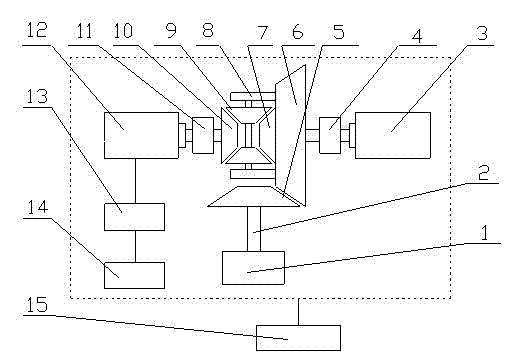

Mechanical synthesizer of rotational speed and torque

A speed torque, mechanical synthesis technology, applied in the direction of electromechanical devices, mechanical equipment, transmission devices, etc., can solve the problem of power synthesis without reverse, achieve stable power supply of the grid, increase load rate, and improve operation stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings, but not limited thereto.

[0022] Firstly, the technical starting point of the rotational speed torque mechanical synthesizing device of the present invention is described, which utilizes the principle of the automobile "differential" and adopts the reverse operation of the "differential" to realize that the two drive wheels of the automobile are passed through Two semi-shafts driven by a power shaft are realized. When the car is running on a straight road, the drive shaft distributes the power equally to the left and right semi-shafts, and the two semi-shafts run forward with equal speed and equal torque. When the car turns right, the power is distributed through the differential, the speed of the right half-shaft decreases, and the speed of the left half-shaft increases, thereby realizing the function of turning right; when the car turns lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com