Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Satisfy heat dissipation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

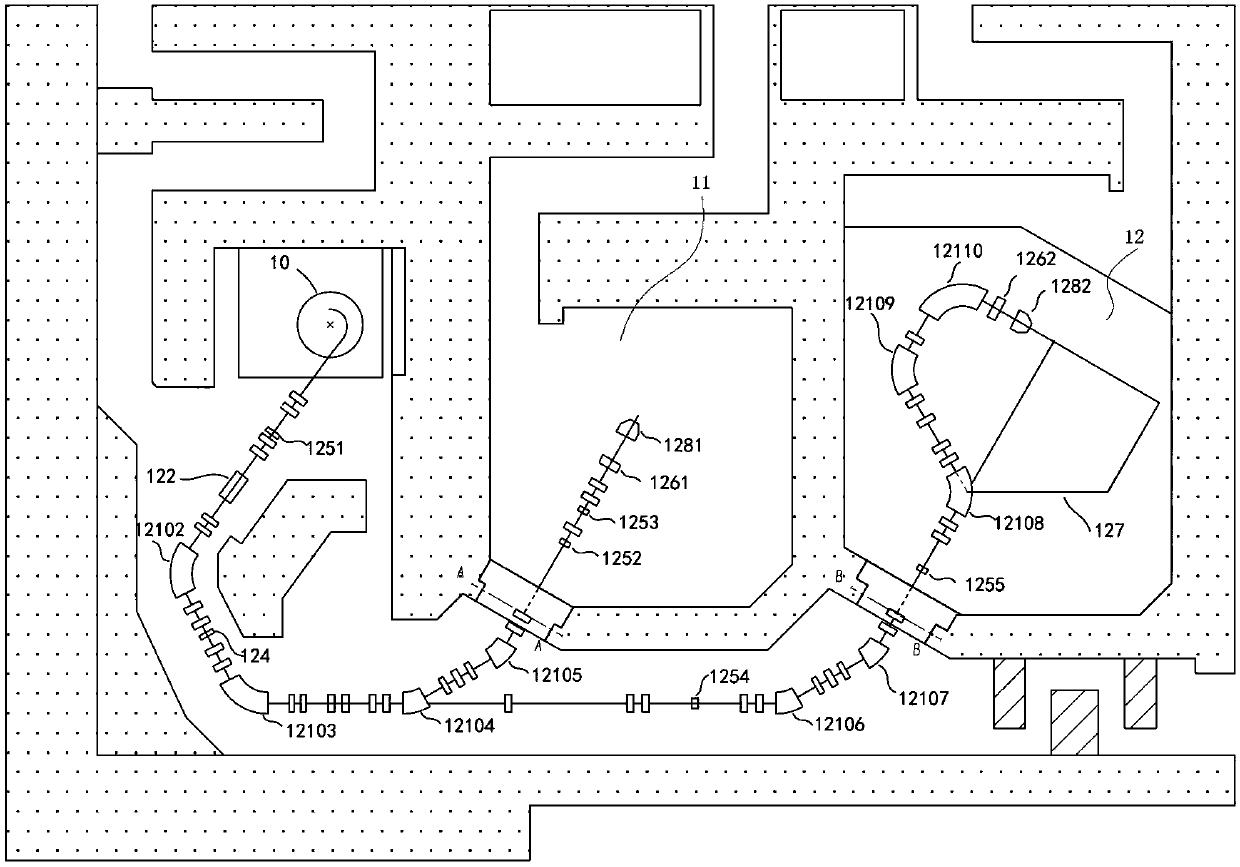

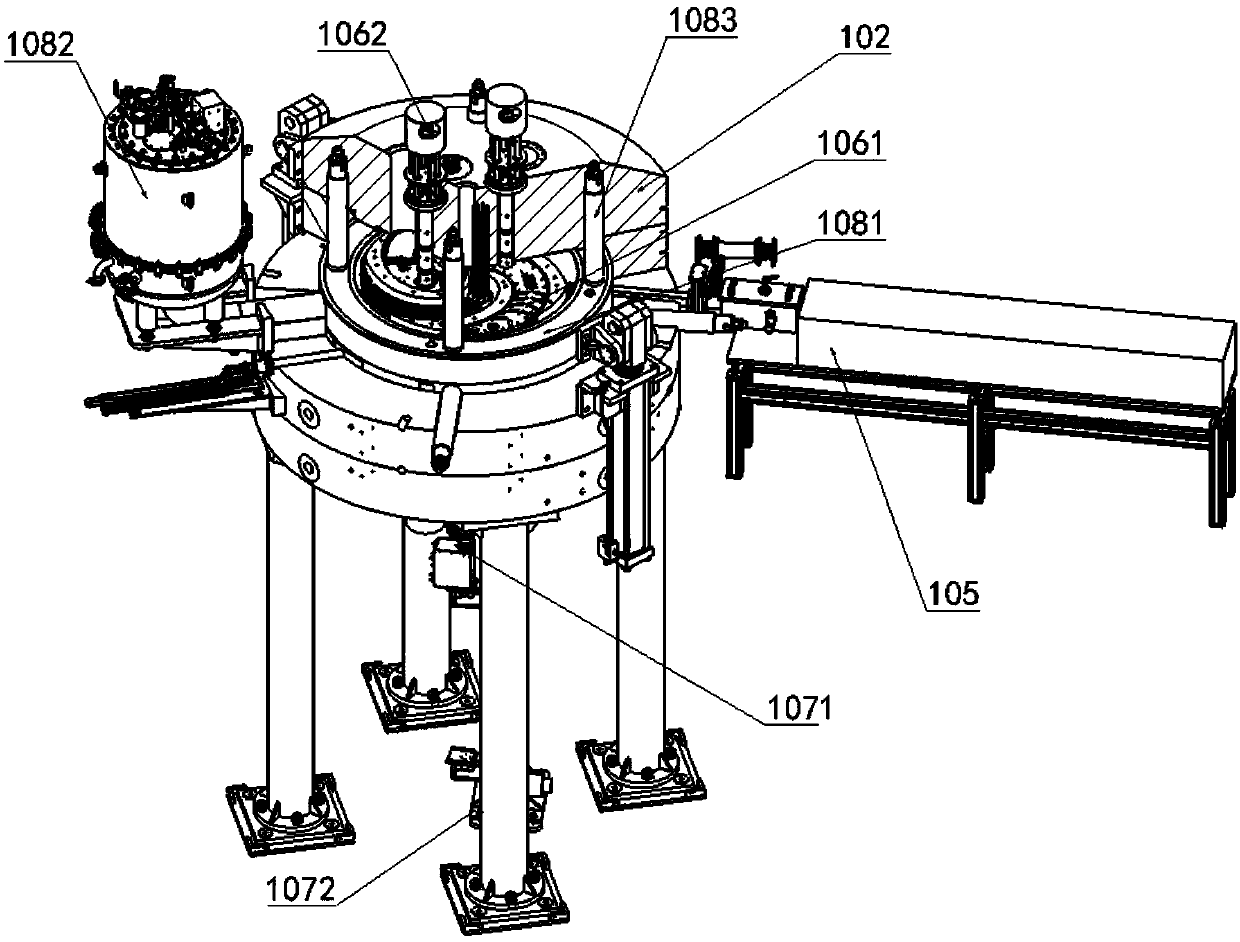

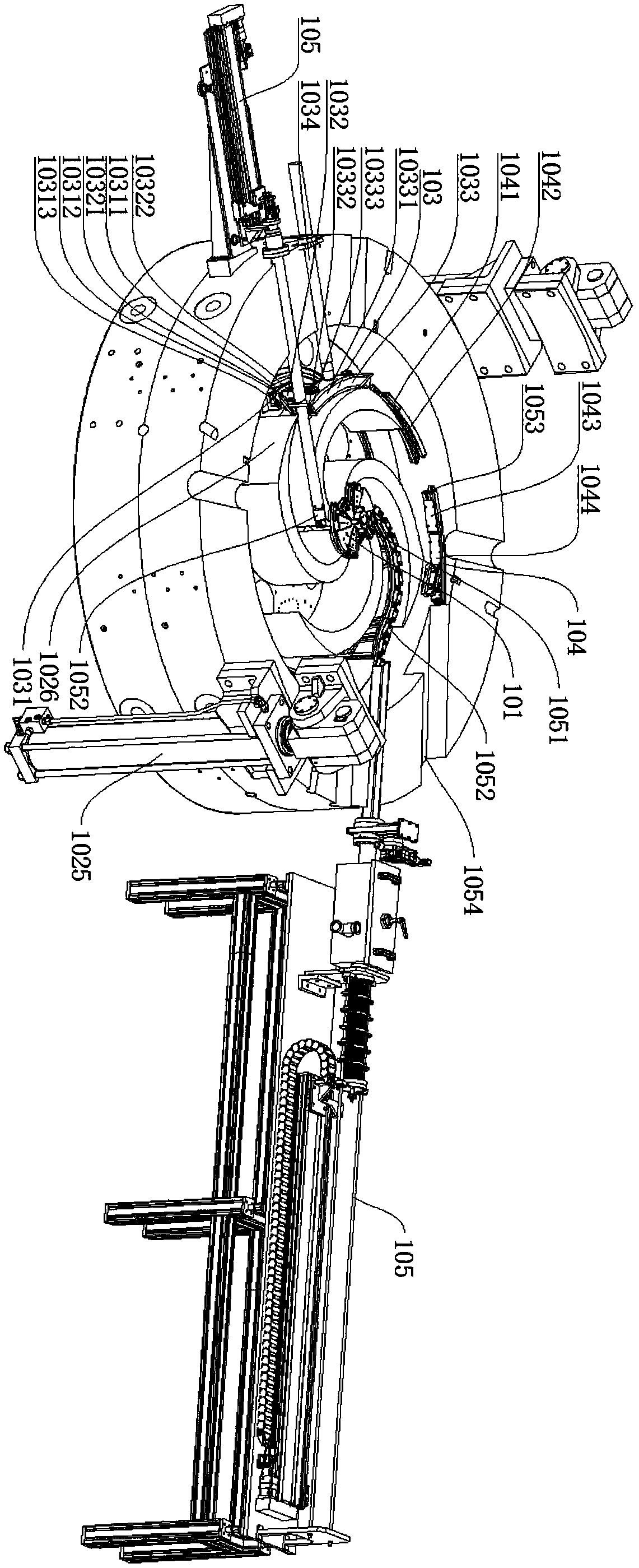

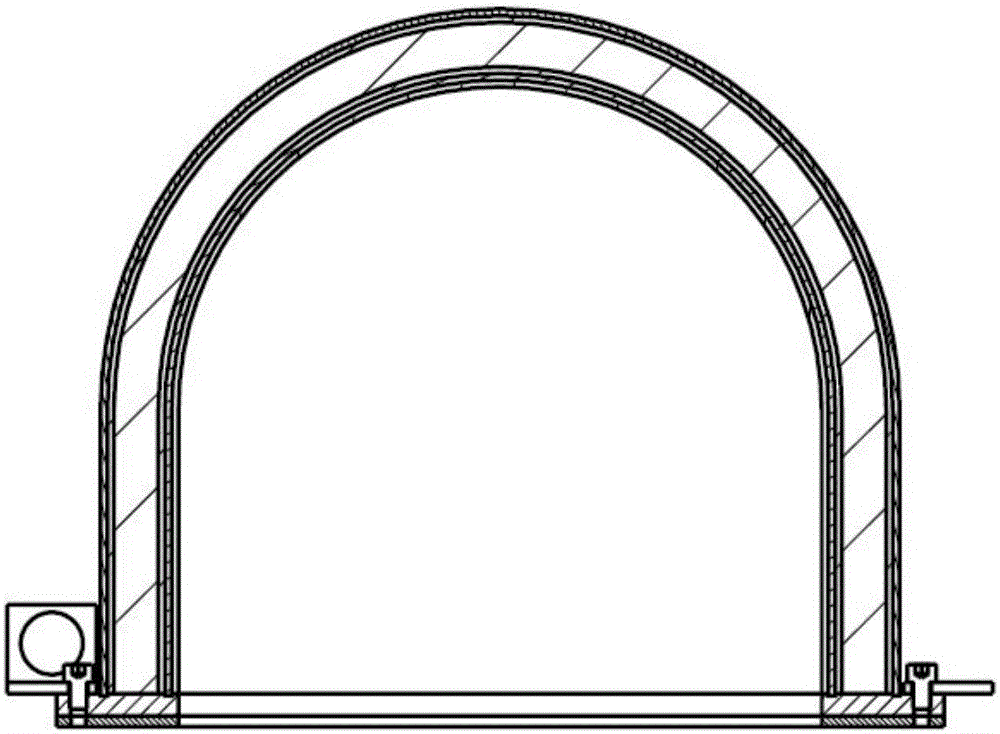

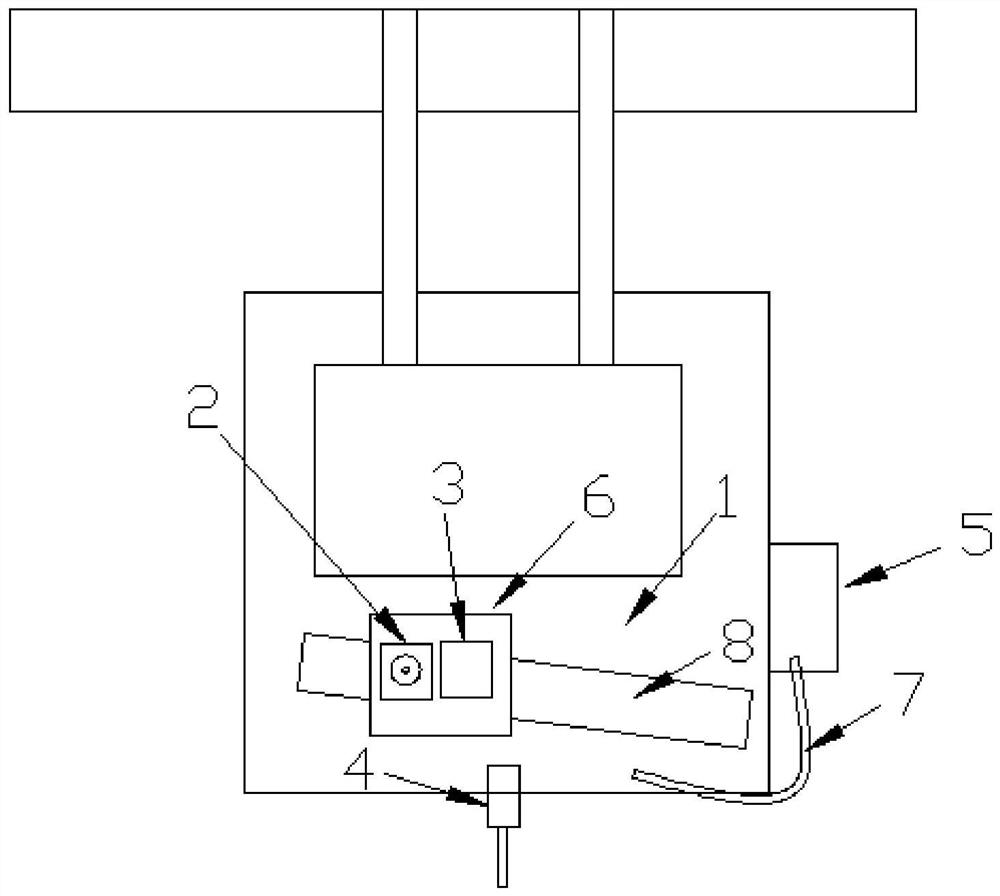

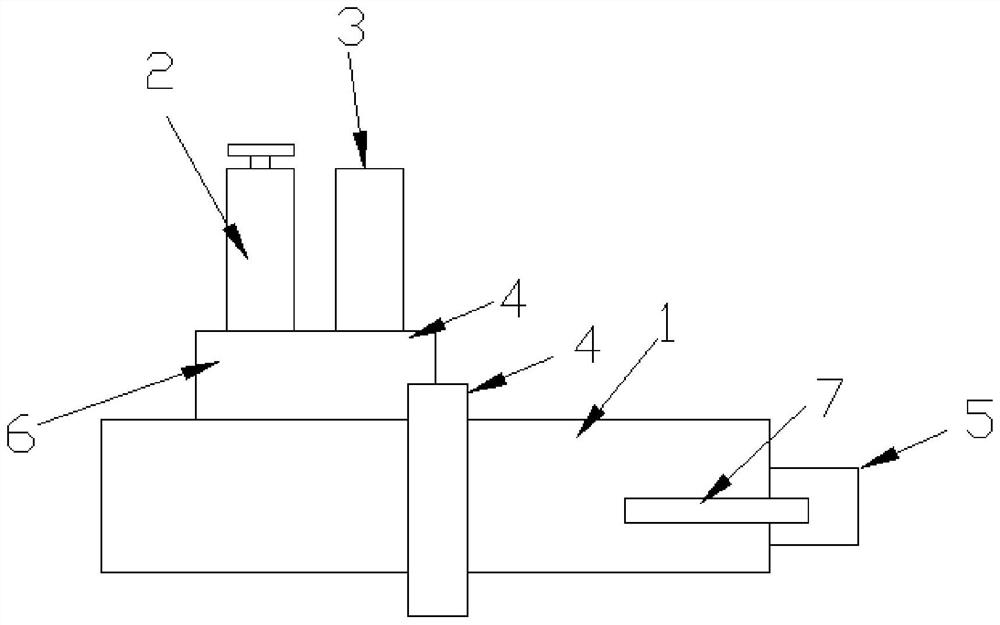

Proton therapy system based on compact superconducting cyclotron

ActiveCN107596579ARealize radial movementGet in and out of bed easilyMagnetic resonance acceleratorsMedical devicesProtonFixed energy

The invention discloses a proton therapy system based on a compact superconducting cyclotron. The proton therapy system includes a superconducting cyclotron system, an energy selection system and a beam transportation system, a fixed treatment room subsystem and a rotary frame treatment subsystem; the fixed energy proton beam led out by the superconducting cyclotron in the superconducting cyclotron system can be a continuously adjusting proton beam of 70-200MeV via the energy selection system, so that the longitudinal adjustment of the range during the proton therapy of tumors can be met; thebeam is transmitted to the fixed treatment room subsystem and the rotary frame treatment subsystem via the beam transportation system; the superconducting cyclotron system, the energy selection system, the beam transportation system and a treatment head are subjected to cooperative control to realize the transverse expansion of the proton beam, so that the intensity modulation treatment of the tumor can be completed. According to the invention, the innovation is good, the practicability is high, the beam intensity of the superconducting cyclotron is adjustable, and the intensity modulation treatment can be realized; and the system has an extremely important promotion effect on the accuracy, effectiveness and high efficiency of tumor treatment of a patient.

