Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

127results about "Tank cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

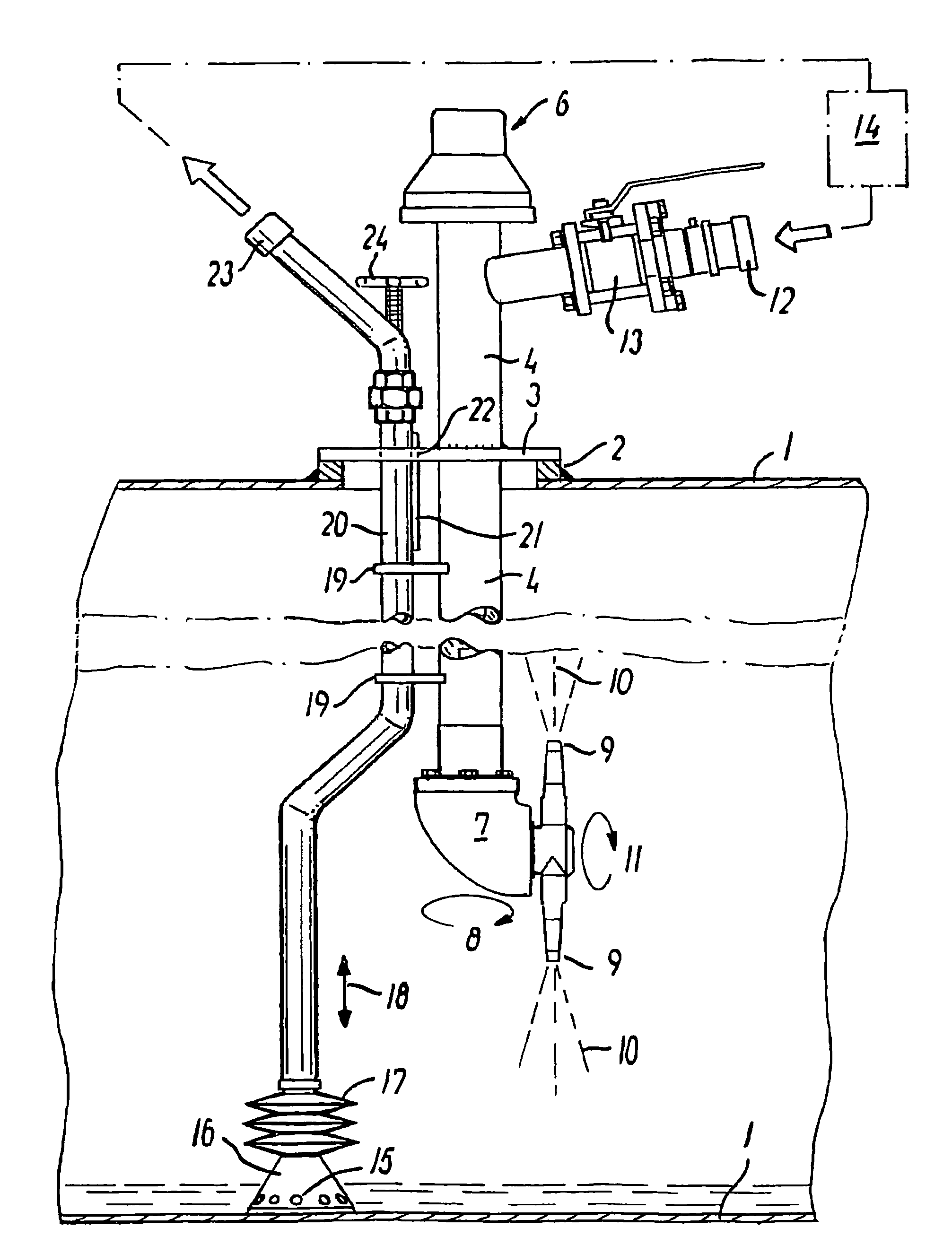

Cleaning equipment and use thereof

InactiveUS20040238009A1Compact installationLimited amountTank vesselsHollow article cleaningReady to useMixed states

By constructing tank cleaning equipment according to the invention such that it comprises a cleaning jetting part (7, 9) as well as a suction part (4), the equipment can work with the same cleaning medium which is recirculated. This saves supply of fresh cleaning medium, and since used medium is thus not discharged, it is not necessary to establish deposit facilities to avoid pollution. Furthermore, this equipment according to the invention may advantageously be used for keeping so-called drilling mud in a mixed and thus ready-to-use state, even when left to stand for an extended period of time in a tank. The nozzle jets (10) thus keep the mud in the tank in a constantly mixed state, and the mud can therefore be sucked through the suction pipe (20) for pumping in the drill pipe, it being ensured that the mud is homogeneous and has a suitable viscosity.

Owner:ALFA LAVAL TANK EQUIP

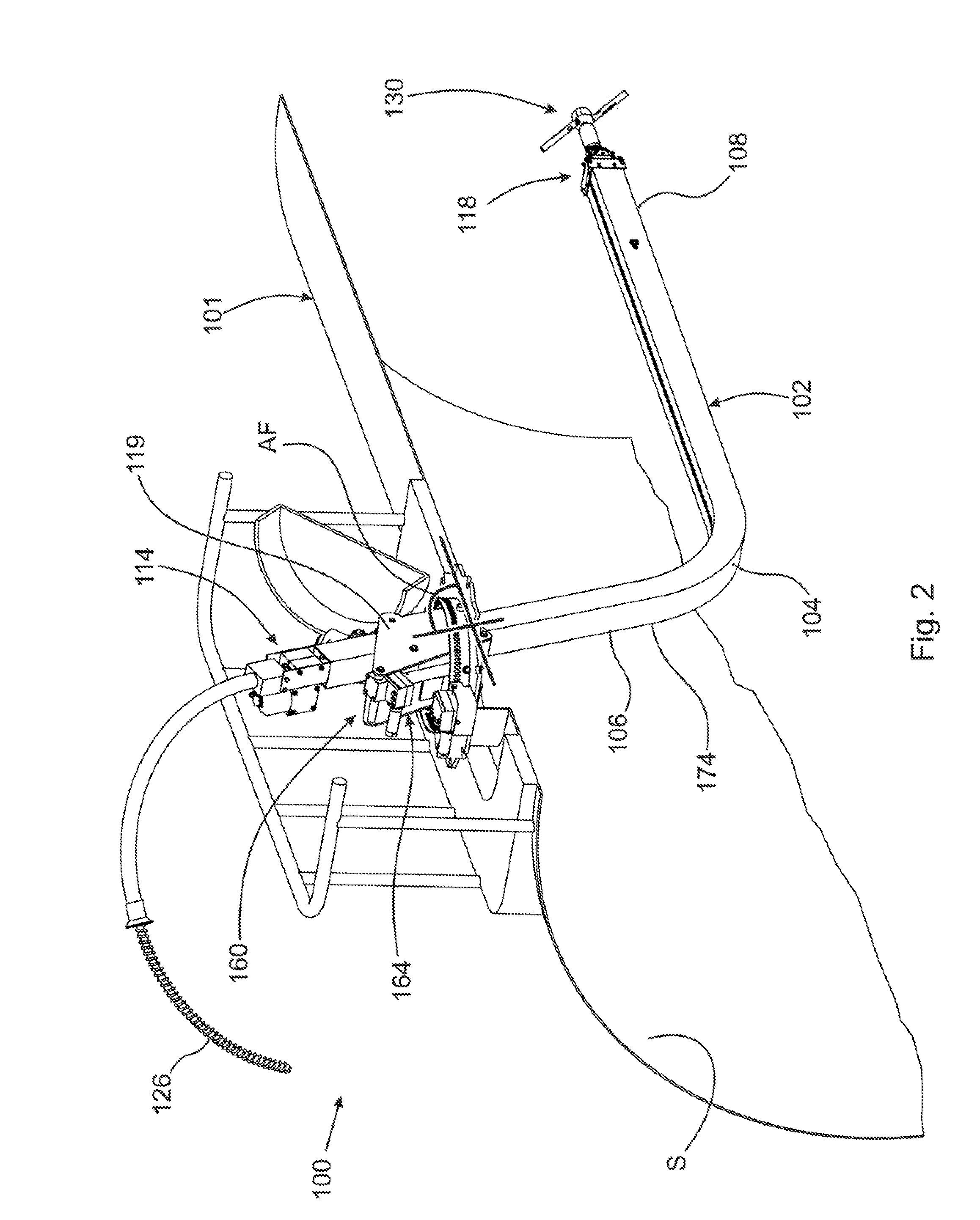

Remotely operated cleaning device, especially suitable for storage tanks on vessels

