Low-temperature curing equipment and control method thereof

A curing equipment, low-temperature technology, applied in the direction of pretreatment surface, coating, device for coating liquid on the surface, etc., can solve the problems of large space occupied by curing furnace or curing room, scrapped products in batches, and increased product inventory, etc. The effect of reducing process inventory, improving efficiency, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention. Apparently, the described embodiments are only some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

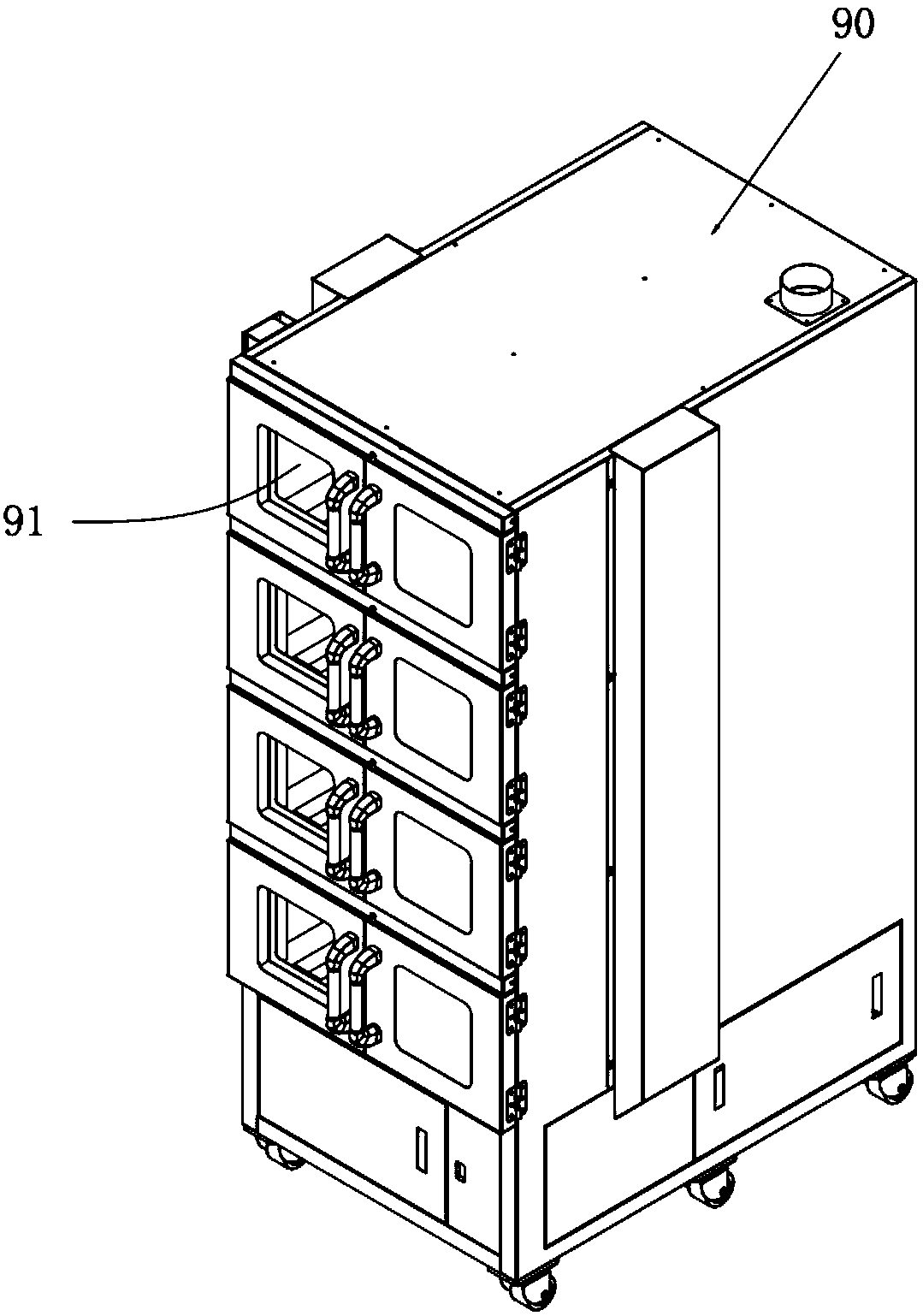