Owner:HEFEI CAS ION MEDICAL & TECHNICAL DEVICES CO LTD +1

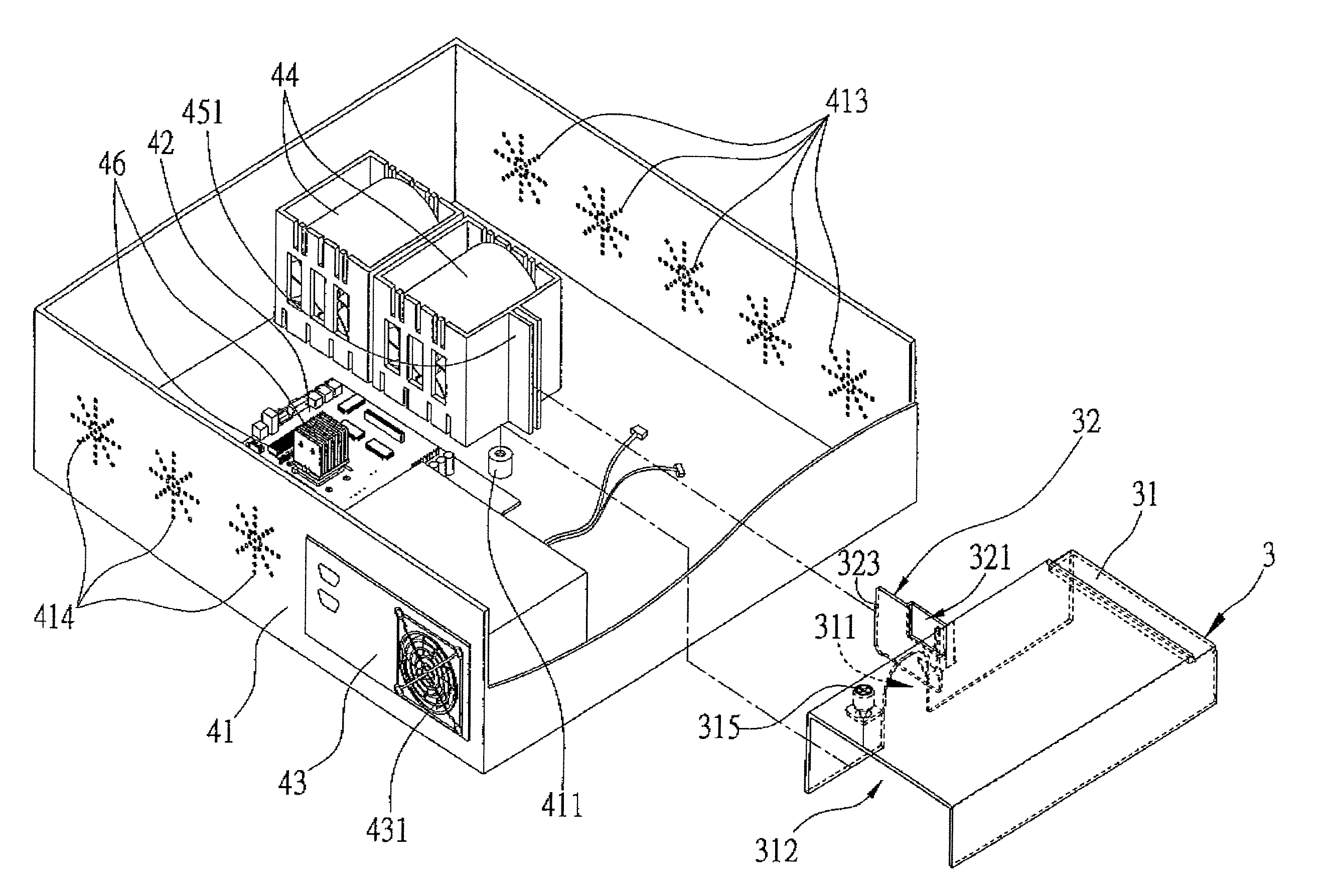

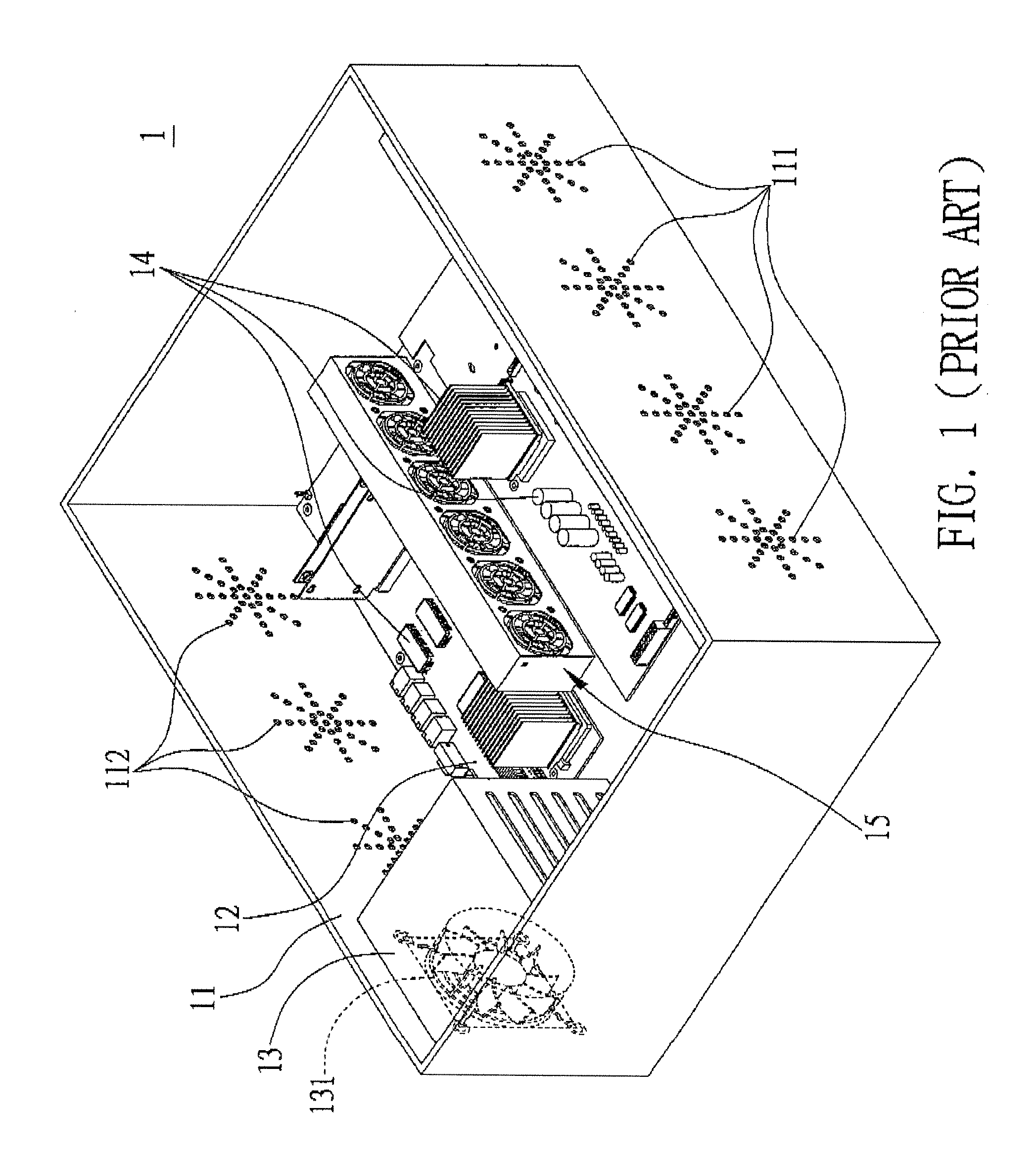

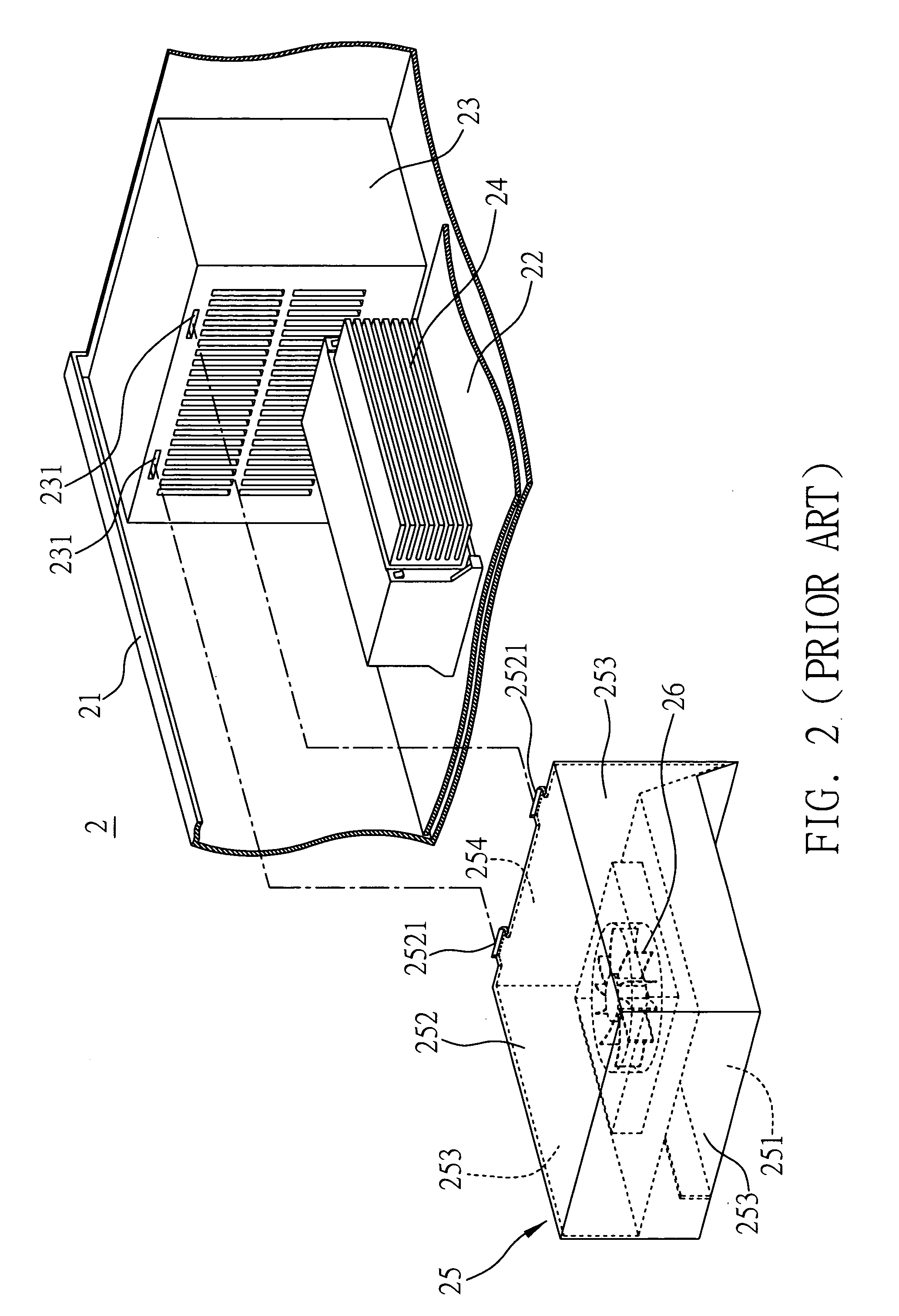

Wind-guiding cover

InactiveUS20070230117A1Satisfied with the effectHeat dissipationDigital data processing detailsCooling/ventilation/heating modificationsCouplingEngineering

A wind-guiding cover is provided, which is mounted in an electronic device having a heat generating component, a first coupling portion, a first positioning portion and an air inlet, wherein the heat generating component has a fan. The wind-guiding cover includes a main body and a separator. The main body is disposed between the heat generating component and the air inlet, and includes a channel for connecting the heat generating component to the air inlet, and a second coupling portion for being coupled to the first coupling portion, so as to allow the fan to directly introduce cooling air from the air inlet to the heat generating component to dissipate heat generated by the heat generating component. The separator is connected to a side of the main body and has a second positioning portion for being coupled to the first positioning portion.

Owner:INVENTEC CORP

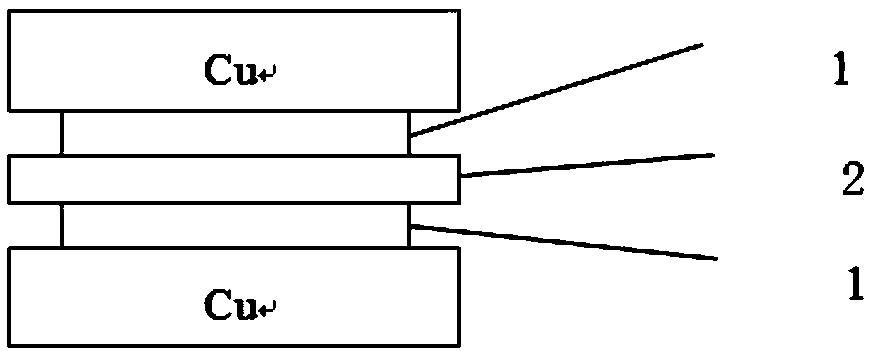

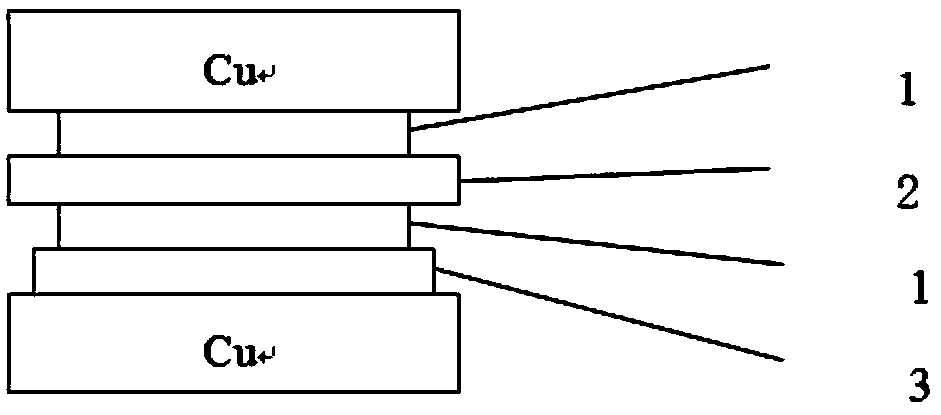

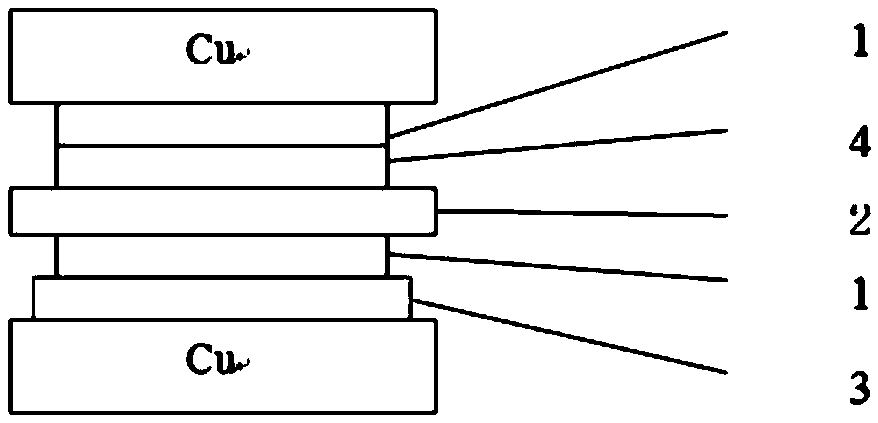

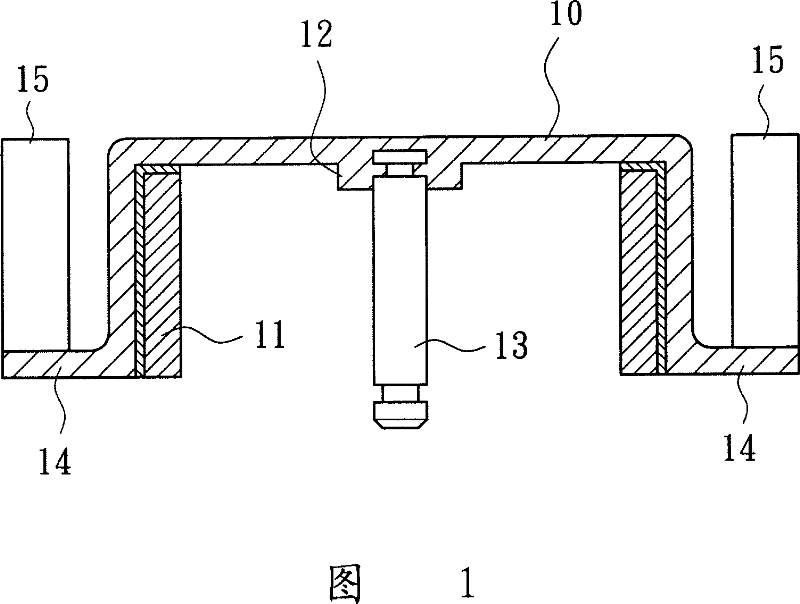

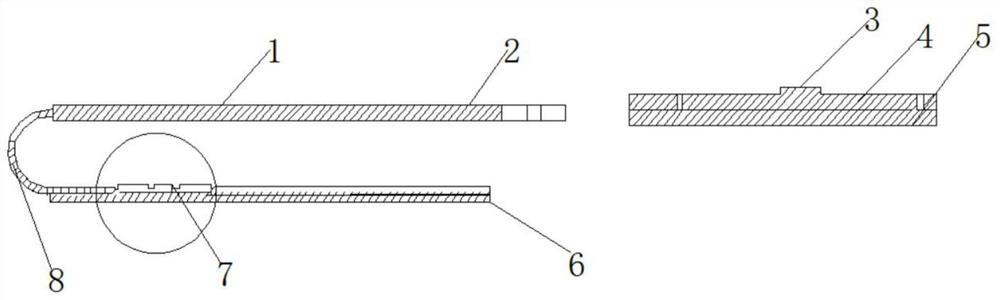

Crimp connection type IGBT internal package structure

PendingCN109659280AImprove thermal conductivityFirmly connectedSemiconductor/solid-state device detailsSolid-state devicesConnection typeCarbide

The invention provides a crimp connection type IGBT internal package structure encapsulated in a ceramic tube casing. The structure comprises an IGBT / FRD chip and silicon carbide aluminum layers. Thesilicon carbide aluminum layers are located on the upper and lower sides of the IGBT / FRD chip. A soldering layer is arranged between the IGBT / FRD chip and each of the silicon carbide aluminum layers,and the upper and lower surfaces of the IGBT / FRD chip are provided with metal layers. The invention provides a silicon carbide aluminum-soldering layer-IGBT / FRD chip-welding layer-silicon carbide aluminum internal structure of a ceramic shell packaged crimp connection type IGBT, so the packaging process operation of the ceramic shell packaged crimp connection type IGBT is greatly simplified; double-sided heat dissipation of the crimp connection type IGBT is ensured; and requirement of high current flow and high reliability are met.

Owner:XIAN YONGDIAN ELECTRIC

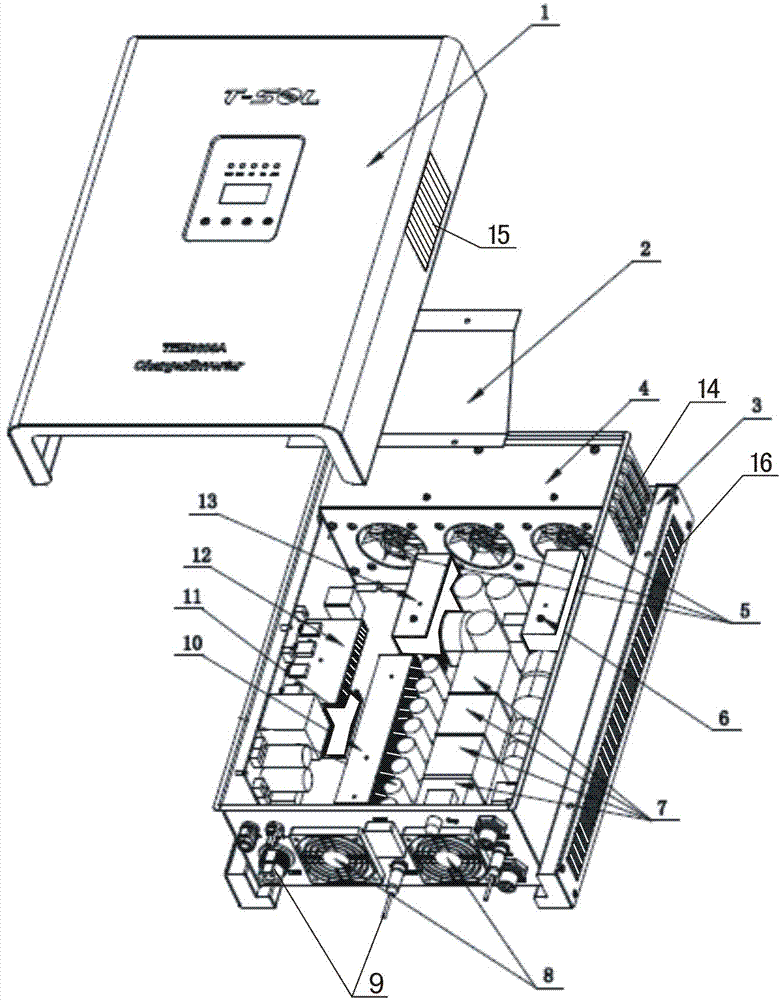

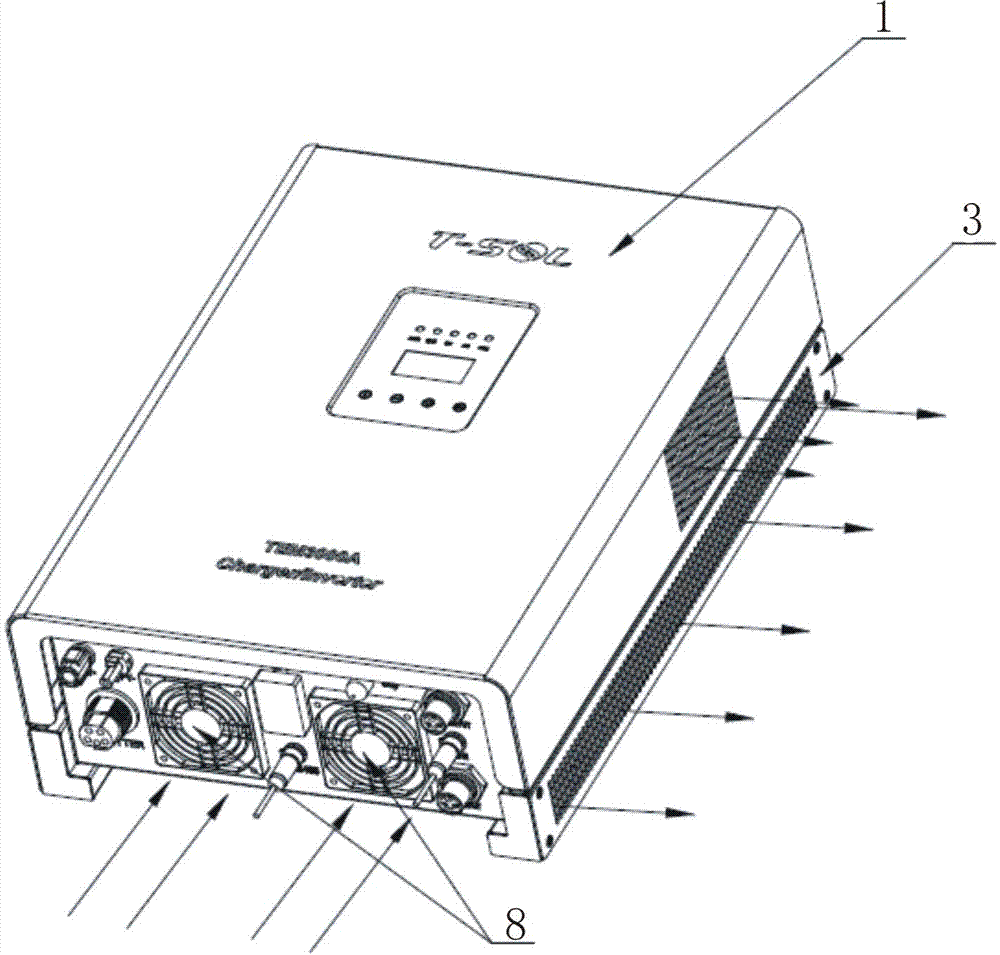

High-efficiency heat dissipation wall-mounted inverting control all-in-one machine

InactiveCN103687456ASave spaceImprove internal ambient temperatureCooling/ventilation/heating modificationsAir volumeTransformer

The invention discloses a high-efficiency heat dissipation wall-mounted inverting control all-in-one machine which comprises a waterproof case and a boosting radiator, a boosting transformer, an inverting radiator, a power supply radiator, a power supply boosting radiator and a rectification radiator which are arranged in the case. One end of the waterproof case is provided with two air inlet fans and a wiring terminal and the other end of the waterproof case is transversely provided with a buffer air duct; both ends of the buffer air duct are provided with air outlets; the side wall of the buffer air duct is provided with three induced draft fans; and the position in the waterproof case and close to the buffer air duct is provided with an air deflector. Due to adoption of the structural form, the problem of the requirements on a high protection grade and high heat exchange is solved. The machine adopts and uses the small-scale radiators, is low in cost, has a small complete machine space and can further meet the requirement on heat dissipation performance; integral waterproofness of the case is adopted; and meanwhile, air inlets and the air outlets are requested to have large air volumes, so that the high-efficiency heat dissipation wall-mounted inverting control all-in-one machine can meet the requirements of the radiators and other heat emitting devices inside on heat dissipation.

