Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Regulating load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

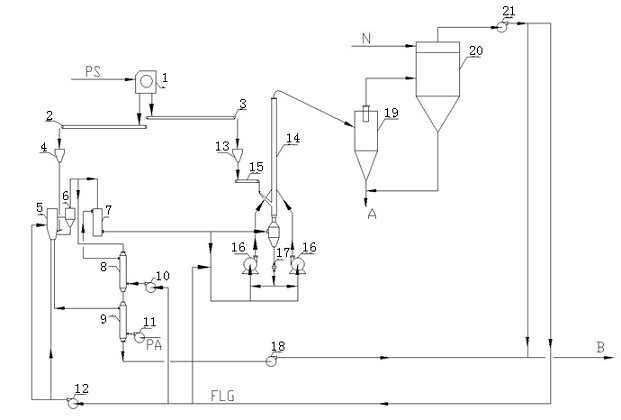

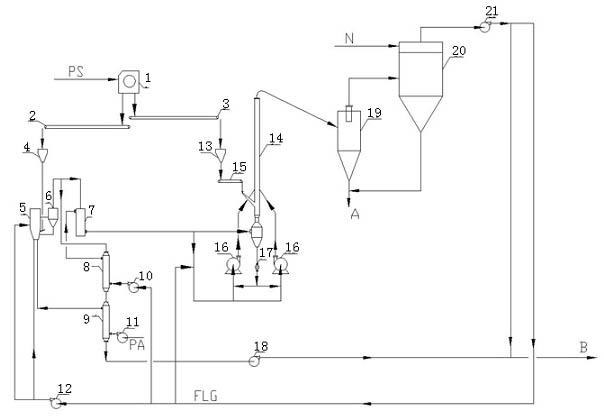

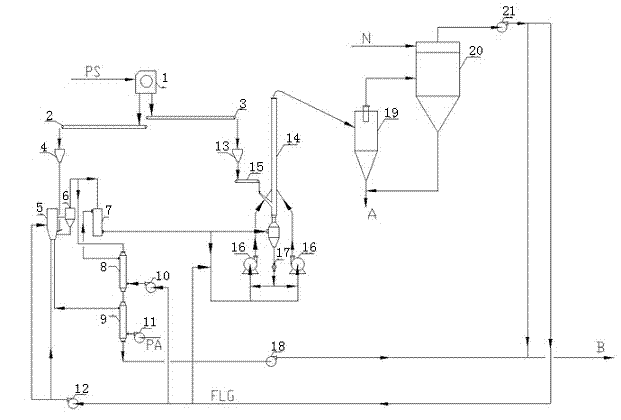

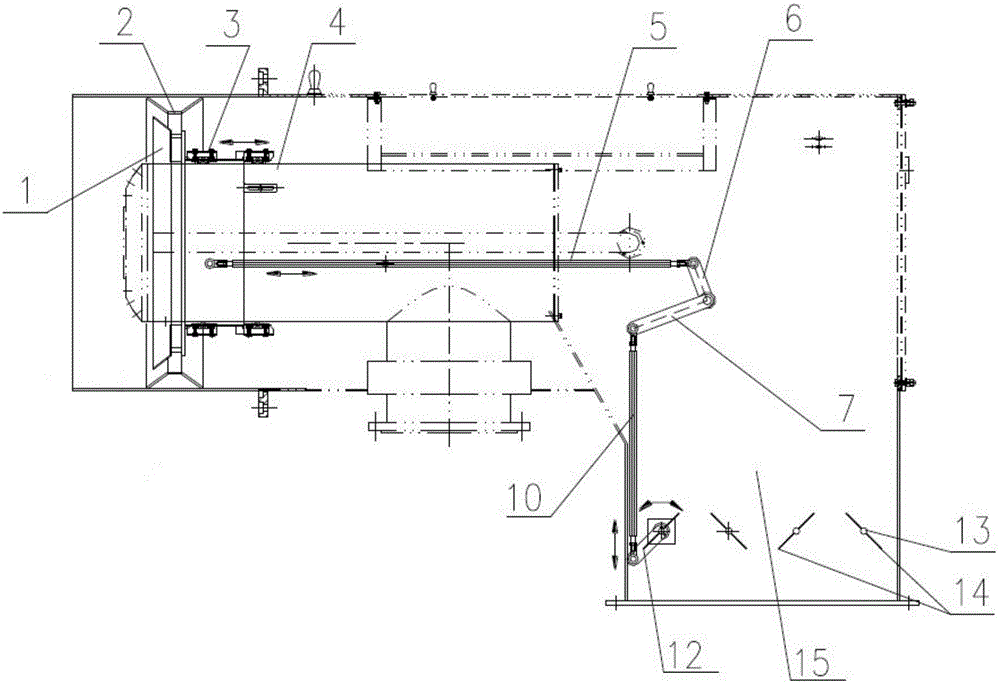

Process for carrying out strengthening circulation, stage grinding and quality improvement on lignite by utilizing superheated steam and system thereof

ActiveCN101870897AOptimize energy distributionMaximize energy utilizationCombination devicesDrying solid materials with heatFlue gasProcess engineering

The invention relates to a process for carrying out strengthening circulation, stage grinding and quality improvement on lignite by utilizing superheated steam and a system thereof. The method comprises the following steps: (1) carrying out grinding on the raw material lignite; (2) burning one part of coal blocks / powder to produce high-temperature flue gas serving as a heat source and carrying out air separation and dring on the other part of coal blocks / powder requiring to be subjected to quality improvement; (3) in the process of air separation, adopting the high-temperature flue gas from the step (2), carrying out drying, separation and dust removal on the qualified coal blocks / powder conforming to the standard grain diameter after air separation, collecting the qualified coal blocks / powder, sending the qualified coal blocks / powder to the forming process, making the unqualified coal blocks / powder drop in a grinding ventilating device to carry out grinding and drying, then continuously completing deep drying by air separation and repeating the steps, wherein the oxygen content in the flue gas is less than 8 percent; and (4) sending one path of waste gas subjected to air separation and drying to the washing process and returning the other path of waste gas serving as a return tail gas part to the step (2) so as to prepare the high-temperature flue gas and carry out air separation. The process has the advantages of safety, energy saving, environment protection, high efficiency, stability and the like.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

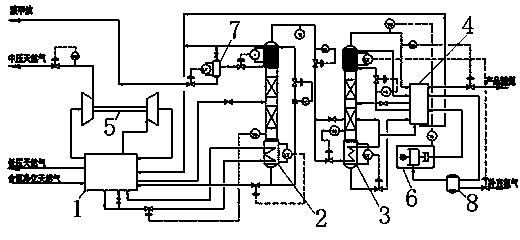

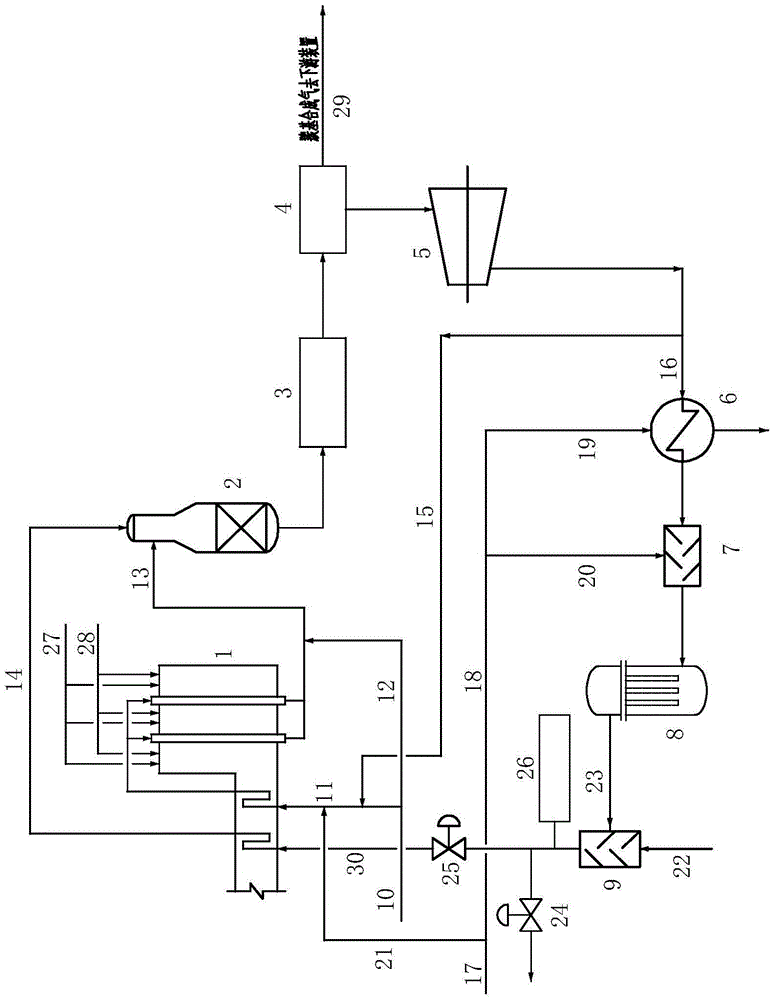

Natural-gas low-temperature helium extracting system and method

ActiveCN102937369ARich adjustment meansReduce energy consumptionSolidificationLiquefactionHigh concentrationEngineering

The invention discloses a natural-gas flow-temperature helium extracting system and a natural-gas flow-temperature helium extracting method. According to the system and the method, the post-expansion and nitrogen circulating refrigerating two-column separating technology is carried out for fully recovering the cooling capacity of the device in order to pre-cool the natural gas which serves as the raw material, and thereby the system can be applied to the natural gas which has an extremely low content of helium, and has the characteristics of being low in energy consumption, high in helium recovery rate, small in investment, flexible in operation, and high in adaptability to variable working conditions. The system and the method have the positive effects that little helium in the helium-containing natural gas can be extracted by a pre-cooling system and a low-temperature rectifying system, an independent nitrogen circulating refrigerating system is adopted and used for supplying an ultralow-temperature cold source required in helium concentration, and the independent system is rich in adjusting means and cannot be influenced by upstream operations; and a post-expansion refrigerating system is adopted, so that the natural-gas low-temperature helium extracting system has the operation pressure higher than that in conventional technology, and higher concentration of the helium can also be obtained at the same refrigerating temperature.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

