Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Reduced reaction area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

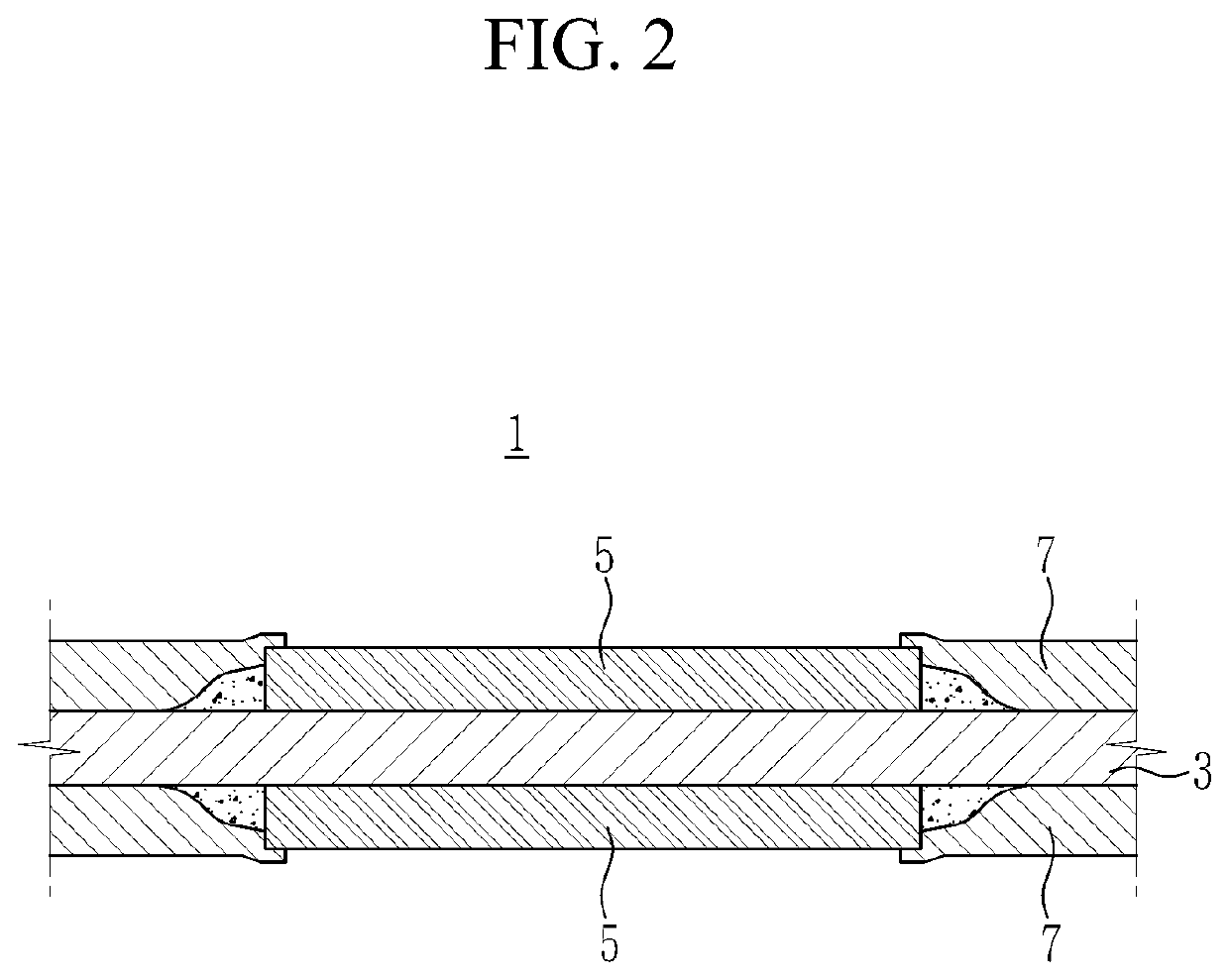

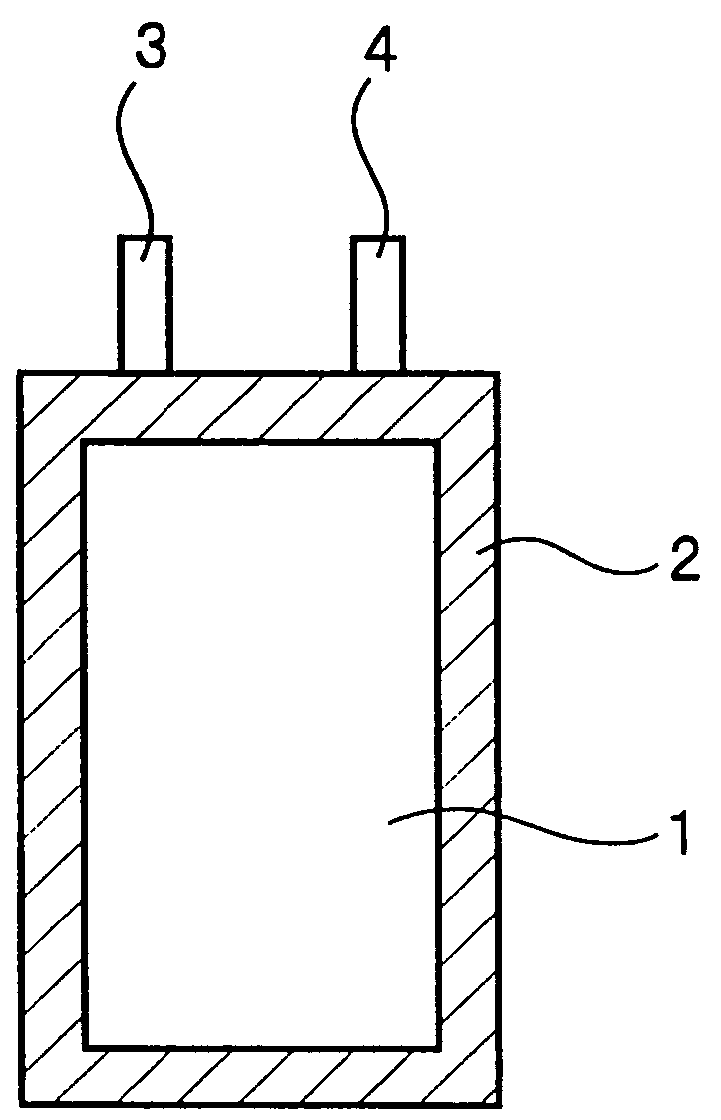

