Screw conveying type heating furnace and horizontal cooling device

A technology of screw conveying and cooling equipment, which is applied in the direction of lighting and heating equipment, furnaces, furnace types, etc., can solve the problems of large floor area, large power loss, and low efficiency, and achieve reduced floor space, improved efficiency, and reduced The effect of power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

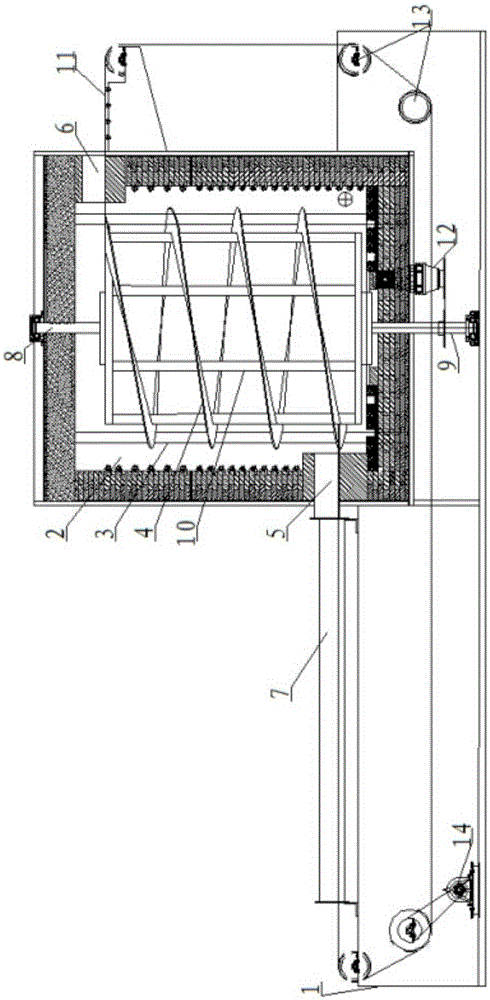

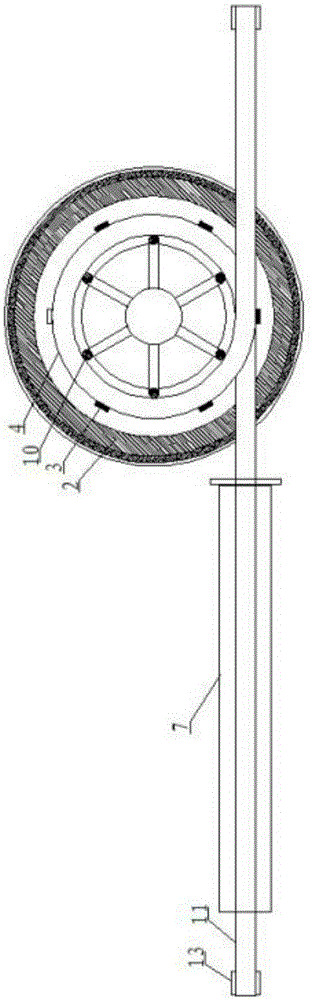

[0017] refer to figure 1 , figure 2 , is a structural schematic diagram of a spiral conveying heating furnace and horizontal cooling equipment of the present invention; the equipment includes a general support frame 1, a heating furnace 2 and a cooling furnace 7 are arranged on the general support frame 1, and a bracket is arranged in the heating furnace 2 3. The support 3 is provided with a spiral spiral support plate 4, and the spiral support plate 4 is provided with a conveyor belt 11 spirally rising along it. The spiral support plate 4 carries the conveyor belt 11 and the workpiece on it, and the spiral support plate 4 starts To support the role of the conveyor belt 11; the heating furnace 2 is provided with a conveyor belt outlet 5 and a conveyor belt inlet 6, and the conveyor belt outlet 5 is connected to the cooling furnace 7; the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com