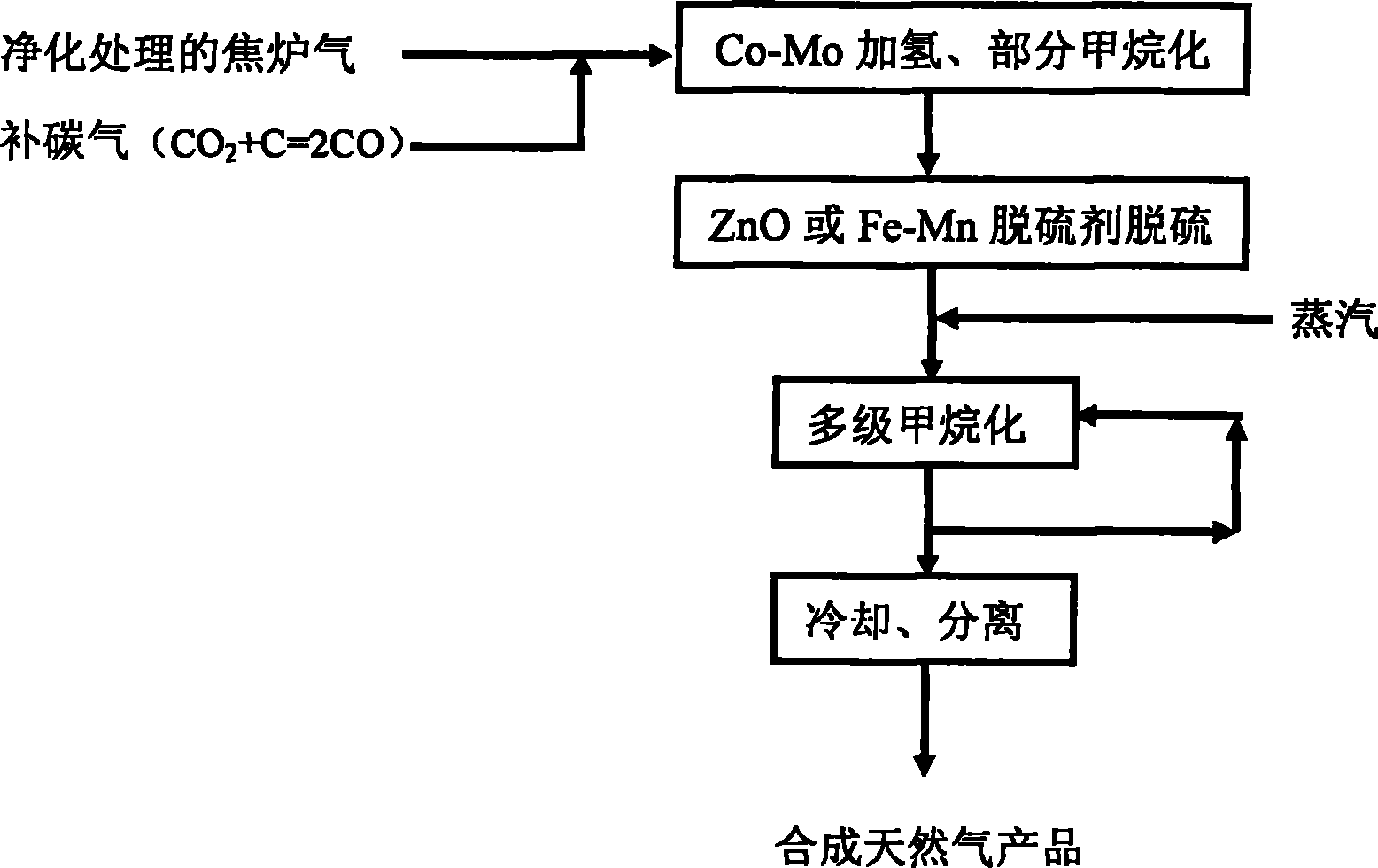

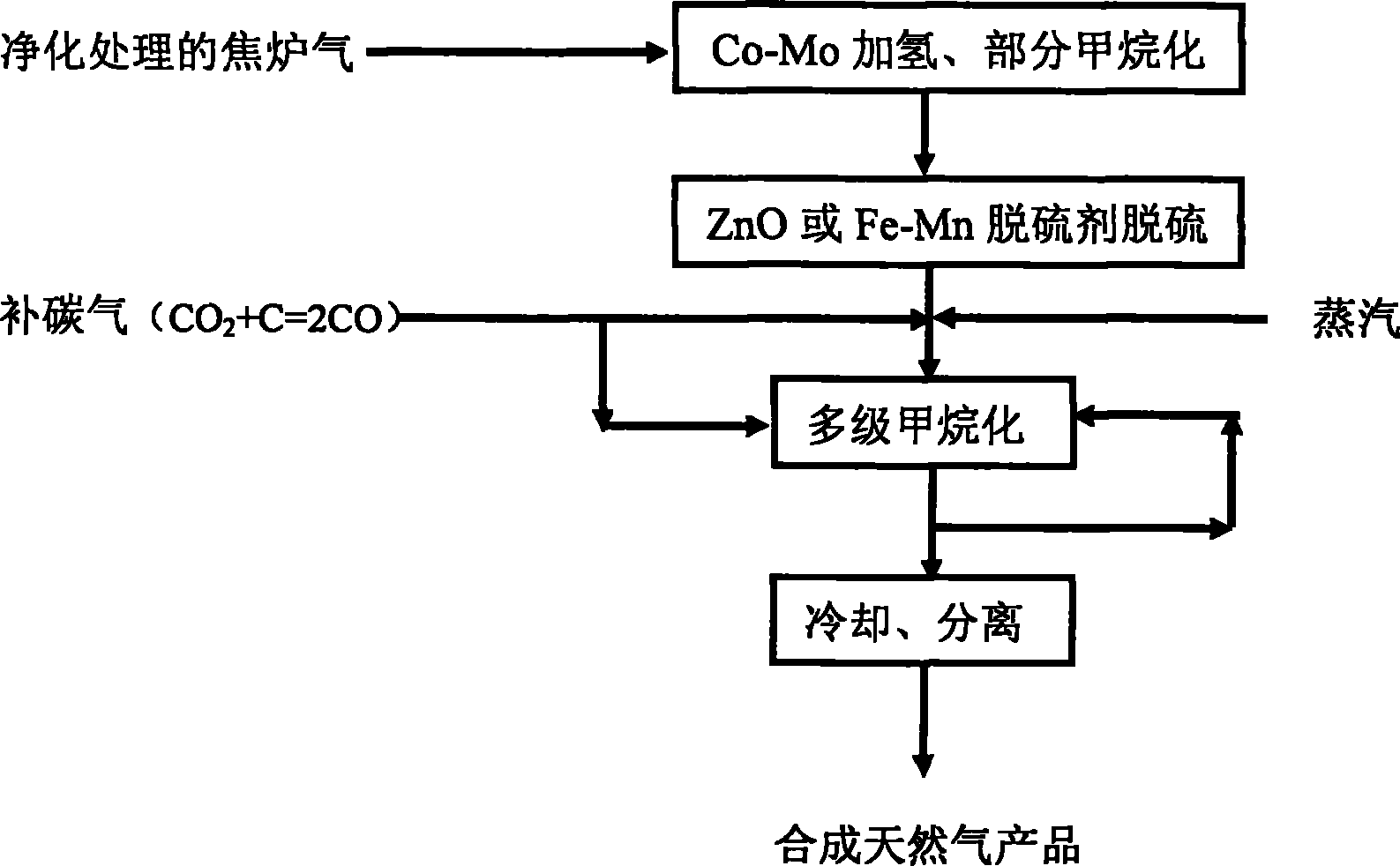

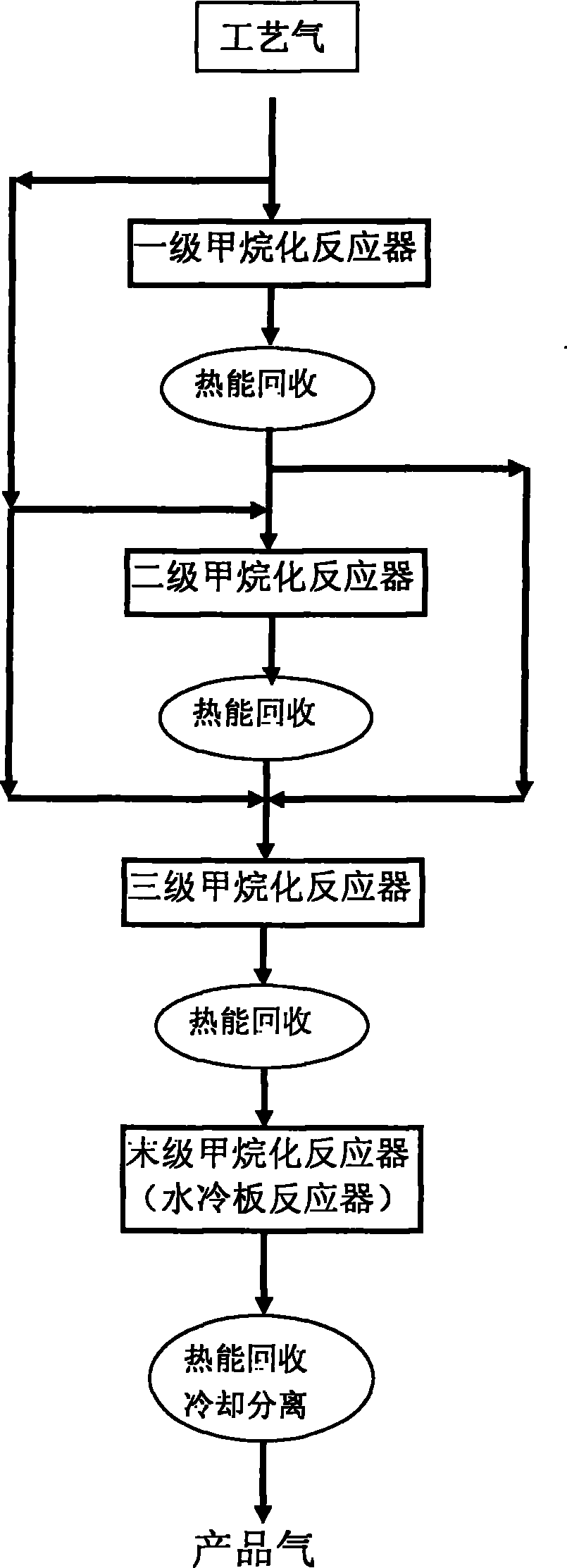

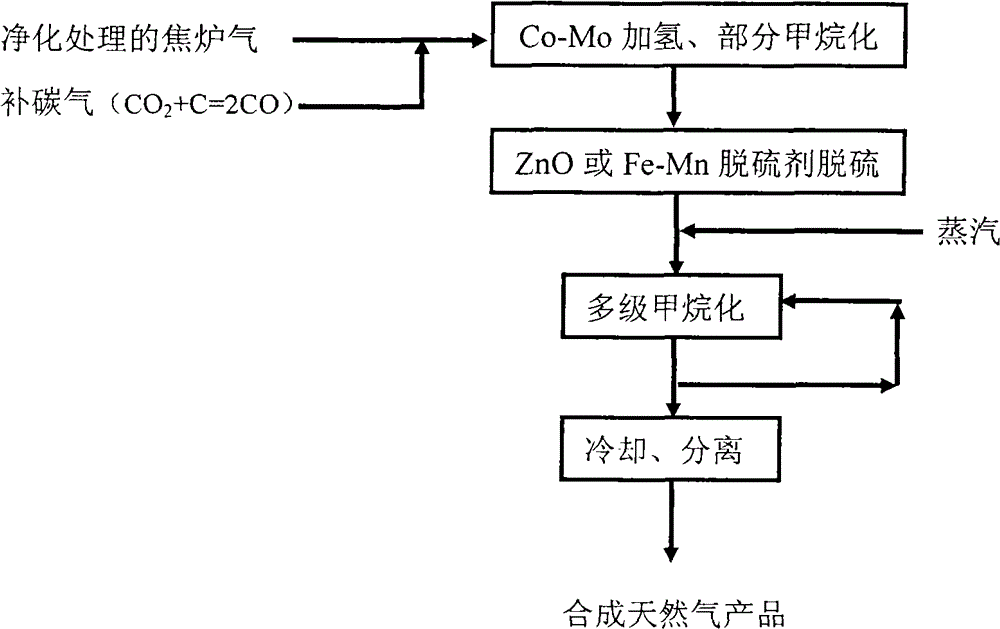

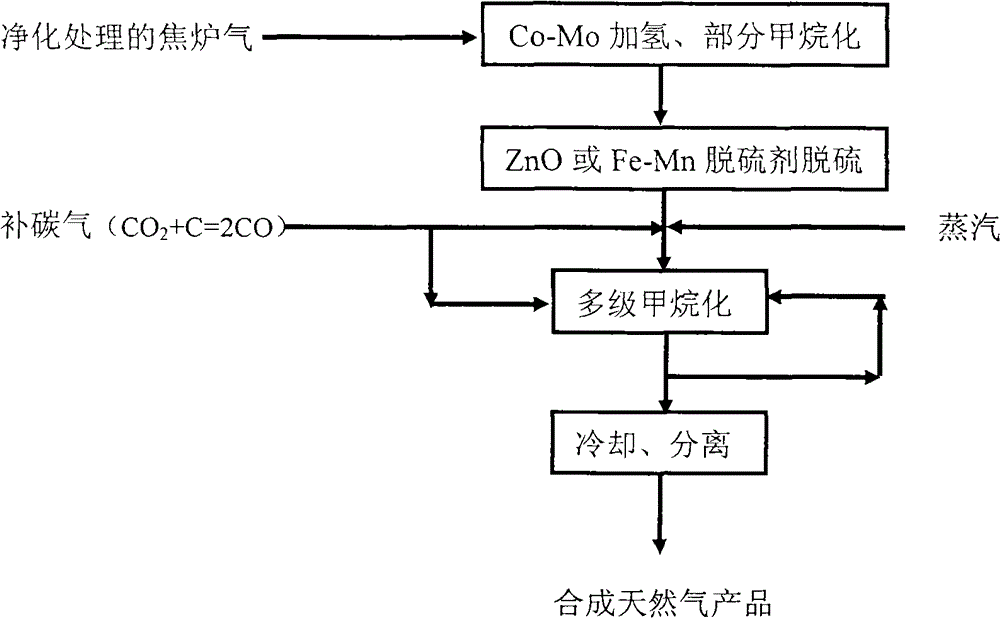

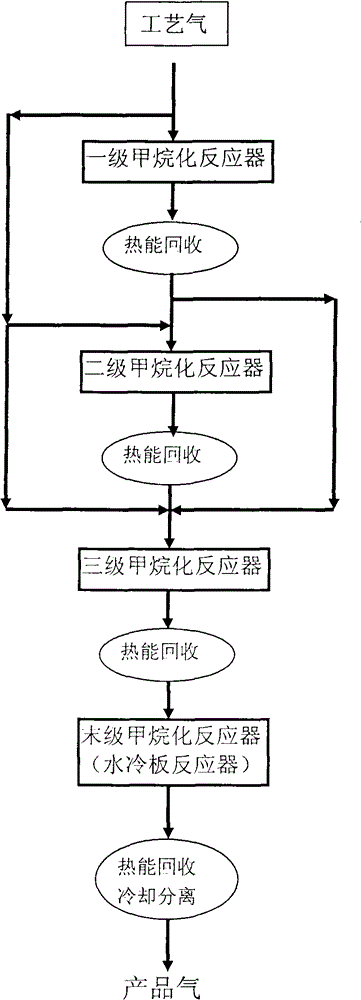

Novel process for making synthetic natural gas by using coke-oven gas

ActiveCN101818087APrevent sulfur poisoningGood recovery of waste heatGaseous fuelsChemistryCoke oven gas

The invention belongs to the field of the comprehensive utilization of coke-oven gas, and discloses a novel process for making synthetic natural gas by using the coke-oven gas. The qualified synthetic natural gas product is produced by the process comprising the steps of hydrodesulfurization, carbon compensation, multi-level methanation, cooling, separation and the like. The process can effectively prevent the temperature runaway phenomenon of a methanation reactor, can reasonably distribute the load of the methanation reactor, improves the conversion rate of CO and CO2, and provides a new method for making the synthetic natural gas by using the coke-oven gas.

Owner:NANJING GOODCHINA CHEM TECH

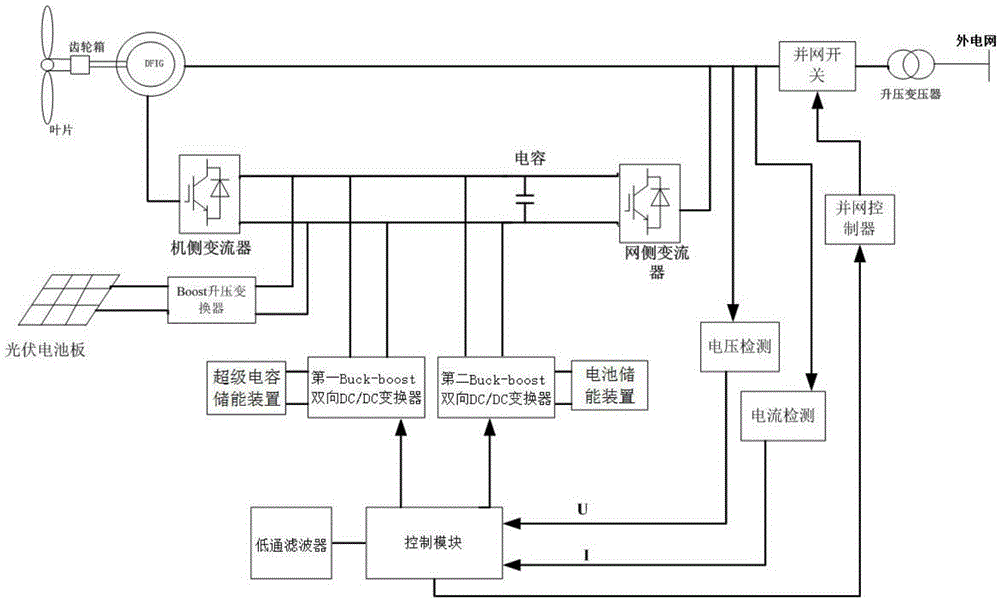

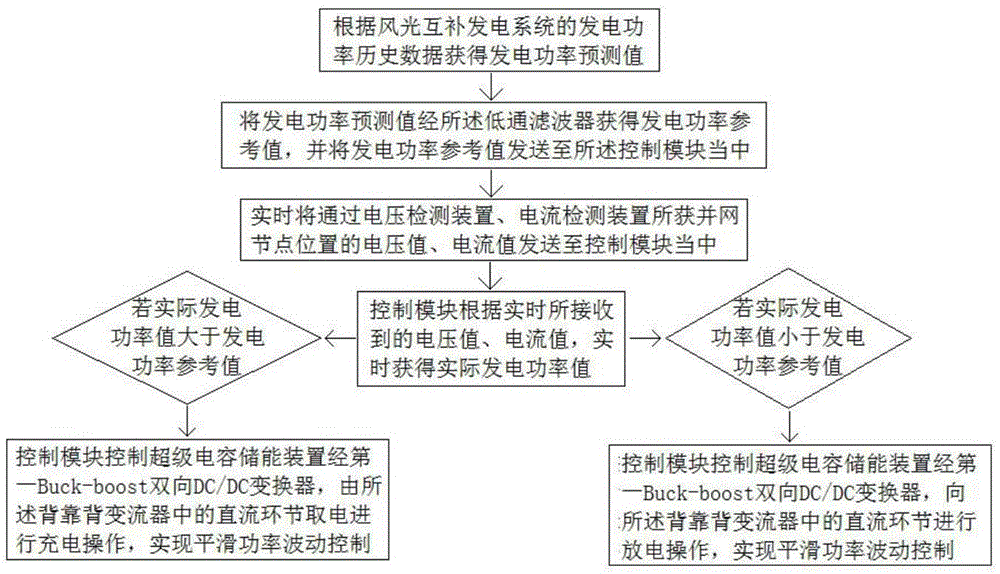

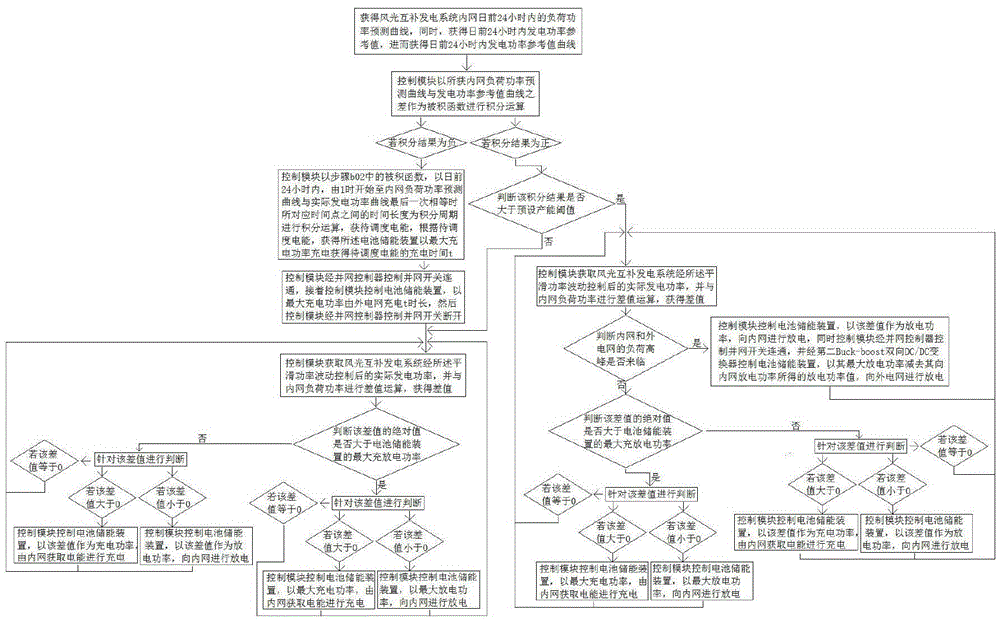

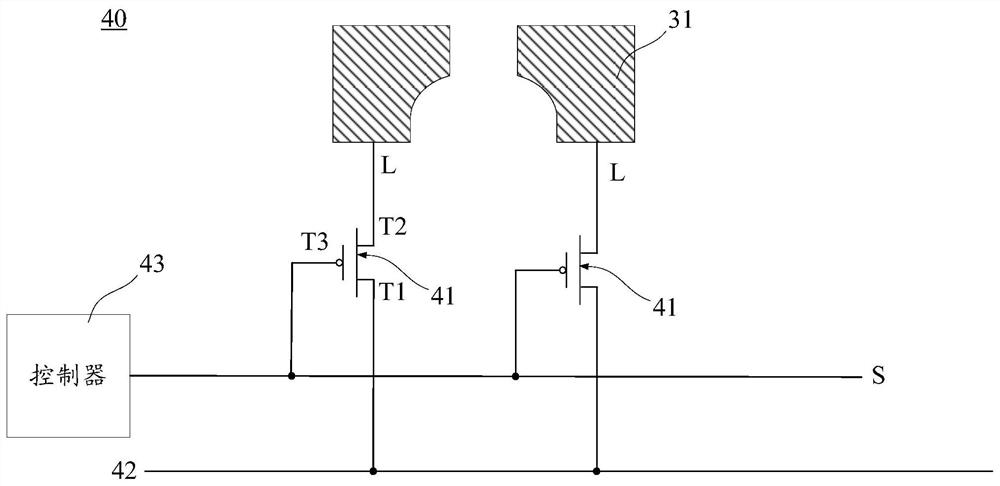

Wind-solar complementary generation system and control method

ActiveCN105680771AImprove work efficiencyRegulating loadPV power plantsEnergy storageMicrogridLow-pass filter

The invention relates to a wind-solar complementary generation system. By a bran-new design framework, a photovoltaic power generation link is embedded into a wind power generation link, so that system output power fluctuation can be stabilized; a load in a microgrid can be adjusted; and the work efficiency of the generation system is effectively improved. The invention further relates to a control method for the wind-solar complementary generation system. The method comprises a combined control method for stabilizing power fluctuation and adjusting the load in the microgrid. By combination of a power prediction technology and a low-pass filter principle, the system generation power in the next 24 hours is predicted in advance by the perspectiveness of the prediction technology. Due to the uncertainty and the volatility of wind and solar radiation, a lot of high-frequency components exist in the actual generation power of the wind-solar complementary generation system. A predicted value is very close to an actual value, the high-frequency component in the predicted value is filtered out through a low-pass filter; and the processed predicted value is taken as a reference value of the system output power, so that the system generation power fluctuation can be effectively stabilized.