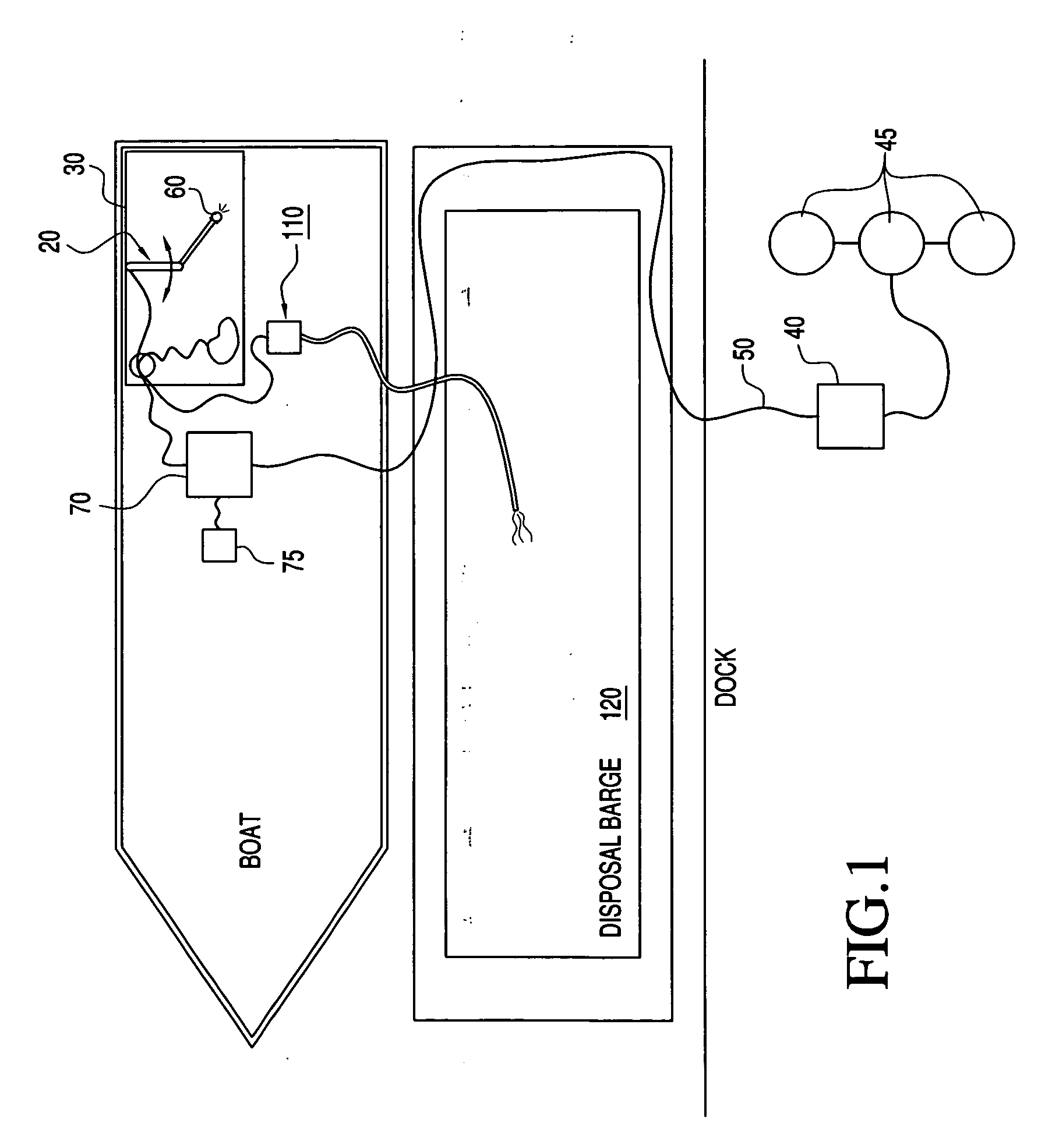

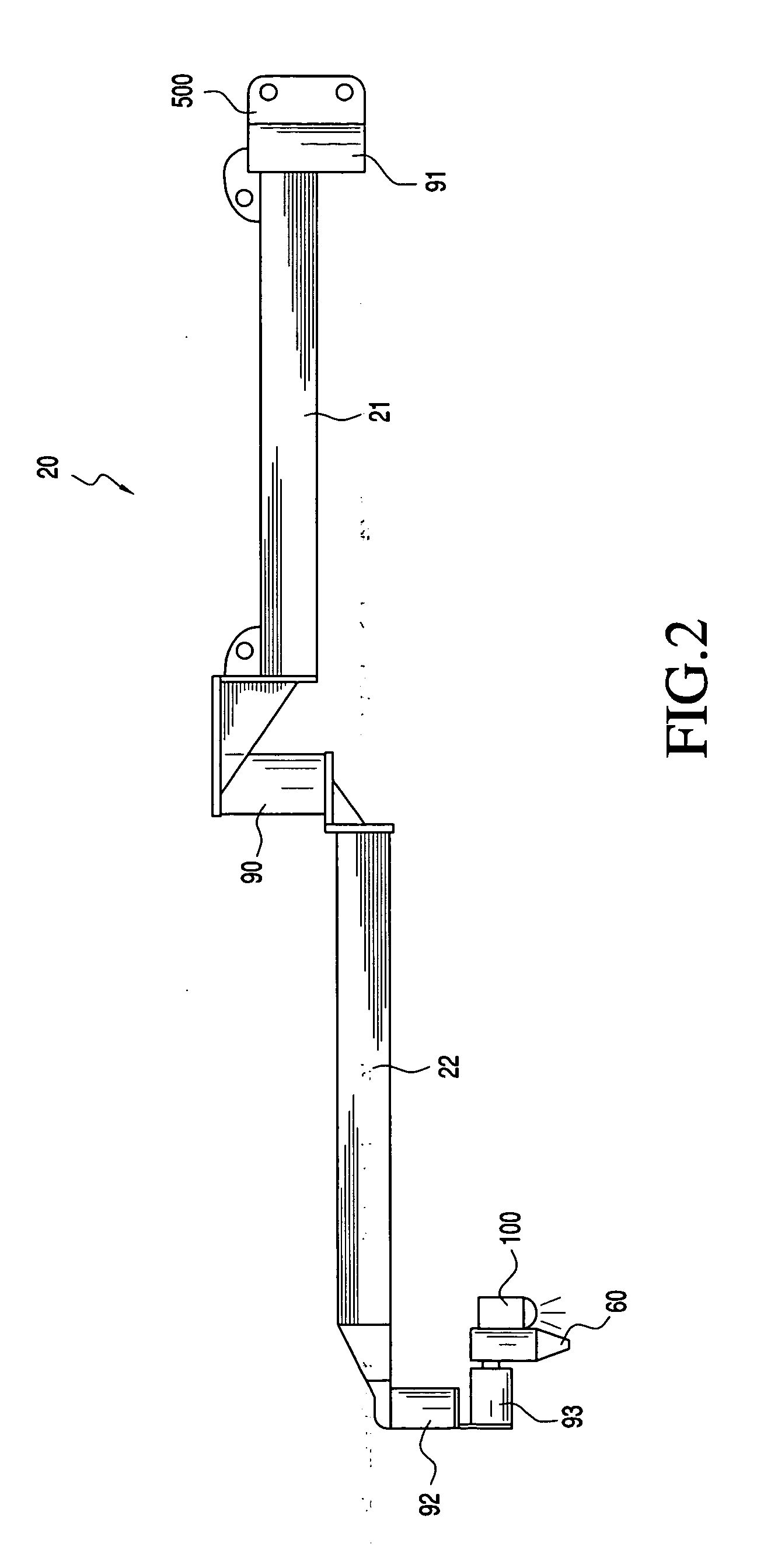

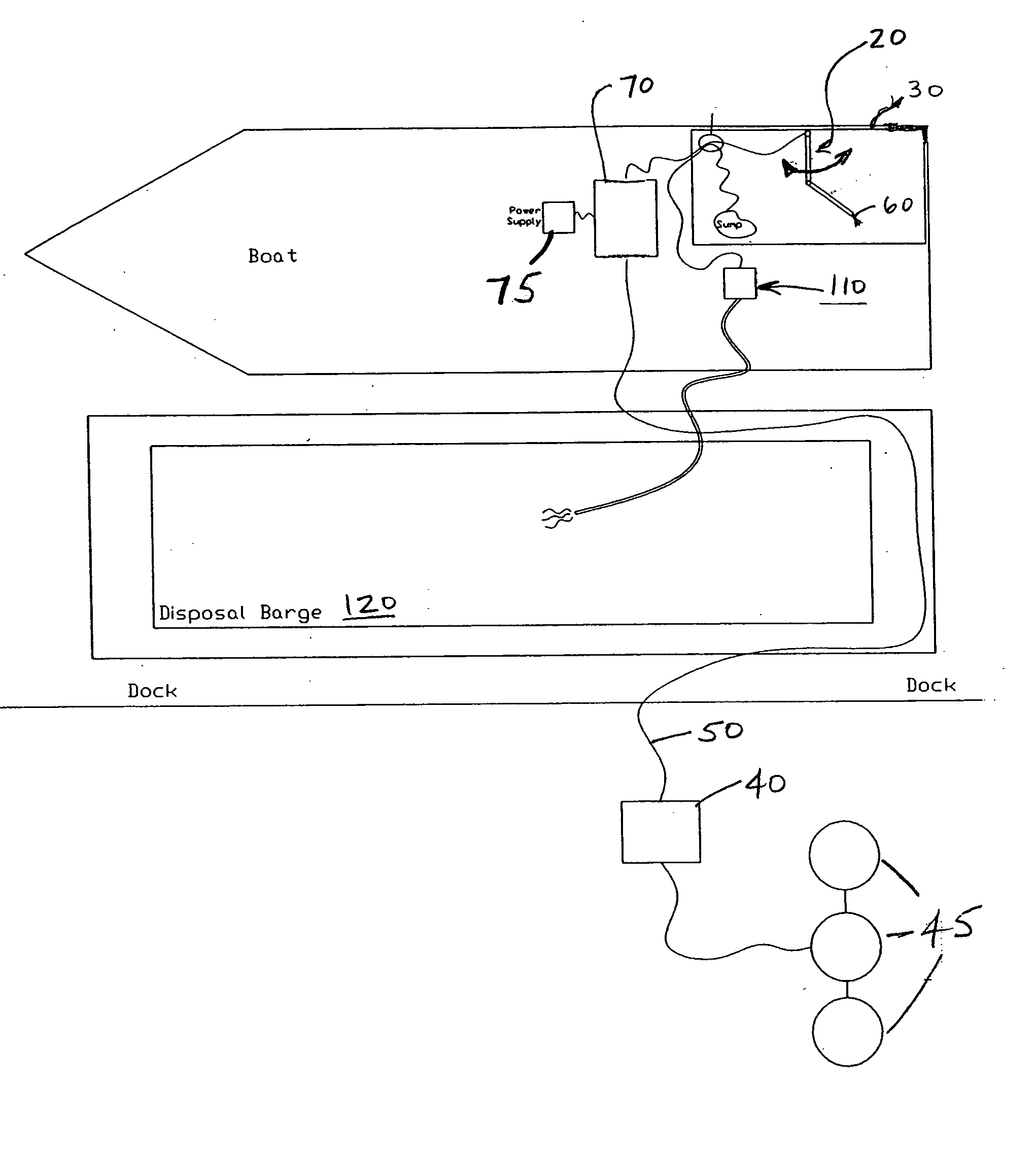

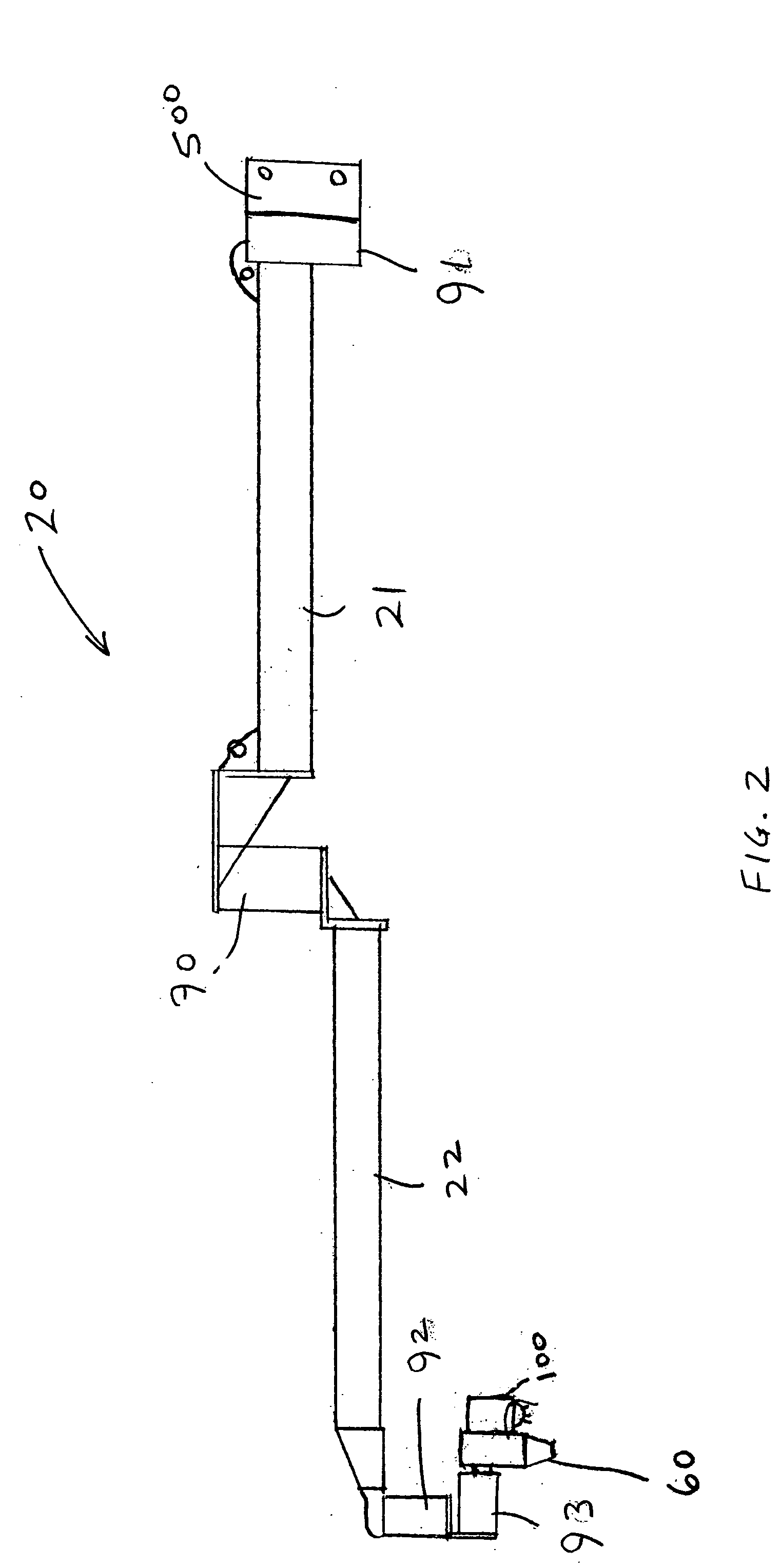

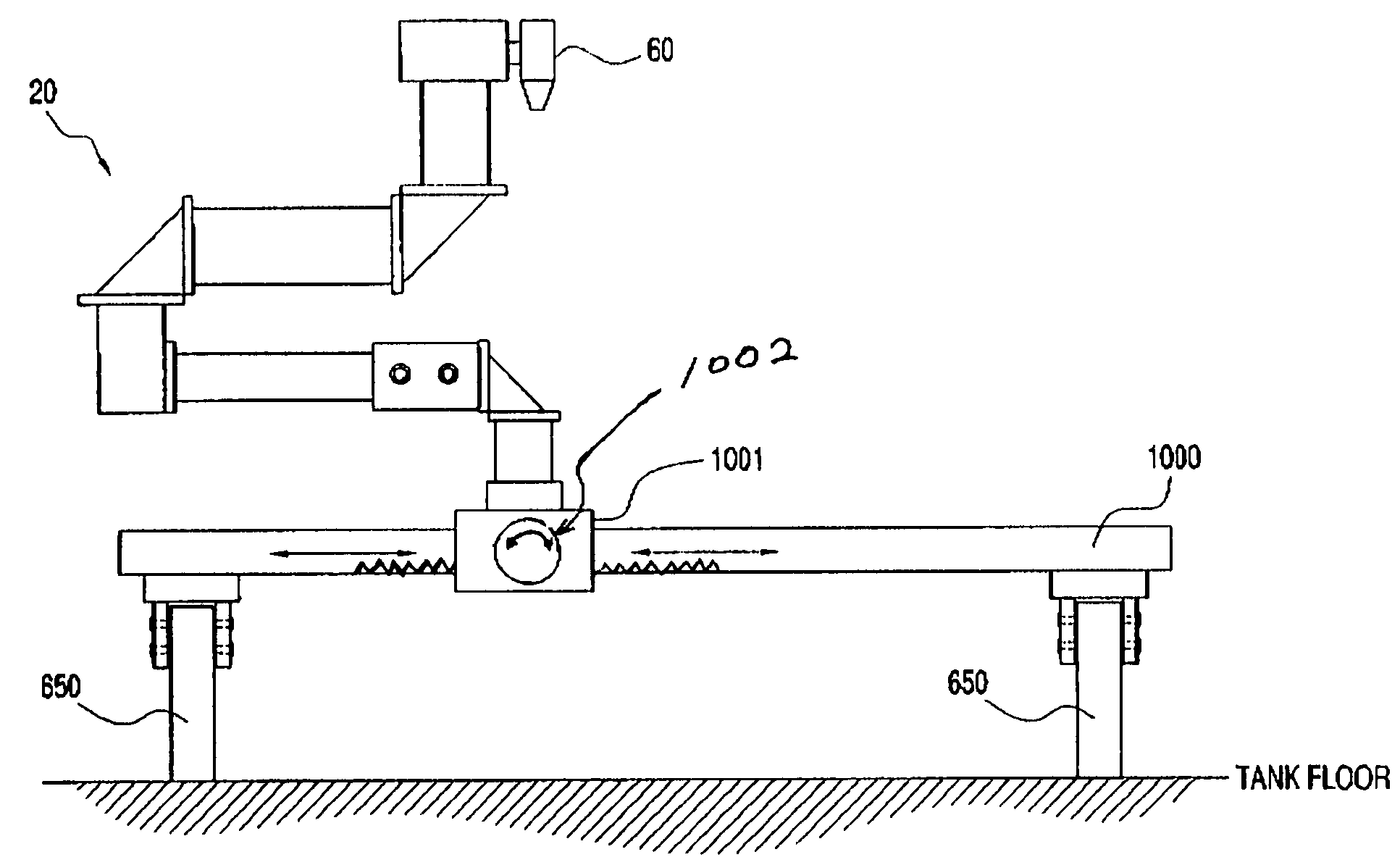

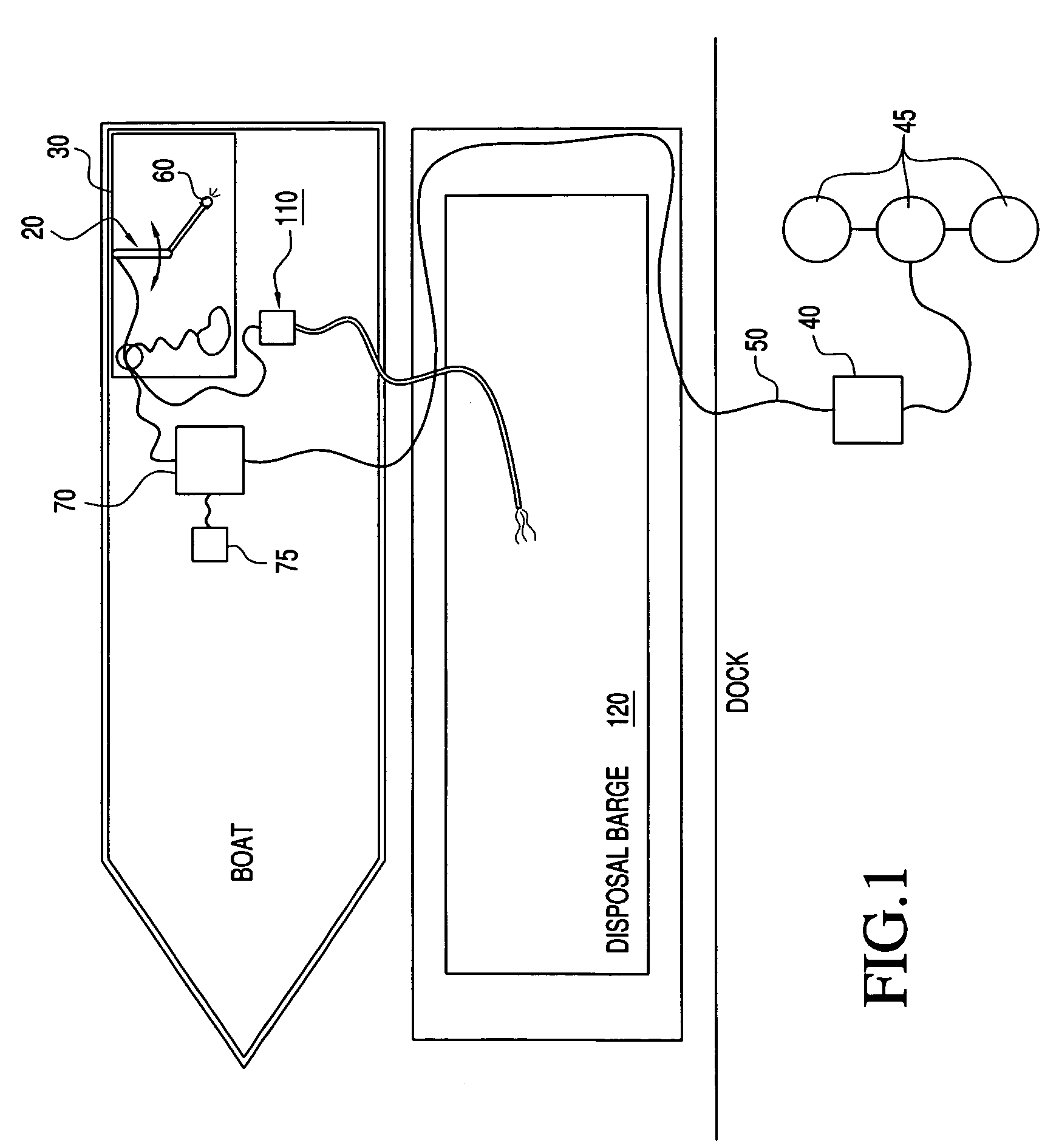

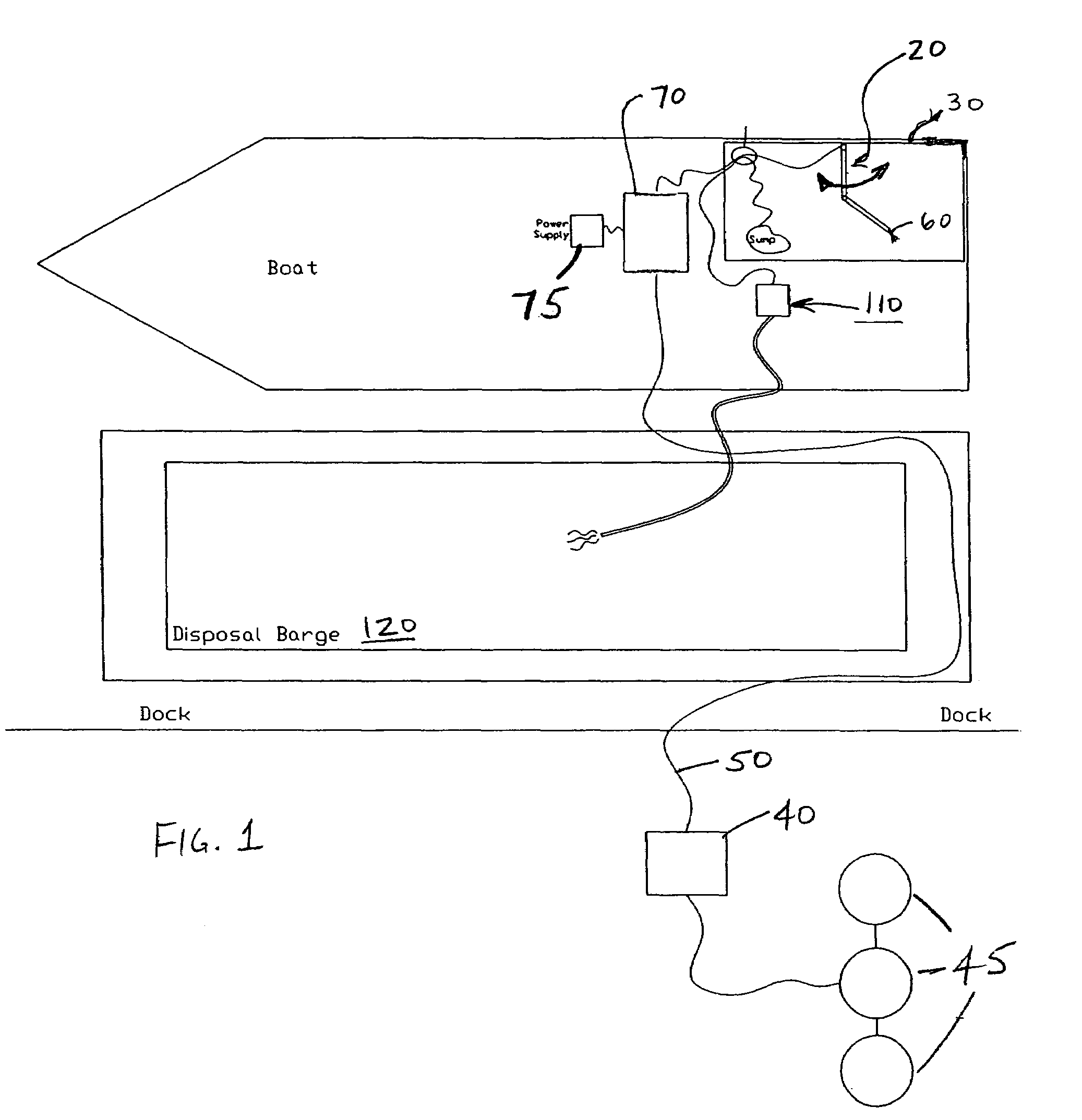

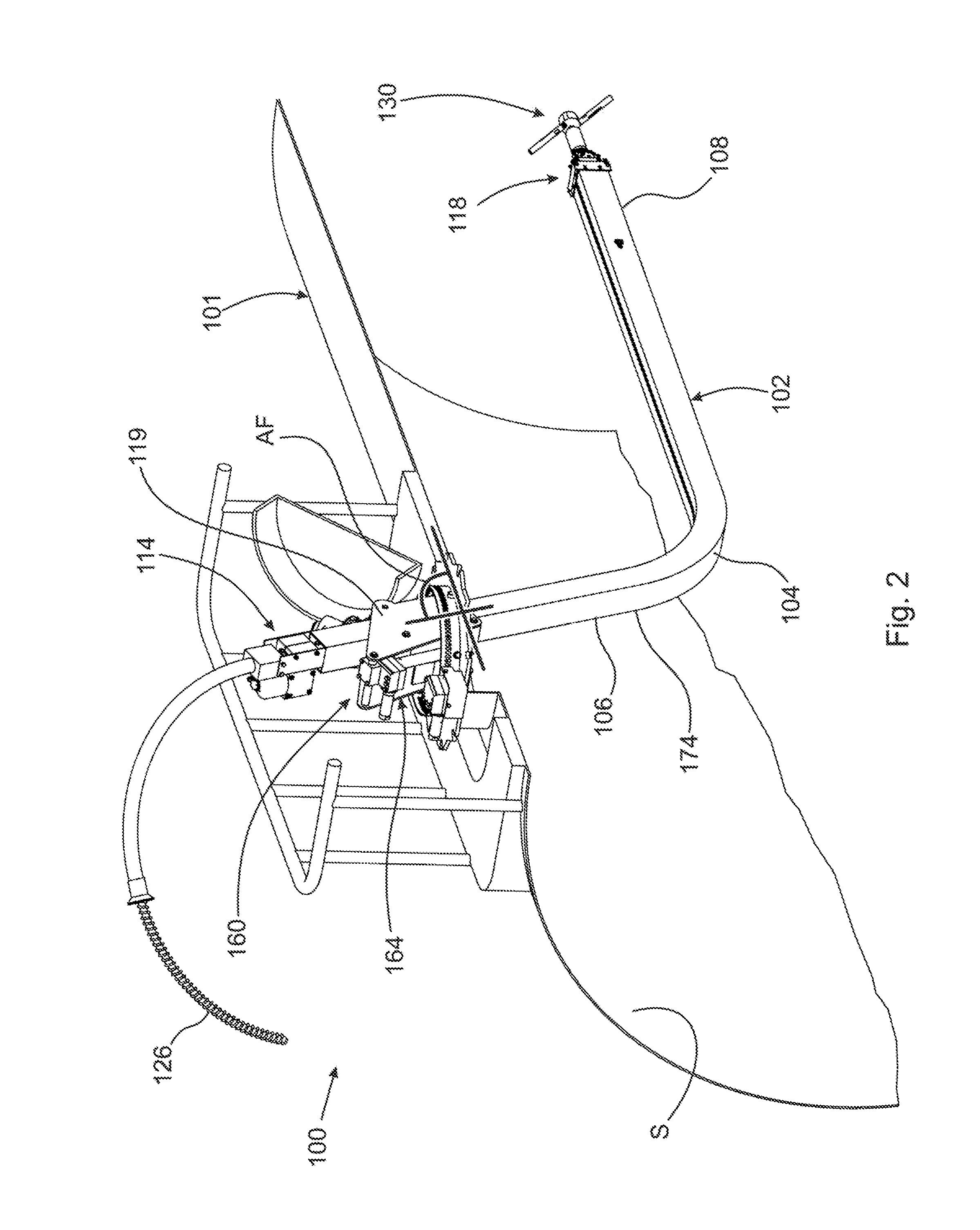

Apparatus for remotely operated fluid pumping in work spaces, particularly suitable for the cleaning of enclosed space tanks such as those on marine vessels. The apparatus comprises one or more arm assemblies, each made up of two or more arm sections each, with the arm assembly mounted within of the tank. Hydraulic rotary actuators disposed between the arm sections provide up to 360 degree rotation of one arm section with respect to the next. A nozzle is mounted on a pair of hydraulic rotary actuators near the end of the arm assembly distal from the mount, with a hose supplying fluid from a supply pump to the nozzle. Fluids and solids from the cleaning operation can be pumped from the area being cleaned via a discharge pump to a holding vessel, such as a disposal barge. A video camera is mounted so as to permit an operator to remotely view the cleaning process and area. A control panel is preferably remotely located where an operator can fully control the device with the assistance of the video camera, including fluid flow, position of the arm assembly, and direction of fluid flow from the nozzle.

Owner:BAKER HUGHES INC

Remotely operated cleaning device, especially suitable for storage tanks on vessels

InactiveUS20060054202A1Simple systemFold compactTank vesselsHollow article cleaningEngineeringRotary actuator

Apparatus for remotely operated fluid pumping in work spaces, particularly suitable for the cleaning of enclosed space tanks such as those on marine vessels. The apparatus comprises one or more arm assemblies, each made up of two or more arm sections each, with the arm assembly mounted within of the tank. Hydraulic rotary actuators disposed between the arm sections provide up to 360 degree rotation of one arm section with respect to the next. A nozzle is mounted on a pair of hydraulic rotary actuators near the end of the arm assembly distal from the mount, with a hose supplying fluid from a supply pump to the nozzle. Fluids and solids from the cleaning operation can be pumped from the area being cleaned via a discharge pump to a holding vessel, such as a disposal barge. A video camera is mounted on the arm assembly, preferably at the nozzle, to permit an operator to remotely view the cleaning process and area. A control panel is preferably remotely located where an operator can fully control the device with the assistance of the video camera, including fluid flow, position of the arm assembly, and direction of fluid flow from the nozzle.