Owner:HUIZHOU TEN SOURCES SOLAR ELECTRICITY

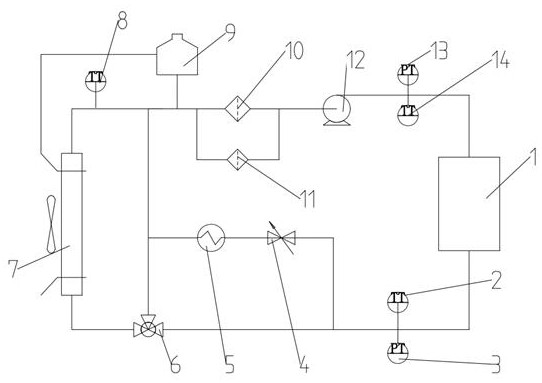

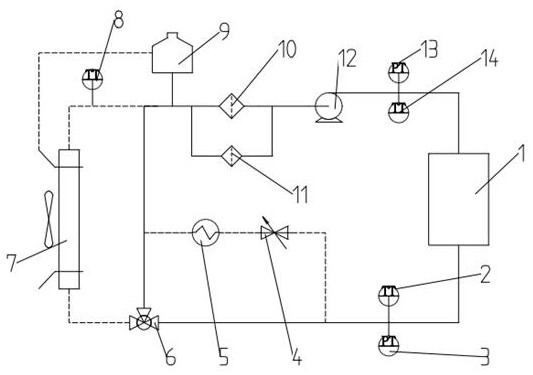

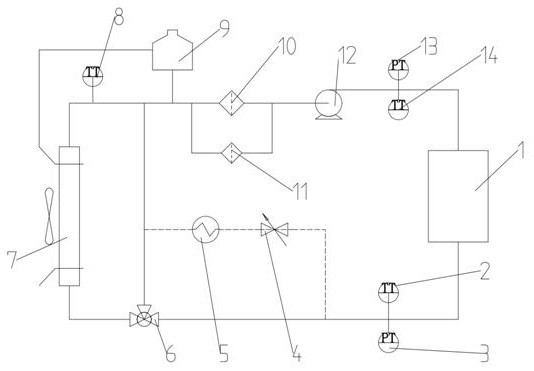

Vehicle fuel cell thermal management system and control method thereof

ActiveCN113130936ASatisfy heat dissipationMeet needsBattery/fuel cell control arrangementMotive system fuel cellsThermodynamicsFuel cells

The invention discloses a vehicle fuel cell thermal management system. The system comprises a fuel cell stack; a first temperature sensor and a second pressure sensor are installed on a water outflow pipeline of the fuel cell stack; an electric control three-way valve is installed on an end opening of the water outflow pipeline of the fuel cell stack; a first water pipe is installed at one connector of the electric control three-way valve; a water filter is installed at one end of the first water pipe; a water pump is installed at one end of the water filter through a drainage pipe; and a water inflow pipe connected with the fuel cell stack is installed on the water pump. The vehicle fuel cell heat management system and the control method thereof can meet high-temperature heat dissipation and low-temperature heating starting requirements of the fuel cell stack; a strategy can be controlled, the water pump and the electric control three-way valve are adjusted, so that the flow is effectively and reasonably distributed;a heat dissipater and a heater can be adjusted, so that system temperature is always in a reasonable temperature range.

Owner:大连擎研科技有限公司

Preparation process for radiator good in sealing performance

The invention discloses a preparation process for a radiator good in sealing performance. The preparation process comprises the steps of preparing die casting aluminum alloy and an insert. A first annular groove is formed in the horizontal contact surface of the insert and the die casting aluminum alloy. A second annular groove is formed in the vertical contact surface of the insert and the die casting aluminum alloy. A first annular protrusion is arranged in the position, matched with the first annular groove, of the die casting aluminum alloy. A second annular protrusion is arranged in the position, matched with the second annular groove, of the die casting aluminum alloy. Preparation of the die casting aluminum alloy and the insert comprises the following steps of raw material smelting, die casting, machining, cleaning and packing, and cleaning and packing are conducted after machining is completed and the die casting aluminum alloy and the insert are qualified after being subjected to leakage testing. According to the preparation process for the radiator good in sealing performance, leakage testing is conducted under the condition of 0.2 MPa air pressure, and leakage is avoided, so that the leakage problem of a part inlaid with the insert in the aluminum alloy die casting industry is solved; the requirements for the sealing performance, the heat dissipation performance, the mechanical strength and other performances in the using process of the radiator can be met, the maintenance cost is reduced, the production efficiency is high, and the market competitiveness is very high.

Owner:NINGBO XUSHENG AUTO TECH CO LTD

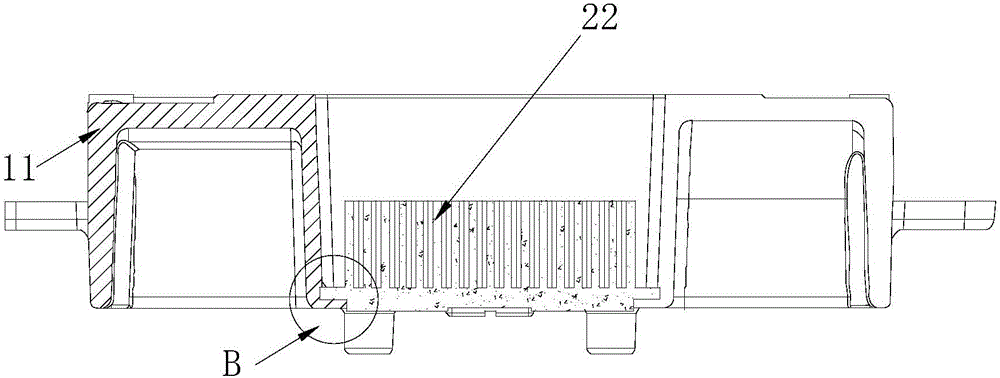

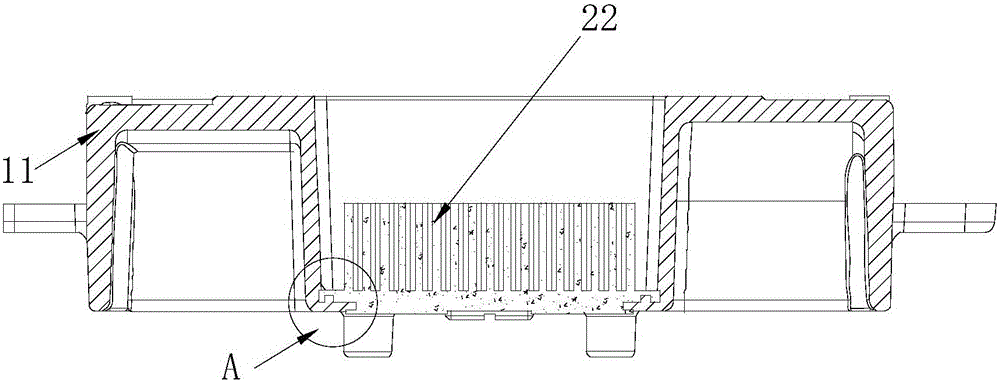

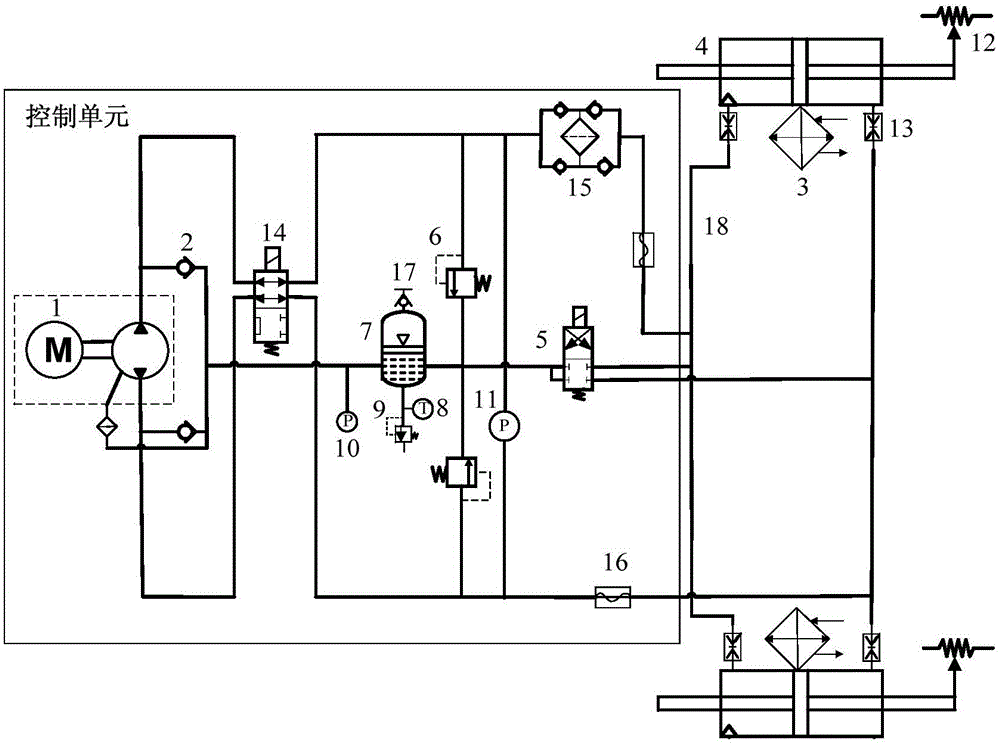

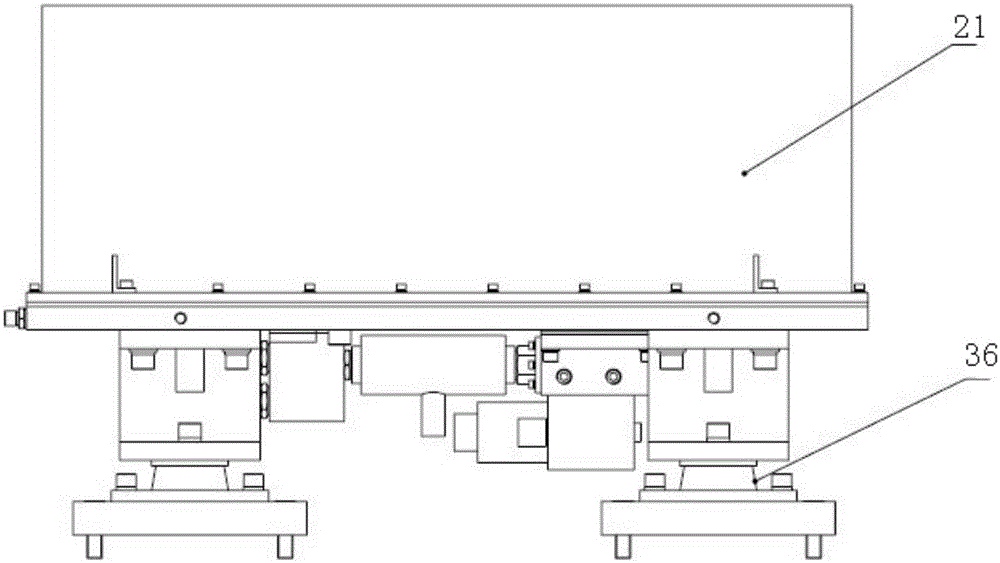

Low-vibration low-noise electromechanical static pressure servo mechanism

ActiveCN105156410ACompact structureEasy to disassembleServomotor componentsFluid-pressure actuator componentsLow noiseIsolation valve

The invention relates to a low-vibration low-noise electromechanical static pressure servo mechanism which comprises a control unit assembly and actuator assemblies, wherein two one-to-two oil ducts of the control unit assembly are respectively connected with two oil ducts of the two actuator assemblies through a hydraulic hose and a self-sealing connector; each actuator assembly comprises two actuators and two displacement sensors, and one displacement sensor is arranged in each actuator; the control unit assembly comprises a servomotor pump, a one-way valve, an isolating valve, a low-pressure pressure sensor, a pressure transducer, a self-pressurization oil tank, a differential pressure transducer, two high-pressure oil ducts and a low-pressure oil duct; and the assemblies are connected into the high-pressure oil duct or low-pressure oil duct. The servo mechanism has the advantages of compact structure, high reliability and favorable sound insulation and sound absorption effects, is convenient for demounting and interchange, and obviously lowers the vibration and noise.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

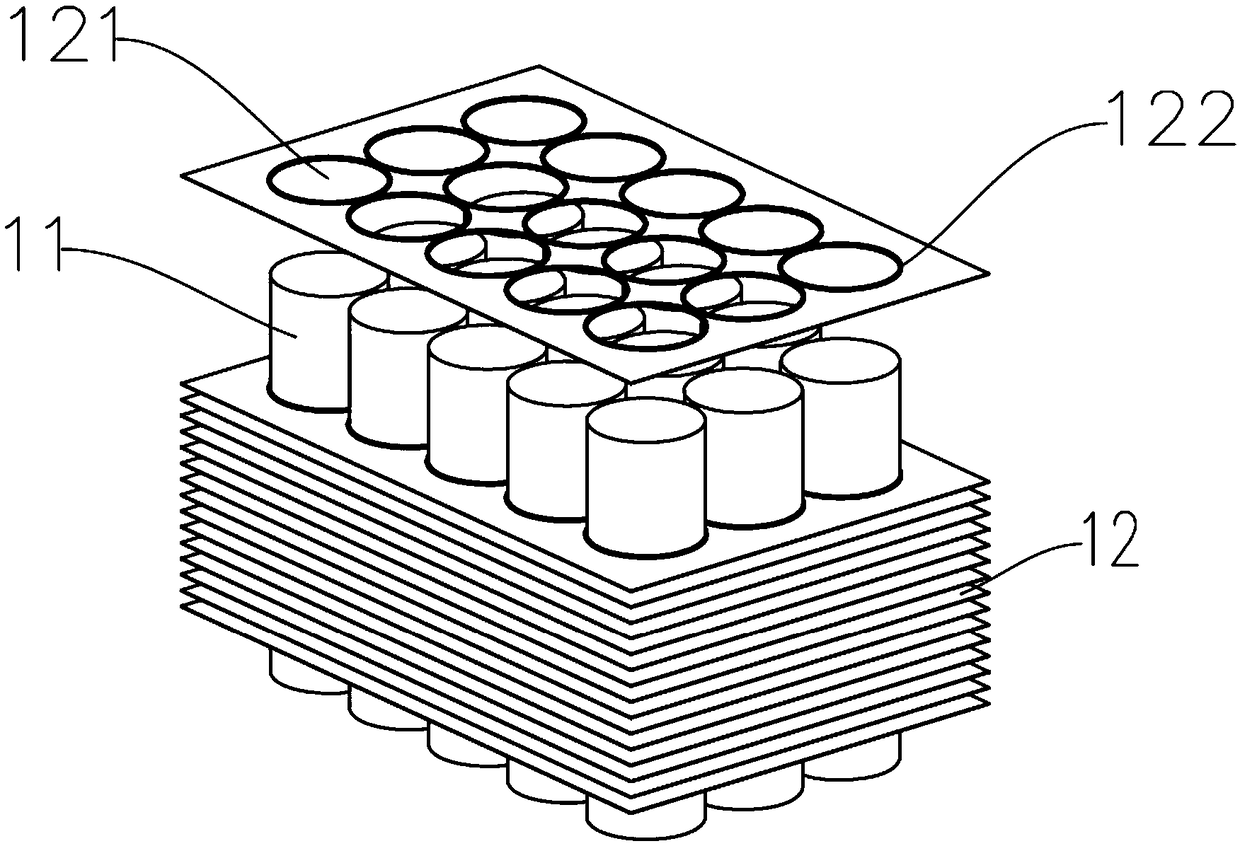

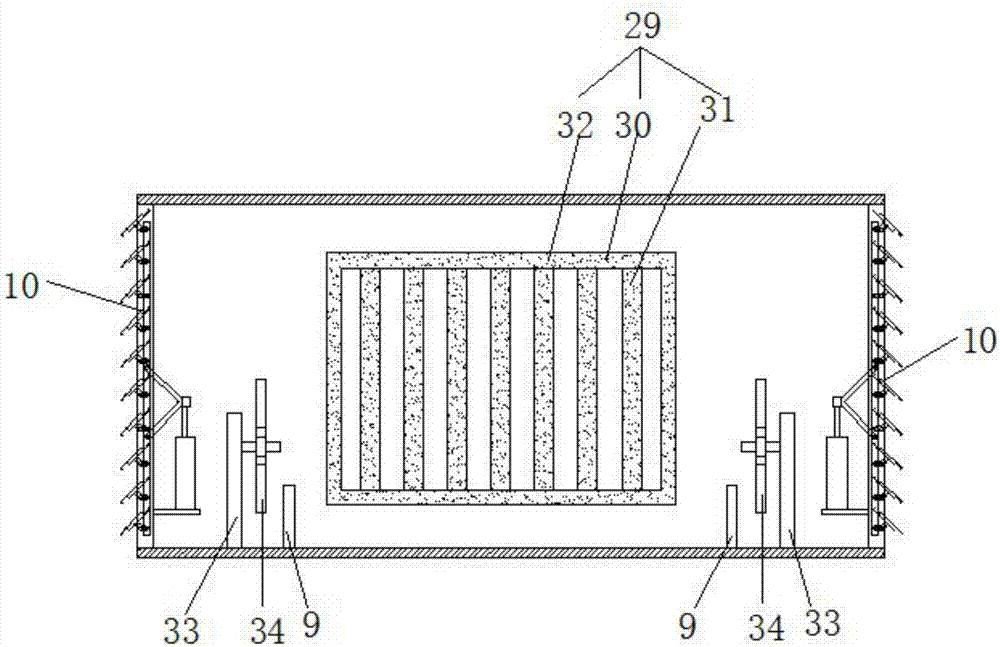

Fin perforation type cylindrical battery pack, battery pack assembly and battery pack array

PendingCN109004302AImprove performanceExtend your lifeSecondary cells servicing/maintenanceTemperature controlState of art

The invention relates to the technical field of battery thermal management, in particular to a fin perforation type cylindrical battery pack, includomg a plurality of cylindrical cells and a fin group, The fin group is composed of a plurality of fins arranged in parallel, and the fin is provided with a plurality of assembly holes matched with the shape and size of the plurality of cylindrical cells, the edges of the assembly holes extend outward to form flanged edges with a certain height, and the plurality of cylindrical cells vertically penetrate the assembly holes on the fins and are matched with the flanged edges. The invention can solve the problems that the temperature field distribution of the cylindrical battery pack in the prior art is uneven and the part of the non-specific areais overheated, and can meet the requirements of good temperature uniformity, temperature control performance and low cost, light weight and manufacturability.