Owner:NANTONG UNIVERSITY

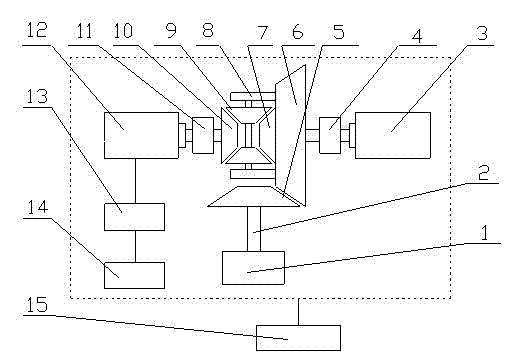

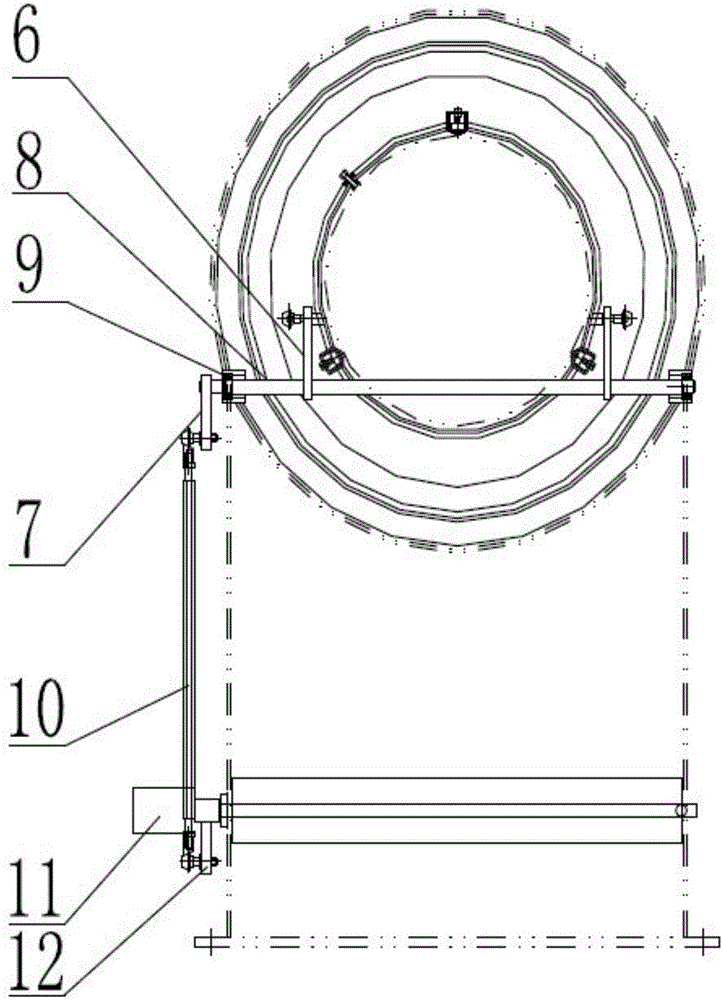

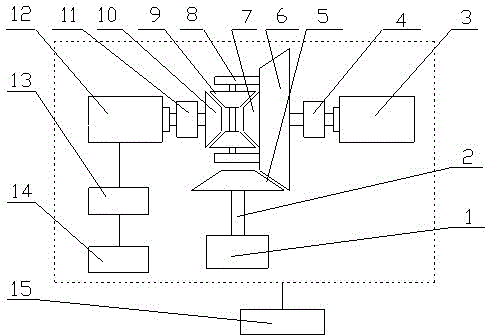

Mechanical synthesizer of rotational speed and torque

InactiveCN103047373ATo achieve composite outputReduce capacityToothed gearingsMechanical energy handlingPower gridControl theory

The invention provides a mechanical synthesizer of rotational speed and torque. The mechanical synthesizer comprises a main motor and gears thereof, a helper motor and gears thereof, planetary gears, driven gears and a capacitor. The planetary gears are respectively meshed with the gears of the main motor and the gears of the helper motor. The driven gears are meshed with the gears of the main motor. When difference of the revolving speed and the torque exists between the gears of the main motor and the gears of the helper motor, the planetary gears synthesize the motive power from the two different revolving speeds and torques and then transmit the motive power to the driven gears, and accordingly synthesizing and output of the motive power are achieved. Through the charge and discharge of the capacitor, the synthesizer for a revolving speed torque machine is capable of storing the reverse load complementary energy of the main motor into the capacitor when the main motor is at low load and discharging the capacitor to drive the helper motor when the main motor is at high load, and accordingly reducing the running load of the power network while synthesizing the motor power and improving the load rate and running efficiency of the motor.

Owner:张万璐

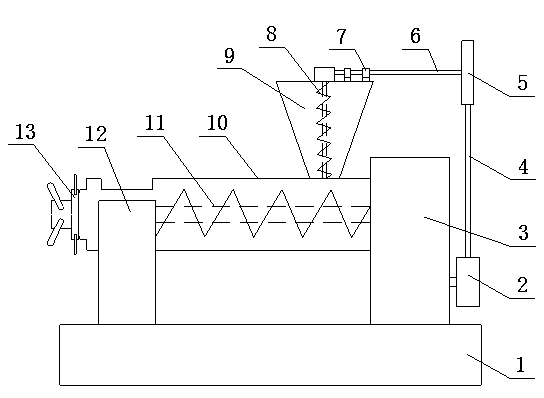

Sesame oil expression device

The invention discloses a sesame oil expression device. The sesame oil expression device comprises a base, a gear set box, a feed hopper, a barrel, a squeezing screw and a supporting frame. A belt pulley is connected with the gear set box, and a driven pulley is connected with the belt pulley through a belt. A transmission shaft penetrates through two supporting sleeves to be connected with the driven pulley, and a feed screw is connected with the transmission shaft. A pressure ring is arranged on the left side of the barrel. The sesame oil expression device is simple in structure. The feed speed is transmitted through the belt pulley, the belt, the driven pulley, the transmission shaft and the feed screw, a motor of the gear set box is used for controlling the feed speed and the feeding speed of the squeezing screw, the pressure ring can adjust the thickness of a squeezed cake and the load in the barrel, and therefore the oil yield is increased, and the oil expression quality is improved.

Owner:ANHUI LONGXI FOREIGN TRADE SESAME OIL MFG

LNG (Liquefied Natural Gas)/liquid oxygen direct combustion mixed working medium power cycle generation device

ActiveCN105756732AMeet the needs of large-scale energy storageLess investmentSolidificationLiquefactionCombustion chamberPower cycle

The invention provides an LNG (Liquefied Natural Gas) / liquid oxygen direct combustion mixed working medium power cycle generation device. The device is composed of an acting subsystem, a regenerative cycle subsystem, and an LNG and liquid oxygen supply and CO2 capturing subsystem; a high-pressure combustion room set and a reheat combustion chamber set are used for replacing a boiler and a re-heater; a LNG / liquid oxygen high-pressure and high-temperature combustion product is mixed with supplied water to generate H2O / CO2 mixed steam for realizing expansion power generation in a turbine set; and after a mixed working medium steam exhaust is condensed in a condenser to separate moisture, CO2 is pre-cooled and pressurized and then is liquefied. Inlet pressure and temperature of a turbine working medium are relatively high, a control strategy of a load of a combustion adjuster set is adopted and a low-pressure turbine is disconnected and operated at an off-peak power period, so that the efficiency of the set can be greatly improved; and therefore, functions of large-scale energy storage, zero emission of CO2 and NOx, high efficiency, peak adjustment and the like are realized.

Owner:SOUTHEAST UNIV

Speed changing system for wind power heating device

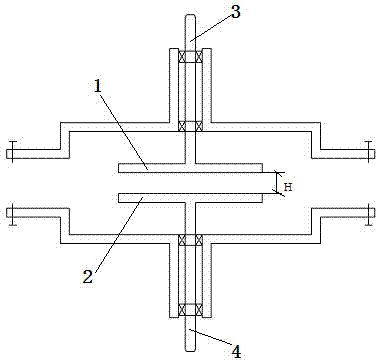

InactiveCN104265583ATake advantage ofImprove thermal efficiencyWind motor combinationsMachines/enginesFluid viscosityTurbine blade

The invention relates to a speed changing system for a wind power heating device. Two discs for driving are arranged in a cavity respectively and connected with wind turbine blades and a stirring barrel respectively through shafts, when the disc which is connected with the wind turbine blades rotates to a certain rotating speed, the disc which is connected with the stirring barrel is driven to rotate under the action of fluid viscosity, and a fluid in the stirring barrel can be heated. The distance H between the two discs is 1-3mm and opposite surfaces of the discs are provided with blades. According to the speed changing system for the wind power heating device, the shaft of the disc which is connected with the wind turbine blades rotates to heat water in the cavity, when wind power is increased, the disc which is connected with the wind turbine blades can drive the disc which is connected with the stirring barrel to rotate, and a stirring plate in the stirring barrel can be driven through the shafts to heat the fluid. Therefore, flexible starting and simultaneous heating can be achieved, especially, the fluid in the cavity can be heated, and the two discs are slightly close so that the heating efficiency is high under extremely high friction function. When wind power is increased, the shafts drive the stirring barrel for heating, and therefore, loads are adjusted and wind energy can be fully utilized.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

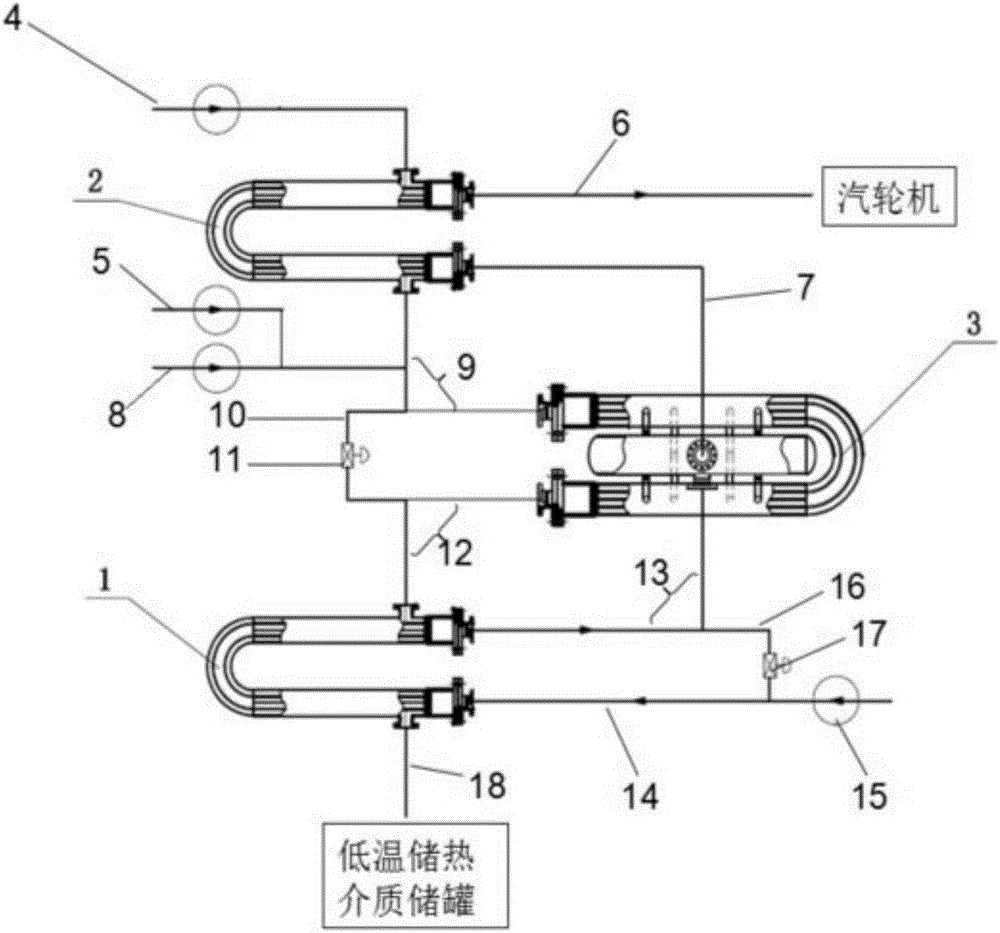

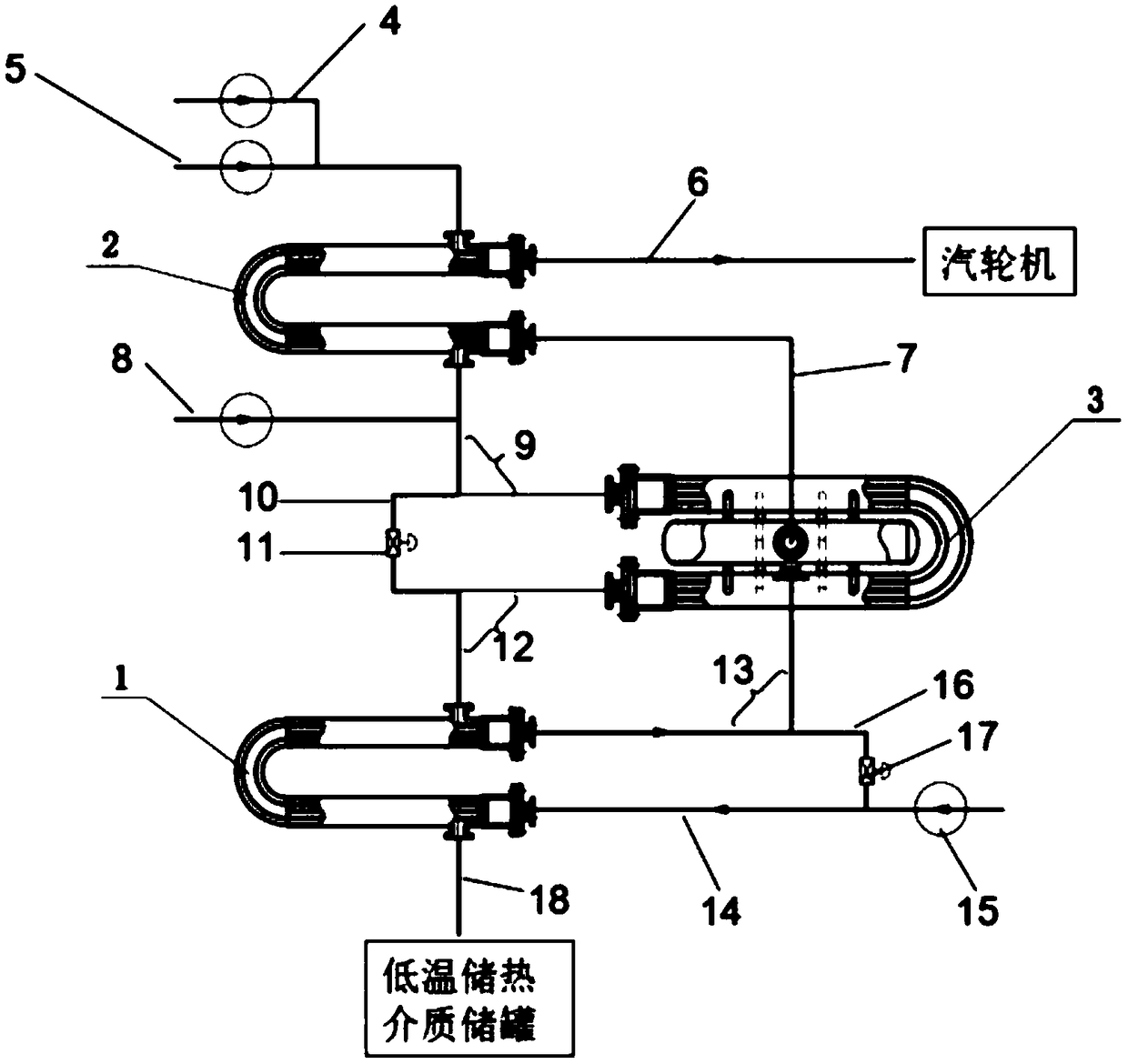

Heat exchange system

ActiveCN105823246ARegulating loadEasy loadingSolar heating energyHeat transfer optimizationSuperheaterEngineering

The invention discloses a heat exchange system. The heat exchange system comprises a first high-temperature heat storage medium conveying pipeline, a first low-temperature heat storage medium conveying pipeline, a second high-temperature heat storage medium conveying pipeline, a preheater, an evaporator, a superheater, a water feeding device and a steam turbine. Compared with the prior art, the heat exchange system has the innovative points that by arranging the second high-temperature heat storage medium conveying pipeline, when a heat storage medium coming from the superheater is cooled after being subjected to heat exchange and consequently cannot meet the load demand of the heat exchange system, a high-temperature heat storage medium can be supplemented into the evaporator through the second high-temperature heat storage medium conveying pipeline, the temperature of the heat storage medium entering the evaporator is increased, and accordingly, the purpose of improving load of the heat exchange system is achieved.

