Method for producing dried mulberries by virtue of closed-loop dehumidification-heat pump technique

A heat pump technology and heat pump drying technology, which is applied in the field of food manufacturing, can solve the problems of short storage time and achieve the effect of good taste, full texture and strong original fruit flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

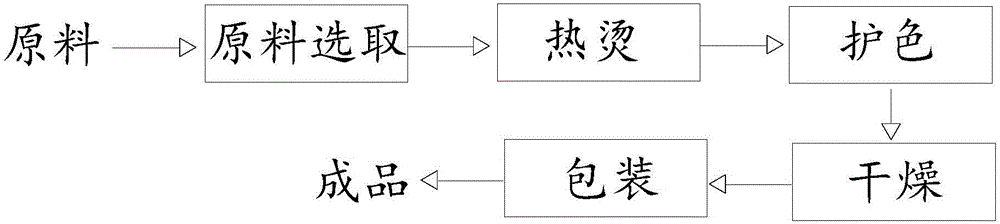

[0023] Example 1, see figure 1 :

[0024] The invention provides a method for making dried mulberries by adopting closed-loop dehumidification-heat pump technology. The closed-loop dehumidification-heat pump drying technology comprises the following steps:

[0025] 1) Raw material selection: select fresh and plump mulberries, nearly mature, free from rot and mechanical damage, and have basically the same shape;

[0026] 2) blanching: blanching the mulberries at 72°C;

[0027] 3) Color protection: pour the blanched mulberries into CaCl with a mass concentration of 0.2%. 2 solution, soak for 38min, remove the mulberries, rinse with clean water, remove Ca 2+ ;

[0028] 4) Drying: Drain the mulberries after color protection, lay them flat on a plate, and send them to a closed-loop dehumidification-heat pump dryer to dry for 480 minutes. The relationship between temperature and relative humidity over time is: 0~20min (80℃, 35%)→21~90min(45℃, 25%)→91~240min(40℃, 25%)→241~480min...

Embodiment 2

[0032] The invention provides a method for making dried mulberries by adopting closed-loop dehumidification-heat pump technology. The closed-loop dehumidification-heat pump drying technology comprises the following steps:

[0033] 1) Raw material selection: select fresh and plump mulberries, nearly mature, free from rot and mechanical damage, and have basically the same shape;

[0034] 2) blanching: blanching the mulberries at 75°C;

[0035] 3) Color protection: pour the blanched mulberries into CaCl with a mass concentration of 0.2%. 2 solution, soak for 55min, remove the mulberries, rinse with clean water, remove Ca 2+ ;

[0036] 4) Drying: Drain the mulberries after color protection, spread them on a plate, and send them to a closed-loop dehumidification-heat pump dryer for 400 minutes. The relationship between temperature and relative humidity over time is: 0~20min (75℃, 25%)→21~90min(45℃, 25%)→91~240min(40℃, 25%)→241~400min(40℃ , 20%);

[0037] 5) Packaging: Cool the...

Embodiment 3

[0040] The invention provides a method for making dried mulberries by adopting closed-loop dehumidification-heat pump technology. The closed-loop dehumidification-heat pump drying technology comprises the following steps:

[0041] 1) Raw material selection: select fresh and plump mulberries, nearly mature, free from rot and mechanical damage, and have basically the same shape;

[0042] 2) blanching: blanching the mulberries at 79°C;

[0043] 3) Color protection: pour the blanched mulberries into CaCl with a mass concentration of 0.2%. 2 solution, soak for 89min, remove the mulberries, rinse with clean water, and remove Ca 2+ ;

[0044]4) Drying: Drain the mulberries after color protection, lay them flat on a plate, and send them to a closed-loop dehumidification-heat pump dryer to dry for 480 minutes. The relationship between temperature and relative humidity over time is: 0~20min (80℃, 35%)→21~90min(50℃, 25%)→91~240min(45℃, 25%)→241~480min(45℃ , 20%);

[0045] 5) Packagi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com