Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Small heating space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

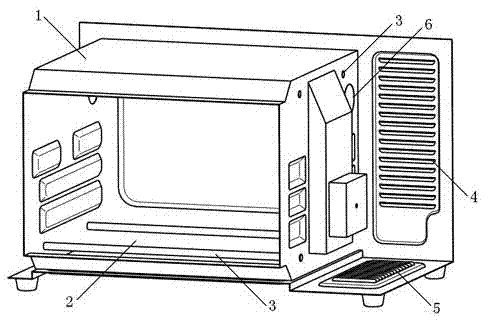

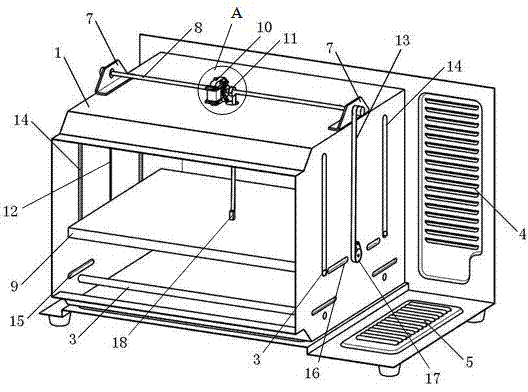

Electric oven with baking pipe capable of moving up and down

InactiveCN102188164AReduce lossesRealize functionRoasting apparatusRoasters/grillsEngineeringMotor shaft

The invention discloses an electric oven with a baking pipe capable of moving up and down. The electric oven comprises an oven shell which defines a cavity. The lower part of the cavity is provided with two baking pipes for cooking food; the two ends of the upper wall of the oven shell are provided with supporting frames for supporting a motor shaft; the motor shaft is connected with a motor fixed on the upper wall of the oven shell and a middle transmission belt; the cavity is internally and horizontally provided with a partition plate and the baking plate is arranged at the lower side of the partition plate; one end of the middle transmission belt is connected with a belt wheel on the motor shaft, and the other end of the middle transmission belt passes through a hole on the top surface of the oven shell and is connected with the partition plate; the two side walls of the oven shell are provided with longitudinal guide grooves corresponding to the baking pipe on the partition plate; and the two ends of the baking pipe on the partition plate go out of the two sides of the partition plate and are connected in the guide grooves. According to the height of food, the size of the cavity of the heating part of the electric oven can be adjusted to reduce redundant heating space, thereby increasing the heating speed and energy loss; and when the partition plate falls to the lowest position, baking trays are respectively put on an upper-layer baking tray support and a lower-layer baking tray support in the cavity, so that the function of an electric baking pan can be achieved.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

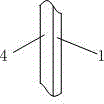

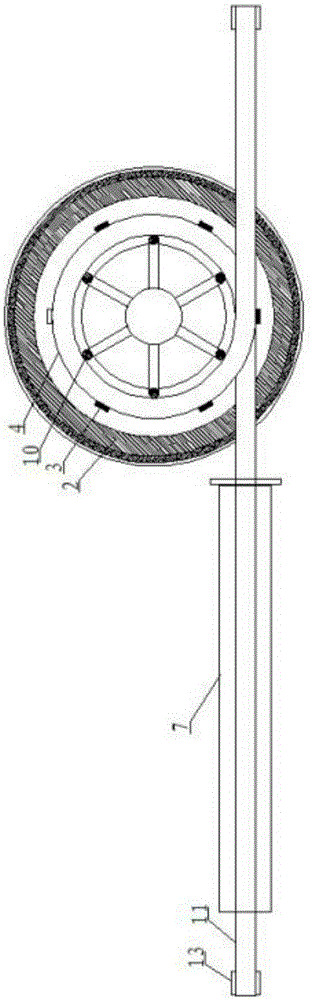

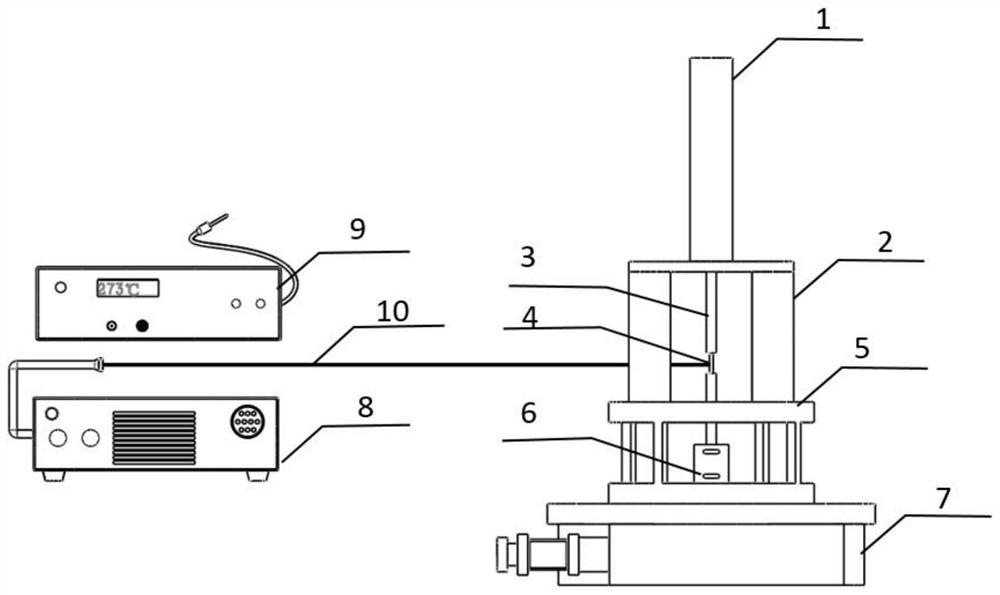

Monitoring equipment lens ITO heating and de-icing device

InactiveCN103957346AHeating fastSmall heating spaceTelevision system detailsColor television detailsTemperature controlEngineering

A monitoring equipment lens ITO heating and de-icing device comprises a monitoring equipment lens (4) and is characterized in that a layer of resistor composed of an ITO transparent conductive film (1) is arranged on the outer surface of the monitoring equipment lens (4), the resistor composed of the ITO transparent conductive film is connected with a temperature control circuit (2), and the temperature control circuit (2) is connected with a temperature sensor (3). The device has the advantages that the monitoring equipment lens can be de-iced quickly or the surface of the monitoring equipment lens is prevented from icing, heating is quick, heating space is small, and the de-icing effect and the de-dewing effect are good.

Owner:徐继胜

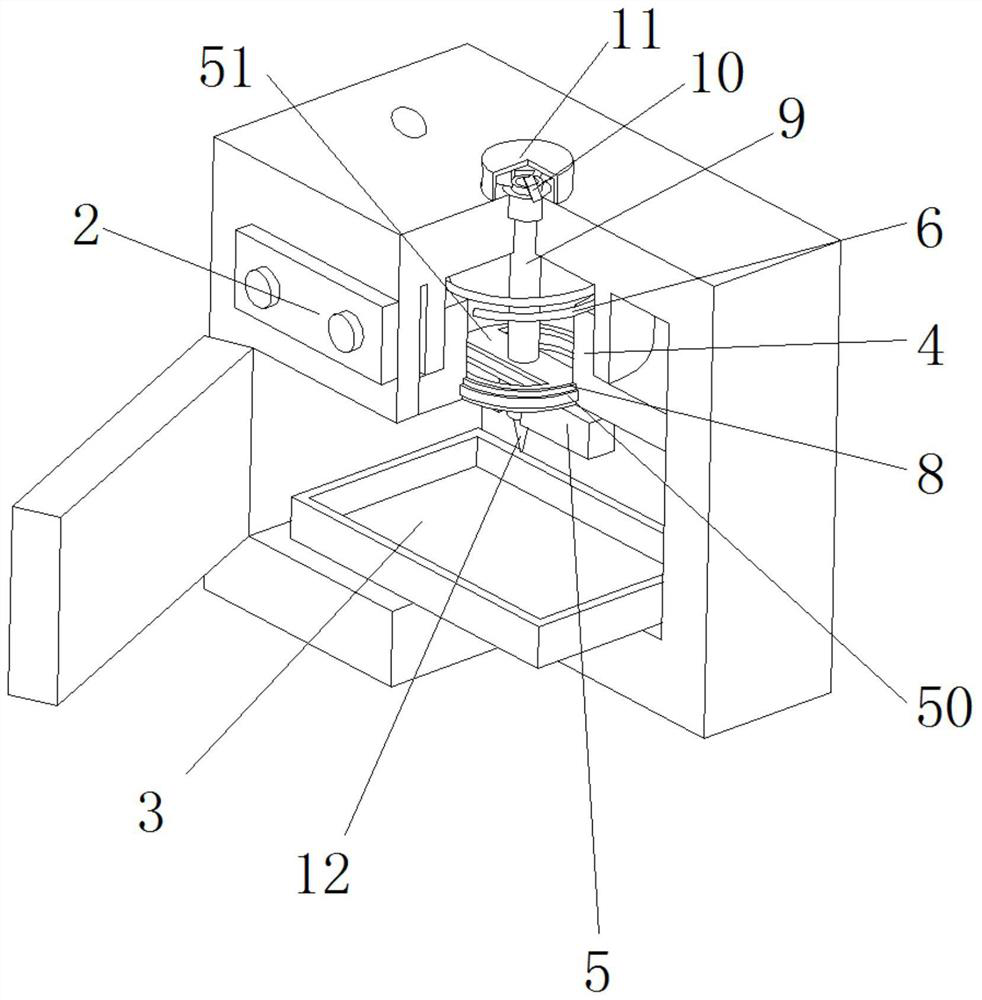

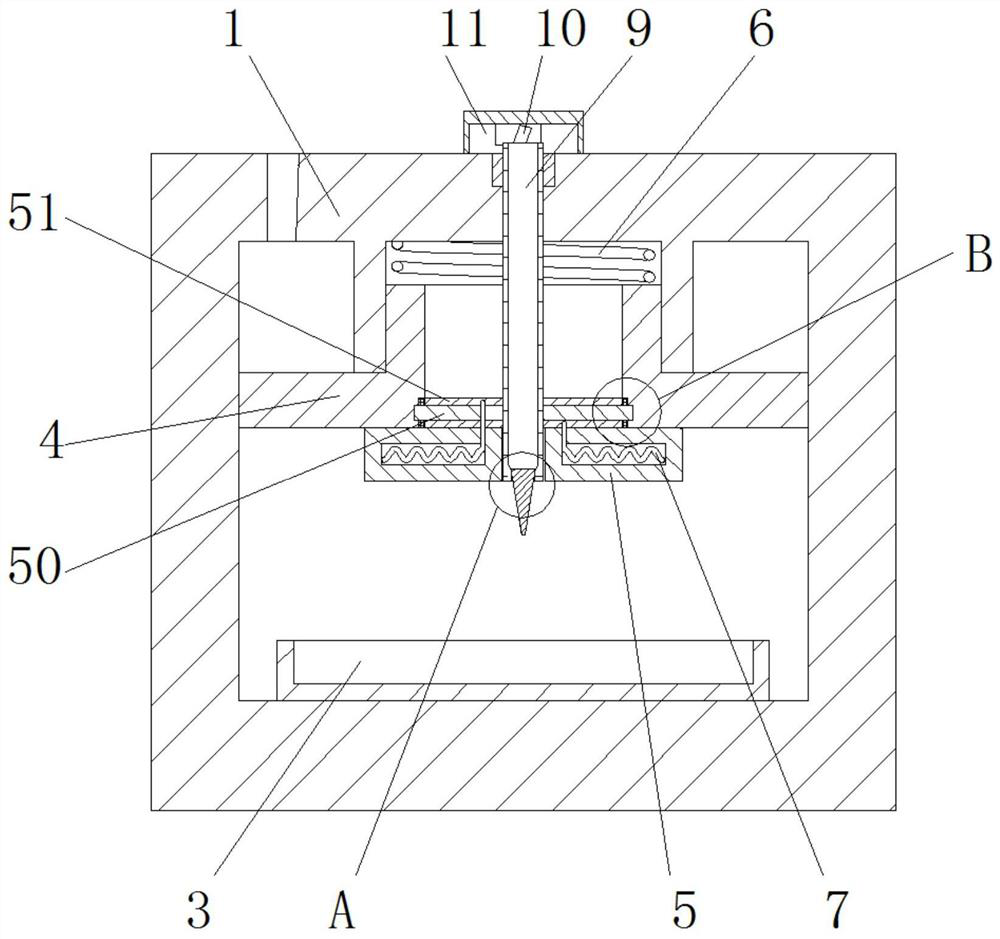

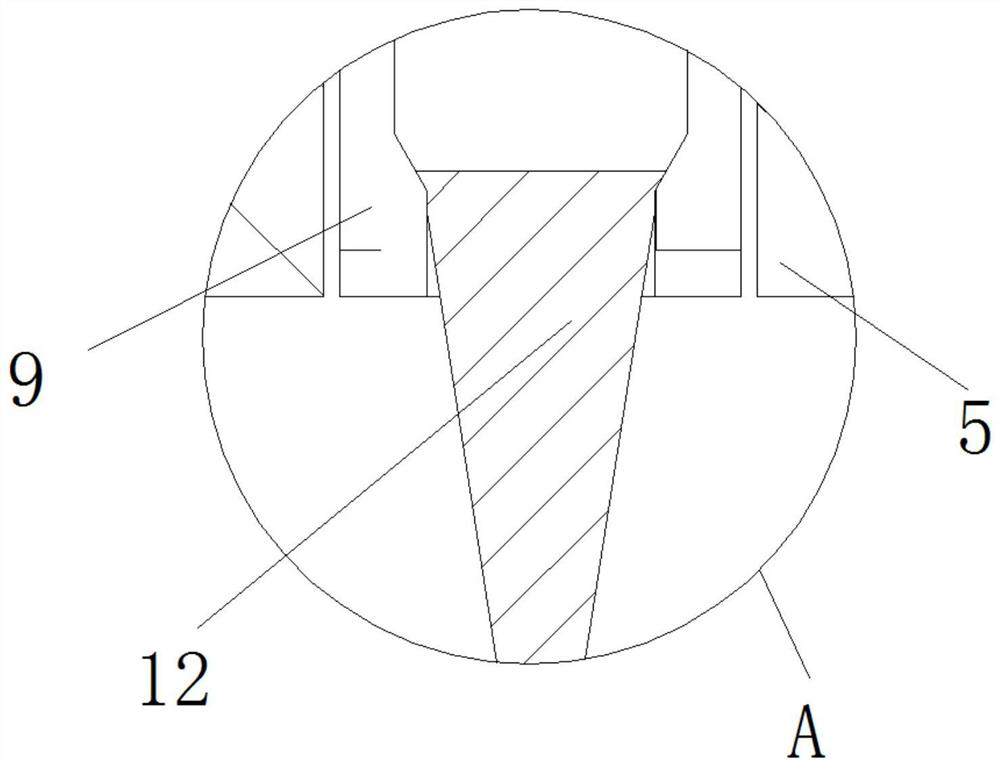

Anti-blocking printing spraying head of FDM three-dimensional printer

The invention discloses an anti-blocking printing spraying head of an FDM three-dimensional printer. The anti-blocking printing spraying head comprises a printing spraying head body, a heating aluminum block, an electric heating pipe, a heating temperature control mainboard, a heating temperature sensor, a feeding pipe and a feeding machine. The anti-blocking printing spraying head is characterized in that the thin-type heating aluminum block, a T-type preheating aluminum block and a constant temperature aluminum block are arranged, the lower end of the T-type preheating aluminum block is connected with the thin-type heating aluminum block, the upper end of the T-type preheating aluminum block is connected with the constant temperature aluminum block, heat of the thin-type heating aluminum block is transmitted to the constant temperature aluminum block through the T-type preheating aluminum block, the thin-type heating aluminum block, the T-type preheating aluminum block and the constant temperature aluminum block are provided with feeding pipe insertion holes, one end of the feeding pipe is connected with the printing spraying head body fixedly arranged on the thin-type heating aluminum block through the feeding pipe insertion holes, and the other end of the feeding pipe is connected with the feeding machine. The heating pipe preheats the printing materials at the constant temperature, then the printing materials enter the printing spraying head body heated by the thin-type heating aluminum block for melt extrusion, the heating space is greatly reduced, melting is rapid, denaturation is avoided, excessive printing materials are avoided, the printing spraying head body can be prevented from being blocked, and the printing stability and precision are improved.