Owner:马海云

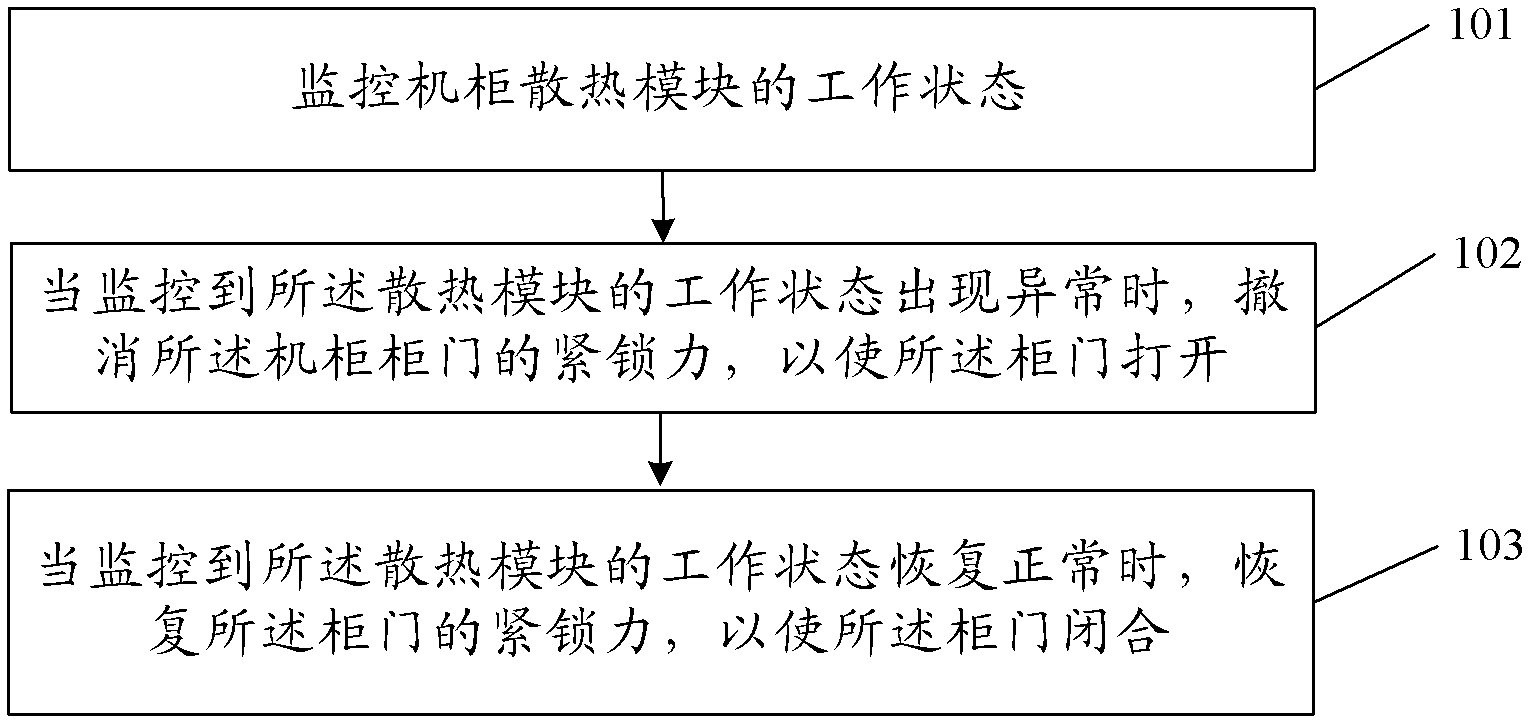

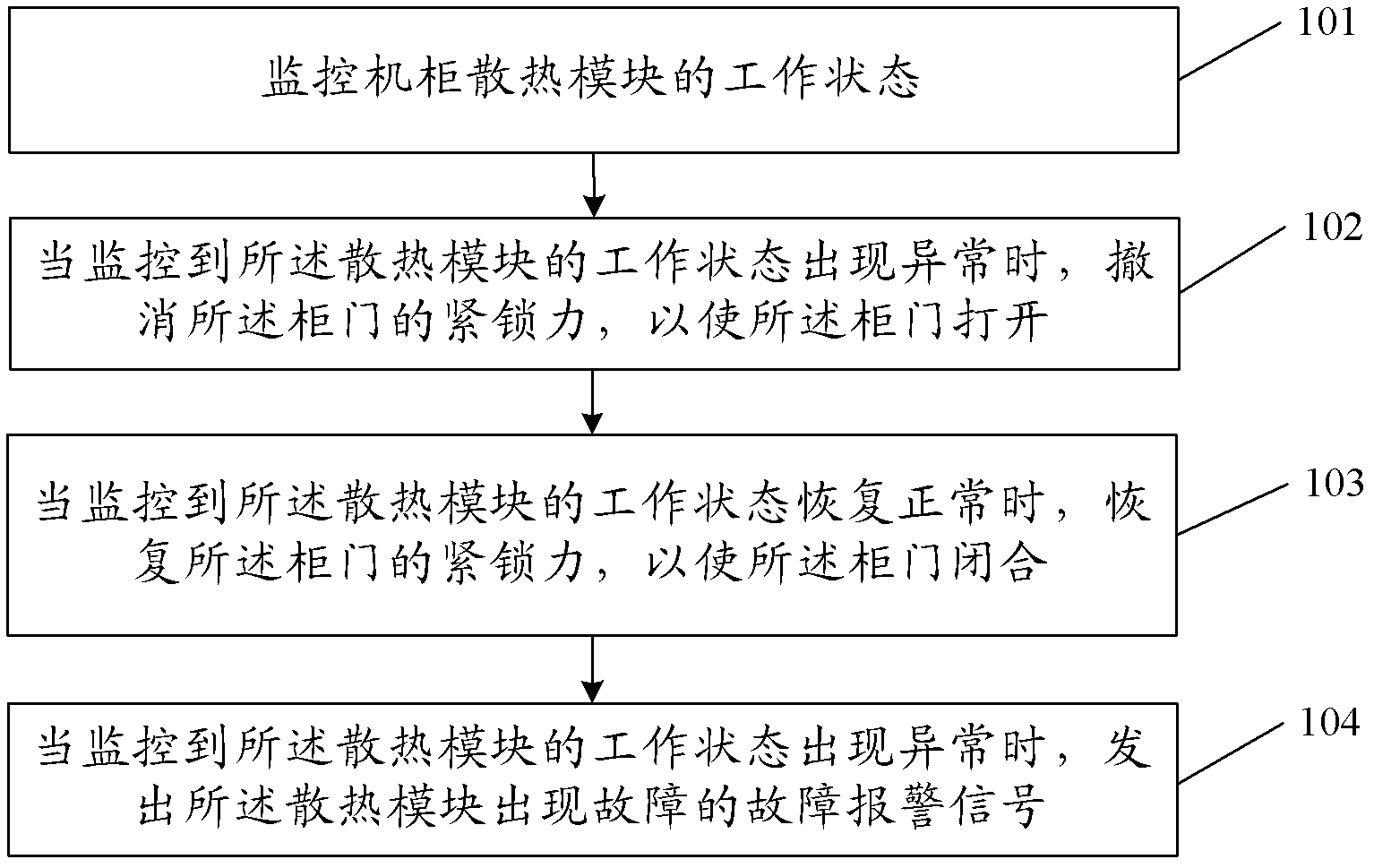

Control method for machine cabinet and communication device

InactiveCN102548363ASatisfy heat dissipationMeet needsCooling/ventilation/heating modificationsComputer moduleWorking environment

The invention discloses a control method for a machine cabinet. The control method for the machine cabinet comprises the following steps of: monitoring the working state of a radiating module of the machine cabinet, wherein the radiating module is arranged inside the machine cabinet and is used for radiating the machine cabinet; and when the working state of the radiating module is abnormal, removing a locking force of a cabinet door of the machine cabinet so as to open the cabinet door. Correspondingly, the invention also discloses a communication device and communication equipment. Through the technical scheme, according to radiating and denoising requirements of a working environment on the machine cabinet, the working state of the machine cabinet is automatically regulated to meet different radiating and denoising requirements on the machine cabinet under different running condition of the machine cabinet or in different working environments so as to fulfill an energy-saving aim.

Owner:HUAWEI TECH CO LTD

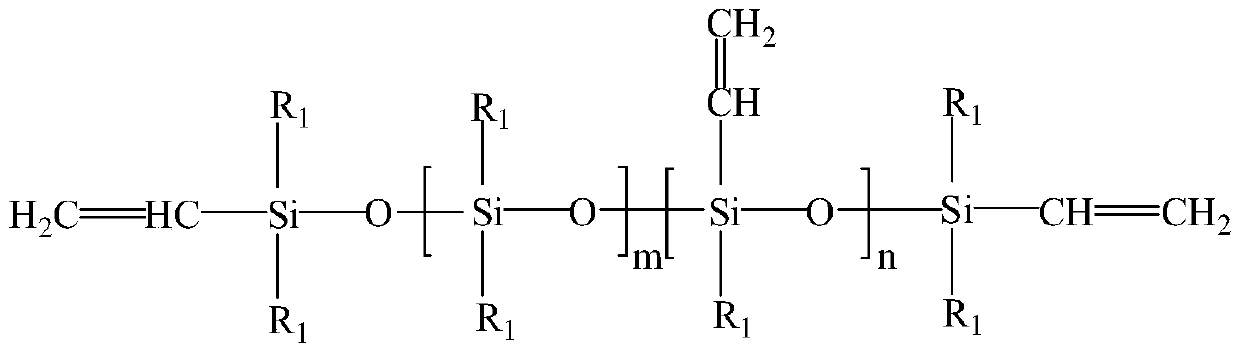

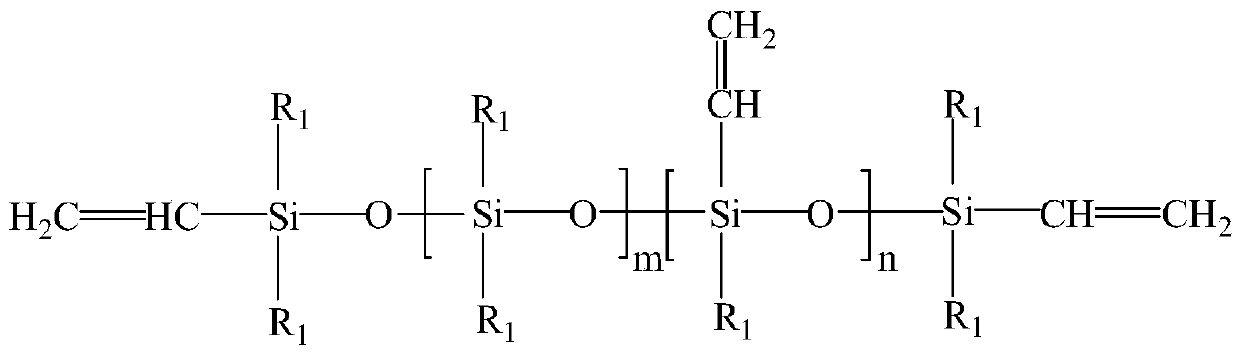

Organic silicon pouring sealant, preparation method and novel electric drive motor

ActiveCN111394055ASuppression temperatureSuppressing too high a problemNon-macromolecular adhesive additivesMacromolecular adhesive additivesPtru catalystPhysical chemistry

The invention discloses an organic silicon pouring sealant. The organic silicon pouring sealant is formed by adding two components and is obtained by mixing a component A and a component B according to the mass ratio of 1: 1, and the component A is prepared from the following components in parts by mass: 100 parts of vinyl polysiloxane, 470-530 parts of heat-conducting filler, 1.5 parts of a coupling agent, 0.5 part of a dispersing agent and 0.2-1.5 parts of catalyst; and the component B is prepared from the following components in parts by weight: 100 parts of vinyl polysiloxane, 2-23 parts of hydrogen-containing polysiloxane, 430-480 parts of filler and 0.1-1 part of an inhibitor. The organic silicon pouring sealant provided by the invention has the beneficial effects of good heat resistance and high heat conductivity coefficient, solves the problem that the temperature rises too fast and too high when an electric drive motor runs, and improves the reliability of the electric drive motor.

Owner:镇江利德尔复合材料有限公司

Battery pack with high heat dissipation performance

ActiveCN107240735ASatisfy tightnessSatisfy heat dissipationProtecting/adjusting hybrid/EDL capacitorCell temperature controlProgrammable logic controllerEngineering

The invention provides a battery pack with high heat dissipation performance. A temperature sensor is used for transmitting an internal temperature signal to a programmable logic controller (PLC), a fan is controlled to work by the PCL according to a temperature in the battery pack, and heat of a battery module is taken away by wind; by a ventilation device, the sealing performance and the heat dissipation performance of the battery pack are simultaneously satisfied, and the working of the ventilation device is controlled by a travel switch and the PLC to achieve automation; by arranging a liquid-cooling device, the rapidness of heat dissipation is ensured, the temperature consistency of the battery module in the battery pack is ensured as well as the heat is dissipated; and by dual cooling of the liquid-cooling device and the ventilation device, the battery module can be enabled to obtain a good ventilation and cooling effect.

Owner:SYST ELECTRONICS TECH ZHENJIANG CO LTD

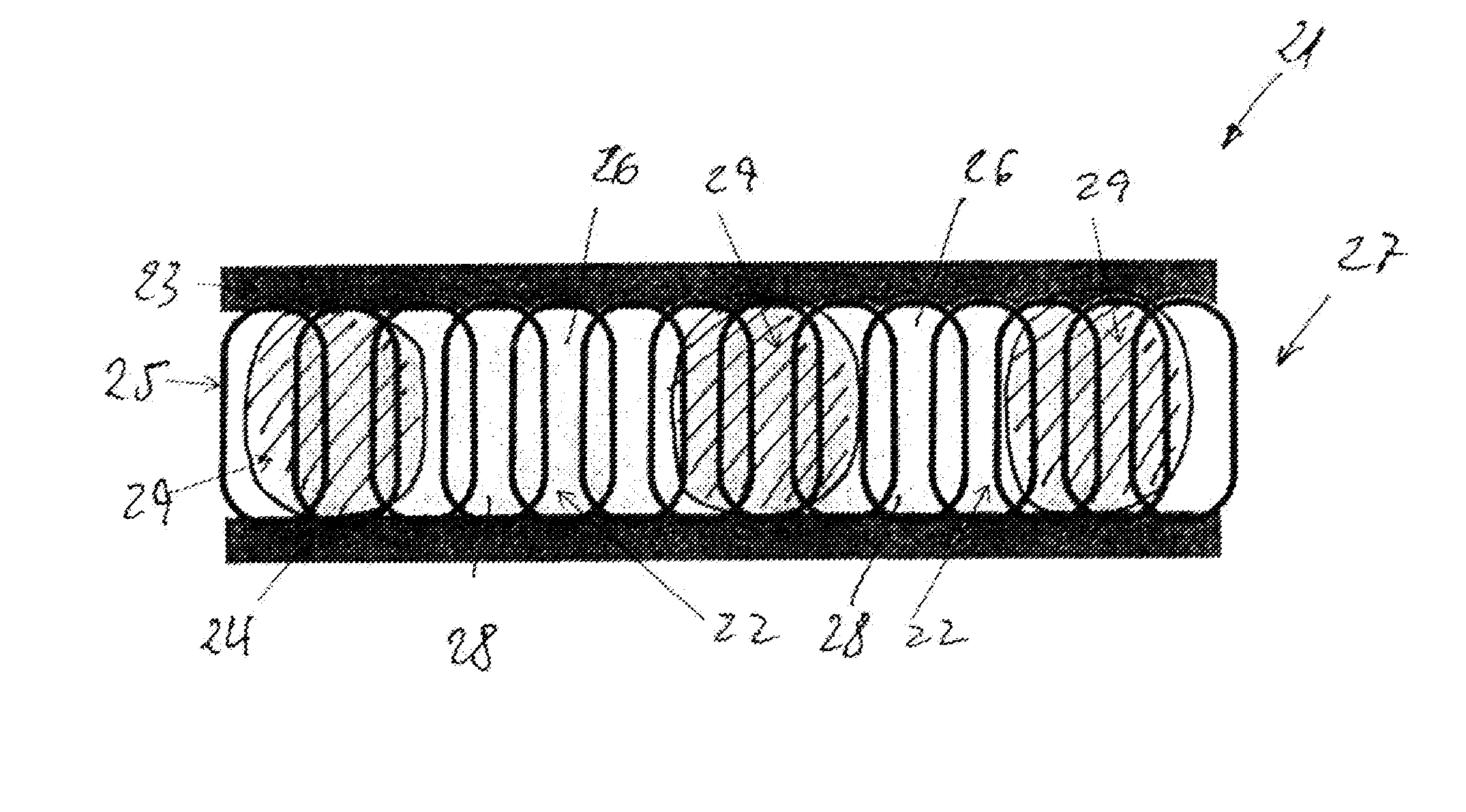

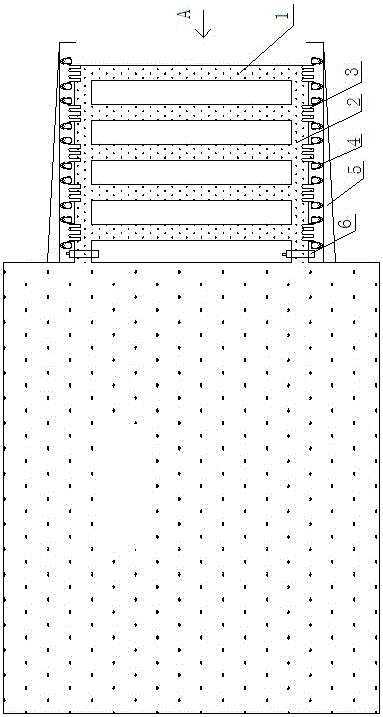

Apparatus for conducting a fluid

InactiveUS20140090824A1Satisfy heat dissipationEasy to produceSecondary cellsIndirect heat exchangersEngineeringElectronic component

The invention relates to an apparatus for conducting a fluid, in particular a cooling fluid for cooling components to be cooled, in particular for cooling electronics components and / or battery cells and / or battery modules, having a first covering plate and a second covering plate and having a structural mesh between the two covering plates for defining a spatial region, through which flow can pass, a division being provided by reshaping of the structural mesh and / or by introduction of a sealant for at least partially sealing the spatial region with respect to an outer space and / or for dividing the spatial region into definable flow channels.

Owner:MAHLE INT GMBH

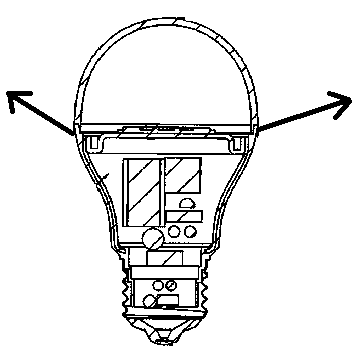

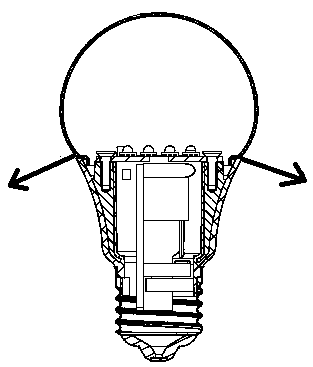

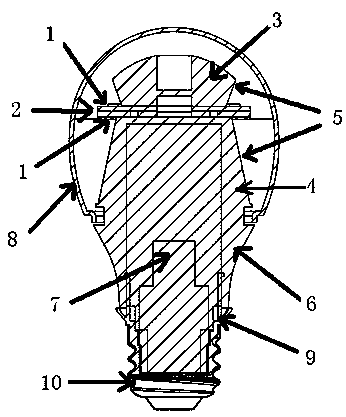

High-power and large-angle light distribution LED (Light Emitting Diode) bulb

InactiveCN103363360AIncrease cooling areaIncrease the light output anglePoint-like light sourceLighting heating/cooling arrangementsEngineeringLuminous flux

The invention relates to a high-power and large-angle light distribution LED (Light Emitting Diode) bulb, which comprises LED lamp beads, an LED lamp panel, an upper radiator and a lamp body radiator. The upper radiator and the lamp body radiator are respectively installed in the middles of the upper surface and the lower surface of the LED lamp panel. The circumferential surface of the upper radiator is inwards contracted from the top to the bottom to form an inverted-cone-shaped reflecting surface. The circumferential surface of the lamp body radiator is inwards contracted from the bottom to the top to form a cone-shaped reflecting surface. The LED lamp beads are arranged on the outer edges of the upper surface and the lower surface of the LED lamp panel and are close to the reflecting surfaces of the upper radiator and the lamp body radiator. The high-power and large-angle light distribution LED bulb has the advantages that since a unique LED lamp panel installation method is adopted, the heat dissipating area is increased; since the radiators are used as reflectors, the high-power heat dissipation and light distribution requirements are satisfied; since the scale dimension of the bulb is large, the light output angle is increased; and at the same time, the requirements on luminous flux and light distribution are satisfied and the industrial standards are met.