Owner:BAKER HUGHES INC

Method and apparatus for cleaning tanks and other containers

InactiveUS20080047587A1Extended maintenance periodEasy to cleanTank vesselsHollow article cleaningClosed loopChemical addition

A closed-loop system for cleaning tanks and other enclosures utilizing adjustably mounted nozzles for spraying water, other wash fluid and / or beneficial chemical additive within the tanks or other enclosures to be cleaned. Effluent wash fluid leaving a tank is directed to a separator unit for separation of liquids and solids. Solids are disposed of or otherwise removed, while recovered liquids are directed for re-use. Exposure of personnel to the inside of such tanks or other enclosures to be cleaned is minimal.

Owner:BALL DAVID M

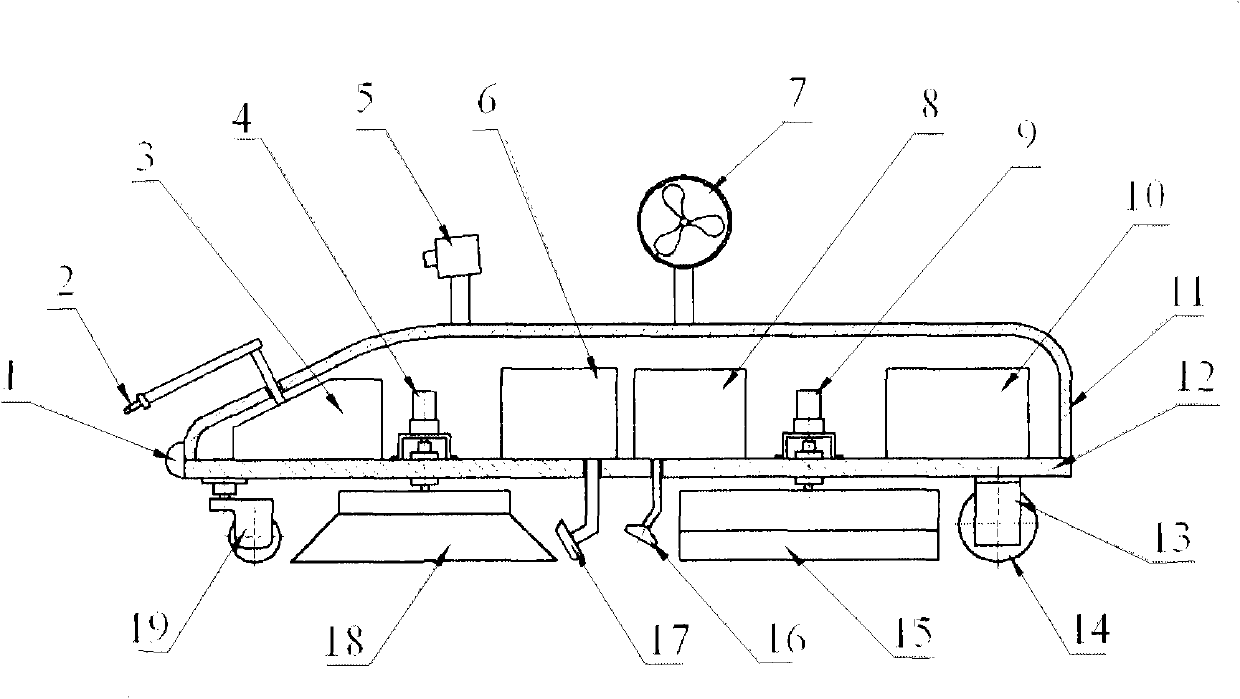

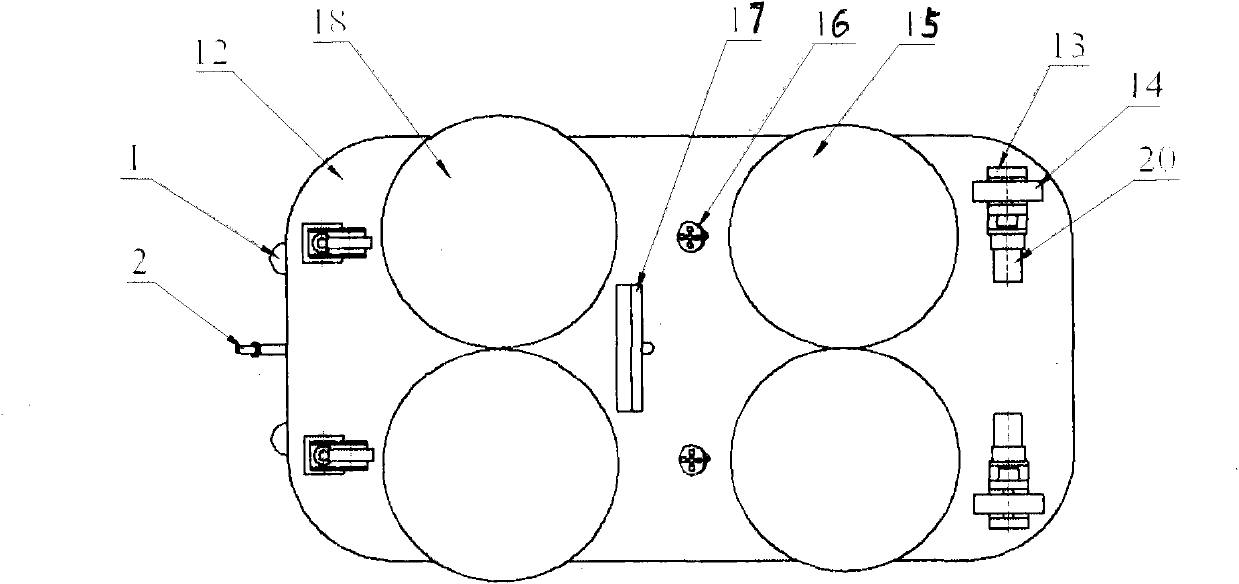

Cabin cleaning robot

InactiveCN102085907AWork reliablyStable structureTank vesselsCleaning using liquidsDrive wheelRemote control

The invention relates to a cabin cleaning robot. The front part of a shell is provided with an illuminating light and a high-pressure water gun; the top of the shell is provided with a camera and a fan; a water tank, a garbage temporary storage bin, a cleaning agent storage bin and a control cabinet are arranged in the shell, a dust collection head is arranged at the bottom of the robot and is connected with the garbage temporary storage bin, the cleaning agent storage bin is connected with a cleaning agent spray head, and all the control circuits of the robot are arranged in the control cabinet; the front part of a chassis is provided with a front cleaning brushing plate controlled by a front brushing plate motor; the halfway rear part of the chassis is provided with a rear cleaning brushing plate; a robot driving wheel is arranged on the chassis by virtue of a wheel frame, and the driving wheel is driven by a travelling motor; and the camera, the high-pressure water gun, the fan, the dust collection head, the travelling motor, the cleaning agent spray head, the front cleaning brushing plate and the rear cleaning brushing plate are respectively connected with a monitoring controller by virtue of circuits, and the monitoring controller is connected with a control room in a wireless communication mode by virtue of a radio wave. In the invention, remote control is adopted to control all the components of the robot.

