Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65results about How to "Stay organized" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fresh keeping agent for water bamboo shoots, production method of bamboo shoot and product

InactiveCN104621246ALess loss of nutrientsMaintain taste and textureFruit and vegetables preservationFood preparationSodium sulfiteCorrosion prevention

The invention discloses a fresh keeping agent for water bamboo shoots, a production method of the bamboo shoot and a product, aiming at solving the problems that a chemical preservative is required to be added for ensuring the shelf life of products such as water bamboo shoots, the health of consumers can be harmed due to excessive adding and abuse of the chemical preservative, a great amount of sodium sulfite is used for corrosion prevention and decoloring when the bamboo shoot raw material is pre-treated, and long-time desulfuration is also required in a later period. The fresh keeping agent meets the organic product processing standard, and can be used for replacing the chemical preservative and solving the problems of microbial spoilage, sack expanding and the like during organic water bamboo shoot processing. The fresh keeping agent is used for processing bamboo shoots, the product quality is ensured, the environment pollution is reduced, the health of consumers is safeguarded, the economic benefit of farmer households is improved and the fresh keeping agent plays an important role; and besides, the method is simple, the operation is convenient, the equipment investment is low, the production period is short, the fresh keeping agent is suitable for industrial production requirement of small and medium sized bamboo shoot processing enterprises and has wide application prospect.

Owner:SICHUAN AGRI UNIV

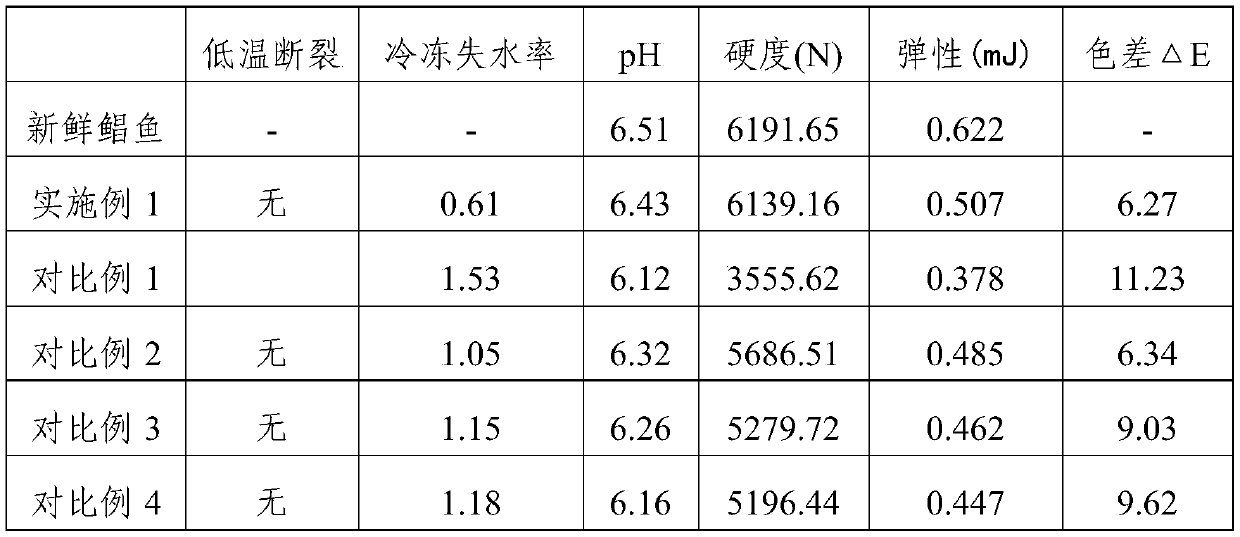

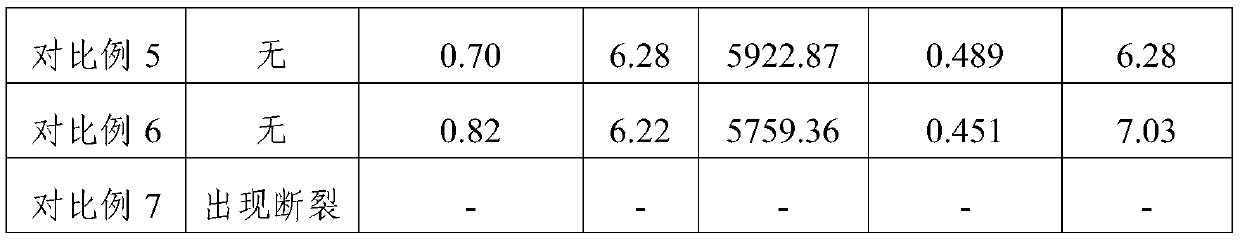

Method for quickly freezing belt fish and belt fish products

ActiveCN103070221AGreat tasteTo satisfy the market's needsMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsQuick FreezeGift giving

The invention discloses a method for quickly freezing belt fish and products thereof. According to the invention, the belt fish are preprocessed, cleaned and leached to obtain clean belt fish raw materials, then the belt fish raw materials are processed by the selected quick-freezing technology, wherein the quick-freezing technology comprises temperature reducing or seasoning processing, quick-freezing processing and freezing storage processing. Through the processing method provided by the invention, the freshness and nutritional ingredients of the belt fish and the products thereof are kept favorable, the shelf life is remarkably prolonged, the belt fish harvest period is avoided and the problem of poor quality by conventional freezing storage is solved; and the quickly frozen belt fish and products thereof can be taken as ideal goods for catering or gift giving and the like.

Owner:OCEAN RES CENT OF ZHOUSHAN ZHEJIANG UNIV +1

Processing method of instant Chinese chestnuts

InactiveCN104223204AAchieve freshnessKeep the color and fragranceFruits/vegetable preservation by irradiation/electric treatmentNatural extract food ingredientsBiotechnologyPropolis

The invention discloses a processing method of instant Chinese chestnuts. The processing method of the instant Chinese chestnuts comprises the following seven steps: pretreating raw materials, immersing the raw materials in a plant preservation solution, rinsing, quickly freezing, steaming, packaging and carrying out pulse highlight sterilization. According to the processing method, the Chinese chestnuts are immersed with an extraction solution of pure natural plant raw materials; the preservation of the Chinese chestnut kernels is realized through natural effective components with the functions of sterilizing, disinfecting and inhibiting microorganisms in Chinese herbal medicines, and the color, aroma and taste and tissue states of the Chinese chestnut kernels are kept; the light natural aroma of the Chinese chestnuts can be increased and the flavor is unique; the nutritional and health value is increased by pure natural plant components, namely medlar, propolis and the like; and other preservatives or chemical additives are not added in a processing process of the product so that the instant Chinese chestnuts are of an environmental friendly and convenient snack food.

Owner:DOSHAN NEW STRATEGY INTPROP CULTURECO

Fish flesh recombining and processing method

The fish flesh re-combining and processing method is to add glutamine transminase (TG) in 0.05-3.0 wt% into fish flesh or fish sheet with fish head, internal organs, fish bone, etc eliminated and react at 0-20 deg.c for 0.5-24 hr to form new combined fish flesh product. The present invention has simple technological process, and the product may be in the fish shape, or be various fish segment, fish block or fish sheet. The fish flesh product may be frozen or heated without shape change and has mouth feeling, flavor and nutritious value the same as fish flesh.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Vegetarian meat ball based on wheat gluten protein and making method thereof

The invention discloses a vegetarian meat ball based on wheat gluten protein and a making method thereof, belonging to the field of food processing. The making method comprises the following steps: soaking textured soybean protein at normal temperature, removing impurities, cleaning the textured soybean protein and chopping the textured soybean protein into small broken pieces; adding water into isolated soybean protein to prepare a solution, adding soybean oil and carrying out stirring until complete emulsification; adding the chopped textured soybean protein into the obtained emulsion, then successively adding a flavor composite material, food coloring, cooking wine, salt, sugar, wheat gluten protein and modified starch and carrying out uniform mixing through stirring; and subjecting the obtained mixture to mixing and kneading, molding and steaming so as to obtain the vegetarian meat ball. The vegetarian meat ball prepared in the invention has a high meat simulation degree, appropriately-soft viscoelastic gel, chewy feeling, texture and flavor of real meat, no beany flavor, moderate mouthfeel and thick and delicious taste; and the making method is low in cost and applicable to industrial large-scale production and can provide more abundant options for consumers of vegetarian foodstuffs.

Owner:FUZHOU UNIV

Frozen dry jujube and preparation thereof

InactiveCN1423950AAvoid breaking downReduce lossesFruit and vegetables preservationAdditive ingredientFreeze-drying

A freeze dried jujube is prepared from fresh jujube through removing kernel, pre-freezing and freeze drying in vacuum freeze drier where water is directly sublimated. Its advantages are less loss of nutrients, and original color and taste.

