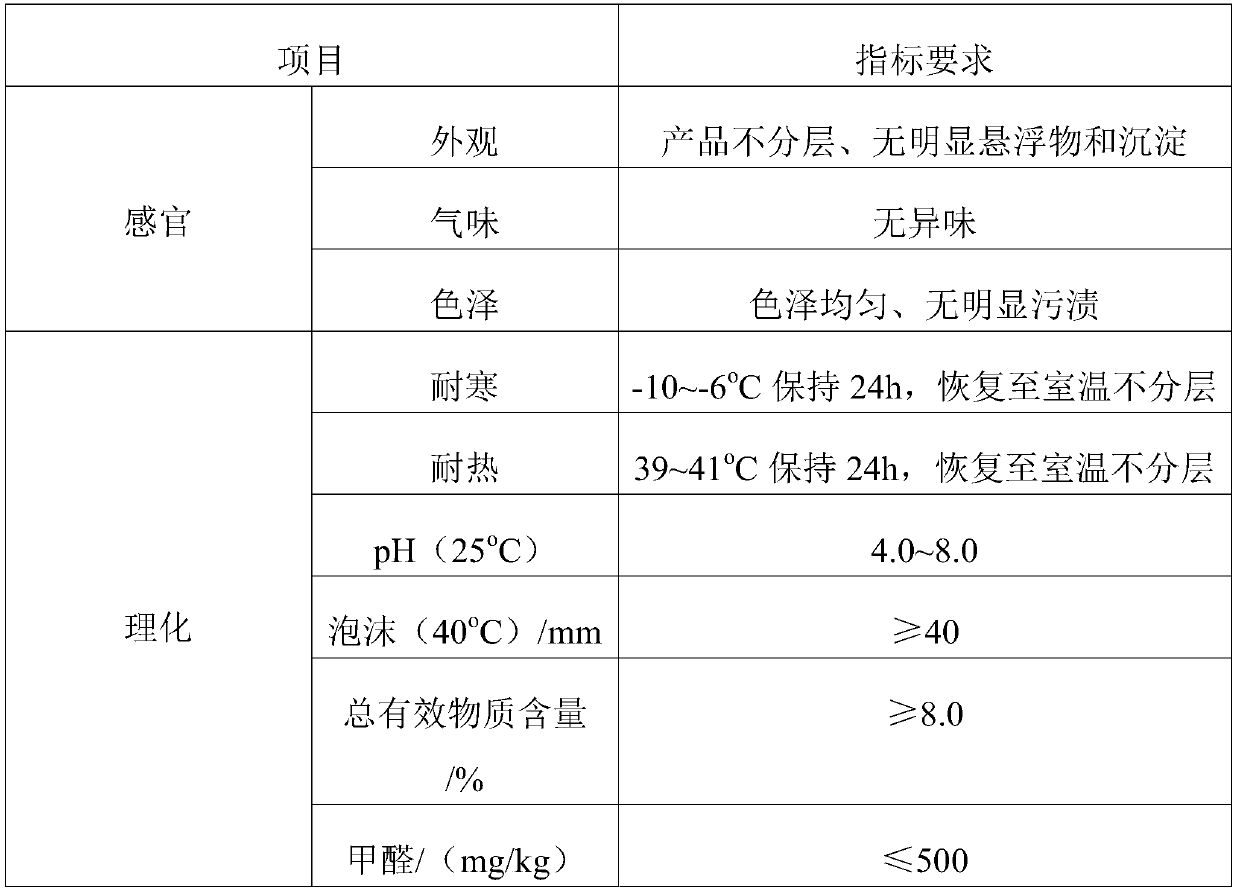

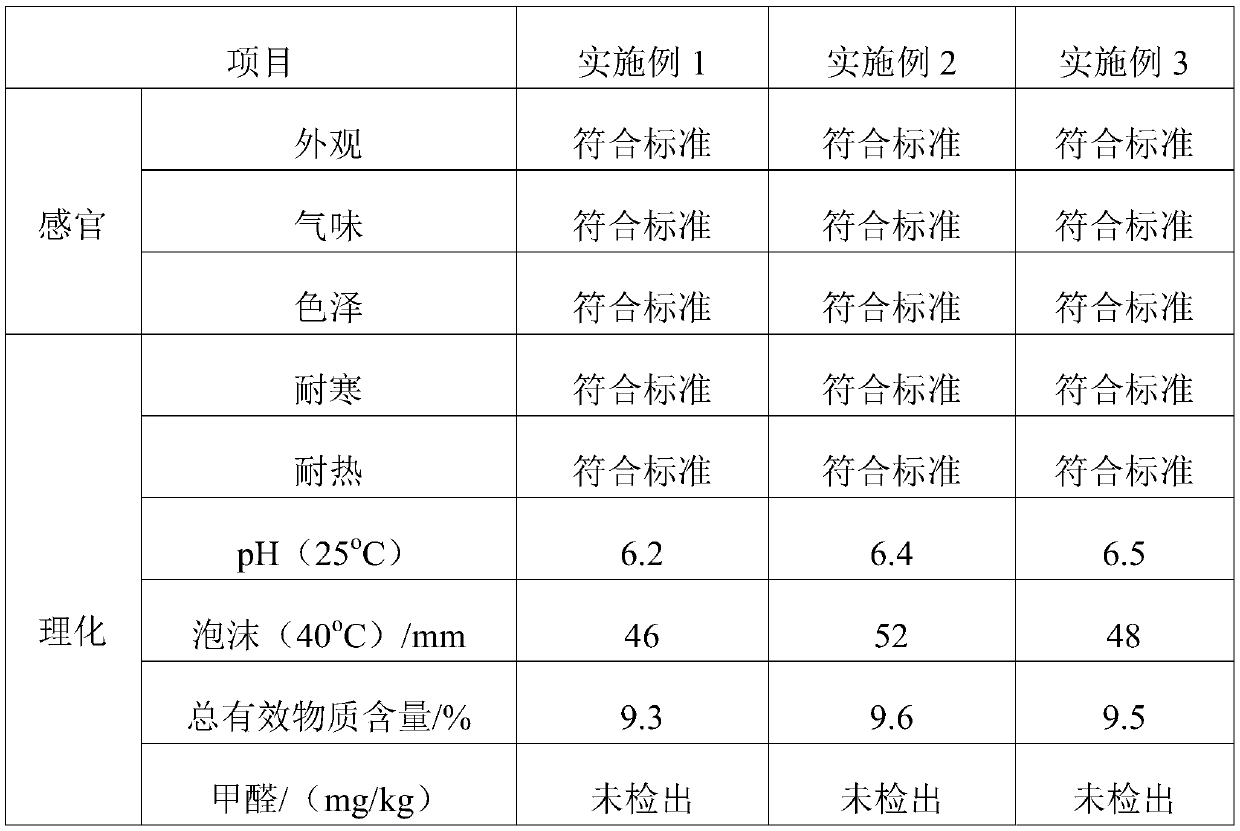

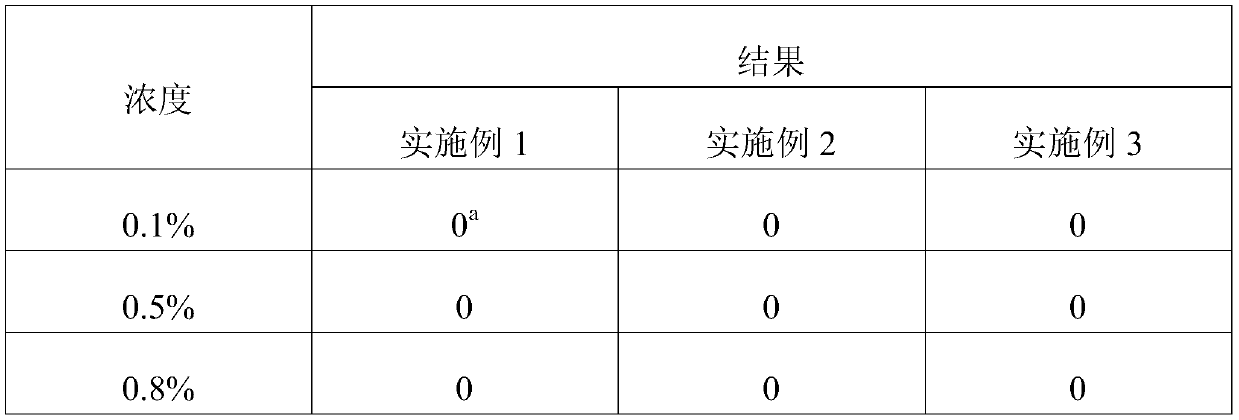

Preparation method of environment-friendly printing ink cleaner

InactiveCN106479258ALow organic solvent contentEasy to cleanChemical paints/ink removersEnvironmental resistanceSide effect

The invention discloses a preparation method of an environment-friendly printing ink cleaner and belongs to the technical field of printing ink cleaners. Potato starch, ethylene glycol, n-dodecanol and the like are used as raw materials and subjected to a heating reaction, then the pH of a mixed solution is adjusted, reduced pressure distillation is performed, starch-based dodecyl glycoside is prepared, a mixed microemulsion is prepared from starch-based dodecyl glycoside, sodium dodecyl sulfate, n-butyl alcohol, deionized water and the like, D-limonene, ethanolamine, the mixed microemulsion and the like are placed in a high-shear dispersion emulsifying machine for stirring emulsification, the mixture is left to stand and cooled, and the environment-friendly printing ink cleaner is prepared. The raw materials of the printing ink detergent are environment-friendly, the toxic and side effects of the detergent are effectively reduced, damage to human health and the environment is avoided, and the printing ink detergent is high in deterging speed, high in detergency efficiency and better in stability, can effectively protect base materials and prolong the service life of equipment and has broad application prospect.

Owner:TRUSYN CHEM TECH

Blended fuel oil capable of substituting petrochemical diesel and preparation method thereof

ActiveCN102093917AImprove stabilityQuality improvementLiquid carbonaceous fuelsFuel additivesFuel oilPower equipment

The invention discloses a blended fuel oil capable of substituting petrochemical diesel and a preparation method thereof. The blended fuel oil comprises standard diesel, an alcoholic solvent, C9 fraction, heavy benzol, a surface active agent, a detergent dispersant and a cetane number improver. The blended fuel oil can be used for power equipment, i.e. diesel vehicles, boilers, equipment for ships, equipment for power plants, air conditioner, power generators, and the like, has the advantages of energy saving , environmental protection, extensive raw material source, simple configuration and low cost, can also effectively prevent a fuel spray nozzle of a direct injection compression ignition engine from coking, achieves the fuel ratio saved by 5-25 percent and is a superior-quality substitute of the petrochemical diesel.