Owner:WUXI VOCATIONAL & TECHN COLLEGE

Cargo venting system

Owner:SINGLE BUOY MOORINGS INC

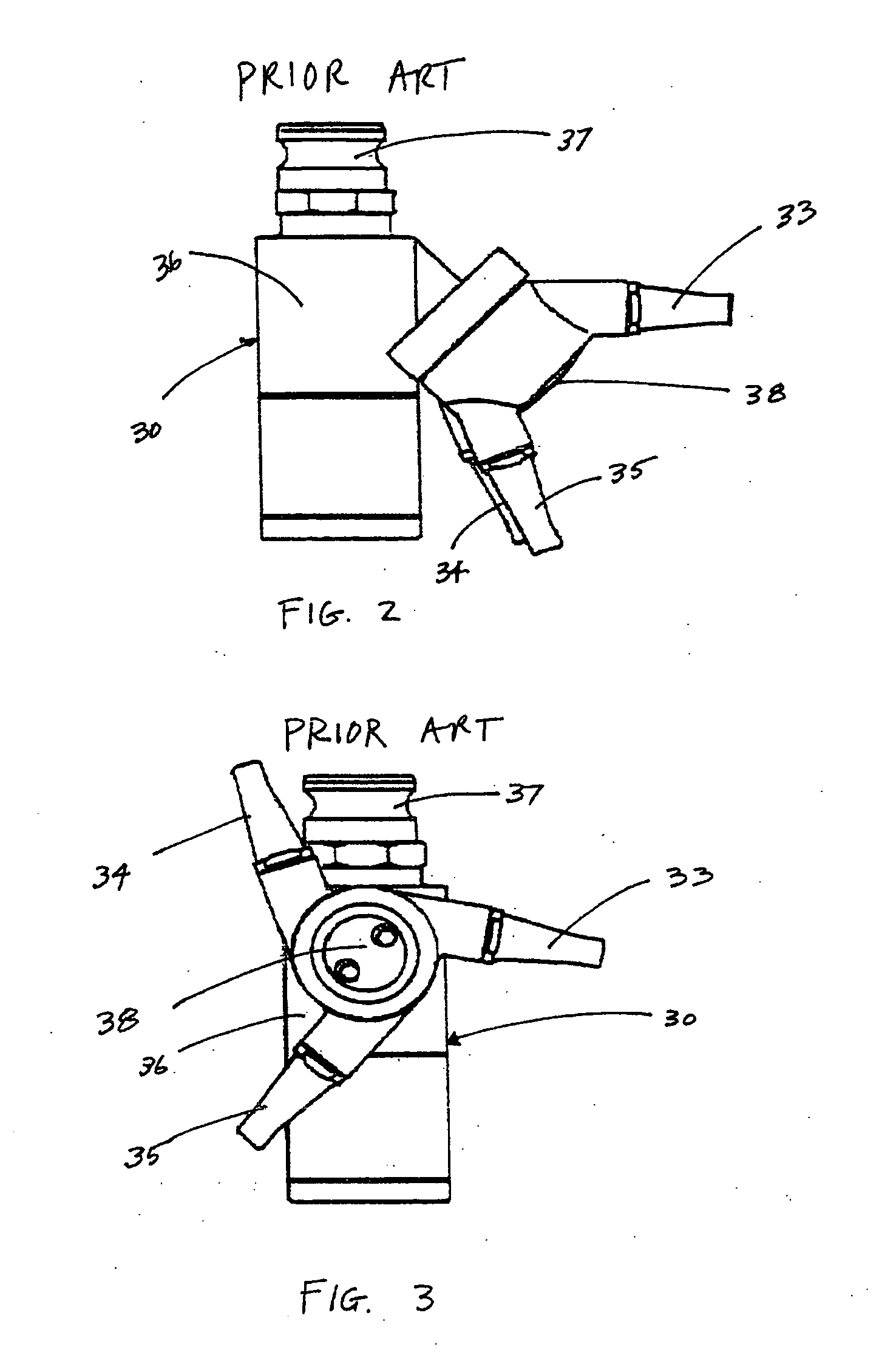

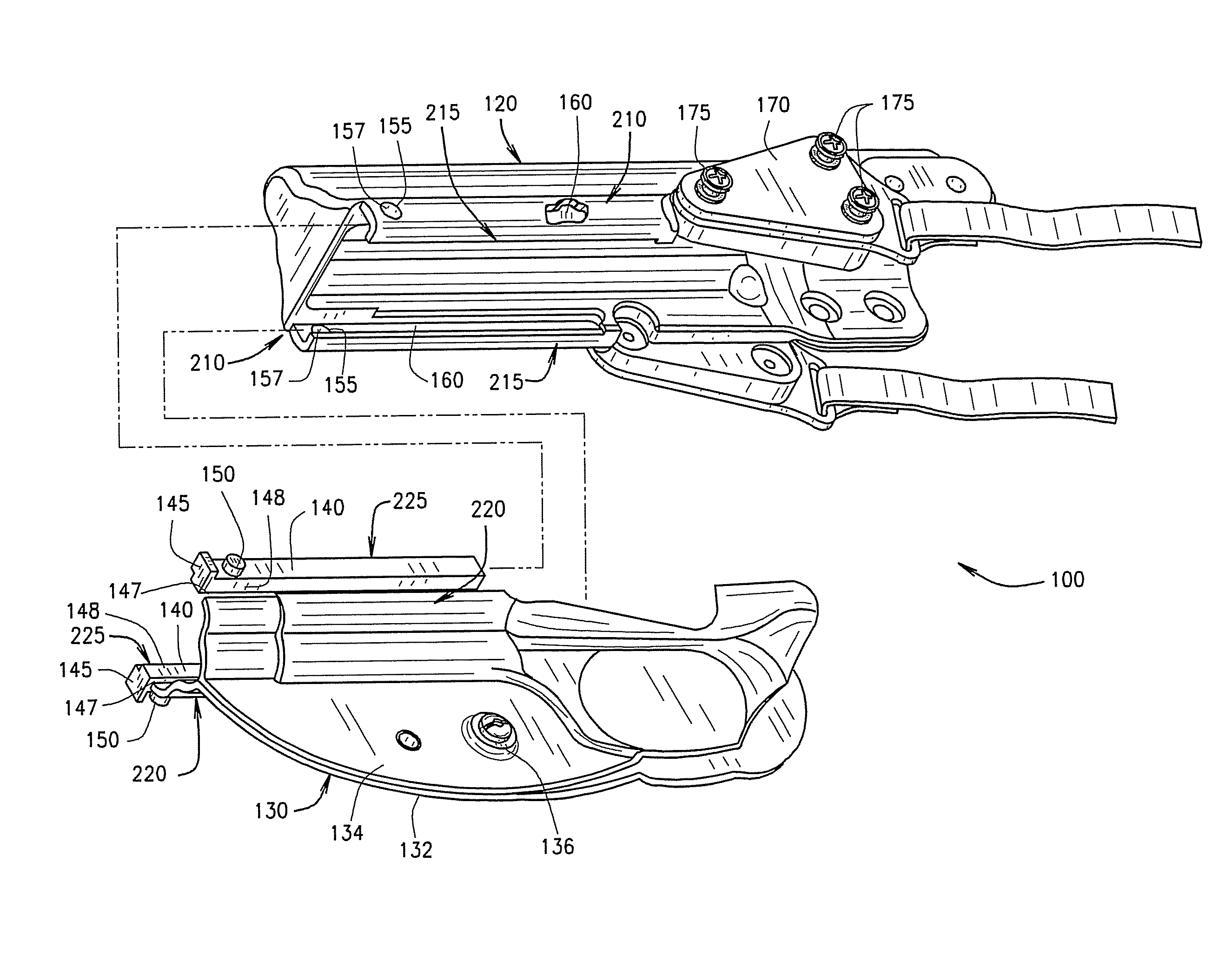

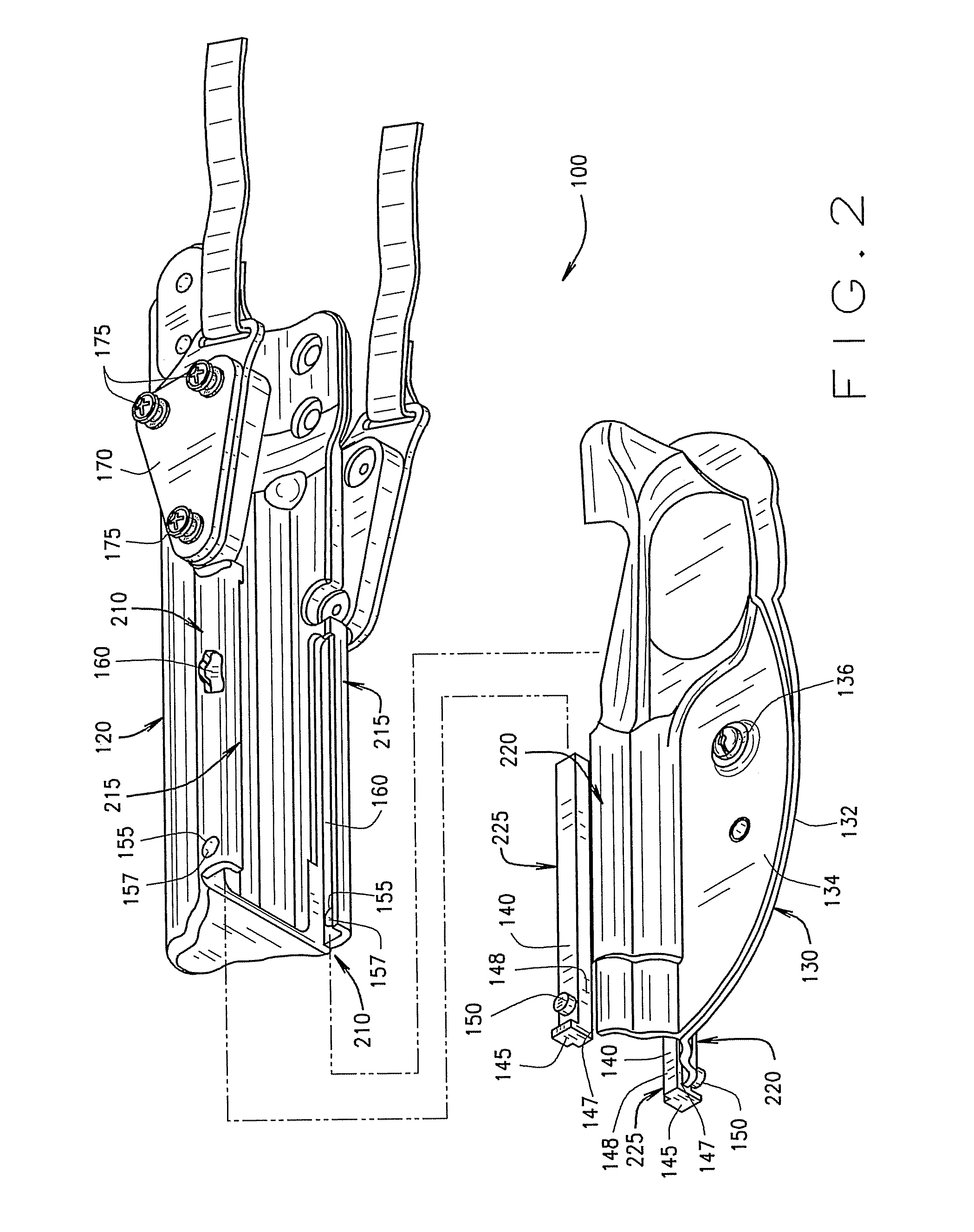

Holster with interchangeable cowlings

A holster with interchangeable cowling members for reconfiguring the holster pocket to accommodate pistols of varying sizes including pistols with add-on attachments including a frame member forming at least a first portion of a holster pocket, a cowling member cooperatively associated with the frame member forming a second portion of the holster pocket, at least one slide member associated with one of the frame member and cowling member, at least one groove associated with the other of the frame member and cowling member, the groove being adaptable to receive the slide member for selective longitudinal movement therealong, and a latch device having a first portion cooperating with the frame member and a second portion cooperating with the cowling member and operable to selectively prevent relative movement therebetween. The groove, slide member and latch device releasably mount the cowling member to the frame member.

Owner:EAGLE INDS UNLTD

Remotely operated cleaning device, especially suitable for storage tanks on vessels

Owner:BAKER HUGHES INC

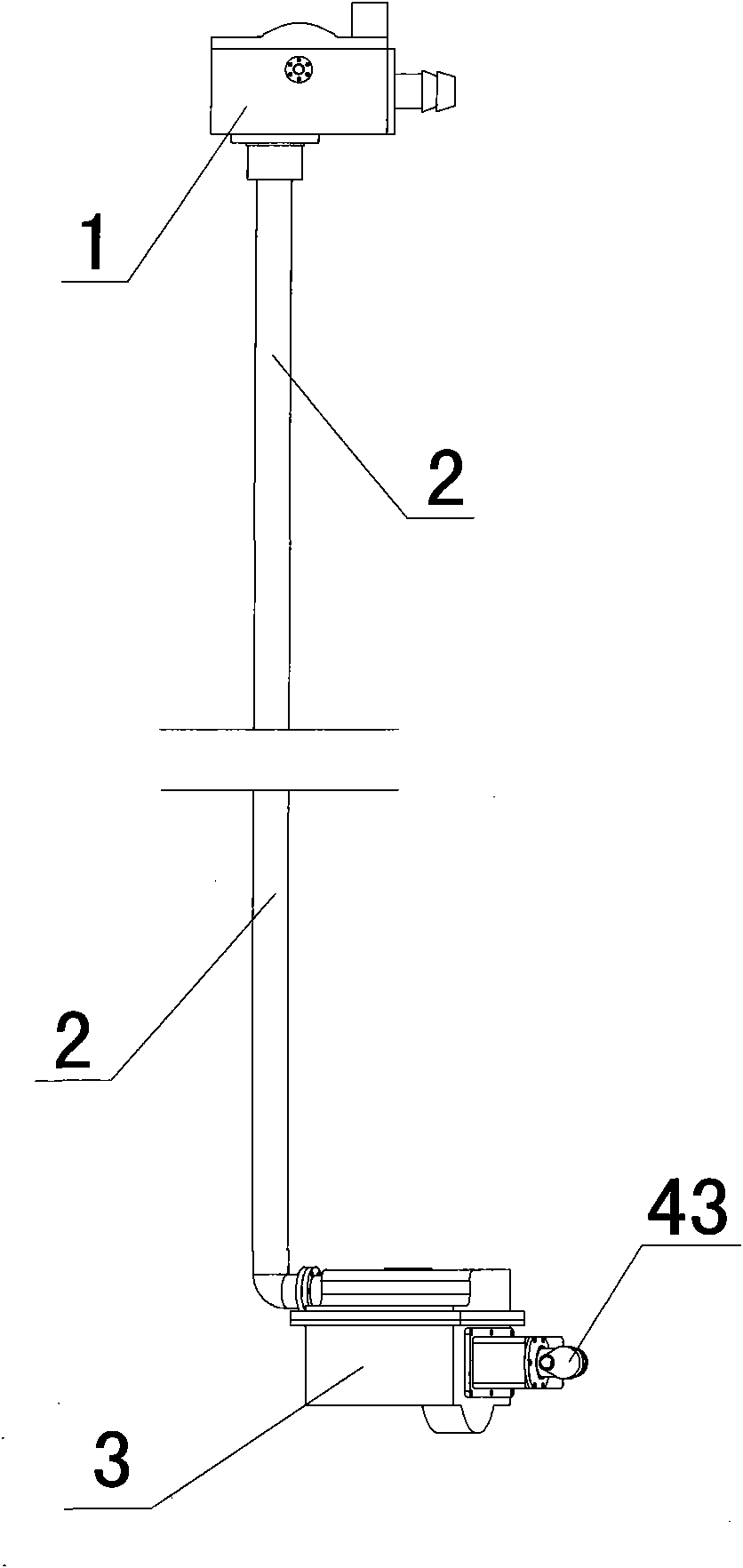

Fixed type crude oil washing machine

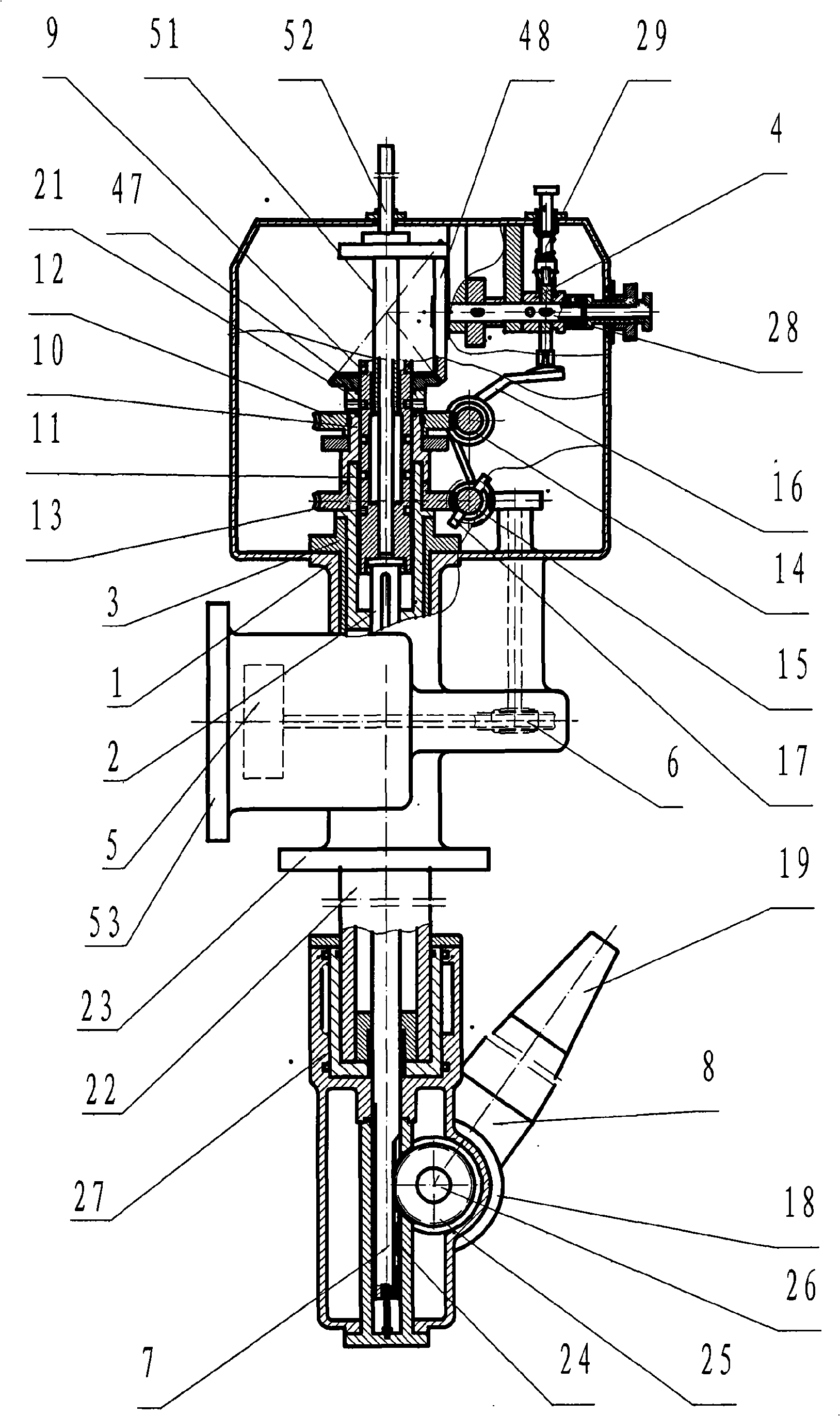

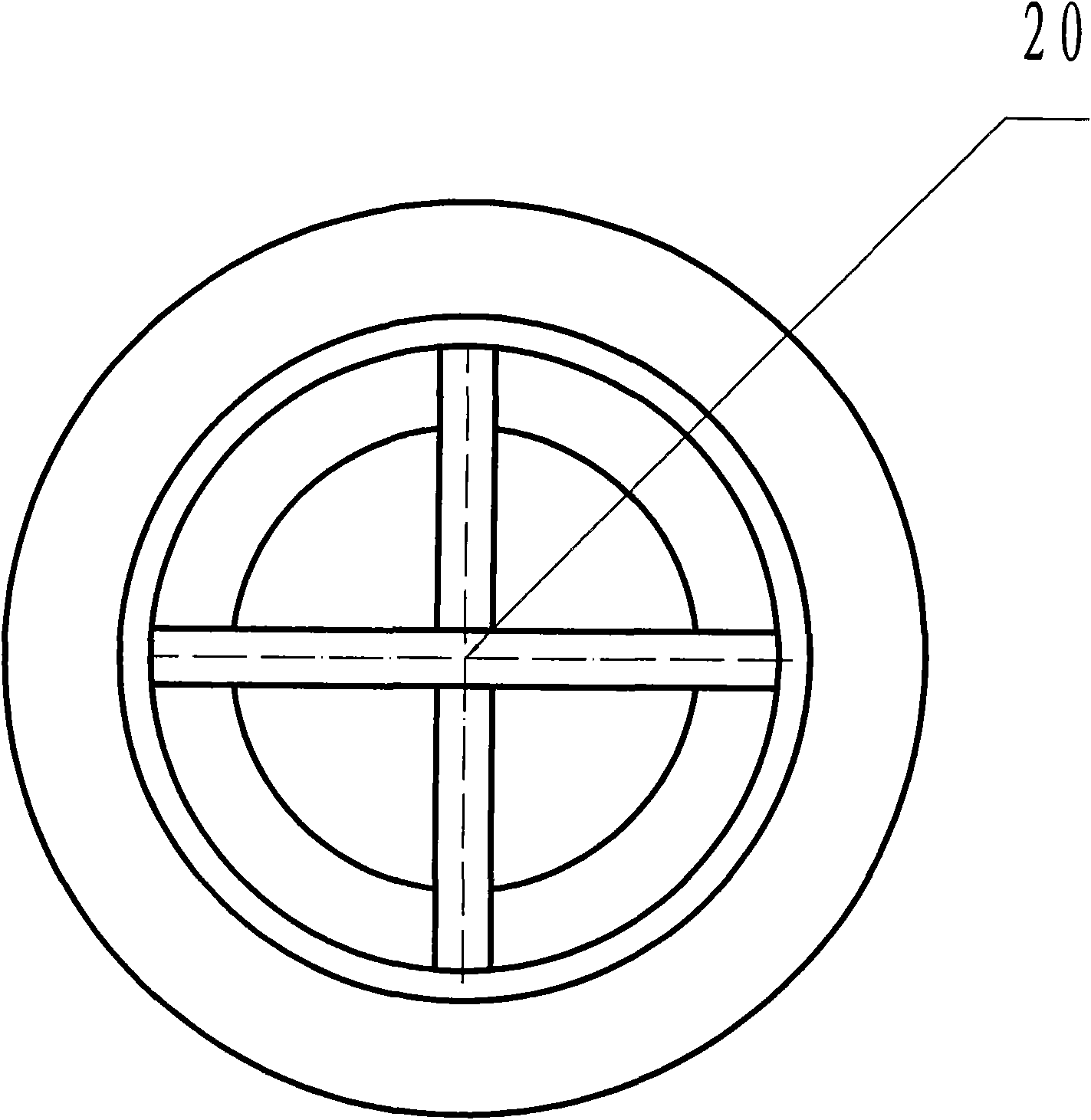

ActiveCN101565093AEnable mobilityThe rotation speed in the vertical direction is evenly adjustableTank vesselsTank cleaningImpellerHelical blade

The invention discloses a fixed type crude oil washing machine, which comprises a body, a main shaft arranged in the body, a main driving part of the main shaft, a control mechanism of the main shaft, an impeller, a driving part of the impeller, a nozzle connected with the main shaft through a driving device, wherein the main driving part of the main shaft comprises a double-ended reciprocating threaded bush sleeved on the main shaft, the upper half part of the double-ended reciprocating threaded bush is sleeved with a connecting sleeve, while the lower half part is sleeved with a horizontal rotating sleeve; the connecting sleeve is sleeved with an upper worm wheel and a nut block, the horizontal rotating sleeve is sleeved with a lower worm wheel, and the upper worm wheel and the lower worm wheel are meshed with an upper worm and a lower worm respectively; a driving shifting block of the lower worm is connected with a one-way driving deflector rod of the upper worm; a one-way driving speed regulation swing stem of the upper worm is connected with the control mechanism of the main shaft; a rack driving device at the utmost low end of the main shaft is connected with the nozzle; and the nozzle comprises a nozzle body, a nozzle head, and two pieces of cross bearing helical blades are arranged in an inner hole of the nozzle head. By adopting the double-ended reciprocating threaded sleeve and parallel double worms, the rotation and the up and down movement of the main shaft can be realized simply and conveniently; and because the nozzle adopts the two pieces of the cross bearing helical blades, a jetting liquid column is in a spiral line form, and the fixed type crude oil washing machine is favorable for enhancing the washing effect and protecting a ship plate.