Owner:张海洋

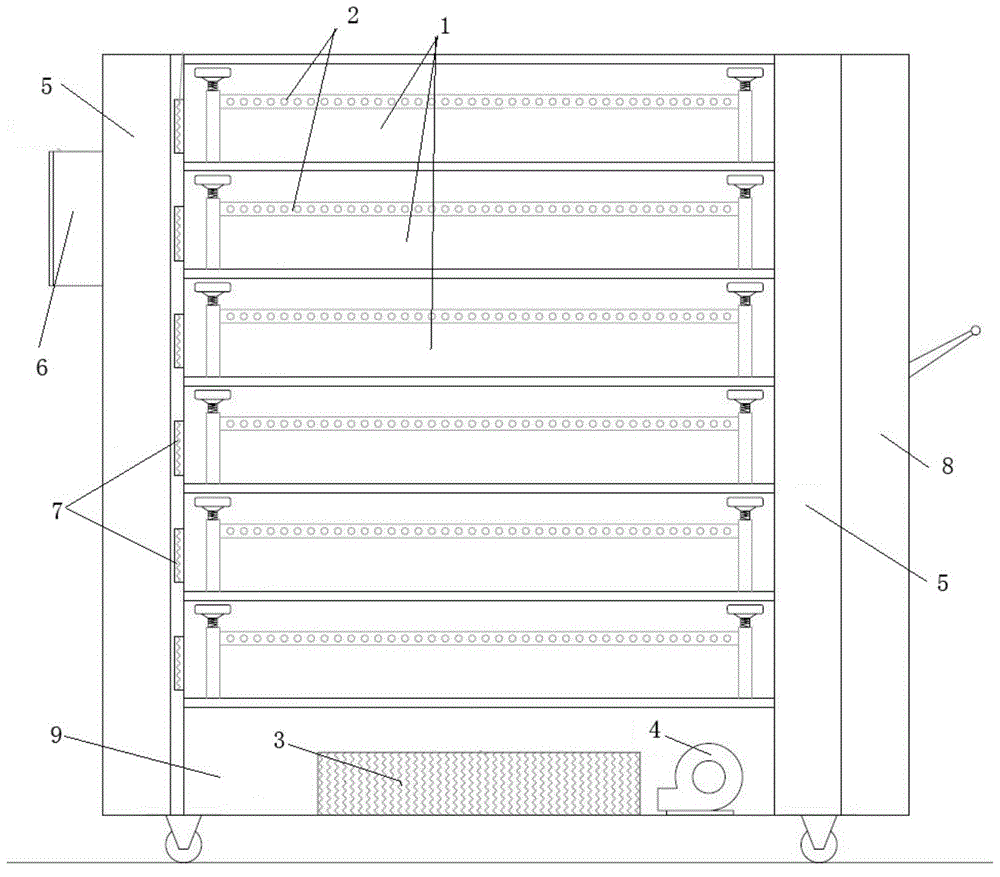

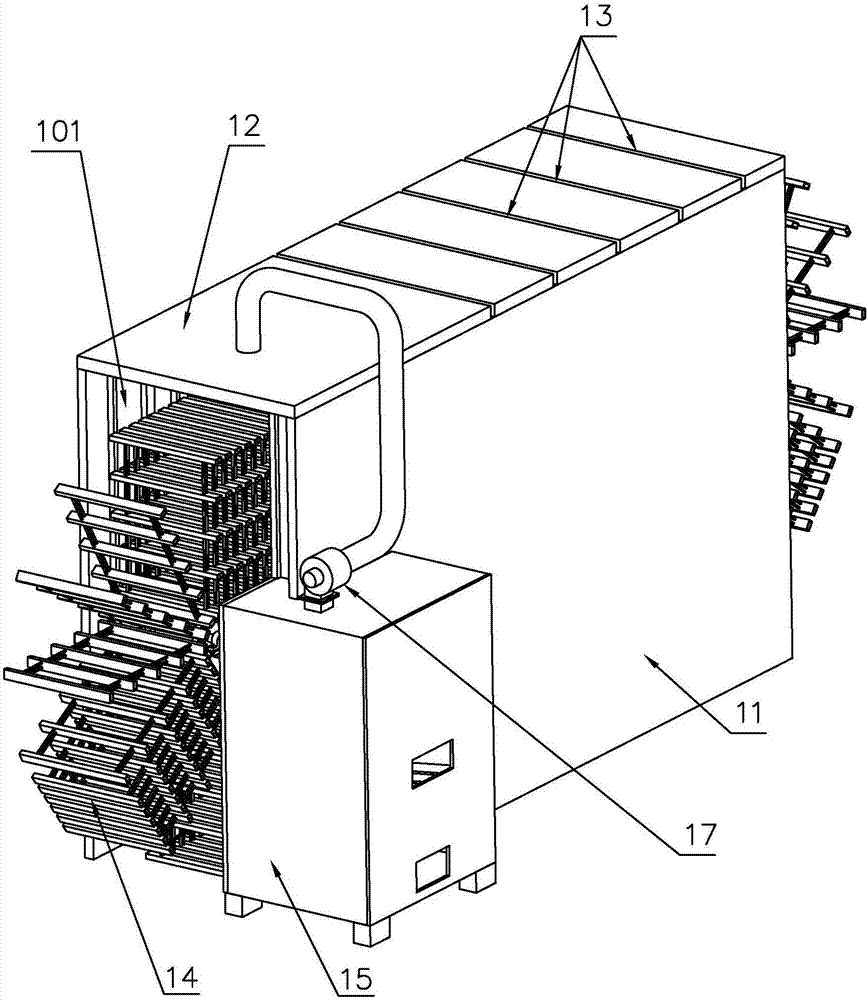

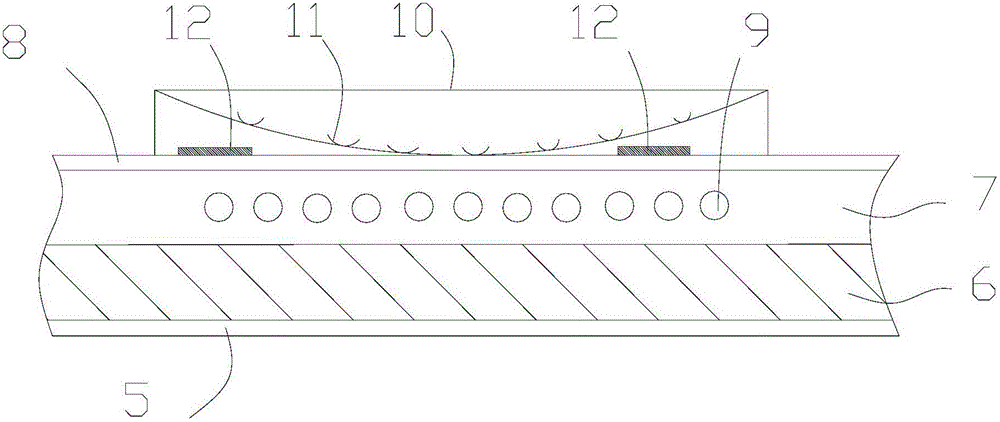

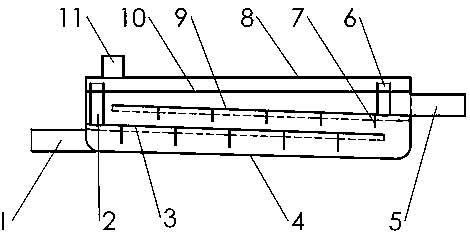

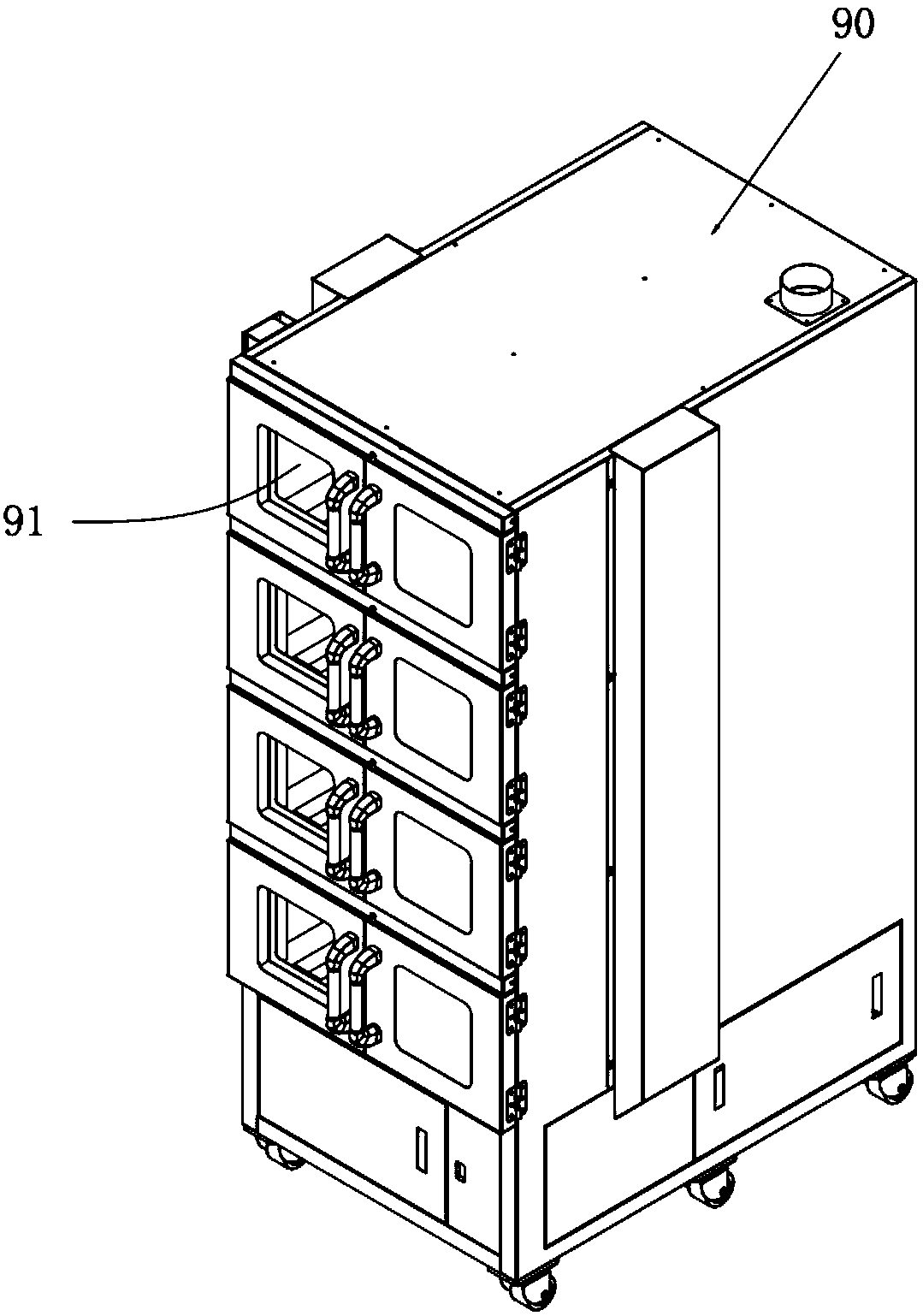

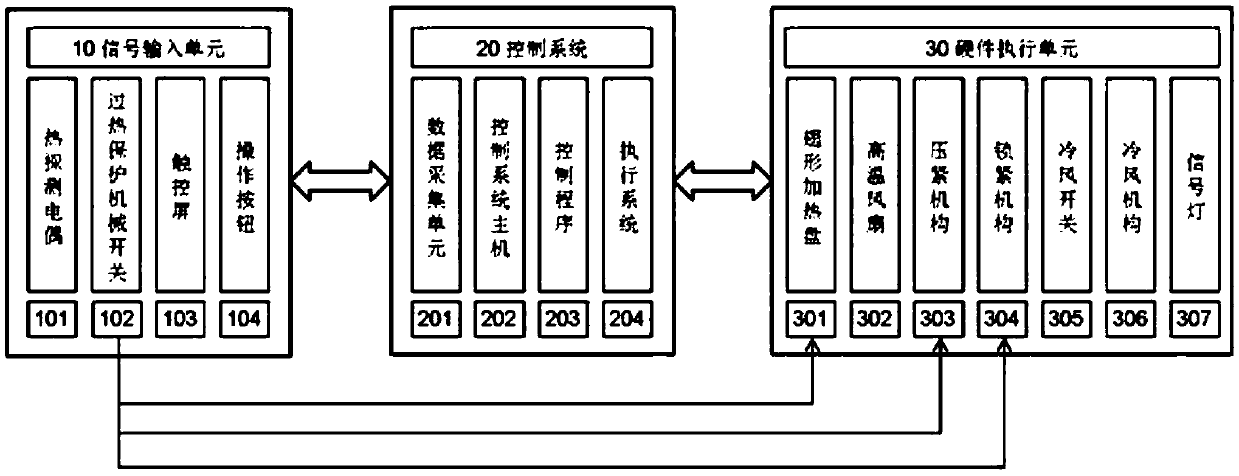

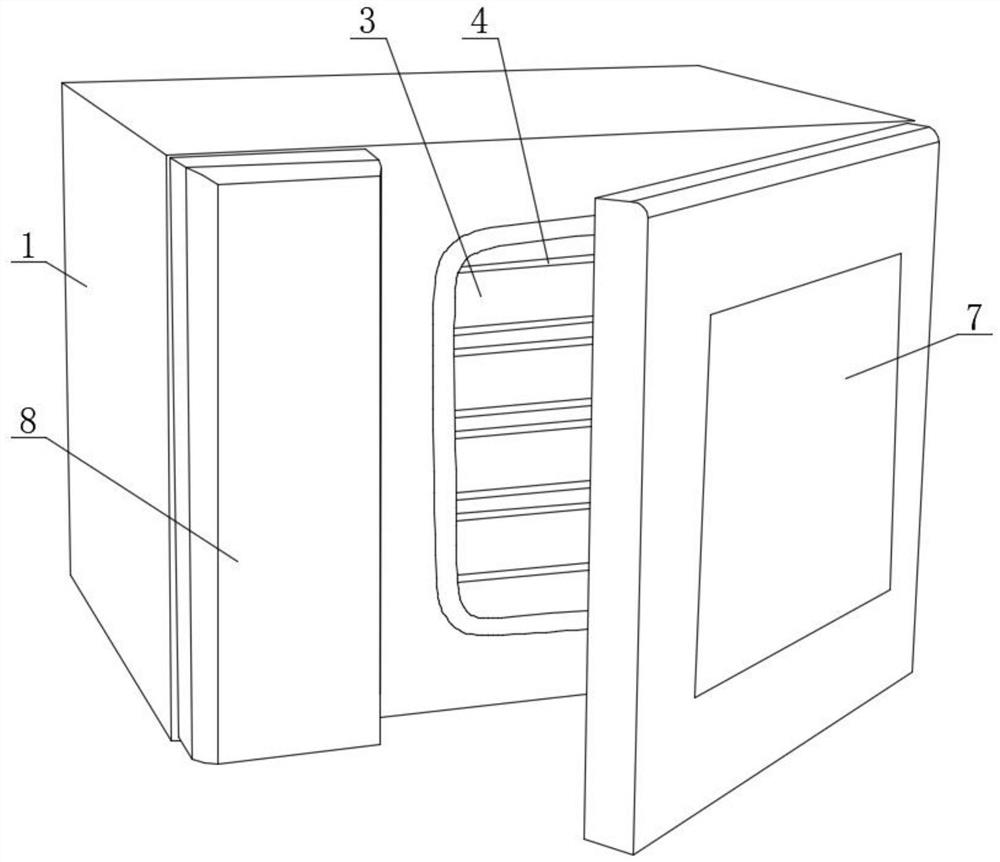

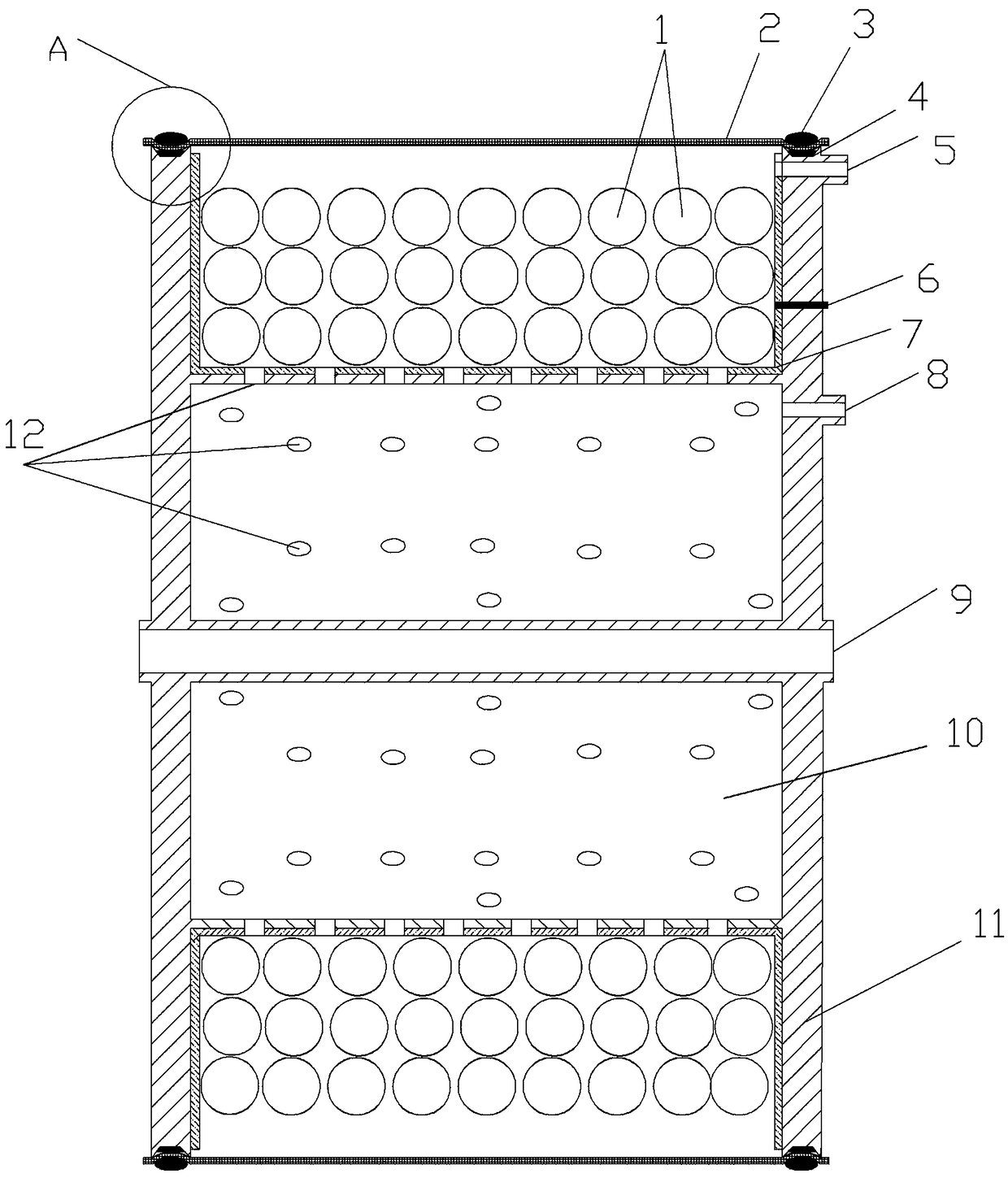

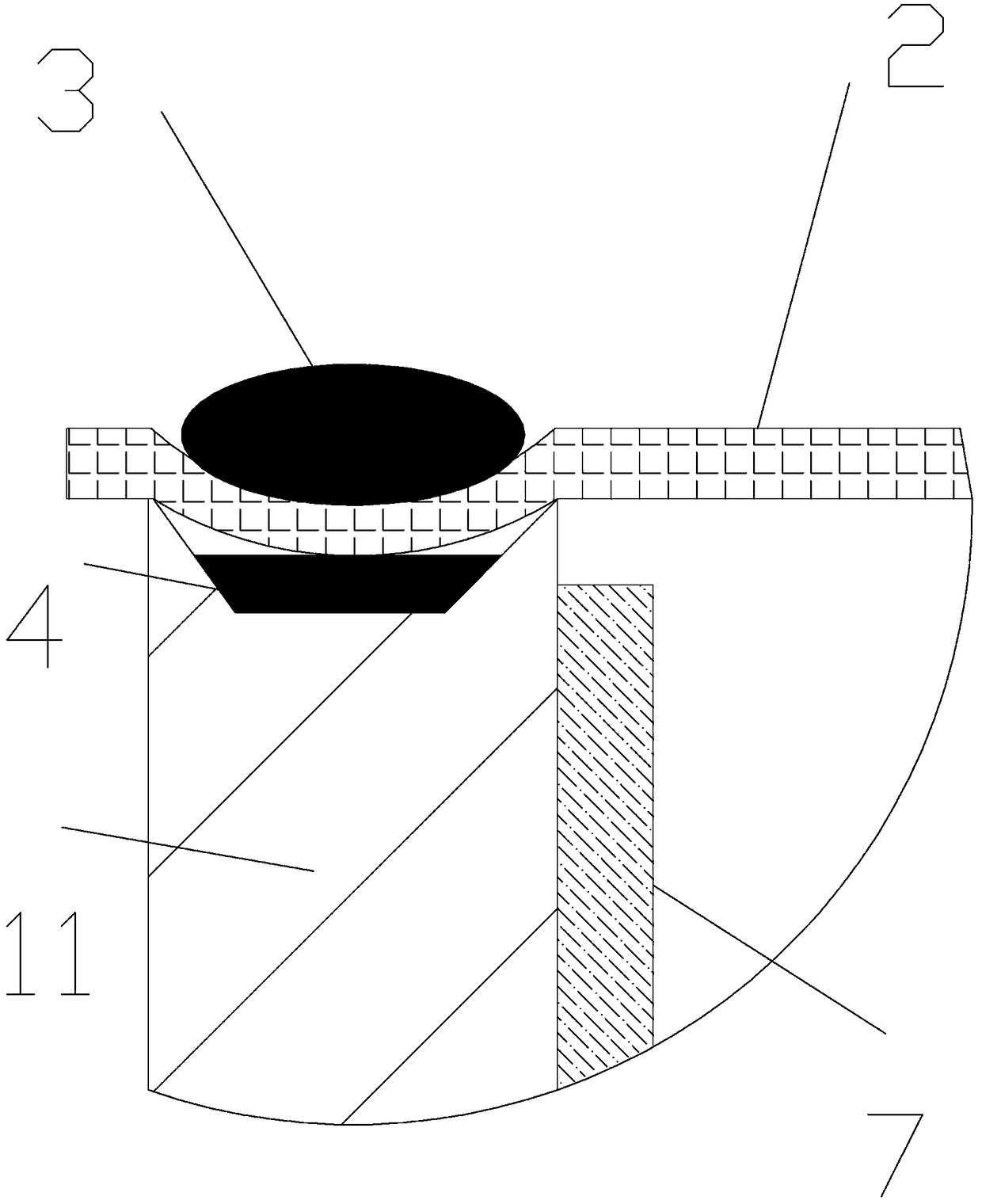

Aging trolley for delivery power source aging tests of PCBs

InactiveCN103558563AAvoid Burn-in ProblemsSmall heating spacePower supply testingFixed frameAging test