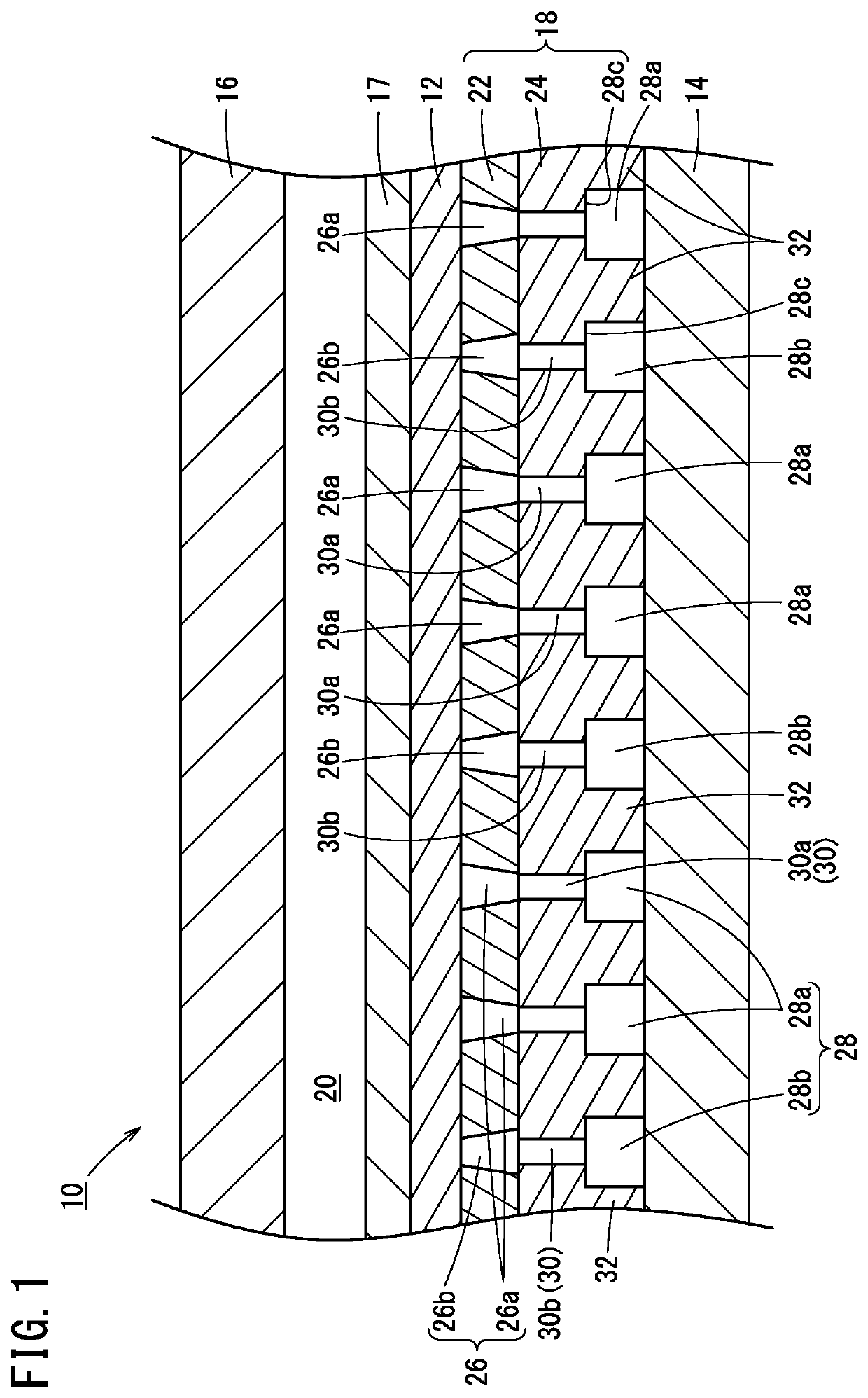

Lithium secondary battery and electrode for lithium secondary battery

InactiveUS20080268348A1Improve reliabilityImprove featuresSolid electrolyte cellsLi-accumulatorsMolten saltLithium-ion battery

