Rotary drum delivering platform vehicle

A technology for conveying trolleys and rollers, which is applied to conveyor objects, locomotives, motor vehicles, etc., to save turnover time, improve storage efficiency, and save storage area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following structural drawings and embodiments further illustrate the present invention.

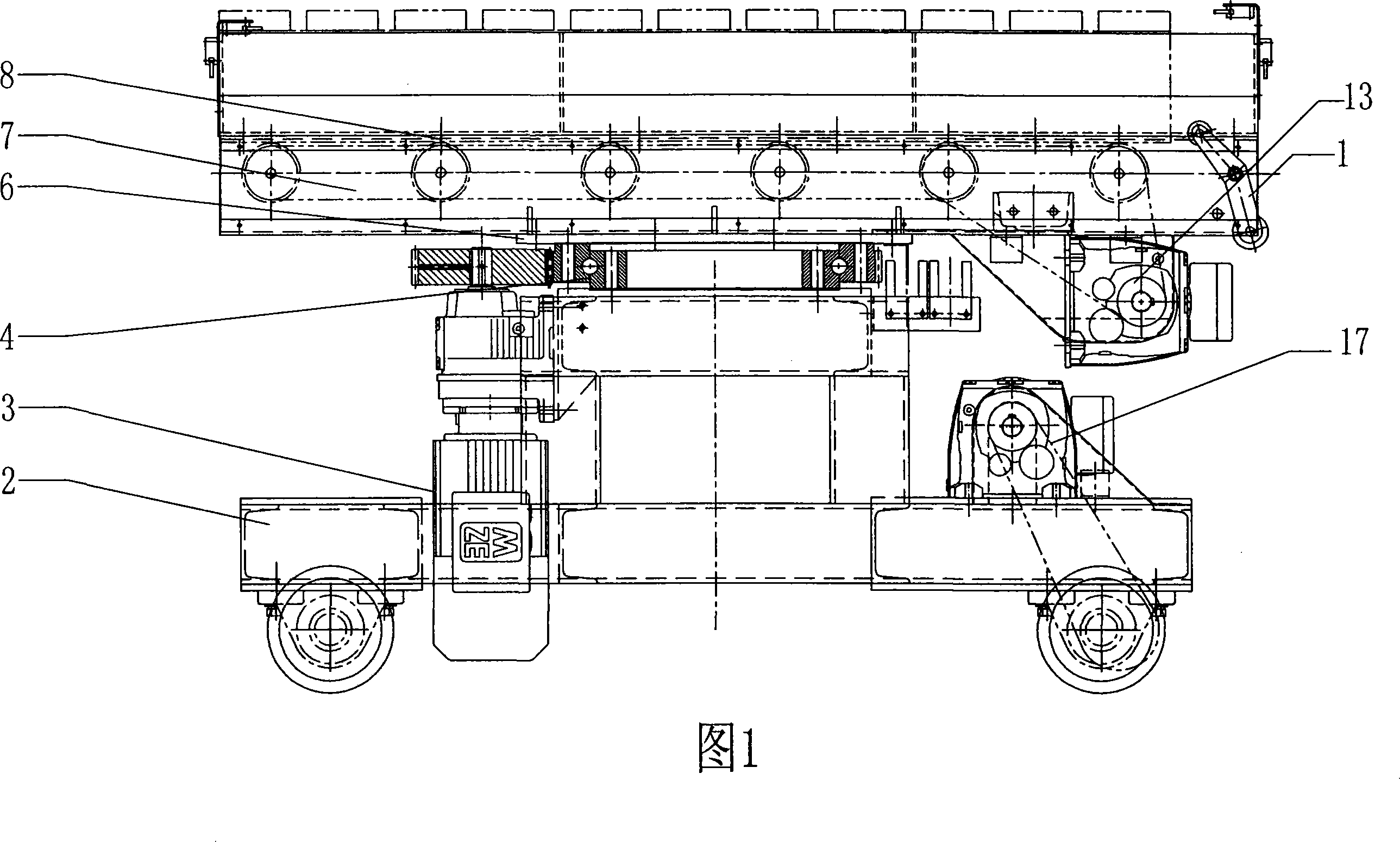

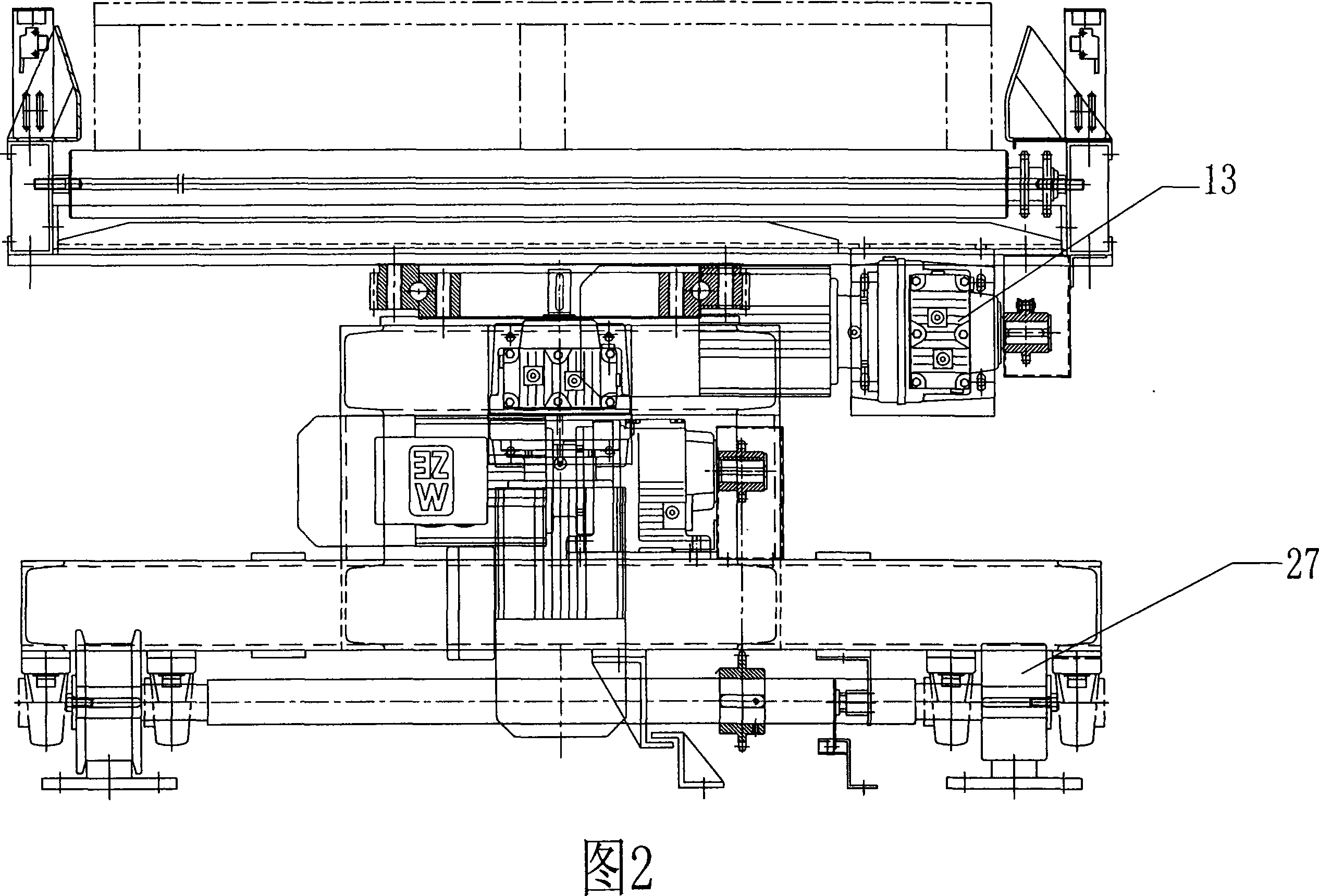

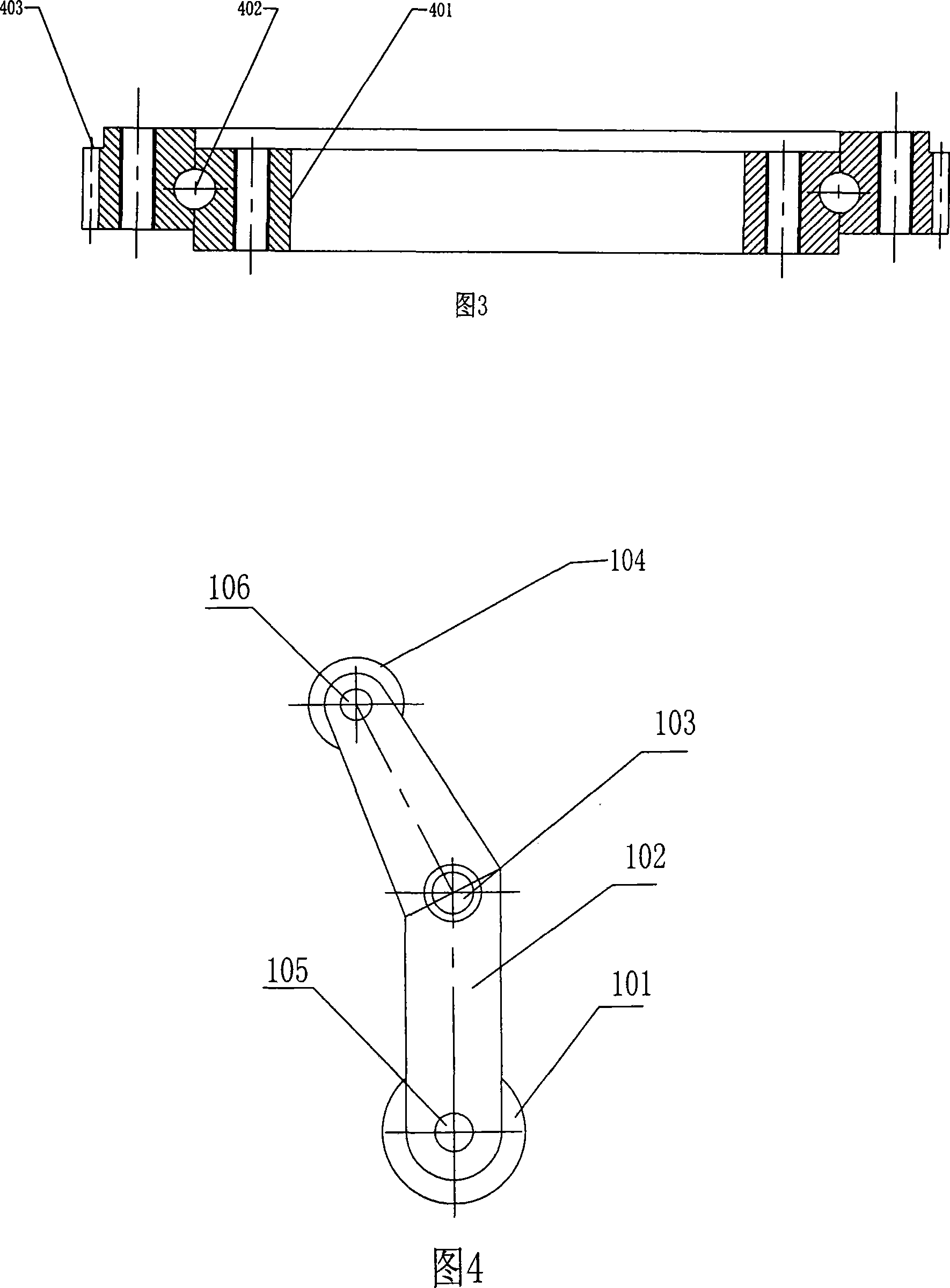

[0018] As shown in Figures 1, 2, 3, and 4.

[0019] A rotating roller conveying trolley, which is mainly composed of a chassis 2, a traveling drive motor 17, a slewing bearing 4, a slewing motor 3, a support seat 6, a bracket 7, a roller 8 and a conveying motor 13, and the chassis 2 is supported on the traveling wheel set 27 Above, the traveling wheel set 27 is driven by the traveling driving motor 17 installed on the chassis 2; the slewing support 4 is installed on the support platform, and the support platform is fixed on the chassis 2, and the driving gear on the outer ring of the slewing support 4 and the rotary motor 3 output The shaft gears on the shaft are meshed, the rotary motor 3 is also installed on the chassis 2, the support seat 6 is inserted and fixed in the slewing support 4 and rotates synchronously with the slewing support 4, the bracket 7 is installed on both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com