Owner:SHANGHAI DANGOO ELECTRONICS TARDING

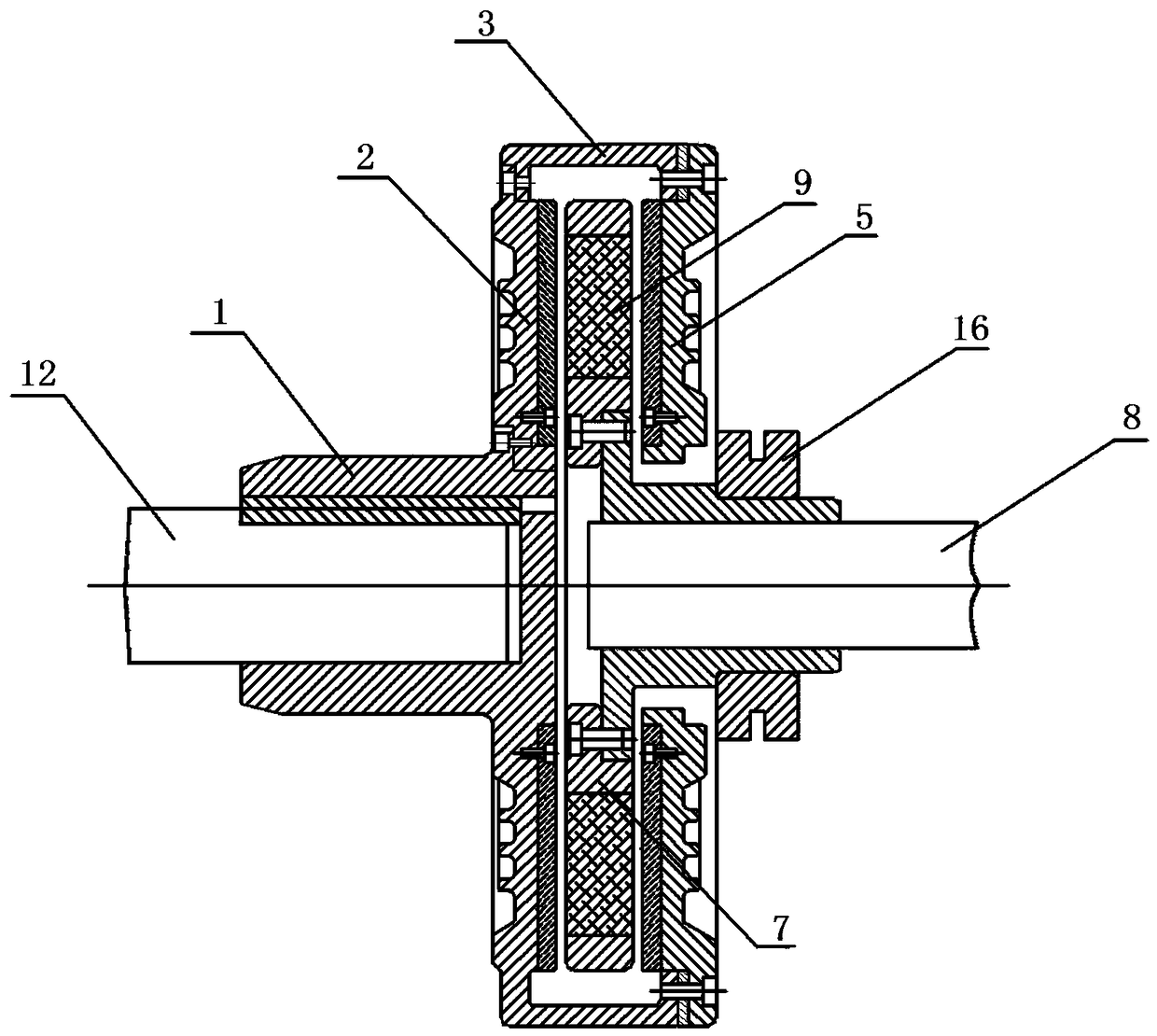

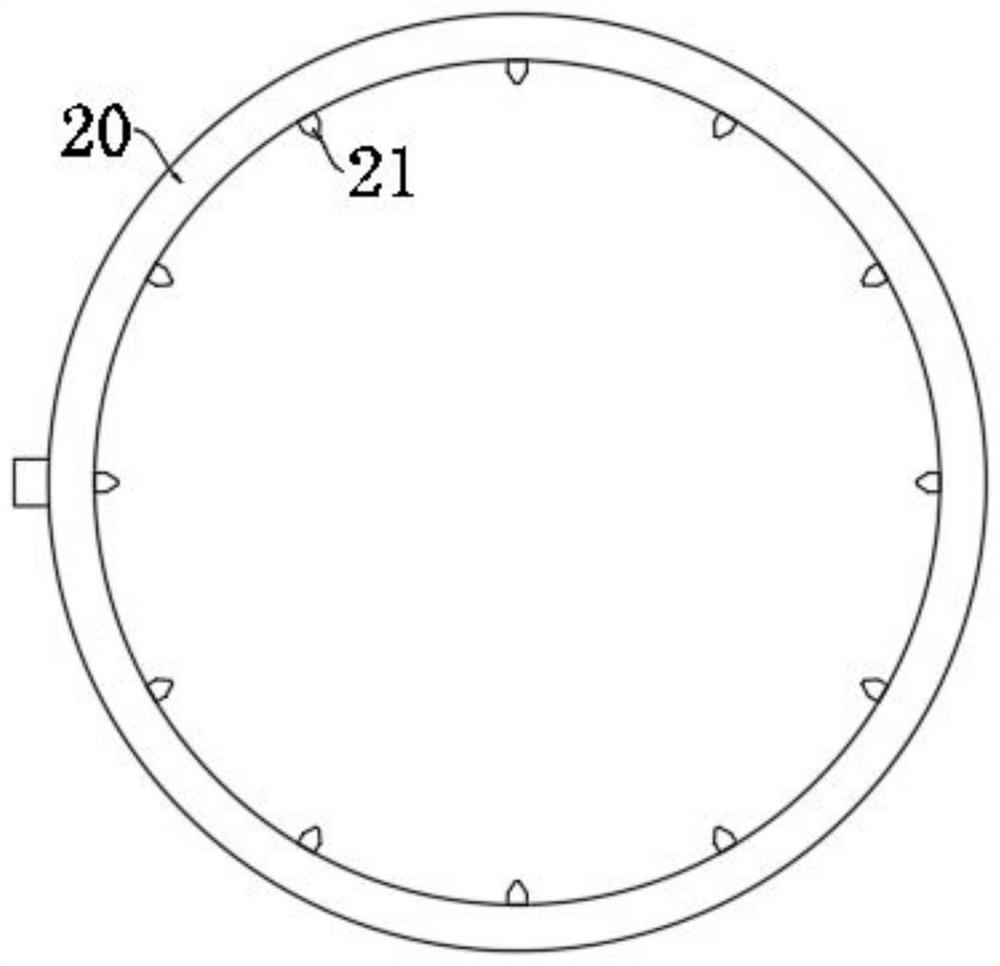

Explosion-proof low-noise permanent magnet coupler

PendingCN108631544AEnsure production safetyImprove explosion-proof performanceAsynchronous induction clutches/brakesPermanent-magnet clutches/brakesLow noiseElectrical conductor

The invention relates to the technical field of permanent magnetic eddy current transmission and especially relates to an explosion-proof low-noise permanent magnet coupler. The explosion-proof low-noise permanent magnet coupler is characterized in that the explosion-proof low-noise permanent magnet coupler comprises an active hub, which is an integrated structure formed by a shaft sleeve body, asteel disc body and an external circular sleeve body, wherein the inner side of the steel plate body is connected with a conductor disc 1; after the external circular sleeve body is connected with a load-end steel disc, a semi-closed space, opened to the axis direction, is formed between the steel disc body and the load-end steel disc; and the inner side of the load-end steel disc is connected with a conductor disc 2. The explosion-proof low-noise permanent magnet coupler also comprises a load hub, which comprises a flange and a sleeve. After the active hub and the load hub are combined, a magnetic rotor disc is arranged in the semi-closed space. The outer sides of the steel disc body and the load-end steel disc are respectively provided with a mute ring belt. The cross section of the mutering belt is shaped like an arc or a trapezoid, the inner side of which is narrow and the outer side of which is wide. The shaft sleeve body, the steel disc body and the external circular sleeve bodycan be in a combined connection structure; and compared with the prior art, the explosion-proof low-noise permanent magnet coupler has the advantages of 1) good explosion-proof performance; 2) good heat radiation and noise reduction effect; and 3) matching various specifications and types of water pumps and fan loads.

Owner:MAGNA MAGNETOMOTIVE CO LTD

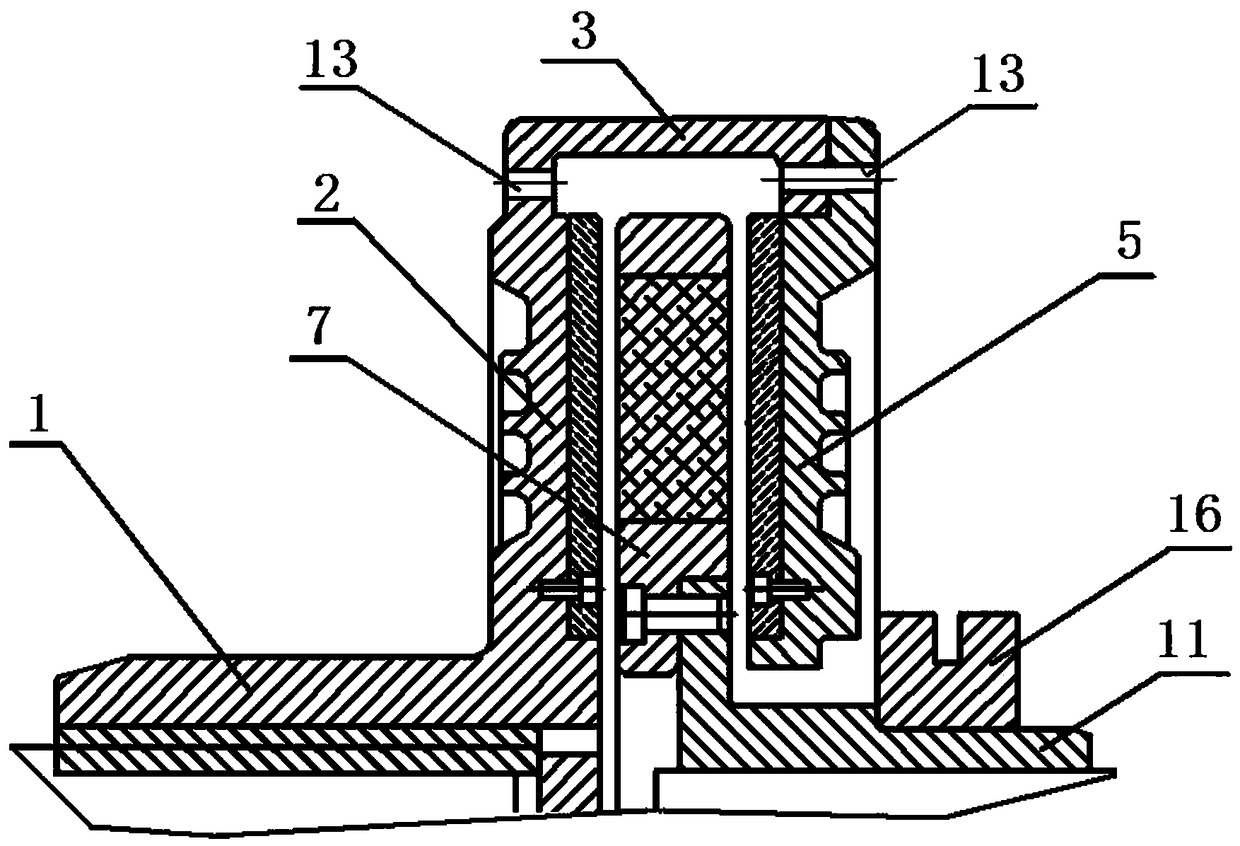

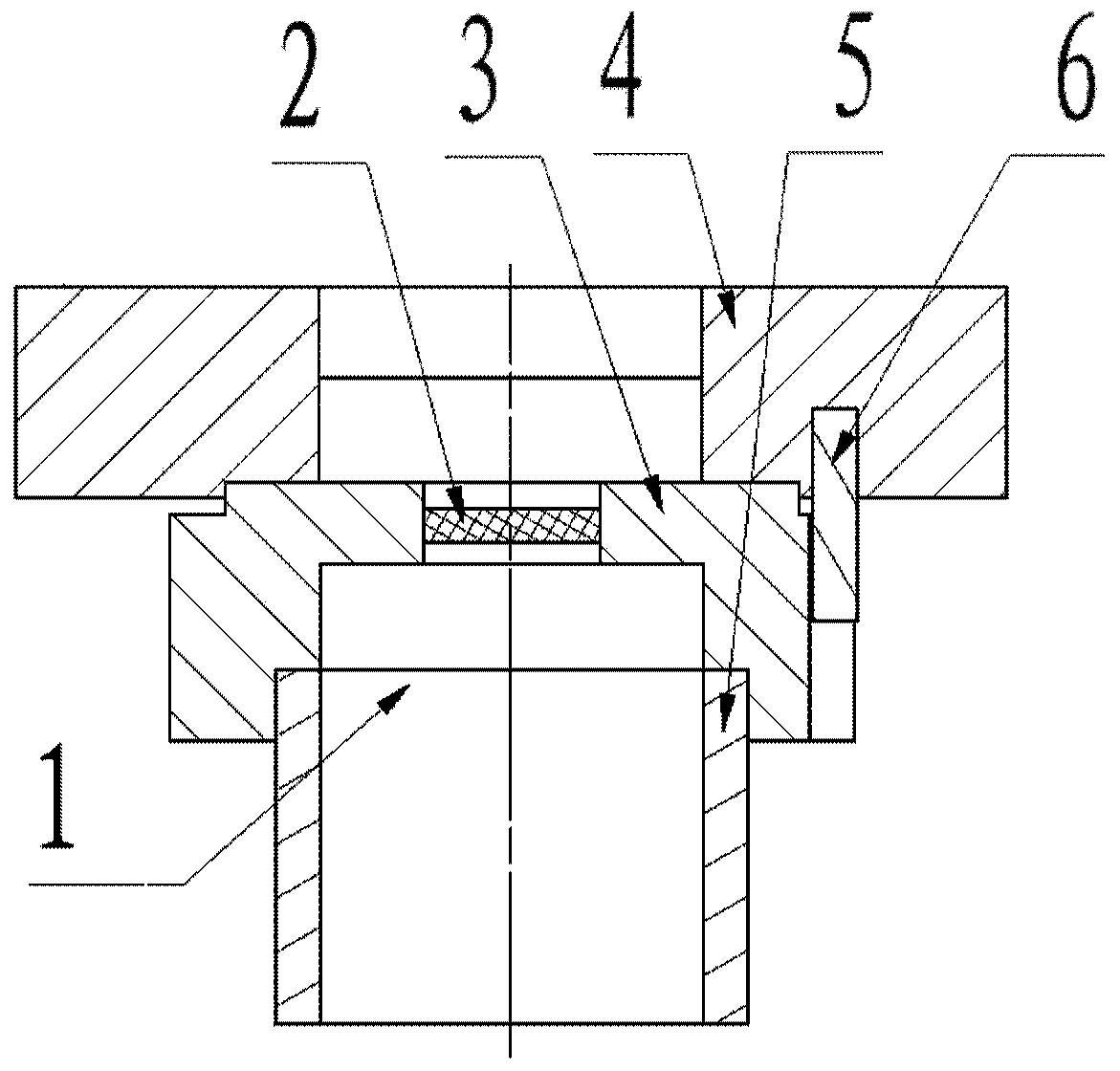

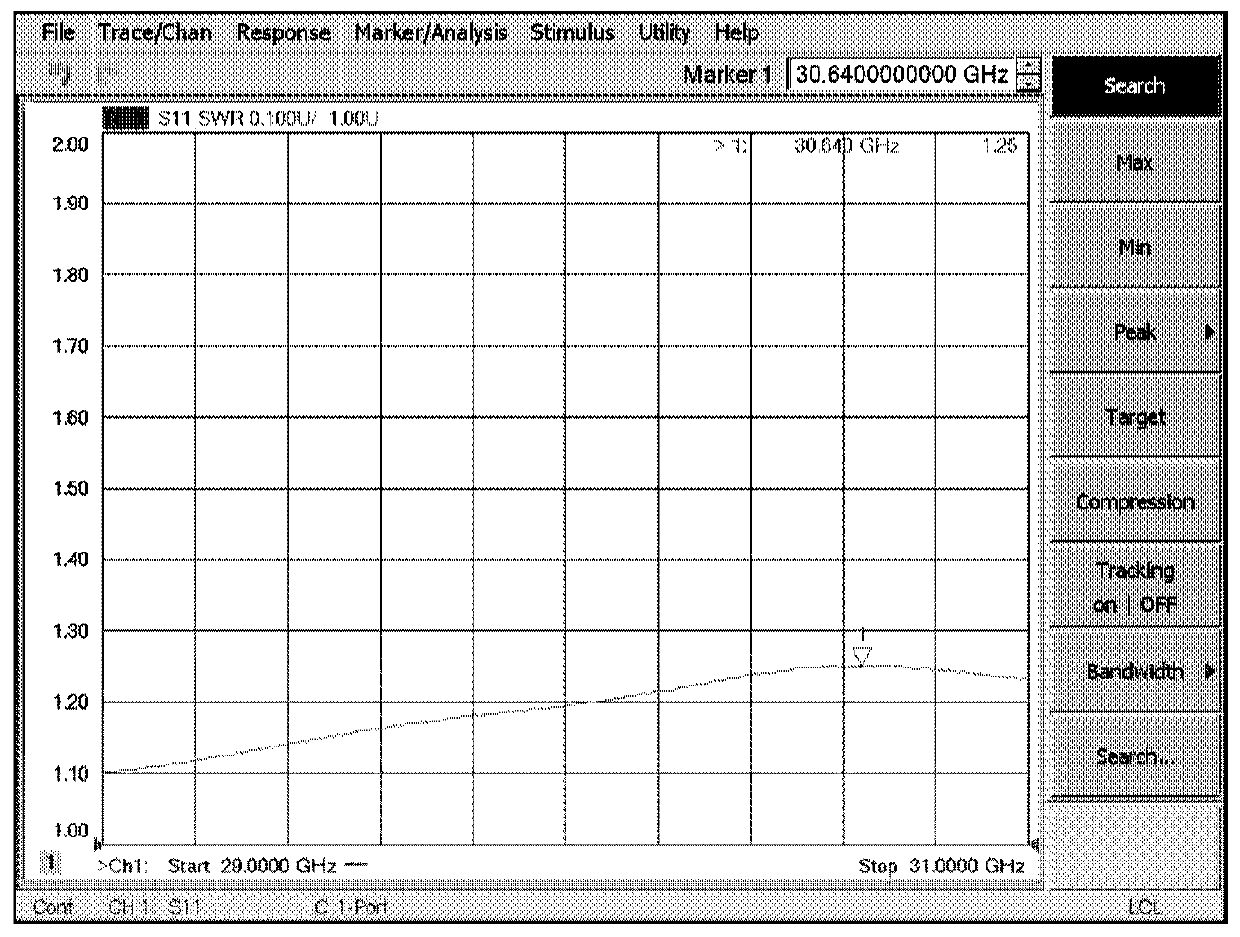

Output waveguide window for Ka-waveband high-power space traveling-wave tube

ActiveCN111524769ASimple structureImprove cooling effectTransit-tube vessels/containersTransit-tube cooling methodsWave tubeMechanical engineering

The invention provides an output waveguide window for a Ka-waveband high-power space traveling wave tube. The window comprises a window piece, a sealing piece, a waveguide flange and a transition waveguide, and is characterized in that the sealing piece sleeves the outer side of the window piece and is connected with the circumference of the window piece in a sealing manner; the waveguide flange is connected with the upper side of the sealing piece; the transition waveguide sleeves the lower side of the sealing piece and is hermetically connected with the sealing piece; and a vacuum cavity isformed in the sealing piece, the waveguide flange and the transition waveguide. The structure is simple, the reliability is high, and the requirements of small standing wave, temperature impact resistance, mechanical vibration resistance and good heat dissipation performance of the traveling wave tube are met.

Owner:AEROSPACE INFORMATION RES INST CAS

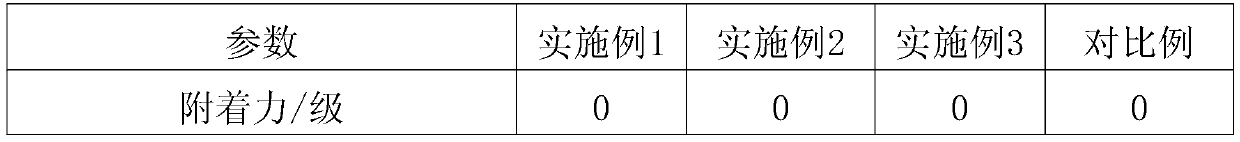

Graphene heat dissipation coating and graphene heat dissipation material for aluminum electrolytic capacitor, and preparation methods thereof

InactiveCN111117443AImprove adhesionImprove insulation performanceLiquid surface applicatorsAnti-corrosive paintsEpoxyCarbide silicon

The invention relates to a graphene heat dissipation coating and graphene heat dissipation material for an aluminum electrolytic capacitor, and preparation methods thereof. The graphene heat dissipation coating for the aluminum electrolytic capacitor disclosed in the invention comprises a bottom-layer graphene heat dissipation coating and a surface-layer graphene heat dissipation coating, whereinthe bottom-layer graphene heat dissipation coating comprises, in percentage by weight, 30 to 65% of polyester resin, 0.5 to 10% of modified graphene oxide powder, 1 to 5% of a coupling agent, 5 to 15%of silicon carbide, 0.5 to 5% of a rheological agent, 0.1 to 2% of a dispersing agent and 10 to 45% of a solvent; and the surface graphene heat dissipation coating comprises, in percentage by weight,30-65% of epoxy resin, 0.5-10% of modified graphene oxide powder, 1-5% of a coupling agent, 5-15% of silicon carbide, 0.5-5% of a rheological agent, 0.1-2% of a dispersing agent and 10-45% of a solvent. According to the graphene heat dissipation coating for the aluminum electrolytic capacitor, a coating scattering material has excellent heat dissipation performance and stable performance, and heat dissipation capacity is greatly improved in a later period that the aluminum electrolytic capacitor is coated with the heat dissipation coating.

Owner:新疆烯金石墨烯科技有限公司

Magnesium alloy and method of manufacturing same

ActiveUS20160348217A1Satisfactory mechanical propertySatisfactory thermal conductivityRare earthMechanical property

A magnesium alloy is provided which does not contain a rare earth and which achieves, in a high-temperature region of about 200° C., both satisfactory mechanical properties and thermal conductivity. A magnesium alloy including Mg, Ca, Al and Si,where a content of Ca is less than 9.0 mass %,a content of Al is equal to or snore than 0.5 mass % but less than 5.7 mass %,a content of Si is equal to or less than 1.3 mass % and Al+8Ca≧20.5%.

