Drive System for a Cleaning Head Disposed in a Tank

a technology for rotating cleaning heads and tanks, which is applied in the direction of tank cleaning, tank cleaning, hollow article cleaning, etc., can solve the problems of not always operating reliably, its speed cannot be adjusted, and it is difficult to make such a magnetic coupling having permanent magnets work in connection with cleaning heads for tanks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

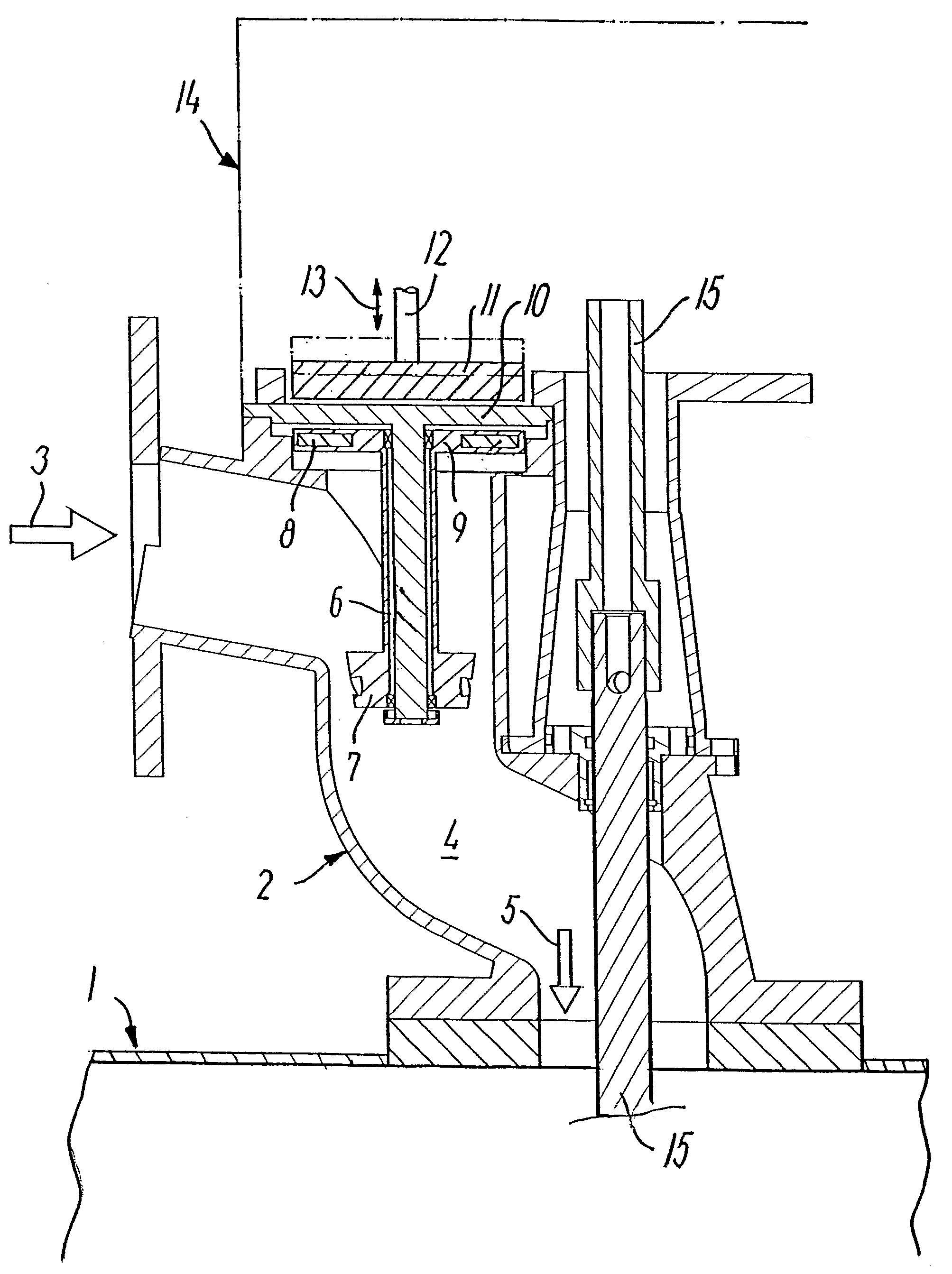

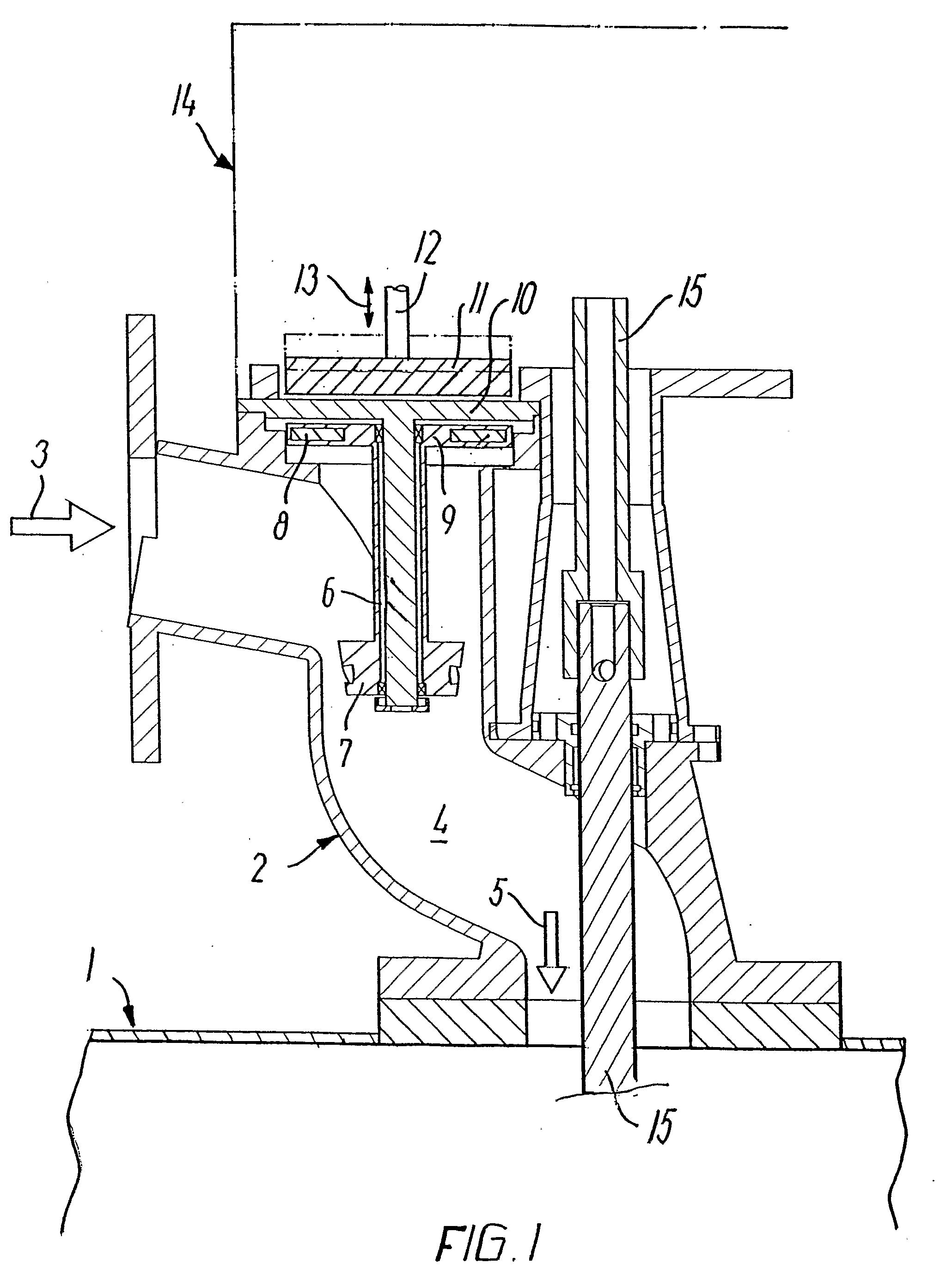

[0019]Three exemplary embodiments shown in FIG. 1, FIG. 2 and FIG. 3, respectively, will be described below.

[0020]Apart from the hysteresis coupling itself, a section through the driving part of the cleaning equipment is shown in the examples, viz. a housing 2 which has a liquid inlet 3 for cleaning liquid under pressure, said liquid flowing past a propeller 7 which is thereby caused to rotate with a speed of rotation of several thousand revolutions per minute. The rotation of the propellers 7 is transferred via a shaft 6 to the magnetic part placed in the housing 2. The liquid flow is conveyed through the channel 4 as liquid which is conveyed via a pipe (not shown) to the cleaning head, which is present down in the tank 1.

[0021]The cleaning head is rotatable by means of a rotary shaft 15, and it is also provided with rotating nozzles to eject cleaning liquid under pressure and thereby to clean the entire internal surface of the tank.

[0022]Since the rotation of the cleaning head tak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com