An object of the invention is to provide a lithium secondary battery using a fused salt at ambient temperature where a high capacity is able to be maintained even when it is stored at a high temperature environment or even when it is subjected to charge and discharge repeatedly and also to provide an electrode for a nonaqueous electrolytic lithium secondary battery. There is disclosed a lithium secondary battery using at least a fused salt at ambient temperature having ionic conductivity in which at least one of the positive and negative electrode contains a powder which solely comprises an inorganic solid electrolyte having lithium ionic conductivity. There is also disclosed an electrode for a lithium secondary battery using, at least, a ionic liquid having ionic conductivity which contains a powder solely comprising inorganic solid electrolyte having lithium ionic conductivity.

Owner:OHARA

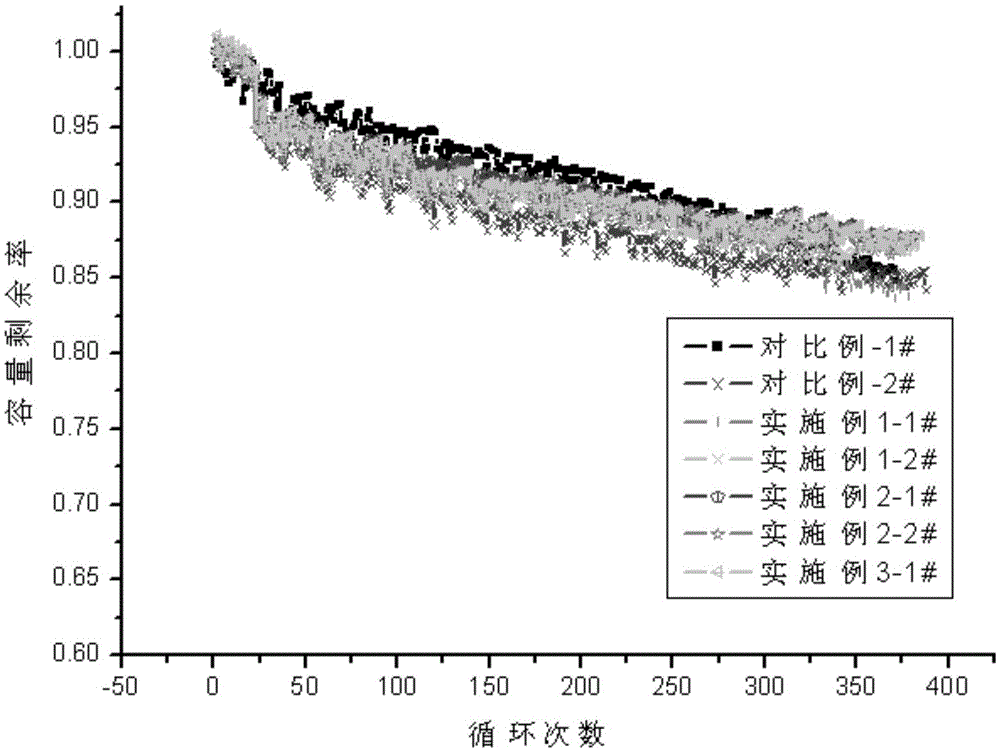

Lithium cobaltate positive electrode material and preparation method thereof, and lithium ion secondary battery

ActiveCN108123109AWithout sacrificing gram capacityWithout sacrificing energy densityCell electrodesSecondary cellsLithiumCompound structure

The present invention provides a high-voltage lithium cobaltate positive electrode material, which is a compound structure of a doped lithium cobaltate substrate and a surface coating layer, wherein the general formula of the doped lithium cobaltate substrate is Li1+zCo1-x-yMaxMbyO2, x is more than or equal to 0 and is less than or equal to 0.01, y is more than or equal to 0 and is less than or equal to 0.01, z is more than or equal to -0.05 and is less than or equal to 0.08, Ma is a doped element with unchanged valence, and is at least one selected from Al, Ga, Hf, Mg, Sn, Zn and Zr, Mb is adoped valence-changing element, and is at least one selected from Ni, Mn, V, Mo, Nb, Cu, Fe, In, W and Cr, and the surface coating layer is a high-voltage (more than 4.5 V) positive electrode material. According to the present invention, the element with unchanged valence is doped through substitution, such that the layered structure distortion caused by lithium removing can be minimized; the valence-changing element is subjected to gap doping, such that the Co<3+> oxidation is blended and delayed during the charging; and the surface coating layer has the stable structure at the voltage of more than 4.5 V, can separate the electrolytic solution from the lithium cobaltate substrate, can reduce the side reaction between the electrolytic solution and the lithium cobaltate substrate, can suppress the dissolution of the transition metal, and further can provide electrochemical energy.