Owner:HONDA MOTOR CO LTD

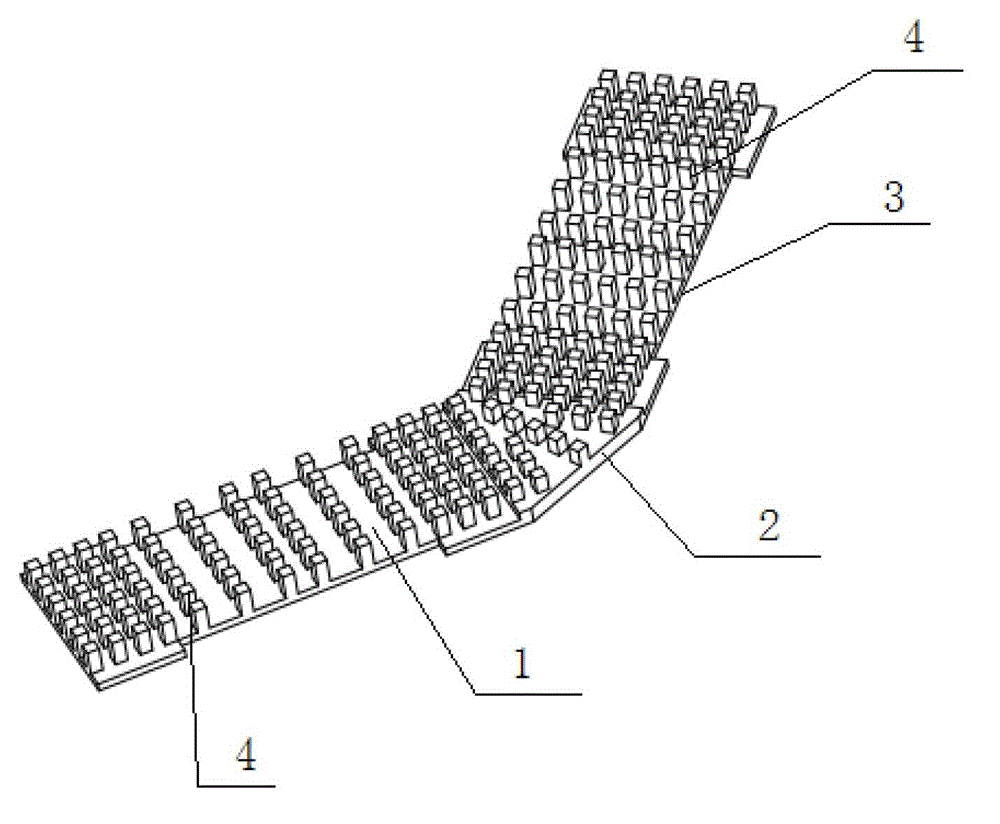

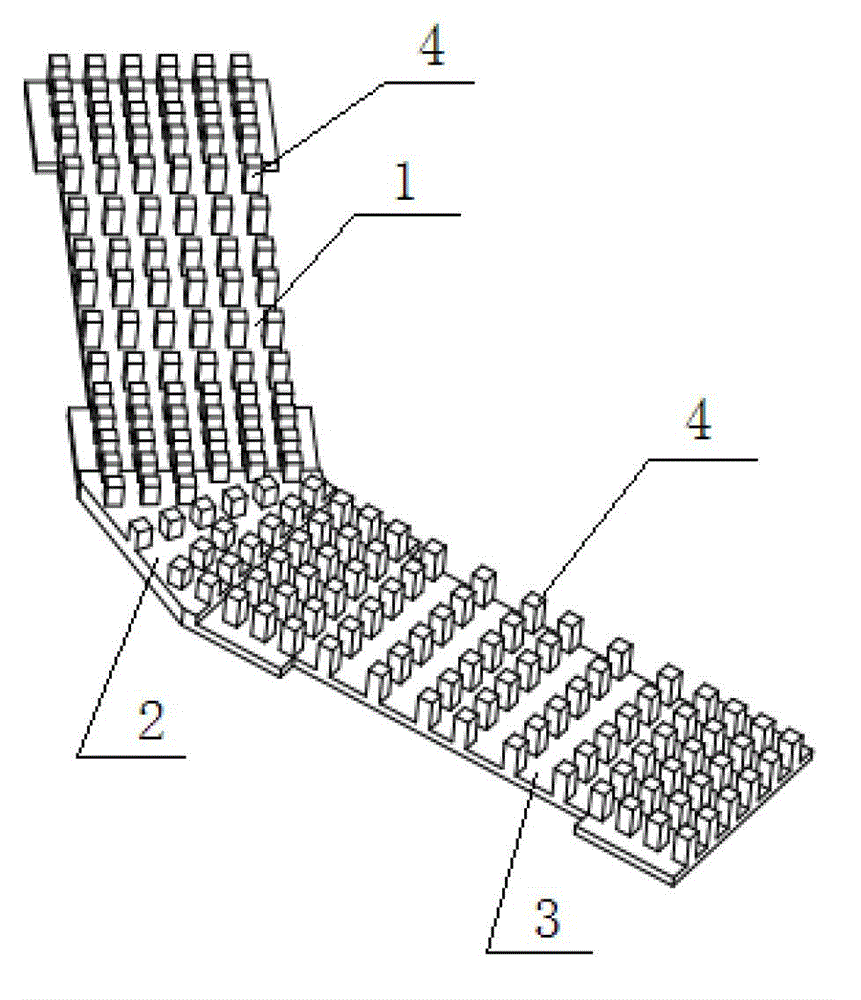

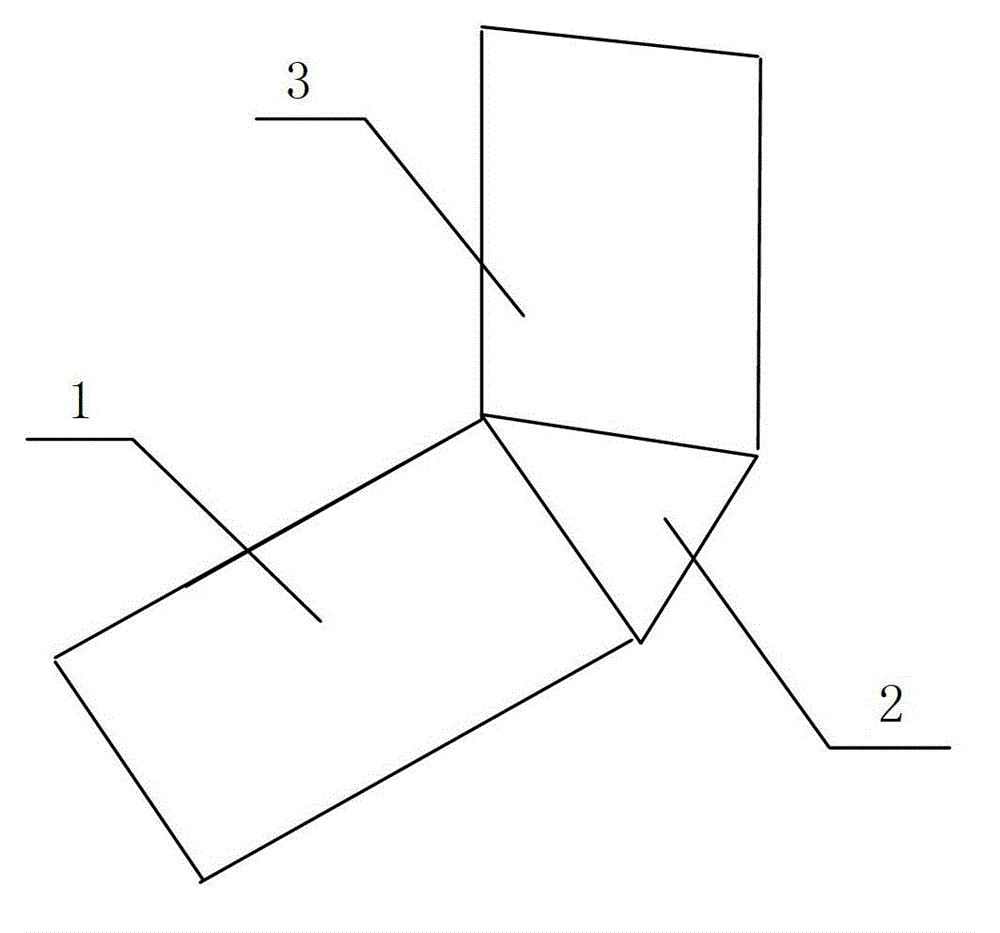

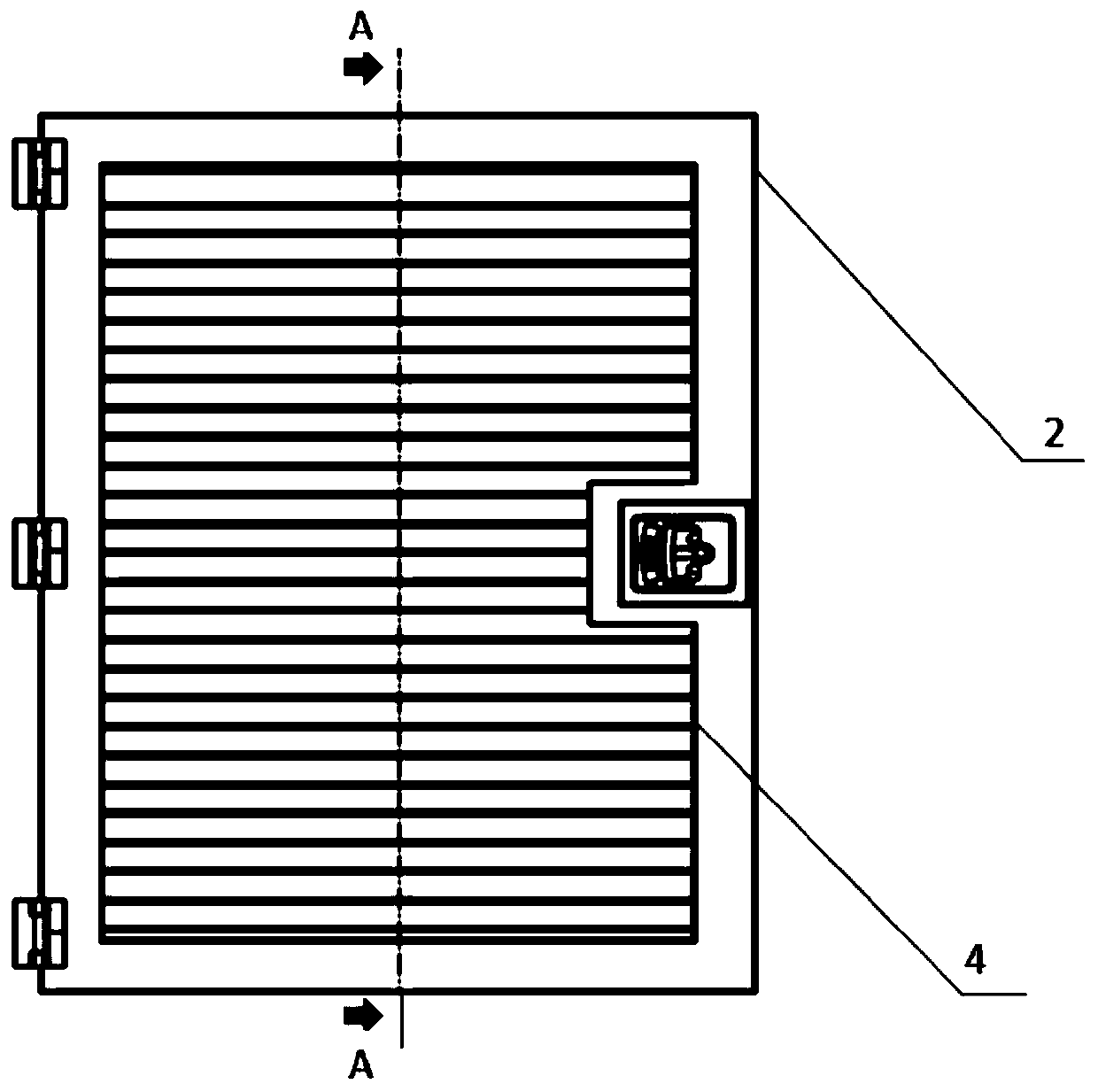

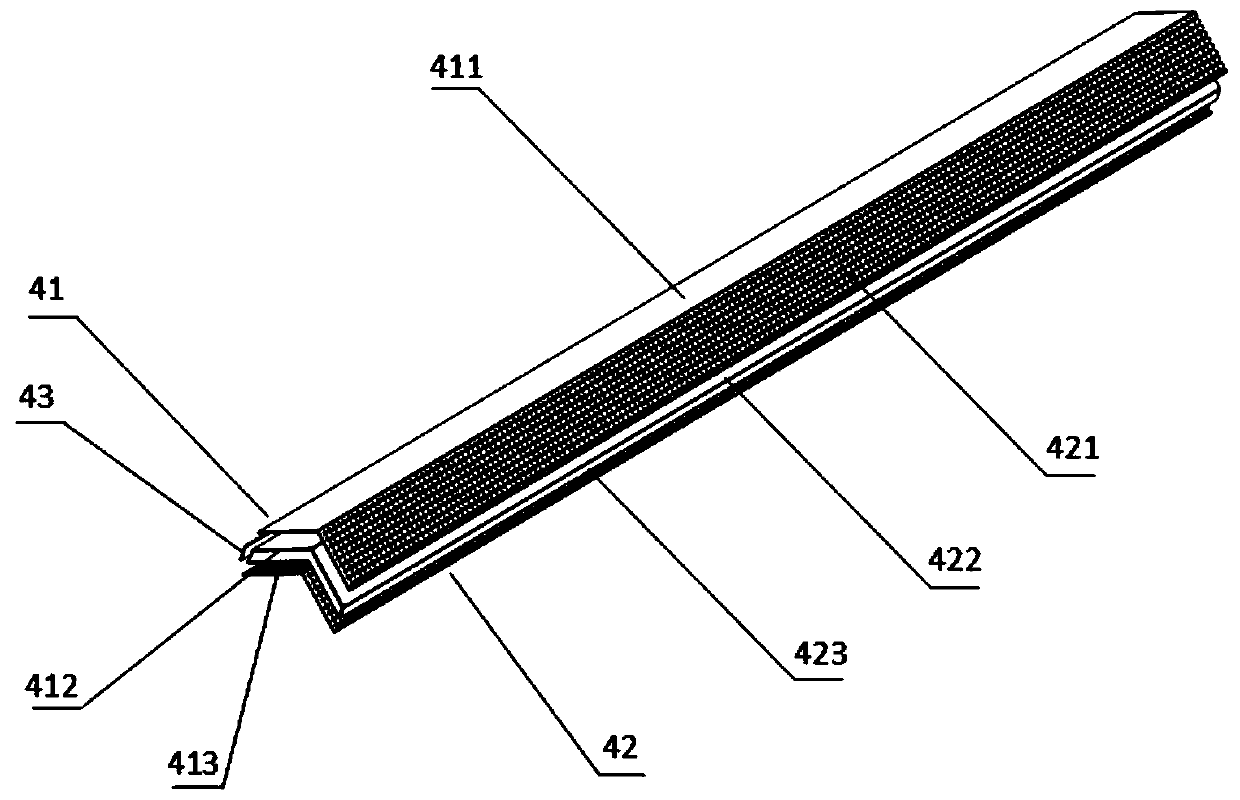

Butterfly radiator and optical module group and optical module group single plate with butterfly radiator

ActiveCN103068208ASatisfy heat dissipationImprove cooling effectFibre transmissionCooling/ventilation/heating modificationsOptical ModuleBiochemical engineering

The invention provides a butterfly radiator and an optical module group and an optical module group single plate with a butterfly radiator, a middle bottom plate is arranged at the tail end of a front bottom plate of the radiator, the other end of the middle bottom plate is connected with a rear bottom plate, a plurality of cooling fins are arranged on the front bottom plate, the middle bottom plate and the rear bottom plate, the middle bottom plate is an isosceles triangle, an included angle beta formed between the two side edges on the same side of the front bottom plate and the rear bottom plate>= 2 alpha, wherein 0 degree< alpha< 90 degrees. The optical module group is provided with a base which is fixedly connected on the rear end of the optical module and a jump ring or tabletting which is arranged on the base, and a butterfly radiator is arranged on the base. The single plate is provided with a plurality of optical module groups with the same structure which complies the arranged angle alpha and abreast arranged on the circuit plate, the optical module groups are provided with the optical module arranged on a single plate panel, the base which is fixed the rear end of the optical module, the jump ring or the tabletting which is arranged the base, and the butterfly radiator which is provided with a bend is arranged on the base. The butterfly radiator and the optical module group and the optical module group single plate with a butterfly radiator have the advantages of being capable of improving level of integration and assembly of the optical module and further improving heat dissipation performance of a single optical module.

Owner:GUANGXUN SCI & TECH WUHAN

MCB (micro circuit breaker) mounting base

ActiveCN104377557AIncrease flexibilityReduce usageBus-bar/wiring layoutsSubstation/switching arrangement boards/panels/desksComputer moduleCopper

The invention discloses an MCB (micro circuit breaker) mounting base. The MCB mounting base comprises a main busbar support and a branch copper bar safety cover. By the aid of a conveniently detachable combined structure, flexibility of the MCB mounting base is improved on the premise of meeting requirements of mounting, positioning, wiring, heat radiation, insulation and the like. When damaged, certain parts can be conveniently replaced. During wiring, wires can be conveniently arranged without detaching the integral mounting base; during production, various parts can be produced integrally, efficiency and speed are high, product quality is improved and production cost is reduced. During detachment, metal screws are reduced, and difficulty in mounting, maintenance and detachment is lowered.

Owner:鹤山市辉域成套设备有限公司

Engineering control cabinet with high IP grade and good radiating effect

InactiveCN103619137ASatisfy heat dissipationFulfil requirementsCasings/cabinets/drawers detailsCooling/ventilation/heating modificationsFiltrationEngineering controls

The invention provides an engineering control cabinet with a high IP grade and a good radiating effect. According to the technical scheme, ventilation openings are formed inside a cabinet body, a filter screen is arranged on the ventilation openings, and a fan is arranged on the top face of the inner side of the fan. The ventilation openings are formed in the top face and / or the bottom face of the cabinet body. The ventilation openings are formed in the side face and / or the back face of the cabinet body. The ventilation openings are formed in a cabinet door. The filter screen is a 400PPI filter screen and / or a 500PPI filter screen. The fan is an axial fan. The engineering control cabinet with the high IP grade and the good radiating effect has the advantages that by the adoption of the technical scheme, the requirement of heat dissipation and the requirement of dust prevention filtration with the high IP grade are met at the same time, and the advantages of being simple in structure, convenient to maintain, low in processing cost, high in production efficiency and the like are further achieved.