Owner:FOOD INST LULIANG DISTRICT SHANXI PROV

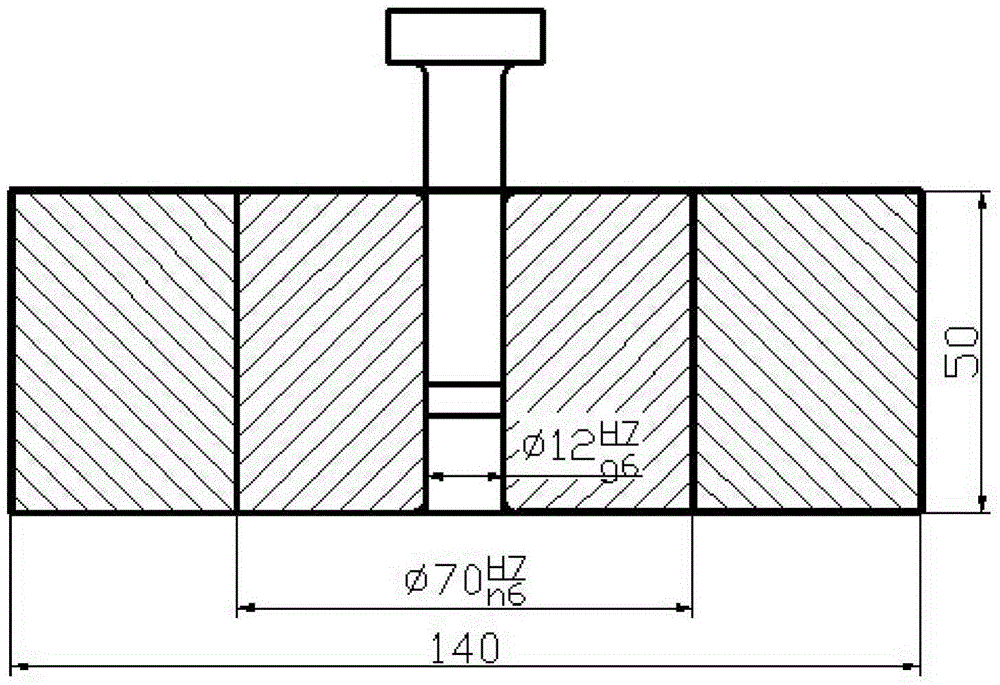

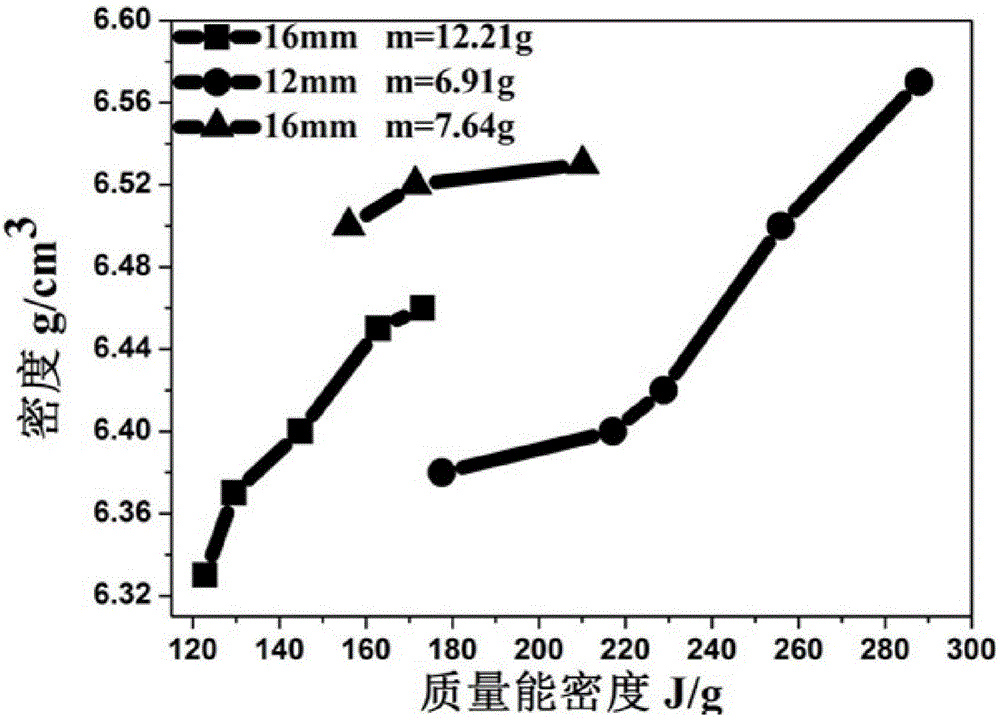

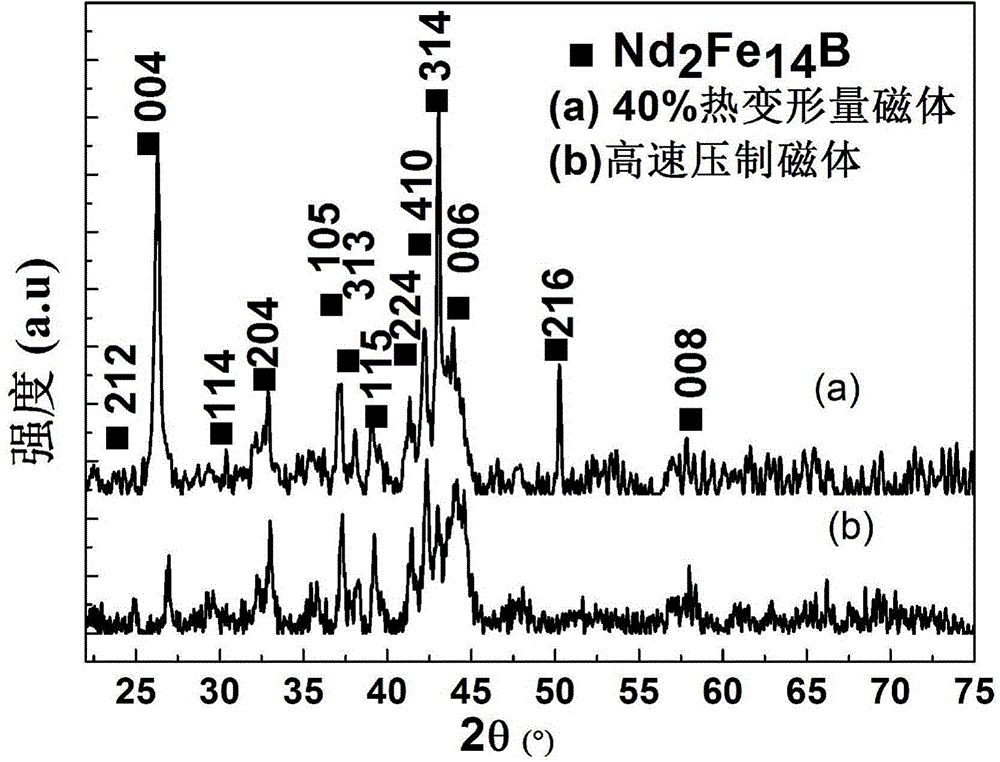

Anisotropic nanocrystal neodymium iron boron magnet, and preparation method and application of magnet

ActiveCN104134529AStay organizedSave energyInorganic material magnetismInductances/transformers/magnets manufactureMetallurgyThermal deformation

The invention belongs to the field of powder metallurgy and magnet preparation, and discloses an anisotropic nanocrystal neodymium iron boron magnet, and a preparation method and an application of the magnet. The preparation method comprises the following steps of allowing neodymium-enriched neodymium iron boron powder to be densified by high-speed pressing, obtaining a thermal deformation precursor, performing thermal deformation on the thermal deformation precursor, and obtaining the anisotropic nanocrystal neodymium iron boron magnet. The preparation method is high in high-speed pressing forming efficiency, allows the powder to be densified instantly, and can improve the production efficiency of a product. The anisotropic nanocrystal neodymium iron boron magnet is excellent in density and magnetic performance, and can be applied to the fields of consumer electronics, acoustics, engines, wind power, traffic, computers, high-performance automobile motors and the like.

Owner:SOUTH CHINA UNIV OF TECH

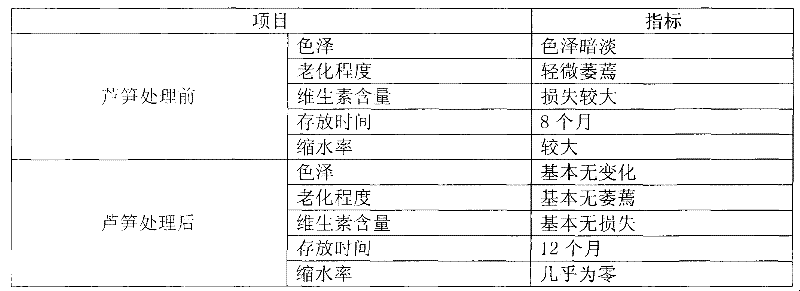

Quick-freezing, color protecting and refreshing method for green asparagus

InactiveCN102204586APrevent oxidative deteriorationAvoid breakingFruit and vegetables preservationPhytic acidSugar

The invention discloses a food color protecting method, in particular relates to a quick-freezing, color protecting and refreshing method for green asparagus, which belongs to the technical field of fruit and vegetable processing. The method comprises the steps of asparagus selecting, blanching, cooling, draining, quick freezing and packaging in sequence and is characterized in that 0.015-0.02wt% of phytic acid, 0.2-0.3wt% of zinc acetate, 0.5-1wt% of sodium chloride and 0.3-0.5wt% of white granulated sugar are added in the blanching step. The asparagus quickly frozen by using the method does not shrink, has bright appearance, does not blacken and remains original tissue structure after being unfrozen, the nutrition values can be effectively maintained, and the shelf life is prolonged from original 8 months to 12 months.

Owner:HENAN ZHONGPIN FOOD IND

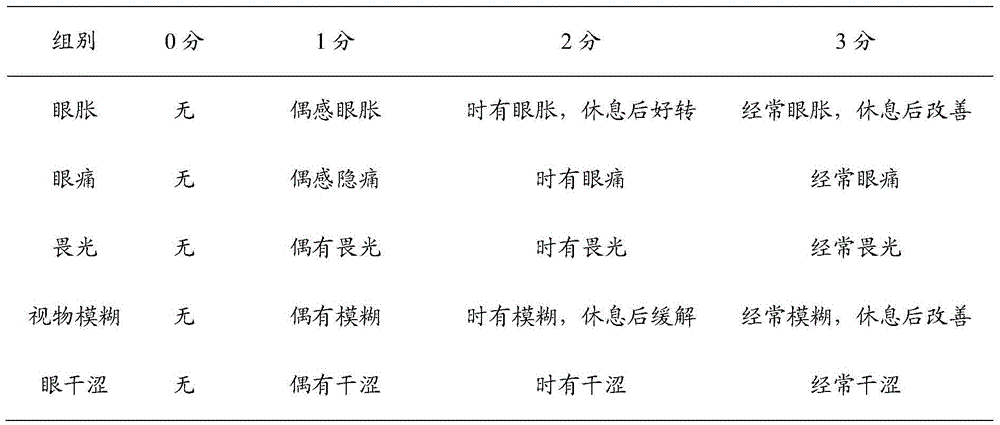

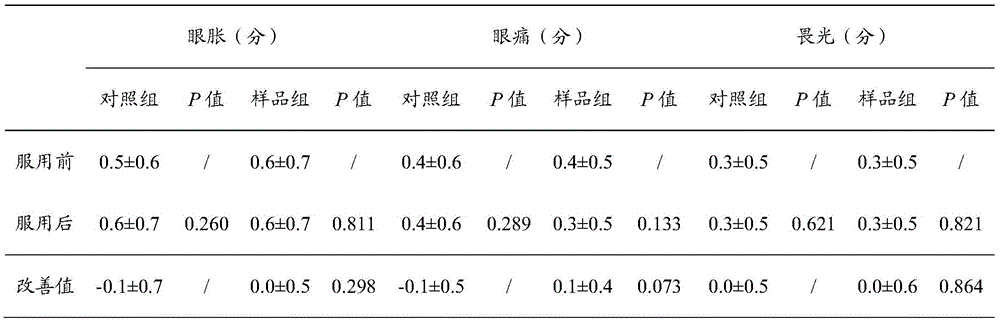

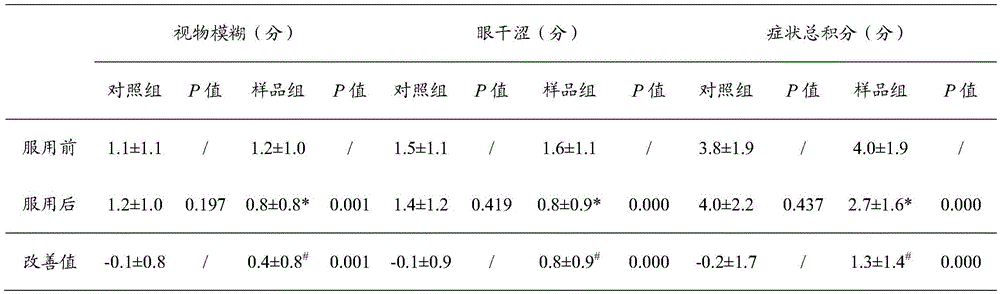

A hydroxytyrosol composition and applications thereof

ActiveCN103316032AAvoid damagePromote absorptionSenses disorderHydroxy compound active ingredientsHydroxytyrosolDiabetes retinopathy

The invention provides a hydroxytyrosol composition used for protecting eyesight. The composition is characterized in that the composition is prepared by preparing an active component by mixing hydroxytyrosol, hyaluronic acid, phytoxanthin, proanthocyanidins and taurine according to a certain ratio, and then preparing oral preparations with the active component and a proper amount of common auxiliary materials. The composition has functions of improving eyesight, and improving eye and visual functions. The composition is used for eyesight protection, asthenopia improvement, prevention and adjuvant therapy for macular degeneration, macular degenerative diseases, and diabetic retinopathy, optic atrophy, and optic nerve degeneration, and the like.

Owner:SHANDONG GUANTIANXIA BIOTECHNOLOGY CO LTD

Vegetarian meat balls containing modified starch and preparation method thereof

InactiveCN110169568AStrengthen the gel structureIncrease elasticityLipidic food ingredientsFood ingredient as mouthfeel improving agentCross-linkVegetable oil

The invention discloses vegetarian meat balls containing modified starch and a preparation method thereof. The vegetarian meat balls are prepared from the following raw materials in parts by weight: 60-80 parts of vegetable protein, 5-10 parts of the modified starch, 10-20 parts of native starch, 1-5 parts of vegetable oil, 1-3 parts of table salt, 1-5 parts of white sugar, 0.2-0.8 part of myristica fragrans powder, 0.1-0.5 part of pepper and 0.1-0.5 part of ginger powder, wherein the vegetable protein is prepared by mixing soy isolate protein, textured soybean protein and wheat protein according to a mass ratio of 1 to (10-20) to 5, and the modified starch is cassava cross-linked esterified oxidized composite modified starch. The vegetarian meat balls prepared by the preparation method are high in meat-imitation degree, and proper in viscoelasticity and hardness, have real fleshy chewing feeling, texture and flavour, have no beany flavor, are moderate in mouthfeel, balanced in nutrition, and low in production cost, and provide more plentiful choices for vegetarian food consumers.