The invention relates to the field of aging tests of electronic and electrical product manufacturing, in particular to an aging trolley for delivery power source aging tests of PCBs. The aging trolley for the delivery power source aging tests of the PCBs is characterized by comprising a trolley body, wherein at least one aging layer (1) and a heating layer (9) are transversely installed in the trolley body, a DC fixing frame (2) is arranged on the aging layer (1), the heating layer (9) is arranged on the lowest layer of the trolley body, a heating device (3) is installed in the heating layer (9), an auxiliary fan (4) is installed beside the heating device (3), an air channel (5) and a control cabinet (6) are installed outside the side wall of the trolley body, and a circulating fan (7) is installed between the portion, of the inner wall, of one side of the trolley body, and the air channel (5). According to the aging trolley for the delivery power source aging tests of the PCBs, the delivery power source aging tests of the PCBs can be conveniently and rapidly carried out; due to the fact that the aging trolley for the delivery power source aging tests of the PCBs has the heating constant-temperature control function, the problem of PCB burning can be solved; due to the fact that the aging trolley for the delivery power source aging tests of the PCBs is small in heating space, the temperature rise is rapid, energy can be saved, use is convenient, and the aging trolley for the delivery power source aging tests of the PCBs can be used anywhere.

Owner:TAICANG T&W ELECTRONICS CO LTD

Environment-friendly efficient veneer drying device

ActiveCN107084607AUniform moisture contentImprove flatnessDrying gas arrangementsDrying chambers/containersDrive shaftFixed frame

The invention provides an environment-friendly efficient veneer drying device comprising a veneer inlet, a veneer outlet, a machine frame, a heat preservation box, a top cover, a plurality of moisture outlets, a conveying mechanism, air blowing devices, a flame path, smoke pipelines and a flue. The heat preservation box is arranged on the outer side of the machine frame. The upper portion of the heat preservation box is provided with a top cover. The top cover is provided with the multiple moisture outlets which are close to the veneer outlet. The conveying mechanism comprises a transmission shaft, clamping arms, supporting cushion blocks, a chain, chain wheels, carrier rollers, a motor, a speed reducer and a motor fixing frame. The supporting cushion blocks are arranged on the upper portion of the chain. The clamping arms are arranged on the upper portion of the supporting cushion blocks. The flame path, the smoke pipelines and the flue are fixedly connected to the machine frame. The air blowing devices are arranged on the two sides of an upper circulation position of the conveying mechanism and the two sides of the flame path. Each air blowing device comprises partition plates, air blowing fans and fan supports. The environment-friendly efficient veneer drying device is low in energy consumption, reduces the production cost of a traditional large-sized drying device, is good in veneer drying effect and solves the problem that after being dried, veneer naturally warps.

Owner:李学淑

Hub forging method

ActiveCN106216952AImprove compactnessSimple structureVehicle componentsPunchingVolumetric Mass Density

The invention discloses a hub forging method which comprises the following steps: a. profile extrusion: extruding an aluminum alloy plate with set thickness and width by an extruding machine; b. preheating: continuously online heating the aluminum alloy plate extruded by the extruding machine through heating equipment; c. hot cutting: cutting the preheated aluminum alloy plate which goes out from the heating equipment into a preset length to form a square-shaped blank by adopting the hot cutting technology; d. forging: putting the blank after being hot cut into a die, and forging and pressing the blank to form a disk shape; e. punching and bulging the disk-shaped blank; f. putting an enamel blank after being punched and bulged into a spinning machine, and carrying out spinning forming; and g. carrying out heat treatment and machining on the enamel blank after spinning forming to obtain a finished hub product. With adoption of the hub forging method, the efficiency of forging the hub, the utilization ratio of a raw material and the density of a product are higher.

Owner:宁波路威汽车轮业有限公司

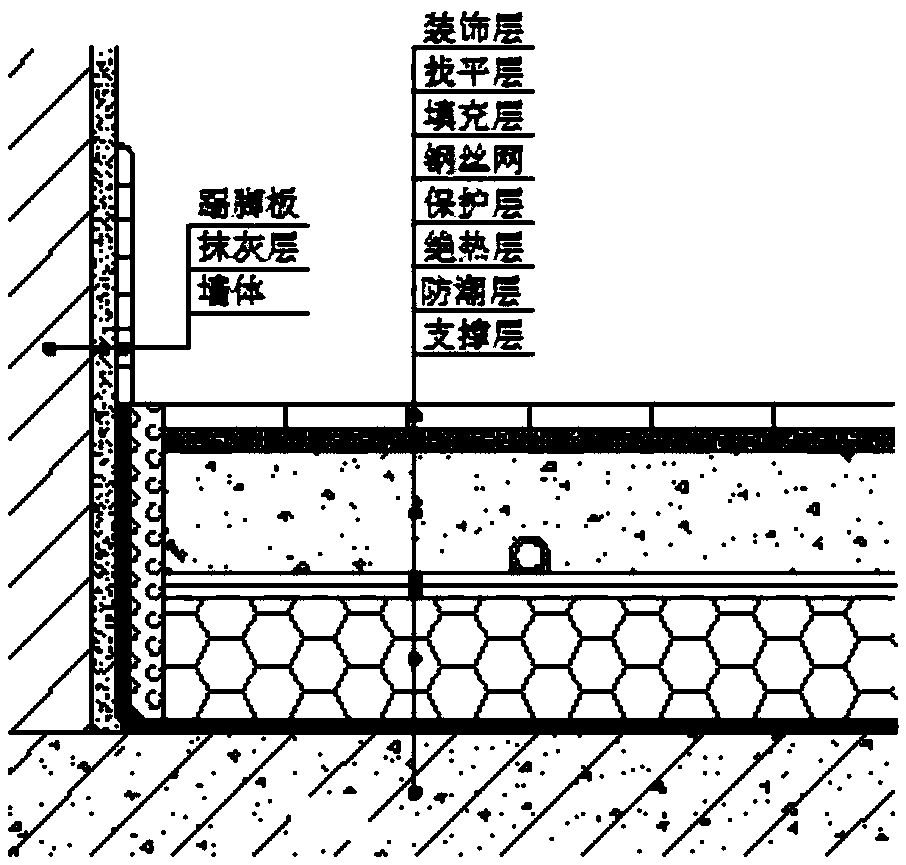

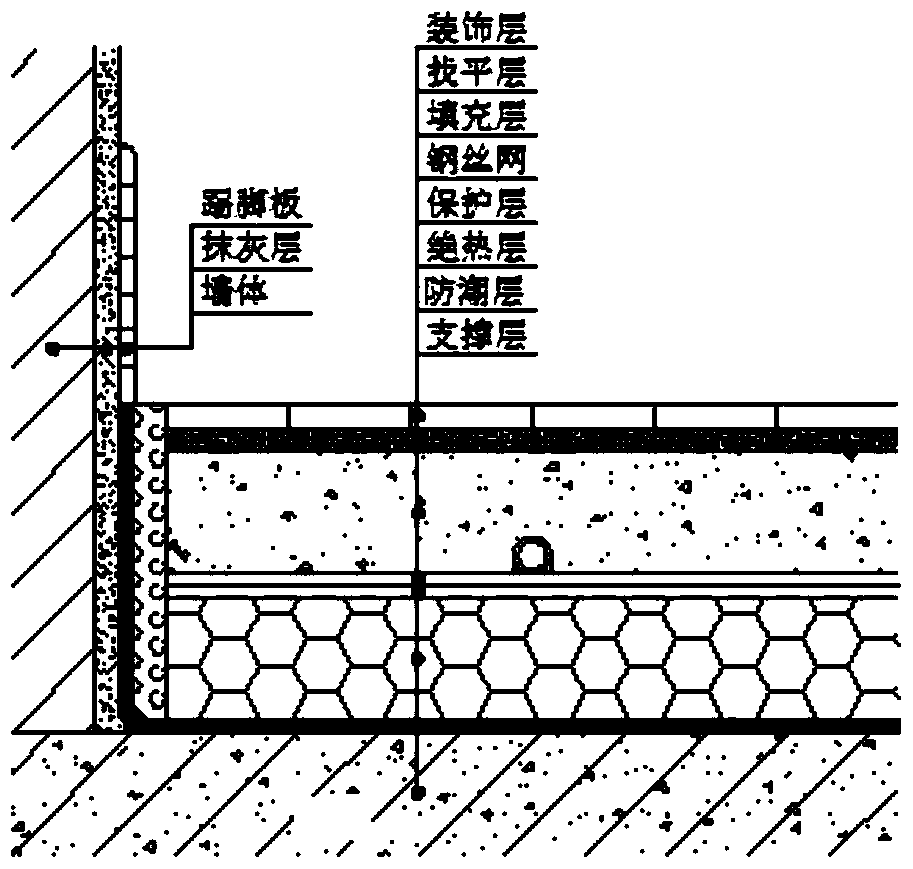

Solar ground surface and kang surface combined heating system

ActiveCN105371342ASolving Oversized ProblemsMeet thermal needsCentral heating with accumulated heatLighting and heating apparatusSocial benefitsControl system

The invention discloses a solar ground surface and kang surface combined heating system. The solar ground surface and kang surface combined heating system comprises a solar heat collecting system, a heat storage system, a kang surface heating system, a ground surface heating system and a control system, wherein the heat collecting system collects solar radiation heat which is then output and stored in the heat storage system, and operation time and supplied heat amount of independent heat supply of the ground surface and kang surface heating system are set through the control system so as to meet the heat demand of people. When a user moves in a room in the daytime, the ground surface heating system supplies heat to the room so as to meet the indoor temperature demand; when the user is in the sleeping state at night, the kang surface heating system provides comfortable quilt temperature. The ground surface and kang surface time-division partition-area heating mode is adopted, and the heat is supplied according to different heat demands in different states and people moving areas in the daytime or at night; the energy consumption of a building is reduced; system scale and cost are reduced; the application is convenient; control is easy; the operability is high; the solar ground surface and kang surface combined heating system is good in economic and social benefits when applied to and popularized in solar heating buildings of villages and small towns.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