Owner:HAIYING ENTERPRISE GROUP

Ballast tank circulation management system

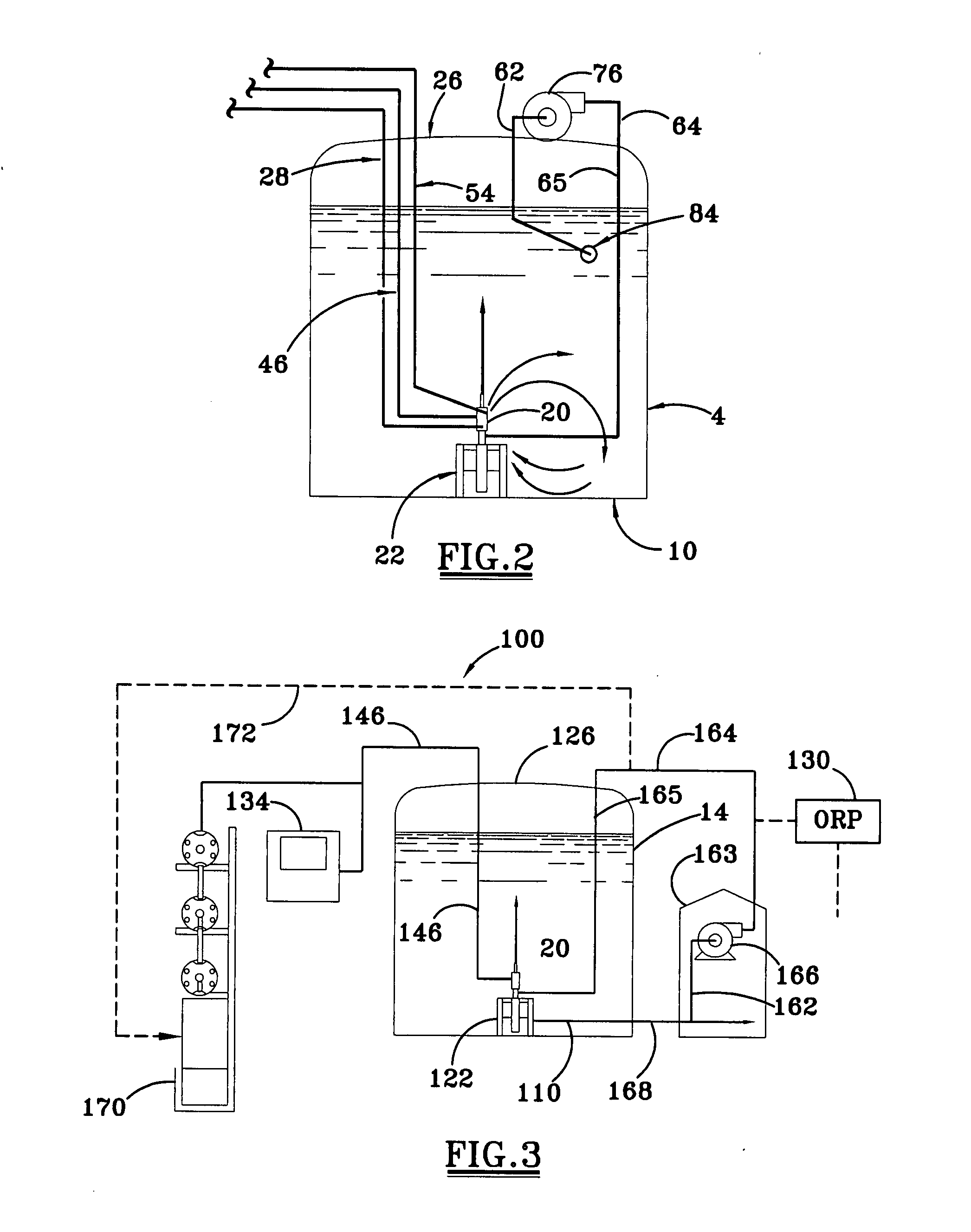

InactiveUS20080017586A1Maximize disinfectionEasy maintenanceAuxillariesIon-exchanger regenerationChemical compositionWater flow

A ballast tank circulation system having inlet and outlet piping and means for adding one or more halogens in controlled amounts to the water within the ballast tank. One or more eductors are positioned within the ballast tank to mix and circulate water within the ballast tank. A recirculating pump is located externally to the ballast tank to ingest water from the ballast tank and discharge a stream of pressurized water. The recirculating pump receives water from the ballast tank through an inlet line that taps into the outlet piping from the ballast tank. An outlet line transport the pressurized water to the ballast tank. The eductor draws in the pressurized water entering the ballast tank and emits a high pressure jet of water that circulates within the ballast tank thereby circulating the chemical content of the ballast water. Test streams of water from the ballast tank can be analyzed to determine the level of at least one of halogens in the test stream to provide a halogen content signal. A controller receives the signal and compares the signal to a set point indicative of the level of halogen desired within the ballast tank to maintain, increase, or decrease the amount of chemical added to the water within the ballast tank in controlled amounts.

Owner:SEVEN TRENT WATER PURIFICATION INC

Remotely operated cleaning device, especially suitable for storage tanks on vessels

Apparatus for remotely operated fluid pumping in work spaces, particularly suitable for the cleaning of enclosed space tanks such as those on marine vessels. The apparatus comprises one or more arm assemblies, each made up of two or more arm sections each, with the arm assembly mounted within of the tank. Hydraulic rotary actuators disposed between the arm sections provide up to 360 degree rotation of one arm section with respect to the next. A nozzle is mounted on a pair of hydraulic rotary actuators near the end of the arm assembly distal from the mount, with a hose supplying fluid from a supply pump to the nozzle. Fluids and solids from the cleaning operation can be pumped from the area being cleaned via a discharge pump to a holding vessel, such as a disposal barge. A video camera is mounted on the arm assembly, preferably at the nozzle, to permit an operator to remotely view the cleaning process and area. A control panel is preferably remotely located where an operator can fully control the device with the assistance of the video camera, including fluid flow, position of the arm assembly, and direction of fluid flow from the nozzle.

Owner:BAKER HUGHES INC

Cleaning equipment and use thereof

InactiveUS7507298B2Limited amountMountingTank vesselsHollow article cleaningMixed statesReady to use

By constructing tank cleaning equipment according to the invention such that it comprises a cleaning jetting part (7, 9) as well as a suction part (4), the equipment can work with the same cleaning medium which is recirculated. This saves supply of fresh cleaning medium, and since used medium is thus not discharged, it is not necessary to establish deposit facilities to avoid pollution. Furthermore, this equipment according to the invention may advantageously be used for keeping so-called drilling mud in a mixed and thus ready-to-use state, even when left to stand for an extended period of time in a tank. The nozzle jets (10) thus keep the mud in the tank in a constantly mixed state, and the mud can therefore be sucked through the suction pipe (20) for pumping in the drill pipe, it being ensured that the mud is homogeneous and has a suitable viscosity.

Owner:ALFA LAVAL TANK EQUIP

Robot for brushing ship body

ActiveCN102910269AAvoid negative effectsControl the direction of walkingTank vesselsTank cleaningAdhesion forceEngineering

The invention discloses a robot for brushing a ship body. The robot comprises a mounting plate; and the robot further comprises a travelling wheel mechanism, a cleaning brush and a rotary wing, wherein the rotary wing is driven by a rotating power device of the rotary wing, the travelling wheel mechanism and the cleaning brush are installed on the front side of the mounting plate, a rotary mechanism is installed on the back side of the mounting plate and comprises a rotating shaft and a rotating shaft power device, the rotating shaft is driven by the power device of the power device, the rotary wing is fixedly connected with the rotating shaft and swings along with the rotation of the rotating shaft. The rotating power device of the rotary wing drives the rotary wing to rotate, so that the robot for brushing the ship body can be adhered to the surface of the ship body, the adhesion force is strong, and the robot not only is applicable to the ship bodies with thick shellfish attachment, but also effectively overcomes the adverse impacts of magnetic adsorption on the ship bodies; and the rotary wing swings along with the rotation of the rotating shaft, so that the travelling direction of the robot for brushing the ship body is controlled through adjusting the rotation direction of the rotary wing which rotates along with the rotating shaft.

Owner:海南斑斓海洋科技有限公司

Air recirculation system for stationary store rooms and for cargo spaces of refrigeration ships with high-bay racks

