Monitoring equipment lens ITO heating and de-icing device

A technology for monitoring equipment and lenses, applied to heating element materials, TVs, color TV parts, etc., can solve the problems of poor deicing effect on the surface of equipment, large heating space, slow heating process, etc., and achieve good dew removal effect , Small heating space, fast heating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

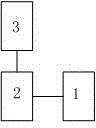

[0011] Referring to the accompanying drawings, the present invention is an ITO heating and deicing device for a monitoring equipment lens, including a monitoring equipment lens (4), characterized in that: there is a layer of ITO transparent conductive film (1) on the outer surface of the monitoring equipment lens (4) The resistance composed of the ITO transparent conductive film is connected to the temperature control circuit (2), and the temperature control circuit (2) is connected to the temperature sensor (3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com