Owner:ZHEJIANG SUPCON SOLAR TECHNOLOGY CO LTD

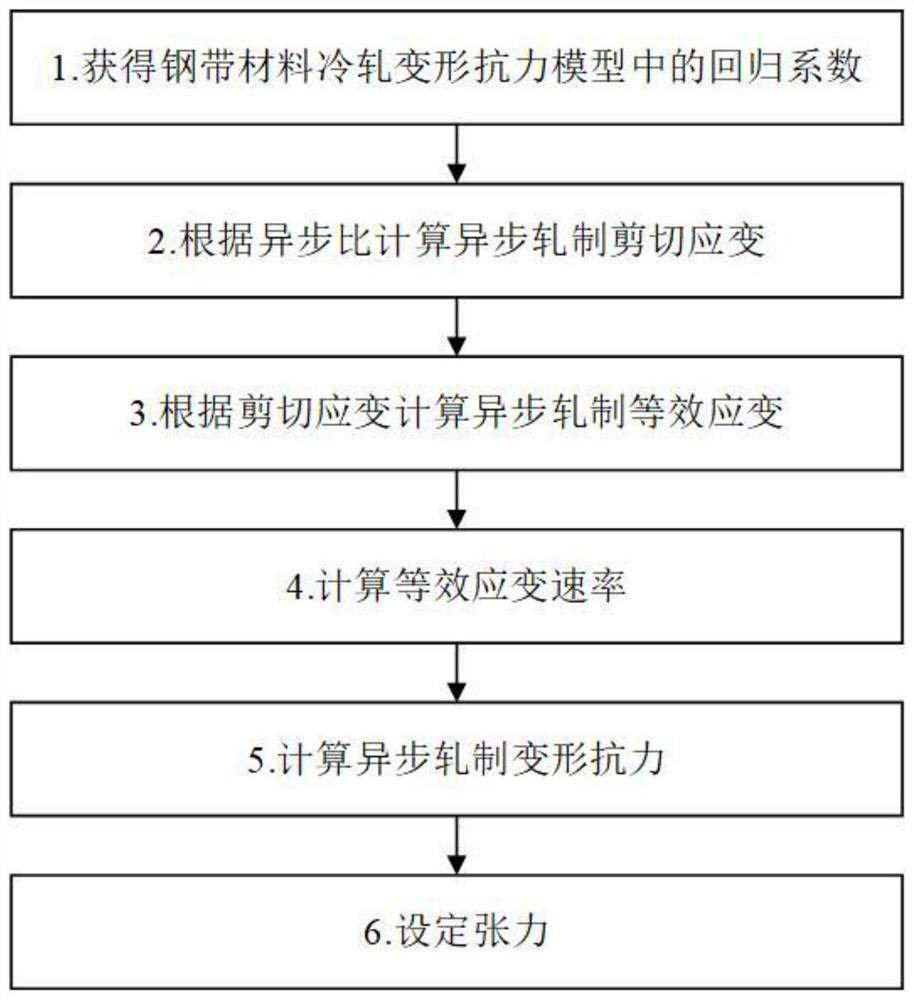

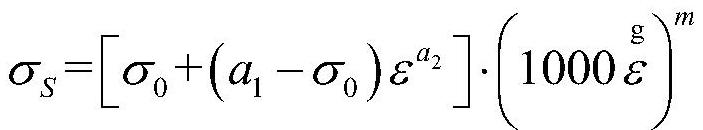

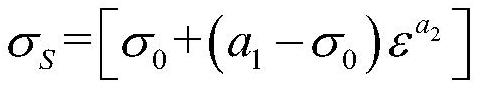

Tension distribution setting method in steel belt asynchronous cold continuous rolling process

PendingCN112131528AImprove calculation accuracyRegulating loadTension/compression control deviceComplex mathematical operationsSteel beltMechanics

The invention belongs to the technical field of rolling production, particularly relates to a tension distribution setting method in the steel belt asynchronous cold continuous rolling process, and solves the problem that a mathematical model and a calculation method for tension distribution in the asynchronous cold continuous rolling process are lacked in the prior art. The method includes: obtaining a regression coefficient related to a steel strip material in the cold continuous rolling deformation resistance mathematical model according to a conventional rolling experiment, and calculatinga tension distribution set value according to parameters such as the radius of a roller at each rack, the linear speed of the roller and the thickness of the strip before and after rolling in the cold continuous rolling process and the regression coefficient, so as to achieve the purposes of accurately setting tension parameters in the steel belt asynchronous rolling process, adjusting loads of all racks and stabilizing the rolling process.

Owner:NORTHEASTERN UNIV

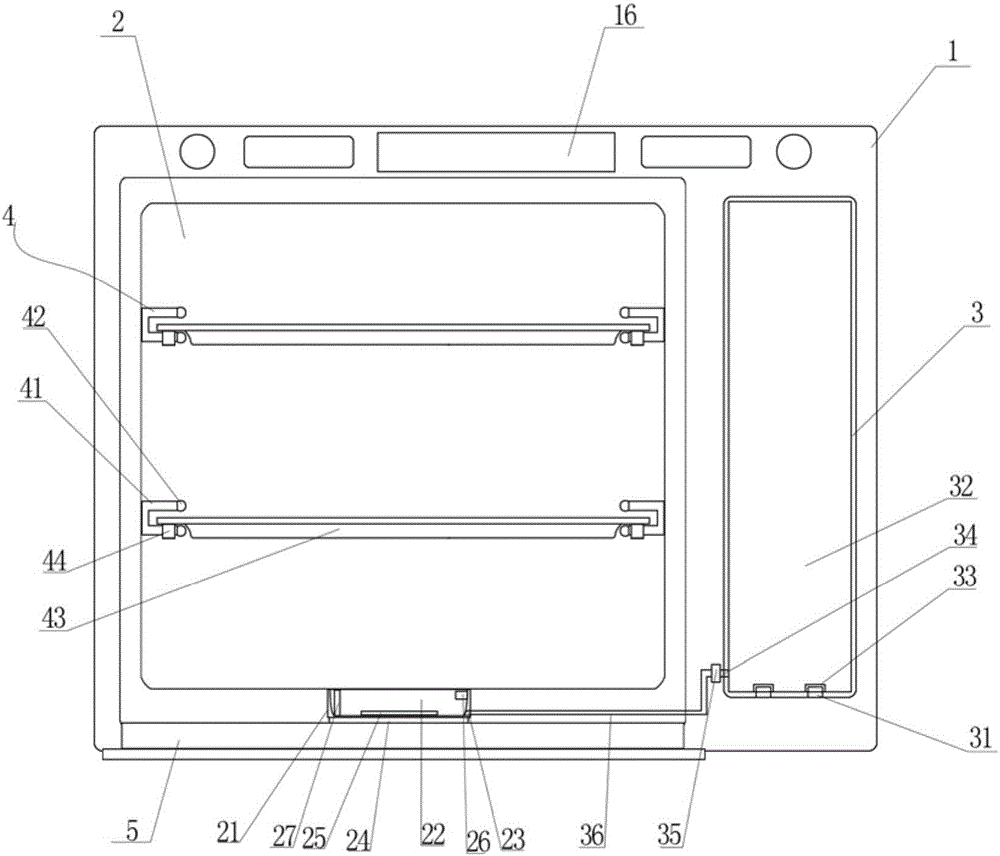

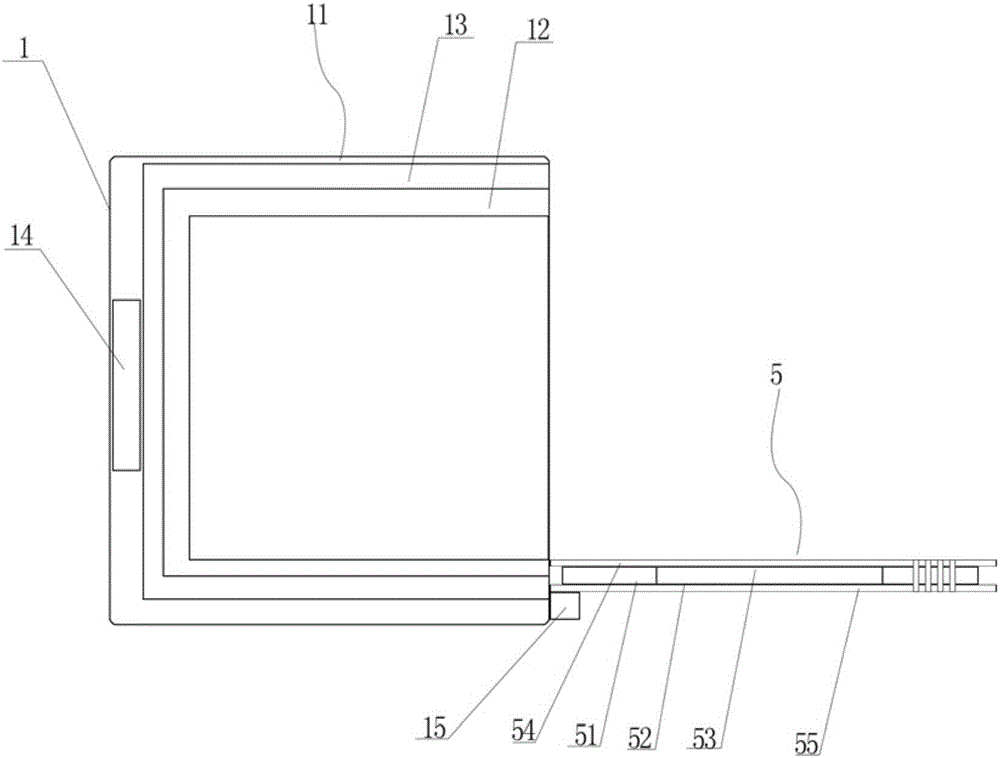

Embedded electric steaming box

InactiveCN106724770AReduce power consumptionReduce lossSteam cooking vesselsWarming devicesEngineeringWater tanks

The invention discloses an embedded electric steaming box comprising a box body and a box door which is installed at one side of the box body; the box body is provided with a steaming chamber therein; a heat insulation assembly is arranged between the steaming chamber and the box body; a part, positioned at one side of the steaming chamber, of the box body is provided with a groove; the groove is provided with a water tank therein; the bottom of the groove is provided with two parallel guide rails; the bottom of the water tank is provided with slideways which are corresponding to the guide rails; the water tank is installed in the groove through the slideways being embedded in the guide rails; one end of the bottom of the water tank is provided with a water outlet; the bottom of the steaming chamber is provided with a circular groove; the circular groove is provided with a heating plate therein; the bottom of one side surface of the heating plate is provided with a hidden water filling opening; the water outlet is provided with a water pump; the hidden water filling opening is connected with the water outlet through a pipeline; the bottom of the heating plate is provided with a heater; the heating plate is provided with a Hall element water level detector and a probe type water level detector; the box body is provided with a controller therein; the controller is connected with the Hall element water level detector, the probe type water level detector and the water pump; the steaming chamber is provided with a steaming plate assembly therein.

Owner:SUZHOU HEMEI ELECTRIC APPLIANCE TECH CO LTD

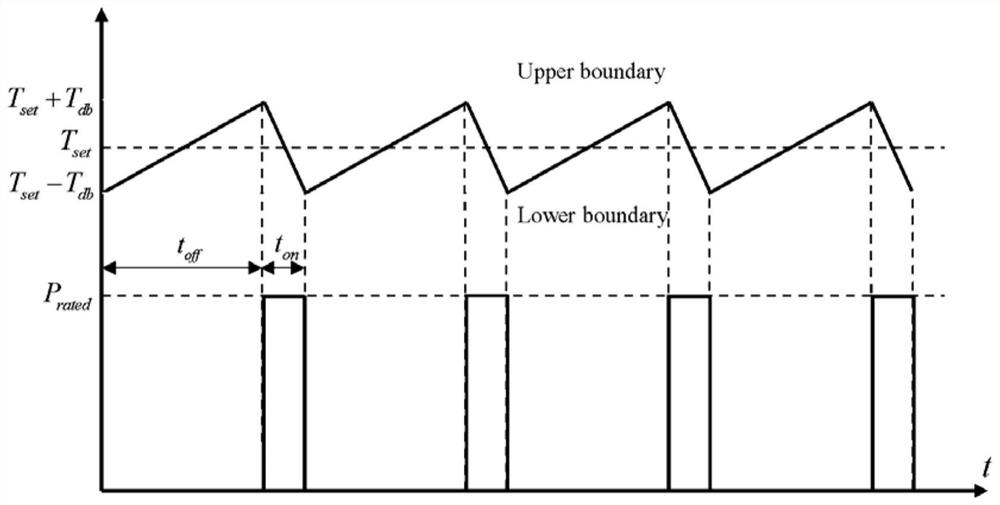

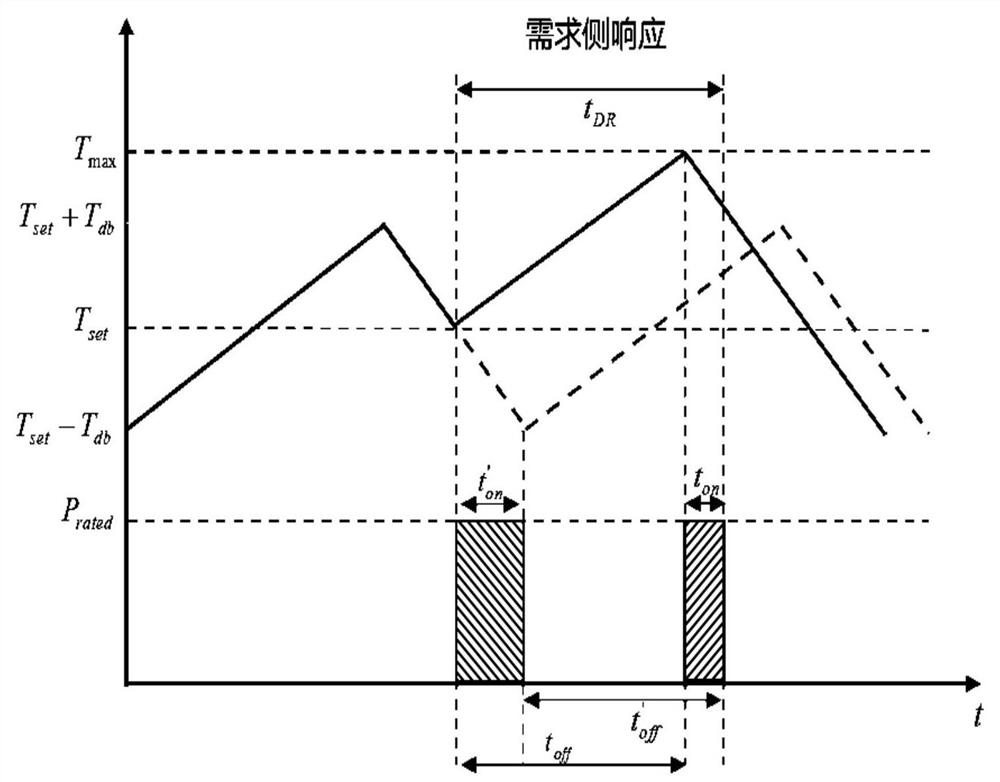

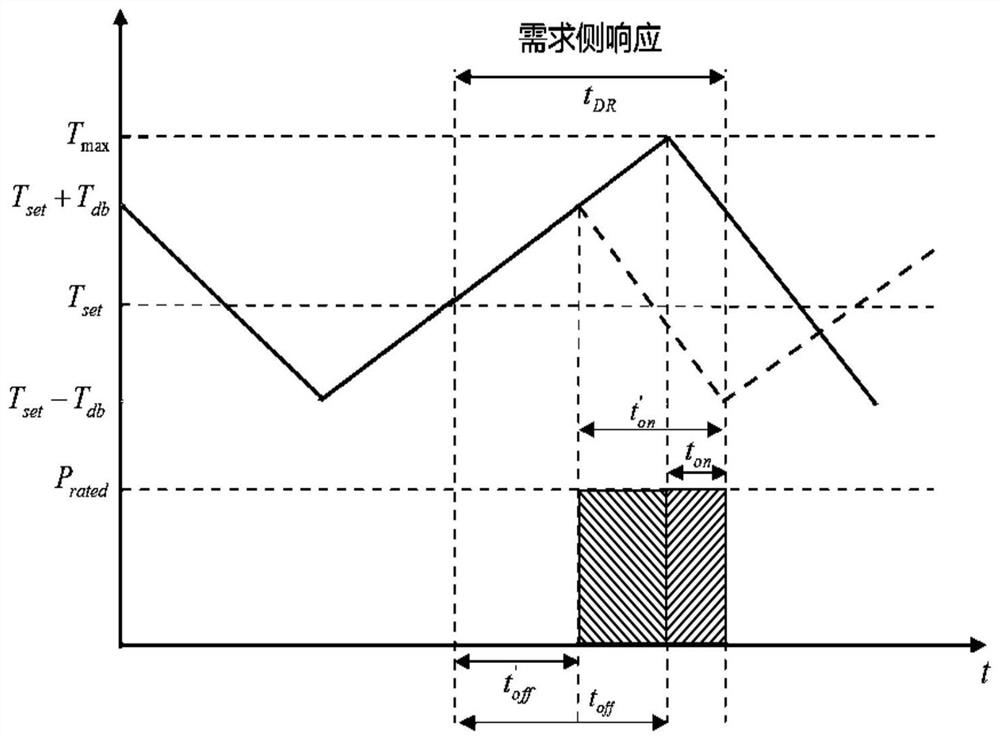

Method for evaluating adjustability of air conditioning unit participating in demand side response