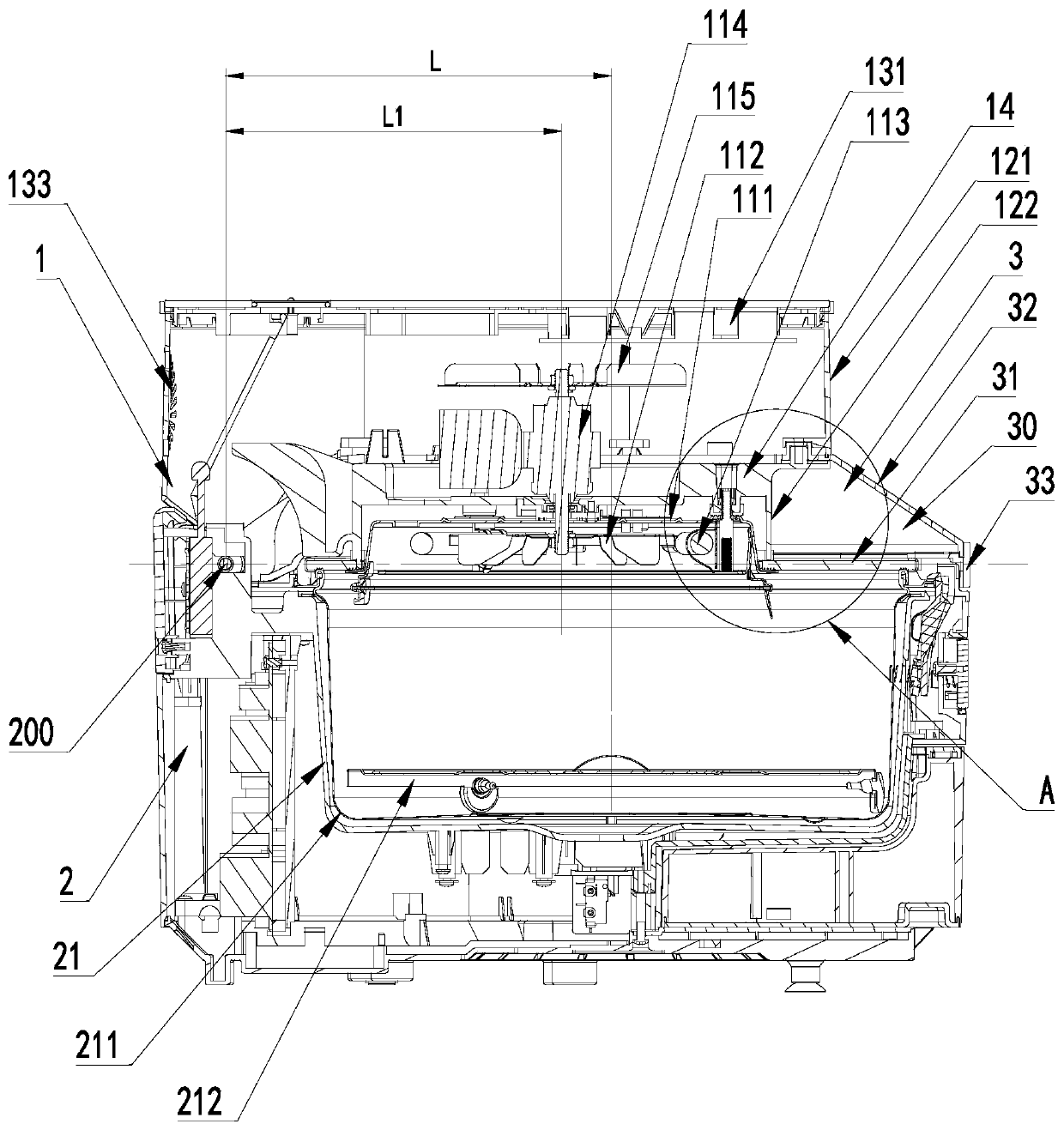

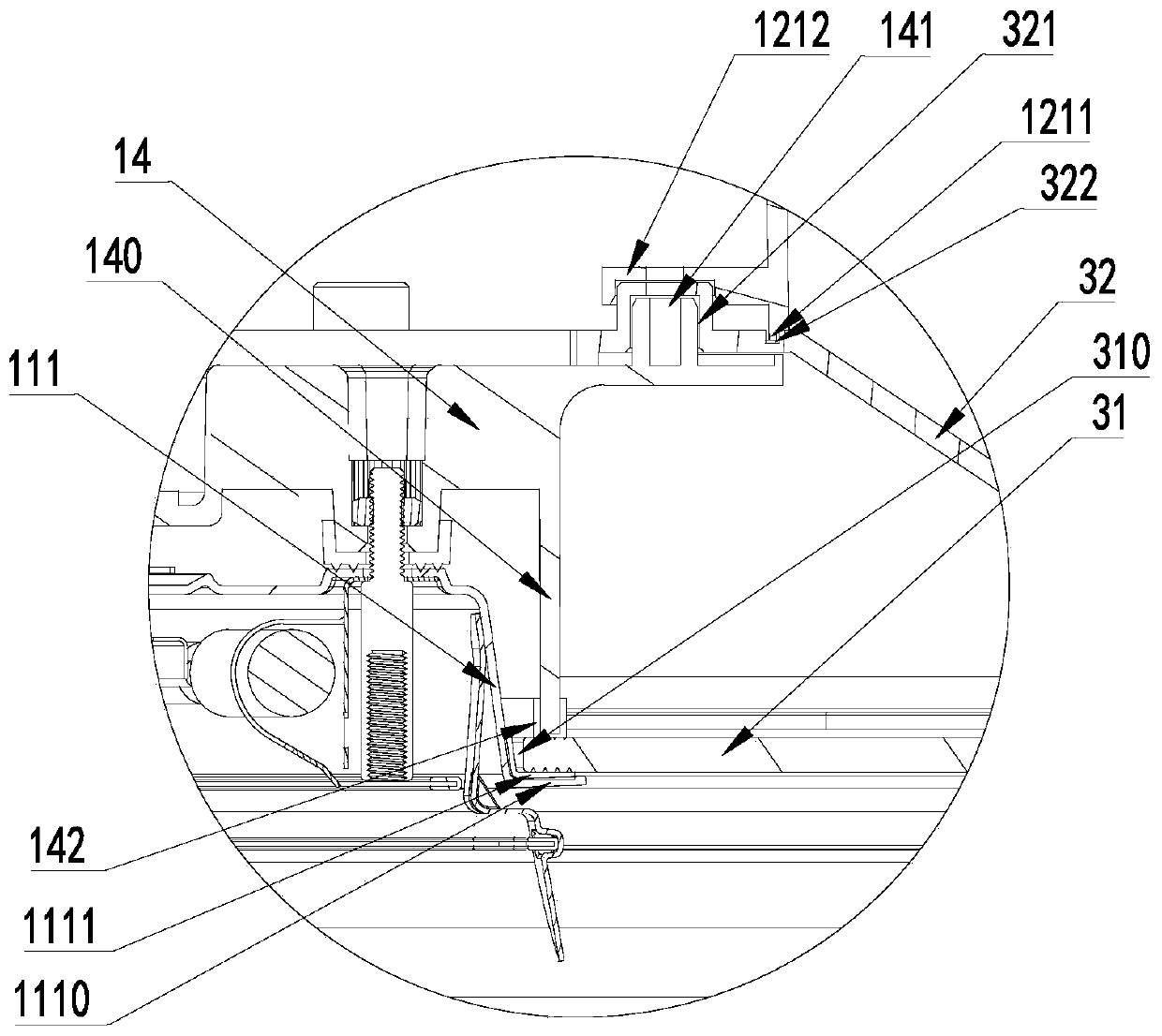

Air fryer reliable in control

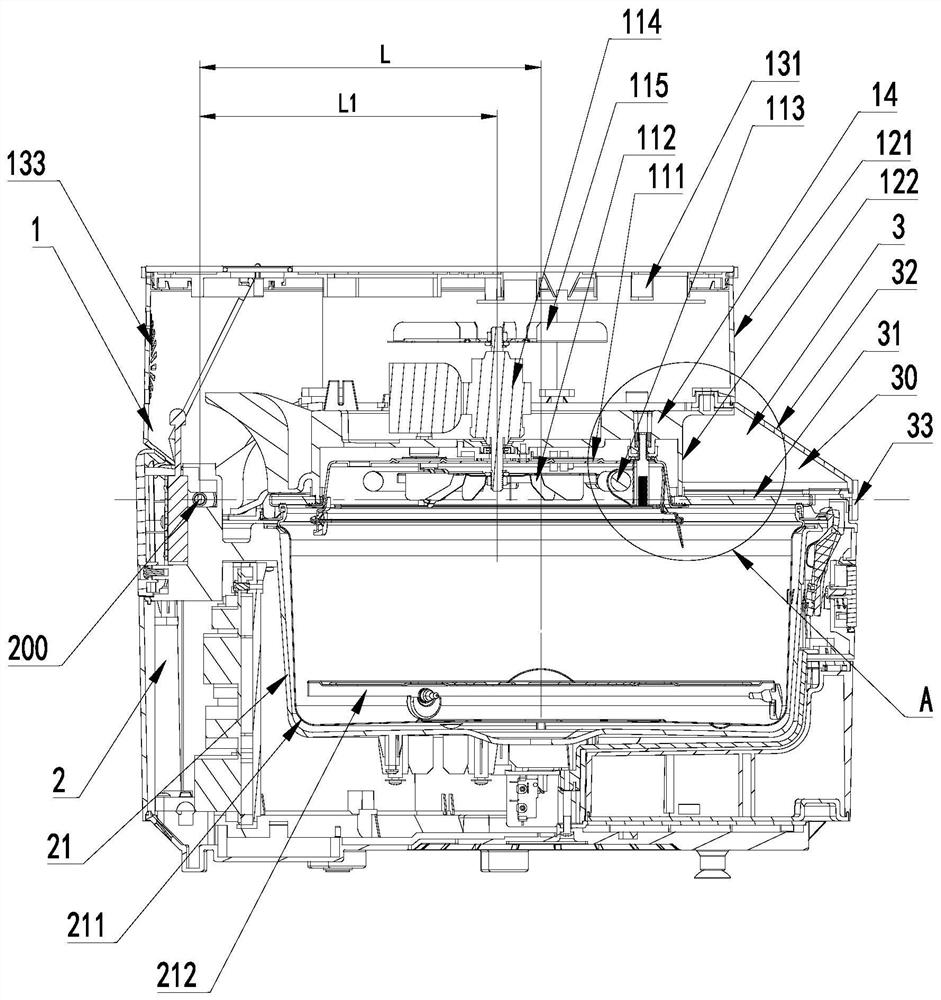

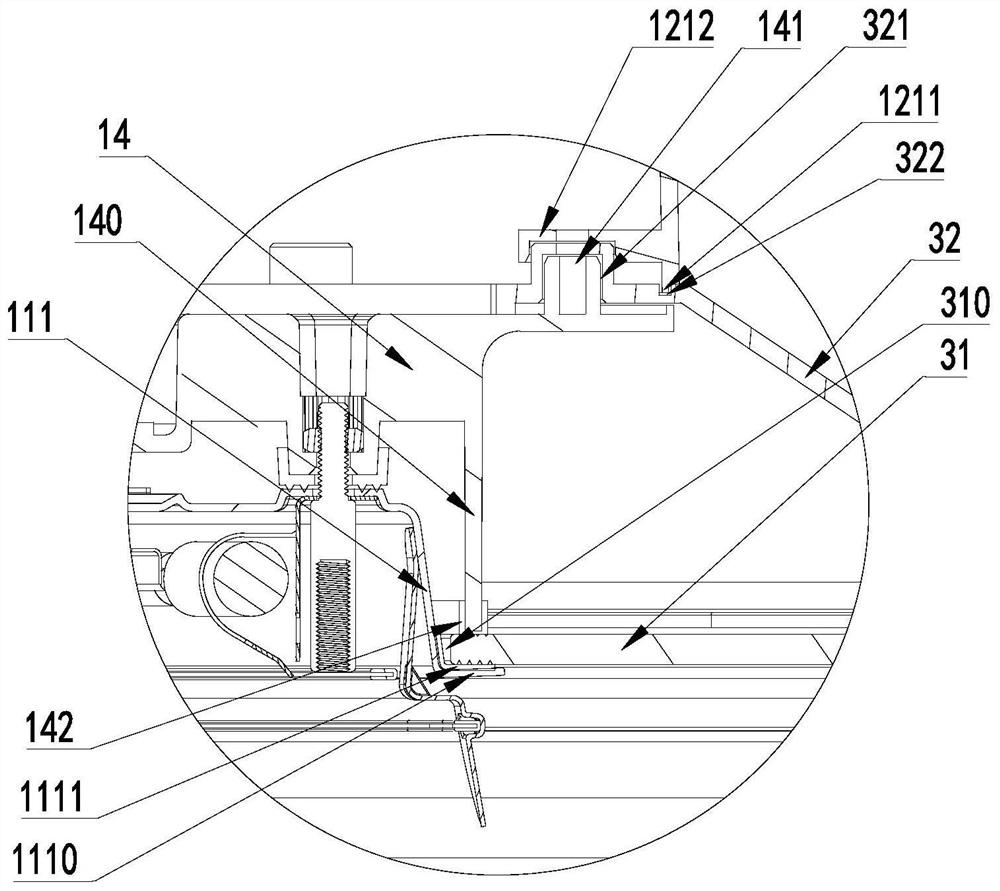

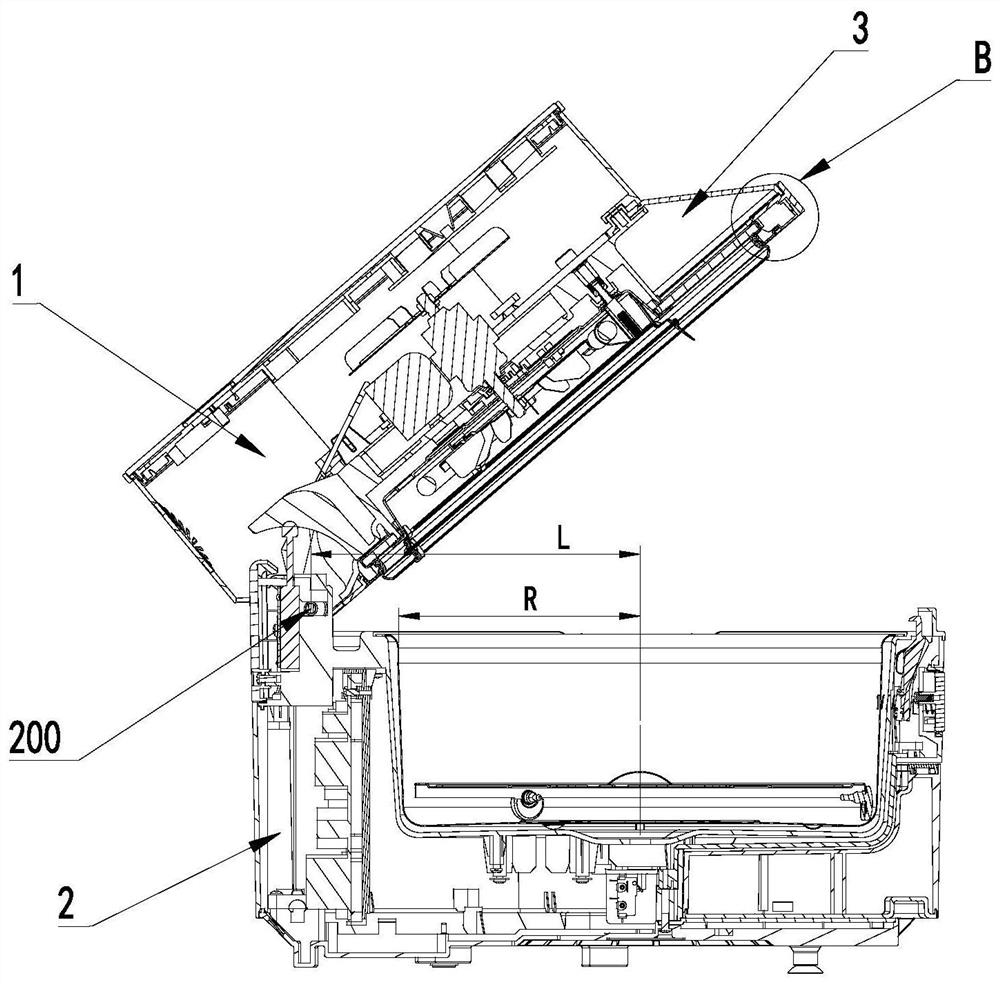

ActiveCN110876567AGuaranteed effective use of the areaGuaranteed Proportional DemandCooking-vessel lids/coversLighting elementsEngineeringGravity center

The invention relates to an air fryer stable in control. The air fryer comprises a base and a cover body hinged to the base. A fyer assembly is arranged in the machine base. The fryer assembly comprises an inner pot. A hot air assembly is arranged in the cover body, the hot air assembly comprises an air guide plate, a fan and a heating piece. The fan and the heating piece are positioned below theair guide plate; a transparent visual window is arranged on the cover body, the center of the hot air assembly deviates from the center of the fryer assembly, the distance between the center of the hot air assembly and the hinge center is smaller than the distance between the center of the fryer assembly and the hinge center, and the visual window surrounds the hot air assembly and is located above the inner pot. The hot air assembly is far away from a user relative to the fryer assembly, the area of the visual window located on one side of the user is enlarged, and therefore the user can visually observe the interior of the fryer assembly through the visual window. Meanwhile, the heights of the cover body and the whole air fryer can be effectively reduced, the gravity centers of the coverbody and the whole air fryer are reduced, and when the cover body is opened or closed, the whole air fryer is stably operated.

Owner:JOYOUNG CO LTD

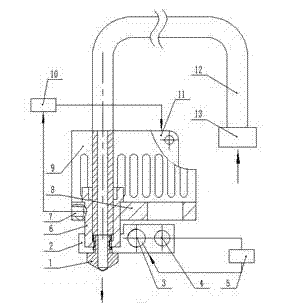

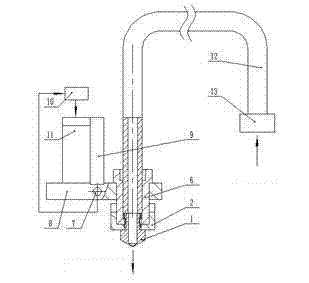

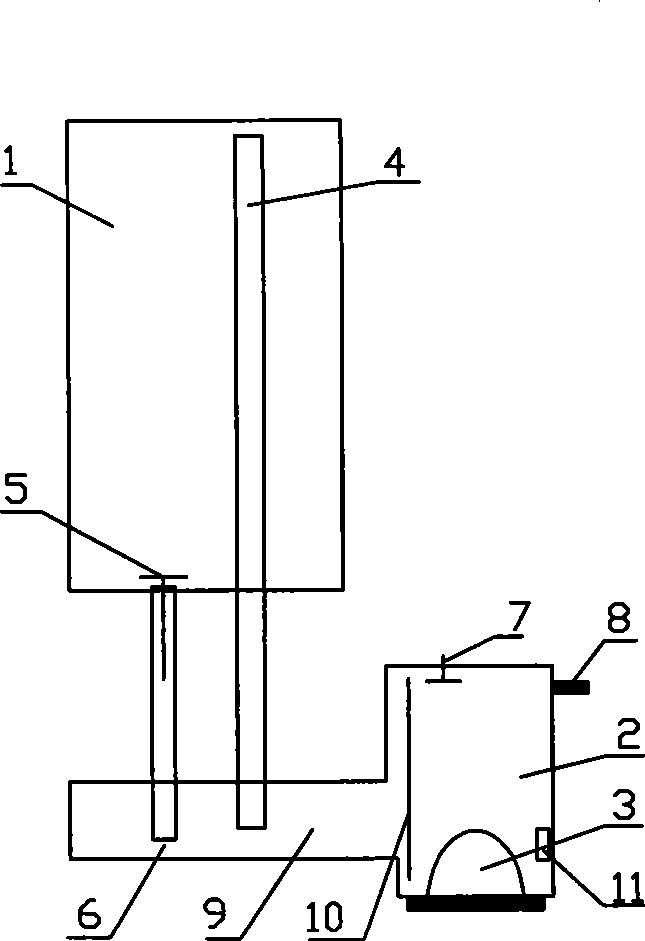

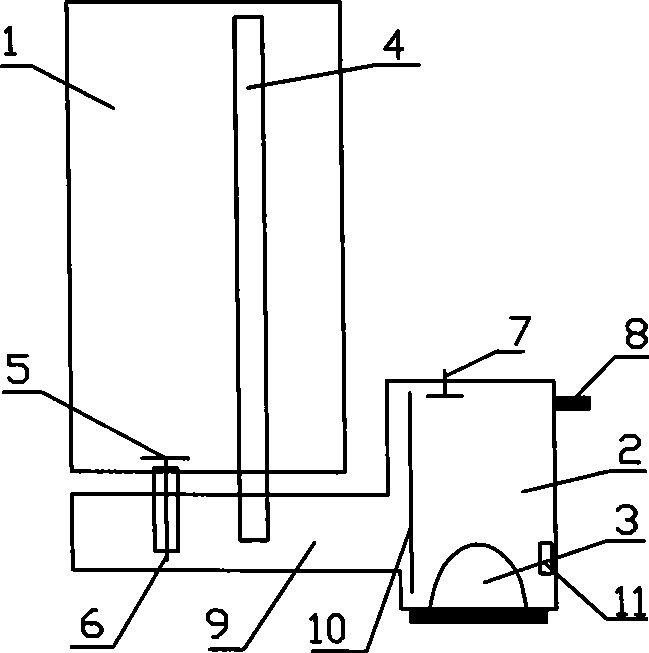

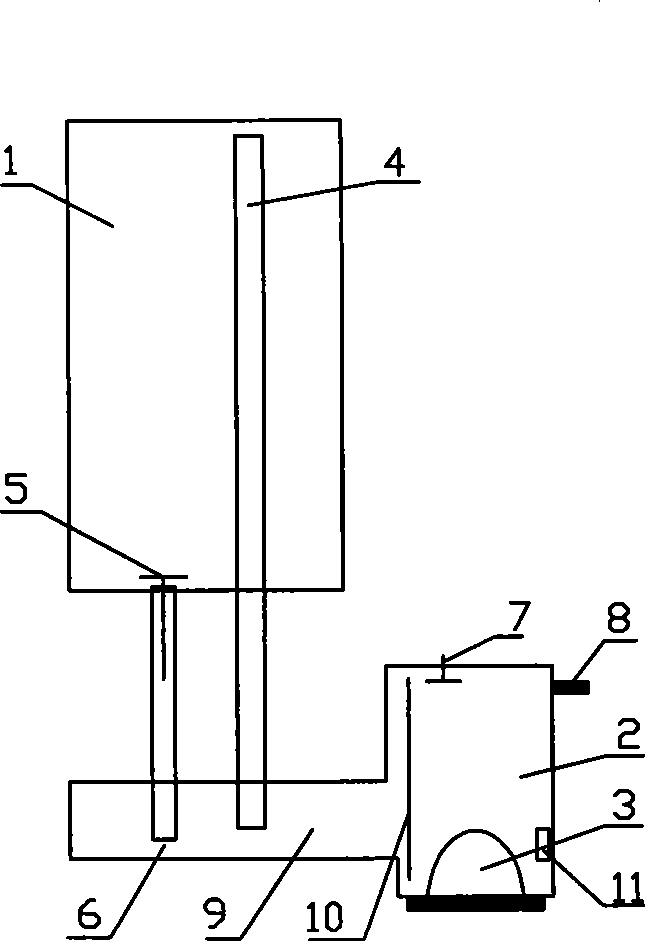

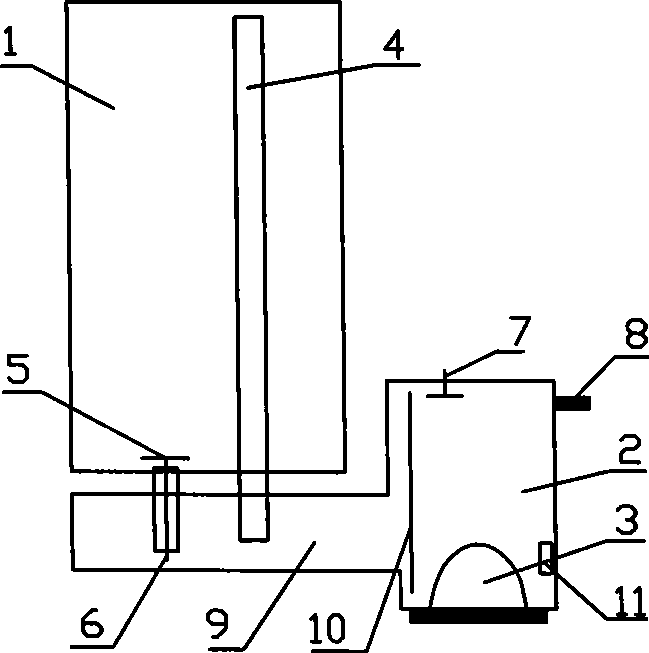

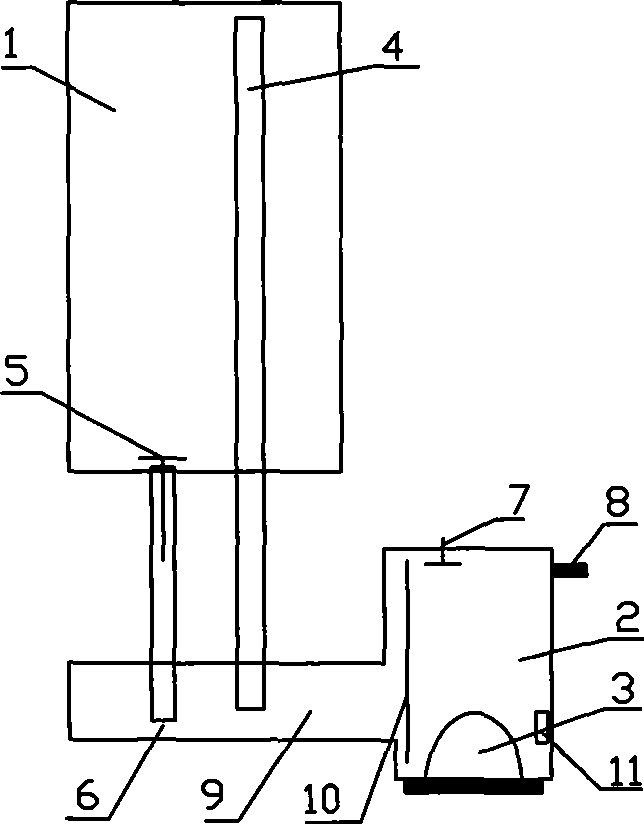

Self-water supply quick vapor generator

The invention discloses a self water supply type rapid steam generator, which comprises a water tank and a heating chamber which is provided with an electrothermal conversion component, wherein, the heating chamber is provided with a steam outlet; the heating chamber and the water tank are independent components; the heating chamber is provided with a junction board which forms a water supply channel with the water tank, wherein, the heating chamber below the junction board is communicated with the heating space of the hating chamber, and a balance tube is arranged in the heating chamber to balance the water level in the heating chamber; the water tank is provided with a balance tube faucet to insert the balance tube and can be used for water sealing. The self water supply type rapid steam generator of the invention adopts such a structure that the water tank is separated from the heating chamber generating steam, and generates steam in a mode of simultaneous heating and water supply, which not only facilitates the water supply to the water tank and discharging of the remaining water and cleaning, but also is convenient for selecting the water tank with suitable volume for use. A separator board is also provided to reduce the heating space, which also significantly shortens the time for steam generation.