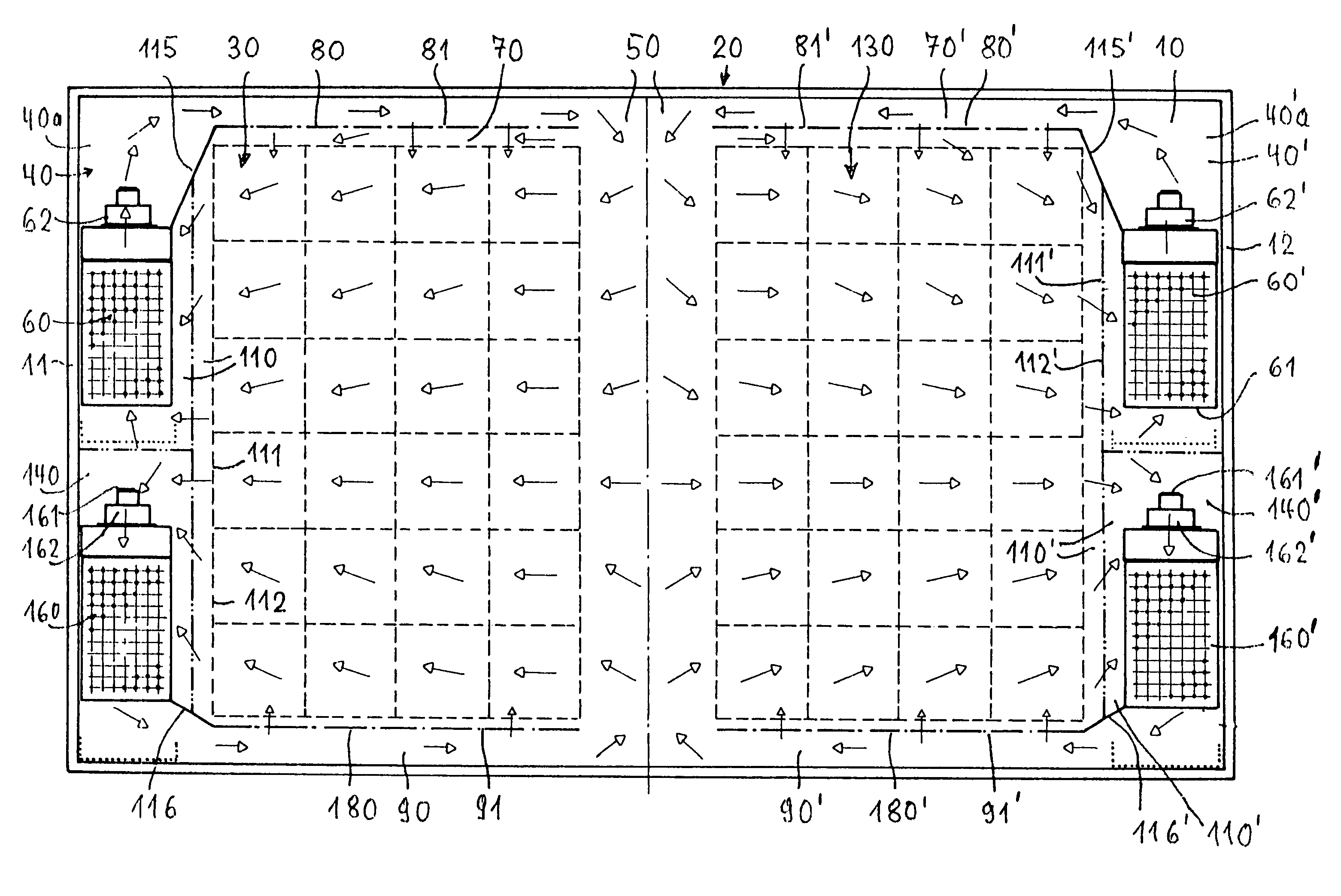

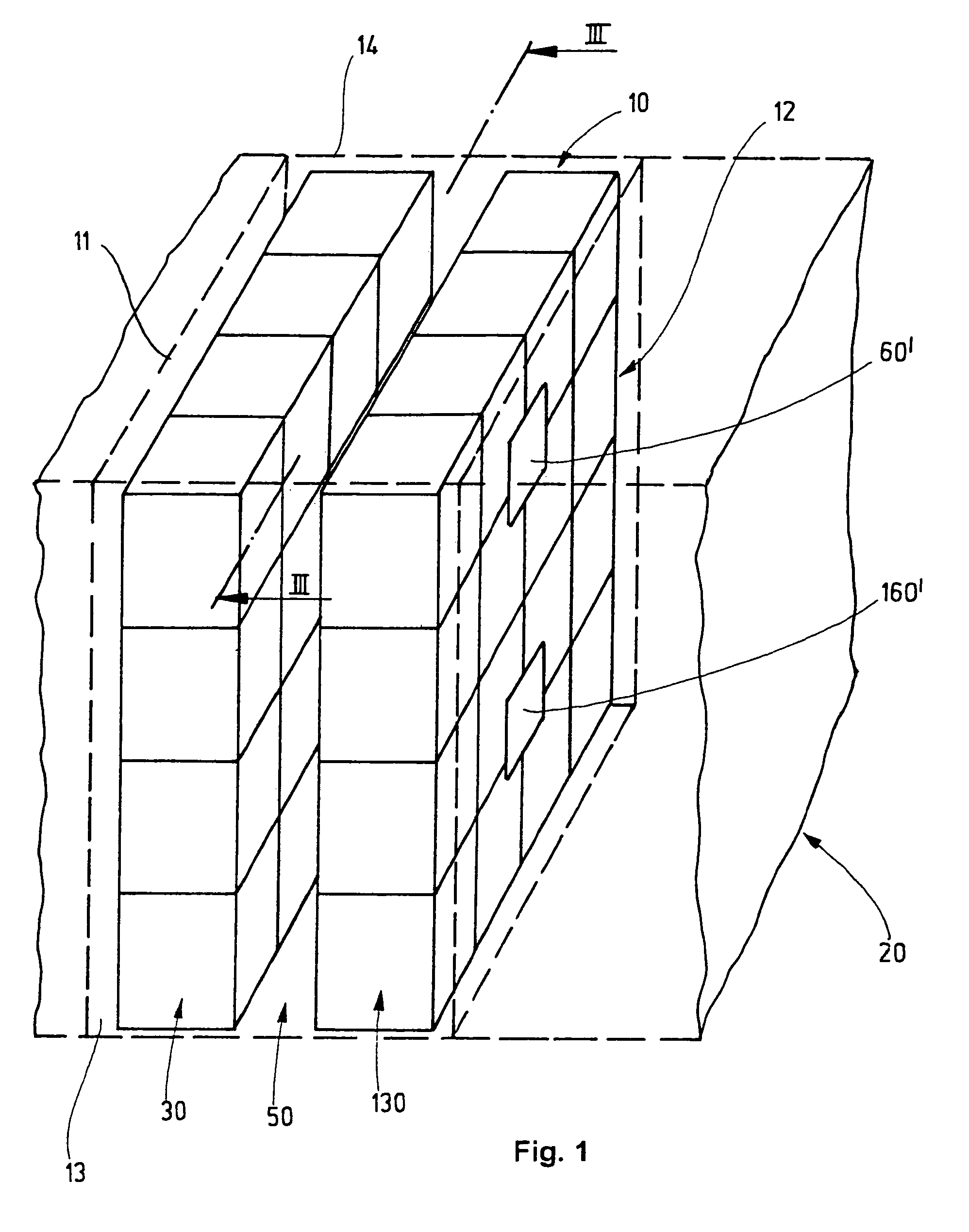

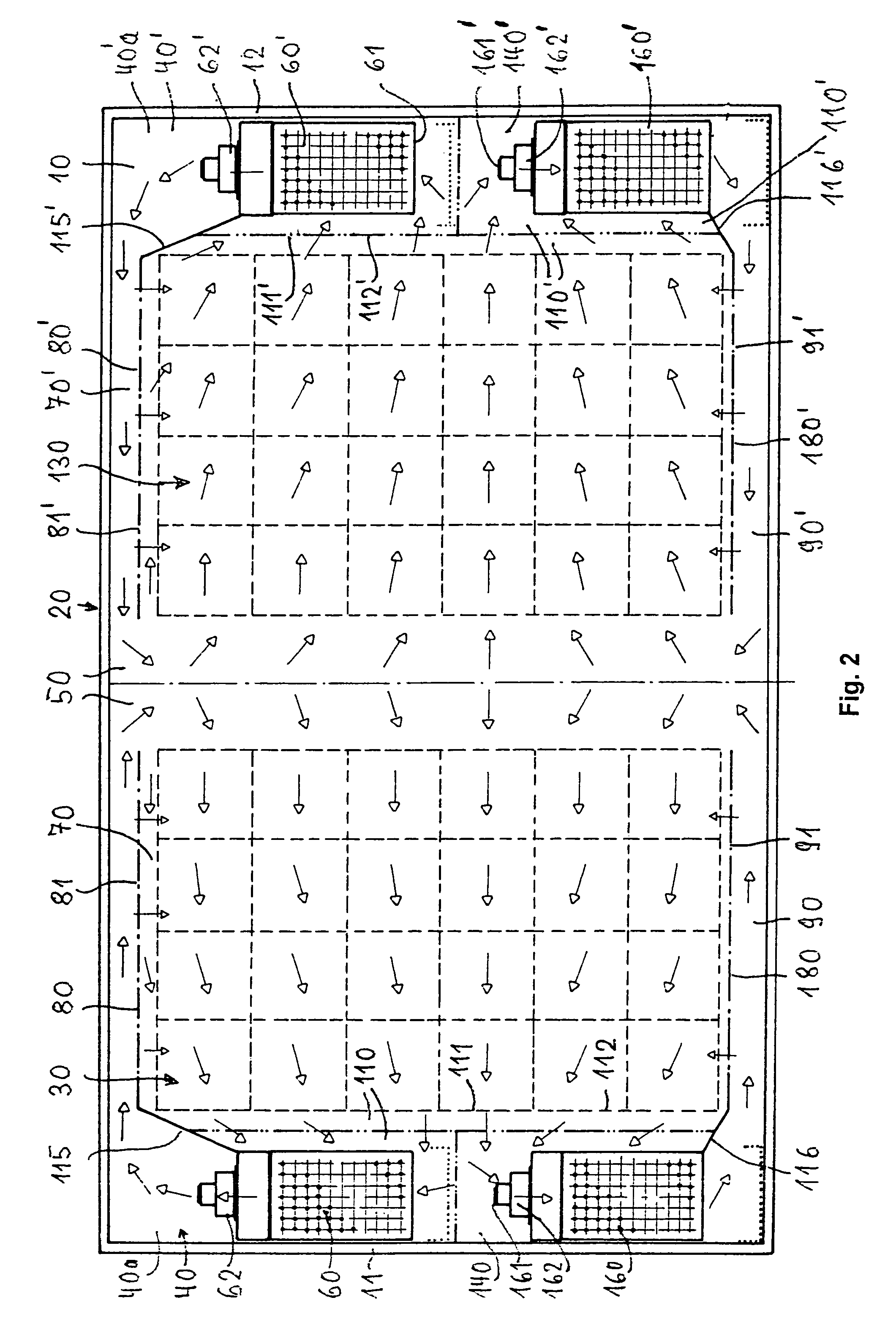

In order to flush with cooling air the goods stacked or palletized in a high-bay rack placed in a stationary store room or in the cargo space of a refrigeration ship by maintaining a constant cooling temperature in all the layers, an air recirculation system is proposed for which two superimposed air circuits (40, 140; 40′, 140′) are configured in the area of every rack module (30; 130), whereby at least one rack module, preferably two rack modules (30; 130), are placed in the cargo space and whereby a shaft (50) for the rack stacker is assigned to each rack module (30; 130) or a shaft (50) for the rack stacker is placed between the two rack modules (30; 130) placed the one besides the other, whereby the shaft (50) serves a common pressure distribution chamber of the inlet air for each rack module (30; 130).

Owner:BECKER MARINE SYST

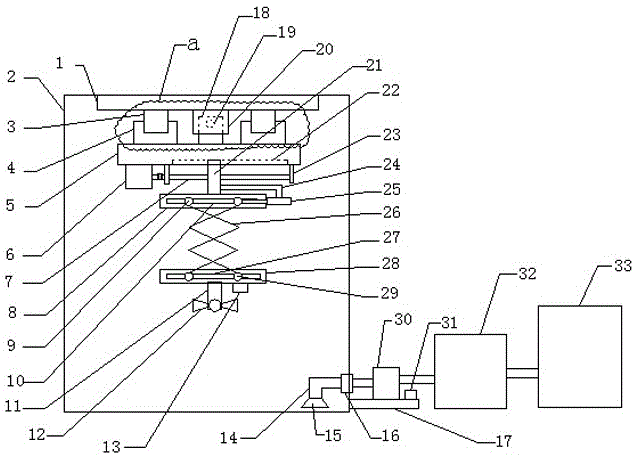

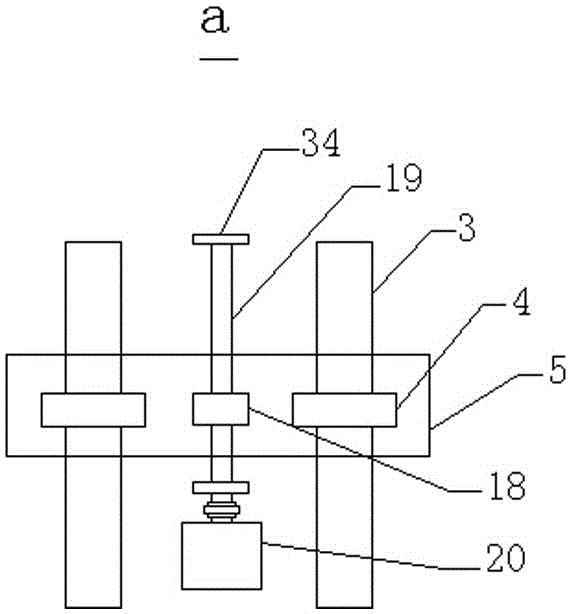

Cabin water-washing device for 8200T chemical/product oil tanker

InactiveCN105059496AExpand the scope of cleaningAdjust cleaning heightTank vesselsTank cleaningWater storage tankSewage

The invention provides a cabin water-washing device for a 8200T chemical / product oil tanker, which belongs to the technical field of ship assignment. The cabin water-washing device comprises a top plate, a cabin, a sliding rail, a sliding block, a cross plate, a first motor, a first screw, a first support plate, a first pin shaft, a first hollow-out part, a bracket, a water washing machine, an inert gas blowout device, a supporting pipe, a suction head, a pipeline joint, a stand, a second nut, a second screw, a second motor, a first nut, a slide way, a first bearing frame, a supporting frame, a cylinder, a shears-fork arm, a second hollow-out part, a second support plate, a second pin shaft, a water suction pump, a controller, a sewage purifying device, a water storage tank and a second bearing frame, wherein the pipeline joint is mounted on the right side wall of the cabin; the supporting pipe is mounted at the left end of the pipeline joint; the suction head is mounted under the supporting pipe; and the right end of the pipeline joint is connected with the water suction pump through a pipeline. The cabin water-washing device for the 8200T chemical / product oil tanker, provided by the invention, has the advantages of convenience in operation and high safety factor.

Owner:YANGFAN GROUP

Fixed type crude oil cabin washing machine

ActiveCN101590902AEvenly adjustable vertical rotation speedControllable vertical rotation speedTank vesselsTank cleaningImpellerEngineering

The invention discloses a fixed type crude oil cabin washing machine which comprises a body, a mainshaft arranged inside the body, a main drive part of the mainshaft, a control mechanism of the mainshaft, an impeller, an impeller drive part and a nozzle connected with the mainshaft through a drive device; the control mechanism comprises a control shaft, a speed regulation lever and a nozzle stalling control lever; the control shaft and a vertical shaft of the nozzle have synchronous rotating angles; the control shaft is provided with an automatic speed regulation cam and a stalling cam; one end of the speed regulation lever is contacted with the automatic speed regulation cam; the other end of the speed regulation lever is contacted with a manual speed regulation cam; the middle part of the speed regulation lever is contacted with a speed regulation swing rod; a limit sleeve is sleeved on the nozzle stalling control lever of the control mechanism; the inside of the limit sleeve is provided with a spring; the limit sleeve is connected with the stalling cam through a rotary supporting; the lower end of the nozzle stalling control lever is contacted with a middle supporting shaft of the speed regulation lever; one end of the nozzle stalling control lever of the control mechanism far from the speed regulation lever is provided with a pull rod positioning sleeve; the inside of the pull rod positioning sleeve is provided with at least two slots with different lengths; and the nozzle stalling control lever is provided with a small positioning key block which is inserted into the slot of the pull rod positioning sleeve. An effective oscillation angle value of the speed regulation swing rod can be adjusted through the speed regulation lever to allow the nozzle of the cabin washing machine to have an even and controllable vertical rotational speed.

Owner:HAIYING ENTERPRISE GROUP

Sand discharge device and sand discharge method for ballast tank

A sand discharge device, which discharges mud and sand deposited in ballast tanks (2) comprising multiple tank compartments (5) in a ship (1) equipped with a port-side water injection / drainage pump (21) and a starboard-side water injection / drainage pump (11), which inject water into and drain water from the ballast tanks (2), wherein this sand discharge device is equipped with: nozzles (19) which are provided near the tank floor plate (8) of the tank compartments (5), and which spray water; a water feed pipeline (13) that feeds water to the nozzles (19); a water discharge pipeline (22) that discharges from the ballast tanks (2) muddy water in which mud and sand that has been washed away by the water sprayed from the nozzles (19) has been dispersed and suspended; and a water feed / discharge control means (100) which, when mud and sand is discharged from the port-side ballast tanks (2), opens / closes a valve in the water feed pipeline (13) and operates the starboard-side water injection / drainage pump (11) so as to feed water into the port-side water feed pipeline (13) from the starboard-side water injection / drainage pump (11), and opens / closes a valve in the water discharge pipeline (22) and operates the port-side water injection / drainage pump (21) so as to discharge muddy water from the port-side water discharge pipeline (22) by means of the port-side water injection / drainage pump (21). Thus, the mud and sand accumulated in the ballast tanks (2) can be discharged efficiently.

Owner:JFEENG CORP +1

Sludge removing structure in large ship ballast water tank

ActiveCN101954963AEfficient removalReduce labor intensityTank vesselsTank cleaningSludgeMarine engineering

The invention discloses a sludge removing structure in a large ship ballast water tank, comprising a ship bottom plate, rib plates, longitudinal keels and water flowing holes, wherein a plurality of rib plates are arranged in parallel on the ship bottom plate at equal intervals along the width direction of the ship; a plurality of longitudinal keels are arranged in parallel between adjacent rib plates at equal intervals along the length direction of the ship; and the longitudinal keels are provided with a plurality of water flowing holes at equal intervals, and the water flowing holes on the adjacent longitudinal keels are staggered, i.e. the water flowing holes on adjacent longitudinal keels are not on the same cross section. The invention effectively clears sludge accumulated in a ballast tank, lightens the labor intensity of clearing the sludge of crews and improves the economic benefit of ship operation.

Owner:NANTONG COSCO KHI SHIP ENG

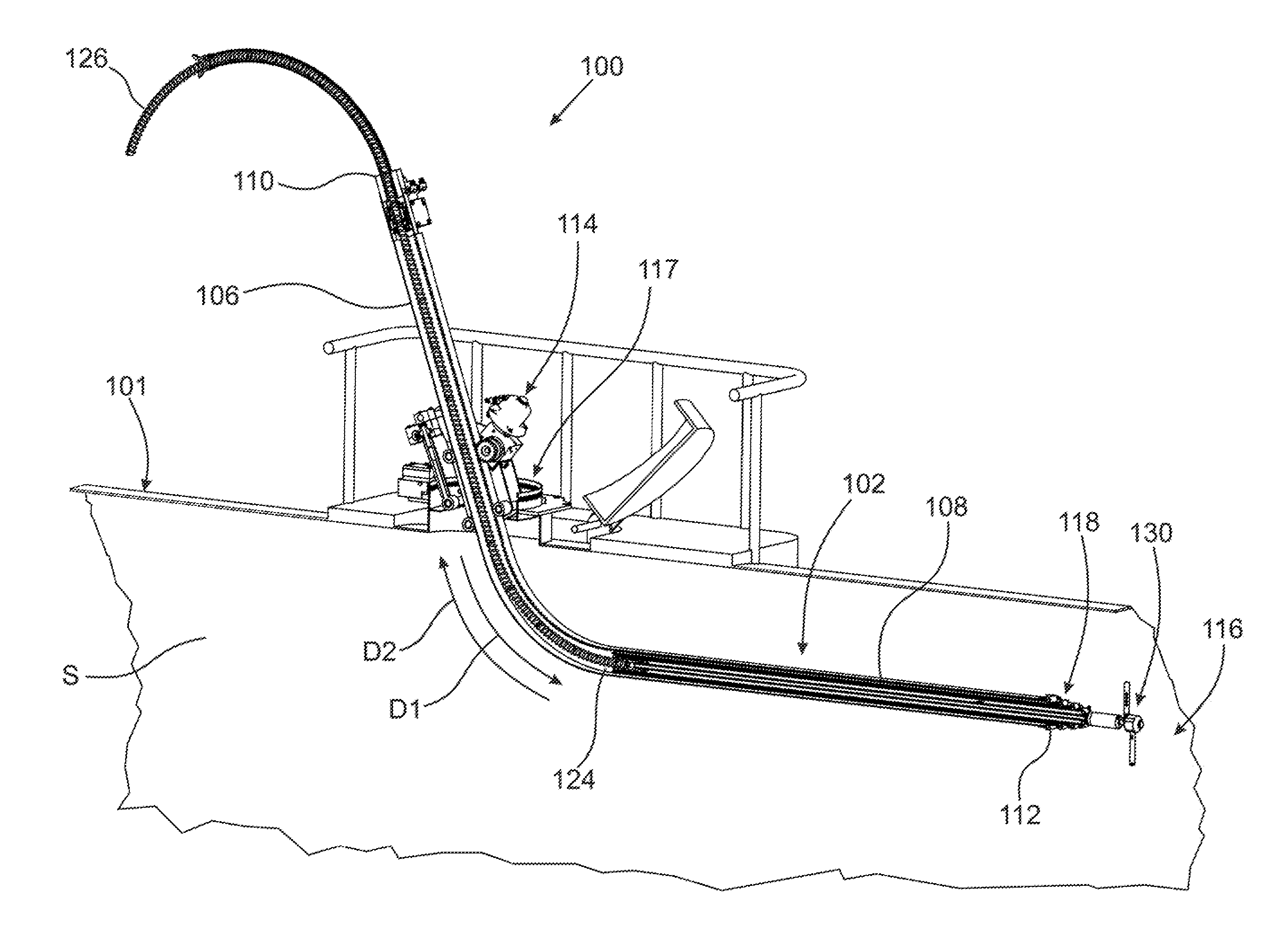

Apparatus for insertion in a tank and method thereof

An apparatus for insertion in an enclosed space, including: a tube with: first and second substantially straight portions including first and second ends of the tube, respectively; and a curved portion connecting the first and second portions. The apparatus includes: a plurality of nested segments at least partially disposed within the first substantially straight portion of the tube and connected to the first substantially straight portion; and a first actuator engageable with the tube to displace the first and second substantially straight portions of the tube into and out of the enclosed space through an opening into the enclosed space. The tube is arranged to accept a hose passing through the tube, and a distal segment from the plurality of nested segments is connectable to the hose.

Owner:STONEAGE

Fully automatic tank washing machine

ActiveCN101948003ASuitable for cleaningExtended service lifeTank vesselsTank cleaningWater flowFully automatic

The invention relates to a cleaning device, in particular to a fully automatic tank washing machine for the ship. The tank washing machine comprises an upper water inlet base, a main water pipe, a lower water inlet base and a nozzle, wherein the inside of the upper water inlet base is provided with a rotating mechanism; the inside of the lower water inlet base is provided with a swinging mechanism; one end of the main water pipe is connected with the rotating mechanism, the other end is fixedly connected with a water inlet on the lower water inlet base; the nozzle is connected with the swinging mechanism; another water inlet is arranged on the upper water inlet base and the water current which flows in the upper water inlet base through the water inlet can drive the rotating mechanism to move, thus the main water pipe can be used to drive the lower water inlet base to rotate; and the water current which flows in the upper water inlet base can flow into the lower water inlet base through the main water pipe and drive the swinging mechanism to move and drive the nozzle to swing and spray water. In the entire cleaning process adopting the fully automatic tank washing machine, the only power is the pressurized water and the entire moving process is completed in the mechanical mode, thus the tank washing machine is particularly suitable to clean the oil tanker.

