A Downhole Ultrasonic Vibration Cementing System and Its Vibration Cementing Method

An ultrasonic and cementing technology, which is used in wellbore/well components, vibration generating devices, earth-moving drilling and other directions, can solve the problems of uneven vibration distribution, affecting cementing quality, low vibration frequency, etc. Improve cementing quality and uniform vibration distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention provides a downhole ultrasonic vibration cementing system and its vibration cementing method: the present invention will be further described below in conjunction with the accompanying drawings.

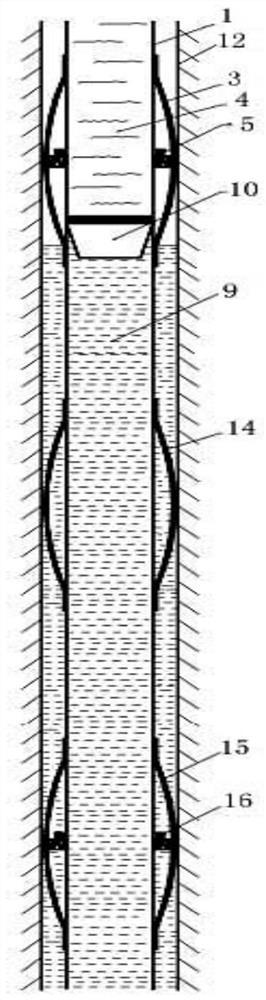

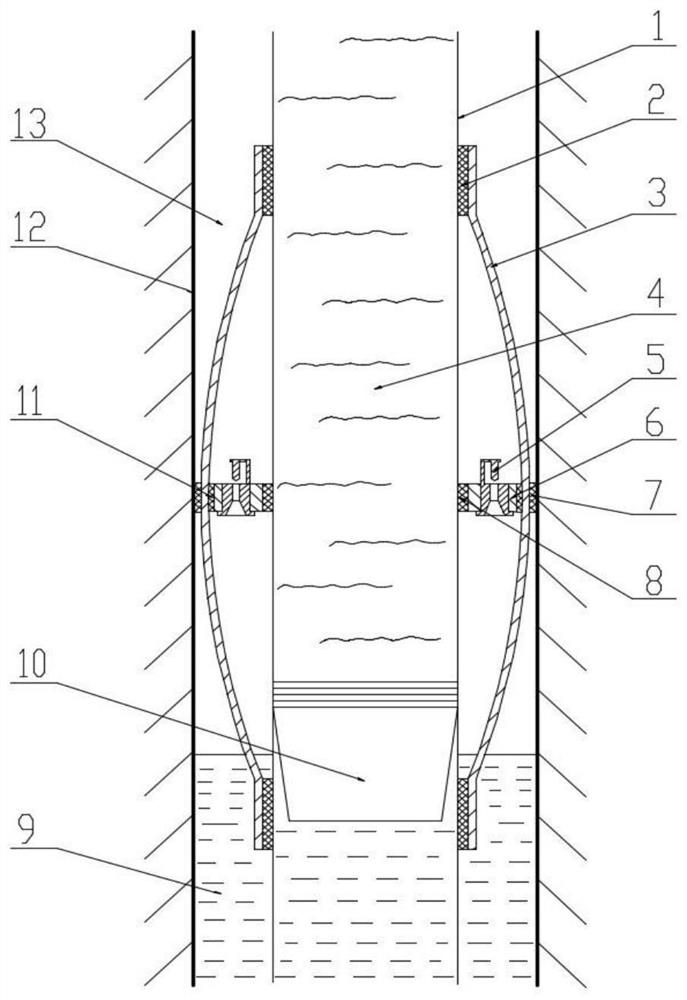

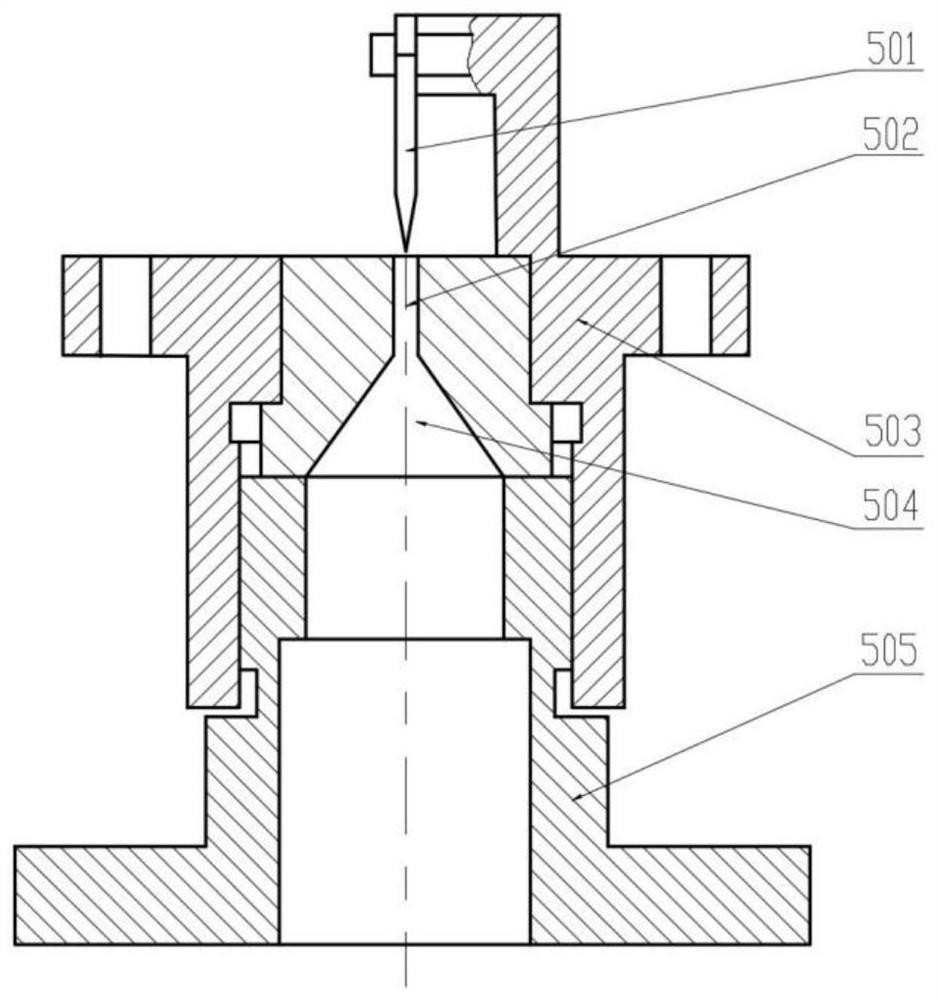

[0025] Such as figure 1 The structure diagram of the downhole ultrasonic vibration cementing system shown and figure 2 The partial enlarged view of the part where the centralizer is installed is shown in the figure, which shows a hydraulic ultrasonic vibration cementing system, including a casing string 1 that can be lowered into the preset position of the oil and gas well; the casing string 1 is connected with the oil and gas well An annular space 13 is formed between the well walls 12; on the casing string 1, 1# centralizer centralizer 3, 2# centralizer 14 and 3# centralizer 15 are installed sequentially from top to bottom; 2# Perlman generator 16 is installed in the middle of 15; a self-expanding sealing ring 7 is installed between the 1# centralizer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com