Owner:TIANJIN BAILI SWITCHGEAR

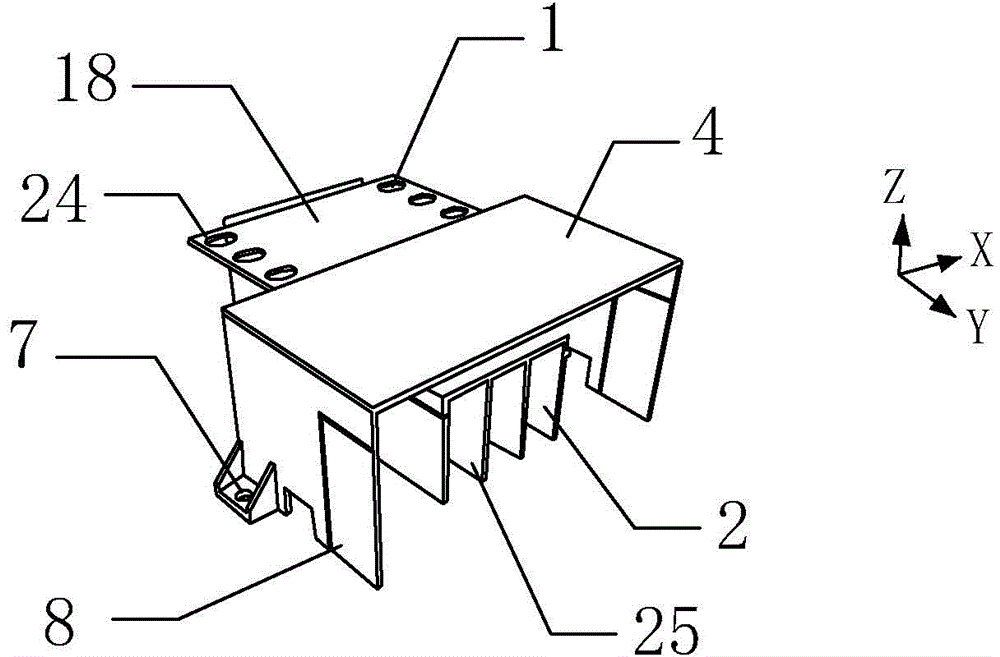

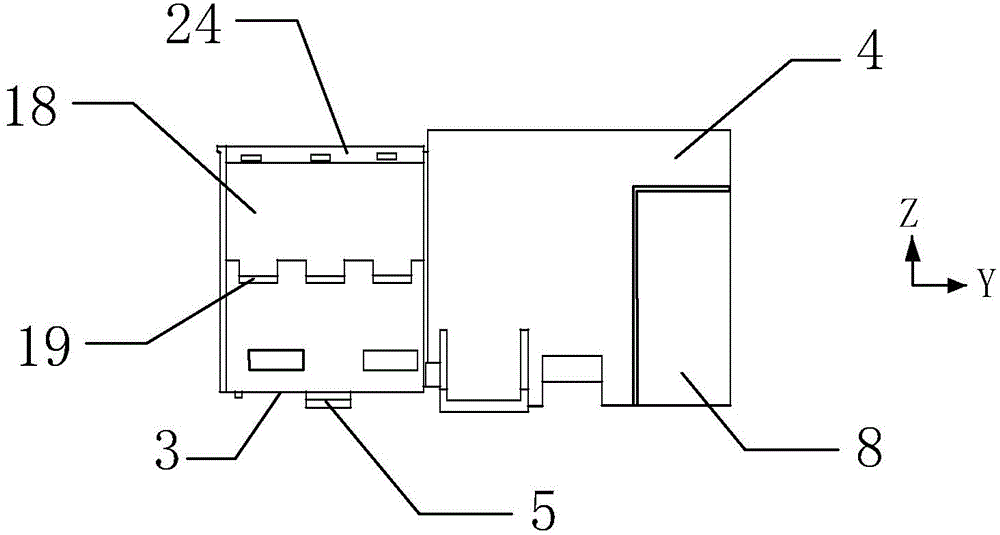

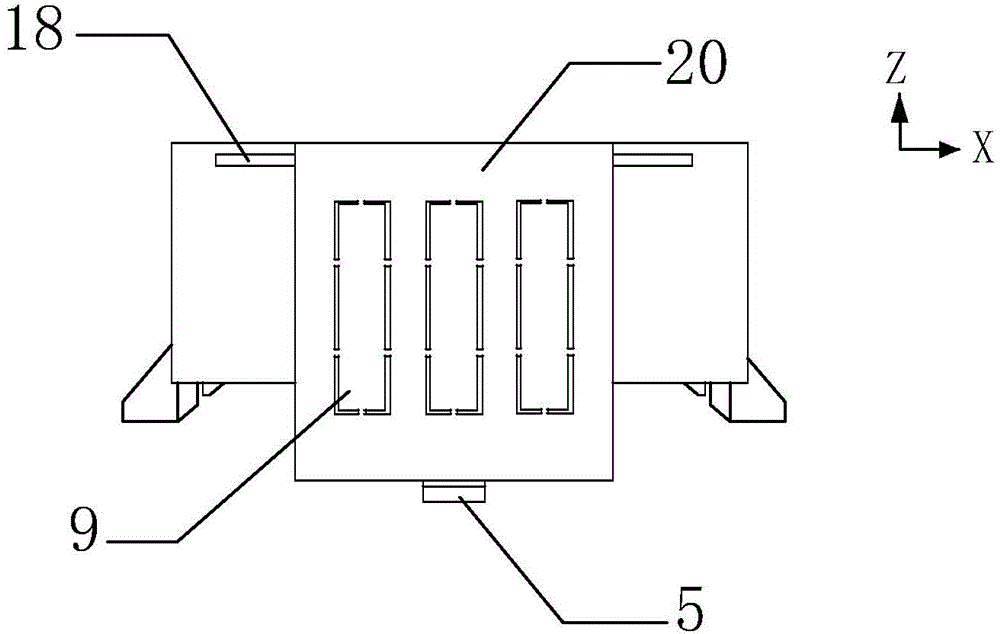

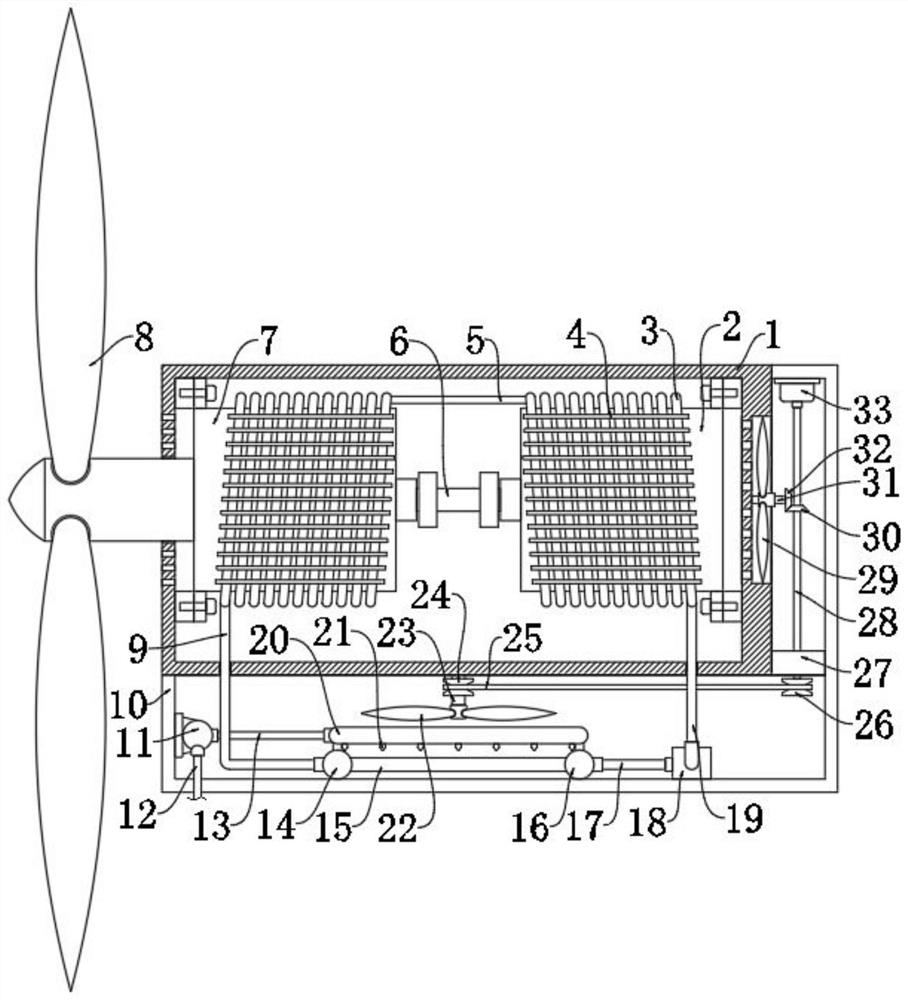

Novel cooling device for wind driven generator

InactiveCN112761906AImprove ventilationSatisfy heat dissipationMachines/enginesMechanical power transmissionWind drivenCooling effect

The invention discloses a novel cooling device for a wind driven generator. The wind driven generator is included, a generator set and a transmission set are arranged in the wind driven generator, the generator set and the transmission set are installed on the two sides of the interior of the wind driven generator correspondingly, and the generator set and the transmission set are in transmission connection through a coupler. The front end of the wind driven generator is provided with wind power fan blades in transmission connection with the transmission set, the front end and the rear end of the wind driven generator are both provided with heat dissipation holes, the exterior of the wind driven generator is fixedly connected with a mounting frame, and the inner side wall of the mounting frame is provided with a ventilation mechanism corresponding to the rear end of the wind driven generator. A liquid cooling heat dissipation mechanism used for conducting heat dissipation on the generator set and the transmission set is installed at the inner bottom of the mounting frame. Through combination of air cooling and liquid cooling, a good heat dissipation and cooling effect is achieved, the service life of the wind driven generator is prolonged, and a wide market prospect is achieved.

Owner:河北上广网络科技有限公司

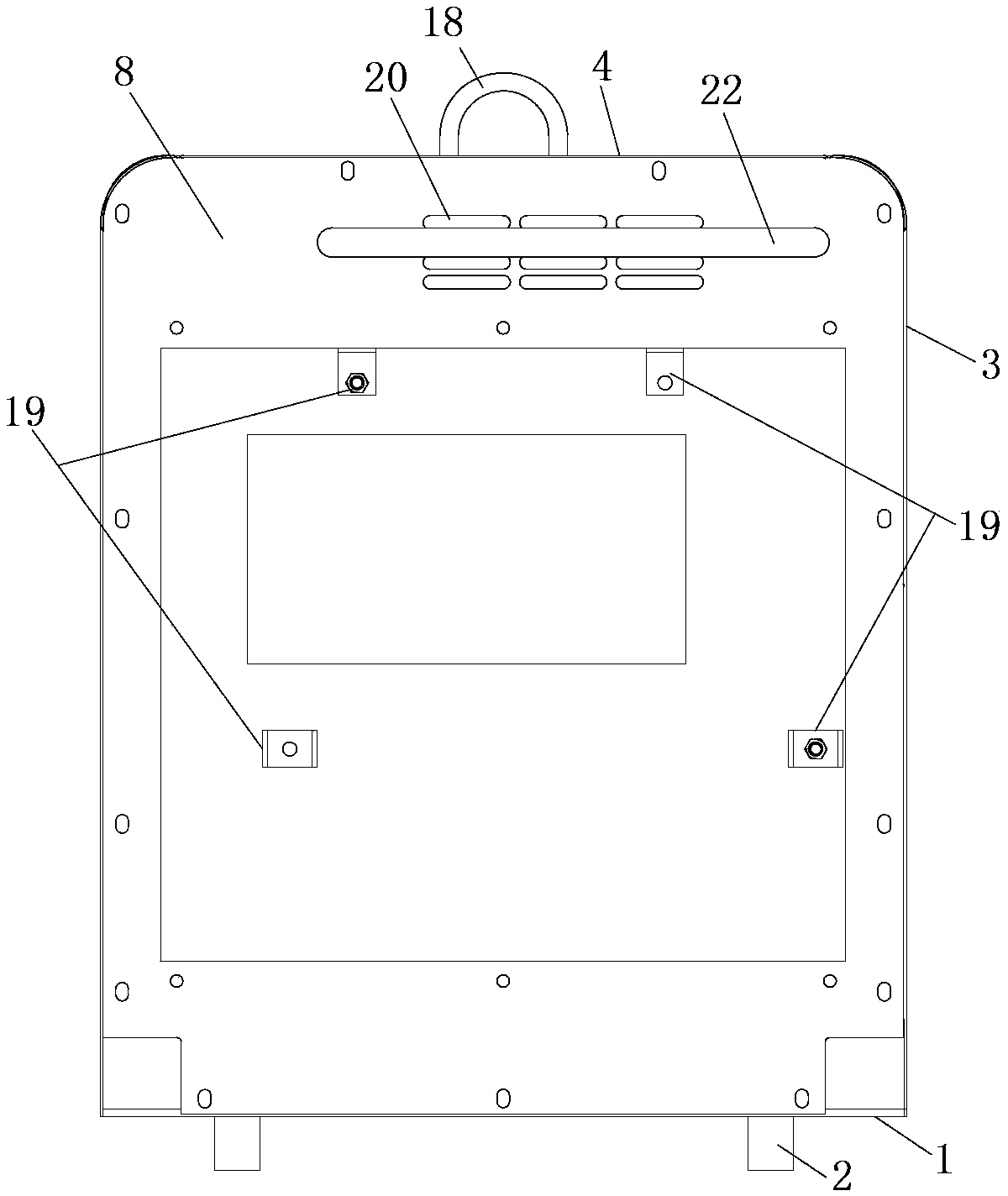

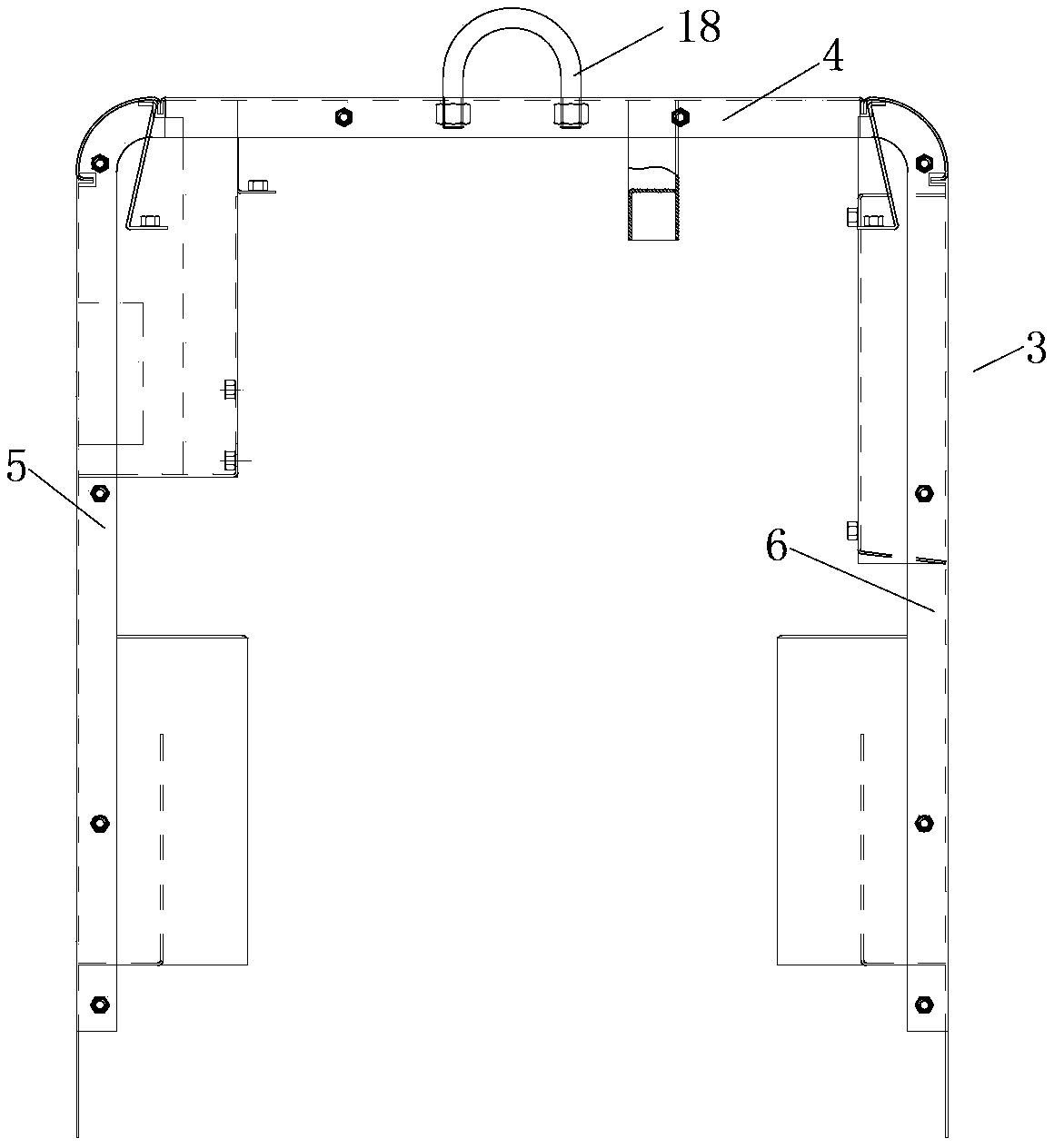

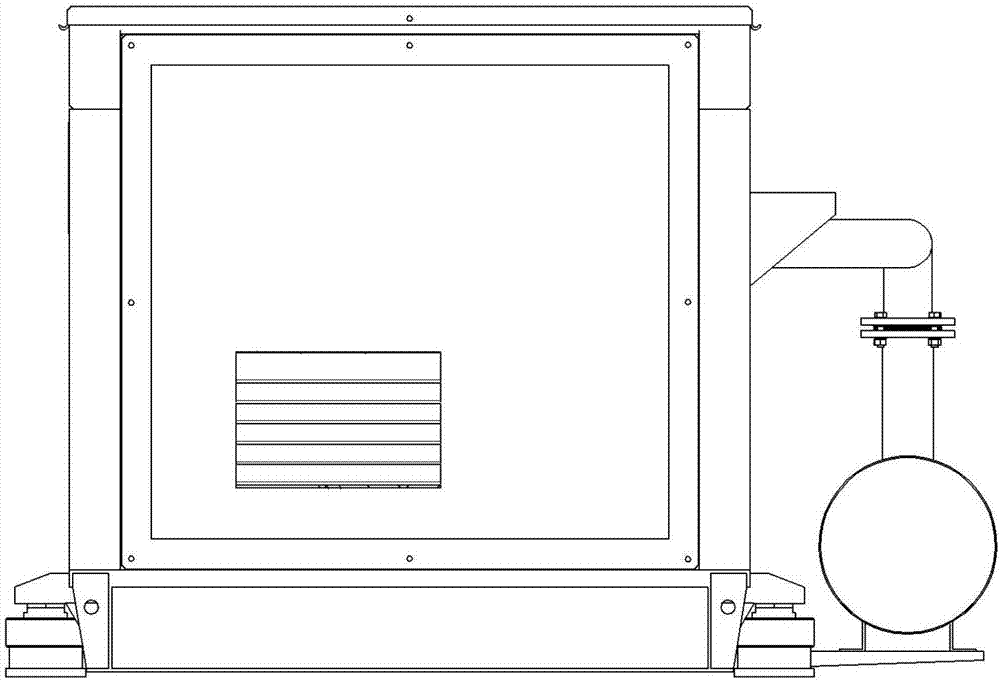

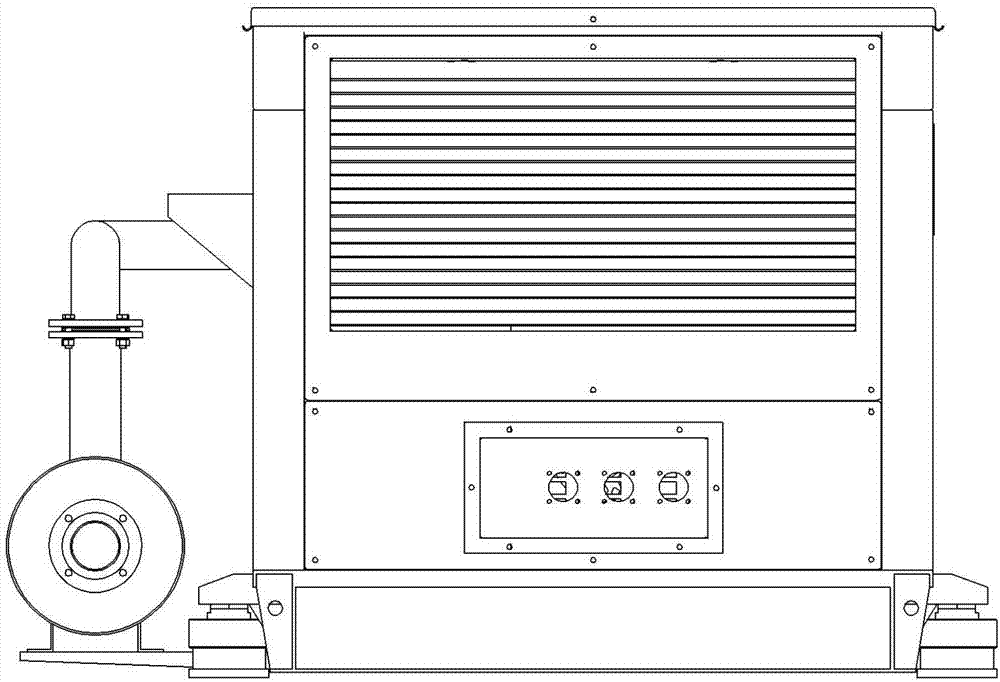

Engine cabinet

The invention relates to an engine cabinet for mounting an engine. The engine cabinet comprises a base, a door-shaped frame and side plates, wherein the frame is arranged on the base, and the side plates are arranged on sides of the frame and used for covering the door-shaped frame. The frame comprises a top cover plate, a first side plate and a second side plate, the top cover plate is integrated with the first side plate and the second side plate, the side plates include a third side plate and a fourth side plate, the third side plate is positioned on one side of the frame, the fourth side plate is positioned on the other side of the frame, an upper induced air plate with an induced air port is arranged on the upper portion of the third side plate, a middle induced air plate with an induced air port is arranged in the middle of the third side plate, and a silencing cavity for mounting a silencer is formed in the inner side of the fourth side plate and comprises the fourth side plate and a silencing plate fixedly arranged on the fourth side plate. The engine cabinet is reasonable in structural design and can meet the requirements of the engine for heat dissipation and noise reduction.