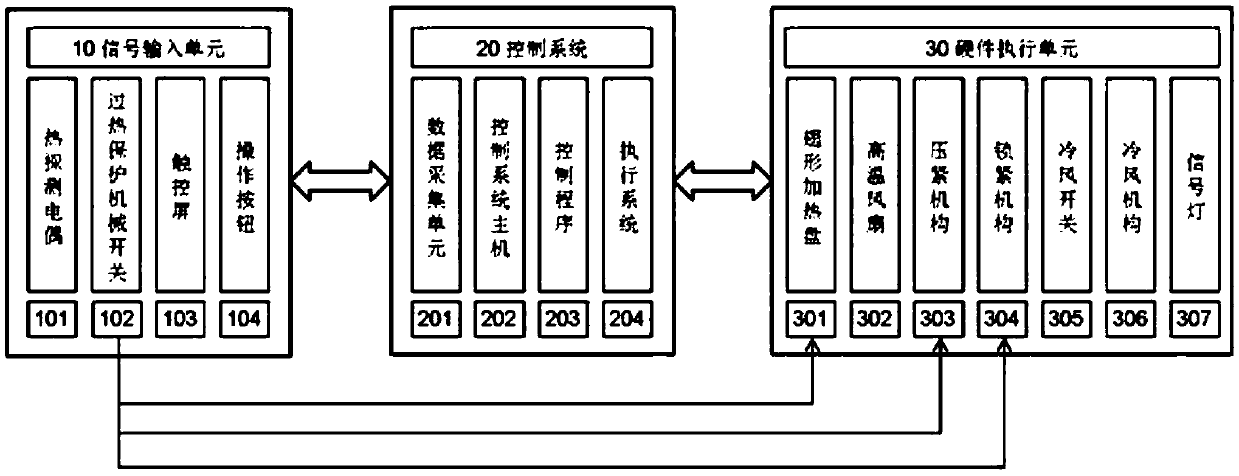

[0016] A low-temperature curing device, which includes a cabinet body 90, a plurality of independent heating grids 91 arranged in a square array are formed inside the cabinet body 90, and it is characterized in that it also includes a signal input unit 10, a control system 20 and hardware Unit 30.

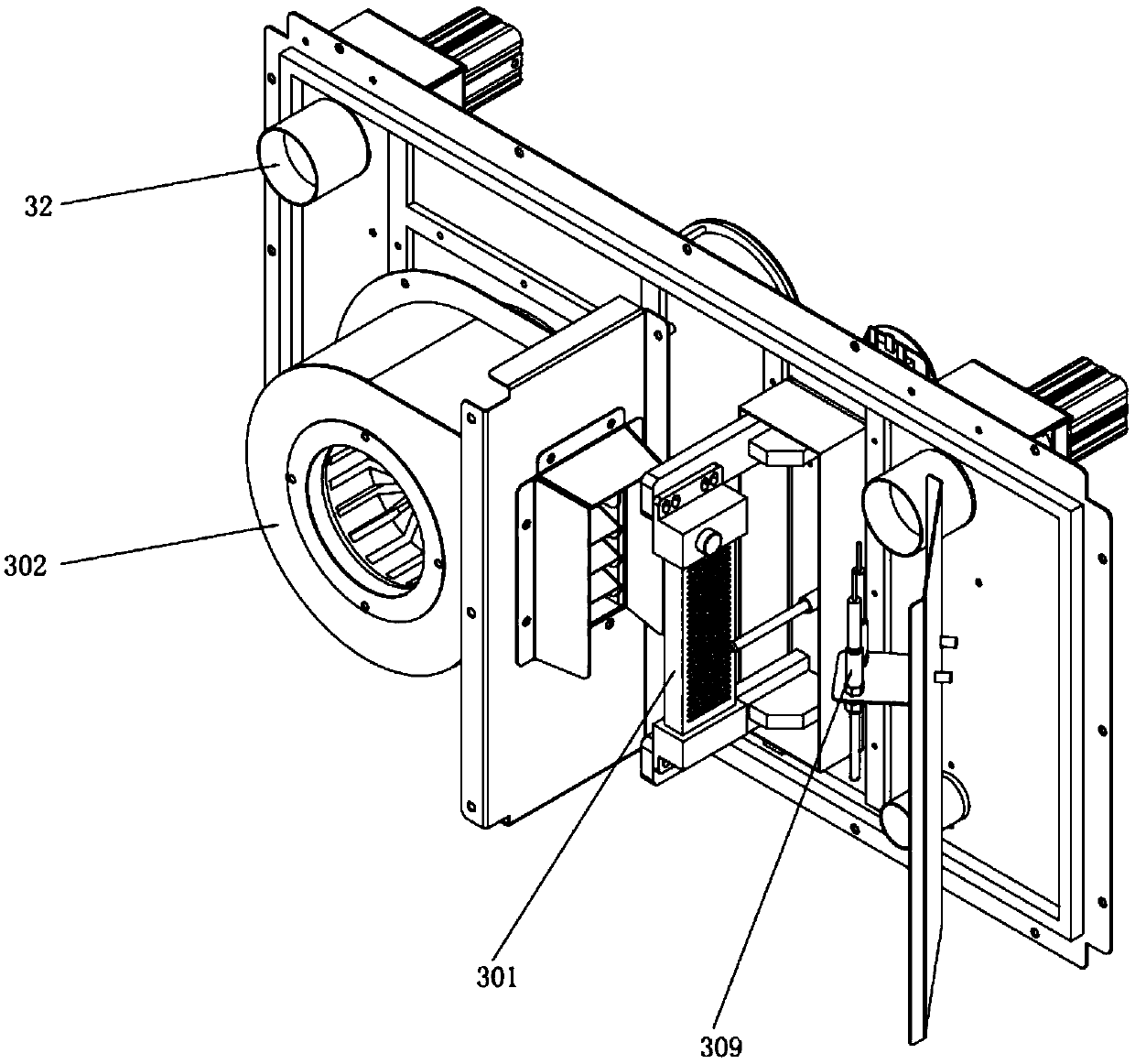

[0017] The hardware unit 30 includes: a fin-shaped heating plate 301, a high-temperature fan 302, a pressing mechanism 303, a locking mechanism 304, a cold air s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com