Owner:HUAWEI TECH CO LTD

Compound bricks of phosphogypsum, and producing method

This invention discloses a method for producing phosphogypsum composite bricks, which are produced from: steam-cured phosphogypsum 30-55 parts, gel material 10-30 parts, curing agent 5-15 parts, aggregrate 5-37 parts, and reinforcer 1-5 parts. The method comprises: (1) steam-curing phosphogypsum, mixing and strring with the other raw materials; (2) adding water so that the water content is 12-20%; (3) molding under 10-80 MPa; (4) steam-curing at high temperatures and high pressure for 5-24 h. The composite bricks have such advantages as high flexural strength, high compressive strength and good freeze resistance, thus can be used on main walls. The method efficiently and largely consumes phosphogypsum, thus saving soil resources and preventing environmental pollution by phosphogypsum piling. Besides, the method has high profit, and is environmentally friendly.

Owner:HUAZHONG UNIV OF SCI & TECH

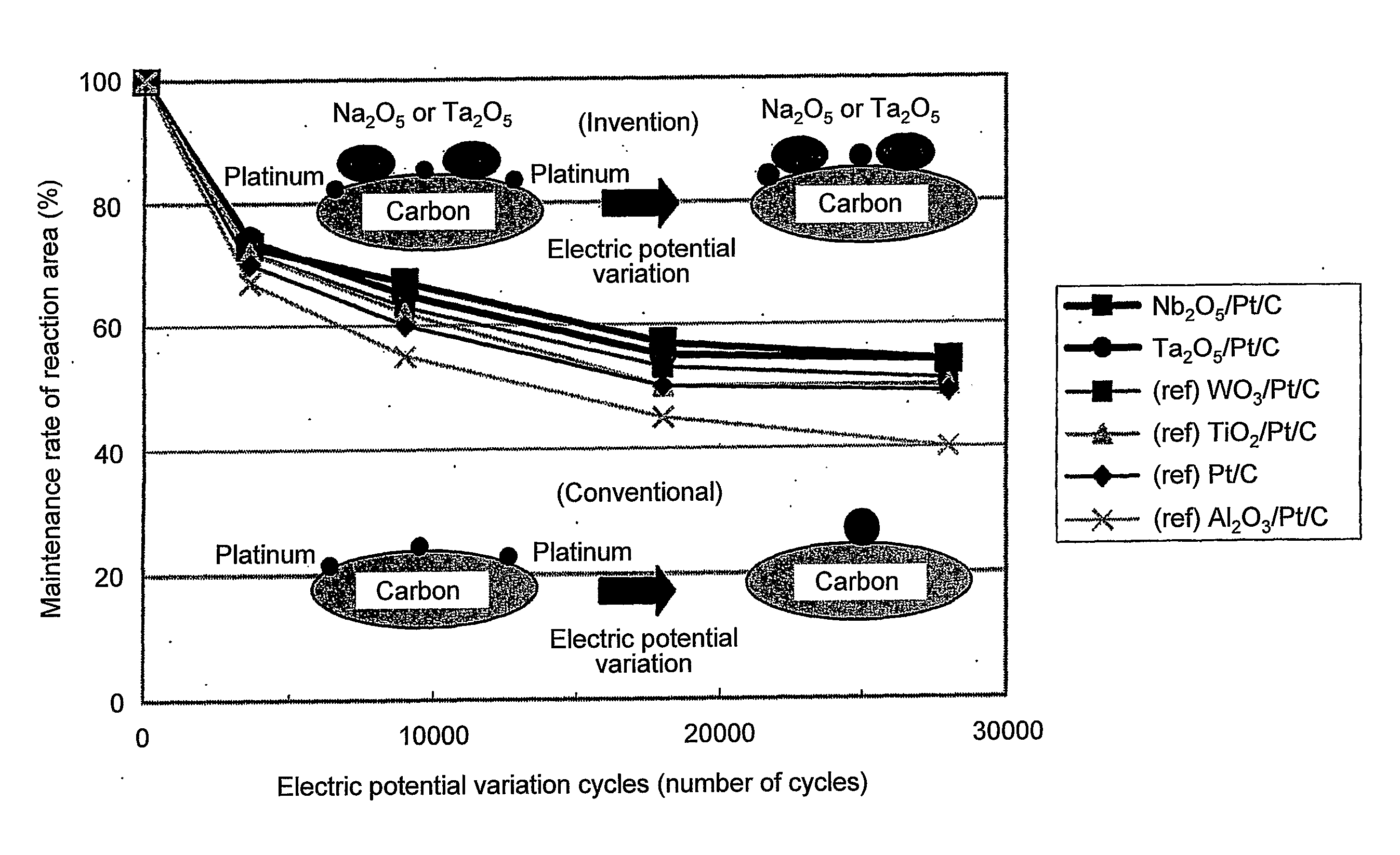

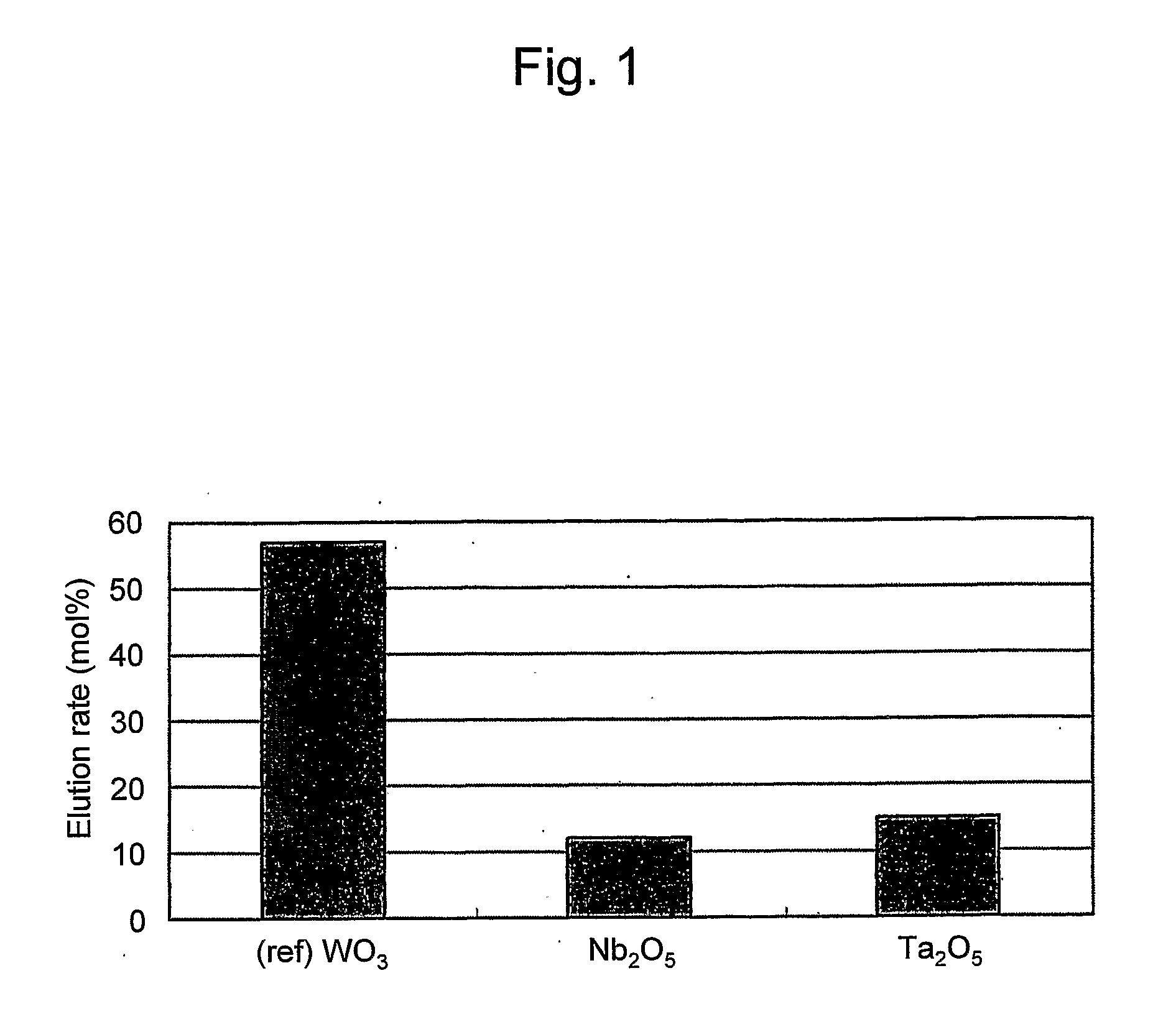

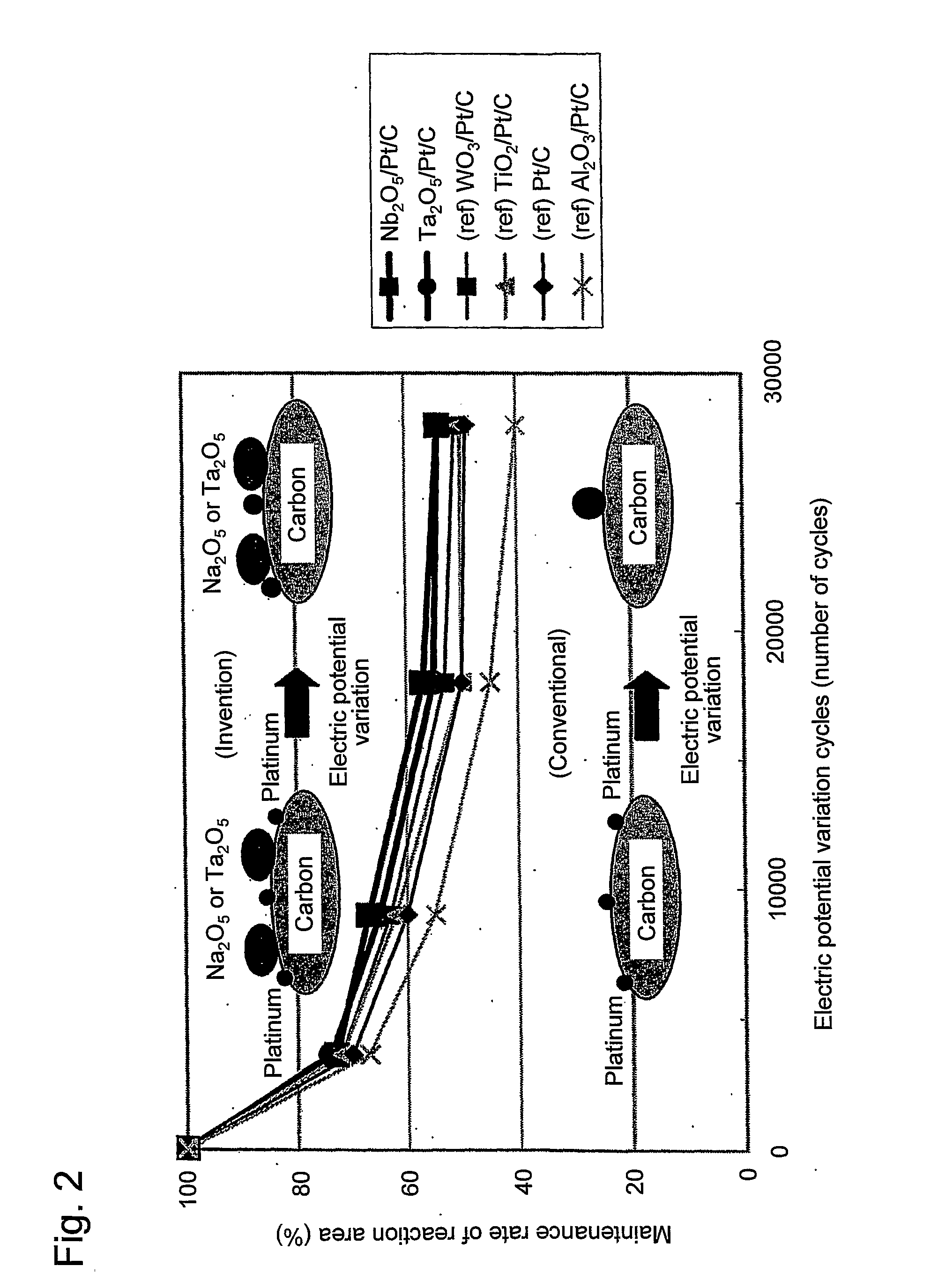

Fuel cell catalyst, fuel cell cathode and polymer electrolyte fuel cell including the same

InactiveUS20100068591A1Increase power generation capacityIncreased durabilityCell electrodesFuel cell auxillariesFuel cellsNiobium

The present invention actualizes a polymer electrolyte fuel cell that exhibits a high durability even when undergoing electric potential variation cycles. Used is a fuel cell catalyst characterized in that a metal catalyst, and an oxide of niobium (Nb2O5) and / or an oxide of tantalum (Ta2O5) are supported on a conductive material.

