Special drum for cable steam crosslinking

A technology of steam cross-linking and trays, which is applied in home appliances, other home appliances, applications, etc., can solve the problems of large steam consumption, affecting production progress, and long time, so as to achieve low steam and energy consumption and convenience The effect of turnover and use, good heat preservation and sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

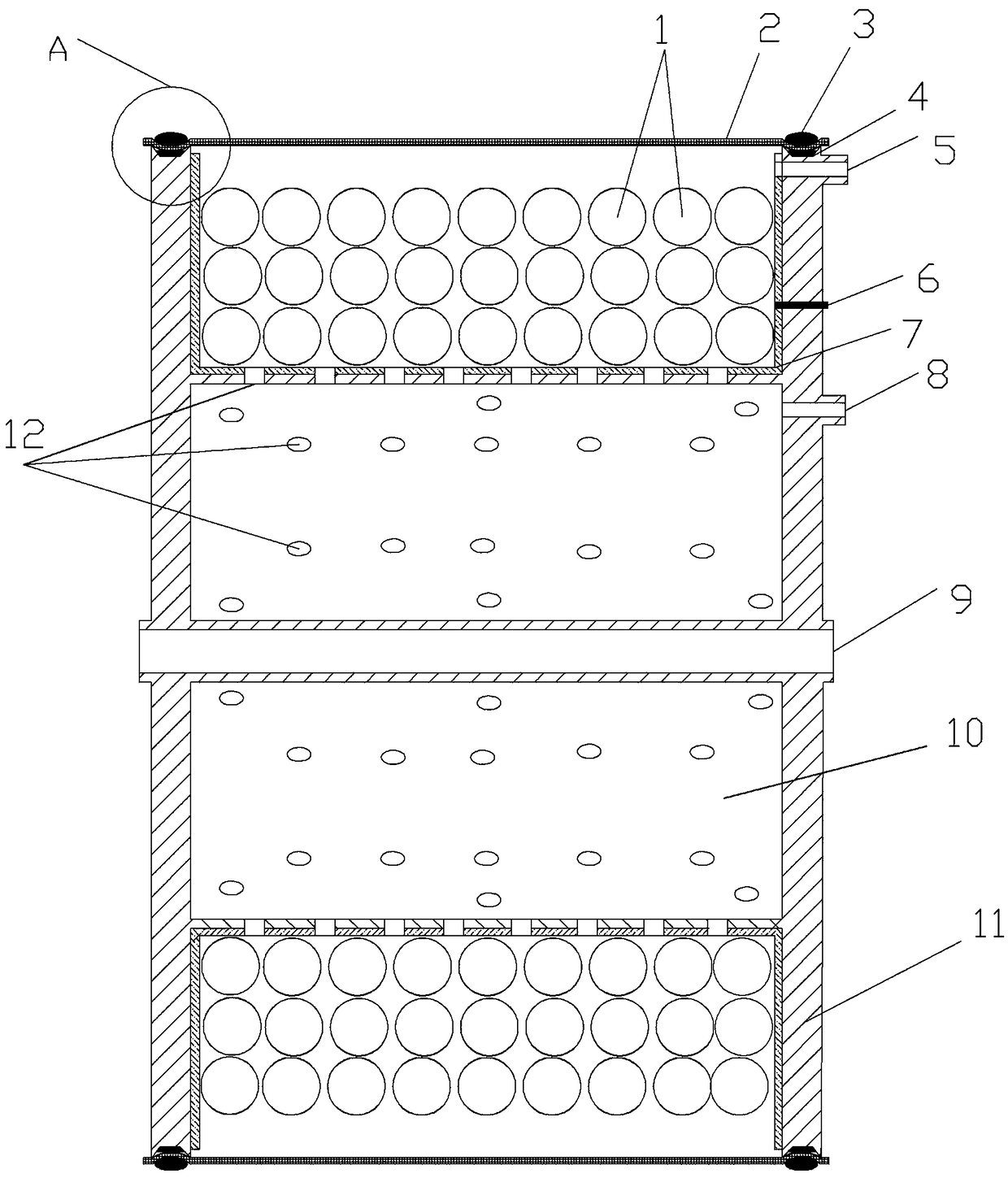

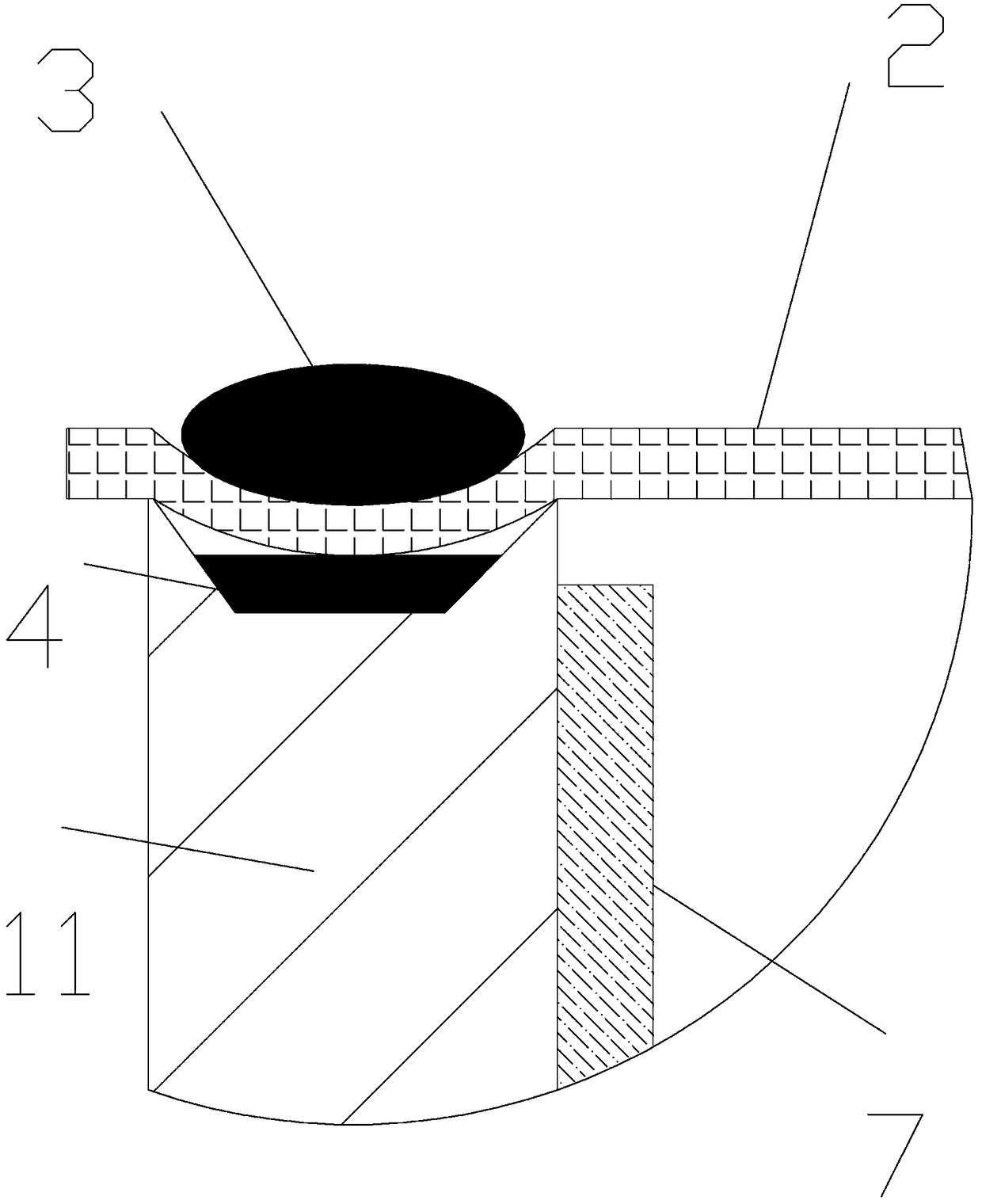

[0016] In order to make the solutions and advantages of the present invention more clear, the following will further describe the specific implementation manners of the present invention in detail with reference to the accompanying drawings.

[0017] The invention is a special pan for cable steam cross-linking. The extruded and insulated cable is wrapped on the thermal insulation rock wool board on the outer surface of the cylinder, and sealed by two disc-shaped side plates and the thermal insulation canvas layer. The surface and the inner surface of the cylinder form an annular inner air-filled space, and an outer air-filled space is formed between the waterproof canvas layer and the cylinder. The inner inflatable space and the outer inflatable space are connected through the air holes on the cylinder body, and the inner inflatable space and the outer inflatable space are inflated through the air inlets on the end surface and the side plate of the cylinder by using the small v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com