Owner:SHANDONG TAIDE NEW ENERGY

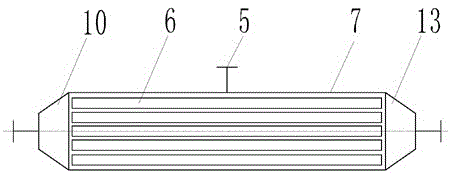

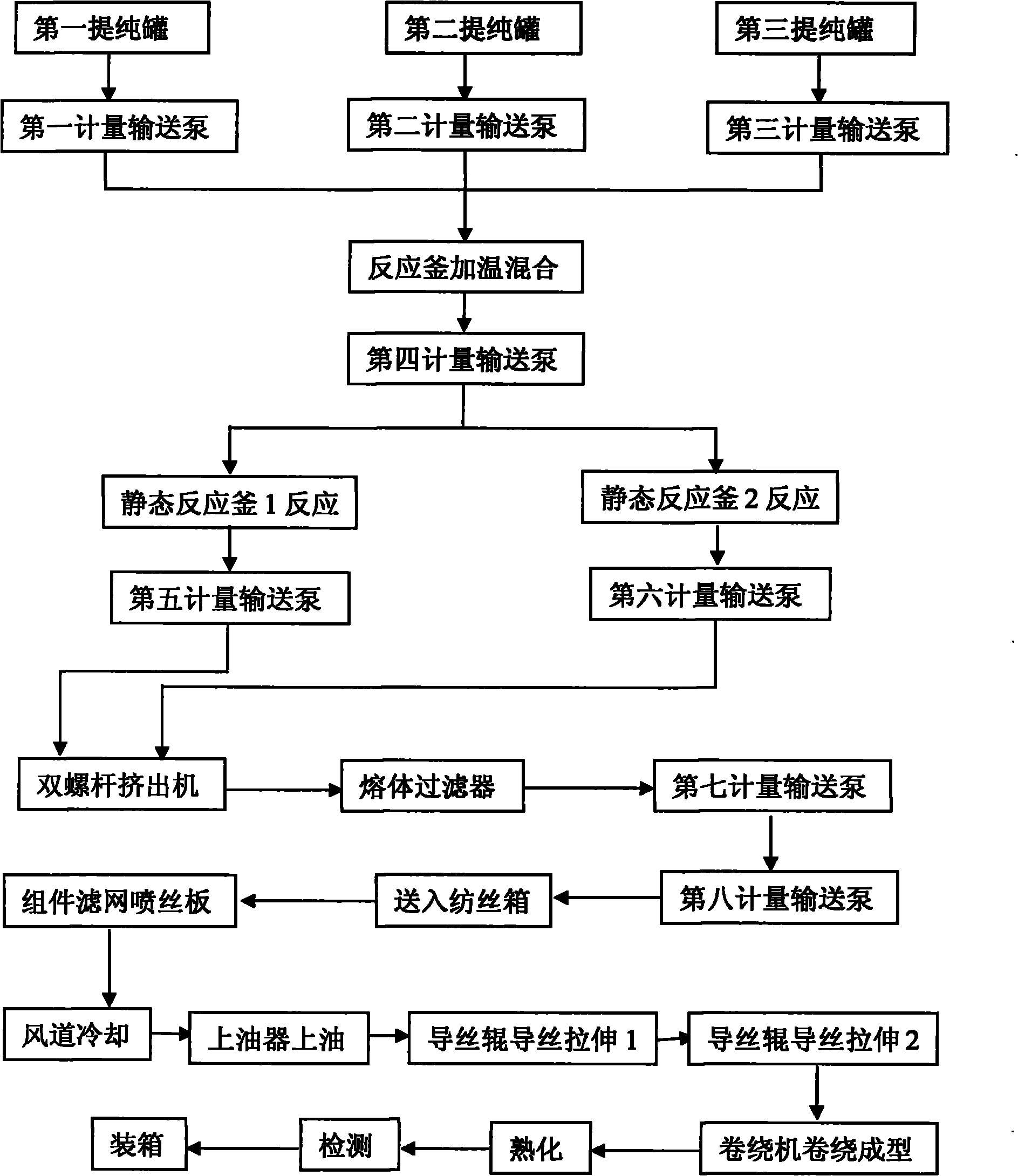

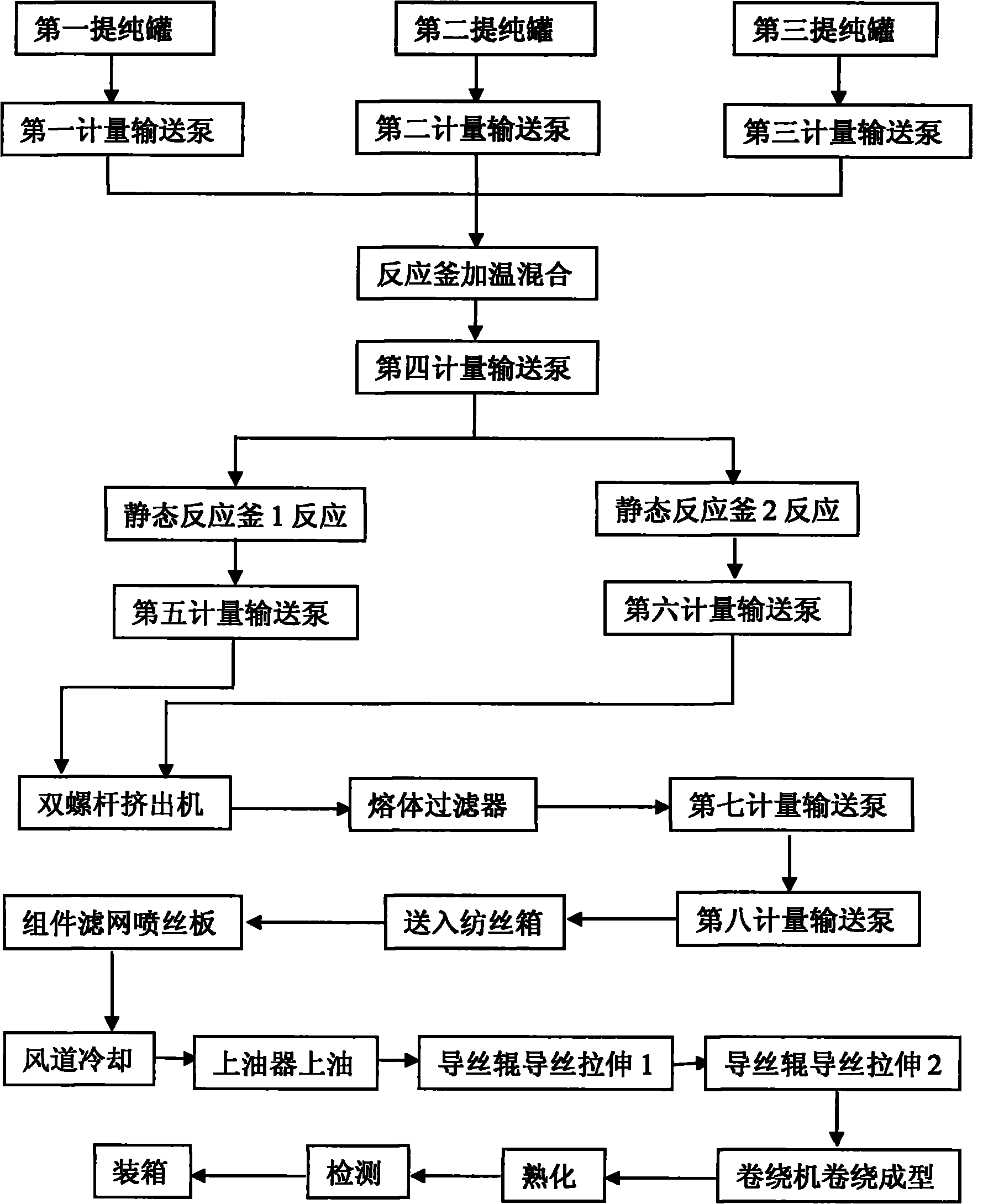

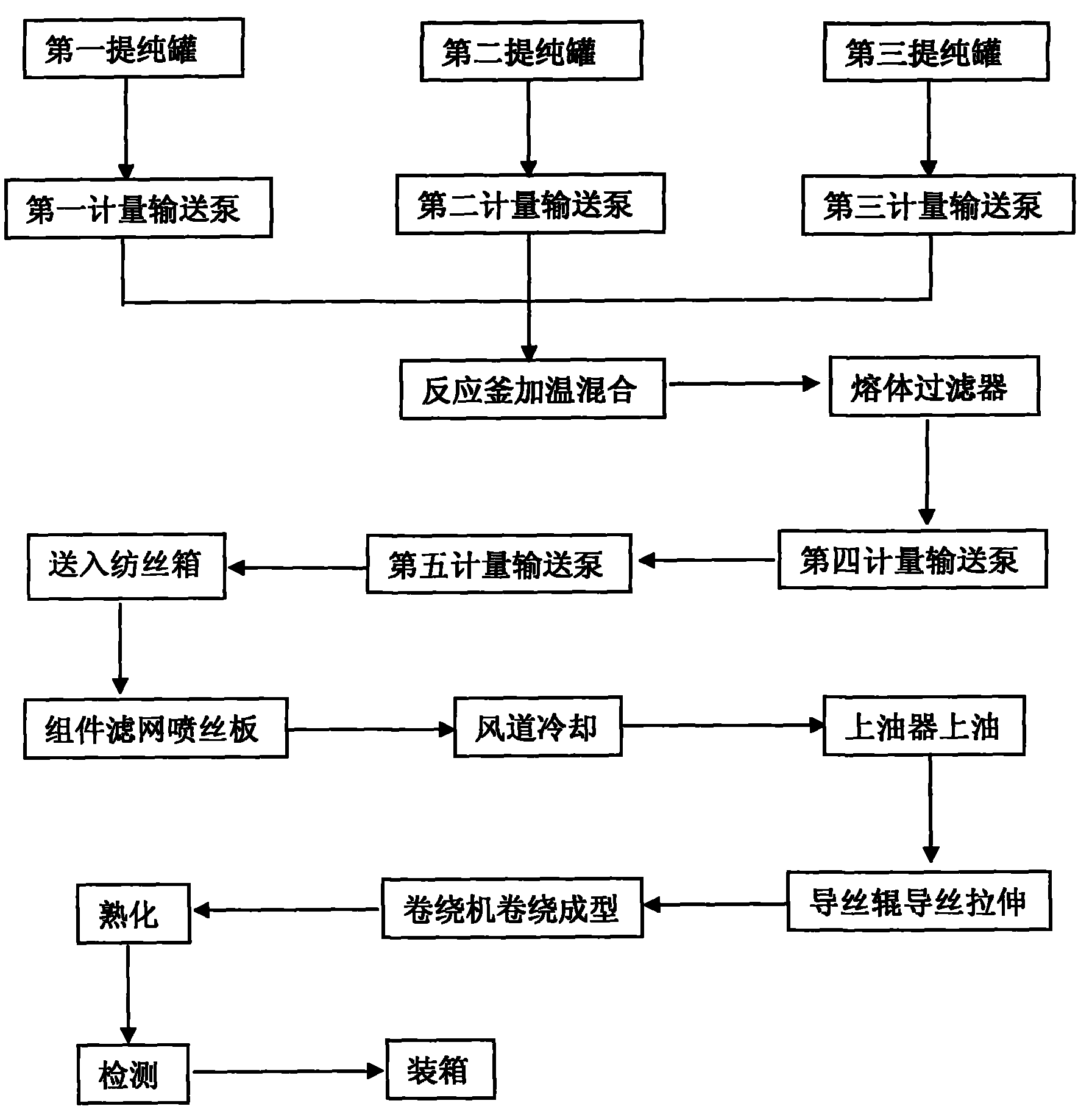

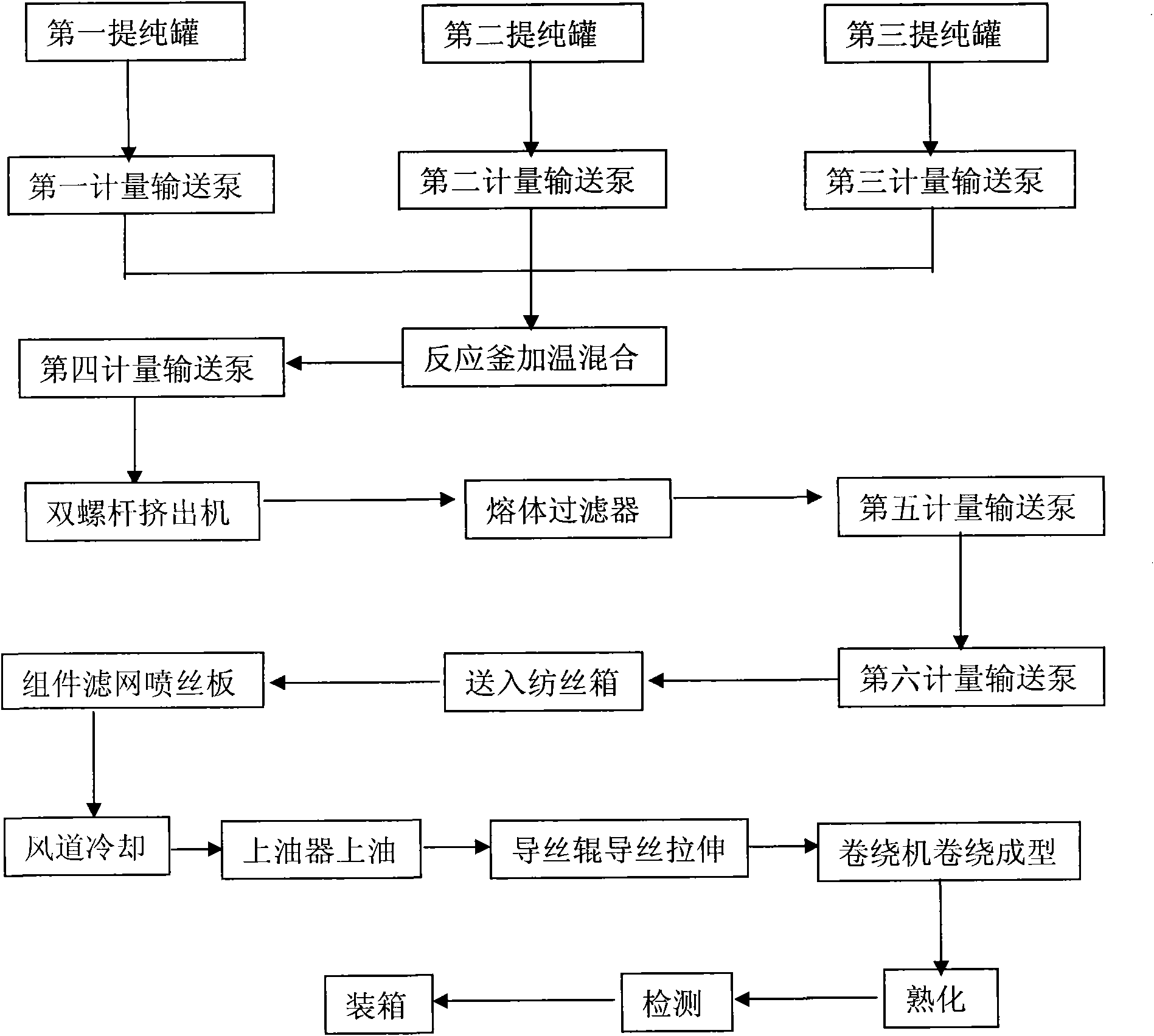

Melting and direct-spinning superfine denier (4.6-5.5 denier) high-elastic modulus polyurethane fiber equipment

InactiveCN102115919AImprove water absorptionIncrease fiber surface areaMonocomponent polyurethanes artificial filamentArtificial thread manufacturing machinesFiberHigh density

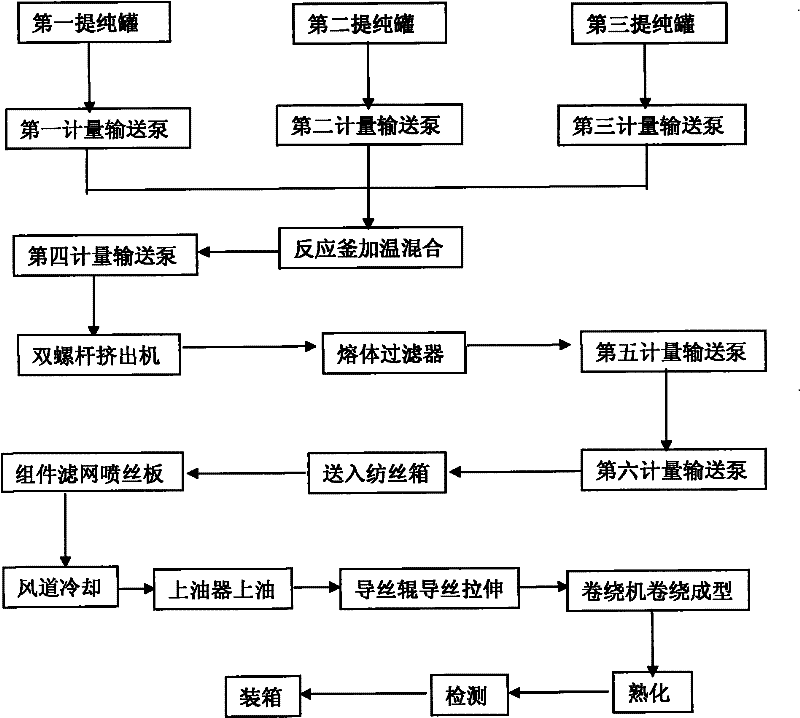

The invention discloses melting and direct-spinning superfine denier (4.6-5.5 denier) high-elastic modulus polyurethane fiber equipment. The equipment is characterized in that the equipment comprises a purification tank, a reaction tank, a metering and conveying pump, a reaction kettle warming mixer, a static reaction kettle, a double-screw extruder, a melt filter, a thread spinning box, a component filter screen spinneret plate, an air duct cooling system, an oiling device, a godet guide thread stretching device, and a winder winding and forming device. The equipment has the advantages that the produced superfine denier polyurethane fibers have very small bending rigidity and very soft hand feel; the surface areas of the fibers are very large, so that the spreadability, the bulkiness andthe heat retention property of fabrics are obviously improved, and the fabrics achieve a powerful cleaning function; when the superfine fibers are manufactured into super-high density fabrics, the size of gaps among the fibers is between the diameter of a water drop and the diameter of a water vapor droplet, so that the superfine fabrics have the waterproof and vapor-permeable effects; and when the superfine fibers are processed into fabrics like towels which can be wetted by water, the fabrics have high water absorbability, so that moisture of washed hair can be quickly absorbed by the towels, and the hair can be quickly dried. The equipment can be applied to various fields.