Owner:TOYOTA JIDOSHA KK

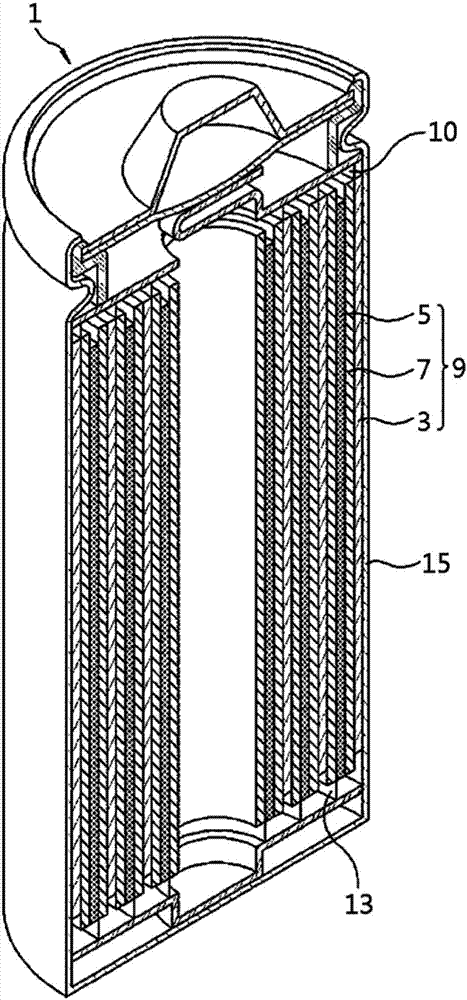

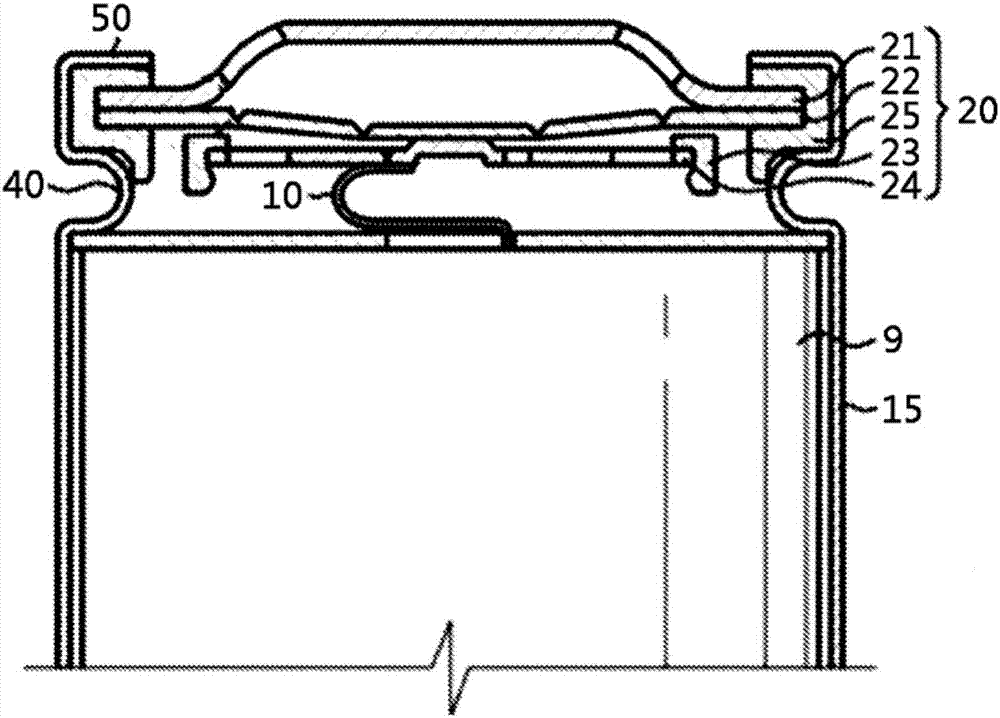

Nonaqueous electrolyte secondary battery

ActiveUS20060127769A1Suppress gas evolutionImprove featuresNon-aqueous electrolyte accumulatorsSmall-sized cells cases/jacketsPurified waterComposite oxide

A nonaqueous electrolyte secondary battery wherein a material capable of occludeing / discharging lithium is used as a negative electrode material and a lithium-trasition metal composite oxide which contains Ni and Mn as the transition metal and has a layered structure is used as a positive electrode material is characterized in that a lithium-transition metal composite oxide having a BET specific surface area less than 3 m2 / g and a pH of 11.0 or less when 5 g of the lithium-transition metal composite oxide is immersed in 50 ml of purified water is used as the positive electrode active material.