Owner:CHANGZHOU SINO TEXTILE

Small-sized blowing fan

InactiveCN101042143ASatisfy the air volumeSatisfy heat dissipationRadial flow pumpsNon-positive displacement fluid enginesMagnetComputer fan

A small blower fan comprises a shaft base whose center fixed with a rotary shaft and whose outside fixed several vanes and magnets, with each vane arranged in regular radiation, magnets located within the boundary covered by the vanes in rotation, and the height of the vane must be over thirty percent of the total height of the magnet. It is not only small and thin, it can meet the wind blowing volume and heat radiation requirement.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

Protective clothing with excellent waterproof, breathable and barrier properties

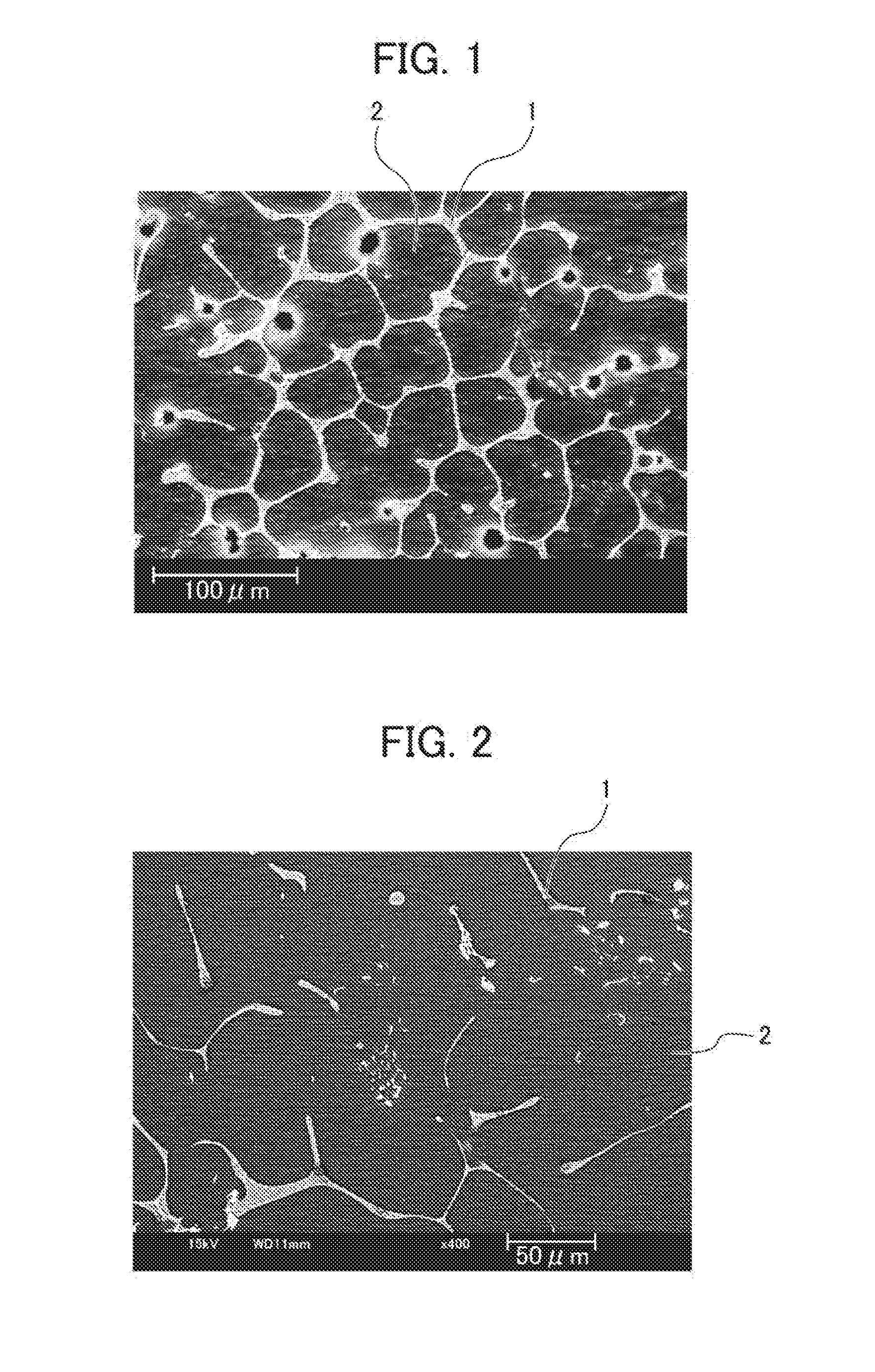

InactiveCN111407028AStable leakControllable leakProtective garmentSpecial outerwear garmentsPolymer scienceEngineering

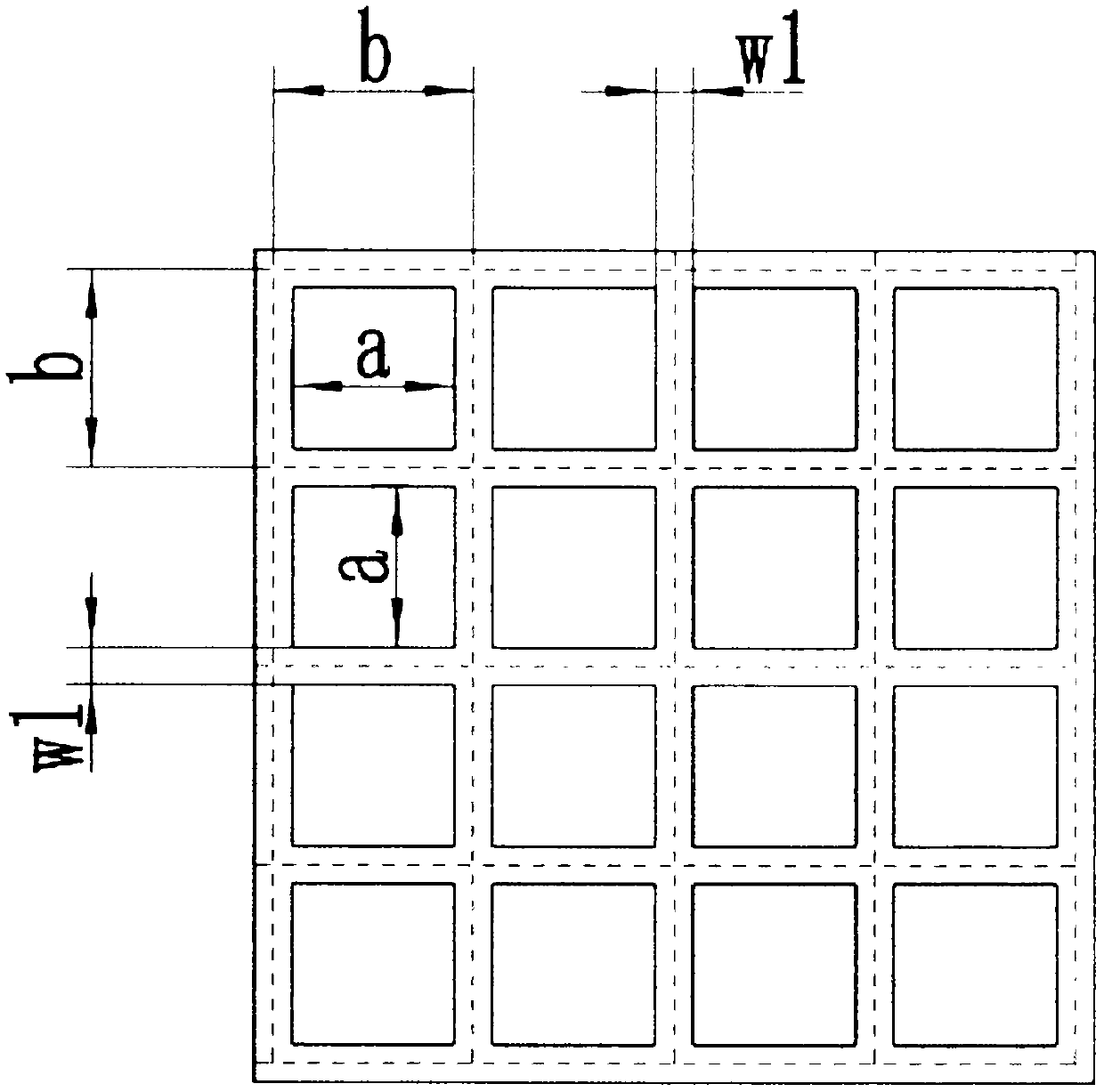

The present invention provides a protective clothing with excellent waterproof, breathable and barrier properties. The protective clothing has excellent waterproof, breathable and barrier properties,is waterproof and precise in breathability, keeps effective barrier to blood and viruses, is prepared from a microporous laminated composite material, is used in a positive pressure type protective clothing manner, and mainly comprises a protective hood, and a jacket and trousers with waterproof and precise breathable functions, when the air inlet flow of the protective clothing is adjusted between 85 L / min and 510 L / min; the micro-porous laminated composite material adopted by the main body part of the protective clothing has the capability of stably leaking air and water vapor outwards; theair inlet flow and the leaked air flow of the protective clothing can be balanced, stable positive pressure ranging from 300 Pa to 1500 Pa can be established in the protective clothing, and the dehumidification capacity of the protective clothing is larger than 500 g / (m<2>*h). The micro-porous laminated composite material adopts a three-layer structure: a middle layer adopts a micro-porous PE filmwith a nanoscale aperture as a gas precision slow-release layer, two sides adopt non-woven fabrics as protective layers, and an interface adopts a hot melt adhesive for strip-shaped or gridding hot-pressing composite connection reinforcement.

Owner:北京久硕新材科技发展有限公司

Generator set

PendingCN110630380AEnsure normal intake and exhaustGuaranteed cooling effectMachines/enginesEngine componentsWater flowBroadband

The invention relates to a generator set. The generator set comprises a generator assembly and a sound insulation hood arranged outside the generator assembly in a covering mode. The sound insulationhood comprises a sound insulation hood body and an access door arranged on the sound insulation hood body. A functional opening is formed in the access door. A plurality of waterproof noise-elimination pieces are vertically arranged at the functional opening in parallel, and a functional channel is formed between every two adjacent waterproof noise-elimination pieces. Each adjacent waterproof noise-elimination piece comprises a waterproof part and a noise-elimination part, wherein the waterproof part is located on the outer side of the sound insulation hood body and inclines in the direction of the functional channel to guide a water flow out of the sound insulation hood body, and the noise-elimination part is located on the inner side of the waterproof part and is used for eliminating noise. According to the generator set, rainwater can be prevented from entering the sound insulation hood while good air intake and heat dissipation are guaranteed, so that the generator set is protected; and meanwhile, the noise elimination quantity within a broadband range is improved, outward radiation of noise is reduced, the noise of the generator set is effectively reduced, and pollution of thenoise to the environment is reduced.

Owner:CHONGQING IONCIN NAVIGATION ENGINE MFG C0 LTD

Motor vertical swing arm module of three-in-one welding trolley

InactiveCN113146117AStable jobImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryThermal radiation

The invention discloses a motor vertical swing arm module of a three-in-one welding trolley. The motor vertical swing arm module comprises a telescopic arm installed on a trolley body; a vertical motor and a gear box are arranged on the telescopic arm; the motor is connected with the gear box; and a welding gun clamp located on one side of the motor is further arranged on the telescopic arm. The distance between the motor and a heat source reaches 200MM, the motor is not directly irradiated by heat radiation, the module is heated from a face to a point, the heating face is reduced, and long-time continuous welding is met. After the swing arm module is assembled, debugging is conducted according to corresponding welding parameters, the swing direction, the telescopic distance and the like are adjusted, and the welding operation requirement is met. The problem that due to continuous welding, three-in-one trolley parts are overheated, and swing arms fail is avoided, the effect is good, a welding machine works stably, the welding quality is stable, the overheating shutdown phenomenon does not occur after high-strength use, and the manual reworking situation is correspondingly avoided.

Owner:CHENGXI SHIPYARD

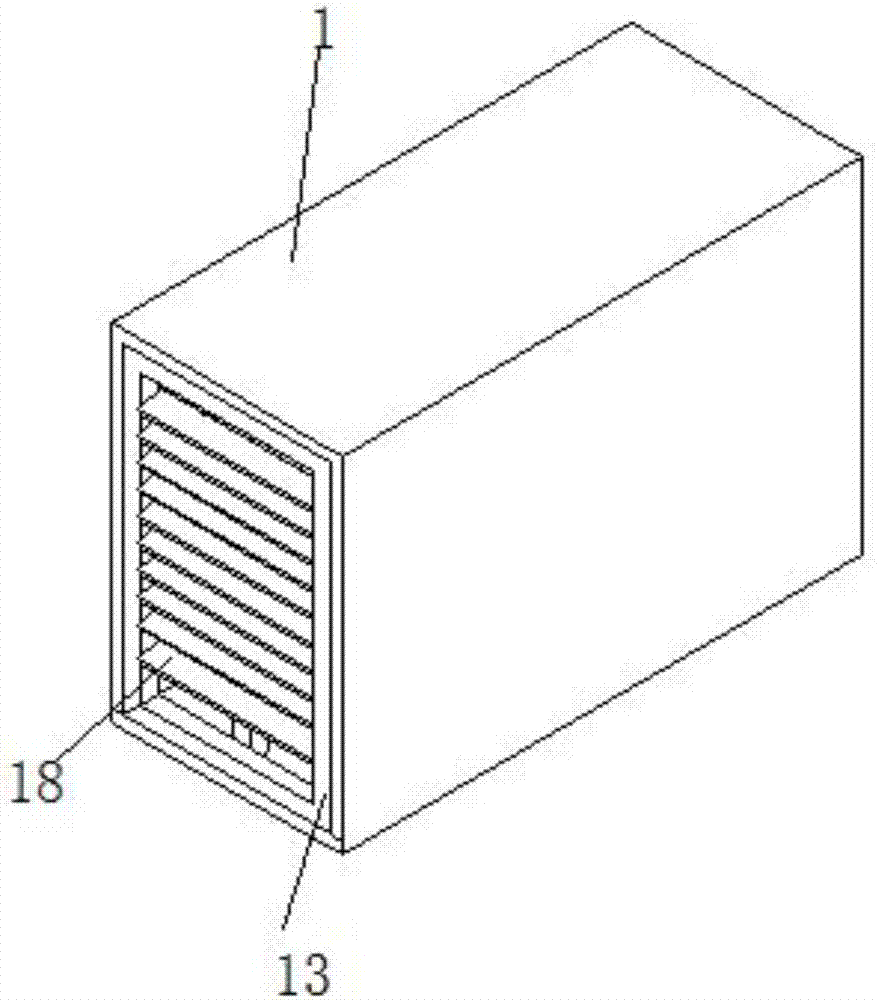

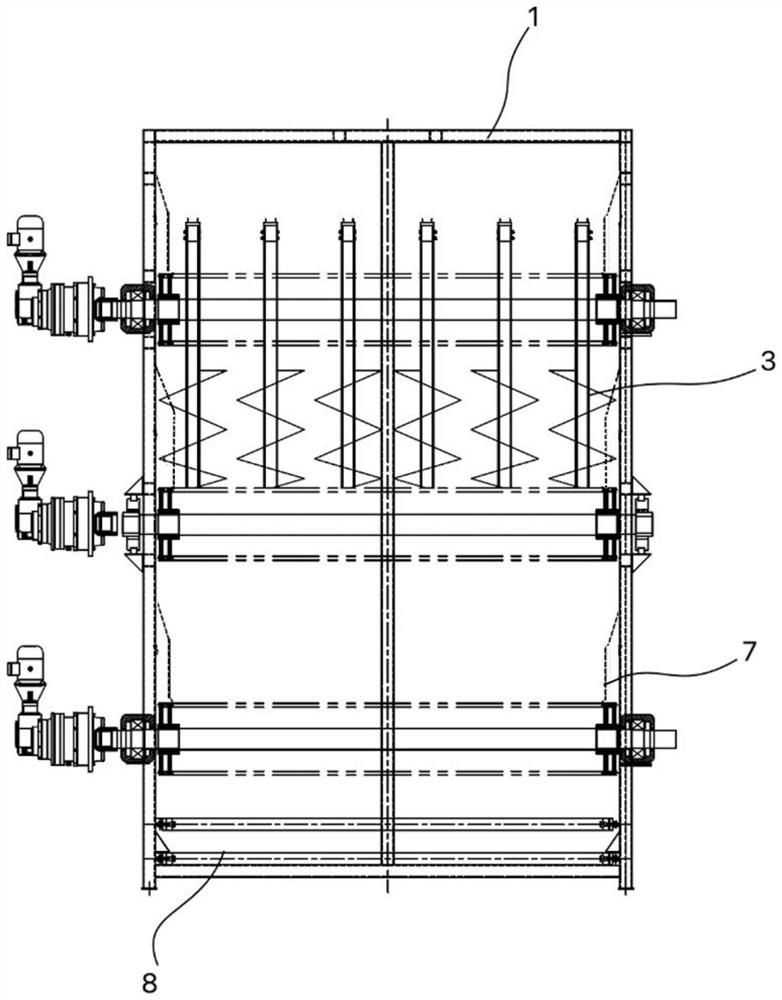

Thick-layer ventilation belt type fermentation machine

InactiveCN113913287AMonitor temperature in real timeAir volume reductionBioreactor/fermenter combinationsBiological substance pretreatmentsAir volumeEngineering

The invention discloses a thick-layer ventilation belt type fermentation machine. The thick-layer ventilation belt type fermentation machine comprises a machine box, a ventilation opening formed in the top side of the machine box and a multi-layer conveying mechanism transversely arranged in the machine box. The running directions of the adjacent conveying mechanisms are opposite, and the starting ends and the stopping ends are staggered by a certain distance; a bearing surface of the conveying mechanism is provided with a temperature sensor in the same conveying direction as the bearing surface, and a non-bearing surface is provided with an air duct system; the air duct system comprises a draught fan and an air volume controller used for adjusting the air volume of the draught fan according to the temperature measurement height of the temperature sensor. The material temperature is monitored in real time by configuring the temperature measuring cable consistent with the material advancing direction, and the temperature measuring cable is in communication connection with the fan controller, so that the air volume of the fan is controlled in real time along with the material temperature, and the fermentation material temperature is consistent with the optimal growth temperature of fermentation strains.

Owner:安徽东方新新生物技术有限公司

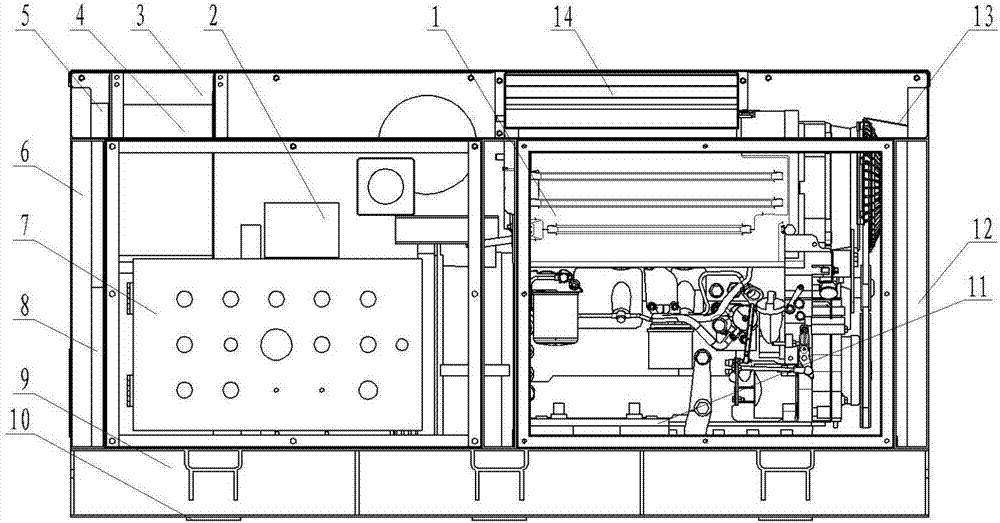

High power density mute diesel engine generator

PendingCN107339155AMeet heat dissipationNo added bulkAir coolingVentilation arrangementNoise reductionDiesel generator

The invention relates to a mute diesel engine generator, in particular to a high power density mute diesel engine generator. The high power density mute diesel engine generator can be applied to the narrow space and high-temperature and low-temperature severe environments. The high power density mute diesel engine generator comprises a mute box body and a power generator assembly, wherein the power generator assembly can be held in the mute box body. The high power density mute diesel engine generator further comprises a heat dissipation air channel. Due to a noise reduction structure with a muffler and the mute box body, the mute effect is further enhanced. Due to the fact that the independent heat dissipation air channel is designed under the condition that the size of the diesel engine generator is unchanged, the requirement for heat dissipation of the diesel engine generator is met, and the size and the weight of the diesel engine generator are not increased.

Owner:SHENYANG AEROSPACE XINGUANG GRP

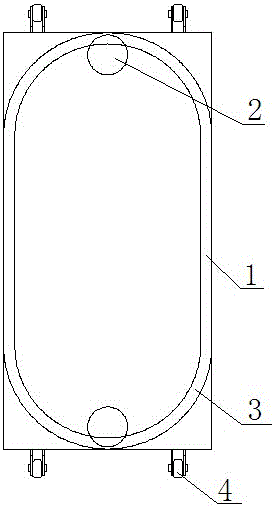

Device for compensating pressure of transformer cooling oil liquid on basis of effect

ActiveCN106057421AMeet compensationSatisfy heat dissipationTransformers/inductances coolingTransformerEngineering

The invention discloses a device for compensating pressure of transformer cooling oil liquid on the basis of effect. The device comprises a capsule-shaped body, an overlapped plate (1) and a guiderail (5), wherein the capsule-shaped body is filled with transformer cooling oil liquid and the volume of the capsule-shaped body can be changed; the overlapped plate (1) is arranged on the capsule-shaped body and is used for supporting the capsule-shaped body and driving the capsule-shaped body to move; and the guiderail (5) is connected with the overlapped plate (1). The overlapped plate (1) drives the capsule-shaped body to move along the guiderail (5), so that oil liquid in a cooler of a transformer is compensated and the condition of only using an oil conservator body prevented; therefore the performance requirements for the compensation and cooling of the transformer cooling oil liquid are satisfied.

Owner:SHANDONG WUYUE ELECTRICAL APPLIANCES

High-speed mini photoelectric conversion module design and process method

InactiveCN112505856AImprove yieldReduce processing difficultyCoupling light guidesOptical ModuleData port

The invention discloses a high-speed mini photoelectric conversion module design and process method. The process method comprises the following steps: S1, firstly employing an integrated design schemeof eight hard boards, four soft boards and six hard boards for a PCB part, successfully controlling the thickness of the soft boards to be within 0.35 mm through reducing the number of layers of thesoft boards in order to reduce the difficulty of a PCB plate making process, improve the rate of finished products of PCB plate making and improve the reliability of long-term bending of the soft plate part, and replacing the metal wall-filling plate by the design of the tungsten-copper heat sink and the ceramic gasket to make the process simple and the cost low; and S2, inputting 12 paths of differential electric signals to a 12-channel VCSEL drive through 12 paths of data ports of an optical module at a transmitting end, simultaneously modulating and driving the 12 paths of VCSEL to emit light through the 12-channel VCSEL drive, coupling the 12 paths of optical signals to an optimal state through a 12-channel lens array, and transmitting the 12 paths of optical signals to a far-end signal processor through an optical fiber, thereby realizing electro-optical conversion.

Owner:JIANGSU ALLRAY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com