A spiral conveying heating and cooling equipment

A technology of cooling equipment and screw conveying, applied in the field of industrial heating furnaces, can solve the problems of large floor space, large power loss, low efficiency, etc., and achieve the effect of reducing floor space, improving efficiency and reducing power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

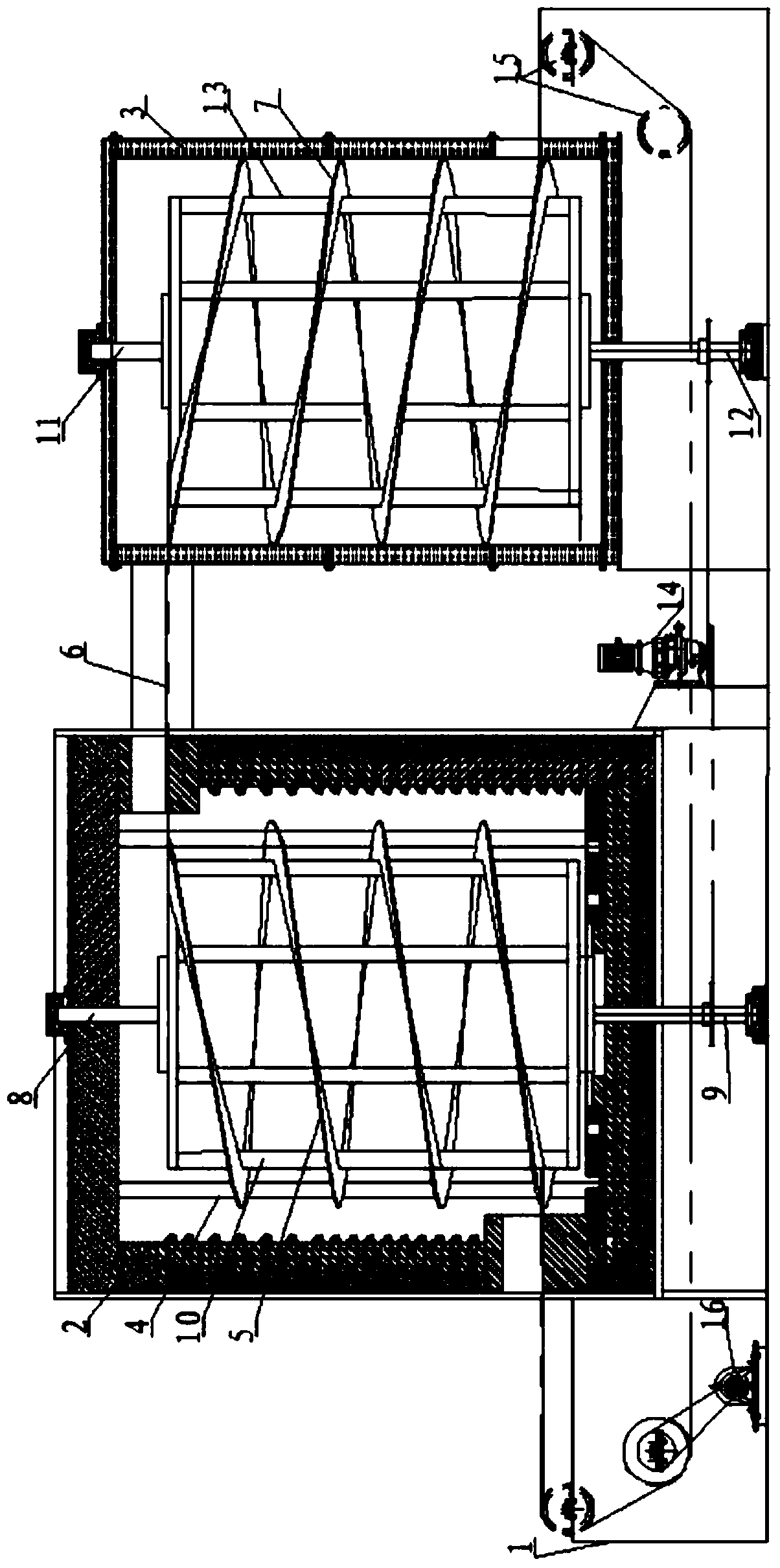

[0017] refer to figure 1 , is a structural schematic diagram of a spiral conveying heating and cooling equipment of the present invention; the spiral conveying heating and cooling equipment includes a general support frame 1, and a heating furnace 2 and a cooling furnace 3 connected to each other are arranged side by side on the general support frame 1 . The heating furnace 2 is composed of a furnace shell, a refractory layer, an insulating layer, and a heating element. The main function is to provide the workpiece with the temperature required for heat treatment and other heating. The heating furnace 2 and the cooling furnace 3 are connected by a conveyor belt transition device. A bracket 4 is arranged inside the heating furnace 2, and a first spiral support plate 5 of a spiral type is arranged on the support 4, and a conveyor belt 6 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com