PendingCN113988560ARegulating loadReduce power consumptionDesign optimisation/simulationResourcesControl engineeringPower grid

The invention discloses a method for evaluating the adjustability of an air conditioning unit participating in demand side response. The method comprises the steps of building an indoor thermodynamic model; under the condition that the single air conditioner participates in the demand side response and does not participate in the demand side response, calculating the operation time and standby time of the single air conditioner according to the initial state of the single air conditioner; comparing the running time not participating in the demand side response and within the duration of the demand side response with the running time participating in the demand side response and within the duration of the demand side response; calculating the adjustability of the single air conditioning unit by combining the cooling power and the energy efficiency ratio of the air conditioning unit, the sum of the adjustability of all air conditioners in the air conditioning unit being the total adjustable capacity; and regulating and controlling the total adjustability on the aspect of power grid control. According to the invention, the adjustability of the air conditioning unit is accurately evaluated, and the high efficiency that the air conditioning unit participates in demand side response is achieved.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD HANGZHOU POWER SUPPLY CO

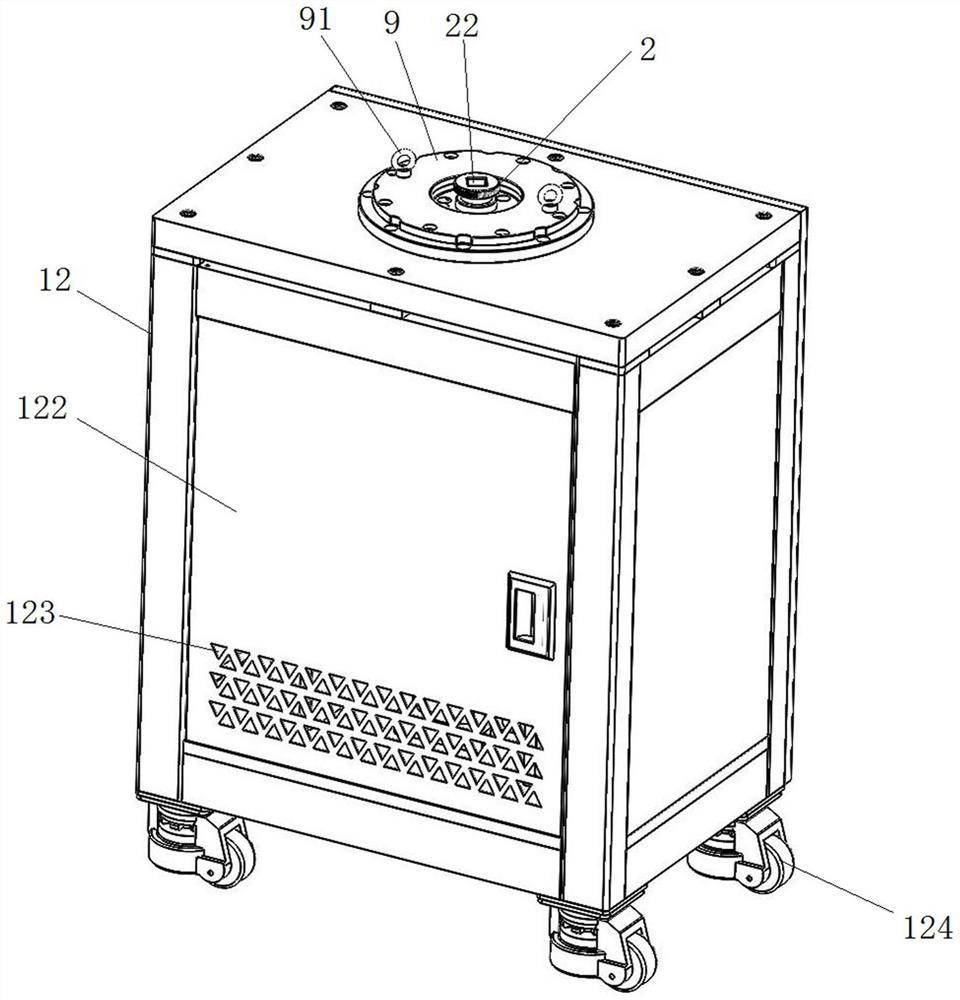

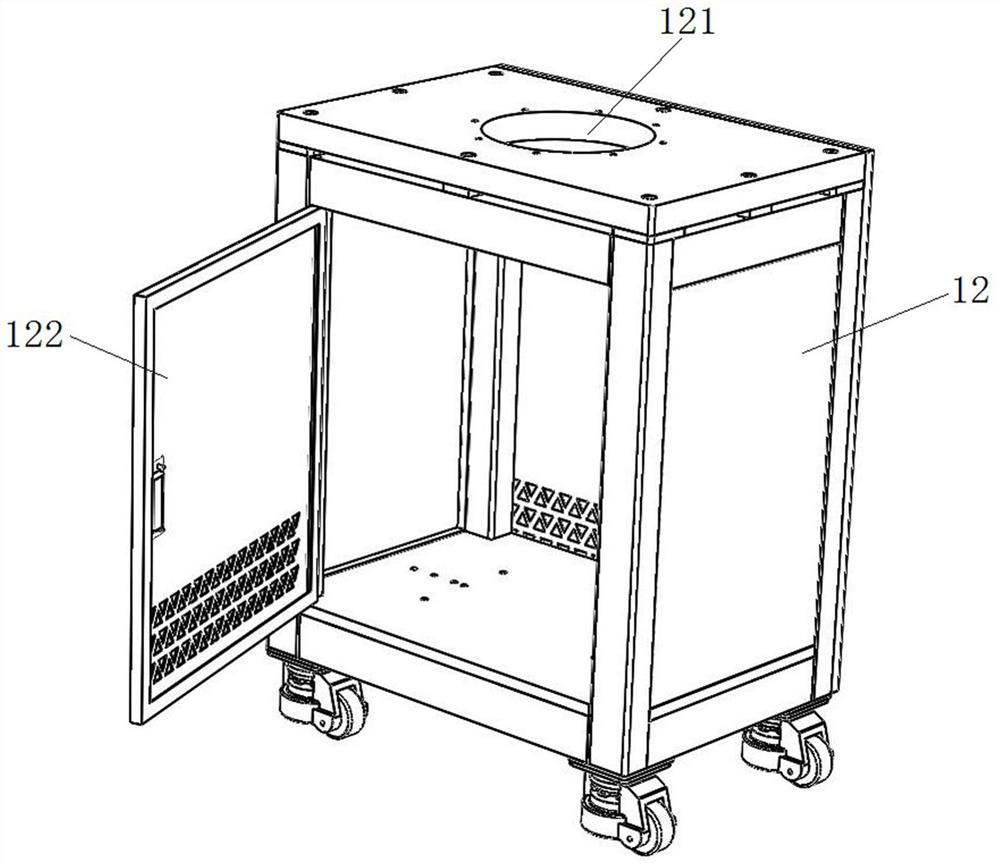

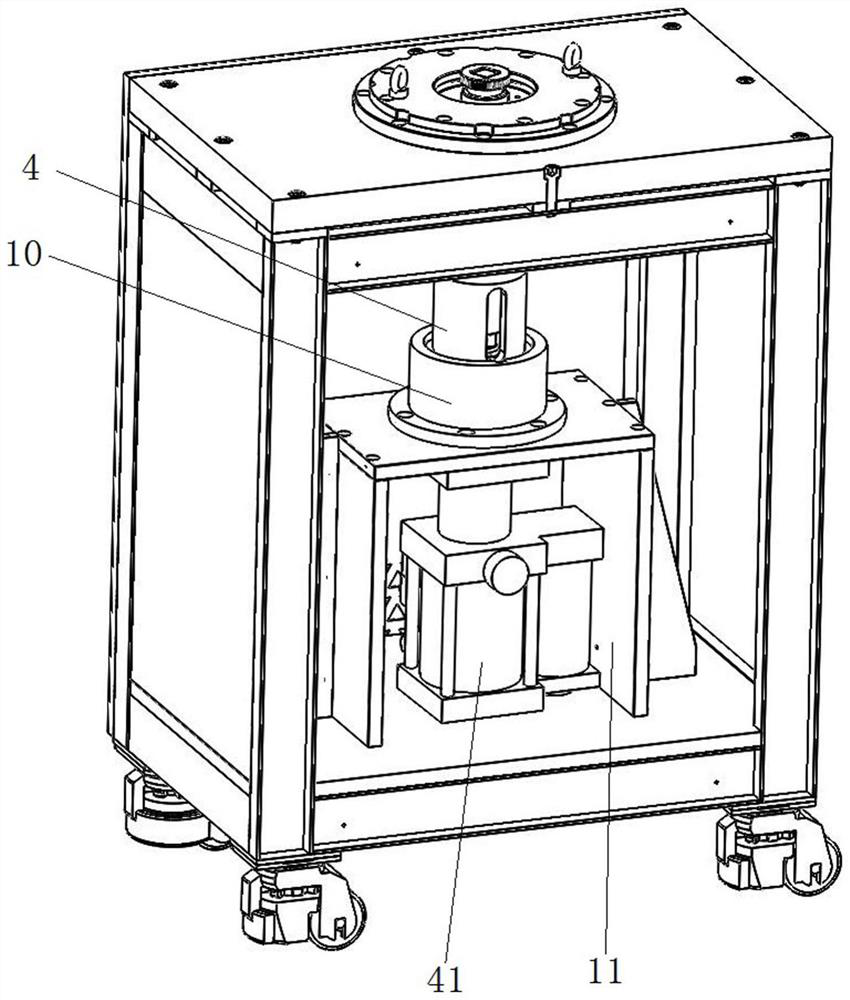

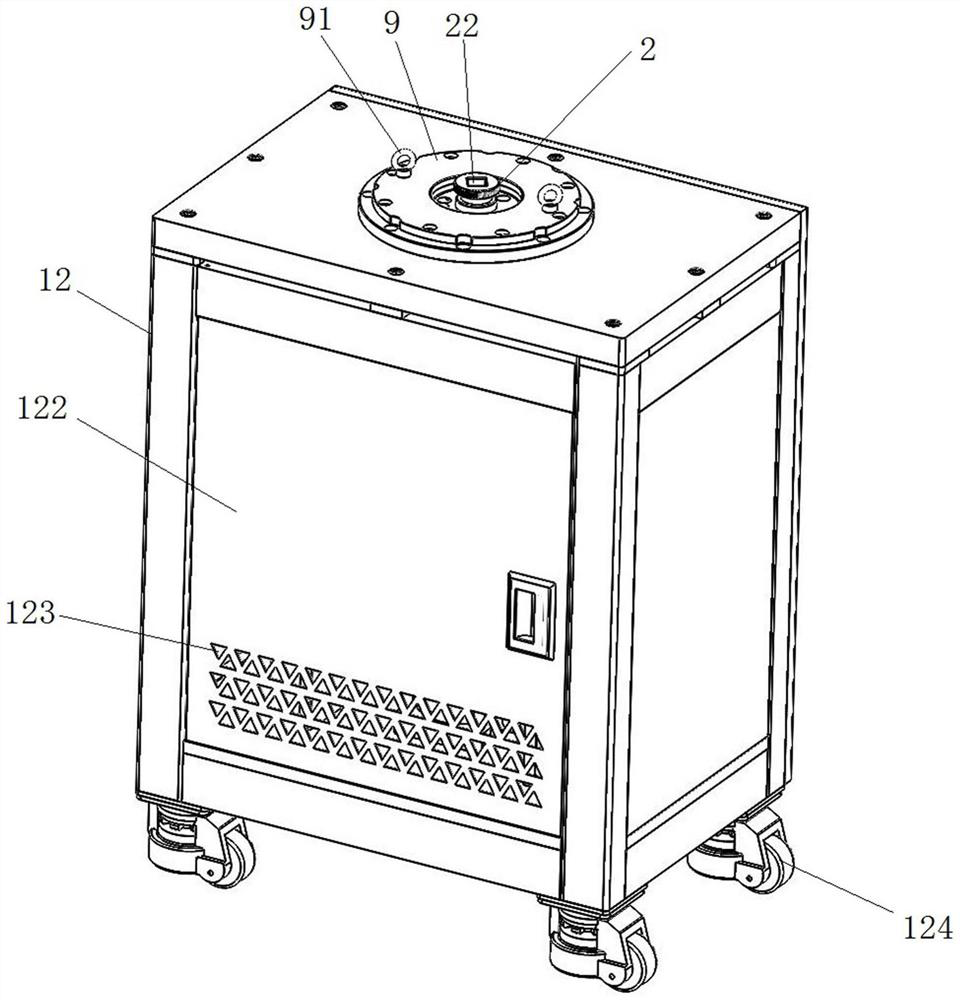

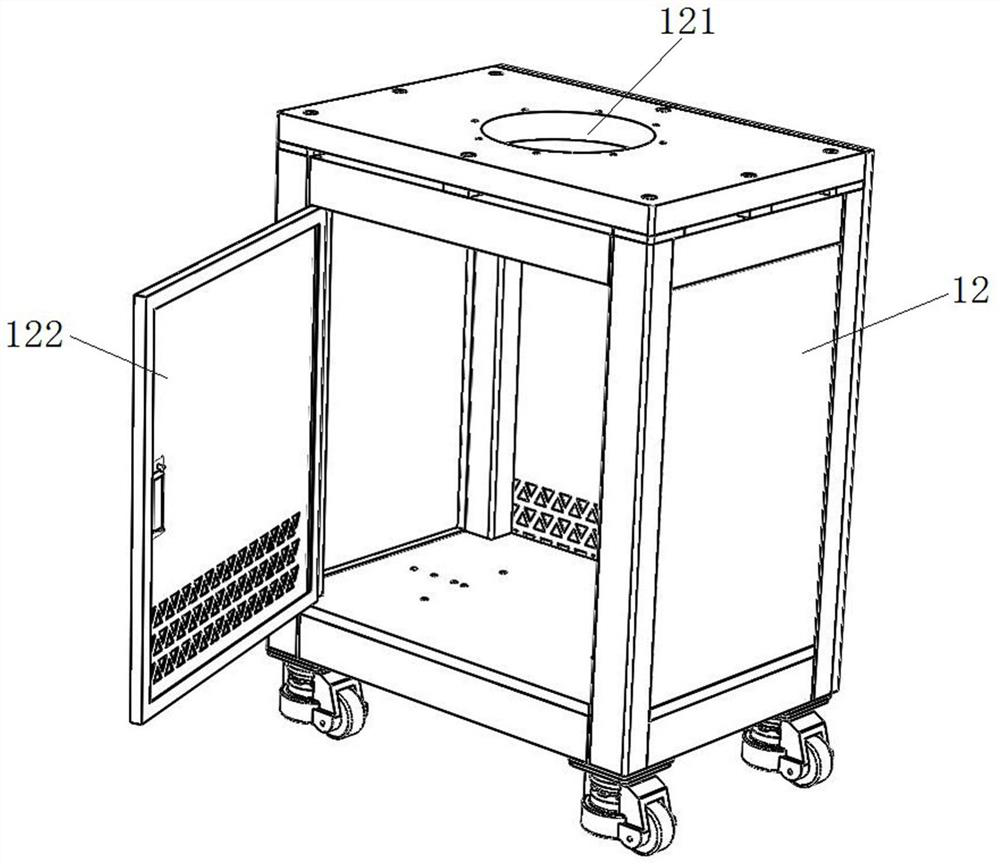

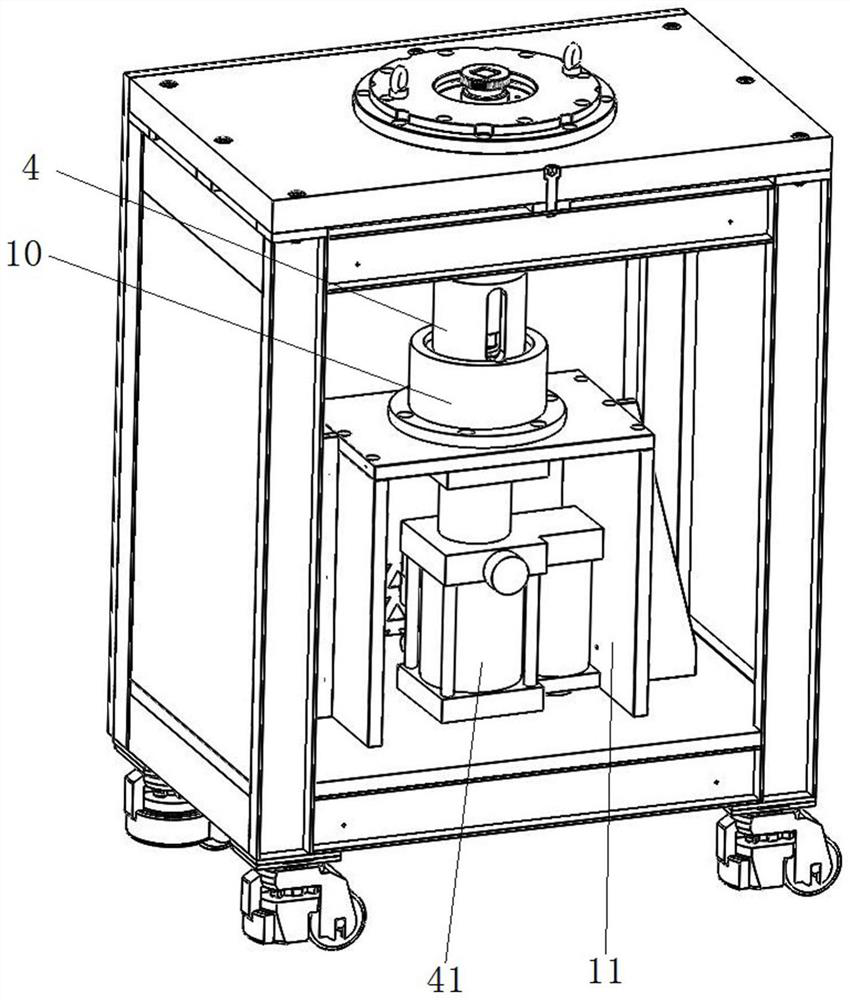

Portable torque wrench online detection device

ActiveCN113324698AHigh measurement accuracyHigh precision measurementForce/torque/work measurement apparatus calibration/testingPhysicsTorque sensor

The invention discloses a portable torque wrench online detection device. The portable torque wrench online detection device comprises a box body and a torque wrench detection device; the torque wrench detection device comprises a fixed outer sleeve and a rotary inner sleeve assembly, an elastic assembly is arranged in the rotary inner sleeve assembly, and a rotary lifting assembly is assembled at the top end of the rotary inner sleeve assembly in a threaded mode; and a lifting loading mechanism is arranged below the elastic assembly, a torque sensor is arranged in the lifting loading mechanism, and torque transmission assemblies are assembled in the rotary inner sleeve assembly and the lifting loading mechanism in an up-down sliding mode. According to the invention, the torque sensor is arranged in the lifting loading mechanism, the torque of the rotary lifting assembly is transmitted to the torque sensor through the torque transmission assemblies, and the torque sensor does not transmit force, so that the lifting loading mechanism does not affect the torque sensor when loading the elastic assembly; therefore, the torque sensor does not need to be mounted and dismounted during torque detection, and the detection is convenient.

Owner:河北省计量监督检测研究院廊坊分院

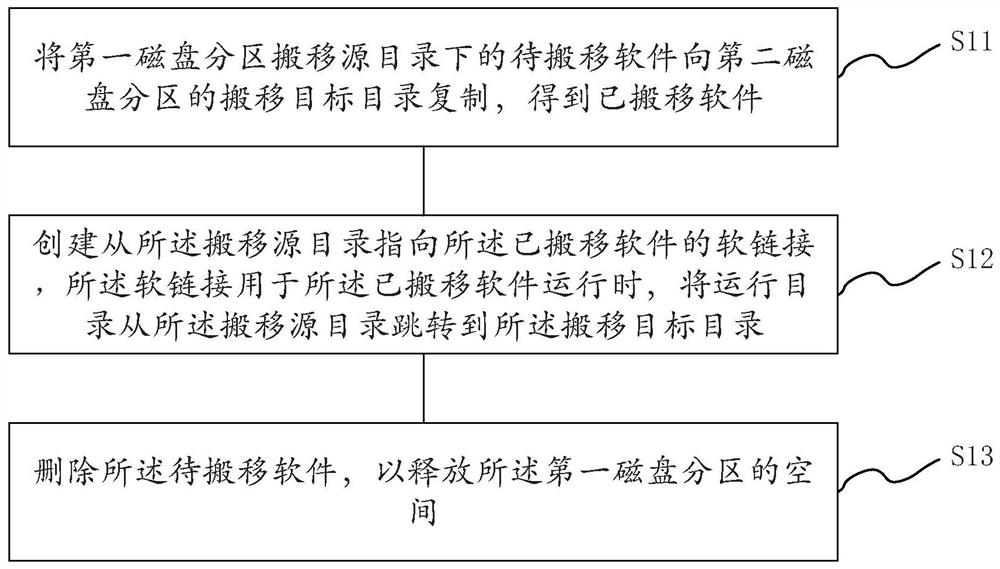

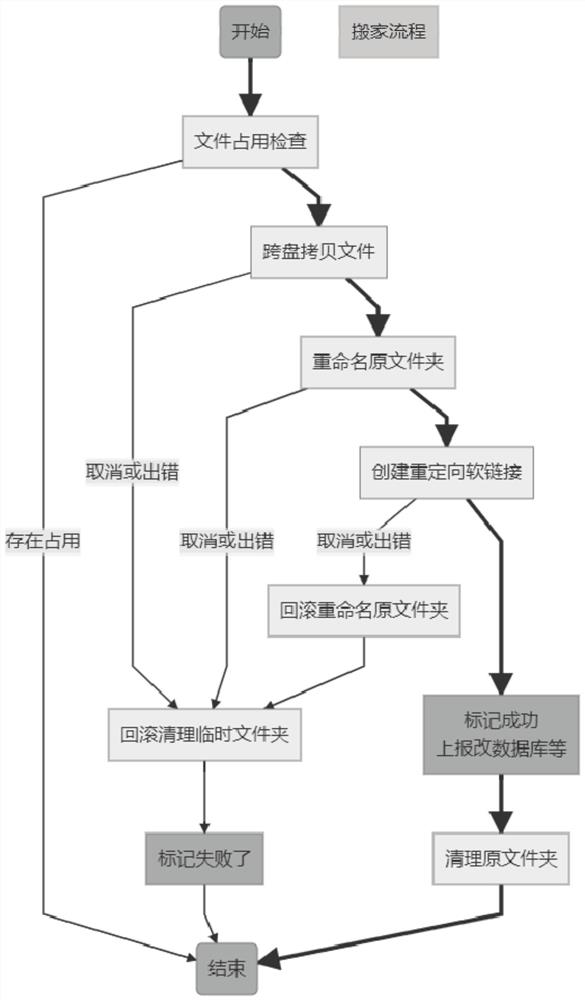

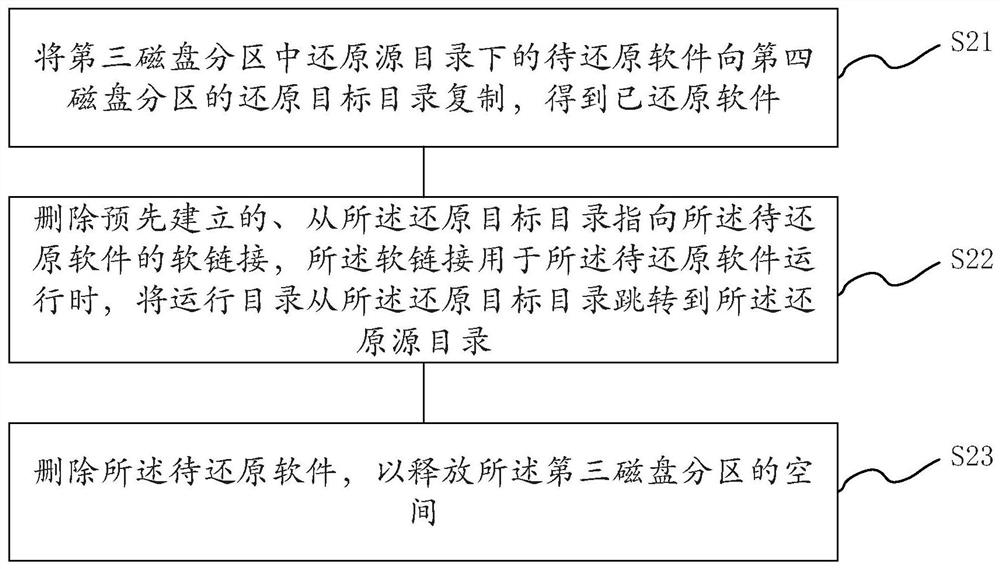

Software migrating method, and method and device for restoring migrated software

PendingCN112799600ARegulate Disk LoadImprove system operating efficiencyInput/output to record carriersMagnetic disksDirectory

The embodiment of the invention discloses a software migrating method and a method and device for restoring migrated software, relates to the technical field of computers, and aims to effectively adjust the disk load and improve the system operation efficiency. The migrating method comprises the following steps: copying to-be-migrated software in a migration source directory of a first disk partition to a migration target directory of a second disk partition to obtain migrated software; creating a soft link pointing to the migrated software from the migration source directory , wherein the soft link is used for skipping a running directory from the migration source directory to the migration target directory when the migrated software runs; and deleting the to-be-migrated software to release the space of the first disk partition. The method can be used in the computer technology.

Owner:ZHUHAI BAOQU TECH CO LTD

Strengthening system and process for preparing polyethylene based on solution method

InactiveCN112500510AFully contactedIncreased phase boundary areaLiquid-gas reaction processesMass transfer resistanceEmulsion