Owner:TAICANG JINXIANG SPANDEX FIBER

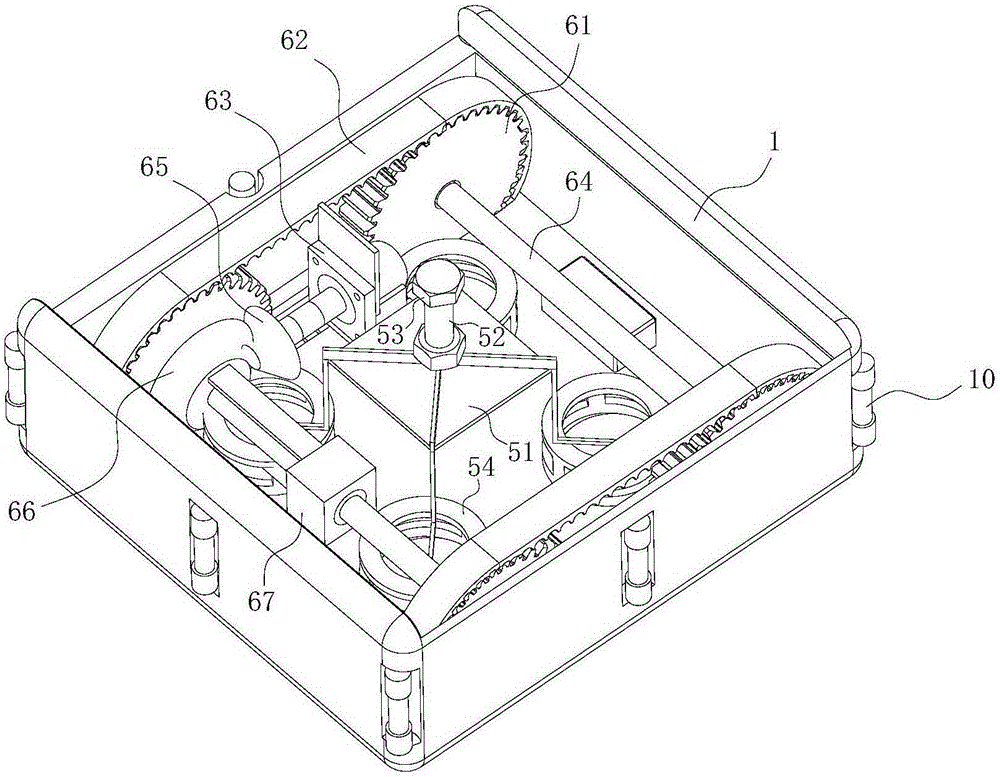

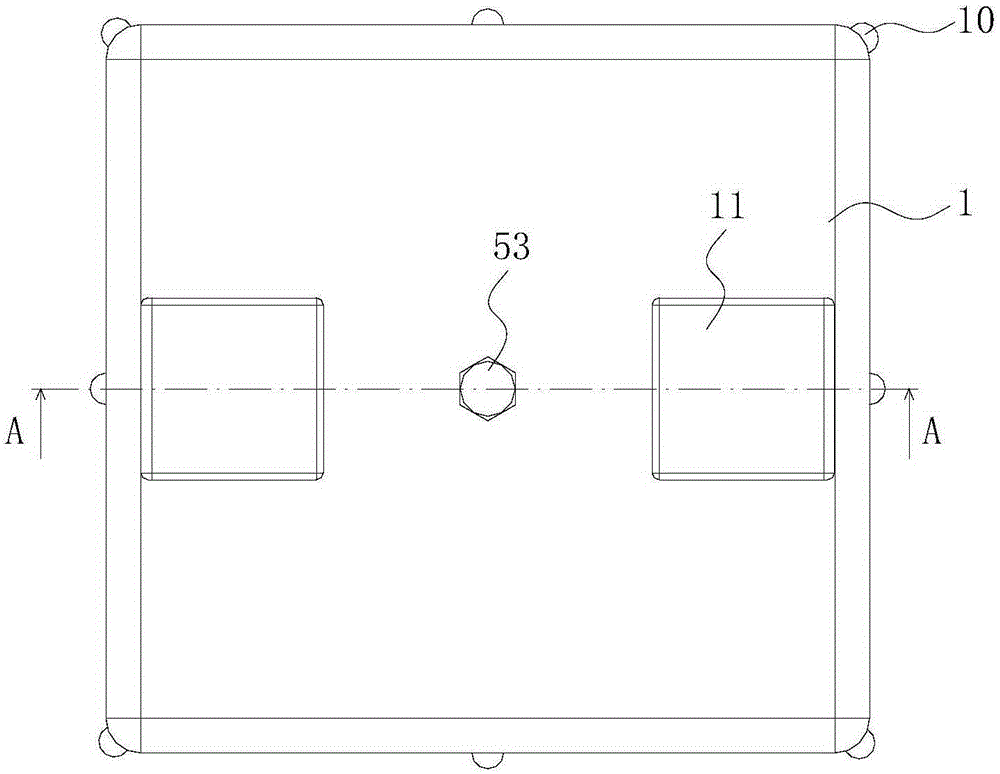

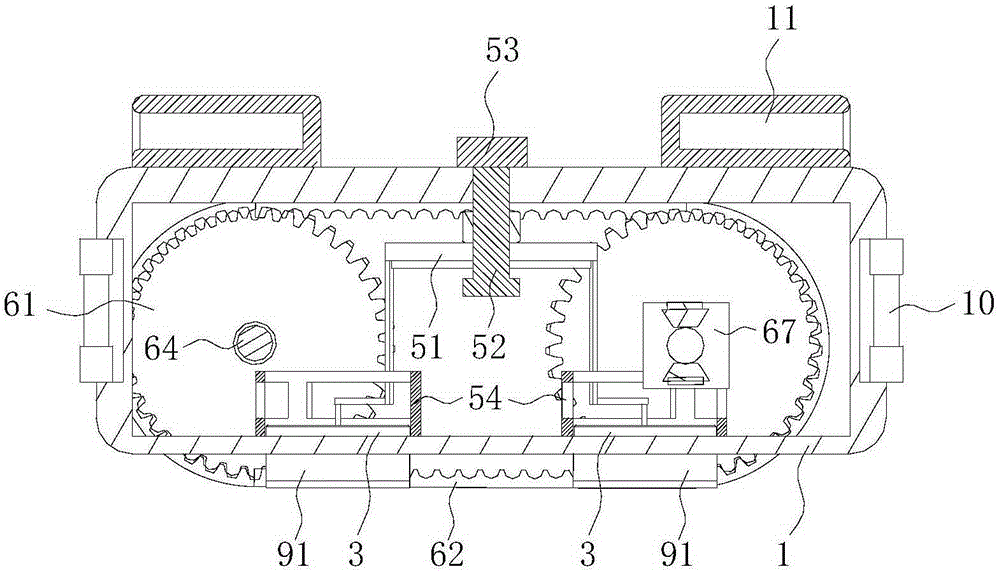

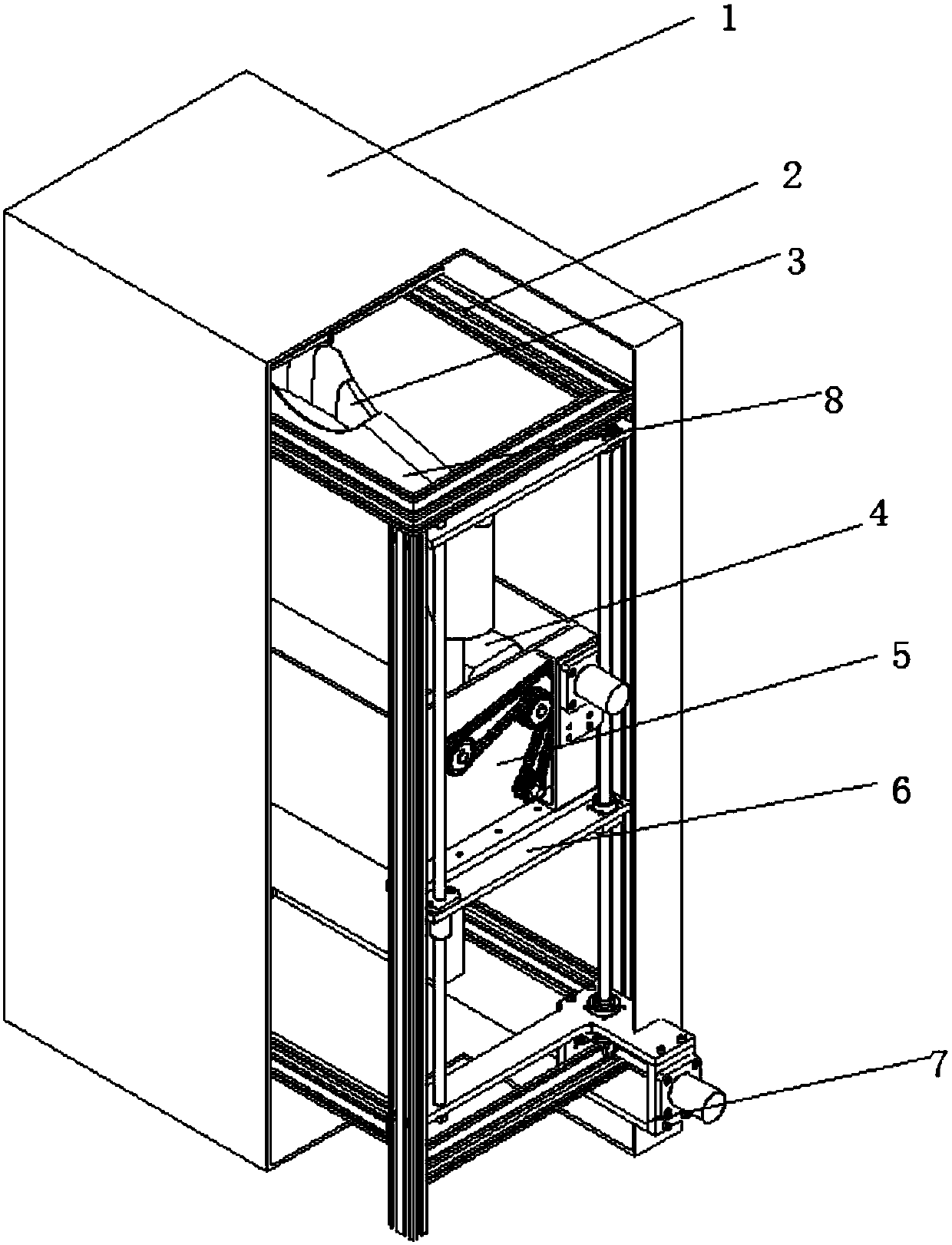

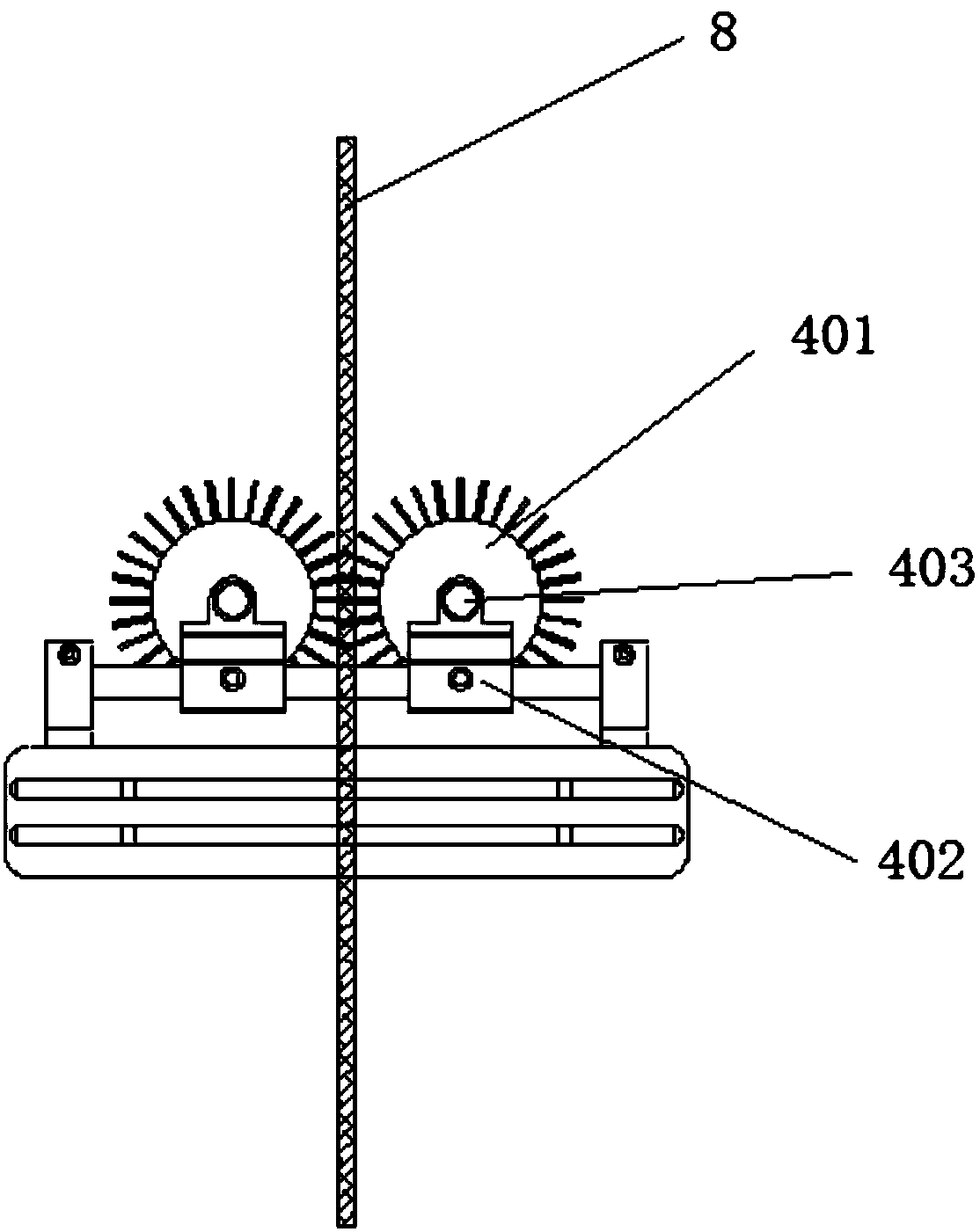

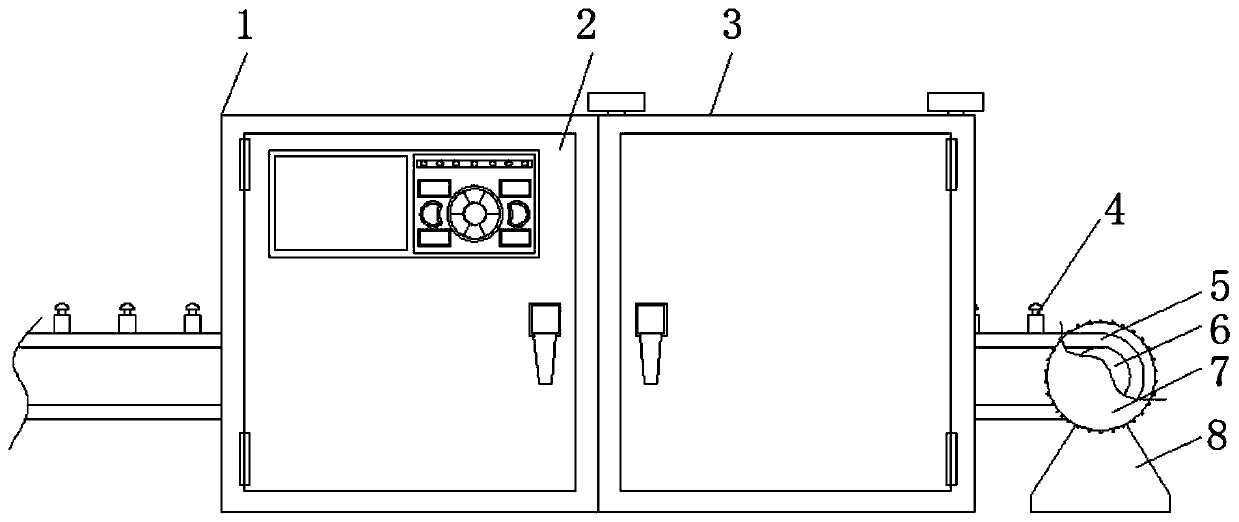

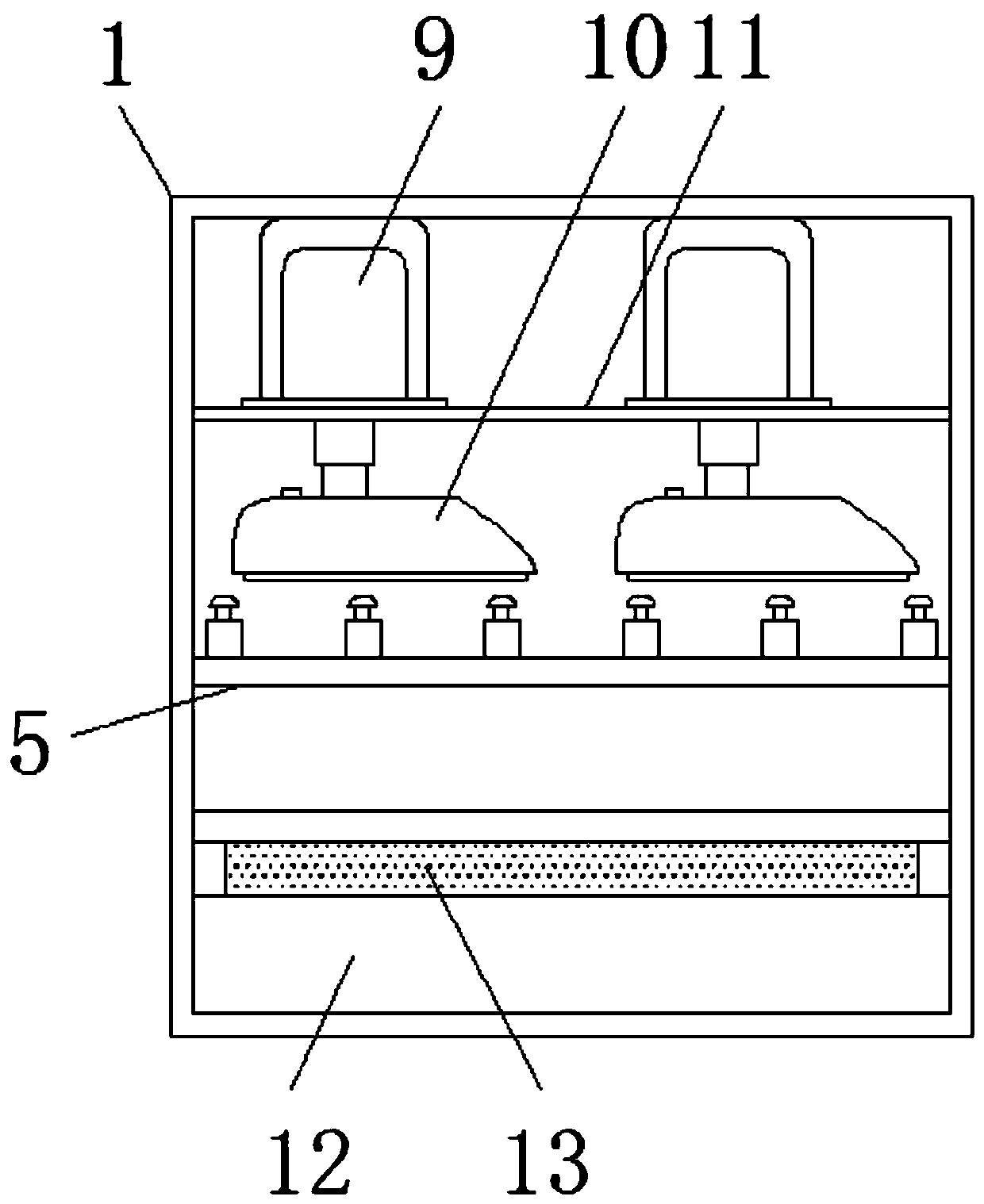

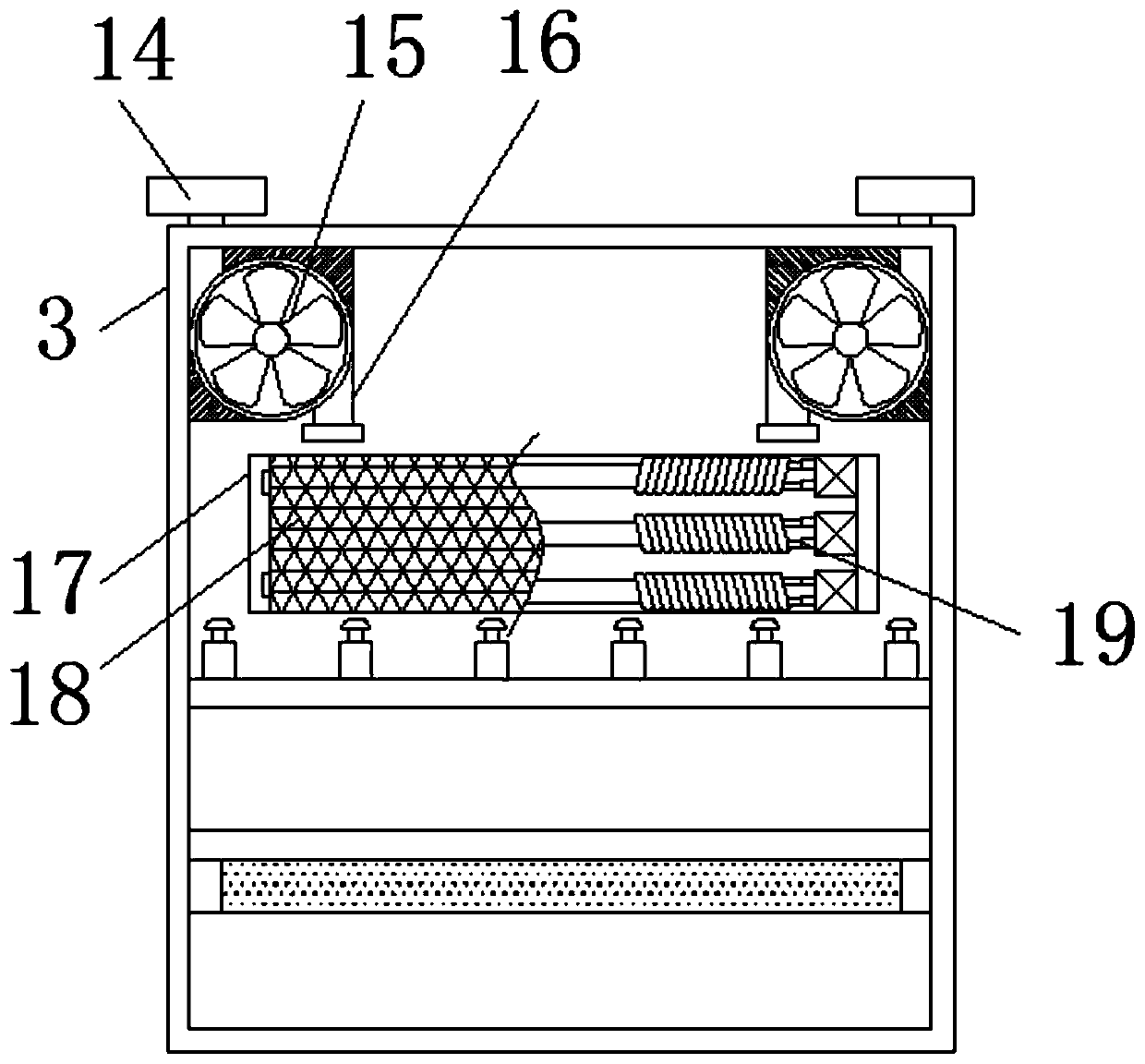

Hand washing type simulation type washing machine device

PendingCN108049099ANo damageAvoid stainsBrushing washing machinesTextiles and paperEngineeringCross infection

The invention discloses a hand washing type simulation type washing machine device. The device comprises a shell, a rack, a clothes brushing mechanism, a rotational mechanism, a lifting mechanism anda power transmission mechanism, wherein the rack is arranged inside the shell, the clothes brushing mechanism is actively and connectively arranged on the rack, the rotational mechanism and the lifting mechanism are both arranged on the rack, and the power transmission mechanism is arranged at the bottom end of the rack. The rack provided by the invention can automatically lift up and down and isprovided with brush rollers, clothes is in the middle of two brush rollers, the clothes is rubbed through relative rotation of the two brush rollers so as to achieve the effect of simulating hand washing of clothes. A clothes hanging mechanism hanger is adopted to hang and wash the clothes, the washing efficiency is high, and the washing machine device is suitable for washing in batches; no damageis caused to the clothes either; the whole rack can move up and down at a certain speed through lead screw transmission, so that the purpose of washing the whole surface of the clothes is achieved; the washing machine device has a very strong cleaning function specific to the whole position of the clothes, and meanwhile, dyeing or cross infection between the clothes can be avoided.