Owner:GUANGXI GAOYUAN STARCH

Low-calorie whole-grain coarse-cereal crisp biscuit and manufacturing method thereof

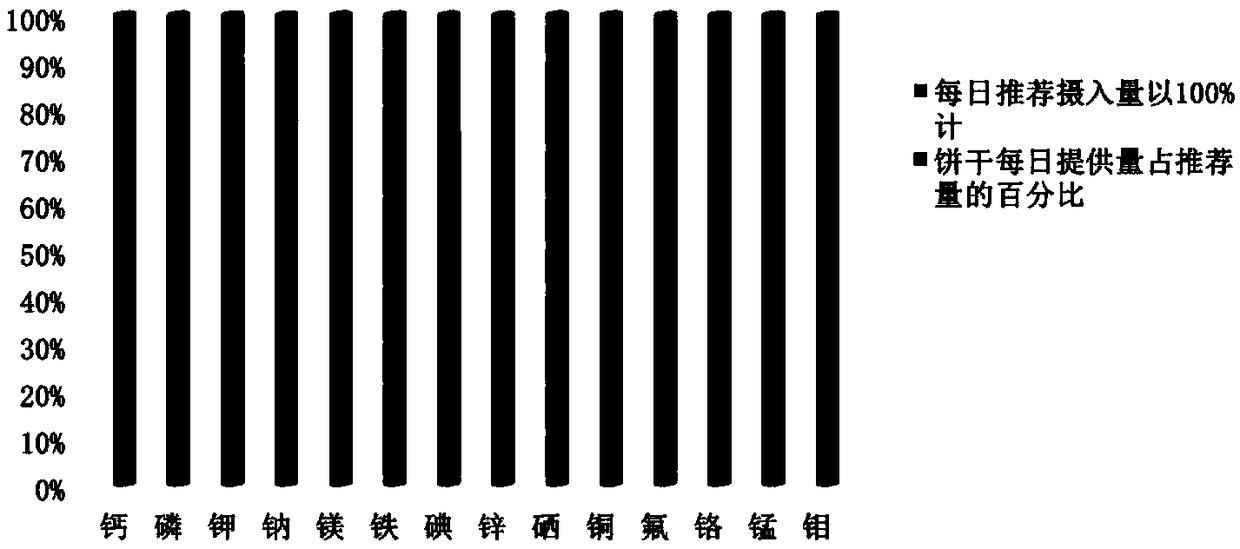

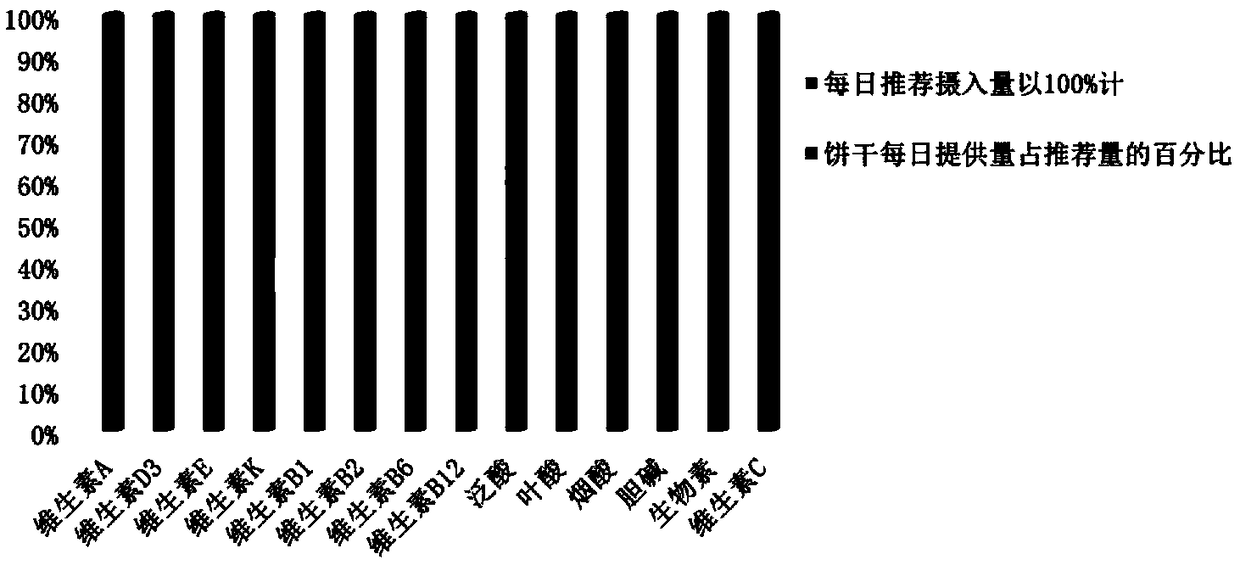

InactiveCN109105421ALow generation indexDelayed digestionDough treatmentBakery productsNutrientWhey protein powder

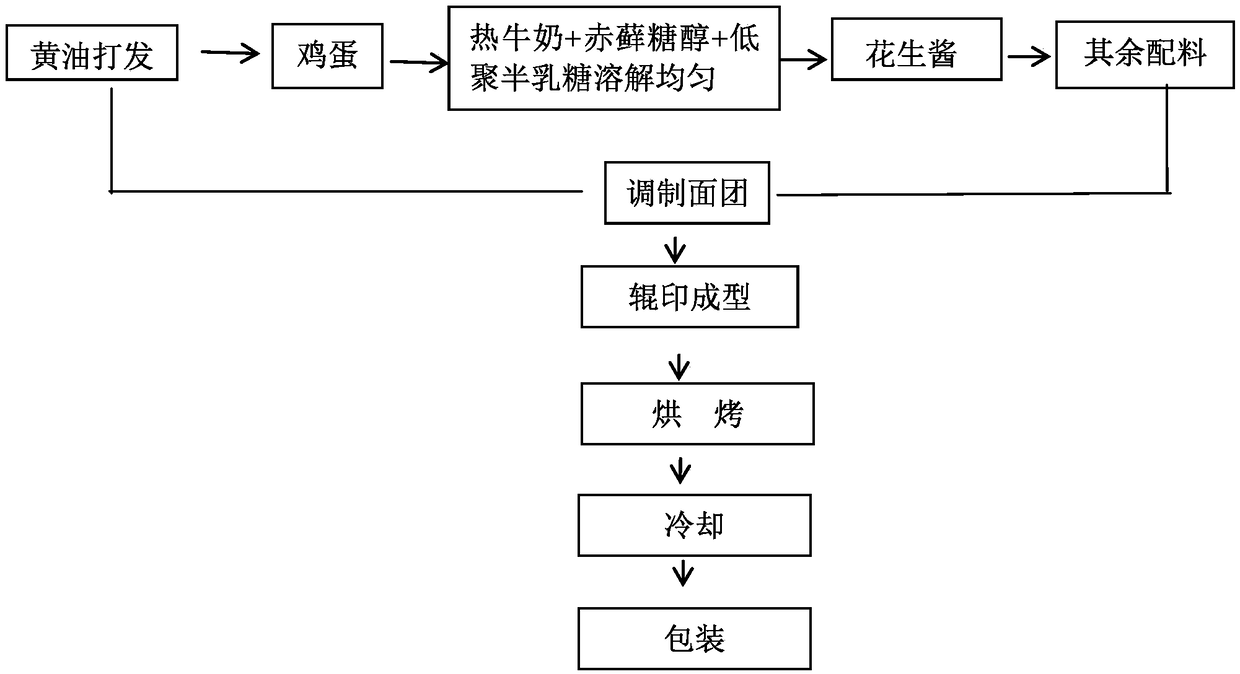

A low-calorie whole-grain coarse-cereal crisp biscuit and a manufacturing method thereof belong to the biscuit manufacturing field. The biscuit comprises, by weight, 300-400 parts of a mixed coarse-cereal flour, 80-120 parts of erythritol, 20-80 parts of galacto-oligosaccharides, 80-150 parts of butter, 100-150 parts of eggs, 80-120 parts of peanut butter, 80-120 parts of milk, 20 to 80 parts of resistant dextrin, 10 to 30 parts of whey protein powder, 10 to 30 parts of white kidney bean extract, 5 to 10 parts of chia seeds, 5 to 10 parts of modified starch, 2 to 10 parts of baking soda, 2 to10 parts of baking powder and 0.2-1.0 parts of selenium-enriched yeast. Aiming at problems that nutrients in existing biscuits are not comprehensive and a high calorie is possessed, the low-calorie whole-grain coarse-cereal crisp biscuit is manufactured. The biscuit is suitable for people with abnormal glucose tolerance and people who need to lose weight.