The invention relates to a strengthening system and process for preparing polyethylene based on a solution method. The strengthening system comprises an ethylene storage tank, a reactor, a micro-interface generator, a killer, a solvent removal tank, a rectifying tower, a flash tank, a separation tank, a first drying tower and a second drying tower. According to the invention, ethylene is crushed to form micron-sized bubbles, and the micron-sized bubbles are mixed with a solvent to form a gas-liquid emulsion, so that the phase interface area of a gas phase and a liquid phase is increased, the thickness of a liquid film is reduced, the mass transfer resistance is reduced, and the mass transfer effect is enhanced within a lower preset operation condition range; and meanwhile, all the micron-sized bubbles can be fully mixed with the solvent to form the gas-liquid emulsion, and ethylene and an initiator in the system can be in full contact with the solvent by fully mixing gas and liquid phases, so that the polymerization efficiency of the system is further improved.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

Natural-gas low-temperature helium extracting system and method

ActiveCN102937369BRich adjustment meansIncrease operating pressureSolidificationLiquefactionHigh concentrationNitrogen

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Process for carrying out strengthening circulation, stage grinding and quality improvement on lignite by utilizing superheated steam and system thereof

ActiveCN101870897BOptimize energy distributionMaximize energy utilizationCombination devicesDrying solid materials with heatFlue gasProcess engineering

The invention relates to a process for carrying out strengthening circulation, stage grinding and quality improvement on lignite by utilizing superheated steam and a system thereof. The method comprises the following steps: (1) carrying out grinding on the raw material lignite; (2) burning one part of coal blocks / powder to produce high-temperature flue gas serving as a heat source and carrying out air separation and dring on the other part of coal blocks / powder requiring to be subjected to quality improvement; (3) in the process of air separation, adopting the high-temperature flue gas from the step (2), carrying out drying, separation and dust removal on the qualified coal blocks / powder conforming to the standard grain diameter after air separation, collecting the qualified coal blocks / powder, sending the qualified coal blocks / powder to the forming process, making the unqualified coal blocks / powder drop in a grinding ventilating device to carry out grinding and drying, then continuously completing deep drying by air separation and repeating the steps, wherein the oxygen content in the flue gas is less than 8 percent; and (4) sending one path of waste gas subjected to air separation and drying to the washing process and returning the other path of waste gas serving as a return tail gas part to the step (2) so as to prepare the high-temperature flue gas and carry out air separation. The process has the advantages of safety, energy saving, environment protection, high efficiency, stability and the like.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

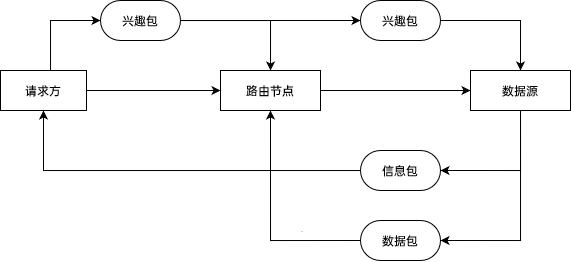

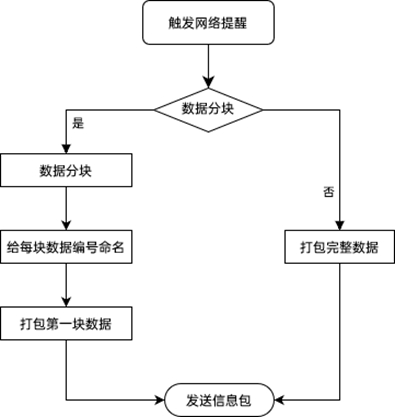

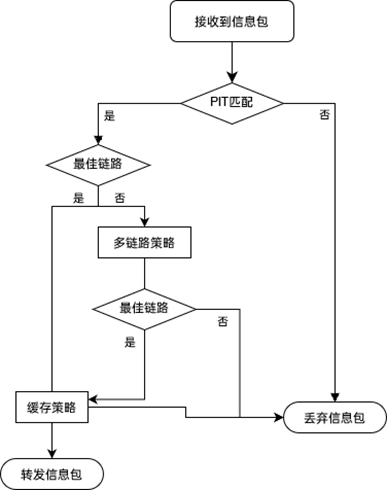

A method and system for marine buoy-oriented cooperative multi-point active cache networking

ActiveCN114401317BImprove transmission efficiencyRegulating loadNetwork traffic/resource managementTransmissionData packInformation transmission

The invention belongs to the field of digital information transmission, and in particular relates to a method and system for a multi-point cooperative active cache networking oriented to marine buoys. The method includes: obtaining a request instruction from a requester, and sending a data packet related to the request instruction to the requester and a backup node according to the request instruction; if the backup node receives the request instruction from other requesters, sending the Packets are returned to other requesters. The invention can not only perform free networking of marine edge nodes and active data packet buffering more actively, but also can efficiently utilize marine edge nodes, reduce data transmission delay, and improve overall system robustness.

Owner:SHANDONG COMP SCI CENTNAT SUPERCOMP CENT IN JINAN

a heat exchange system

ActiveCN105823246BRegulating loadEasy loadingSolar heating energySolar heat collector controllersSuperheaterEngineering

The invention discloses a heat exchange system. The heat exchange system comprises a first high-temperature heat storage medium conveying pipeline, a first low-temperature heat storage medium conveying pipeline, a second high-temperature heat storage medium conveying pipeline, a preheater, an evaporator, a superheater, a water feeding device and a steam turbine. Compared with the prior art, the heat exchange system has the innovative points that by arranging the second high-temperature heat storage medium conveying pipeline, when a heat storage medium coming from the superheater is cooled after being subjected to heat exchange and consequently cannot meet the load demand of the heat exchange system, a high-temperature heat storage medium can be supplemented into the evaporator through the second high-temperature heat storage medium conveying pipeline, the temperature of the heat storage medium entering the evaporator is increased, and accordingly, the purpose of improving load of the heat exchange system is achieved.