Owner:SHENZHEN ZOFU TECH

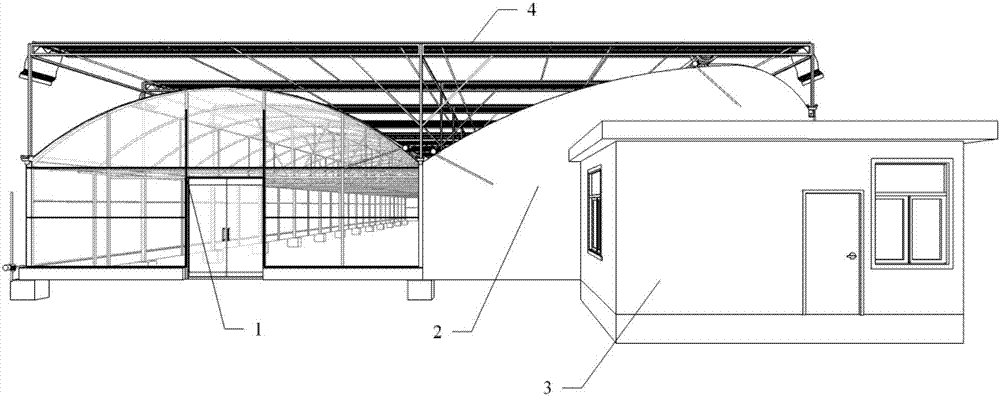

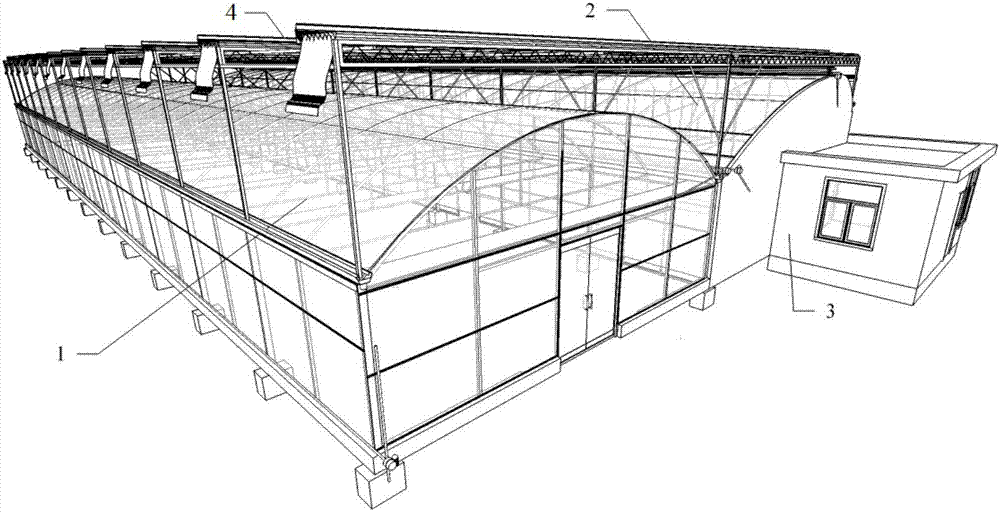

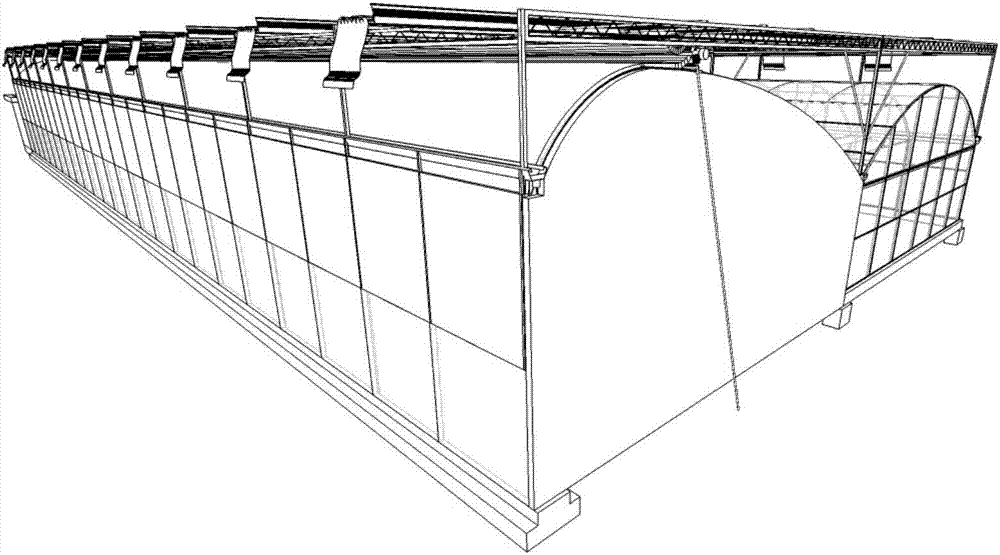

Multi-span solar greenhouse used for annual production in Yangtze River basin region

InactiveCN106962067AEasy constructionEasy maintenanceClimate change adaptationRenewable energy machinesDaylightEngineering

The invention discloses a multi-span solar greenhouse used for annual production in the Yangtze River basin region. The greenhouse comprises a circular-arch-shaped greenhouse body, a sunlight greenhouse body and a workshop. The circular-arch-shaped greenhouse body and the sunlight greenhouse body are connected side by side in the length direction and isolated from each other by a plastic thin film; an outer shading system is arranged above the circular-arch-shaped greenhouse body and the sunlight greenhouse body, a first inner heat preserving system is arranged in the circular-arch-shaped greenhouse body, and a second inner heat preserving system is arranged in the sunlight greenhouse body. Greenhouse framework structures are installed in an assembled mode, time and labor are saved, construction and maintenance are convenient, and the greenhouse can be transferred to a different place to be installed for repeated use. The greenhouse overcomes defects that common plastic greenhouses and dual-layer thin film greenhouses are poor in heat preservation and sunlight greenhouses are high in temperature and humidity in summer, a wall is good in heat preservation and heat storage property, solar energy is fully used, a rear wall can increase the light-permeating area, and light is fully used. The greenhouse is high in compatibility and suitable for regions to the south of the Huaihe River.

Owner:NANJING AGRICULTURAL UNIVERSITY

Vehicle-mounted heating bag

The invention discloses a vehicle-mounted heating bag and relates to the field of heating bag structures. The vehicle-mounted heating bag comprises a bag body; a sealing opening is formed in the bag body; a power supply base is arranged at one end, opposite to the opening, of the bag body; a coupling vehicle-mounted power supply connector is arranged on the power supply base; a controller is arranged in the power supply base; the bag body is made of a flexible material and sequentially comprises a waterproof outer layer, a heat insulating layer, a heat conducting layer and a waterproof inner layer from outside to inside; the heat conducting layer is made of thermally conductive silica gel; heating coils connected with the power supply base are respectively arranged on two sides, relative to the sealing opening, of the bag body; the heating coils are arranged in the heat conducting layer and are opposite in position; inwards-raising structures are separately arranged at positions, corresponding to the heating coils, in the bag body and are annular raising structures; the middles of the annular raising structures are of inwards-concaved cambered surfaces; a plurality of suckers are uniformly arranged on the raising structures; a temperature sensor is arranged in each raising structure; the controller controls the opening or closing and passing current of the heating coils according to input signals of the temperature sensors. By arranging the flexible heating bag with heat insulation and quick heating, the vehicle-mounted heating bag disclosed by the invention has the advantages of convenience in carrying, no occupation of space, convenience for placement of bag heating objects or food with different shapes, capability of being used in a carriage and the like.

Owner:JINGXI XIUMEI BIANCHENG AGRI SCI & TECH CO LTD

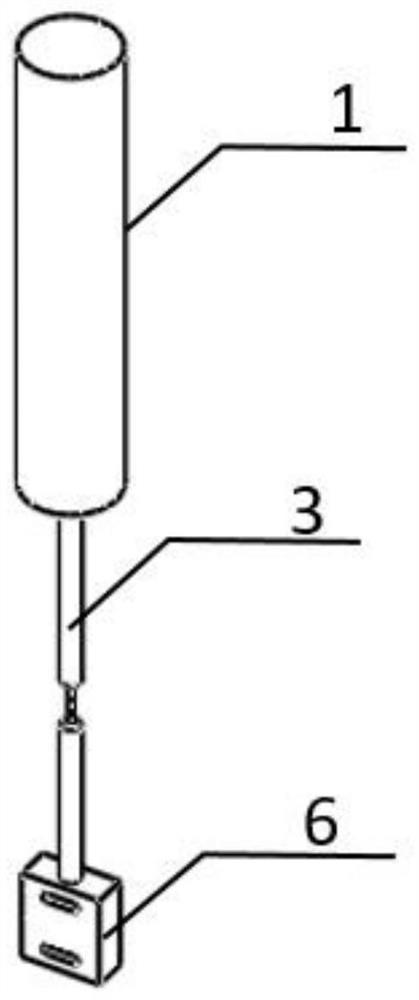

Single-tubular gas protection fiber thermal treatment device

InactiveCN102382972ASmall tube spaceUniform and easy to control temperatureFurnace typesHeat treatment furnacesFiberShielding gas

The invention relates to a single-tubular gas protection fiber thermal treatment device. The device comprises a heating pipe which is provided with two opening ends and made of high temperature alloy, wherein sealing heads are fixed at the opening positions at the two ends of the heating pipe; the two sealing heads are respectively provided with a feeding port and a discharging port which are corresponding; a left side electrode clamping end and a right side electrode clamping end are respectively fixed on the outer wall of the heating pipe; and the pipe wall of the heating pipe is provided with a protection gas inlet. According to the invention, the heating pipe made of high temperature alloy is adopted; and the heating pipe has small internal space and uniform and controllable temperature, thereby ensuring thermal treatment property and saving energy.

Owner:WUXI BEYOND AOK ELECTRIC

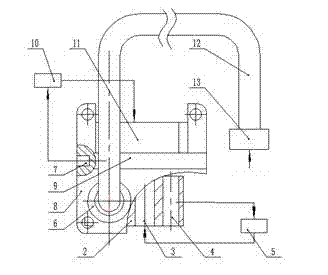

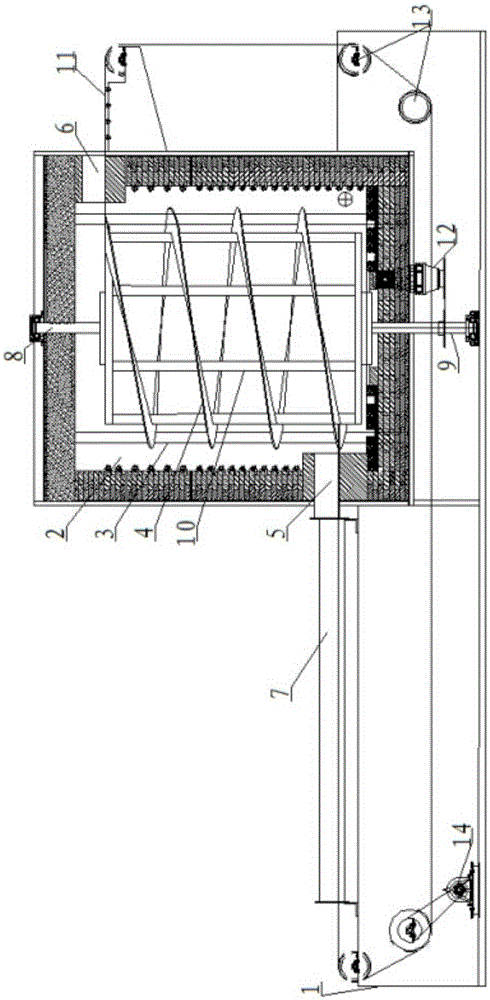

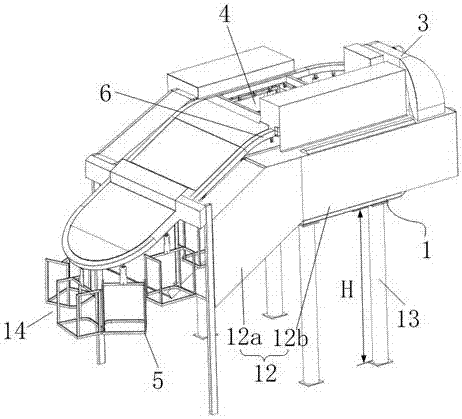

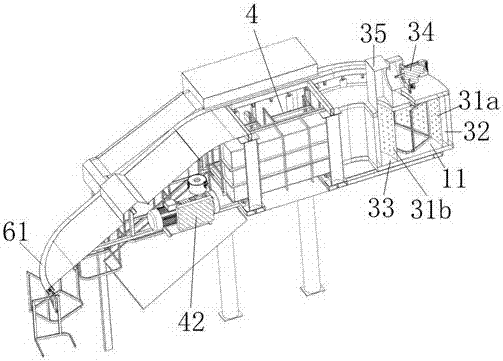

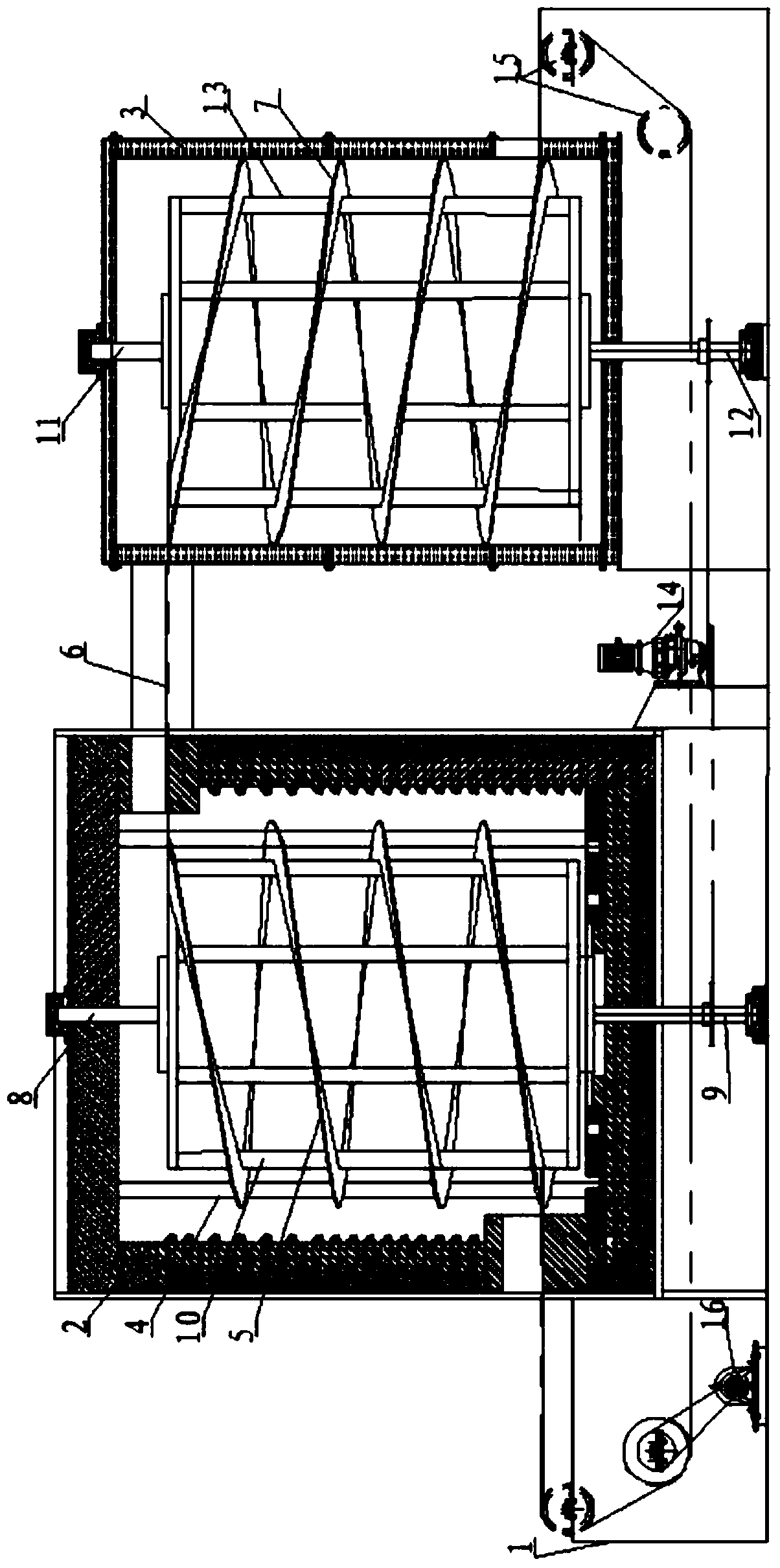

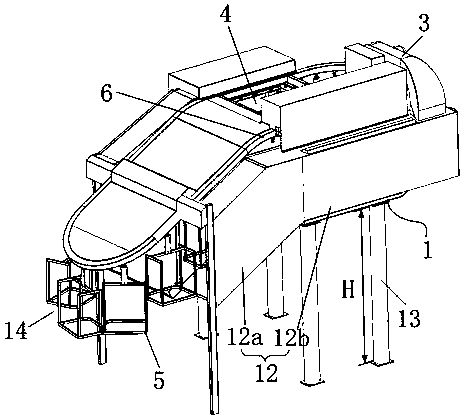

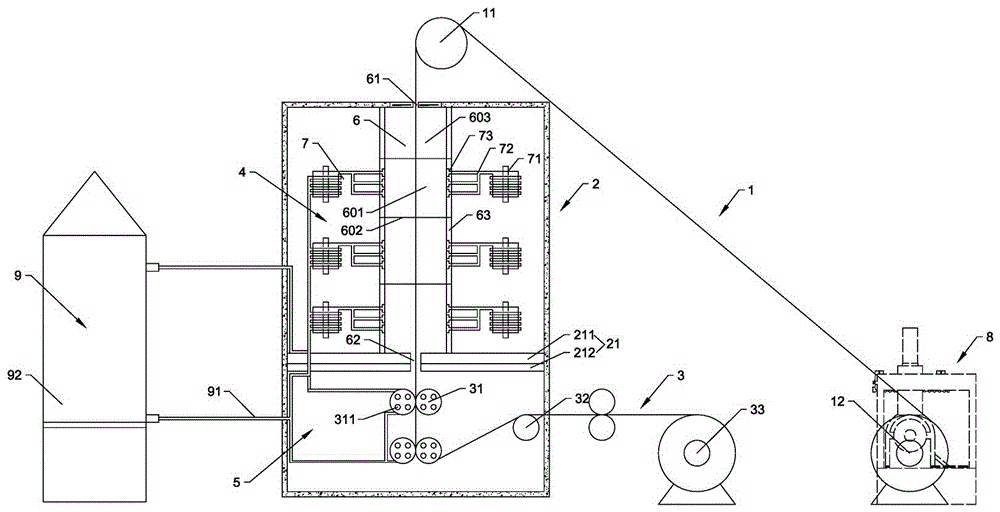

Screw conveying type heating furnace and horizontal cooling device

ActiveCN105241246ASmall footprintSmall heating spaceCharge manipulationFurnace typesEngineeringHeating furnace

The invention belongs to the technical field of industrial heating furnaces, and discloses a screw conveying type heating furnace and horizontal cooling device. The screw conveying type heating furnace and horizontal cooling device comprises a main supporting frame on which a heating furnace body and a cooling furnace are arranged, wherein a bracket is arranged in the heating furnace body; a screw type supporting plate is arranged on the bracket and used for bearing a conveyor belt and a workpiece on the conveyor belt; a conveyor belt outlet and a conveyor belt inlet are formed in the heating furnace body; the conveyor belt outlet is connected to the cooling furnace; a transmission mechanism for driving the conveyor belt to move is arranged at the outside of the heating furnace body; the conveyor belt runs through the conveyor belt inlet to be distributed along the screw type supporting plate, then sequentially runs through the conveyor belt outlet and the inner part of the cooling furnace, and finally forms a circulating loop through the transmission mechanism. With the adoption of the screw conveying type heating furnace and horizontal cooling device, the energy can be saved, the high efficiency can be achieved, the area for equipment can be saved, and the productivity can be greatly increased under the same used area and energy consumption.