Owner:黑龙江省农业科学院食品加工研究所

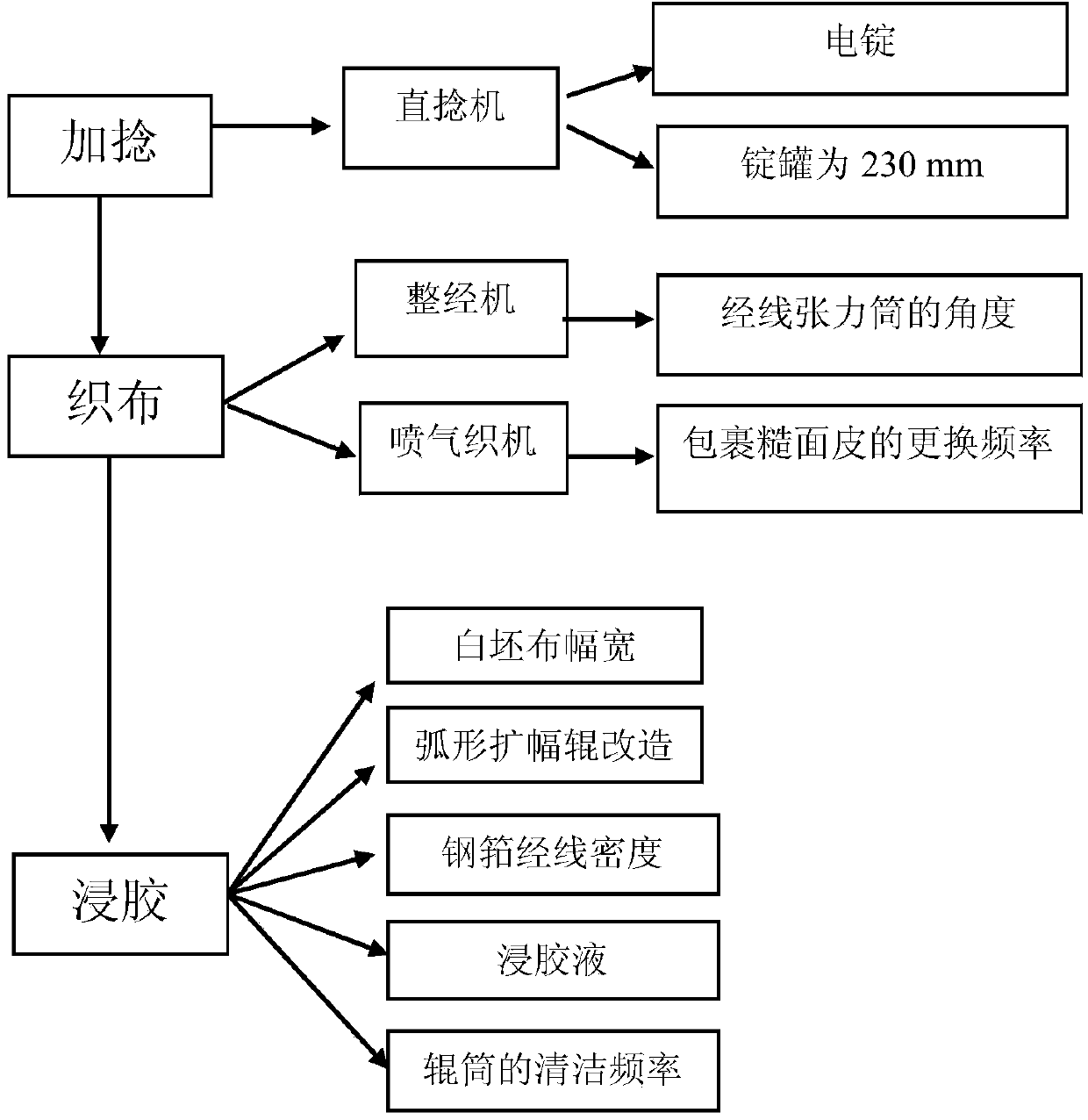

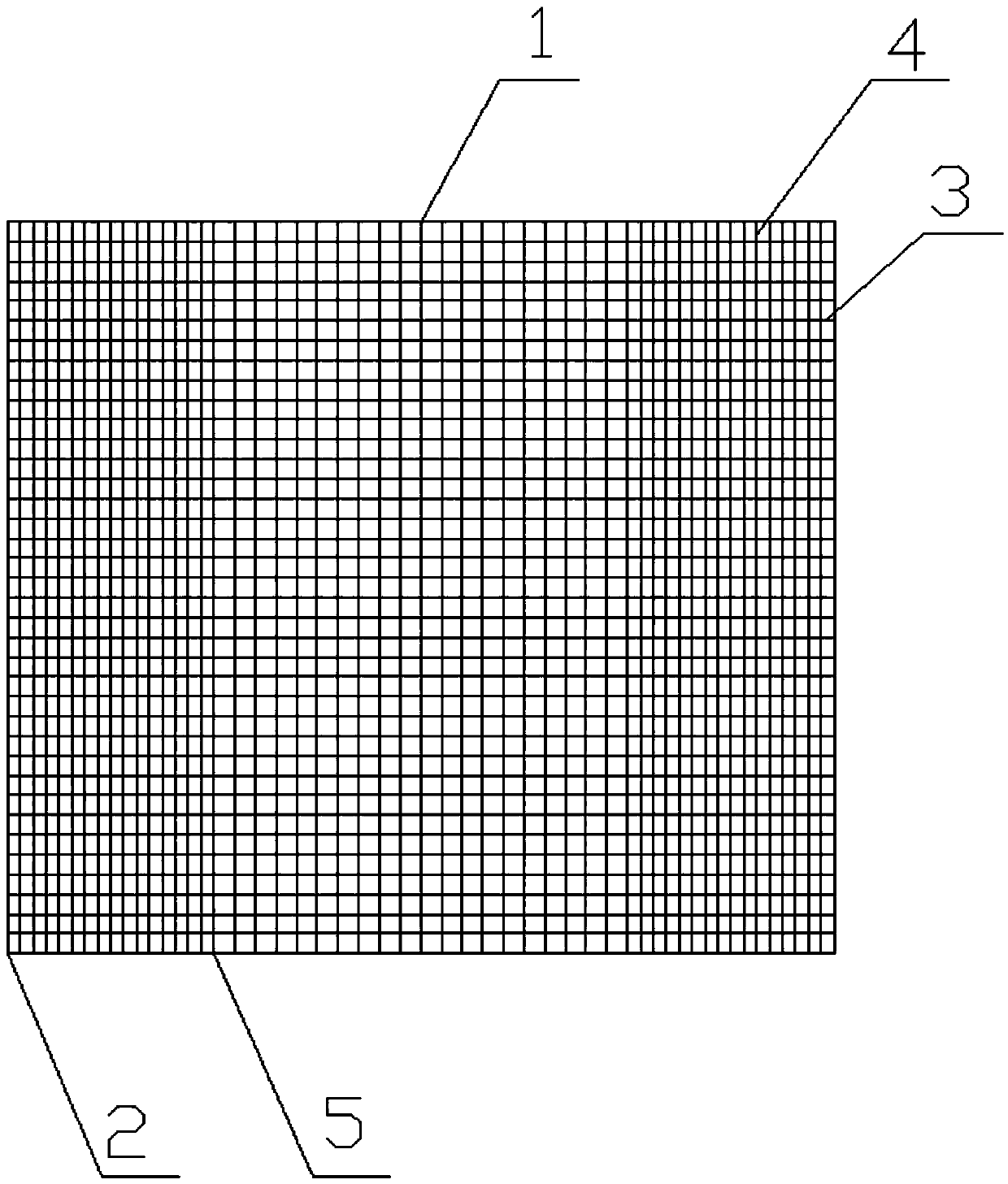

Production technology of tyre fabric for tyres

InactiveCN103993402AMaintain physical propertiesMaintain qualityWoven fabricsStretchingAir-jet loomEngineering

The invention provides a production technology of tyre fabric for tyres. The production technology includes the operating steps of twisting, fabric weaving and rubber dipping. The tyre fabric is produced according to the parameters that a straight twisting machine, a warping machine and an air jet loom are adopted for production, the width of grey cloth is set between 155 cm and 160 cm, an arc-shaped spreading roller is changed into a three-finger full-range expander and a semi-range expander, the rubber dipping liquid is a Pexul system, the density of warps of reeds is reduced, the angle of a side warp tension drum is smaller by 1 degree to 5 degree than that of a middle tension drum, the replacing frequency of a rough-face shell wrapping the surface of a warp pacing roller is replaced once every 24 hours to 48 hours, and a roller on the rubber dipping machine is cleaned once every 48 hours to 72 hours. Due to the improvement in the production technology, the density of the warps of the tyre fabric tends to be consistent, not only are the texture and the structure guaranteed, but also the physical performance and the appearance quality of the tyre fabric are kept, rubber can permeate mutually easily in the calendaring process, the stress borne by a tyre can be consistent easily, side lines of the tyre are prevented from being exposed, and large potential safety hazards such as delaminating are avoided.

Owner:天津市金天马铝业有限公司

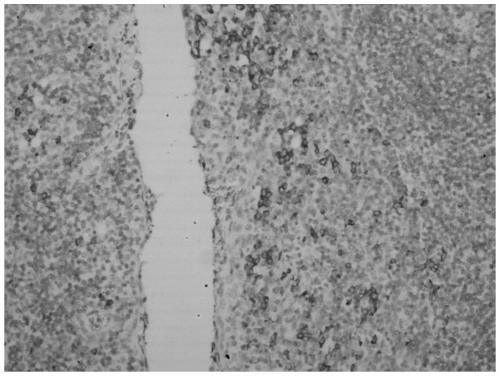

Specimen preserving fluid

InactiveCN108432740AStay organizedMaintain colorDead animal preservationHazardous substanceChemistry

The invention discloses a specimen preserving fluid. The specimen preserving fluid is prepared from raw materials in parts by weight as follows: 3-5 parts of potassium sorbate, 5-7 parts of industrialethanol, 1-3 parts of laurocapram, 1-3 parts of disodium zinc ethylenediaminetetraacetate tetrahydrate, 0.8-1.2 parts of a protein crosslinking agent, 1-2 parts of a penetrant, 1-3 parts of glycerin,1-2 parts of glutaraldehyde, 7-9 parts of sodium chloride, 8-12 parts of citric acid and 80-100 parts of deionized water. The specimen preserving fluid is a colorless and transparent liquid, has no pungent smell, has excellent sterilization and anti-mold property, can effectively keep the tissue form and color and luster of an original biological specimen, contains no volatile substances, has lasting effects, can effectively reduce the cost, does not contain toxic or harmful substances, is green and environmentally friendly and can relieve the burden on the environment.

Owner:黄名义

Color protection preservative solution for pathological tissue specimen

InactiveCN106818713AStay organizedMaintain colorDead animal preservationCross-linkEnvironmental resistance

The invention discloses a color protection preservative solution for a pathological tissue specimen. The color protection preservative solution is prepared by mixing the following raw materials in parts by weight: 1 to 3 parts of laurocapram, 1 to 3 parts of ethylenediaminetetraacetic acid disodiu, 5 to 15 parts of menthol, 0.5 to 1 part of protein cross-linking agents, 1 to 2 parts of penetrating agents, 0.4 to 1 part of potassium sorbate, 10 to 20 parts of glycerol, 10 to 16 parts of sodium hydroxide powder and 80 to 120 parts of water. The color protection preservative solution of the specimen is colorless and transparent liquid without pungent odor; the sterilization, mildewproof and anti-corrosion performance is excellent; the tissue form and color of the original biological specimen are maintained; no volatile substance exists; the effect is durable; the cost can be effectively reduced; toxic and harmful substances are not contained; green and environment-friendly effects are achieved; the environment burden is reduced.

Owner:GUILIN MEDICAL UNIVERSITY

Medicine composition capable of alleviating asthenopia and preparation method of medicine composition

InactiveCN105535257ACompatibility is reasonableCompatibility is safe and effectiveSenses disorderHydroxy compound active ingredientsBlueberry extractLingonberry extract

The invention discloses a medicine composition capable of alleviating asthenopia and a preparation method of the medicine composition. The medicine composition is prepared from gingko leaves, cowberry blueberry extract, wolfberry fruits, fructus ligustri lucidi, radix polygoni multiflori, flos chrysanthemi, semen cassiae, taurine, zinc gluconate and vitamin A. The medicine composition has the effects of regulating meridians, nourishing liver and tonifying kidney, and clearing liver and improving eyesight; by relaxing blood vessels and eliminating free radicals in retinas, the generation of retina purpurin is promoted, so that the function of alleviating asthenopia is realized; a relative test shows that the medicine composition is reasonable in medicine compatibility, is safe and effective, and has no toxic and side effects; the medicine composition can be used for alleviating asthenopia and improving the sub-health state of people with asthenopia.

Owner:同溢堂药业有限公司

High-efficiency drying method for shepherd's purse

ActiveCN104770465AStay organizedMaintain nutrientsFruits/vegetable preservation by dehydrationWater contentMicrowave

The invention provides a high-efficiency drying method for shepherd's purse. The method is characterized by comprising the following steps: 1, pretreatment: a step of cleaning, draining and segmenting the shepherd's purse and pre-freezing the shepherd's purse at a temperature of -15 to -20 DEG C for no less than 6 h; 2, freeze drying: a step of freezing the prefrozen shepherd's purse, then sublimating the shepherd's purse at a temperature of -3 to -7 DEG C for 3 to 4 h and desorbing the shepherd's purse at a temperature of 3 to 7 DEG C for 2 to 3 h, wherein the processed shepherd's purse has water content of 50 to 60%; 3, vacuum drying: a step of drying the shepherd's purse at a vacuum degree of -0.065 to -0.075 MPa for 50 to 60 min when temperature uniformly rises to 50 DEG C from 30 DEG C so as to allow the water content of the shepherd's purse to drop to 25 to 30% and then drying the shepherd's purse at a vacuum degree of -0.08 to -0.09 MPa for 40 to 50 min when temperature uniformly rises to 70 DEG C from 50 DEG C so as to allow the water content of the shepherd's purse to drop to 15 to 20%; and 4. microwave drying: a step of drying the shepherd's purse at a power of 5 to 10 W / g, wherein overturning is carried out during drying, drying is stopped for 10 to 20 s every 0.8 to 1.2 min, the water content of the shepherd's purse drops to less than 8%, and drying is completed. The method provided by the invention maintains the structural form and nutritional components of the shepherd's purse, enables the dried shepherd's purse to have a good color, a good water regaining characteristic and richer flavor, shortens drying time and improves drying efficiency.

