Preparation method of fruit-vegetable crisps applying trehalose

A technology for fruit and vegetable chips and trehalose, which is applied to the preservation of fruits/vegetables with sugar, preservation of fruits and vegetables, confectionery, etc., can solve the problems of inability to achieve immersion preservation, inability to effectively increase the osmotic pressure of food, and low sweetness of trehalose, etc. , to maintain the original color, increase the glass transition temperature, and prolong the preservation period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

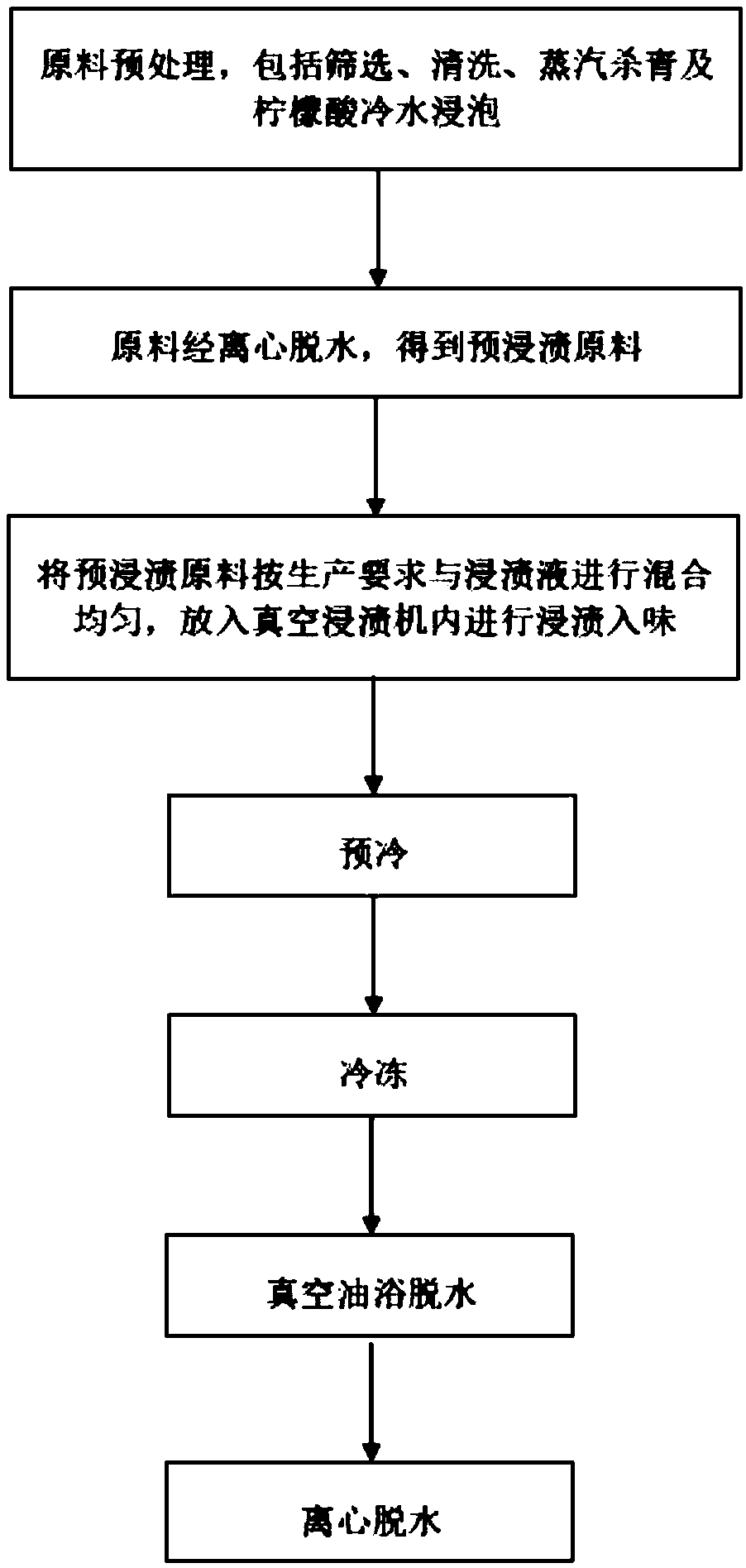

[0023] combine figure 1 As shown, a method for preparing apple crisps mainly includes the following steps: pretreatment, centrifugal dehydration, dipping, precooling, freezing, vacuum oil bath dehydration, centrifugal deoiling;

[0024] (1) Pretreatment: classify the raw materials, select qualified raw materials, and then process them into certain specifications, clean them, and fix them with 100°C hot steam for 80 seconds, then soak them in cold water containing 0.8% citric acid and cool them to normal temperature to obtain Pretreatment of raw materials;

[0025] (2) Centrifugal dehydration: carry out centrifugal dehydration to the pretreated raw materials to obtain pre-impregnated raw materials; the centrifugal dehydration parameters are centrifuge speed 250 rpm, dehydration time 3min;

[0026] (3) Impregnation: Mix the pre-impregnated raw materials with the impregnating liquid evenly according to the production requirements, and put them into a vacuum impregnating machine ...

Embodiment 2

[0032] combine figure 1 As shown, a preparation method of carrot chips mainly includes the following steps: pretreatment, centrifugal dehydration, dipping, precooling, freezing, vacuum oil bath dehydration, centrifugal deoiling;

[0033] (1) Pretreatment: classify raw materials, select qualified raw materials, and then process them into certain specifications, clean them, and fix them with 140°C hot steam for 60 seconds, then soak them in cold water containing 1.2% citric acid and cool them to normal temperature to obtain Pretreatment of raw materials;

[0034] (2) Centrifugal dehydration: carry out centrifugal dehydration to the pretreated raw materials to obtain pre-impregnated raw materials; the centrifugal dehydration parameters are centrifuge speed 200 rpm, dehydration time 5min;

[0035] (3) Impregnation: Mix the pre-impregnated raw materials with the impregnating liquid evenly according to the production requirements, and put them into a vacuum impregnating machine for...

Embodiment 3

[0041] combine figure 1 Shown, a kind of preparation method of sweet potato chips mainly includes the following steps: pretreatment, centrifugal dehydration, dipping, precooling, freezing, vacuum oil bath dehydration, centrifugal deoiling;

[0042] (1) Pretreatment: classify the raw materials, select qualified raw materials, then process them into certain specifications, clean them, and fix them with 120°C hot steam for 70 seconds, then soak them in cold water containing 1.0% citric acid and cool them to normal temperature to obtain Pretreatment of raw materials;

[0043] (2) Centrifugal dehydration: carry out centrifugal dehydration to the pretreated raw materials to obtain pre-impregnated raw materials; the centrifugal dehydration parameters are centrifuge speed 230 rpm, dehydration time 4min;

[0044](3) Impregnation: Mix the pre-impregnated raw materials with the impregnating liquid evenly according to the production requirements, and put them into a vacuum impregnating m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com