Owner:XI AN AOJIE ELECTRIC HEATING EQUIP ENG CO LTD

Clarifying device and clarifying method for glass

InactiveCN107827338AIncrease the flow distanceAvoid flowGlass furnace apparatusBiochemical engineeringOptical glass

The invention provides a clarifying device and a clarifying method for glass, belonging to the technical field of manufacturing of optical glass. The invention is to solve the problems of excessivelylong clarifying groove, easy damage of a platinum product and low clarifying efficiency for optical glass. The clarifying device is mainly characterized by comprising an inlet pipe, a clarifying groove, an outlet pipe and a chimney, wherein the clarifying groove is a cavity with a cuboid shape or a covered U-shaped groove shape; the front end and the rear end of the clarifying groove are respectively welded with the inlet pipe and the outlet pipe which are respectively used as an inflow channel and an outflow channel for liquid glass; the interior of the clarifying groove is provided with partition plates which are used for up-down separation, so independent separate layers with a plurality of layers in communication are formed, and the flowing route of the liquid glass in the clarifying groove is prolonged; a groove cover and the clarifying groove are seal-welded; and the chimney is arranged at the top part of the clarifying groove and used for discharging gas in the clarifying groove. The clarifying device provided by the invention has the characteristics of high efficiency and small size, and is mainly used for clarifying the optical glass.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

Steam crosslinking technology adopting steam crosslinking special tray

The invention discloses a steam crosslinking technology adopting a steam crosslinking special tray. The special tray is adopted in the crosslinking technology, and has the characteristics of a conventional cable tray. An extruded-insulated cable is wound on the tray, the edge of the tray is wrapped by heat insulation canvas to form a wrapped layer, a steel belt is used for fastening, fixing and sealing, two sealed inflation spaces on the inner layer and the outer layer of the tray are formed and communicate through an air hole formed in the body of an inner barrel of the tray, heating steam isintroduced through air inlets on the inner layer and the outer layer at the same time, heating steam permeates into a silane modified polyethylene cable insulation layer mixed with a silanol condensation catalyst from the inner layer and the outer layer in two directions, the pressure and temperature in the tray rapidly reach the conditions needed when organosilane crosslinked polyethylene completes crosslinking reaction within a short time, crosslinking reaction is rapidly completed, the sealing canvas is removed after crosslinking is finished, the whole tray of cable can enter a next working procedure for production after being cooled, and the crosslinking technology is thorough, rapid and saves time and steam.

Owner:JINSHUI CABLE GRP

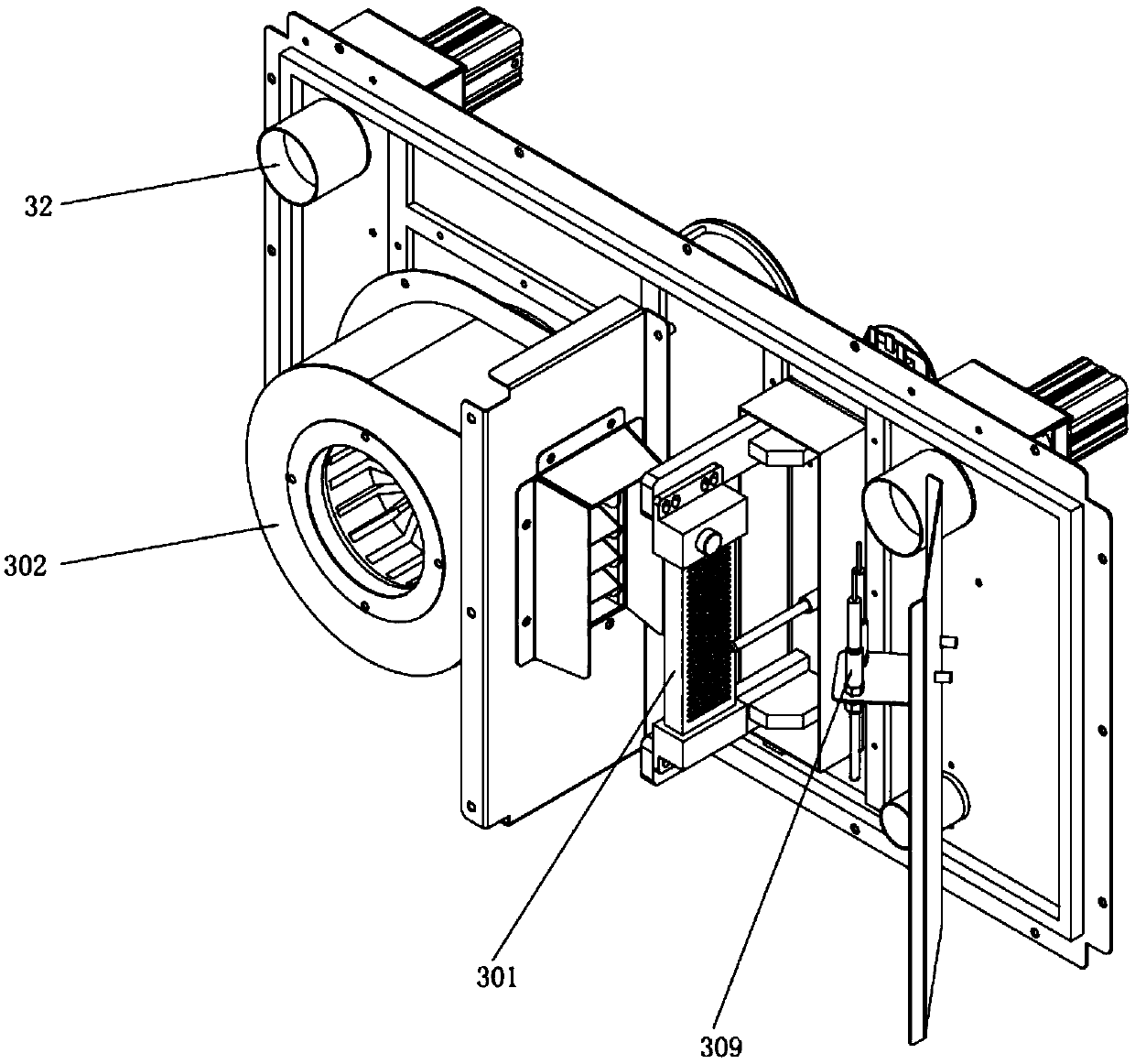

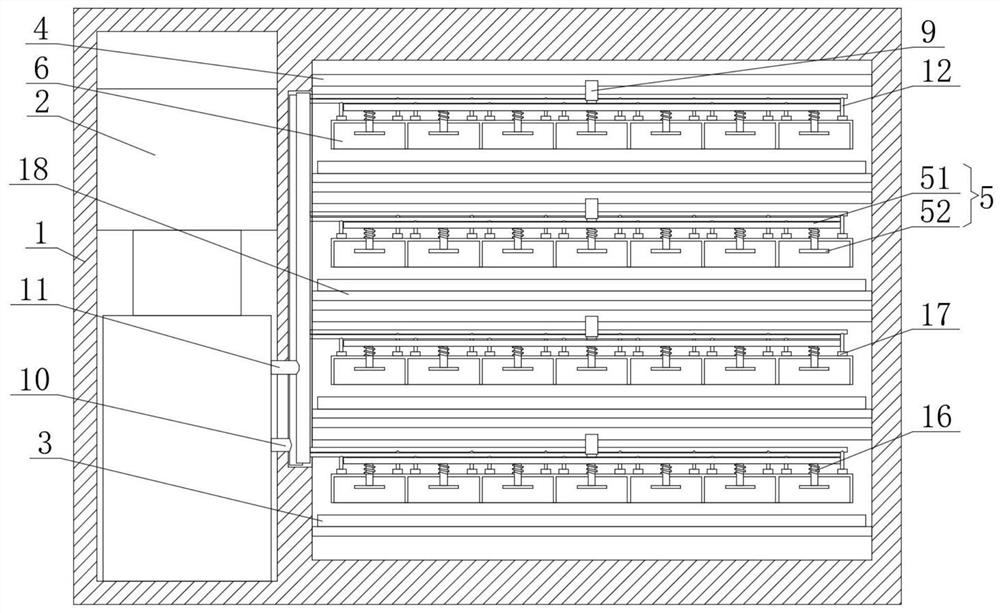

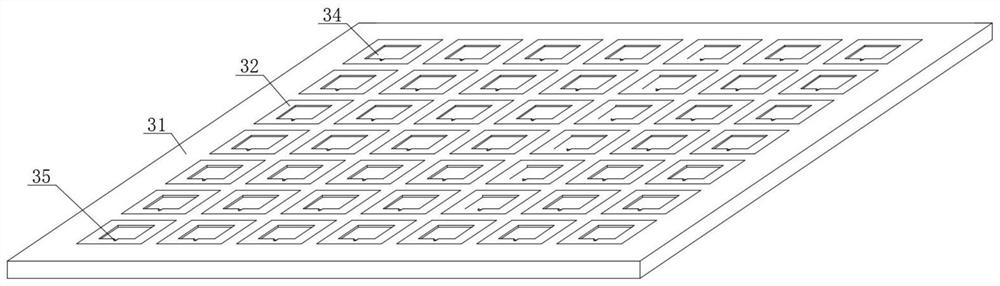

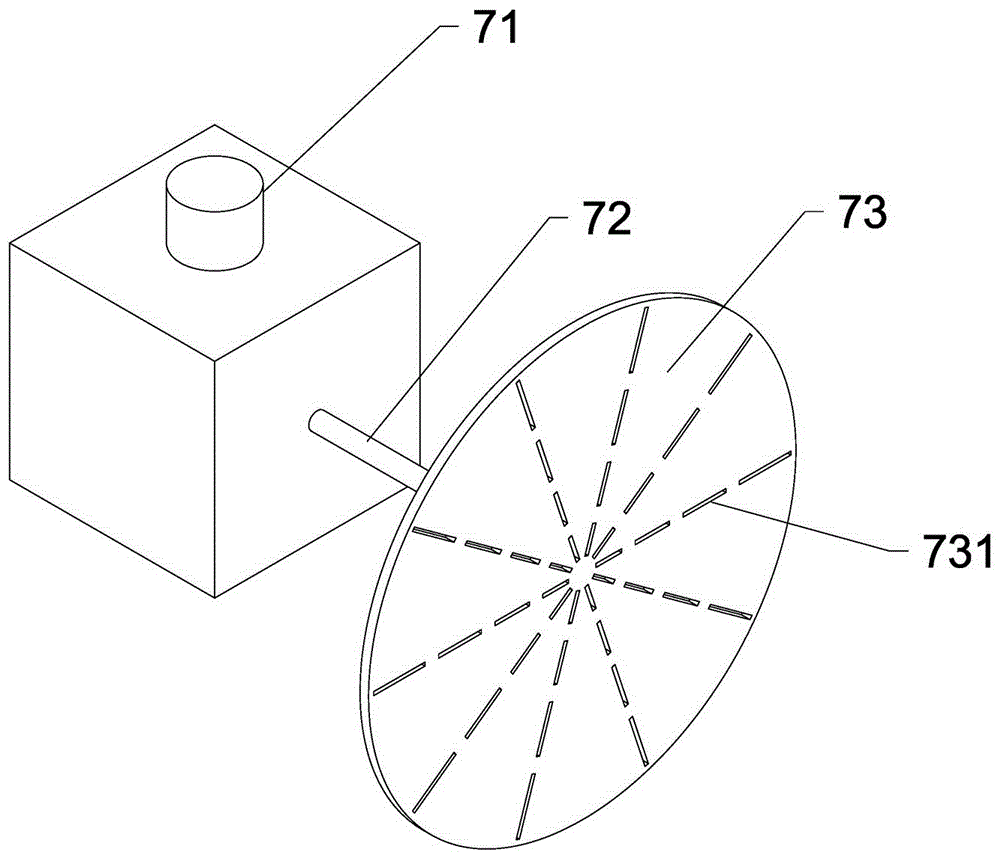

Low-temperature curing equipment and control method thereof

InactiveCN109926288ASmall footprintFast heatingPretreated surfacesCoatingsSquare arrayControl system

The invention relates to low-temperature curing equipment and a control method thereof. The low-temperature curing equipment comprises a cabinet body, a signal input unit, a control system and a hardware unit, multiple independent heating grids which are distributed in square array are formed in the cabinet body, and to-be-cured products can be placed in the heating grids respectively. The equipment and the method have the advantages that a manner of independently curing by adopting each heating grid is adopted, the equipment has the advantages of less space, fast heating speed, reduced heating space, greatly reduced energy consumption of the equipment compared with a traditional curing furnace, the cost of the whole equipment is reduced while the efficiency is improved, an asynchronous parallel curing method is adopted, separate and simultaneous curing of multiple products by using a piece of equipment at the same time can be achieved, the curing time is greatly shortened, and the process inventory is reduced.

Owner:HUIZHOU DESAY SV AUTOMOTIVE

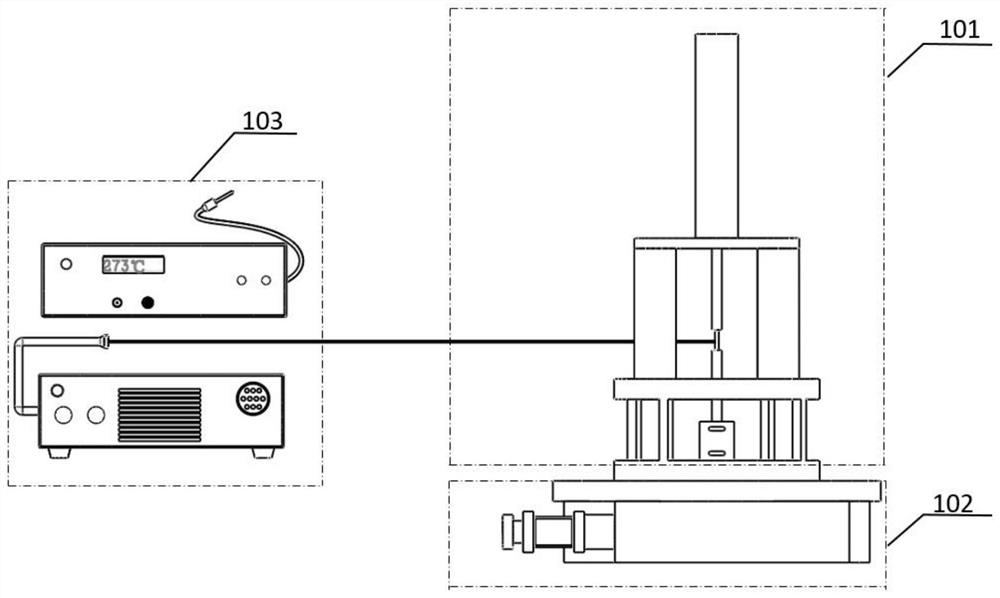

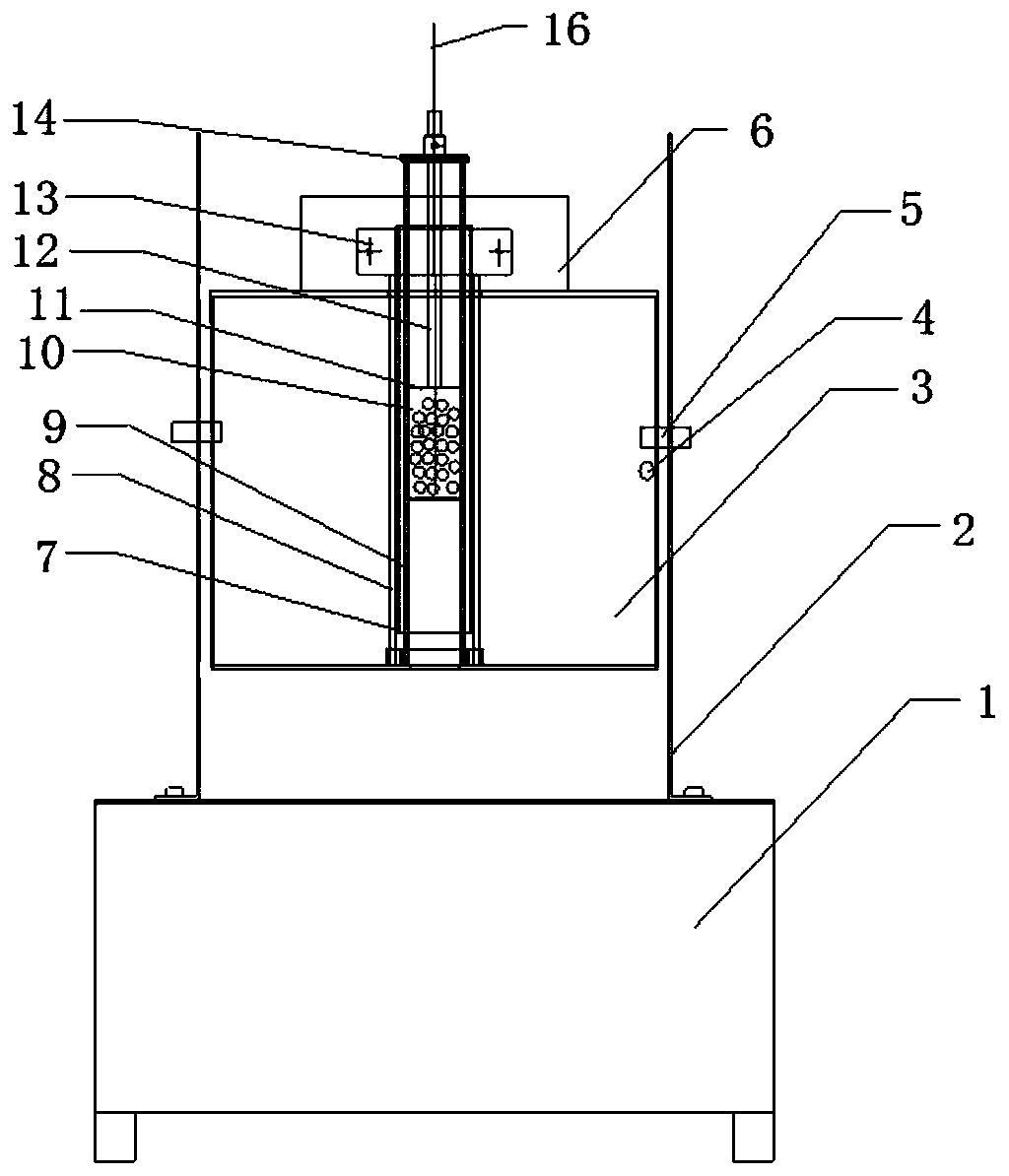

High-temperature fatigue force loading experiment instrument suitable for CT experiment