Owner:SHANGHAI OZNER COMFORT ENVIRONMENT & SERVICE

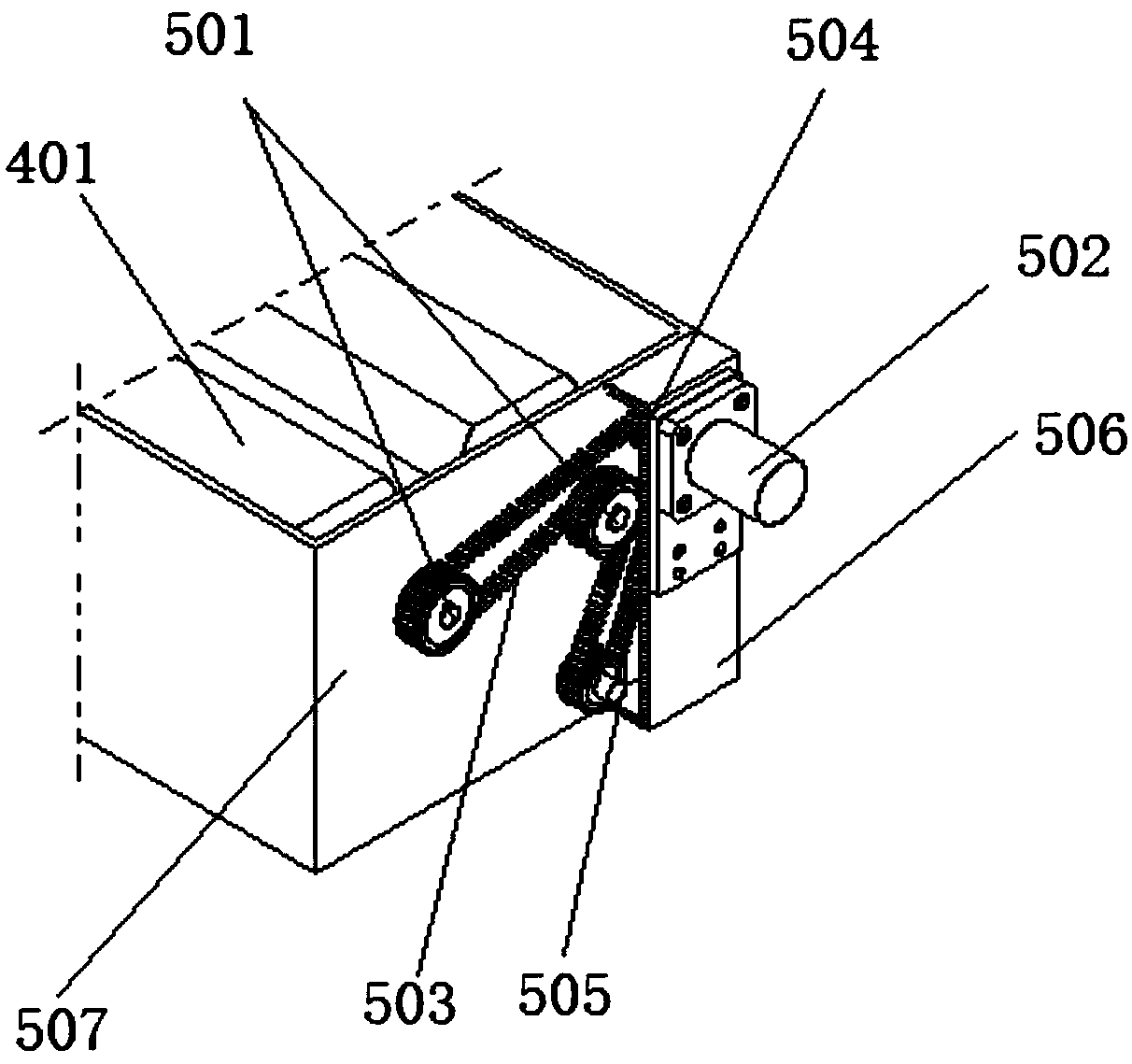

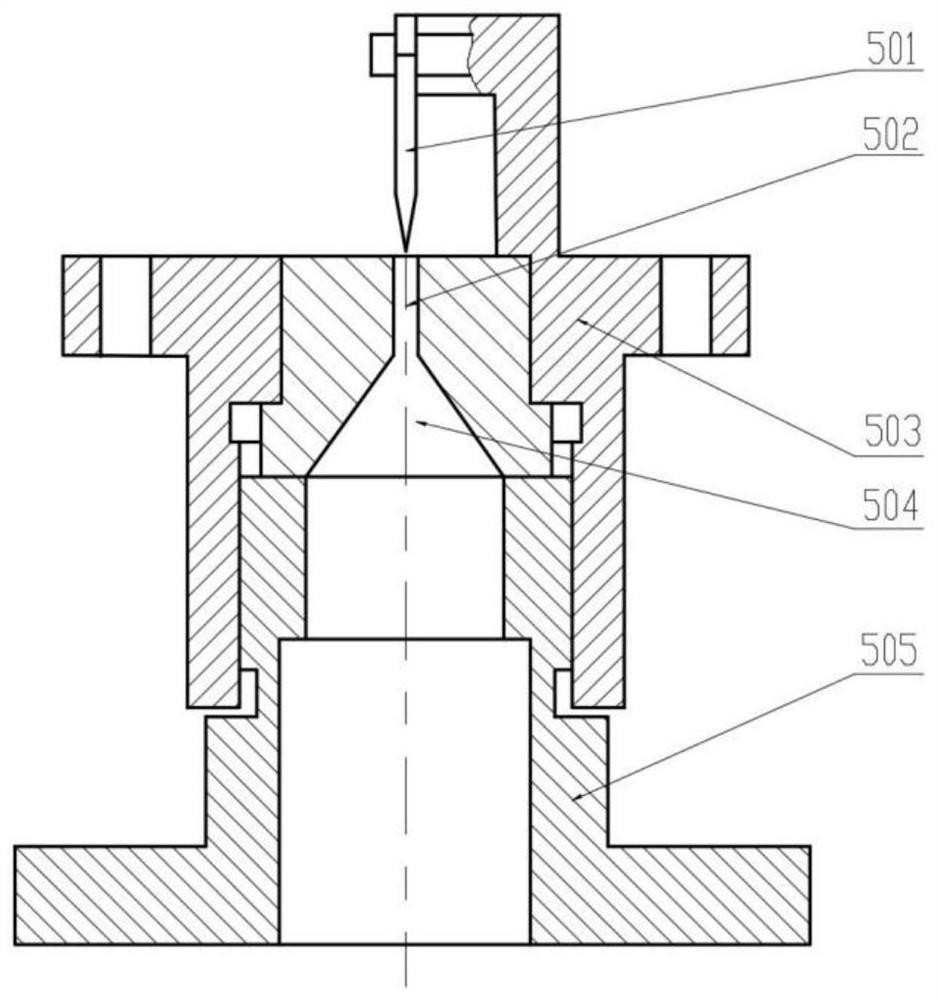

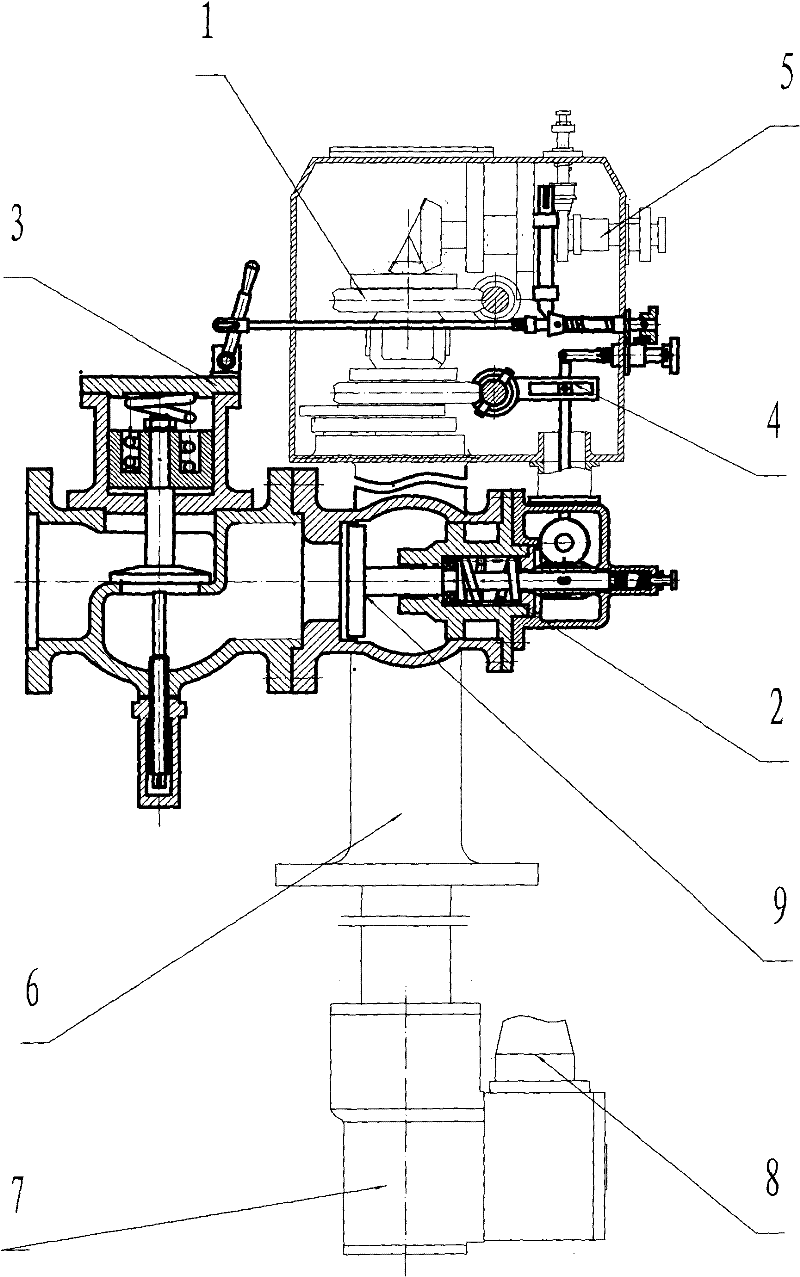

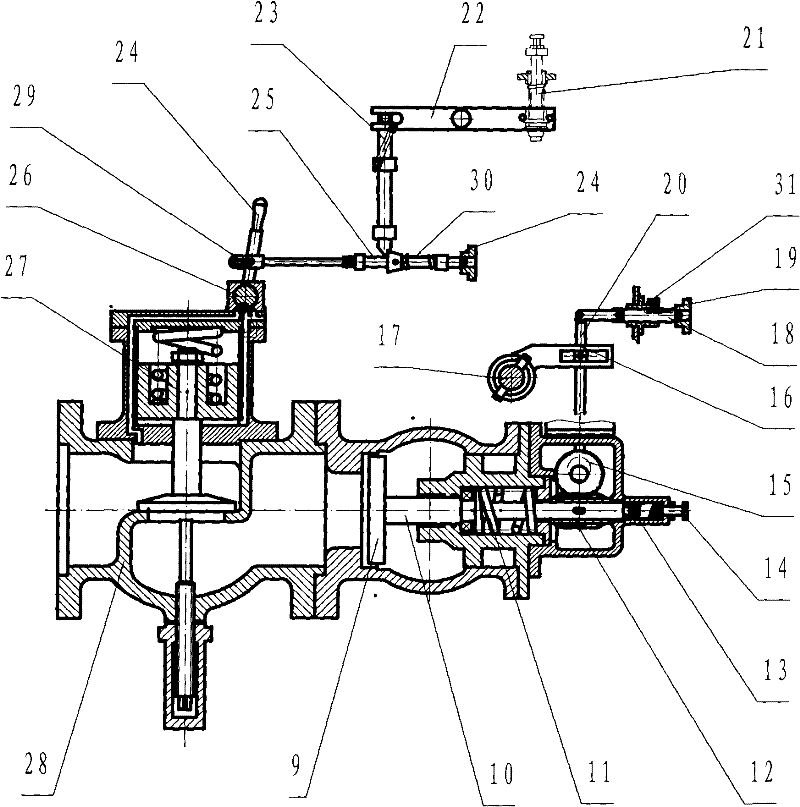

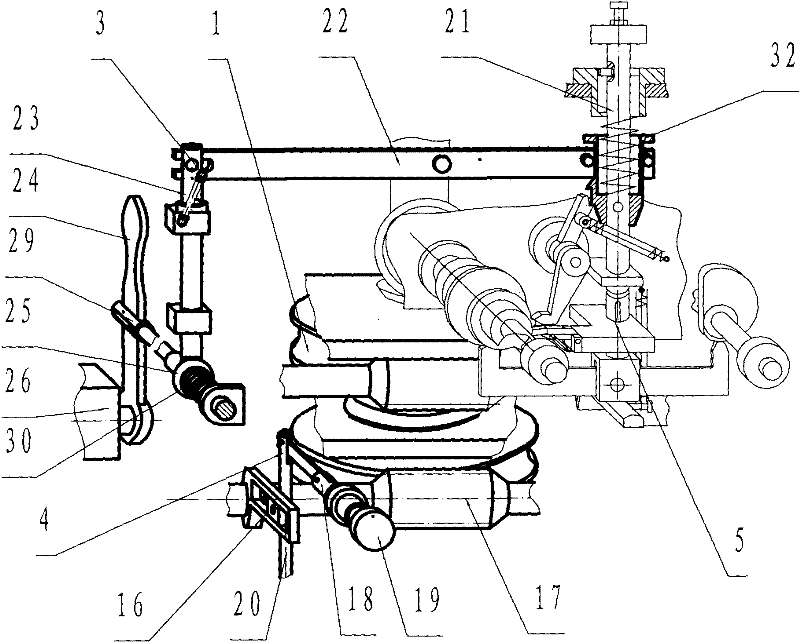

Impeller drive control mechanism of stationary crude oil tank washing machine

The invention discloses an impeller drive control mechanism of a stationary crude oil tank washing machine, comprising a main transmission part arranged in the main body, an impeller drive part, an impeller drive start-stop control part and a nozzle horizontal rotation speed adjustment mechanism connected with the impeller drive part. The impeller drive part comprises an impeller, a hydraulic control stop valve at the front end of the impeller, a transmission shaft connected at the rear end of the impeller, a main spring sleeved on the transmission shaft, an auxiliary spring and a worm. The warm is connected with the nozzle horizontal rotation speed adjustment mechanism via a worm gear engaged with the worm. The nozzle horizontal rotation speed adjustment mechanism comprises an eccentric gear and a transmission rod arranged on the worm gear. The lower end of the transmission rod is connected with the eccentric gear on the worm gear. A speed adjustment rod and a speed adjustment swing rod are connected at the top of the transmission rod. A slide block is arranged on the transmission rod. The slide block is connected with the sliding way of the speed adjustment swing rod. The speed adjustment swing rod is connected with the main transmission worm rod. The impeller drive start-stop control part comprises a control valve connected with the hydraulic control stop valve, a handle connected with the control valve, a manual control rod connected with the handle via a connection rod as well as an upright rod, a lever, a vertical control pull rod and a stop block on the vertical control pull rod which are connected with each other. The mechanism can automatically adjust the axial position of the impeller, and the nozzle horizontal rotation speed is adjustable. The mechanism can realize the single machine automatic shutdown by means of the mechanism.

Owner:HAIYING ENTERPRISE GROUP

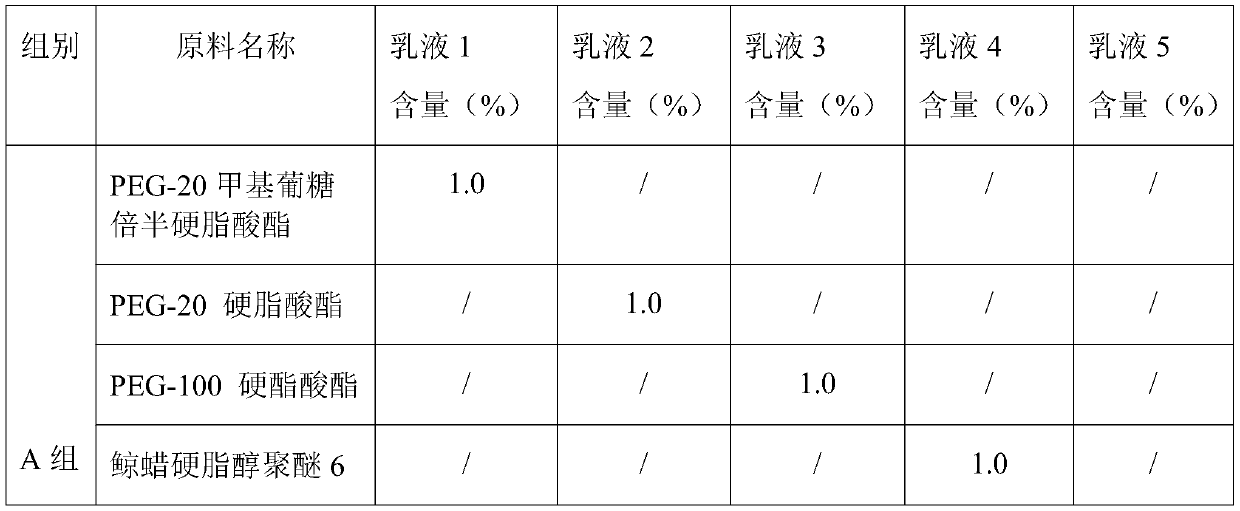

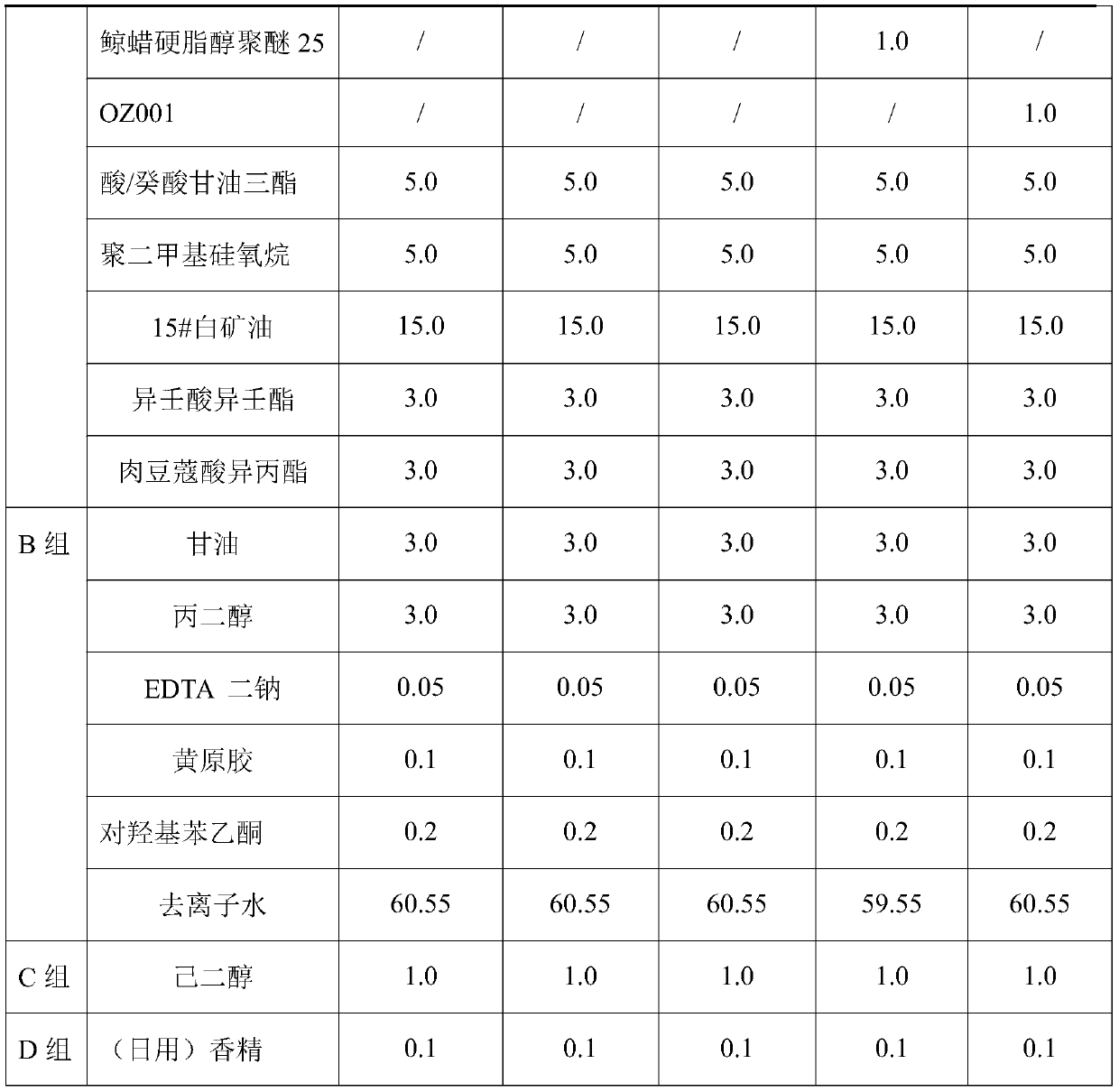

Polyglycerol compound emulsifier and preparation method thereof

PendingCN110897918AWon't clogGood moisturizing effectCosmetic preparationsToilet preparationsActive agentGlycerol

The invention discloses a polyglycerol compound emulsifier and a preparation method thereof, and aims to provide a compound emulsifier that does not contain PEG and EO surfactants, does not cause skindamage when applied to a product, and has mild, cleaning, moisturizing, breathable and oil-water general effects and the like, and comprises the following components (by weight): 18.0-22.0% of polyglycerol-10-stearate, 10.0-18.0% of cetanol, 45.0-55.0% of polyglycerol-10 laurate and 10.0-20.0% of glyceryl stearate. The HLB value of the emulsifier is 9-13. The invention belongs to the technical field of cosmetics.

Owner:广州欧正化妆品技术研究院有限公司

Shampoo having effects of removing dandruffs and caring hair and preparation method thereof

InactiveCN107049872AReasonable formulaLess irritatingCosmetic preparationsHair cosmeticsSesamumIrritation

The invention discloses a shampoo having effects of removing dandruffs and caring hair. The shampoo comprises and is prepared from the following raw materials by weight: 100 parts of saponin, 20-30 parts of polygonum multiflorum, 5-8 parts of tribute chrysanthemum, 10-15 parts of mint, 15-20 parts of gypsum, 15-20 parts of rice, 4-6 parts of radix sophorae flavescentis, and 10-15 parts of black seasame. The invention further provides a preparation method of the shampoo. The shampoo is mainly prepared by extracting from plants, is reasonable in formula, is low in irritation on the scalp, does not damage the hair, and prevents the dandruffs; the shampoo has a quite strong cleaning function and eliminates the dirt on scalp pores and hairs, the scalp and the hair are fresh and cool after using the shampoo to clean the hair, the shampoo has the effects of nourishing and protecting hair due to the ingredients of polygonum multiflorum, rice and black rice; the shampoo has the effects of killing bacteria and parasites.

Owner:方耀

Ceramic membrane sewage filter system with automatically-vibrating filter screens

InactiveCN105417764AImprove single cleaning operation timeLower acquisition costsTreatment involving filtrationReverse osmosisWater resourcesFilter system

The invention discloses a ceramic membrane sewage filter system with automatically-vibrating filter screens. The ceramic membrane sewage filter system comprises a sewage tank, a clean water tank, a water pump and connecting pipelines. The sewage tank is connected with the water pump through the corresponding pipeline, the water pump is connected with one or more ceramic membrane filters through the corresponding pipelines, the ceramic membrane filters are connected with the sewage tank through the corresponding pipelines, and clean water outlets of the ceramic membrane filters are connected with the clean water tank through the corresponding pipelines. The ceramic membrane filters are formed by arranging ceramic membrane pipes in sealed shells, the sealed shells are provided with clean water outlets, and the two ends of each sealed shell serve as a sewage inlet and a sewage outlet respectively and are connected with the corresponding pipelines. The automatically-vibrating filter screens are installed in the sewage tank, and vibrating pumps are installed on the automatically-vibrating filter screens. A pressure gage and a pressure switch are installed on the pipeline through which the sewage tank and the water pump are connected. The ceramic membrane sewage filter system can be widely applied to sewage treatment under harsh road conditions, and the sewage circulating filter system can be effectively prevented from being blocked. A cleaning and sweeping vehicle with the ceramic membrane sewage filter system can greatly prolong effective operating time, reduce vehicle purchase and use cost per unit operating area, reduce the emission of sewage and increase the utilization rate of water resources.