Owner:ZHEJIANG SUPCON SOLAR TECHNOLOGY CO LTD

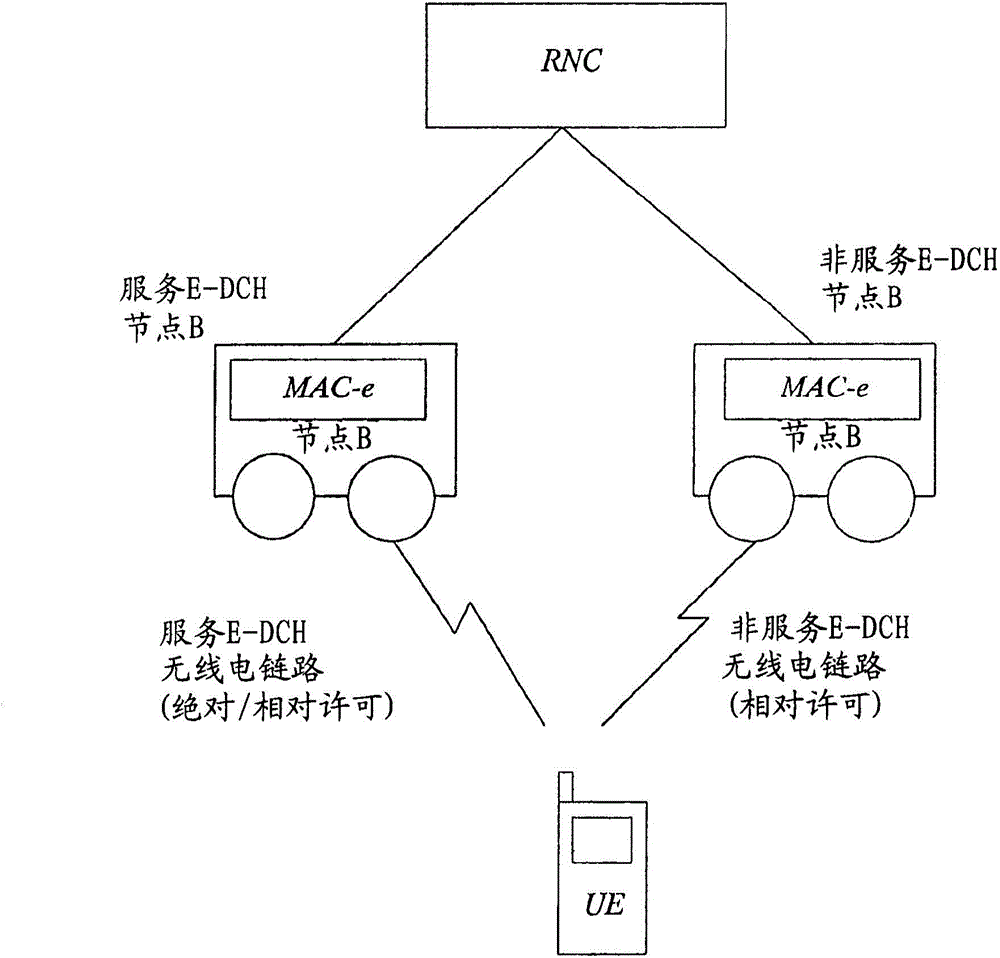

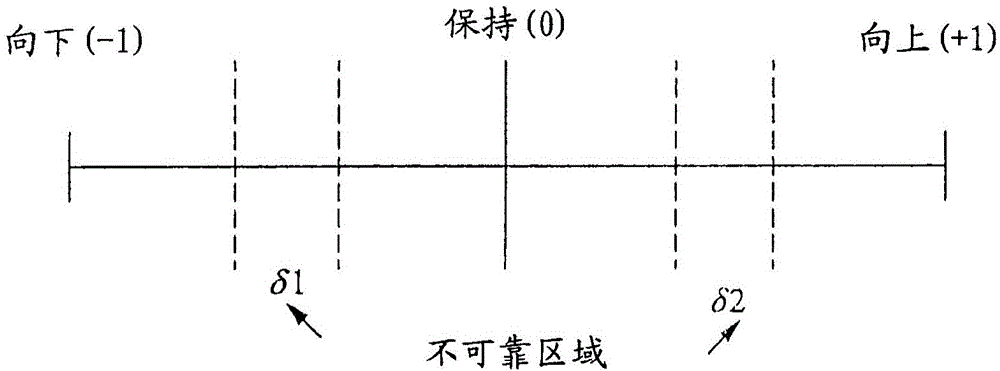

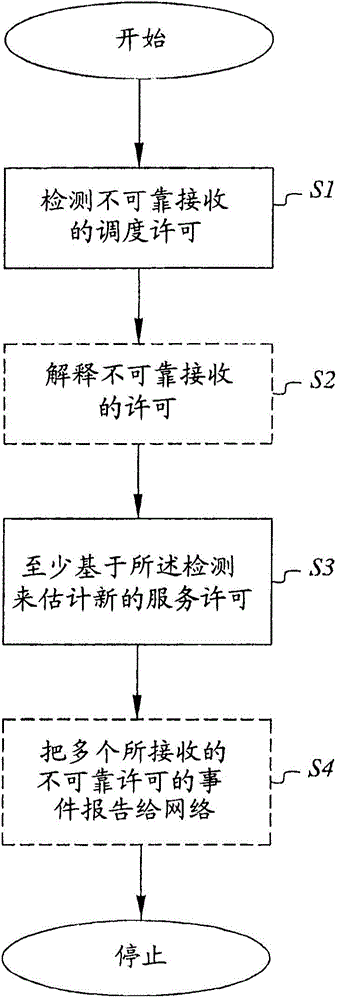

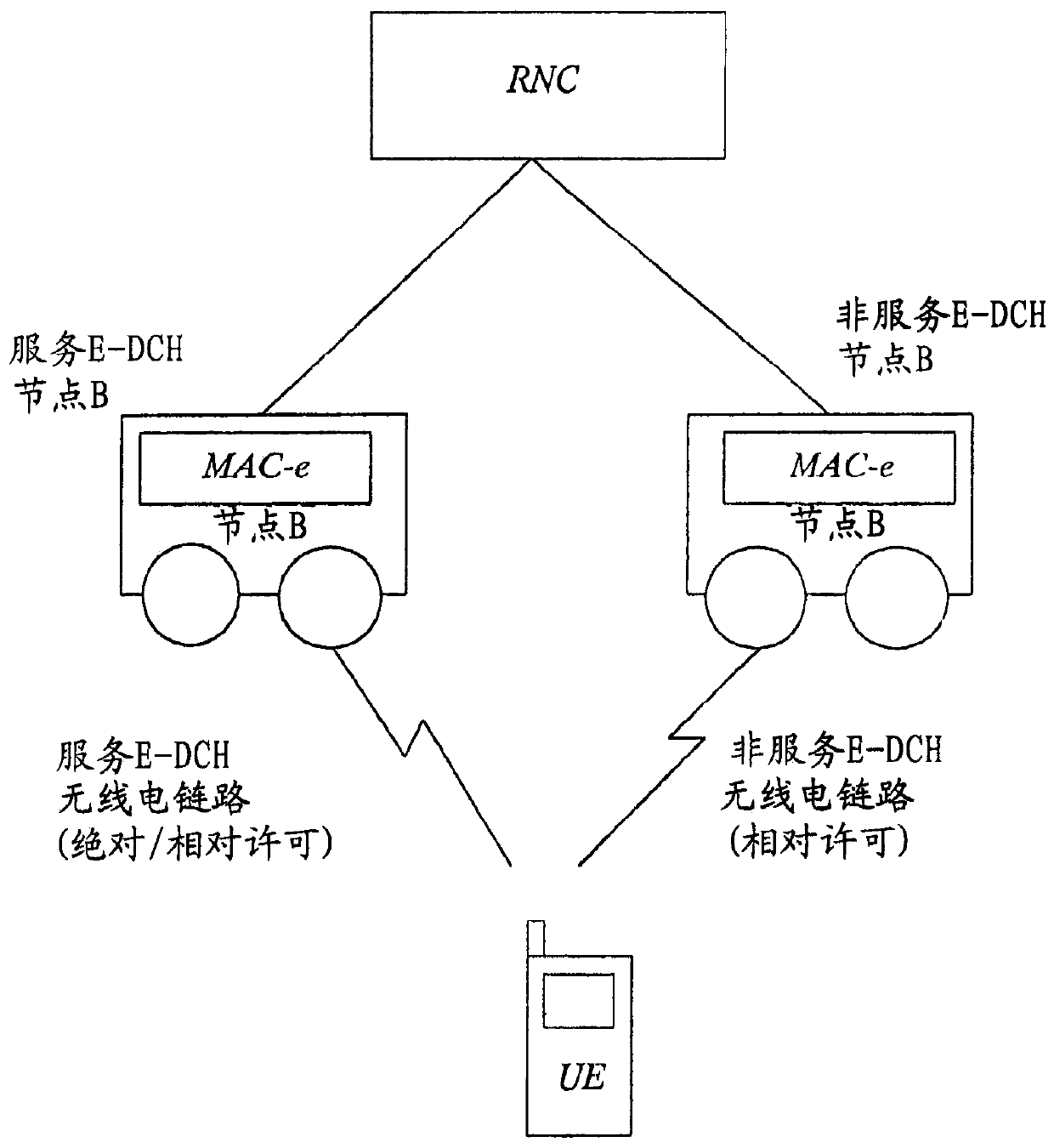

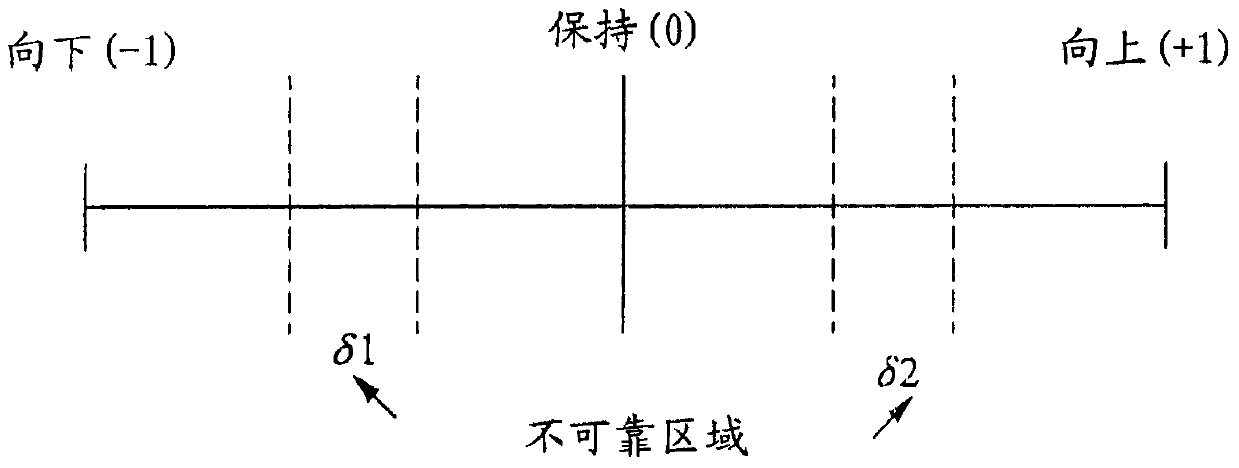

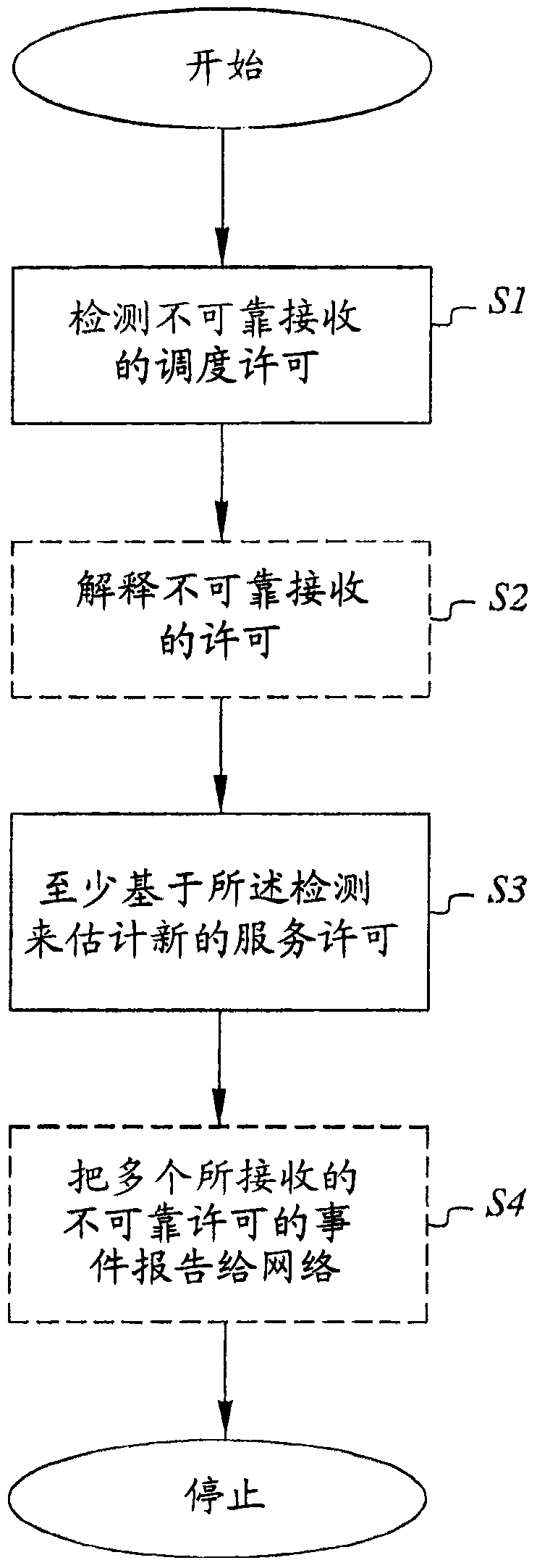

Methods And Arrangements For Handling Unreliable Scheduling Grants In A Telecommunication Network

ActiveCN104869657AAvoid interferenceAdjust power offsetPower managementNetwork traffic/resource managementTelecommunications networkCommunications system

The present invention relates to methods and arrangements for handling unreliable scheduling grants in a WCDMA-communication system. A user equipment detects that a received scheduling grant is unreliable and adjust its serving grant based on that information. The user equipment is also able to report continuously received unreliable grants as an event to the network, allowing the network to adapt its operation to reduce the unreliable grants.

Owner:TELEFON AB LM ERICSSON (PUBL)

A kind of air circulation cross-section adjustment device

ActiveCN103574634BRegulating loadEfficient mixingAir supply regulationGaseous fuel burnerCombustorAir volume

The invention discloses an air circulation cross-section adjusting device comprising a shell. The shell is provided with an air inlet and an air outlet, the air inlet is provided with an air adjusting door, a driving device, a driving crank, a crank connecting rod, a linkage crank, a moving part pull rod and a moving part are arranged inside the shell, the air adjusting door is connected with the driving device, one end of the driving crank is connected with the driving device, the other end of the driving crank is connected with the linkage crank through the crank connecting rod, and the linkage crank is connected with the moving part through the moving part pull rod. The air outlet is provided with an inclined reducing adjusting device, and the top end of the moving part is inserted into the inclined reducing adjusting device. The inclined reducing adjusting device is in the shape of a tube with taper. The air circulation cross-section adjusting device has the advantages that when combustor load adjustment is performed, air inlet amount is adjusted along with opening and closing of an air door plate of the air inlet, and size of the cross section of an air outlet of a flame tube can be adjusted synchronously, so that air speed at the flame tube is ensured to be basically unchanged during combustor load changing in size.

Owner:江阴德尔热能机械有限公司

Mechanical synthesizer of rotational speed and torque

InactiveCN103047373BTo achieve composite outputReduce capacityToothed gearingsMechanical energy handlingPower gridControl theory

Owner:张万璐

Novel process for making synthetic natural gas by using coke-oven gas

ActiveCN101818087BAvoid poisoningPrevent "flying temperature" phenomenonGaseous fuelsMethanationHydrodesulfurization

The invention belongs to the field of the comprehensive utilization of coke-oven gas, and discloses a novel process for making synthetic natural gas by using the coke-oven gas. The qualified synthetic natural gas product is produced by the process comprising the steps of hydrodesulfurization, carbon compensation, multi-level methanation, cooling, separation and the like. The process can effectively prevent the temperature runaway phenomenon of a methanation reactor, can reasonably distribute the load of the methanation reactor, improves the conversion rate of CO and CO2, and provides a new method for making the synthetic natural gas by using the coke-oven gas.

Owner:NANJING GOODCHINA CHEM TECH

Catalytic Partial Oxidation of Natural Gas and Carbon Dioxide Mixture to Syngas

The invention relates to a process for preparing synthesis gas through catalytic partial oxidation of natural gas and carbon dioxide mixed gas. The process comprises the following steps: dividing natural gas into two parts, wherein the first part of the natural gas is mixed with medium pressure steam and a first part of CO2 gas and is converted in a one-stage converter after heat exchange, and the second part of the natural gas is mixed with outlet converted gas of the one-stage converter and continues to react in a two-stage converter; outlet converted gas of the two-stage converter is transmitted to downstream side after condensate and CO2 are sequentially separated out of the outlet converted gas; the separated CO2 is compressed and then divided into two parts, wherein the second part of CO2 gas is mixed with medium pressure steam after heat exchange and small particles are filtered, then the second part of the CO2 gas is mixed with pure oxygen; molar concentration of oxygen in a second mixer is controlled at 20-35% (a critical oxygen state, oxygen enriched is less than or equal to 23%, and critical oxygen is less than 23%, which are inconsistent); the CO2 gas participates in heat exchange on a convection section of the one-stage converter and is burned together with converted gas in the two-stage converter, so as to supply heat energy required by reactions in the two-stage converter. The process disclosed by the invention solves the problems that conventional natural gas steam reformed synthesis gas is relatively high in H2 / CO ratio and fails to meet a requirement of carbonyl synthesis gas on a hydrogen-carbon ratio.