Owner:江苏太湖地区农业科学研究所

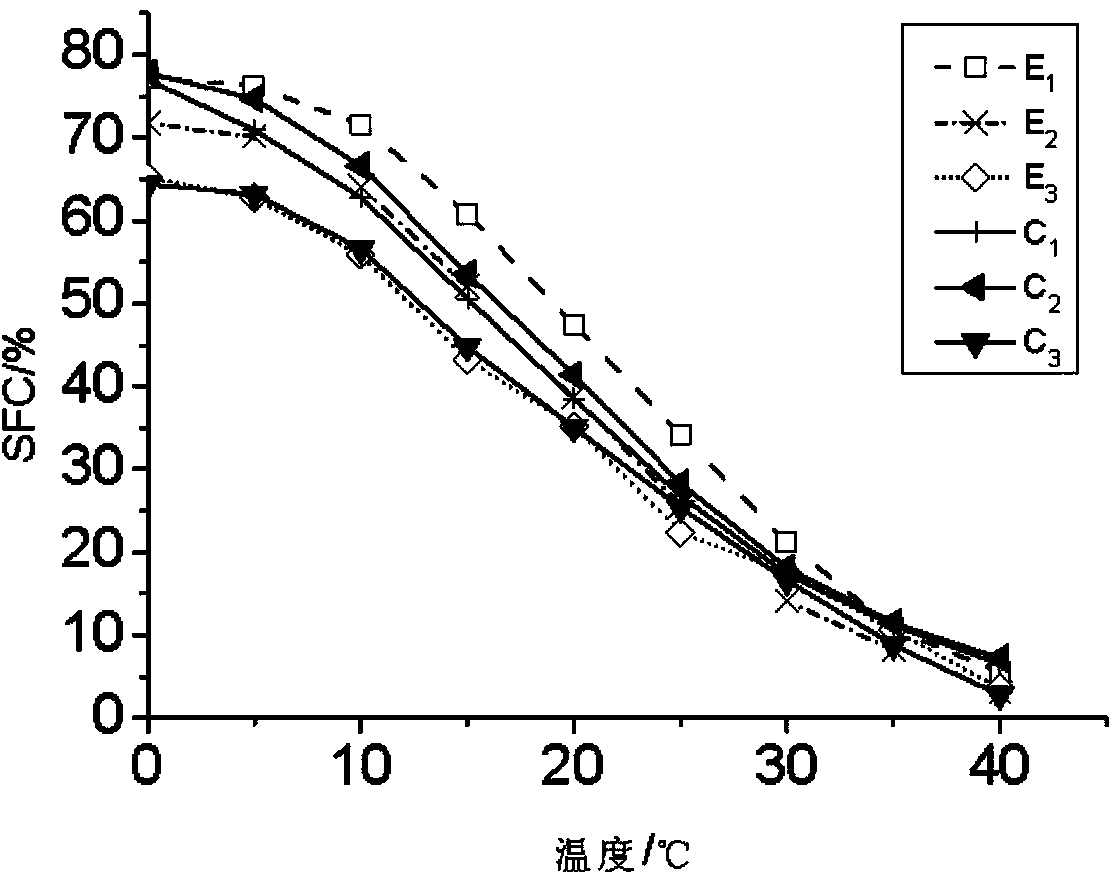

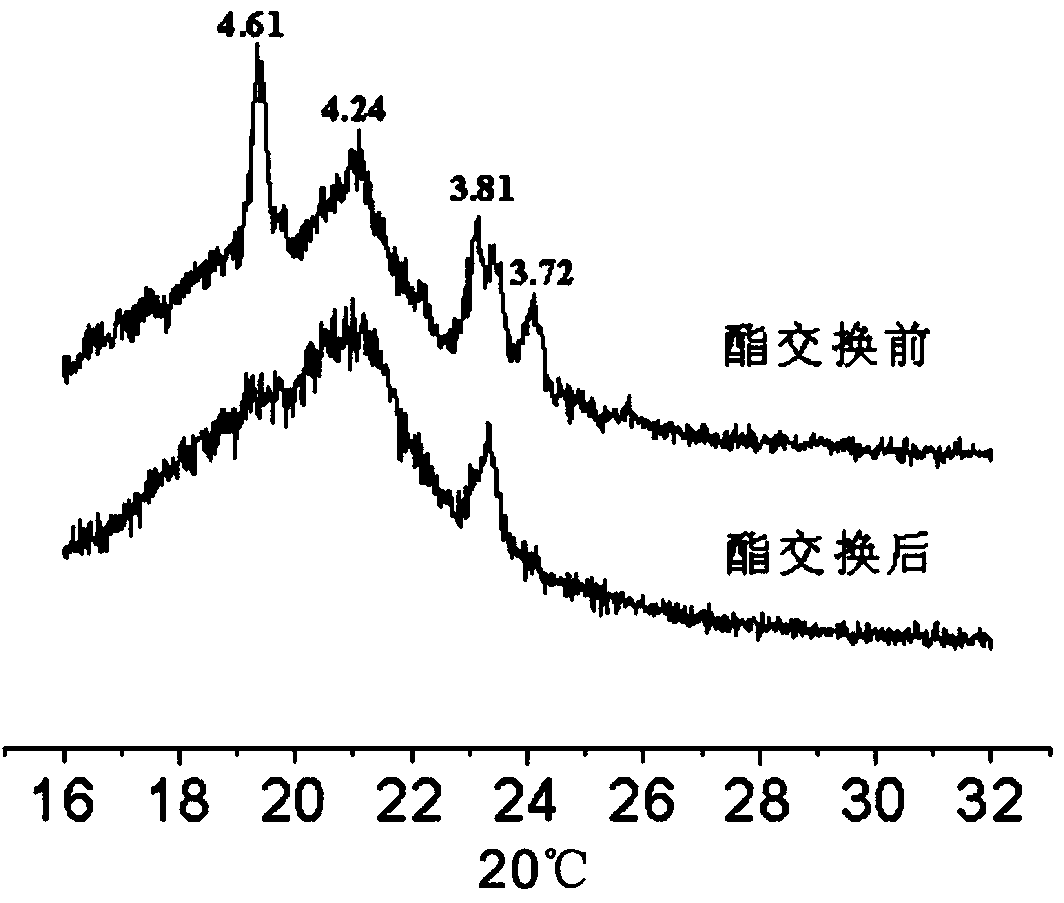

Preparation method of shortening without trans-fatty acids

The invention discloses a preparation method of shortening without trans-fatty acids. The preparation method comprises steps as follows: rice bran solid lipid, perhydrogenated soybean oil and coconut oil are melted and proportionally mixed at the mass ratio of 41.6%-63.6% : 27.3%-41.6% : 9.1%-16.8%; 5%-8% of immobilized lipase Lipozyme RMIM catalytic system by mass is added for transesterification at the reaction temperature of 60 DEG C-70 DEG C for 5-7 hours; and molecular distillation deacidification is performed at the distillation temperature of 160 DEG C-200 DEG C and at the cooling water temperature of 10 DEG C-20 DEG C to obtain shortening. The invention provides an application method of the rice bran solid lipid, and the rice bran solid lipid can be sufficiently developed and utilized.

Owner:JIANGNAN UNIV

Dried figs prepared by virtue of closed loop dehumidification-heat pump technique and preparation method of dried figs

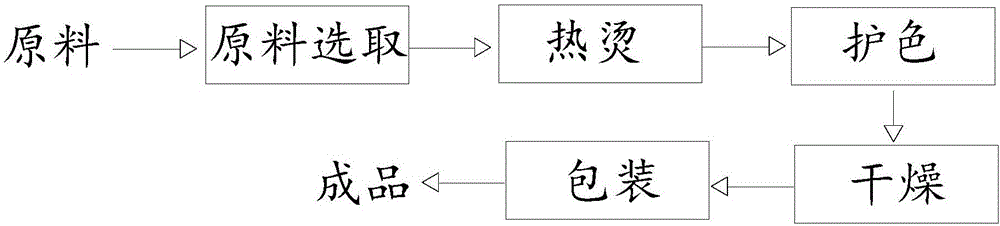

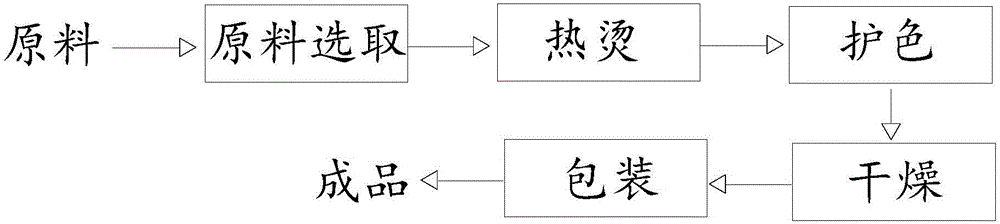

InactiveCN106720204AStay organizedKeep the smellFood processingFruits/vegetable preservation by heatingFlavorNutrient content

The invention provides a method for preparing dried figs by virtue of a closed loop dehumidification-heat pump technique. The dried figs are prepared through raw material selection, hot ironing, color protection, drying and packaging by virtue of the closed loop dehumidification-heat pump technique. According to the closed loop dehumidification-heat pump technique, the original organizational form, smell, good sensory evaluation and nutrient content of the figs can be furthest preserved, the moisture content of the products is low, the internal cellular structure is undamaged, and the original state, color, smell, flavor and active ingredients of the fresh figs can be basically preserved; and furthermore, the process is simple, the production efficiency is high, the energy consumption is low, and the clean production requirements of energy saving, emission reduction and effect enhancement are met.

Owner:FOSHAN UNIVERSITY

Preparation method of human homologous tendon

InactiveCN102166373AEffectively control the concentration rangeGuaranteed mechanical propertiesProsthesisLoose connective tissueBiological materials

