Tension distribution setting method in steel belt asynchronous cold continuous rolling process

A setting method, cold continuous rolling technology, applied in the field of rolling production, to achieve the effect of high calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

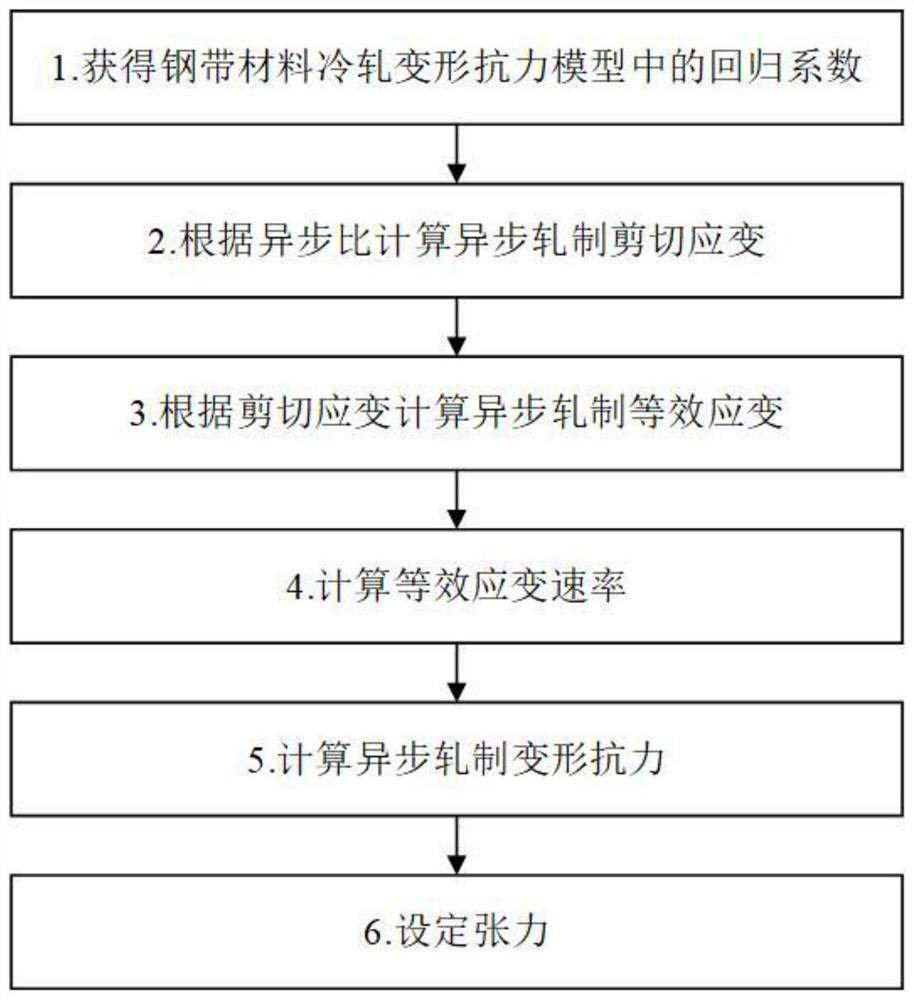

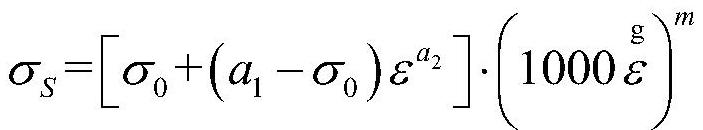

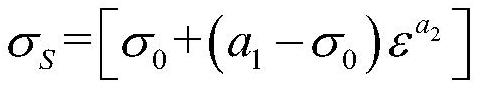

Method used

Image

Examples

Embodiment 1

[0035] Taking the 2150mm five-stand six-high tandem cold rolling unit as an example, the working roll diameter of the unit is 430-570mm, the middle roll diameter is 580-650mm, the support roll diameter is 1325-1485mm, and the maximum rolling force of the unit is 32MN. Set the tension before the first stand of steel strip asynchronous continuous cold rolling. Among them, the chemical composition of the steel strip by weight percentage (≤, %) is: C: 0.15, Si: 0.63, Mn: 1.66, Cr: 0.57, P: 0.014, S: 0.008, the asynchronous ratio is 1.3, and the rolling speed is v u = 1.8m / s, v b =2.34m / s, the hot-rolled raw material is 4mm, the thickness of the entrance of the first frame is 4mm, and the thickness of the exit of the first frame is 2.8mm.

[0036] (1) Using the experimental cold rolling mill, the steel strip material samples are 10%, 15%, 20%, 25%, 30%, 35%, 40%, 45%, 50%, 55%, 60%, 65% %, 70%, 75%, 80%, 85%, 90% reduction rate for cold rolling, the cold rolling rolling speed is...

Embodiment 2

[0048] Taking the 2150mm five-stand six-high tandem cold rolling unit as an example, the working roll diameter of the unit is 430-570mm, the middle roll diameter is 580-650mm, the support roll diameter is 1325-1485mm, and the maximum rolling force of the unit is 32MN. Set the front tension of the second stand of steel strip asynchronous continuous cold rolling. Among them, the chemical composition of the steel strip by weight percentage (≤, %) is: C: 0.20, Si: 1.82, Mn: 2.43, Cr: 0.11, P: 0.014, S: 0.004, the asynchronous ratio is 1.18, and the rolling speed is v u = 4.1m / s, v b =4.84m / s, hot-rolled raw material 3mm, entrance thickness 2.1mm, exit thickness 1.3mm.

[0049] (1) Using the experimental cold rolling mill, the steel strip material samples are 10%, 15%, 20%, 25%, 30%, 35%, 40%, 45%, 50%, 55%, 60%, 65% %, 70%, 75%, 80%, 85%, 90% reduction rate for cold rolling, the cold rolling rolling speed is 5m / s. The room temperature uniaxial tensile test was carried out on t...

Embodiment 3

[0061] Taking the 2150mm five-stand six-high tandem cold rolling unit as an example, the working roll diameter of the unit is 430-570mm, the middle roll diameter is 580-650mm, the support roll diameter is 1325-1485mm, and the maximum rolling force of the unit is 32MN. Set the front tension of the fourth stand of steel strip asynchronous continuous cold rolling. Among them, the chemical composition of the steel strip by weight percentage (≤, %) is: C: 0.15, Si: 0.7, Mn: 0.8, Ni: 0.35, P: 0.04, S: 0.03, the asynchronous ratio is 1.07, and the rolling speed is v u =5m / s, v b =5.35m / s, hot-rolled raw material 3.5mm, entrance thickness 1.2mm, exit thickness 0.8mm.

[0062] (1) Using the experimental cold rolling mill, the steel strip material samples are 10%, 15%, 20%, 25%, 30%, 35%, 40%, 45%, 50%, 55%, 60%, 65% %, 70%, 75%, 80%, 85%, 90% reduction rate for cold rolling, the cold rolling rolling speed is 3m / s. The room temperature uniaxial tensile test was carried out on the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com