Owner:SINOPEC NINGBO ENG +2

Portable torque wrench online detection device

ActiveCN113324698BRealize dynamic measurementGuaranteed rotational freedomForce/torque/work measurement apparatus calibration/testingTorque transmissionEngineering

The invention discloses a portable torque wrench online detection device, comprising a box body and a torque wrench detection device; the torque wrench detection device comprises a fixed outer sleeve and a rotating inner sleeve assembly, and an elastic assembly is arranged inside the rotating inner sleeve assembly, The top end of the rotating inner sleeve assembly is threadedly equipped with a rotating lifting assembly; a lifting loading mechanism is arranged below the elastic assembly, a torque sensor is arranged inside the lifting loading mechanism, and the inner parts of the rotating inner sleeve assembly and the lifting loading mechanism slide up and down Equipped with torque transfer components. In the present invention, the torque sensor is arranged inside the lifting and loading mechanism, and the torque of the rotating lifting assembly is transmitted to the torque sensor through the torque transmission component, and the torque sensor transmits torque but not force, and the lifting and loading mechanism does not load the elastic component. It affects the torque sensor, so there is no need to install and remove the torque sensor during torque detection, and the detection is very convenient.

Owner:河北省计量监督检测研究院廊坊分院

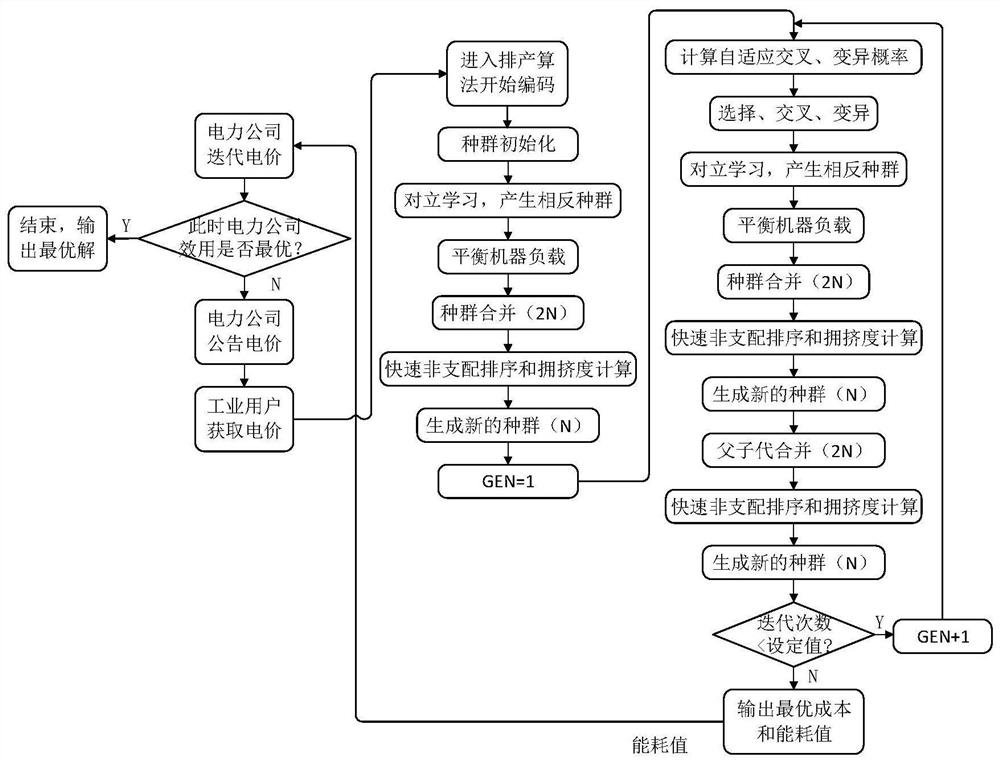

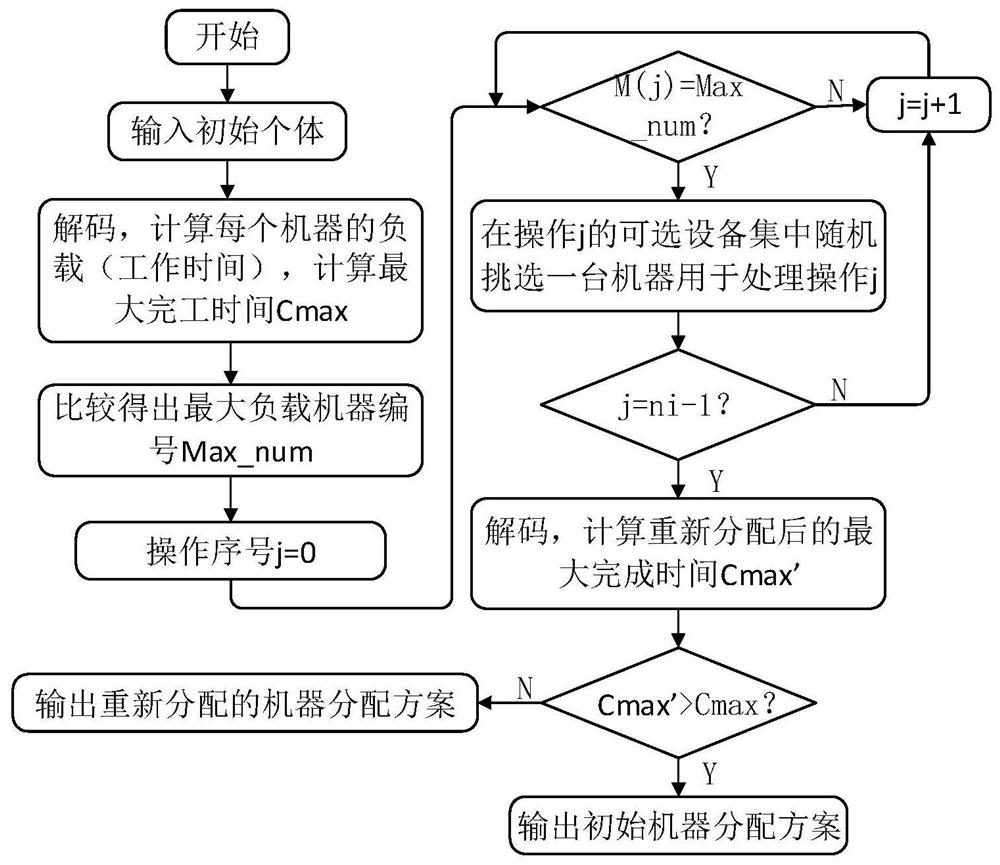

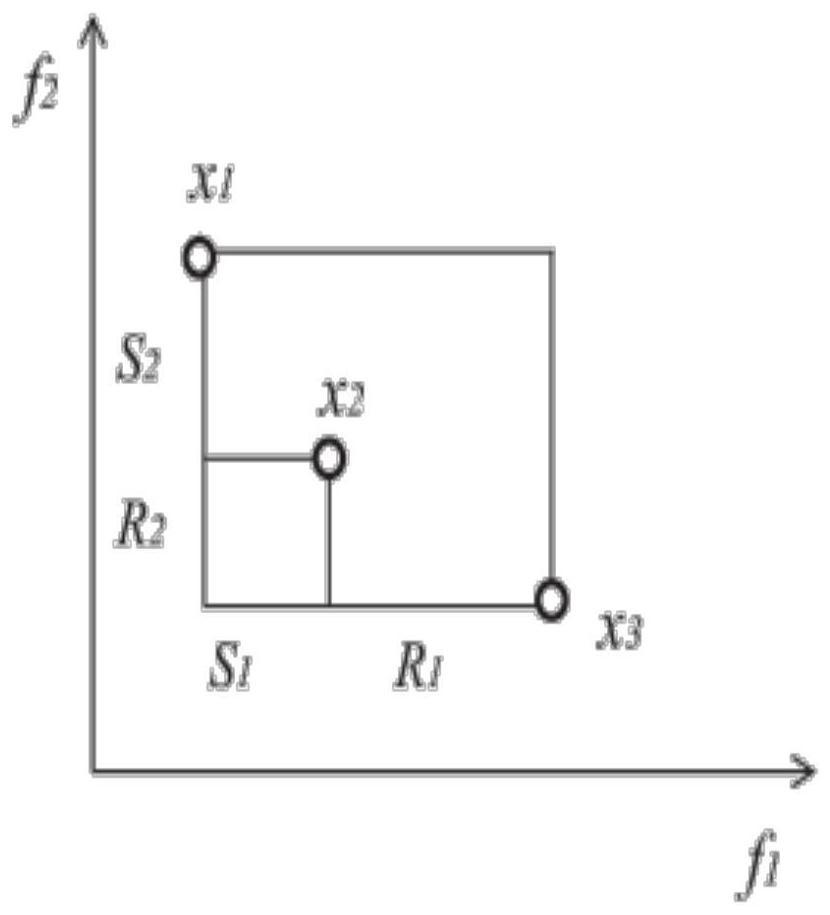

Flexible manufacturing workshop demand response scheduling method based on hierarchical game

PendingCN114118805ARegulating loadIncrease load factorEnergy industryArtificial lifeElectric power systemPower grid

The invention relates to a flexible manufacturing workshop demand response scheduling method based on a hierarchical game, which belongs to the technical field of production scheduling, and comprises the following steps: firstly, constructing a flexible manufacturing workshop production scheduling management and control model based on time-of-use electricity price, and then aiming at the convergence and diversity problems of an algorithm on the basis of an NSGA-II algorithm, establishing a flexible manufacturing workshop production scheduling management and control model; introducing an opposite learning strategy and a self-adaptive crossover and mutation probability strategy; for the problem of machine load balancing, a machine load balancing strategy is adopted. According to the invention, flexible manufacturing workshop production scheduling based on time-of-use electricity price and demand response plays an important role in adjusting the load of a power grid and improving the load rate and operation stability of a power system; and the energy consumption cost of flexible manufacturing production is effectively reduced through production scheduling.

Owner:YANSHAN UNIV

Method and arrangement for handling unreliable scheduling grants in a telecommunications network

InactiveCN104869657BAvoid interferenceAdjust power offsetPower managementNetwork traffic/resource managementTelecommunications networkCommunications system

The present invention relates to methods and arrangements for handling unreliable scheduling grants within a WCDMA communication system. The user equipment detects that the received scheduling permission is unreliable and adjusts its service permission based on this information. The user equipment is also able to report continuously received unreliable grants as an event to the network, allowing the network to adapt its operation to reduce unreliable grants.

Owner:TELEFON AB LM ERICSSON (PUBL)

A heat exchange system for solar thermal power generation system

ActiveCN105841368BRegulating loadIncrease temperatureSolar heating energySolar heat storageSuperheaterEngineering

The invention discloses a heat exchange system for a solar heat power generation system. The heat exchange system for the solar heat power generation system comprises a first high-temperature heat storage medium conveying pipeline, a preheater, an evaporator, a super heater, a water feeding device, a turbine and a first valve. Compared with the prior art, the heat exchange system for the solar heat power generation system has the characteristics that an eighth pipeline is provided with the first valve, the first valve can be opened when the load at the evaporator of the heat exchange system needs to be decreased so that heat storage media from the super heater can be shunted, one part of the heat storage media enter the evaporator, the other part of the heat storage media directly enter the preheater, then the amount of the heat storage medium entering the evaporator is made to be reduced, and accordingly the purpose of regulating the load of the heat exchange system is achieved.

Owner:ZHEJIANG SUPCON SOLAR TECHNOLOGY CO LTD

Display compensation circuit, display substrate, display device and driving method

ActiveCN109817148BRegulating loadAvoid uniformityStatic indicating devicesControl signalDisplay device

The invention discloses a display compensation circuit, a display substrate, a display device and a driving method, and belongs to the field of display technology. The display compensation circuit includes: a switch subcircuit; each of the switch subcircuits has an input terminal, an output terminal and a control terminal; the output terminal of the switch subcircuit is electrically connected to one of the first common electrodes; the switch subcircuit The circuit is configured to be turned on under the control of the control signal received by the control terminal, and to provide the compensation voltage signal received by the input terminal to the corresponding first common electrode when it is turned on. The display uniformity problem caused by the load difference between the first common electrode and the second common electrode is solved.

Owner:BOE TECH GRP CO LTD +1

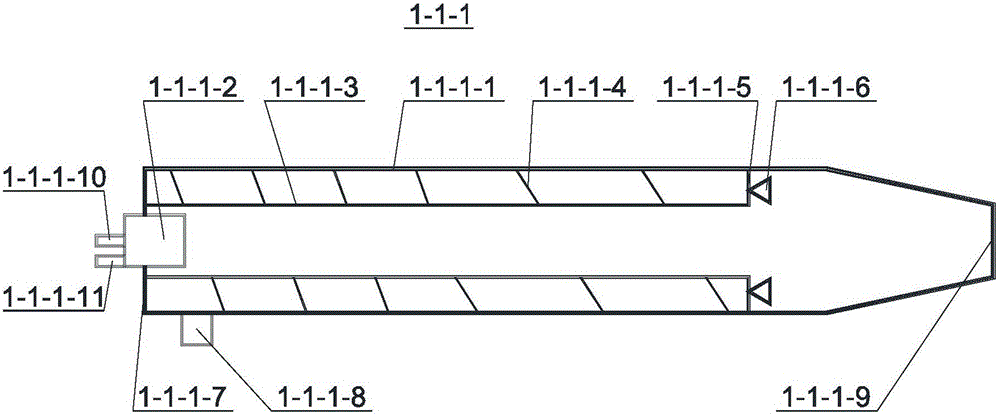

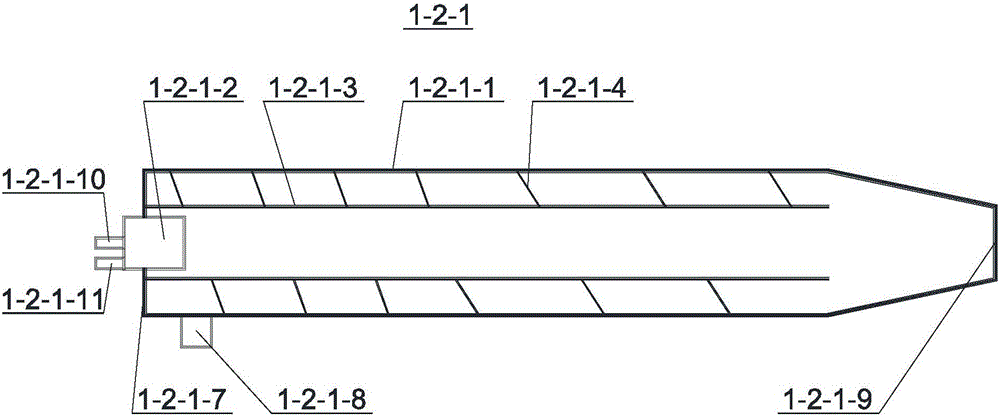

Wear-preventive low-resistance high-efficiency Venturi scrubber for cold hydrogenation process

InactiveCN106467302AReduce impact wearImprove dust removal efficiencyHalogenated silanesScrubberNozzle

The invention provides a wear-preventive low-resistance high-efficiency Venturi scrubber for a cold hydrogenation process. The Venturi scrubber is characterized in that the Venturi scrubber comprises a vertical tubular shell and a spraying device; the shell comprises, from top to bottom, a gas inlet, a receiving section, a mixing section and a gas outlet which are successively connected; the diameter of the receiving section is greater than the diameter of the mixing section; the spraying device comprises a washing liquid pipe and three nozzles arranged at the receiving section; the washing liquid pipe is communicated with external washing liquid and comprises three outlets, wherein one of the outlets is formed in the central axis of the upper part of the receiving section, the other two outlets are symmetrically located in the lower part of the receiving section and the openings of the other two outlets are arranged along a horizontal direction; and each outlet is provided with one nozzle. According to the invention, through bumping between washing liquid sprayed by the nozzle at the upper part and washing liquid sprayed by the nozzles at the lower part, reaction gas undergoes adequate cooling and dedusting; and the washing liquid is employed at the inlet for capturing silicon powder particles, so impact wearing of the shell by the silicon powder particles is reduced; and the receiving section and the mixing section are provided with throats, so dedusting efficiency is improved by changing the flow velocity of the reaction gas.

Owner:宋一整

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com