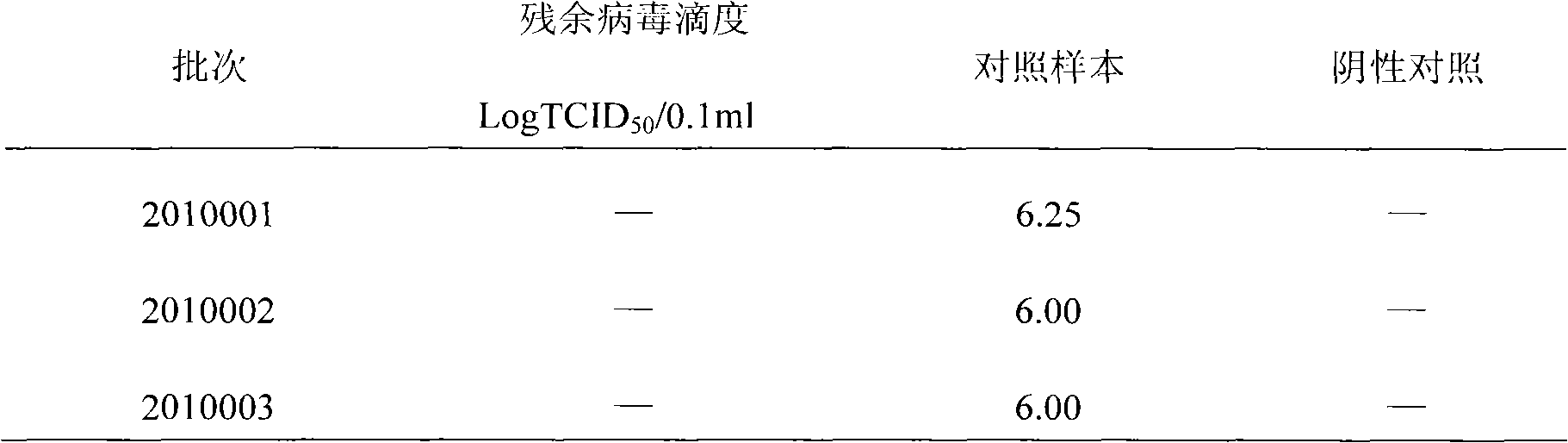

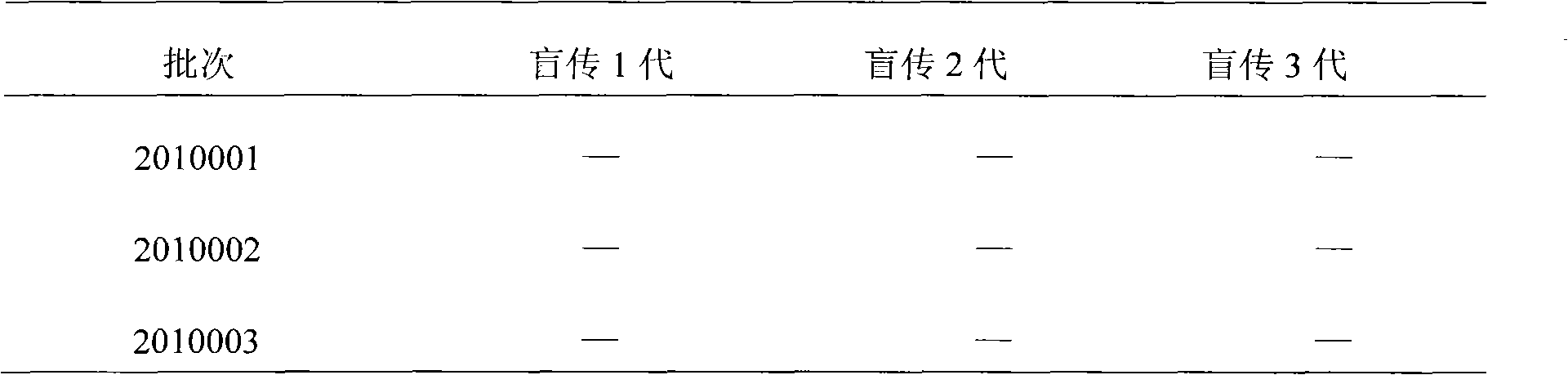

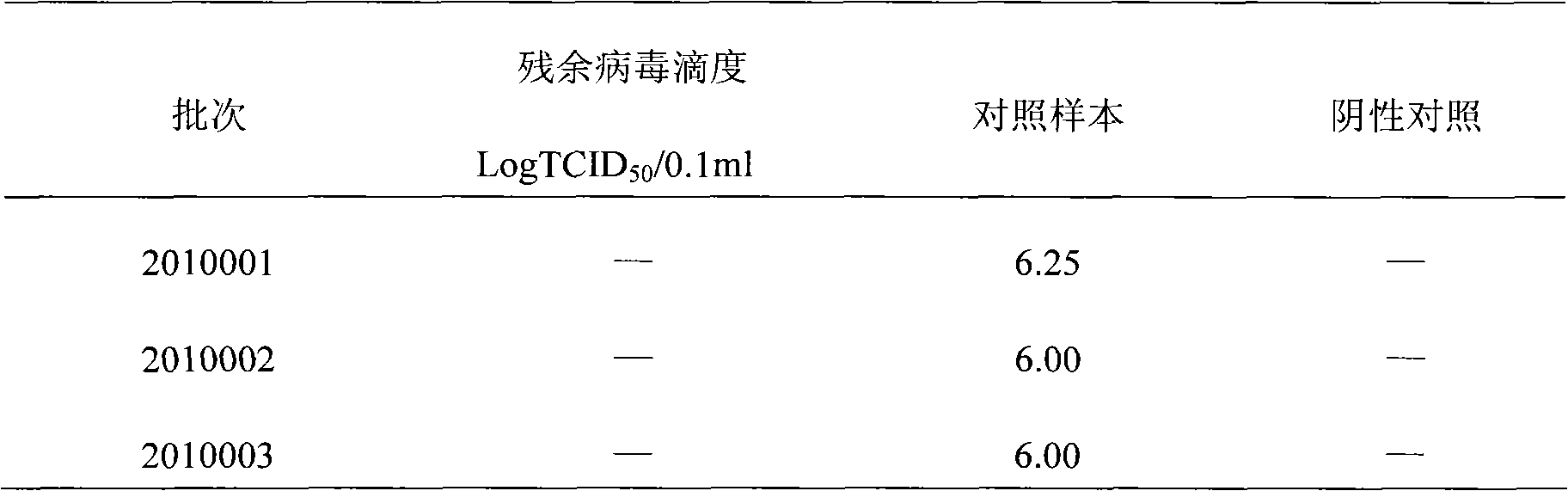

The invention relates to a preparation method of human homologous tendon, which belongs to the technical field of biomedical materials. The invention mainly solves the technical problems of immunological rejection, bacterial infection, virus infection, complicated operation steps, and the like in the traditional method for transplanting homologous tendon. The preparation method of human homologous tendon comprises the following steps of: (1) cleaning the human homologous tendon; (2) freezing the cleaned human homologous tendon for 30-90 days; (3) trimming loose connective tissues surrounding the tendon; (4) immersing the trimmed tendon material in a mixed solution of peroxyacetic acid, ethanol and water, standing still for inactivation of viruses; (5) cleaning the inactivated tendon with water until the content of the peroxyacetic acid in the cleaning solution reaches a certain value for the last time; (6) trimming the tendon again, dripping the water on the surface of the tendon, vacuumizing the trimmed tendon under an aseptic condition, and packing twice by common packaging; and (7) radiating the packed tendon by using Cobalt-60 for disinfection again. The invention has the advantages of no immunological rejection, no bacterial or virus infection, easiness for operation, no drug residue, and the like.

Owner:山西奥瑞生物材料有限公司

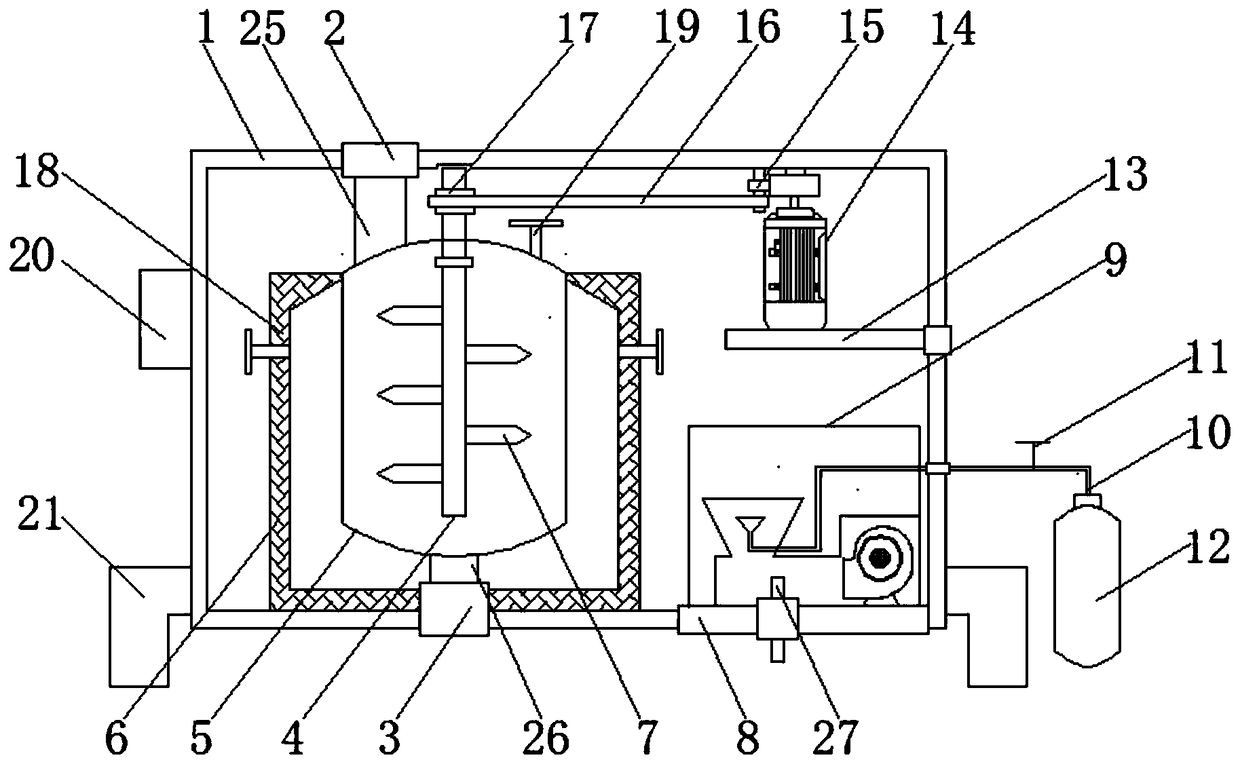

Heat-dissipating type food stirring device

InactiveCN108722307AMaintain colorKeep the flavorTransportation and packagingRotary stirring mixersCold airAgricultural engineering

The invention discloses a heat-dissipating type food stirring device, and relates to the technical field of food processing. The device comprises an outer frame, wherein a feeding port is formed in the top part of the outer frame, and a feeding pipe communicates with the bottom part of the feeding port; a tank body is fixedly connected to the bottom part of the feeding pipe; a cold air circulatingrefrigerating device is fixedly connected to the bottom part of the outer frame; a motor is connected to the inner right side of the outer frame; a first rotating wheel is fixedly connected to an output shaft of the motor through a speed reducer; a second rotating wheel is in transmission connection with the surface of the first rotating wheel through a conveyor belt; and a rotating shaft is fixedly connected to an axis of the second rotating wheel. The heat-dissipating type food stirring device achieves the purposes of circularly cooling air, saving liquid nitrogen source, decreasing primaryinvestment, continuously efficiently dissipating heat, maintaining the color, flavor and structure of foods, and storing well; in addition, continuous feeding is realized through the feeding port; and the device is controlled to run normally through a self-control electric cabinet.

Owner:付欣

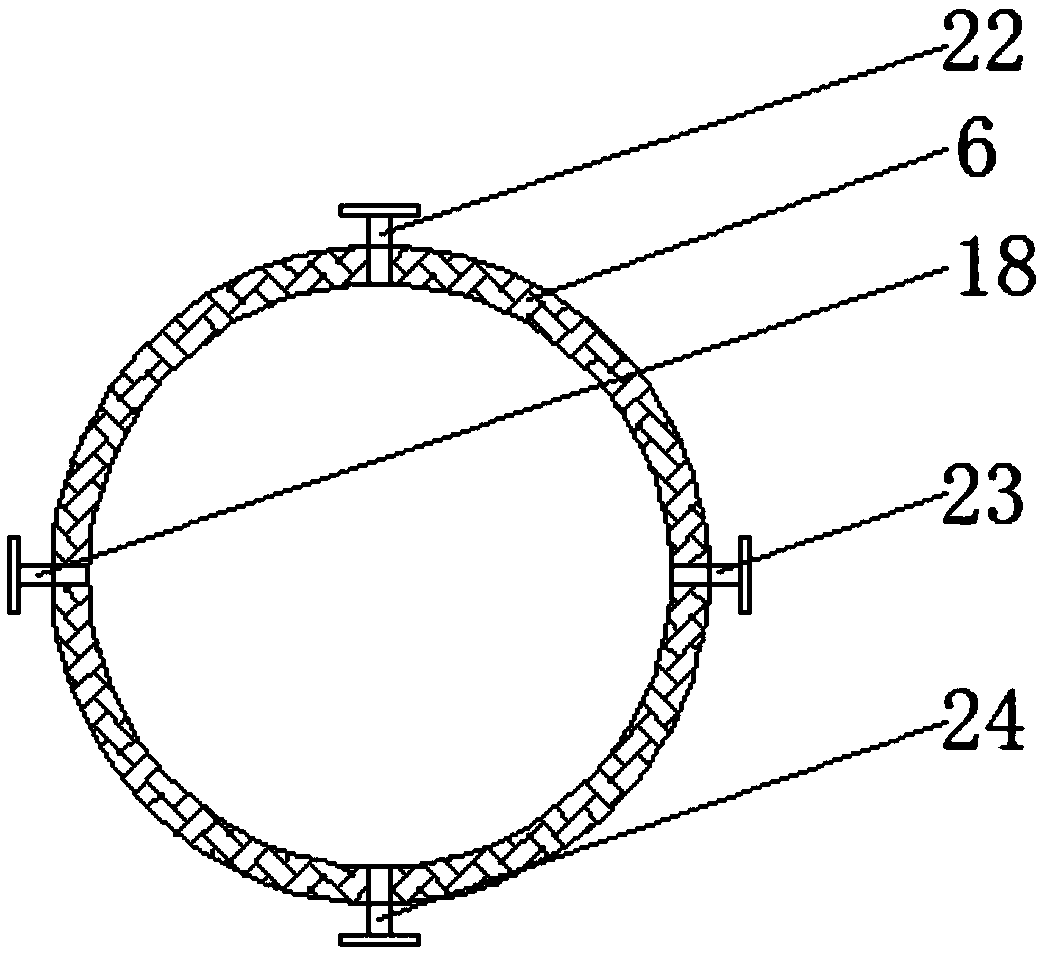

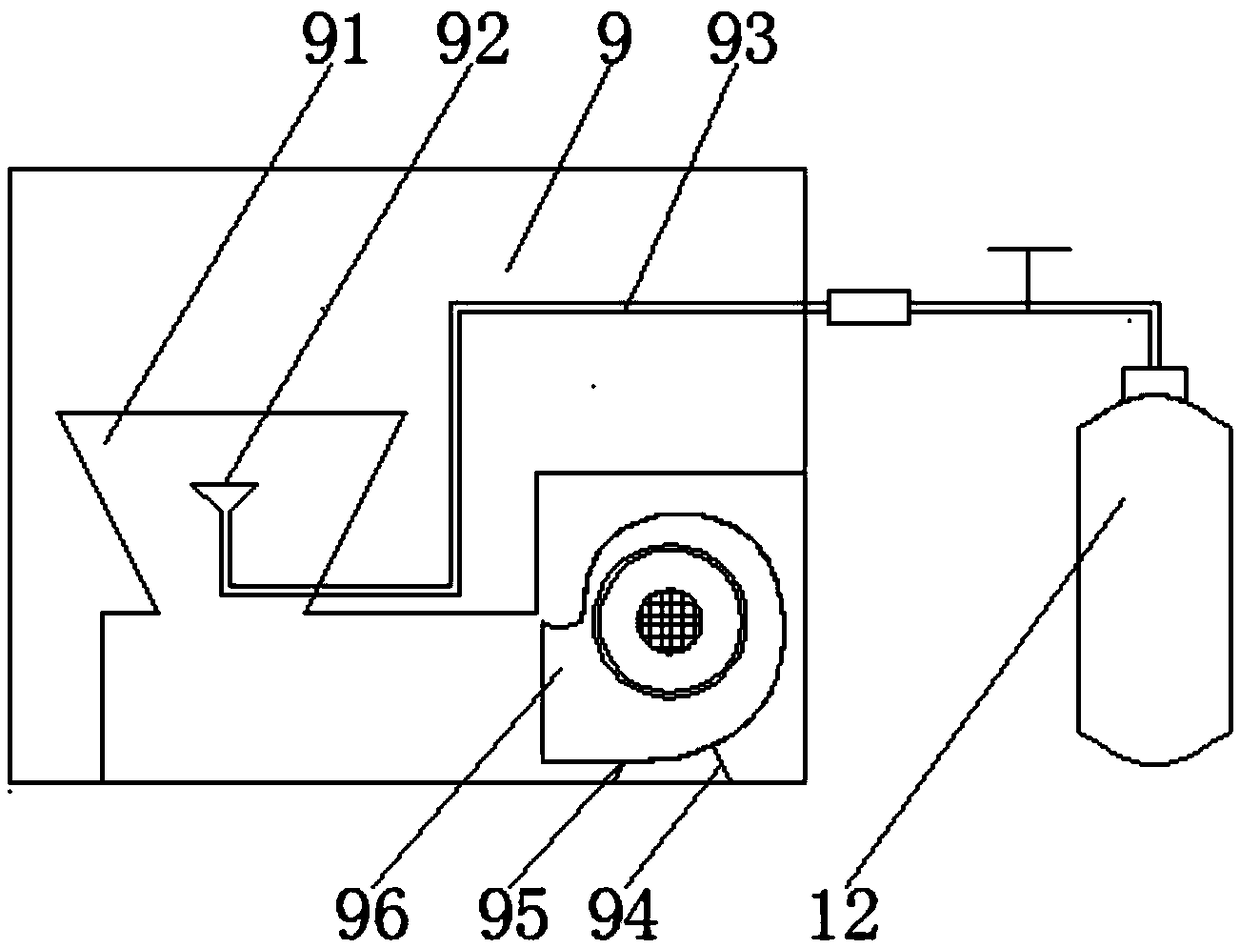

Freezing process for fishes

ActiveCN110100874AGuaranteed preservation qualityPrevent spoilageMeat/fish preservation by freezing/coolingFlavorCryopreservation