Owner:YANTAI HAIDE SPECIAL VEHICLE

Method for window cleaning by remote control window-cleaning robot

InactiveCN106725066AFix security issuesStrong cleaning functionWindow cleanersPosition/course control in two dimensionsRemote controlTeleoperated robot

The invention discloses a method for window cleaning by a remote control window-cleaning robot. The working process of the robot is as follows: an industrial control device of the robot is controlled through a remote controller to send a command, and the robot starts to work; main power for remote control over the window-cleaning robot comes from an energy accumulator; through continuous power supply by the energy accumulator, a pressure sucker is adsorbed to a wall through negative pressure the pressure sucker generates, so the whole remote control window-cleaning robot can run on the vertical wall, and the positioning of the robot on the remote controller is implemented through an axial top positioning instrument, so the robot can run normally. When the remote controller remotely controls the robot to enter a designated operation area, the remote control window-cleaning robot can implement an established window cleaning function through a function key of the remote controller; and after cleaning, the remote control window-cleaning robot enters a next target area to perform operation.

Owner:HECHI UNIV

Weakly acidic hair-washing and hair-care active lotion

PendingCN112294708ALess irritatingImprove growth performanceCosmetic preparationsHair cosmeticsFormularyAcer mandshuricum

The invention discloses a weakly acidic hair-washing and hair-care active lotion. The lotion comprises the following components in parts by weight of 20-30 parts of radix polygoni multiflori, 20-30 parts of herba artemisiae annuae, 8-10 parts of herba ecliptae, 10-20 parts of maple leaves, 8-10 parts of radix angelicae sinensis, 8-10 parts of fructus piperis longi, 8-10 parts of pericarpium citrireticulatae, 6-8 parts of herba barleriae lupulinae, 6-8 parts of herba taraxaci, 6-8 parts of pine tree leaves,6-8 parts of cypress branches and leaves, 6-8 parts of tea bran, 6-8 parts of lemongrass, 6-8 parts of rhizoma zingiberis recens, 6-8 parts of semen sesami nigrum, 6-8 parts of black beans, 6-8 parts of raw papaya, 6-8 parts of star anise, 6-8 parts of flos caryophyllata, 6-8 parts of sapindus mukorossi gaerth and 10-20 parts of compound bacteria. According to the invention, a raw material formula is designed under the guidance of pharmacological experiments of traditional Chinese medicines, and the traditional Chinese medicines are processed through microbial growth metabolism and vital movement, so that a traditional process of frying, boiling, decocting, refining, steaming andsoaking are changed, effective components can be promoted to be fully separated, extracted, enhanced or generate new effects, and the hair quality is repaired.

Owner:莫大潮

Hair washing and bathing two-in-one washing lotion for children and preparation method thereof

InactiveCN111388370AStrong cleaning functionReduce stimulationCosmetic preparationsHair cosmeticsCnidium monnieriGlycerol

The invention relates to a hair washing and bathing two-in-one washing lotion for children and a preparation method thereof. The shampoo comprises sodium methyl cocoyl taurate, sodium laureth sulfate,sodium trideceth sulfate, cocamidopropyl betaine, sodium lauroyl oat amino acid, sodium cocoyl apple amino acid, water, polyquaternium-10, amylopectin, a soapberry peel extract, a tea seed extract, dicocoyl dimethyl ammonium chloride, butanediol, an amur corktree bark extract, a coptis root extract, a radix sophorae flavescentis extract, a rhus semialata gall extract, a cnidium monnieri seed extract, a zanthoxylum bungeanum peel extract, a camphor tree rhizome extract, sodium chloride, phenoxyethanol, ethylhexylglycerin and the like. According to the washing lotion, various natural plant extracts are used as skin conditioners, so that irritation to skin is reduced, and meanwhile, the washing lotion has a relatively strong cleaning function; and the preparation method is easy to operate, the process is easy to control, and large-scale production is facilitated.

Owner:广州市逸轩精细化工有限公司

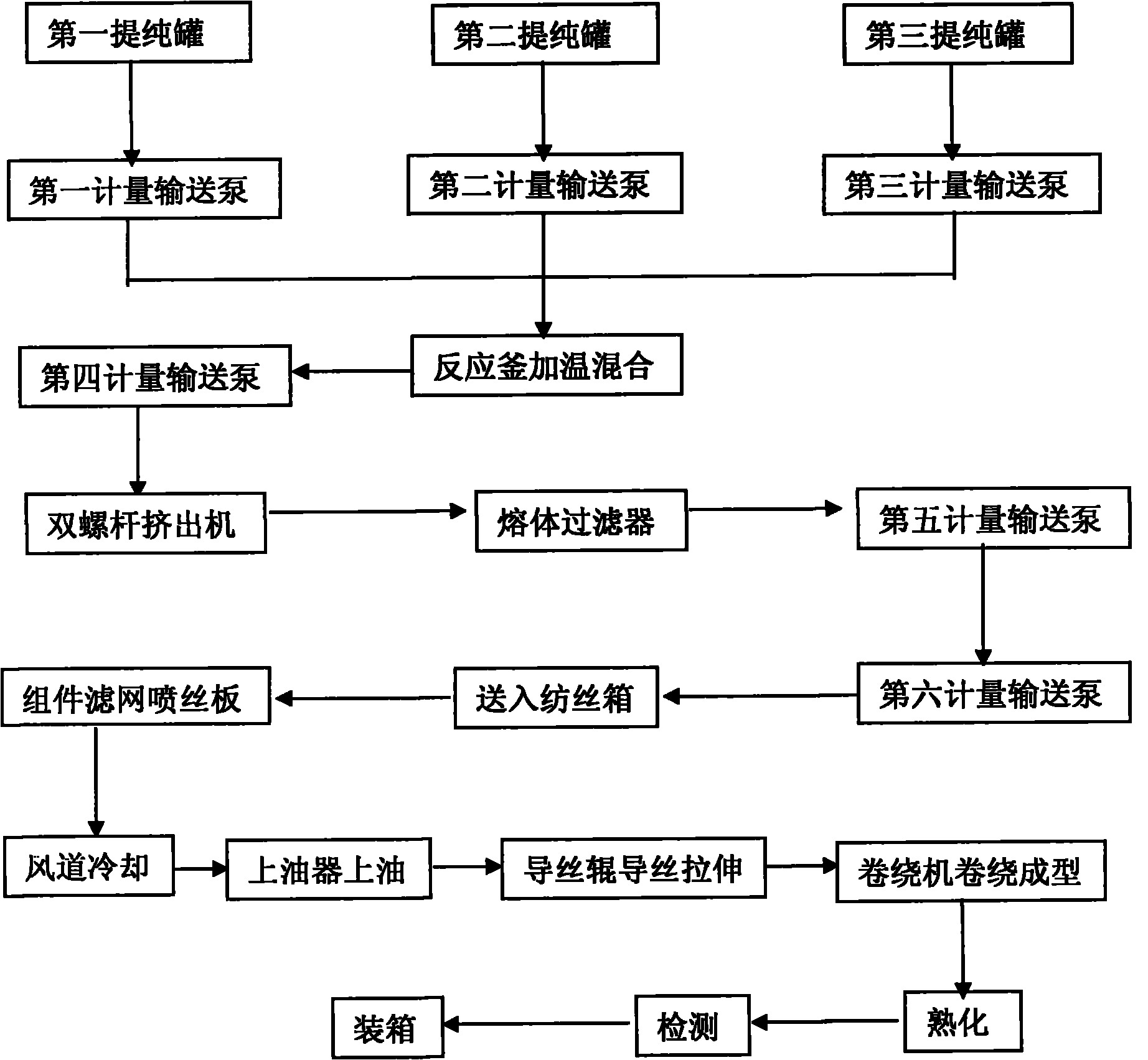

Equipment for producing direct melt filtration fused direct spun ultrafine denier polyurethane fibers

InactiveCN102051698AImprove water absorptionIncrease fiber surface areaArtificial thread manufacturing machinesSpinning head liquid feederFiberFiltration

The invention discloses equipment for producing direct melt filtration fused direct spun ultrafine denier polyurethane fibers. The equipment comprises a purification tank, a reaction tank, a metering delivery pump, a reactor heating mixer, a melt filter, a spinning box, a component filter screen spinning plate, an air channel cooling system, an oiling machine, a guide wire roller guide wire stretching device and a winder winding forming device. The invention has the advantages that: the ultrafine denier polyurethane fibers have small bending stiffness, soft handfeel and large surface area; the coverage, bulkiness and heat retention of a fabric are remarkably improved, and the fabric has strong cleaning function; the ultrafine fibers are prepared into an ultra-dense fabric, a gap among the fibers is between the diameter of a water drop and the diameter of a water vapor microdrop, and the ultra-dense fabric has a waterproof and ventilated effect; and the ultrafine fibers are processed into a towel fabric which can be wetted by water, and the towel fabric has high water absorption, and water of washed hair can be rapidly absorbed by using the towel, so that the hair is rapidly dried. The equipment can be applied to various fields.

Owner:TAICANG JINXIANG SPANDEX FIBER

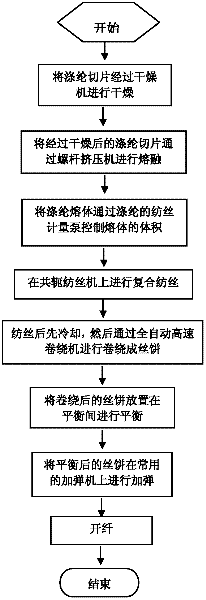

Preparation process of polyester fibers

InactiveCN107287695AIncrease coverageFluffy goodArtificial filament washing/dryingConjugated cellulose/protein artificial filamentsDiolProtein fiber

The invention provides a preparation process of polyester fibers. The preparation process includes the steps of: 1) preparing the following raw materials including: 70-75 parts of organic binary acid, 25-30 parts of dihydric alcohol, 50-60 parts of polyamide fibers, 40-50 parts of protein fibers, and 1-5 parts of a color master batch; 2) performing a condensation polymerization to the organic binary acid and the dihydric alcohol in a high-temperature electric furnace, drying the polyamide fibers, the protein fibers and the color master batch through a drying machine, and crushing the dried mixture to obtain a mixture material; 3) after the condensation polymerization is completed, adding the mixture material into the high-temperature electric furnace to perform high-temperature fusion to obtain a melt mixture; 4) spinning the melt mixture; 5) cooling and water-washing a spinning tow and drafting the spinning tow through a drafting machine; 6) thermal-shaping the spinning tow; and 7) cooling and shaping the spinning tow to obtain a final product. The polyester fiber has uniform color, is high in color fastness and is high in strength.