PendingCN112557221AHeating evenlyAchieve couplingMaterial analysis using wave/particle radiationMaterial strength using repeated/pulsating forcesFatigue loadingData information

The invention discloses a high-temperature fatigue force loading experiment instrument suitable for the CT experiment, an experiment sample is clamped and subjected to fatigue loading through a fatigue loading system, a supporting module is responsible for supporting experiment equipment, protective gas is introduced into a cylinder before the experiment is started, and after a period of time, thesample is heated and monitored in real time; and meanwhile, the rotating system is used for rotating the sample to enable the temperature of the experimental sample to be uniform, fatigue loading isconducted after the temperature is stable, and in the fatigue loading experiment process, the rotating system rotates the sample to conduct data information collection. A laser heating mode is adopted, and an optical material cylinder with high laser transmittance is used as a supporting structure, so that coupling of high-temperature heating, fatigue loading and CT experiments is achieved.

Owner:UNIV OF SCI & TECH OF CHINA

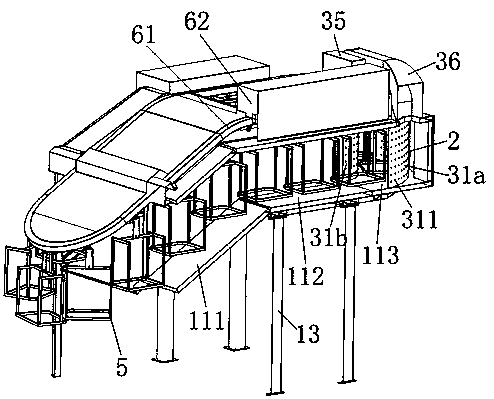

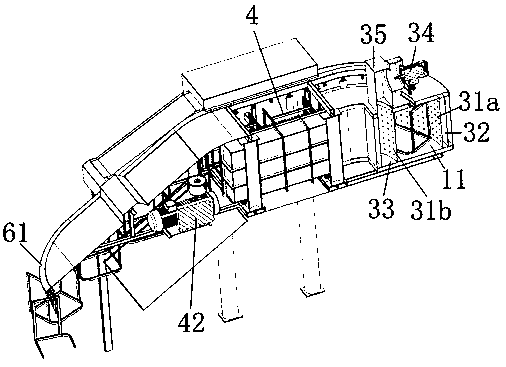

Vacuum vulcanizing machine for shoemaking

The invention discloses a vacuum vulcanizing machine for shoemaking. The vacuum vulcanizing machine comprises a rack, a heating system, a circulating air system, a vacuum pumping system, a shoe rack for conveying shoes, and a conveying system for moving the shoe rack. The conveying system comprises a conveying chain ring and a driving device for driving the conveying chain ring to cyclically move. The conveying chain ring comprises a bent oblique chain and a horizontally bent horizontal chain. The oblique chain is arranged outwards and obliquely towards the oblique lower position from one end of the horizontal chain. The vacuum pumping system is arranged on the left side or the right side of the conveying chain ring, and comprises a vacuum pump, a left side cover and a right side cover. The left side cover and the right side cover are arranged on the two sides of the conveying chain ring on the corresponding side. The left side cover and the right side cover can reciprocate in the width direction of the conveying chain ring. A drying channel for containing the shoe rack is arranged at the position, below part of the conveying chain ring, of the rack, at least part of the drying channel is arranged at the positions, on the opposite sides of the left side cover and the right side cover, of the conveying chain ring, the heating system is used for heating vamps in the drying channel, and the circulating air system is used for supplying circulating air into the drying channel. The vacuum vulcanizing machine is low in energy consumption and high in space utilization rate.

Owner:佛山市誉泰机械自动化科技有限公司

Energy-saving electric oven

InactiveCN113116179ASmall heating spaceContinuous and even heatingRoasters/grillsThermodynamicsEngineering

The invention relates to the technical field of high-efficiency energy-saving industry, and discloses an energy-saving electric oven which comprises a shell, a control switch is fixedly installed at the top of the side wall of the shell, a baking tray is placed in an inner cavity of the shell, and an adjusting plate is movably connected to the top of the inner wall of the shell in a sleeving mode. The electric heating wire is movably mounted on the adjusting plate, so that in the baking process of the shell, high-temperature gas floats upwards to enable the adjusting plate to move downwards so as to reduce the heating space of the inner cavity of the shell, and meanwhile, the continuous high-temperature gas enables airflow in the inner cavity of the shell to flow outwards through the pressure reducing pipe under the condition of thermal expansion, air flow in the pressure reduction pipe rotates the electric heating wire through the fan blades, so that the air flow in the inner cavity of the shell continuously flows, all parts of the inner cavity of the shell are continuously and uniformly heated through the rotating electric heating wire, and finally the purposes of reducing loss and uniformly heating are achieved by reducing the heating space and continuously rotating the heating element.

Owner:黄剑锋

Temperature circulation box for chip security detection

PendingCN113960450AMeet testing needsPracticalElectronic circuit testingTemperature controlElectrical and Electronics engineering

The invention discloses a temperature circulation box for chip safety detection, and belongs to the field of chip safety detection. The technical key points are that the temperature circulation box comprises a circulation box and a temperature control mechanism, the temperature control mechanism is installed in the circulation box, and an air supply pipe and a recovery pipe are installed on the temperature control mechanism; the inner side of the circulation box is fixedly provided with shelving frames which are arranged at equal intervals, the shelving frames are provided with detection discs, the inner side of the circulation box is fixedly connected with detection plates which are arranged at equal intervals, the detection plates and the shelving frames are arranged in a staggered mode, and the bottoms of the detection plates are provided with thermoelectric refrigeration sheet groups. According to the invention, chips to be detected can be separated, the situation that other chips to be detected are influenced when the chips burst, and consequently the detection structure is not accurate is avoided, meanwhile, the interior of the temperature circulation detection box is protected, a temperature changing mode is selected according to the use requirements of a user, the test requirements are met, and the practicability is higher.

Owner:苏州杰裕恩信息技术有限公司

Device and method for calcining oxidized pellets aerobically

The invention relates to the field of ferrous metallurgy and discloses a device and a method for calcining oxidized pellets aerobically. The device comprises a base, at least one furnace body supporting plate, a furnace body, a silicon carbide tube heater, an outer corundum protecting tube, an inner corundum protecting tube and a high-temperature specimen container. The furnace body supporting plates are vertically arranged on the base, the furnace body is mounted on the furnace body supporting plates, the outer corundum protecting tube is vertically arranged at the bottom of the furnace body,the silicon carbide tube heater is vertically arranged on the inner side of the outer corundum protecting tube, and the high-temperature specimen container is detachably mounted on the inner side ofthe inner corundum protecting tube and comprises a specimen container supporting plate, a specimen thermocouple tube and a high-temperature container. The device can guarantee that a specimen is heated in a ventilating state, so that the specimen is in air all the way, and therefore, an oxidative atmosphere is supplied sufficiently; therefore, the content of FeO in prepared pellets is reduced, anda reliable ground and guidance can be provided for industrial production.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

An Air Fryer That Operates Reliably

ActiveCN110876567BGuaranteed effective use of the areaGuaranteed Proportional DemandCooking-vessel lids/coversLighting elementsEngineeringGravity center

The invention relates to an air fryer stable in control. The air fryer comprises a base and a cover body hinged to the base. A fyer assembly is arranged in the machine base. The fryer assembly comprises an inner pot. A hot air assembly is arranged in the cover body, the hot air assembly comprises an air guide plate, a fan and a heating piece. The fan and the heating piece are positioned below theair guide plate; a transparent visual window is arranged on the cover body, the center of the hot air assembly deviates from the center of the fryer assembly, the distance between the center of the hot air assembly and the hinge center is smaller than the distance between the center of the fryer assembly and the hinge center, and the visual window surrounds the hot air assembly and is located above the inner pot. The hot air assembly is far away from a user relative to the fryer assembly, the area of the visual window located on one side of the user is enlarged, and therefore the user can visually observe the interior of the fryer assembly through the visual window. Meanwhile, the heights of the cover body and the whole air fryer can be effectively reduced, the gravity centers of the coverbody and the whole air fryer are reduced, and when the cover body is opened or closed, the whole air fryer is stably operated.