The invention provides a freezing process for fishes. The process comprises the following steps that the to-be-frozen fishes are put in flow-state ice at 0 DEG C to be pre-frozen for 1-2 hours, then quickly frozen at low temperature and subjected to cold preservation after being quickly frozen. By means of the method, the fishes can be actually cryopreserved for a long time (6-12 months), and thefood quality can be kept. The process can be actually applied to the cryopreservation of the fishes, the pre-freezing and quick-freezing techniques have small damage to the cells of the fishes, and flavor components and nutritional characteristics of the fishes can be preserved to a great extent. The process has actual application prospects for the cryopreservation of the fishes.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Method for producing dried mulberries by virtue of closed-loop dehumidification-heat pump technique

The invention provides a method for producing dried mulberries by virtue of a closed-loop dehumidification-heat pump technique. The dried mulberries are produced by the step of raw material selection, hot ironing, color protection, drying and packaging processing by virtue of the closed-loop dehumidification-heat pump technique. By virtue of the closed-loop dehumidification-heat pump technique, the original tissue form, odor, good sensory evaluation and nutrients are furthest maintained, the product is low in moisture content and has complete internal cell structures, and the original form, color, odor, flavor and active components of fresh mulberries can be basically preserved; and furthermore, the process is simple, the production efficiency is high, the energy consumption is low, and the method is accordant with clean production requirements on energy conservation, emission reduction and effect enhancement.

Owner:FOSHAN UNIVERSITY

Quick-freezing liquid for preserving food, preparation method and use method of quick-freezing liquid

InactiveCN107455443AMaintain colorKeep the smellMeat/fish preservation by freezing/coolingQuick FreezeSide effect

The invention provides quick-freezing liquid for preserving food. The quick-freezing liquid comprises the following components in parts by weight: 30-35 parts of purified water, 8-10 parts of sodium chloride, 25-30 parts of ethyl alcohol, 15-20 parts of chitosan, 0.5-2 parts of acetic acid or 1.5-6 parts of alginic acid and 10-15 parts of active components. The quick-freezing liquid for preserving food provided by the invention has an excellent antibacterial property, is free from toxic and side effects or secondary pollution to food and is high in heat conduction rate in the freezing process of food, so that the ice crystal formed in the food histocyte is small, the cells are prevented from mechanical damage and no drying loss is generated; no nutrient substance is lost in the unfreezing process; the original color, flavor and tissue state of food are kept; after the quick-freezing liquid is regulated with a harmless additive, the freezing speed and the antibacterial property are both kept, so that the quick-freezing liquid is reusable, high in use ratio, low in cost and expected to be widely used in the field of food quick-freezing processing.

Owner:明洋

Manufacturing method of quick-freeze taros

InactiveCN108703333AGood lookingAging is not obviousFruits/vegetable preservation by freezing/coolingQuick FreezeCold air

The invention discloses a manufacturing method of quick-freeze taros. According to the technology, on the basis of improving the manufacturing safety and continuity, quick-freezing and freshness retaining are performed on taros by applying the methods for earlier-stage decontamination, continuous steam digestion, sterile cold air cooling and monomer quick-freezing, the quality of the quick-freezetaros is improved, the obtained quick-freeze taros are not likely to age or go bad, the texture structure is perfect, and the taros are easily cooked thoroughly.

Owner:王爱明

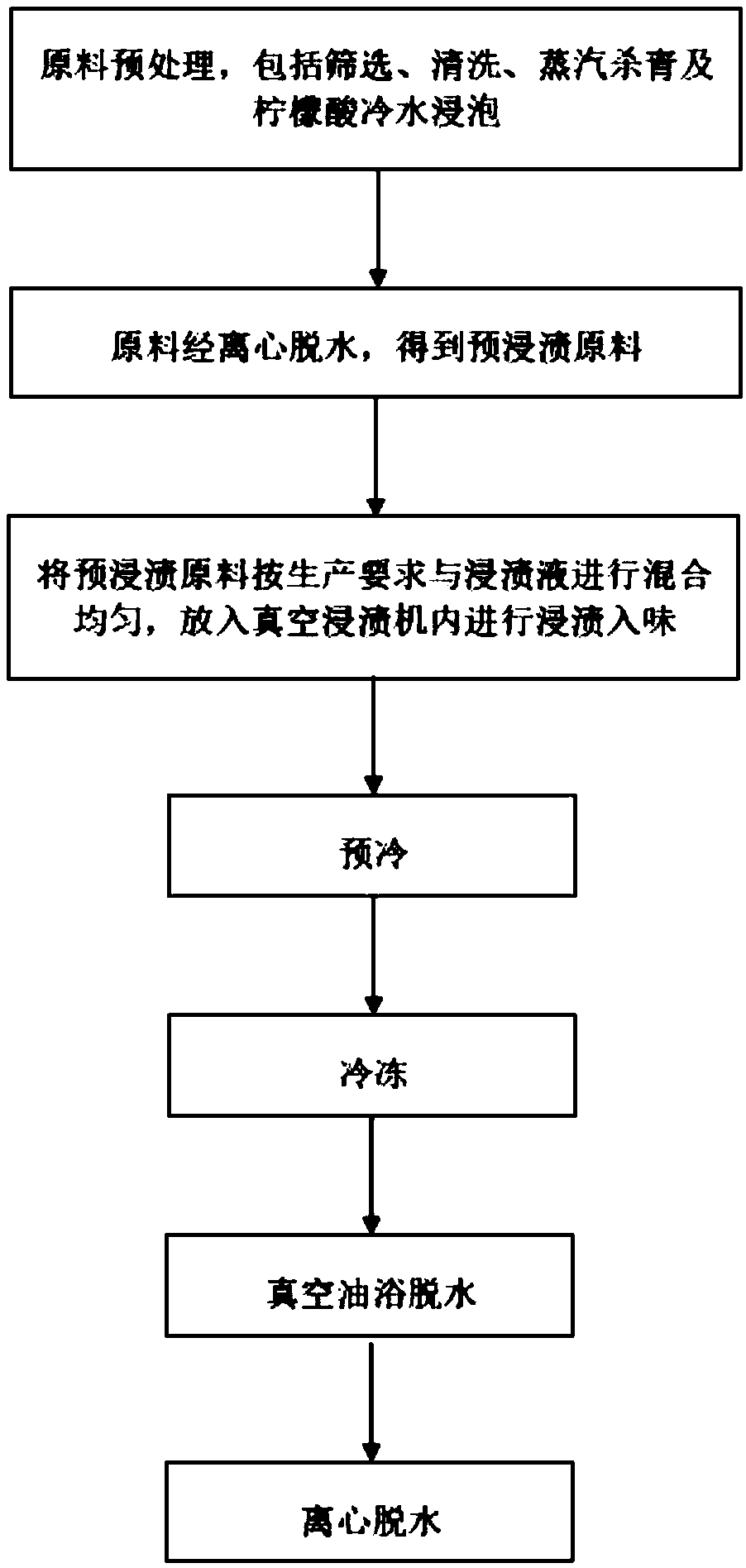

Preparation method of fruit-vegetable crisps applying trehalose

InactiveCN109258783AKeep the original colorLow hygroscopicityConfectionerySweetmeatsPre treatmentFruits vegetables

The invention discloses a preparation method of fruit-vegetable crisps applying trehalose. The method comprises the following steps: performing screening on the raw materials, cleaning, steam de-enzyming and soaking in citric acid cold water to obtain pretreated raw materials; performing centrifugal dehydration on the pretreated raw materials to obtain pre-impregnated raw materials; uniformly mixing the pre-impregnated raw materials with impregnation liquid according to the production requirements, and impregnating in a vacuum impregnation machine for good taste, wherein the impregnation liquid is prepared from trehalose and an emulsifier; sequentially performing pre-cooling, freezing, vacuum oil-bath dehydration and centrifugal oil removal on the impregnated raw materials to obtain the fruit-vegetable crisps. The impregnation technology provided by the invention adopts the trehalose and the emulsifier, maintains original color of the food and avoids shrinking of the raw materials; moreover, rehydration is fast, the tissue structure of original food is maintained, the blood glucose reaction is steady, and the sweetness quality of the food is improved; moreover, the cariogenicity islow. In the treatment of raw materials, a centrifugal dehydration treating technology is added before the impregnation technology, then the yield of semi-finished products is increased by 15%, and the production efficiency is improved.

Owner:BEIJING KAIDA HENGYE AGRI TECH DEV

Preparation method for chicken-vegetable composite pickles

InactiveCN105475926AReduce nitrite levelsNo nitrite poisoningFood scienceBarbed Skullcap HerbUltra high pressure

The invention discloses a preparation method for chicken-vegetable composite pickles. The chicken-vegetable composite pickles are prepared from chicken, bean sprout, cucumber, pumpkin, garlic, salt, water, thick broad-bean sauce, Char siu sauce, coconut milk, coconut oil, oyster sauce, Chinese prickly ash, beet sugar, sucralose, lycopene, taro polysaccharide, protamine, carragheenan, pectin, alcohol extract of Yedo violet and alcohol extract of barbed skullcap herb through cleaning, blanching, standing in ice water, pickling, re-pickling, ultra-high pressure treatment and standing at room temperature. The content of nitrite in the prepared pickles substantially reduces and is almost zero; and the prepared pickles have improved crispiness, taste crispy and refreshing and effectively retain nutritional components in vegetable, and the total bacterium number of the prepared pickles does not exceed standard, so the prepared pickles have good security.