Owner:HEFEI YUANKE GARMENT DESIGN CO LTD

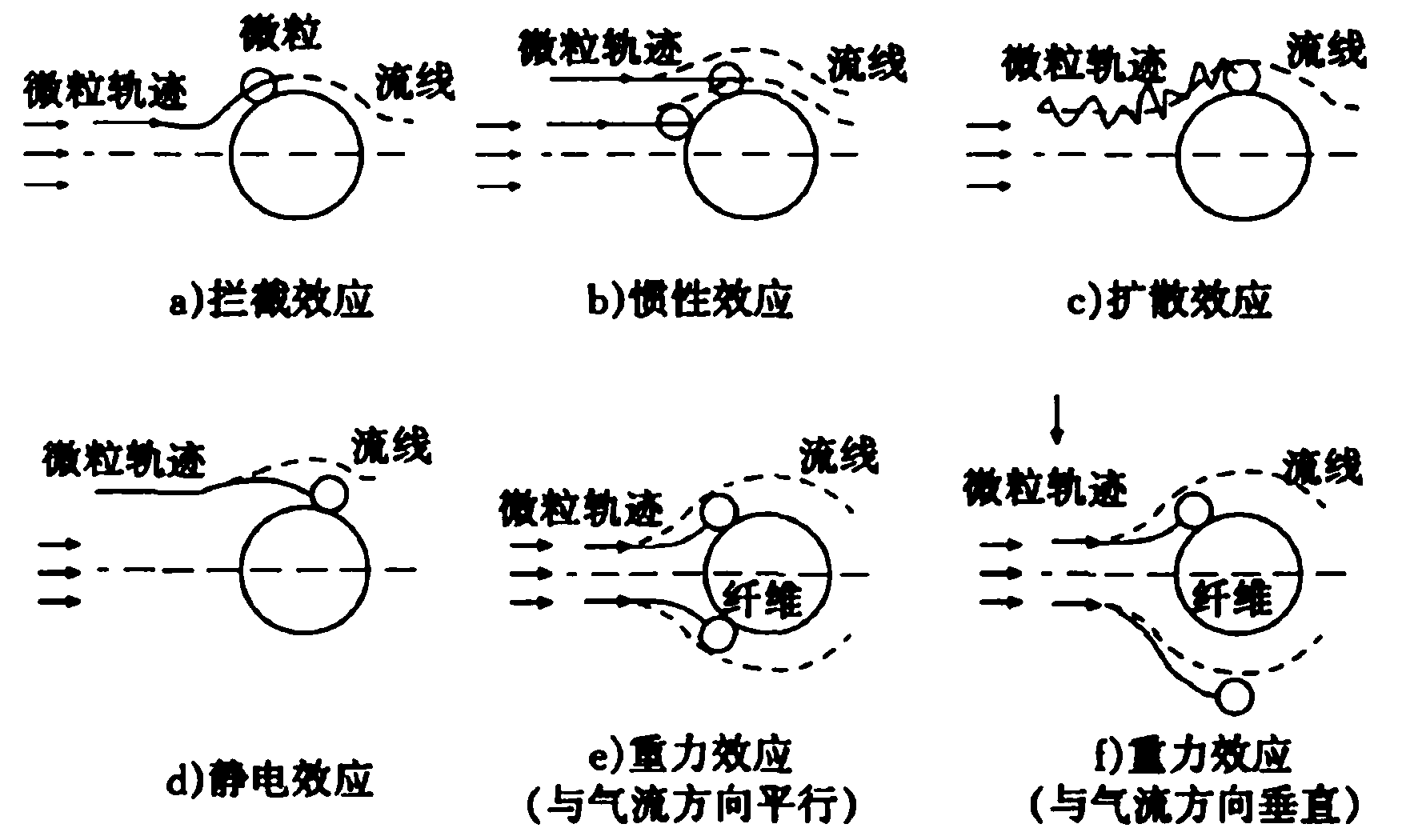

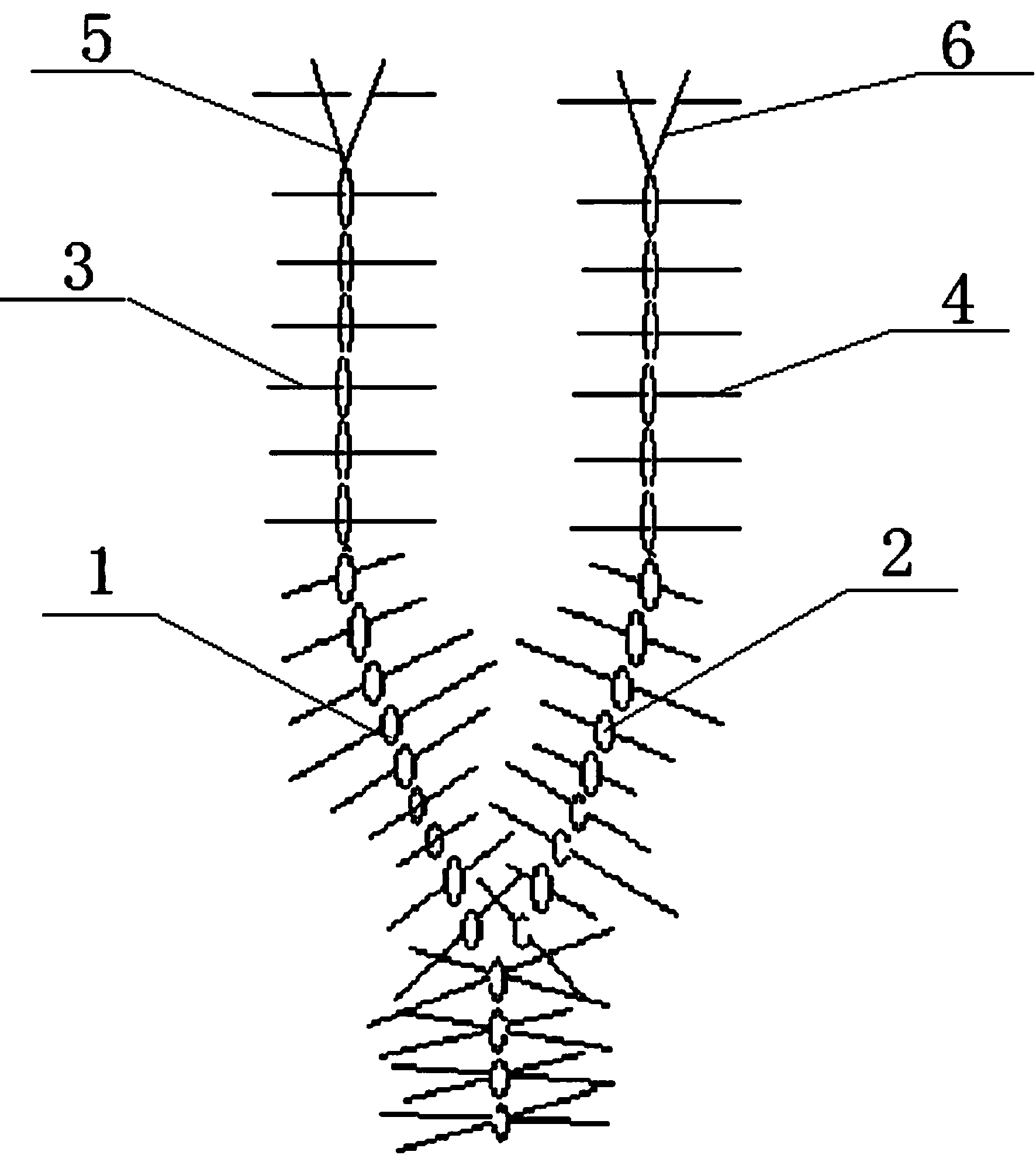

Chenille composite yarn capable of generating static electricity and achieving efficient air filtration and preparation method thereof

The invention discloses chenille composite yarn capable of generating static electricity and achieving efficient air filtration. The chenille composite yarn comprises ultrafine fiber chenille single yarn I and ultrafine fiber chenille single yarn II; camlet I of the ultrafine fiber chenille single yarn I and camlet II of the ultrafine fiber chenille single yarn II are two different fiber materials with quite different dielectric constants. Compared with the prior art, the chenille composite yarn has the advantages that the prepared chenille composite yarn capable of generating static electricity and achieving efficient air filtration is suitable for removing fine particles, and when the chenille composite yarn is adopted for electrostatic dust removal, the advantages of safety, reliability, good maintainability, low operating cost and the like are achieved; the chenille composite yarn has strong electrostatic filtration, adsorption and dust removal abilities, is soft in handfeel and has high dust collection performance and an extremely powerful cleaning function; the production method can adapt to knitting and weaving processing, and knitted or woven fabrics have good air filtration and dust removal performance, so that the life demands of people are enriched.

Owner:ZHONGYUAN ENGINEERING COLLEGE

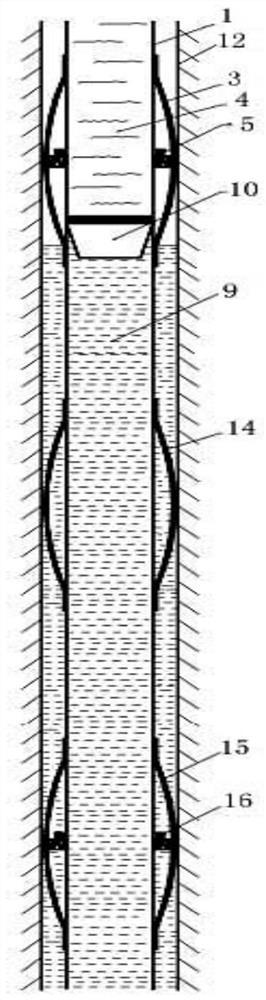

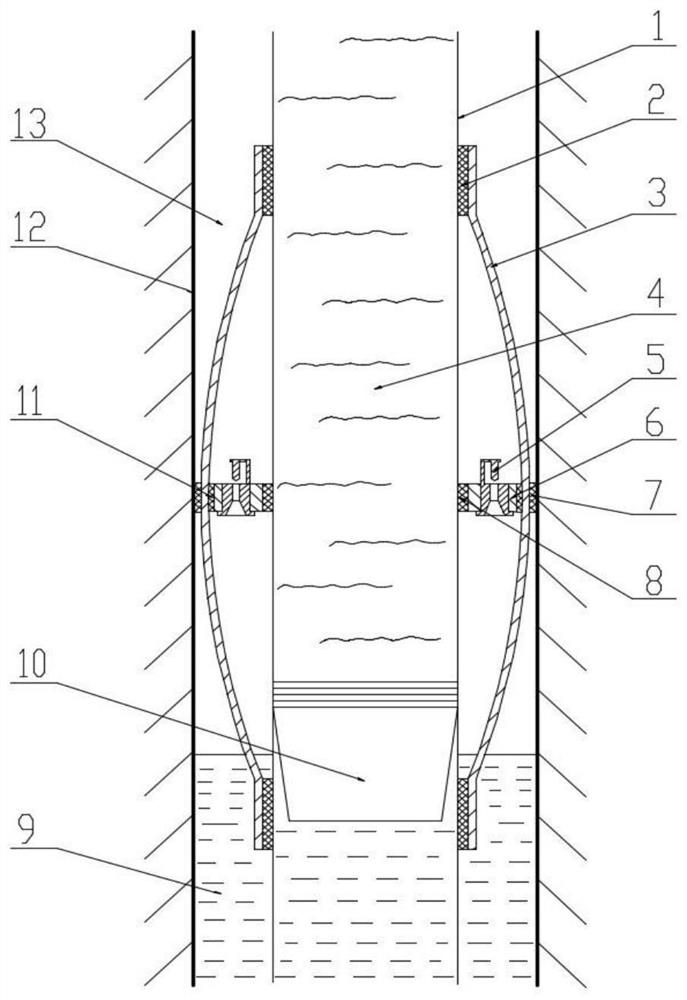

A Downhole Ultrasonic Vibration Cementing System and Its Vibration Cementing Method

ActiveCN111594096BPromotes hydration processImprove rheologyVibration devicesSealing/packingWell cementingEngineering

The invention discloses a downhole ultrasonic vibration cementing system and a vibration cementing method thereof, which belong to the field of oil and gas well engineering. The downhole ultrasonic vibration cementing system includes: a casing string that can be lowered into the preset position of the oil and gas well, a centralizer is installed on the casing string, and a sealing isolation plate is installed on every other casing string of the centralizer, sealing Perlman generators are arranged symmetrically and circularly on the isolation plate; the ultrasonic vibration cementing system uses rubber plugs and displacement fluid to suppress pressure, forcing the rubber plugs to move down, and the displacement fluid squeezes the cement slurry pre-injected into the casing string; The extruded cement slurry flows through the shrinking spray chamber and nozzle of the Pallman generator, causing it to vibrate ultrasonically. The multi-segment Pallman generator can generate long-distance high-frequency vibration, acting on the casing Pipe strings, well walls and cement slurries. The invention has the advantages of simple design, low processing cost, improved vibration effect, cleans the mud cake on the cemented surface, shortens the initial and final setting time, and further improves the cementing quality.

Owner:CHINA AGRI UNIV

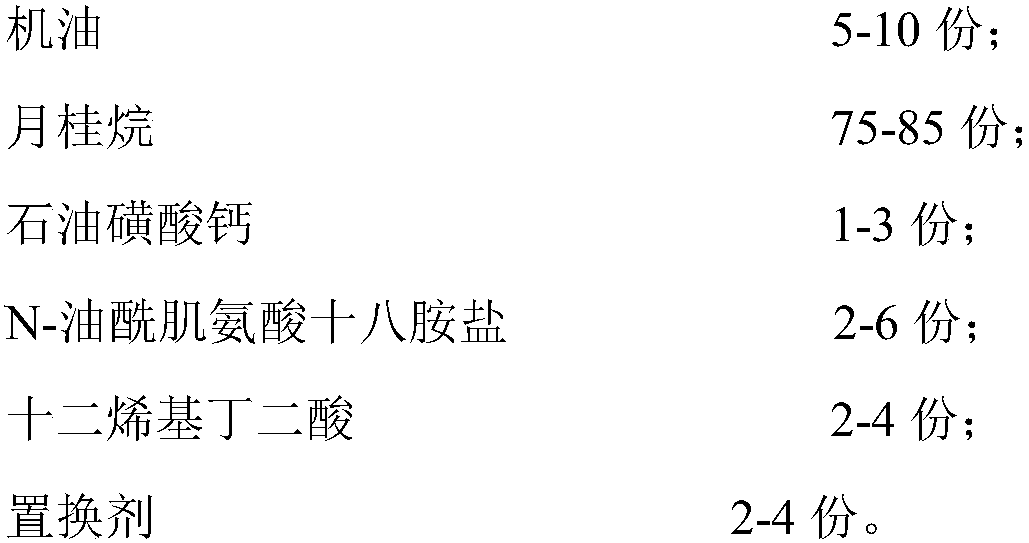

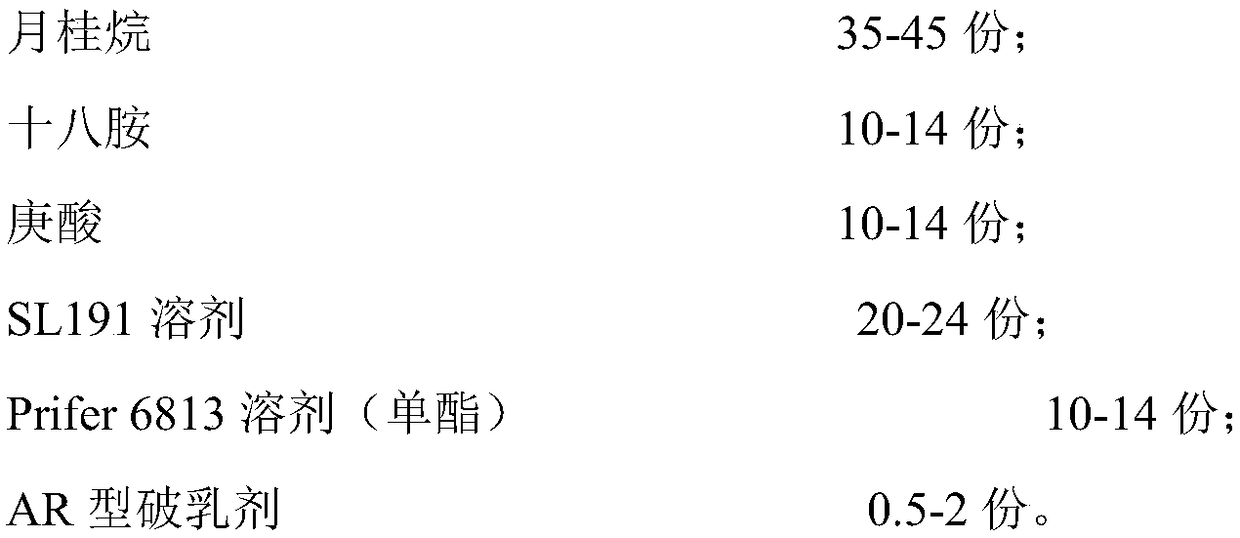

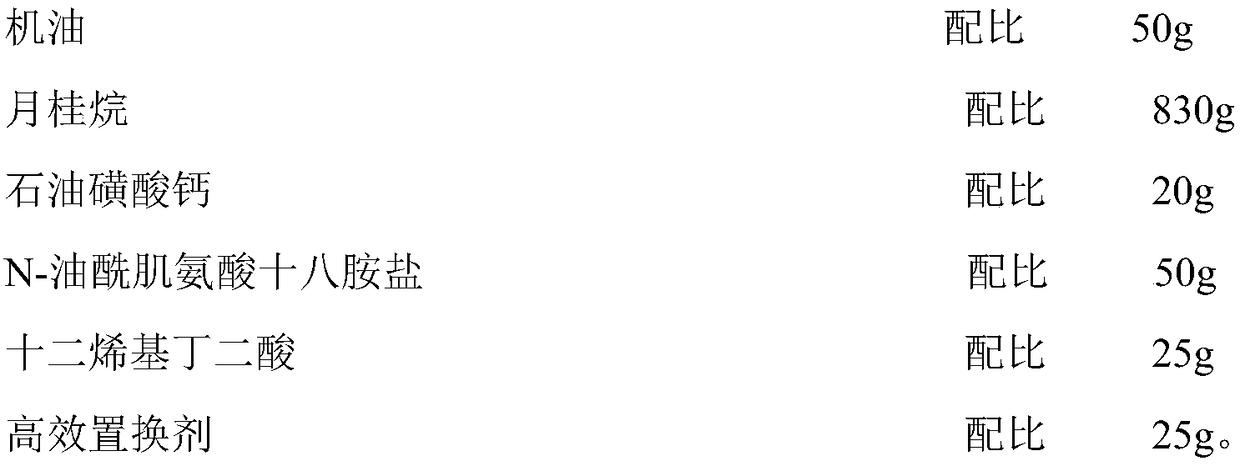

Water displacement type thin-film antirust oil and preparation method thereof

The invention discloses water displacement type thin-film antirust oil. The antirust oil is prepared from the following raw materials in parts by weight: 5-10 parts of engine oil, 75-85 parts of laurane, 1-3 parts of petroleum sulfonate; 2-6 parts of octadecylamine N-oleoyl sarcosinate, 2-4 parts of dodecencylsuccinic acid and 2-4 parts of an efficient displacer. The antirust oil has the characteristics of light odor, thin film, high dehydration property and long antirust period, and is non-flammable. Tests for items such as salt spray, damp heat, water displaceability, film thickness and thelike of the antirust oil show that the antirust oil has the characteristics of excellent antirust performance, efficient water displaceability and thin film, is safe and environmentally and has excellent application prospect.

Owner:华阳新兴科技(天津)集团有限公司

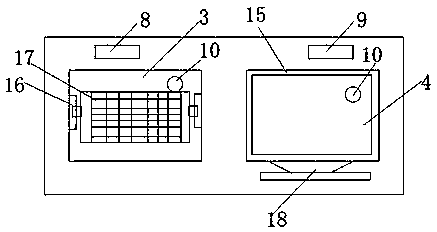

Filtering cleaning washing pool

InactiveCN108301465AStrong cleaning functionImprove filter cleaning efficiencyDomestic plumbingCleaning processes and apparatusWater sourceFixed frame

The invention discloses a filtering cleaning washing pool, which comprises a water pool casing, a water pool panel, a water tank a, a water tank b, a blow-off pipe, a water source connector, a sealingdoor, a water faucet a, a water faucet b, a water outlet, a power supply end opening, a power supply wire, a heating module, a power supply module, a heat insulation plate, a fixing frame and a filtering screen plate, wherein the water pool panel is positioned on the top end of the water pool casing; the two water tanks are formed in the water pool panel; the water tank at the left side is the water tank a; the water tank at the right side is the water tank b; the water faucet a is arranged above the water tank a; the fixing frame is arranged inside the water tank a; the filtering screen plate is arranged on the fixing frame; the water outlet is formed in the bottom of the water tank a; the water faucet b is arranged above the water tank b; the heat insulation plate is arranged at the periphery of the inside of the water tank b; a water outlet is formed in the bottom; the water faucet a and the water faucet b are connected with the water resource connector; the water source connectoris arranged at the right side of the water pool casing. The filtering cleaning washing pool has the advantages that the method of multiplex cleaning by two water tanks is used; foreign smell and grease stain of parts cleaned in the filtering cleaning washing pool can be assisted to be fast and effectively eliminated.