Owner:常熟紫金知识产权服务有限公司

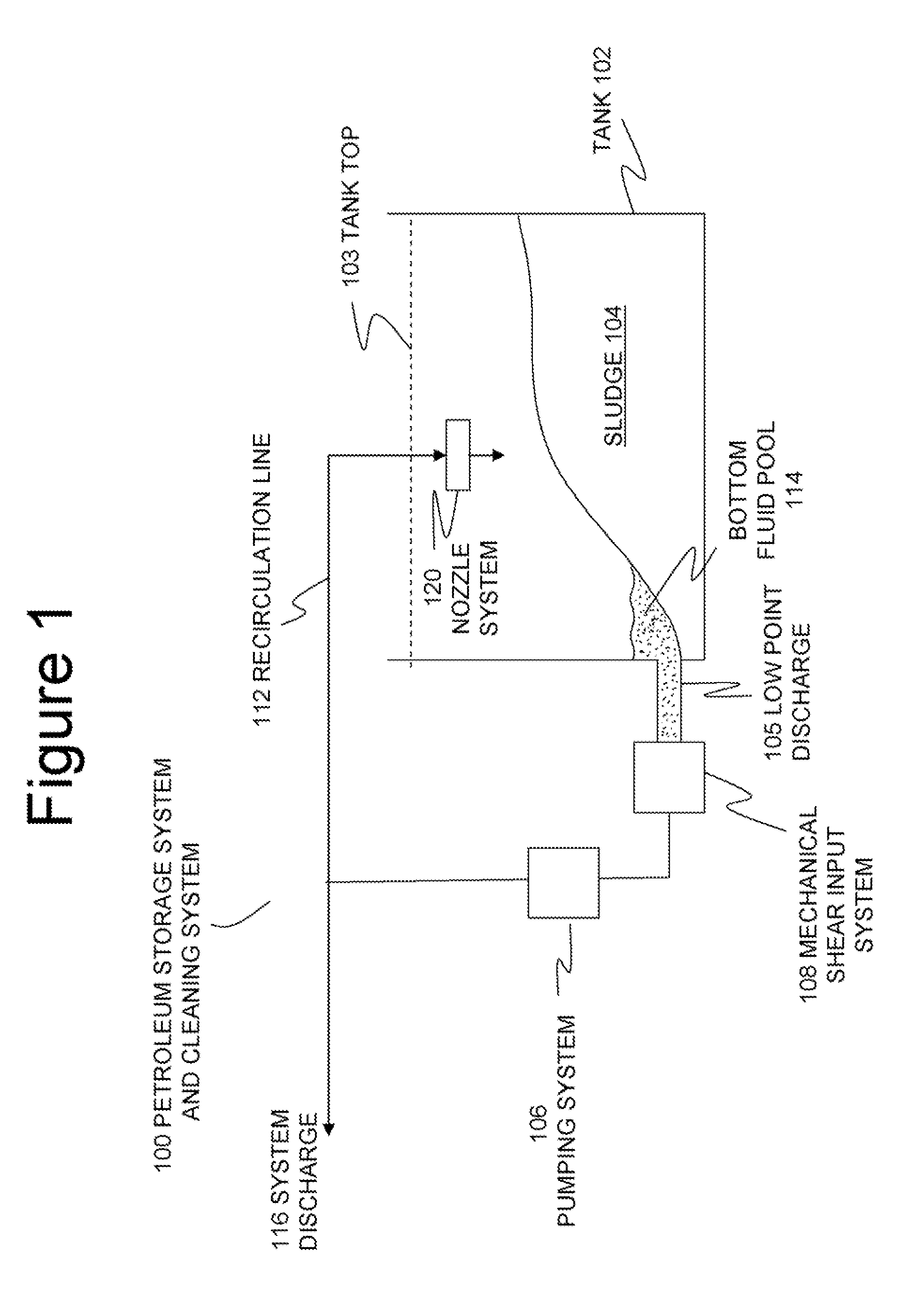

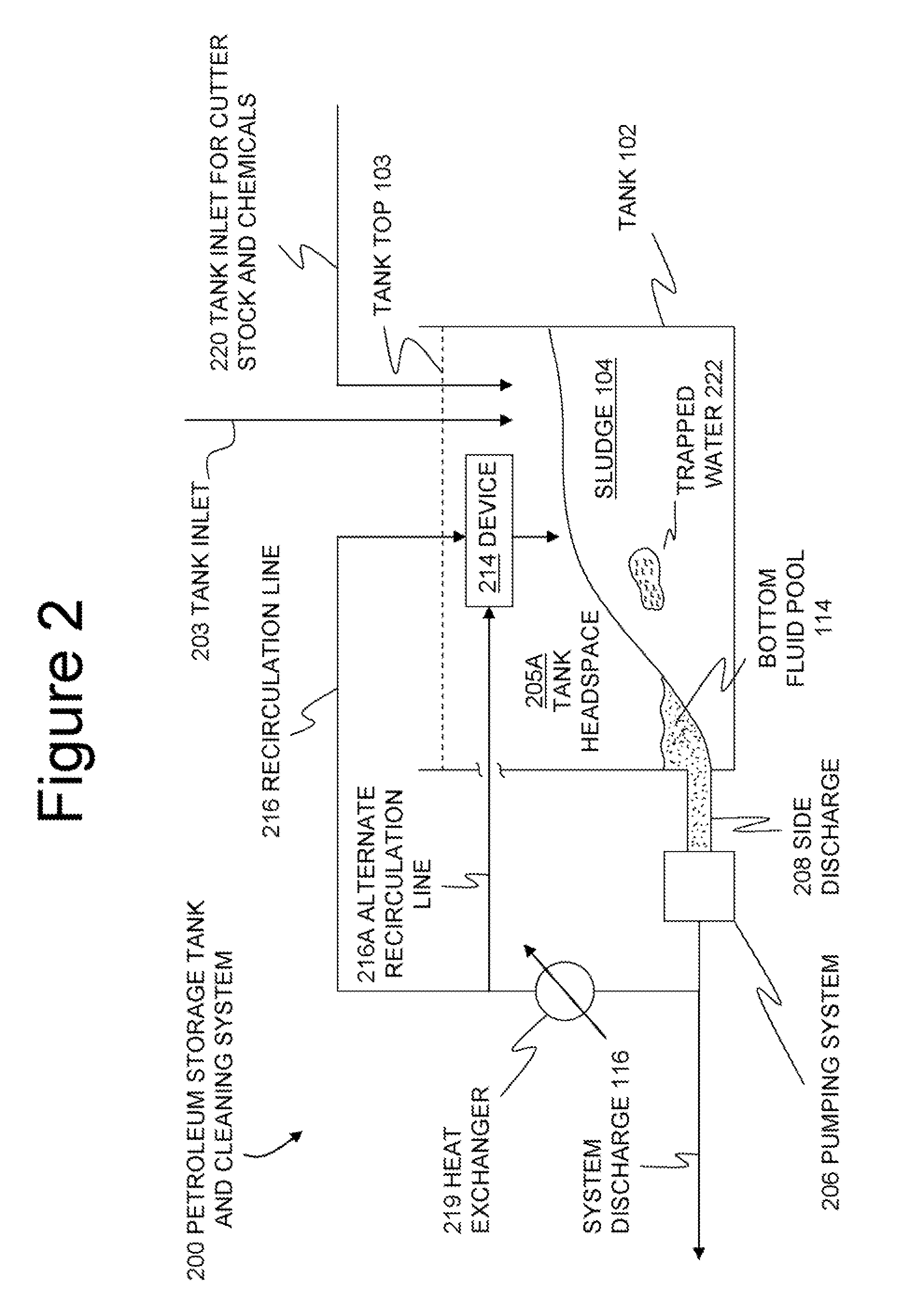

Hydrocarbon Tank Cleaning Systems

InactiveUS20080023050A1Increase vapor pressureSoften sludgeTank vesselsHollow article cleaningSludgeSlurry

Systems for cleaning sludge from a large tank. The sludge from the interior of storage tanks is mobilized using a metered flow agent stream and then subjected to a mechanical comminution or high shear action, e.g. by grinding or chopping. This produces a pumpable slurry which is then recirculated back into the tank to further mobilize sludge.

Owner:JR & JH HLDG

Ballast tank circulation management system

ActiveCN101715431AIncrease or decrease contentTank vesselsWater treatment parameter controlWater flowHigh pressure

Owner:迪诺拉海洋技术有限责任公司

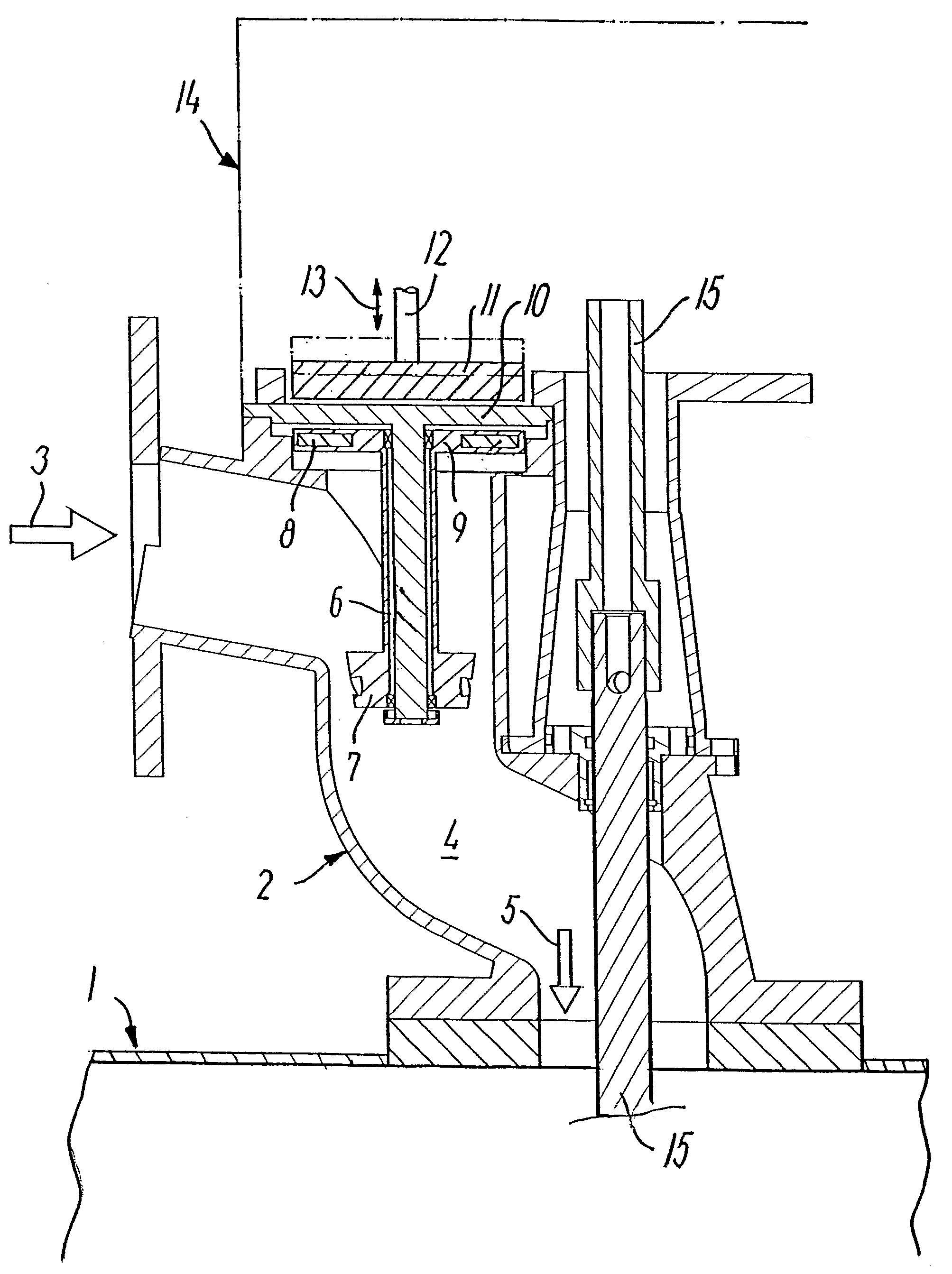

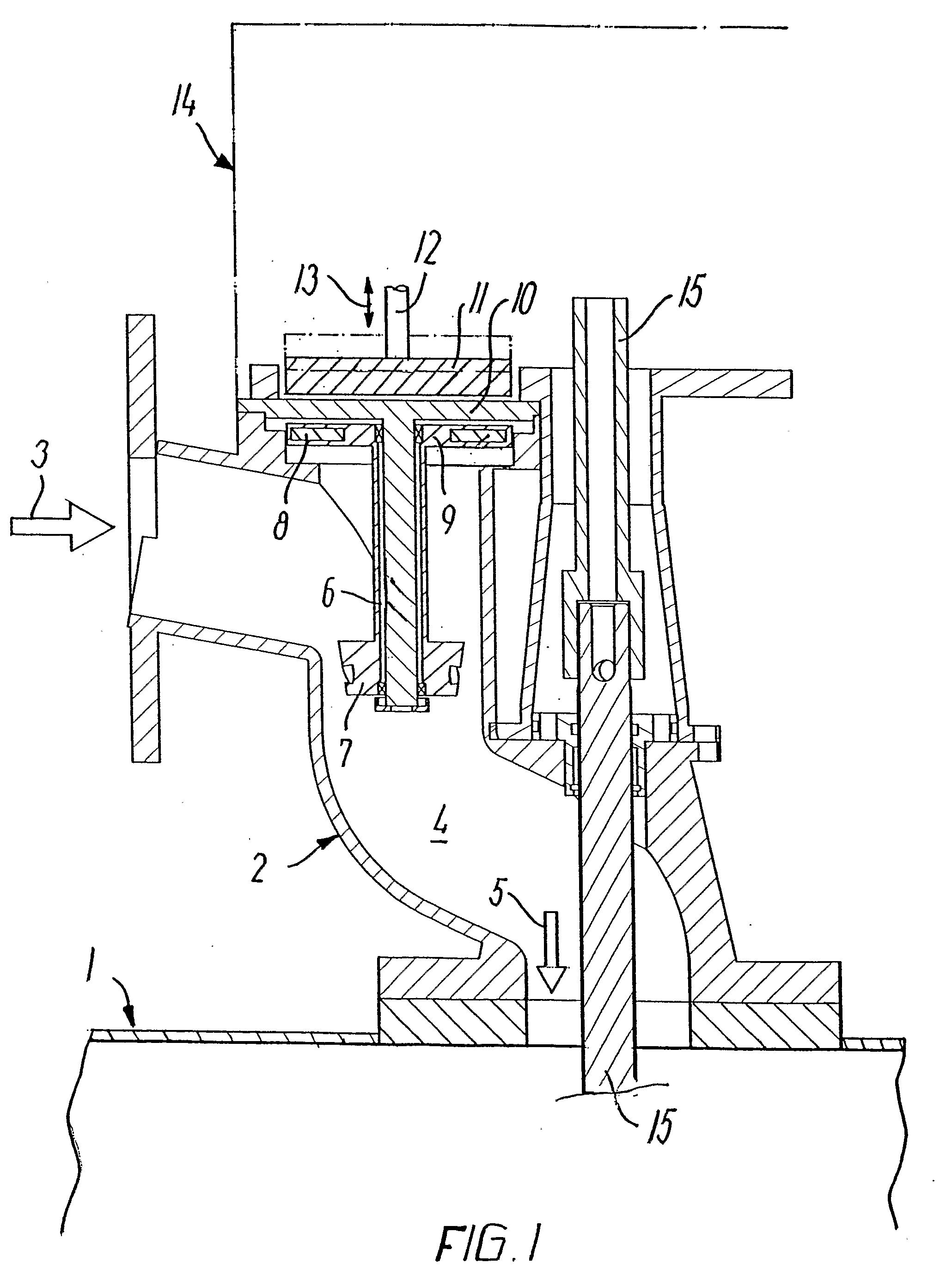

Device for interior flushing of tanks or containers

InactiveUS7713359B2Cheap and energy saving and reliable arrangementCheap, energy saving and reliable arrangementTank vesselsMovable spraying apparatusEngineeringInjector

The present invention relates to a device for interior flushing of spaces in tanks or containers. At least one rotatable part (8) of a pipe (6, 8, 11) for the supply of flushing liquid (7) is provided in the space (2) and said rotatable part (8) has at least one flushing nozzle (9) for discharging jets (10) of flushing liquid. A driving or operating device (22) is provided to rotate said rotatable part (8) about a geometric rotation axis (R1A) and the flushing nozzle (9) about another geometric rotation axis (R2A). The driving device (22) is provided to be brought to rotate in opposite rotary directions (R1, R2) by reversing its rotary direction. A switch device (23) is provided to bring either said rotatable part (8) or the flushing nozzle (9) to rotate in dependence of the rotary direction (R1 or R2) of the driving device (22). A control device (48) is provided to control the driving device (22) to rotate in one or the opposite rotary direction (R1 or R2).