Owner:CHONGQING SHENGYAN FOOD

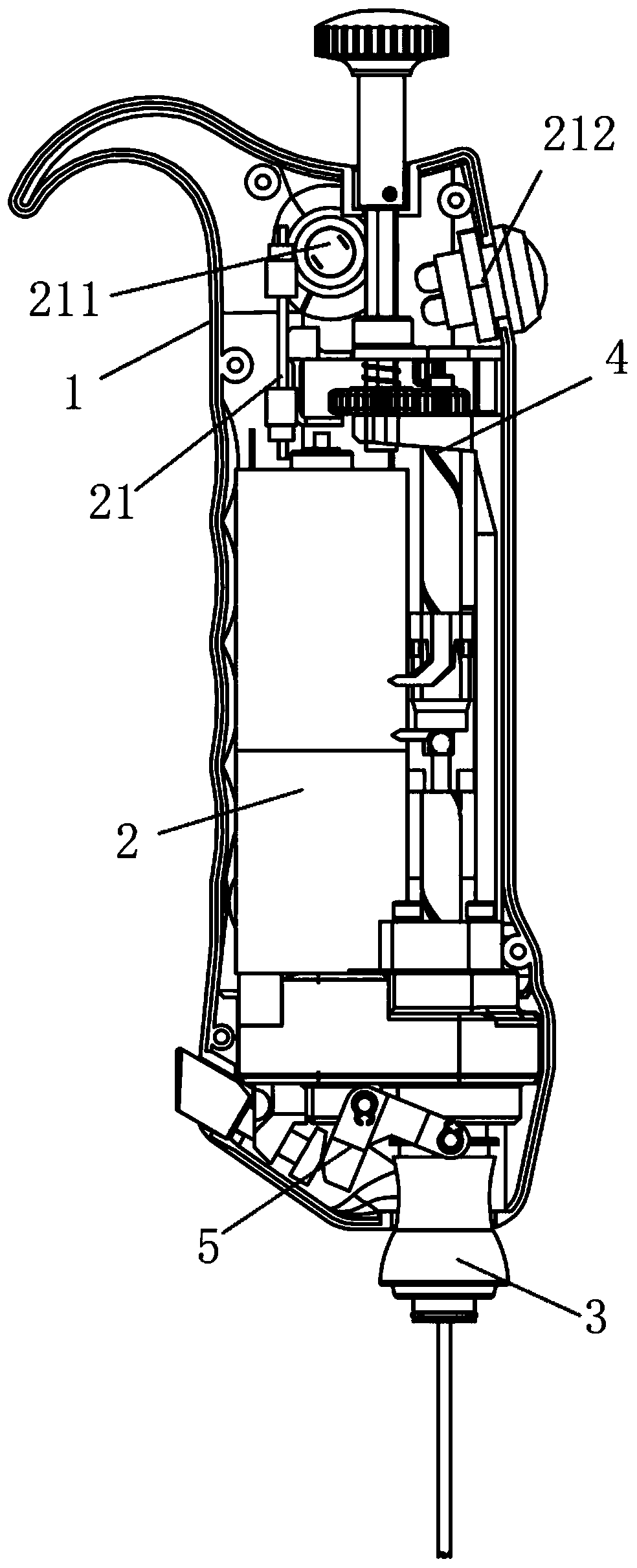

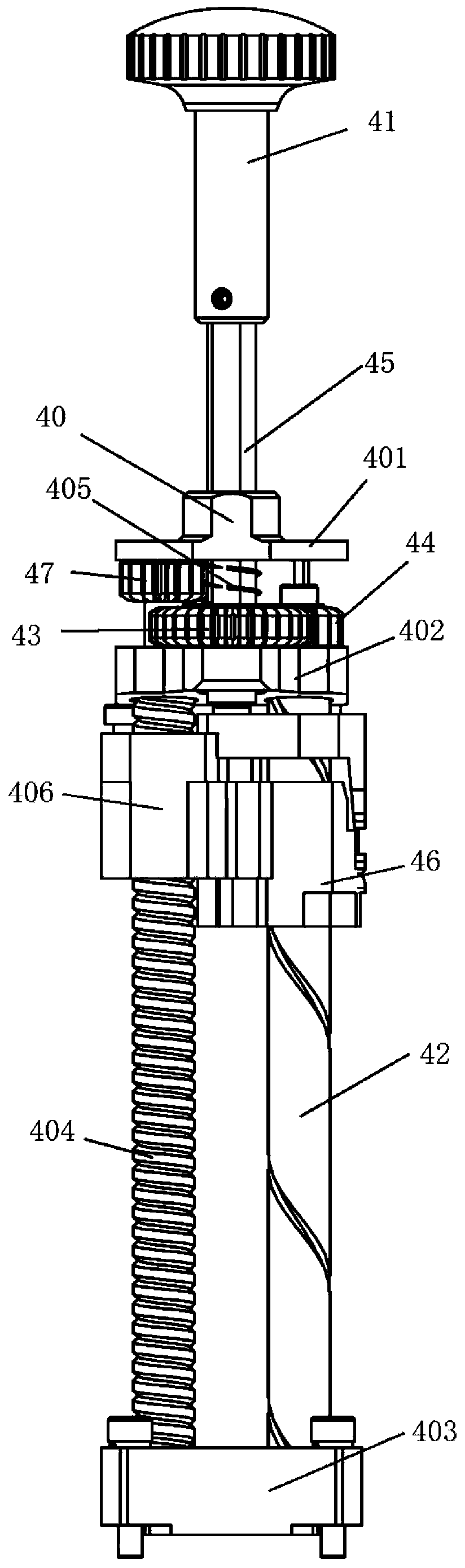

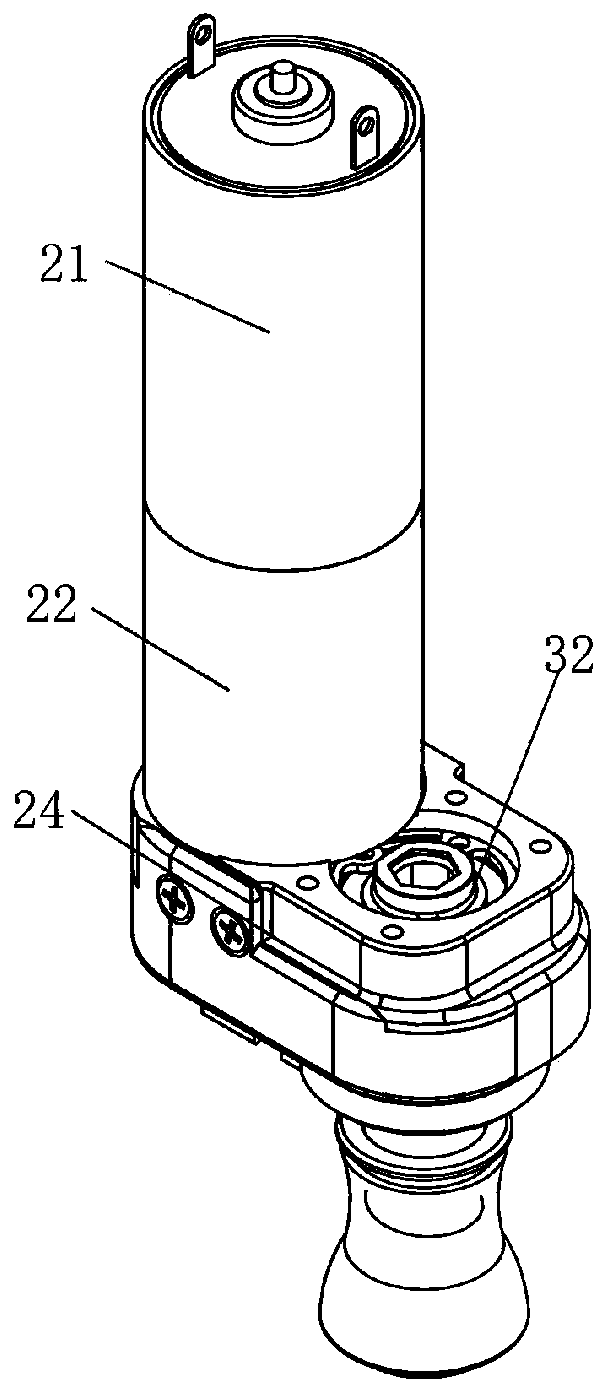

Sampling device

The invention discloses a sampling device, which comprises a shell, wherein a drive assembly, a drill pin assembly and a discharge assembly are arranged in the shell; the drill pin assembly comprisesa drill pin and a drill pin mounting shaft; the drill pin mounting shaft is connected with the drive assembly and can drive the drill pin to rotate under the drive of the drive assembly; the dischargeassembly comprises a knob and a discharge screw rod; the discharge screw rod is connected with the drill pin assembly; the knob is connected with the discharge screw rod and can drive the discharge screw rod to rotate to discharge materials; and an experimenter operates the sampling device with one hand, clamps a to-be-sampled mother sample on a special freezing table, clamps a special limiting sleeve on a sampling test tube, starts a button and presses the sampling device to carry out sampling work. The sampling work is completed when the sampling quantity meets the original set quantity, and the sampled sample is spun out into a target container. The frozen sample is quantitatively taken out in a targeted manner on the premise of keeping the mother sample in a non-frozen-thawed state, and the original tissue property of an experimental sample is kept to the maximum extent.

Owner:SHANGHAI LIGOU SENSOR SCI & TECH

Preparation method of human homologous tendon

InactiveCN102166373BEffectively control the concentration rangeGuaranteed mechanical propertiesProsthesisLoose connective tissueBiological materials

The invention relates to a preparation method of human homologous tendon, which belongs to the technical field of biomedical materials. The invention mainly solves the technical problems of immunological rejection, bacterial infection, virus infection, complicated operation steps, and the like in the traditional method for transplanting homologous tendon. The preparation method of human homologous tendon comprises the following steps of: (1) cleaning the human homologous tendon; (2) freezing the cleaned human homologous tendon for 30-90 days; (3) trimming loose connective tissues surrounding the tendon; (4) immersing the trimmed tendon material in a mixed solution of peroxyacetic acid, ethanol and water, standing still for inactivation of viruses; (5) cleaning the inactivated tendon with water until the content of the peroxyacetic acid in the cleaning solution reaches a certain value for the last time; (6) trimming the tendon again, dripping the water on the surface of the tendon, vacuumizing the trimmed tendon under an aseptic condition, and packing twice by common packaging; and (7) radiating the packed tendon by using Cobalt-60 for disinfection again. The invention has the advantages of no immunological rejection, no bacterial or virus infection, easiness for operation, no drug residue, and the like.

Owner:山西奥瑞生物材料有限公司

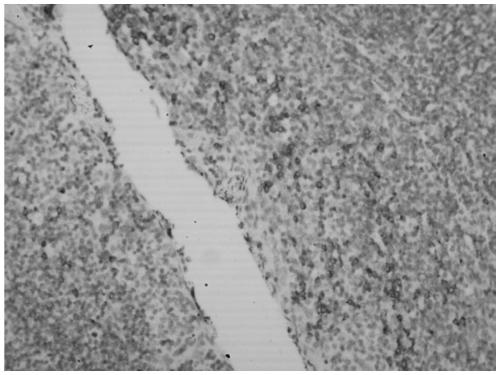

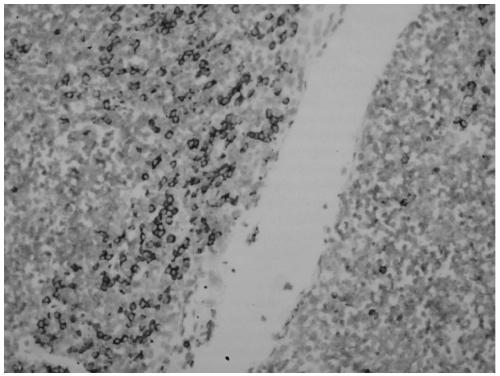

Hybridization solution for in-situ hybridization, preparation method of solution and detection kit

ActiveCN110257483AImprovement of organizational formReduce damageMicrobiological testing/measurementIn situ hybridizationChemistry

The invention relates to a hybridization solution for in-situ hybridization, a preparation method of the solution and an in-situ hybridization detection kit. The hybridization solution for in-situ hybridization comprises the following final concentration components: formamide with the volume percentage concentration not exceeding 2%, fluoride with the weight percentage concentration of 0.1-10%, SSC with the weight percentage concentration of 2-4 times, 1-10mM of EDTA, Denhardts solution with the concentration of 1-5 times, dextran sulfate with the weight percentage concentration of 5-10%, salmon sperm DNA with 0.1-1mg / mL, and 50-100mM of disodium hydrogen phosphate-sodium dihydrogen phosphate buffer solution or Tris-HCl buffer solution with the pH of 7.0. The hybridization solution for in-situ hybridization can improve hybridization efficiency and shorten hybridization time under the condition of ensuring hybridization signals.

Owner:XIAMEN TALENT BIOMEDICAL TECH CO LTD

Processing method for improving corrosion resistance of pot stewed meat products

InactiveCN108887604ALess damage to nutrientsFull of nutritionFood preservationFood ingredient for microbe protectionNutrientChemistry

The invention relates to a processing method for improving corrosion resistance of pot stewed meat products. The processing method comprises the following steps: unfreezing raw materials, selecting meat materials, stewing or marinating, cooking at a high temperature, cooling, checking, acquiring end products, and the like. In the step of cooking at a high temperature, lysozyme as a preservative and the meat materials are put into a pot, wherein the mass ratio of lysozyme to meat materials is 1:5000. The processing method for improving corrosion resistance of pot stewed meat products is capableof effectively prolonging the shelf life; the lysozyme as a natural protein is capable of acting in stomach and intestine for absorbing nutrients, is nontoxic to human body, will not remain in body,has an excellent insurance effect and meanwhile will not damage the original flavor and taste of the products and has an excellent effect of enhancing taste; the processed pot stewed meat products arerich in nutrition, taste tender and smooth and have an ideal technical effect.

Owner:本溪市双花熟食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com