Filtering cleaning washing pool

A pool washing and cleaning technology, applied in the directions of filtration and separation, cleaning methods and appliances, fixed filter element filters, etc., can solve the problems of reduced work efficiency, incomplete cleaning, and high labor intensity, saving cleaning costs and improving filter cleaning. Efficiency, effect of reducing cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

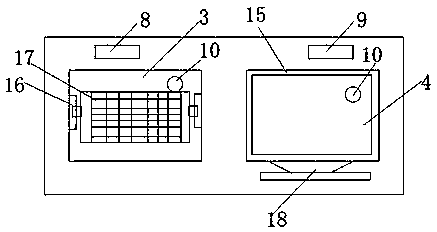

[0012] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0013] A filter cleaning washing pool, which includes a pool shell 1, a pool panel 2, a water tank a3, a water tank b4, a sewage pipe 5, a water source interface 6, a sealed door 7, a faucet a8, a water faucet b9, a water outlet 10, a power port 11, Power line 12, heating module 13, power module 14, heat insulation board 15, fixed frame 16 and filter screen plate 17, pool panel 2 is located at the top of pool shell 1, and there are two sinks on the pool panel 2, the left side is the sink The right side of a3 is the water tank b4, the faucet a8 is installed above the water tank a3, the fixed frame 16 is installed inside the water tank a3, the filter plate 17 is installed on the fixed frame 16, the water outlet 10 is opened at the bottom of the water tank a3; the water tap b9 is installed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com