Owner:SCANJET MARINE AB

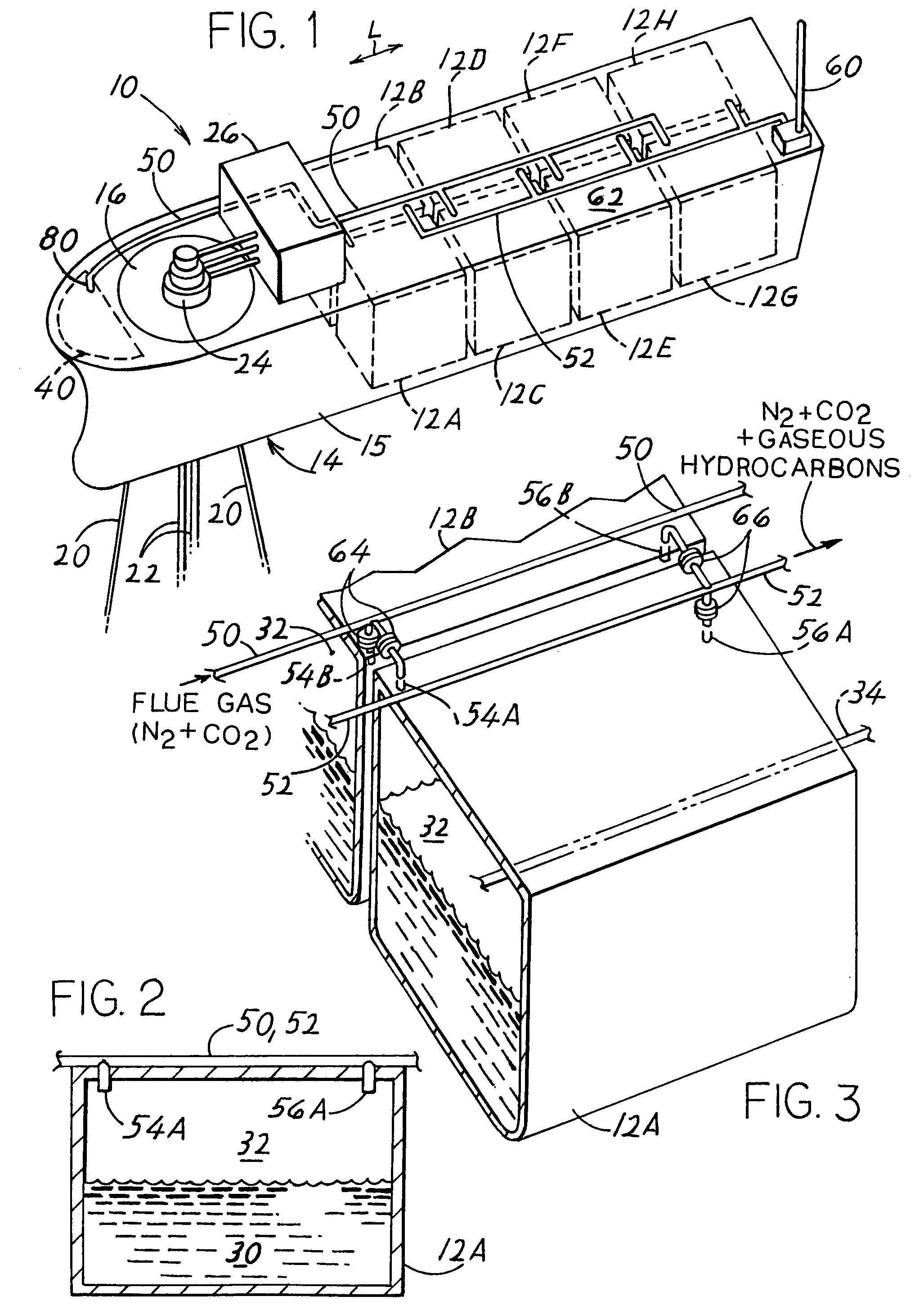

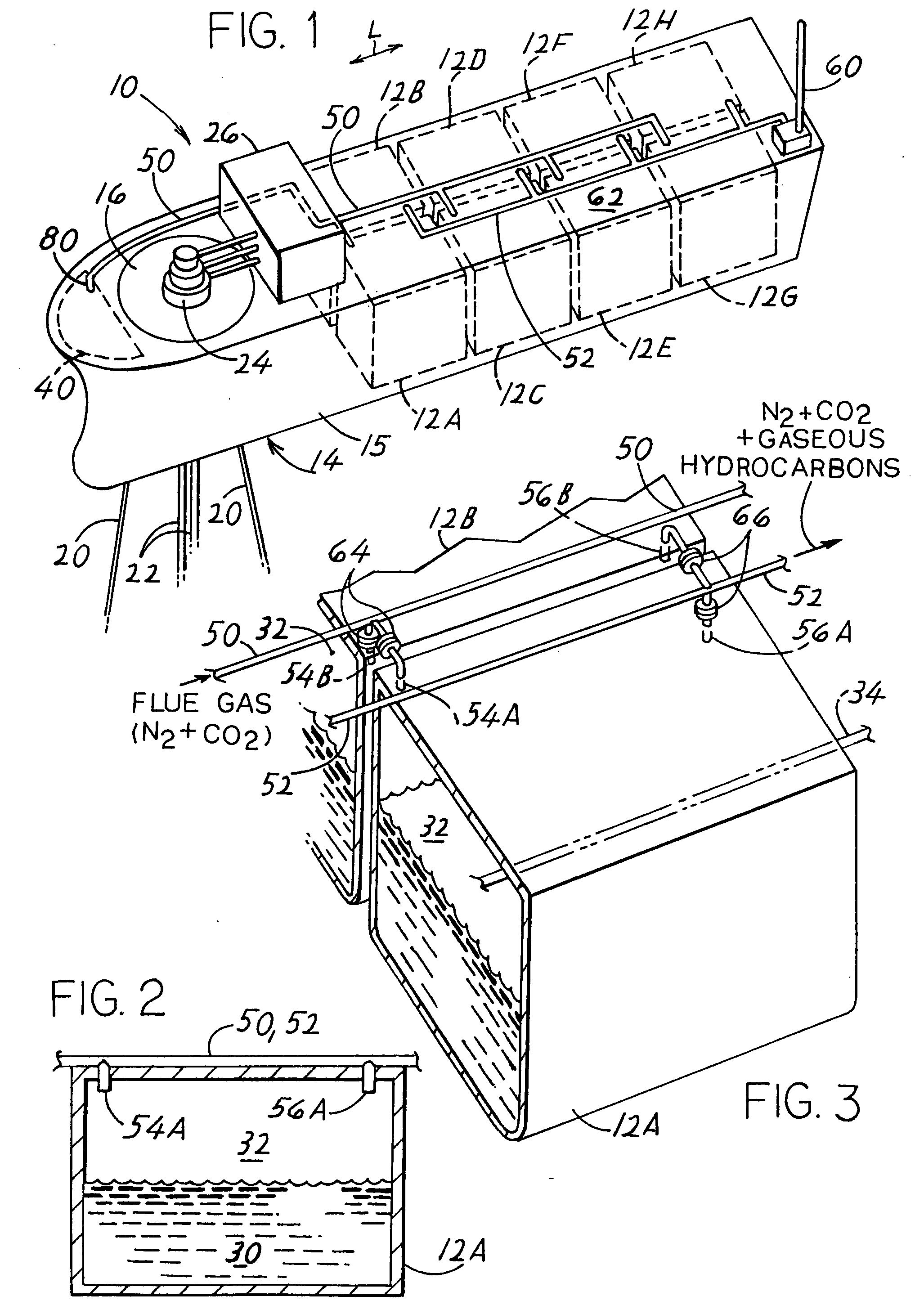

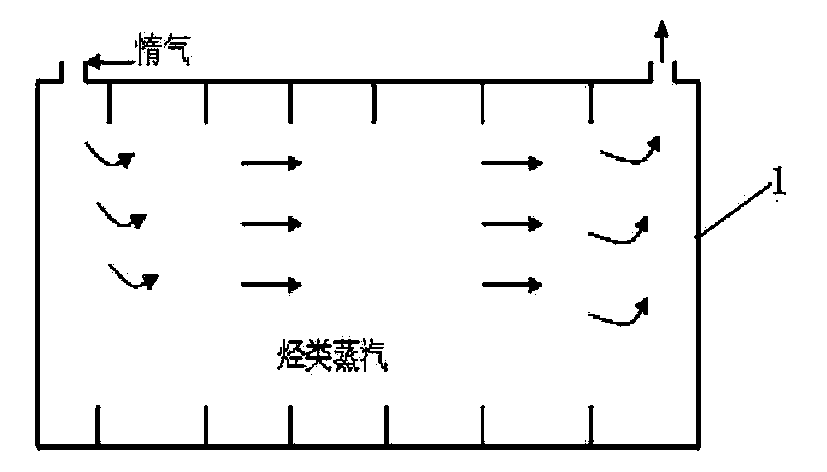

Cargo venting system

InactiveUS20050172877A1Versatile and safePrevent leakageTank vesselsAuxillariesHydrocotyle bowlesioidesFlue gas

A vessel (14) that stores crude oil in tanks (12A-12H) in the vessel hull, maintains oxygen-free gas in the tank spaces (32) that lie above the crude oil. This is achieved by flowing in hydrocarbon-inert gas (gas that does not react with hydrocarbons), such as flue gas, when crude oil is removed so the crude oil level drops, and by flowing out vent gas that includes the inert gas and gaseous hydrocarbons that come from the crude oil, when crude oil flows into the tank and the oil level rises. An inert gas pipe (50) is used to flow inert flue gas into the tanks, and a separate vent gas pipe (52) is used to flow out the vent gas. A vacuum is applied to the vent pipe by connecting the vent pipe to an eductor (102) through which pressured gas, such as steam, is flowed. The vent gas is usually released into the atmosphere, but is burned when there is almost no wind, to prevent a buildup of hydrocarbon gas on the vessel deck.

Owner:SINGLE BUOY MOORINGS INC

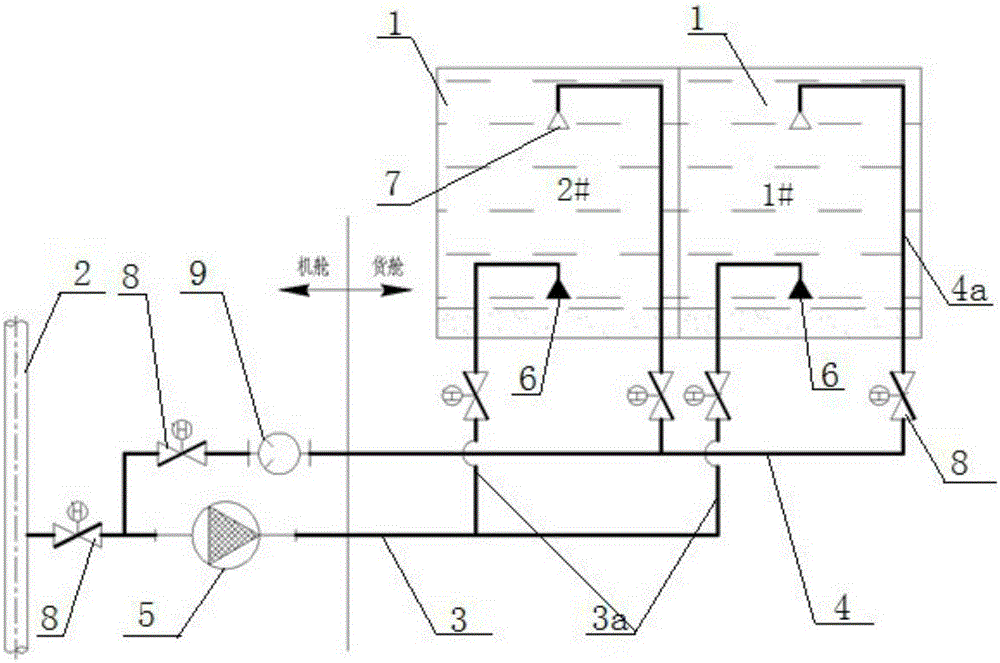

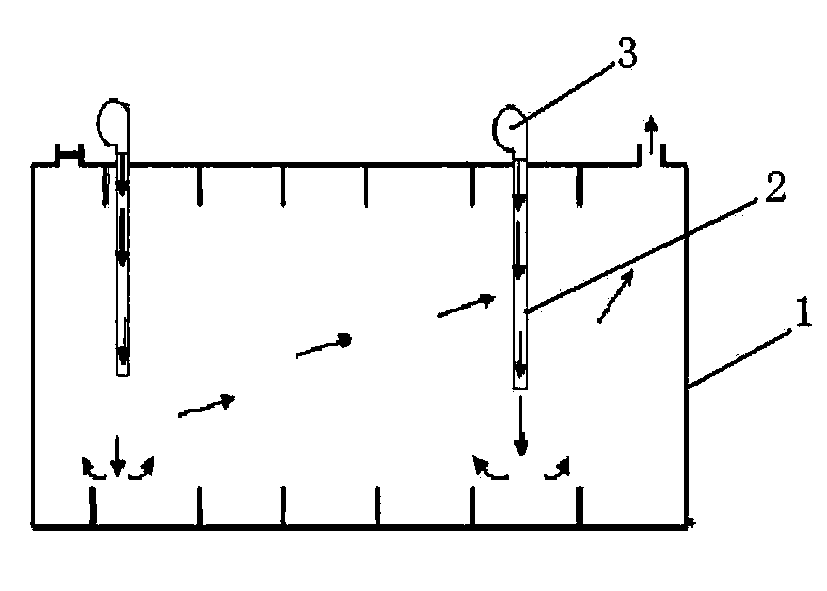

Ballast tank sediment discharge device

ActiveCN105216988AReduce labor intensityEasy to realize remote controlTank vesselsTank cleaningRemote controlEnvironmental engineering

The invention relates to a ballast tank sediment discharge device which comprises a ballast tank (1), a seawater header pipe (2), a ballast header pipe (3) and a water sucking header pipe (4). The ballast header pipe (3) and the water sucking header pipe (4) are connected with the seawater header pipe. The ballast header pipe is provided with a liquid sucking device (5). Preferably, a ballast pump is adopted as the liquid sucking device. A ballast pipeline (3a) is connected between the ballast header pipe and the ballast tank. The end, stretching into the ballast tank, of the ballast pipeline is provided with at least one nozzle (6). A water sucking pipeline (4a) is connected between the water sucking header pipe and the ballast tank. The end, stretching into the ballast tank, of the water sucking pipeline is provided with at least one water sucking opening (7). The water sucking header pipe, the ballast header pipe, the water sucking pipeline and the ballast pipeline are each provided with a remote control valve (8). The water sucking header pipe is provided with a liquid flow observer. The sediment is taken out of a board by reasonably utilizing ballast water in the ballast tank, an existing manual sediment discharge way is replaced, and the labor intensity of staff is greatly lowered.

Owner:上海斯达瑞船舶海洋工程服务有限公司

Drive System for a Cleaning Head Disposed in a Tank

When, according to the invention, constructing a drive system for rotating the cleaning head in a tank and allowing the system to comprise a hysteresis coupling having two magnetic parts which are present inside the liquid space (4) and outside this, respectively, a completely liquid-tight separation between the housing (2) and the gear (14) may be ensured. The magnetic part (8, 18) of the hysteresis coupling may be formed by electromagnets, and with a displaceable (13) position of the one part relative to the other part (11, 19) the coupling may be adjusted with respect to the transferred torque and / or speed.

Owner:ALFA LAVAL TANK EQUIP

Apparatus for insertion in a tank and method thereof

An apparatus for insertion in an enclosed space, including: a tube with: first and second substantially straight portions including first and second ends of the tube, respectively; and a curved portion connecting the first and second portions. The apparatus includes: a plurality of nested segments at least partially disposed within the first substantially straight portion of the tube and connected to the first substantially straight portion; and a first actuator engageable with the tube to displace the first and second substantially straight portions of the tube into and out of the enclosed space through an opening into the enclosed space. The tube is arranged to accept a hose passing through the tube, and a distal segment from the plurality of nested segments is connectable to the hose.

Owner:STONEAGE

Air recirculation system for stationary store rooms and for cargo spaces of refrigeration ships with high-bay racks

In order to flush with cooling air the goods stacked or palletized in a high-bay rack placed in a stationary store room or in the cargo space of a refrigeration ship by maintaining a constant cooling temperature in all the layers, an air recirculation system is proposed for which two superimposed air circuits (40, 140; 40′, 140′) are configured in the area of every rack module (30; 130), whereby at least one rack module, preferably two rack modules (30; 130), are placed in the cargo space and whereby a shaft (50) for the rack stacker is assigned to each rack module (30; 130) or a shaft (50) for the rack stacker is placed between the two rack modules (30; 130) placed the one besides the other, whereby the shaft (50) serves a common pressure distribution chamber of the inlet air for each rack module (30; 130).

Owner:BECKER MARINE SYST

Floating production storage and offloading (FPSO) cargo oil tank cleaning method

InactiveCN103552669AImprove cleaning efficiencyRelieve nervous fatigueTank vesselsTank cleaningCleaning methodsPreparation stage

The invention discloses a floating production storage and offloading (FPSO) cargo oil tank cleaning method. The FPSO cargo oil tank cleaning method comprises a first step of undergoing an early preparation stage; a second step of undergoing an air purging cleaning stage, simultaneously performing production water disturbance tank cleaning at the FPSO cargo oil tank air purging stage, and clearing away the tank bottom tank-cleaning water; a third step of undergoing an air removal stage, utilizing more than two fans to feed air, opening tank covers at two ends to alternately exhaust air, and keeping an oil measuring opening and an air measuring opening open; a fourth step of undergoing an inerting stage, adopting a segmented inerting mode for inerting of more than two cabins, first simultaneously performing inerting on all the cabins for 2-3.5h, and then respectively performing concentrated inerting. According to the method, FPSO cargo oil tank cleaning efficiency is improved, the operation risk is reduced, and the operation cost is reduced.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Ship buoyancy control system

InactiveUS20100018448A1High rateTank vesselsHull interior subdivisionMarine engineeringControl system

A tank (10) of a ship (1) is provided with an inflow port (6) and an outflow port (7) opening through a bottom of the ship (13). The inflow and outflow ports are spaced apart from each other in a headway direction of the hull. The ports are equipped with closure means (9), which closes the ports so as to ensure hull buoyancy by means of air in the tank. The ports allow seawater outside the ship to flow into the tank through the inflow port and the seawater in the tank to flow out of the ship through the outflow port, with use of headway motion of the ship. A partition (2) provides a weir extending in a widthwise direction of the hull in the tank, and divides a region in the tank into an inflow area (3) and an outflow area (4). The tank, partition, inflow port, outflow port and closure means constitute a ship buoyancy control system.

Owner:NAT UNIV CORP YOKOHAMA NAT UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com