Owner:HAIMEN CANGYUN MACHINERY CO LTD

Continuous operating type convenient-locating ironing device for garment production

ActiveCN110965247AImprove work efficiencyEasy to installMechanical cleaningPressure cleaningElectric machineryDrive motor

The invention discloses a continuous operating type convenient-locating ironing device for garment production. The continuous operating type convenient-locating ironing device for garment production comprises an enclosure a and an enclosure b; the enclosure b is fixedly installed on the outer wall of one side of the enclosure a; a driving motor is fixedly installed at one side of the enclosure b through an installation frame; a transmission roll shaft is fixedly installed on one end of a rotating shaft installed on the output end of the driving motor; a conveying belt is installed on the transmission roll shaft; the conveying belt is composed of a combined steel bar frame and a combined transmission steel belt; a locating part can be glidingly installed on a guide rail fixedly installed onthe combined steel bar frame; the locating part is composed of an installation block and a pull rod; and the pull rod is glidingly installed in the installation block. According to the continuous operating type convenient-locating ironing device for garment production in the invention, the conveying belt is installed; clothes can be put on the conveying belt in batches; when ironing is carried out, because the conveying belt operates continuously, the clothes can be ironed continuously; the continuous operating requirement is realized; and the overall working efficiency is greatly increased.

Owner:ZHEJIANG ZHIYIN TEXTILE TECH CO LTD

A washing and sweeping vehicle with a double circulation filter system

ActiveCN105464031BIncrease flow rateImprove filtration efficiencyWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentWater resourcesFilter system

The invention discloses a washing and sweeping vehicle with a double-circulation filter system. The washing and sweeping vehicle comprises a vehicle chassis, a draught fan, a suction air duct, a suction pipe, a suction plate, a brush plate and a water spraying device. According to the double-circulation filter system, a sewage box is connected with a first-stage water pump through a pipeline, the first-stage water pump is connected with a second-stage water pump through a pipeline, the second-stage water pump is connected with one or more filters. The filter is connected with the sewage box through a pipeline. A pressure regulation valve is arranged on the connection pipeline between the filter and the sewage box. The connection pipeline between the first-stage water pump and the second-stage water pump is connected with the connection pipeline between the filter and the pressure regulation valve through a pipeline. The clear water outlet of the filter is connected with a clear water box through a pipeline. The filter is a ceramic membrane filter which comprises a ceramic membrane pipe arranged in a sealed shell. The two ends of the sealed shell are used as a sewage inlet and a sewage outlet respectively to be connected with pipelines. A clear water outlet is formed in the sealed shell. By means of the washing and sweeping vehicle, the effective working time of environmental sanitation devices can be greatly prolonged, the sewage discharge amount can be decreased, and the utilization rate of water resources is increased.

Owner:YANTAI HAIDE SPECIAL VEHICLE

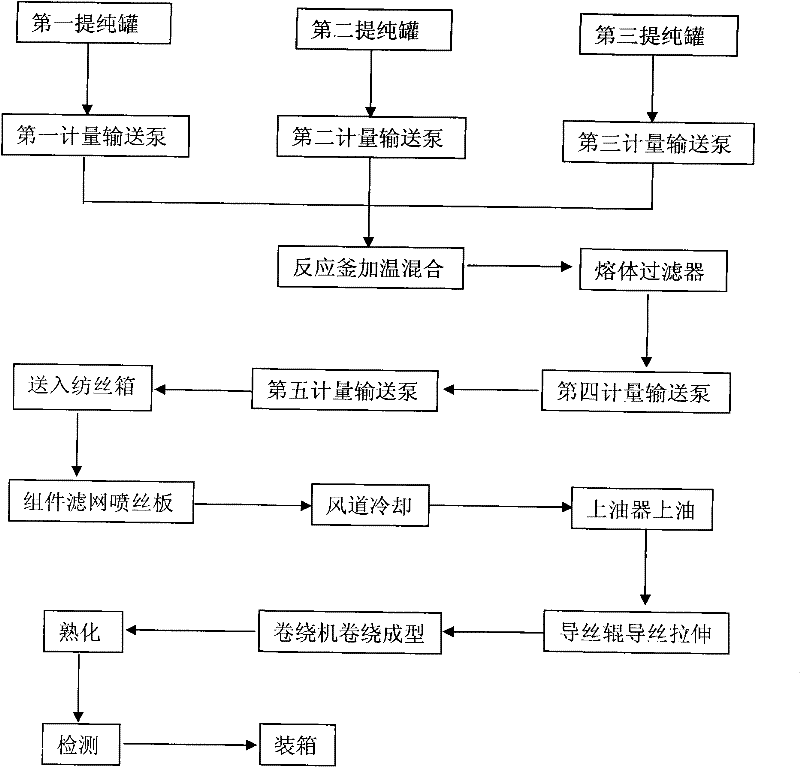

Method for producing melt direct spinning superfine denier polyurethane fibers through guide yarn stretching of double godet rollers

InactiveCN102021666BImprove water absorptionIncrease fiber surface areaSpinning head liquid feederMonocomponent synthetic polymer artificial filamentFiberYarn

The invention provides a method for producing melt direct spinning superfine denier polyurethane fibers through guide yarn stretching of double godet rollers, which is characterized by comprising the following steps: raw materials, charging under negative pressure, addition of 0.8MPa nitrogen pressure, a double-screw extruder, filtration in a melt filter, jetted yarn cooling in an air duct, oiling by an oiling machine, guide yarn stretching by double godet rollers, curing in a drying room and detecting and casing. The method has the following advantages: the superfine denier polyurethane fibers have low bending stiffness and quite soft feel; the surface areas of the fibers are large, thus obviously improving the coverage, bulkiness and heat retention of the fabrics and having extremely strong cleaning function; the superfine fibers are made into superhigh density fabrics and the size of the gaps between the fibers range from the diameter of the water drops to the diameter of the vapordroplets, thus having waterproof and air-permeability effects; and the superfine fibers are processed into such fabrics which can be moistened by water as towels and the towels have high water absorbability and can rapidly absorb the moisture of the washed hairs to rapidly dry the hairs. The method can be applied in various fields.

Owner:TAICANG JINXIANG SPANDEX FIBER

Preparation method of paint cleaning agent

InactiveCN102807781BEasy to cleanQuick Dissolving PeelChemical paints/ink removersKetoneCleansing Agents

The invention relates to a cleaning agent, in particular to a paint cleaning agent which is strong, powerful, economical, high-efficient, energy-saving, environment-friendly, novel and concentrated and a preparation method thereof. The paint cleaning agent is prepared by the following raw materials by weight percent: 15 to 25 percent of dimethoxy dipropylene glycol, 25 to 40 percent of N-methylpyrrolidine, 5 to 8 percent of ethanolamine, 20 to 30 percent of ethyl acetate, 5 to 10 percent of fatty acid ester, 15 to 25 percent of dimethyl ketone and 0.2 percent of fruity essence.

Owner:刘杰

Preparation method for deinking agent of mixed office wastepaper

InactiveCN109233426AImprove lipophilic propertiesLow organic solvent contentChemical paints/ink removersActivated carbonEnvironmental resistance

Owner:FOSHAN CHANCHENG DISTRICT NUOGAO ENVIRONMENTAL PROTECTION TECH CO LTD

Impeller drive control mechanism of stationary crude oil washing machine

The invention discloses an impeller driving control mechanism of a fixed crude oil tank washing machine, which comprises a main transmission part arranged in a body, an impeller driving part, an impeller driving start and stop control part and a nozzle horizontal rotational speed adjustment mechanism connected with the impeller driving part The driving parts of the impeller include the impeller, the hydraulic control shut-off valve at the front end of the impeller, the transmission shaft connected to the rear end of the impeller, the main spring on the transmission shaft, the auxiliary spring and the worm. The mechanism can automatically adjust the axial position of the impeller, and the horizontal speed of the nozzle can be adjusted to realize the automatic shutdown of a single machine.

Owner:HAIYING ENTERPRISE GROUP

Nano silk powder cleaning oil as well as preparation method and cleaning method

InactiveCN107298998AGood removal effectEnhance the infiltration functionLubricant compositionBase oilCleansing Agents

The invention relates to the technical field of cleaning agents of engines, in particular to nano silk powder cleaning oil as well as a preparation method and a cleaning method. The nano silk powder cleaning oil comprises the following raw materials in parts by weight: 3000-5000 parts of base oil, 30-50 parts of dimethyl carbonate, and 5-10 parts of nano silk powder. According to the nano silk powder cleaning oil, a nano cleaning factor, namely, nano silk powder, is added to the base oil, so that the nano silk powder cleaning oil has a super strong cleaning function, and pollutants and deposits such as various carbon deposits in the engines can be quickly removed; low-toxicity and low-viscosity dimethyl carbonate is added, so that the infiltration function of the cleaning oil is improved, and the cleaning oil can quickly infiltrate the carbon deposits in the engines to remove the carbon deposits.

Owner:江力

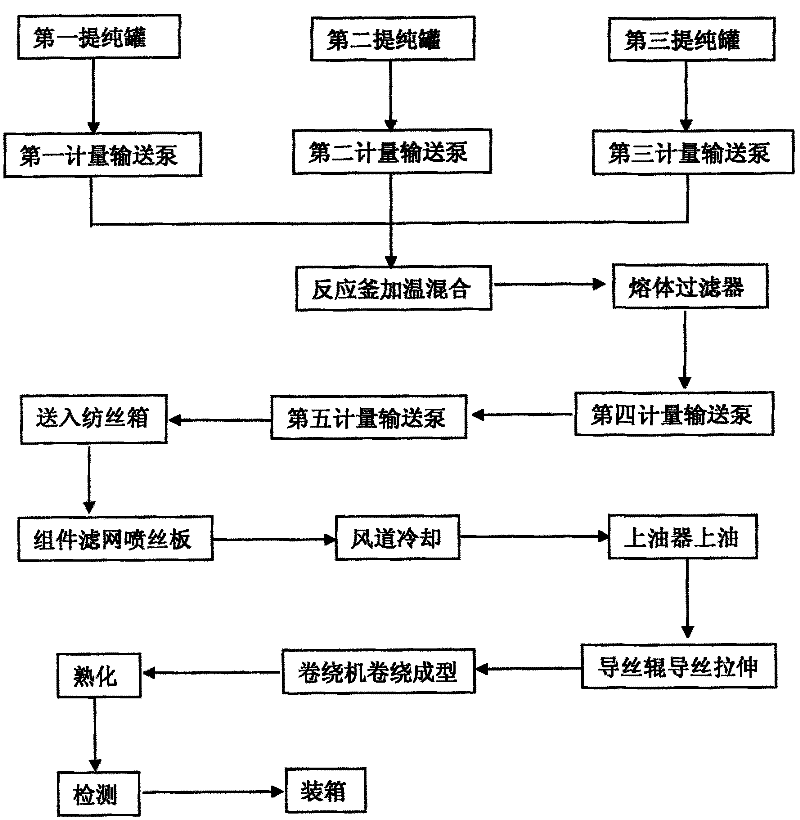

Equipment for producing molten direct spun superfine denier polyurethane fibers by guide silk stretching of double-way silk guide roller

InactiveCN102051699AImprove water absorptionIncrease fiber surface areaArtificial thread manufacturing machinesArtificial filament heat treatmentFiberWater vapor

The invention discloses equipment for producing molten direct spun superfine denier polyurethane fibers by guide silk stretching of a double-way silk guide roller. The equipment is characterized by comprising a purification tank, a reaction tank, a metering delivery pump, a reaction kettle heating mixer, a double-screw extruder, a melt filter, a spinning box, an assembly filter screen spinneret plate, an air flue cooling system, an oiling device, a silk guide roller guide silk stretching device and a winder winding molding device. The equipment has the advantages that: the produced superfine denier polyurethane fibers have low bending rigidity and particularly soft handfeel; the area of the fibers is big, the coverage, bulkiness and heat insulation of fabrics are obviously improved, and the fibers have extremely strong cleaning function; when the superfine fibers are prepared into ultrahigh density fabrics, because the gaps among the fibers are between the diameter of water drops and the diameter of water vapor micro-drops, the fabrics have waterproof and ventilated effects; and when the fibers are processed into the towel fabrics which can be wetted by water, the towel fabrics have high water absorption, and moisture on the washed hair can be quickly absorbed by using the towel so that the hair is quickly dried. The fibers can be applied in various fields.

Owner:TAICANG JINXIANG SPANDEX FIBER

Equipment for producing direct melt filtration fused direct spun ultrafine denier polyurethane fibers

InactiveCN102051698BImprove water absorptionIncrease fiber surface areaSpinning head liquid feederArtificial thread manufacturing machinesFiltrationWater vapor

The invention discloses equipment for producing direct melt filtration fused direct spun ultrafine denier polyurethane fibers. The equipment comprises a purification tank, a reaction tank, a metering delivery pump, a reactor heating mixer, a melt filter, a spinning box, a component filter screen spinning plate, an air channel cooling system, an oiling machine, a guide wire roller guide wire stretching device and a winder winding forming device. The invention has the advantages that: the ultrafine denier polyurethane fibers have small bending stiffness, soft handfeel and large surface area; the coverage, bulkiness and heat retention of a fabric are remarkably improved, and the fabric has strong cleaning function; the ultrafine fibers are prepared into an ultra-dense fabric, a gap among the fibers is between the diameter of a water drop and the diameter of a water vapor microdrop, and the ultra-dense fabric has a waterproof and ventilated effect; and the ultrafine fibers are processed into a towel fabric which can be wetted by water, and the towel fabric has high water absorption, and water of washed hair can be rapidly absorbed by using the towel, so that the hair is rapidly dried. The equipment can be applied to various fields.

Owner:TAICANG JINXIANG SPANDEX FIBER

Equipment for producing molten direct spun superfine denier polyurethane fibers by guide silk stretching of double-way silk guide roller

InactiveCN102051699BImprove water absorptionIncrease fiber surface areaArtificial thread manufacturing machinesArtificial filament heat treatmentFiberWater vapor

The invention discloses equipment for producing molten direct spun superfine denier polyurethane fibers by guide silk stretching of a double-way silk guide roller. The equipment is characterized by comprising a purification tank, a reaction tank, a metering delivery pump, a reaction kettle heating mixer, a double-screw extruder, a melt filter, a spinning box, an assembly filter screen spinneret plate, an air flue cooling system, an oiling device, a silk guide roller guide silk stretching device and a winder winding molding device. The equipment has the advantages that: the produced superfine denier polyurethane fibers have low bending rigidity and particularly soft handfeel; the area of the fibers is big, the coverage, bulkiness and heat insulation of fabrics are obviously improved, and the fibers have extremely strong cleaning function; when the superfine fibers are prepared into ultrahigh density fabrics, because the gaps among the fibers are between the diameter of water drops and the diameter of water vapor micro-drops, the fabrics have waterproof and ventilated effects; and when the fibers are processed into the towel fabrics which can be wetted by water, the towel fabrics have high water absorption, and moisture on the washed hair can be quickly absorbed by using the towel so that the hair is quickly dried. The fibers can be applied in various fields.

Owner:TAICANG JINXIANG SPANDEX FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com