Owner:JOYOUNG CO LTD

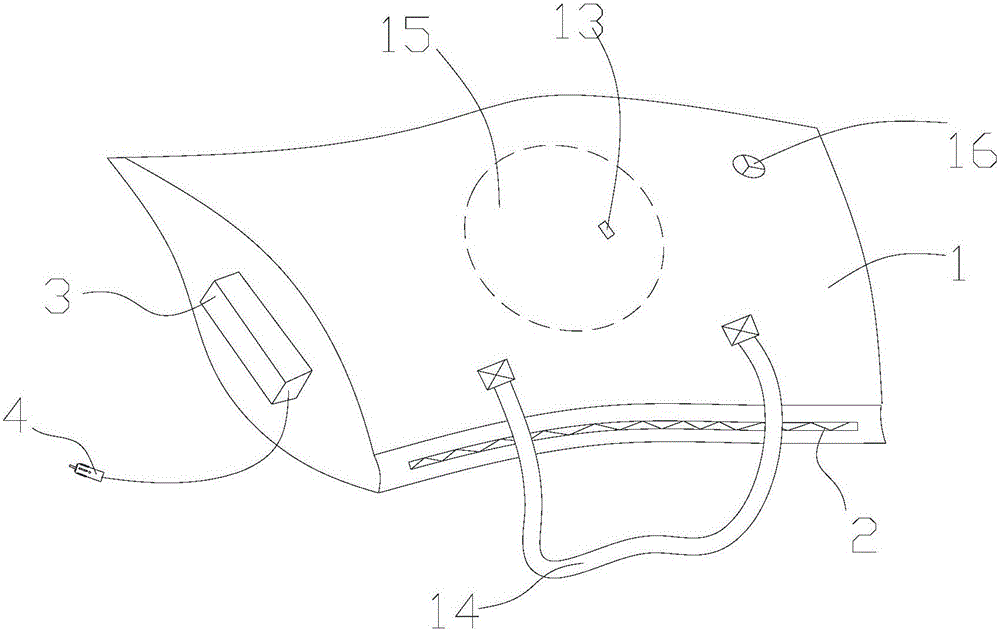

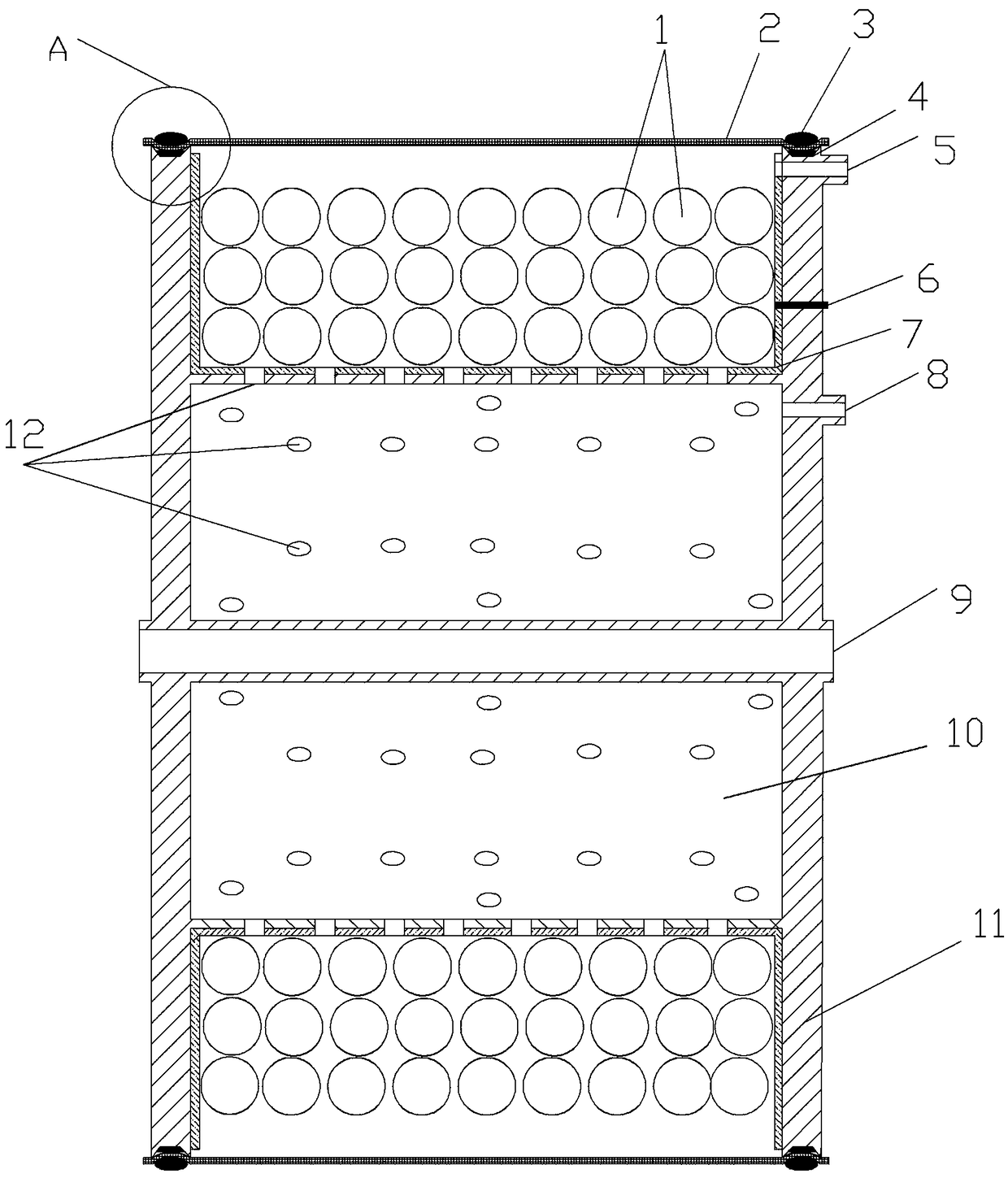

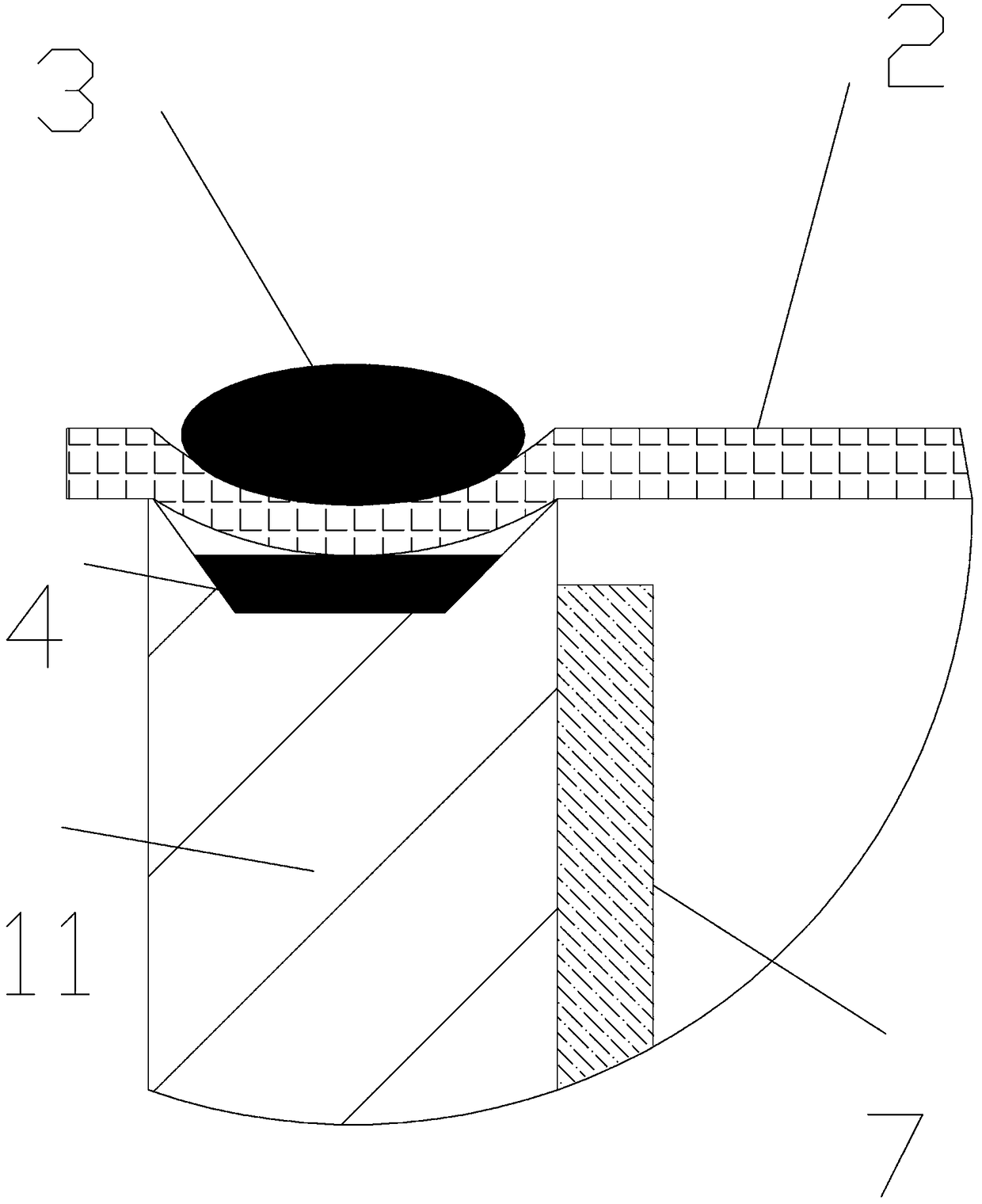

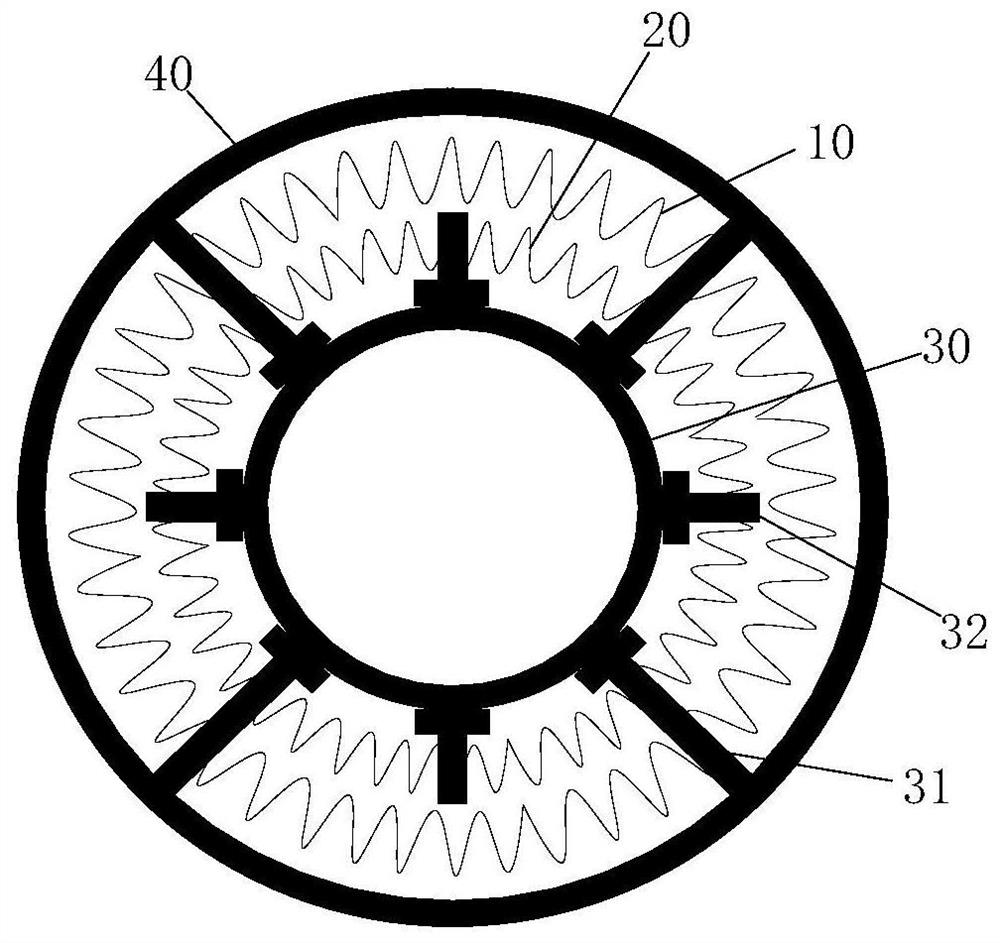

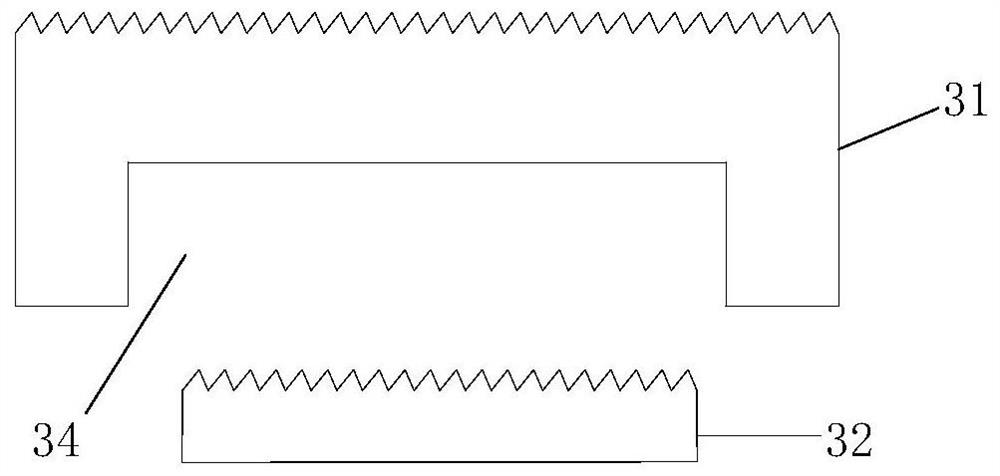

Special drum for cable steam crosslinking

PendingCN108556224AReduce turnaround timeSmall heating spaceDomestic articlesElectric cablesEnergy consumption

Provided is a special drum for cable steam crosslinking. The drum has technological characteristics as a conventional cable and comprises an inner barrel and two side plates; heat insulation rock woolboards are pasted to the outer surface of the inner barrel of the drum and the inner surfaces of the side plates; the side plates of the drum and the side face of the inner barrel are each provided with an air intake hole; a plurality of air pores are formed in a barrel body of the inner barrel; a cable subjected to extruded insulation wraps the drum, and an inner sealed heating space and an outer sealed heating space of the drum are formed by sealing the drum and outer heat insulation canvas; the inner heating space and the outer heating space communicate with each other through the air pores in the barrel body of the inner barrel of the drum; after steam is injected via an inner air inlet and an outer air inlet, the pressure and temperature in the drum can quickly reach the temperatureand pressure conditions required for the cable crosslinking reaction within a short period, the sealing canvas is removed after crosslinking is ended, a whole reel of drum can enter the next procedureto continue to be produced directly after being cooled, and the defects that a current special crosslinking device is large in occupied space, high in energy consumption and long in time consumptionare completely overcome.

Owner:JINSHUI CABLE GRP

A solar ground-kang surface combined heating system

ActiveCN105371342BSolving Oversized ProblemsMeet thermal needsCentral heating with accumulated heatLighting and heating apparatusSocial benefitsControl system

The invention discloses a solar ground-kang surface combined heating system, which includes a solar heat collection system, a heat storage system, a heat storage system, a floor heating system and a control system; the heat collection system collects solar radiation heat and outputs it for storage In the heat storage system, the separate heating operation time and heat supply of the ground-kang surface heating system are set through the control system to meet the heat demand of the human body. When people are active in the room during the day, the floor heating system can heat the room to meet the indoor temperature requirements; at night, when people are sleeping, the kang surface heating system can provide a comfortable bed temperature. The present invention adopts the ground-kang surface time-sharing heating mode to operate, and according to the different heat demands in the day and night human body activity areas and different states, it can be supplied on demand, reduce building energy consumption, reduce system scale and cost, and is easy to apply and easy to control. The operability is strong, and the popularization and application in solar heating buildings in villages and towns has good economic and social benefits.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

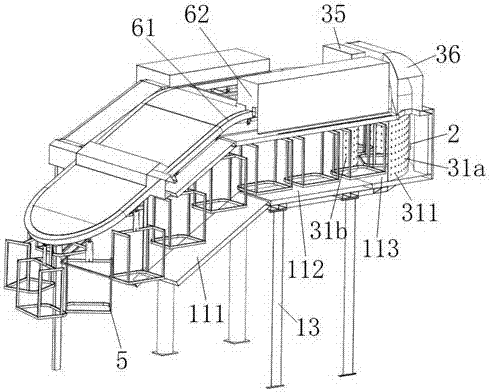

A spiral conveying heating and cooling equipment

ActiveCN105241247BSmall footprintSmall heating spaceCharge manipulationFurnace typesEngineeringHeating furnace

The invention belongs to the technical field of industrial heating furnaces, and discloses a screw conveying type heating and cooling device. The device comprises a main supporting frame on which a heating furnace and a cooling furnace are arranged in parallel, wherein the heating furnace and the cooling furnace communicate with each other; a bracket is arranged in the heating furnace; a first screw type supporting plate is arranged on the bracket; a conveyor belt is arranged on the first screw type supporting plate in the screwing direction; a second screw type supporting plate is arranged in the cooling furnace; the conveyor belt in the cooling furnace is in the same direction as the second screw type supporting plate; a transmission mechanism for driving the conveyor belt to move is arranged on the main supporting frame; the conveyor belt runs through the inner parts of the heating furnace and the cooling furnace and forms a loop through the transmission mechanism. With the adoption of the screw conveying type heating and cooling device, the energy can be saved, the high efficiency can be achieved, and the area for equipment can be saved. The productivity can be greatly increased under the same used area and energy consumption.

Owner:XI AN AOJIE ELECTRIC HEATING EQUIP ENG CO LTD

Heater and electrical equipment

The embodiment of the invention provides a heater and electrical equipment. The heater comprises: a first heating layer; a second heating layer, wherein the second heating layer and the first heatinglayer are stacked, wherein a gap is formed between the second heating layer and the first heating layer; and a supporting body which is provided with a first supporting piece used for supporting the first heating layer and a second supporting piece used for supporting the second heating layer. The embodiment of the invention further provides electrical equipment comprising the heater. According tothe technical scheme provided by the embodiment of the invention, the heating space occupied by the heater is effectively reduced, and the wind resistance is reduced, so that the problem of unbalanced air outlet temperature is solved, and the heating efficiency and the conversion efficiency are improved.

Owner:TIANKE INTELLIGENT TECH CO LTD

Self-water supply quick vapor generator

The invention discloses a self water supply type rapid steam generator, which comprises a water tank and a heating chamber which is provided with an electrothermal conversion component, wherein, the heating chamber is provided with a steam outlet; the heating chamber and the water tank are independent components; the heating chamber is provided with a junction board which forms a water supply channel with the water tank, wherein, the heating chamber below the junction board is communicated with the heating space of the hating chamber, and a balance tube is arranged in the heating chamber to balance the water level in the heating chamber; the water tank is provided with a balance tube faucet to insert the balance tube and can be used for water sealing. The self water supply type rapid steam generator of the invention adopts such a structure that the water tank is separated from the heating chamber generating steam, and generates steam in a mode of simultaneous heating and water supply,which not only facilitates the water supply to the water tank and discharging of the remaining water and cleaning, but also is convenient for selecting the water tank with suitable volume for use. A separator board is also provided to reduce the heating space, which also significantly shortens the time for steam generation.

Owner:SHENZHEN ZOFU TECH

A vacuum vulcanizer for shoemaking

The invention discloses a vacuum vulcanizing machine for shoemaking. The vacuum vulcanizing machine comprises a rack, a heating system, a circulating air system, a vacuum pumping system, a shoe rack for conveying shoes, and a conveying system for moving the shoe rack. The conveying system comprises a conveying chain ring and a driving device for driving the conveying chain ring to cyclically move. The conveying chain ring comprises a bent oblique chain and a horizontally bent horizontal chain. The oblique chain is arranged outwards and obliquely towards the oblique lower position from one end of the horizontal chain. The vacuum pumping system is arranged on the left side or the right side of the conveying chain ring, and comprises a vacuum pump, a left side cover and a right side cover. The left side cover and the right side cover are arranged on the two sides of the conveying chain ring on the corresponding side. The left side cover and the right side cover can reciprocate in the width direction of the conveying chain ring. A drying channel for containing the shoe rack is arranged at the position, below part of the conveying chain ring, of the rack, at least part of the drying channel is arranged at the positions, on the opposite sides of the left side cover and the right side cover, of the conveying chain ring, the heating system is used for heating vamps in the drying channel, and the circulating air system is used for supplying circulating air into the drying channel. The vacuum vulcanizing machine is low in energy consumption and high in space utilization rate.

Owner:佛山市誉泰机械自动化科技有限公司

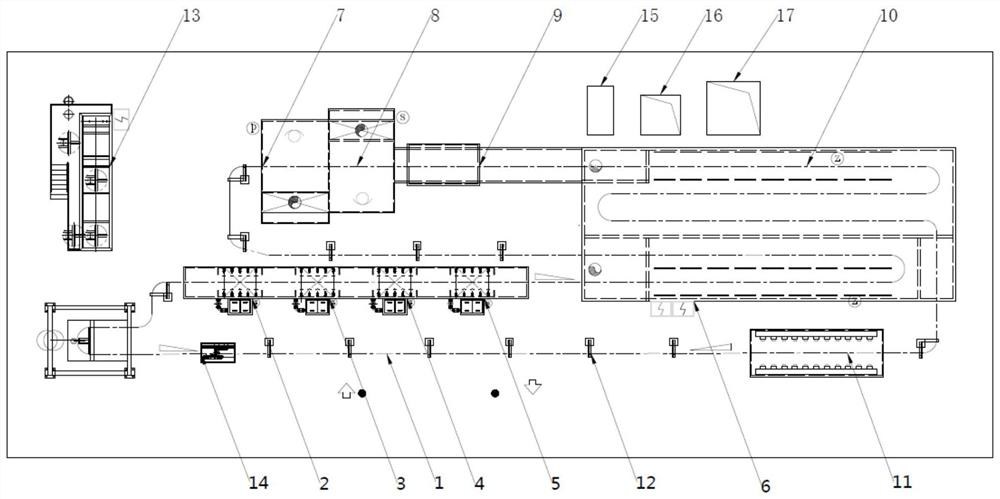

A rail transit integral wheel coating production line and its application method

ActiveCN112076931BReduce painting costQuick changeGas treatmentDispersed particle separationSludgeProcess engineering

The invention discloses a rail transit integral wheel coating production line. The coating production line is sequentially provided with a feeding station 1, a pre-degreasing station 2 for pre-processing the integral wheel, a degreasing station 3, and hot water Cleaning station 4, normal temperature water scoop washing station 5, dehydration and drying station for integral wheels used in rail transit 6, first paint painting station for paint spraying of integral wheels 7, second paint painting station Position 8. Used for the leveling station after the paint coating of the integral wheel for rail transit 9. Used for the paint drying station after the paint leveling of the integral wheel for rail transit 10. Used for drying the paint of the integral wheel for rail transit After the completion of the strong cooling station 11 and the blanking station 12, the coating production line is also equipped with a wastewater treatment station 13 and a sludge filter press station 15. The feeding station 1 is equipped with a cantilever crane, which can realize the hanging type feeding of the wheel hub hole. The invention also discloses a method for using the rail transit integral wheel coating production line.

Owner:MAANSHAN MAGANG JINXI RAIL TRANSPORT EQUIP

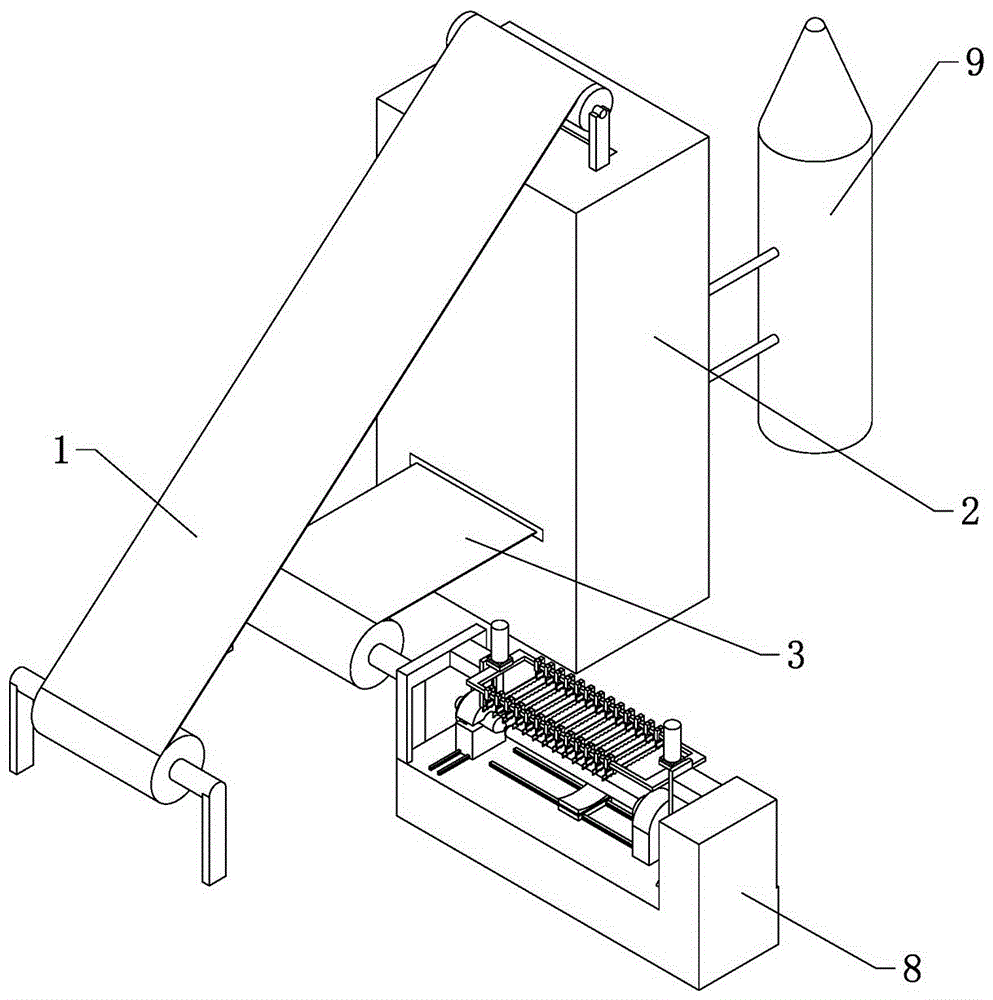

Production line for foam floor mats

The invention relates to the field of floor mat processing, and specifically relates to a production line for foam floor mats. The production line for the foam floor mats comprises a loading device, a processing chamber, a receiving device, a cutting device and a cooling device, wherein the processing chamber comprises a heating area and a cooling area, the heating area and the cooling area are mutually communicated, and an isolation belt is arranged at the junction of the heating area and the cooling area; the heating area comprises a foaming channel and a heating system, and a reflecting layer is arranged on the inner wall of the foaming channel; the heating system comprises a wave source transmitter, a waveguide tube and an energy feed port; the cutting device comprises a rack, a rotating device, a cutting table and a control mechanism; and the cooling device comprises a cooling tube and a cooler, and the cooling tube is wound outside the wave source transmitter and connected with the cooler.

Owner:ZHEJIANG RUNYANG NEW MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com