Owner:PANASONIC ENERGY CO LTD

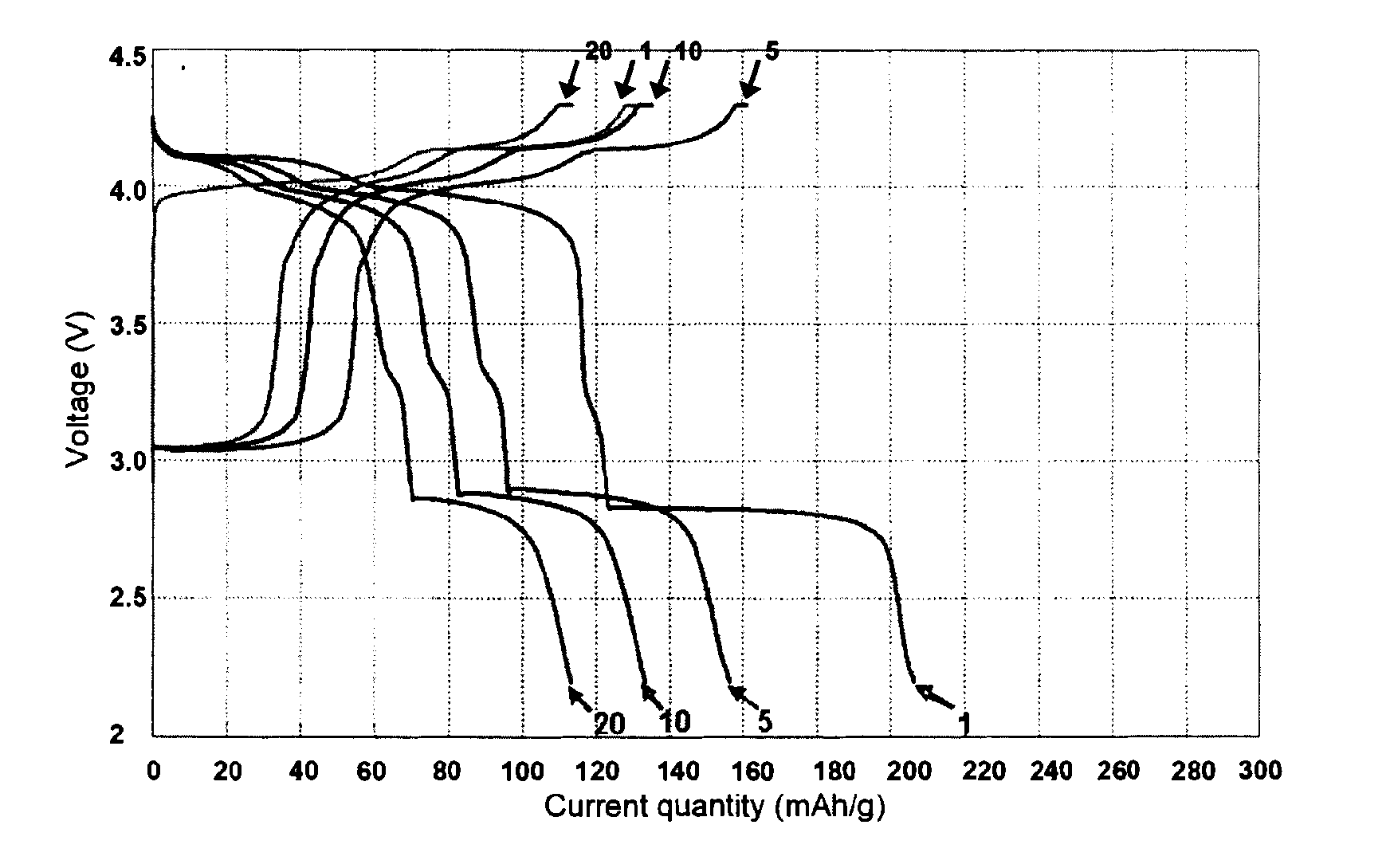

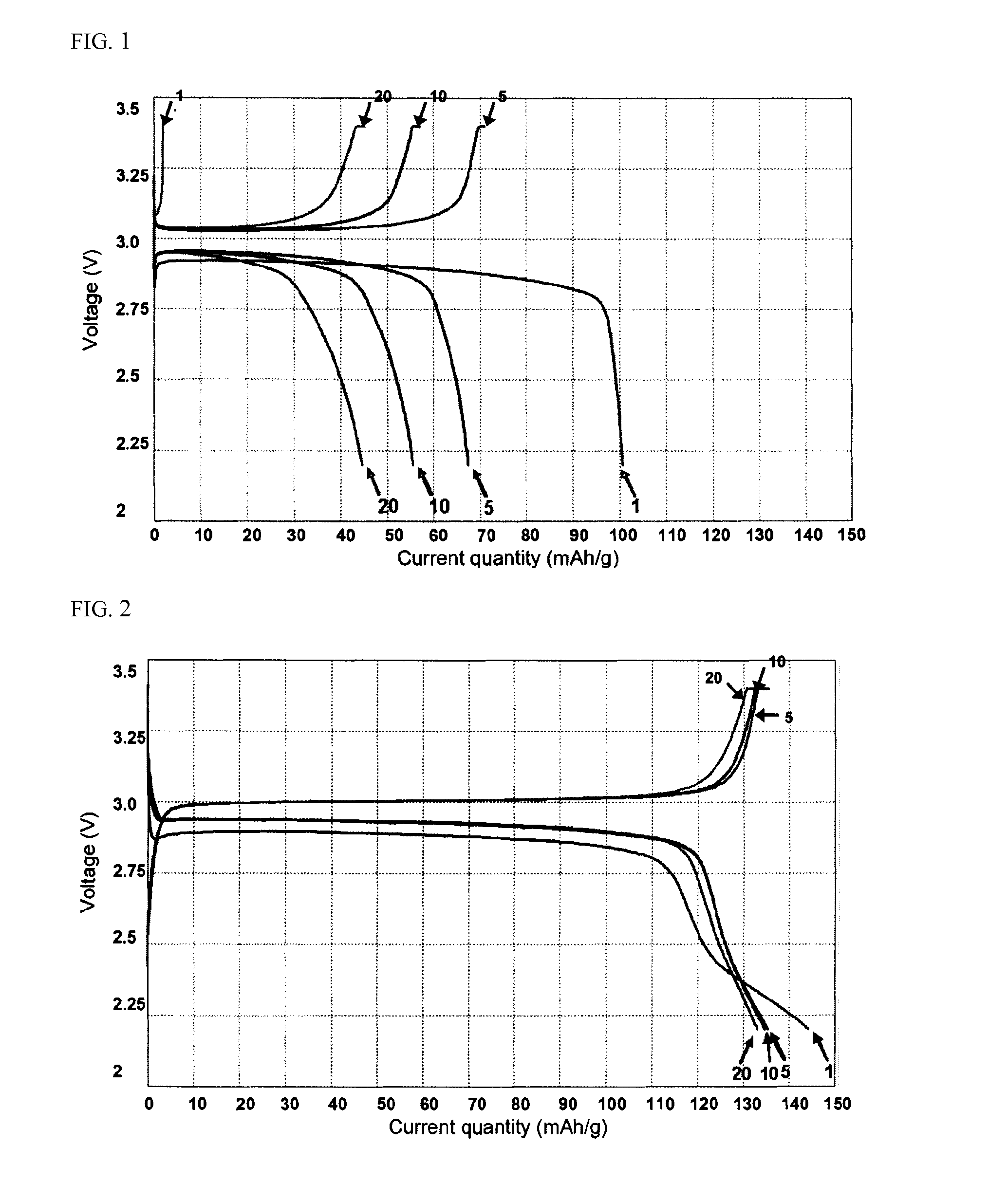

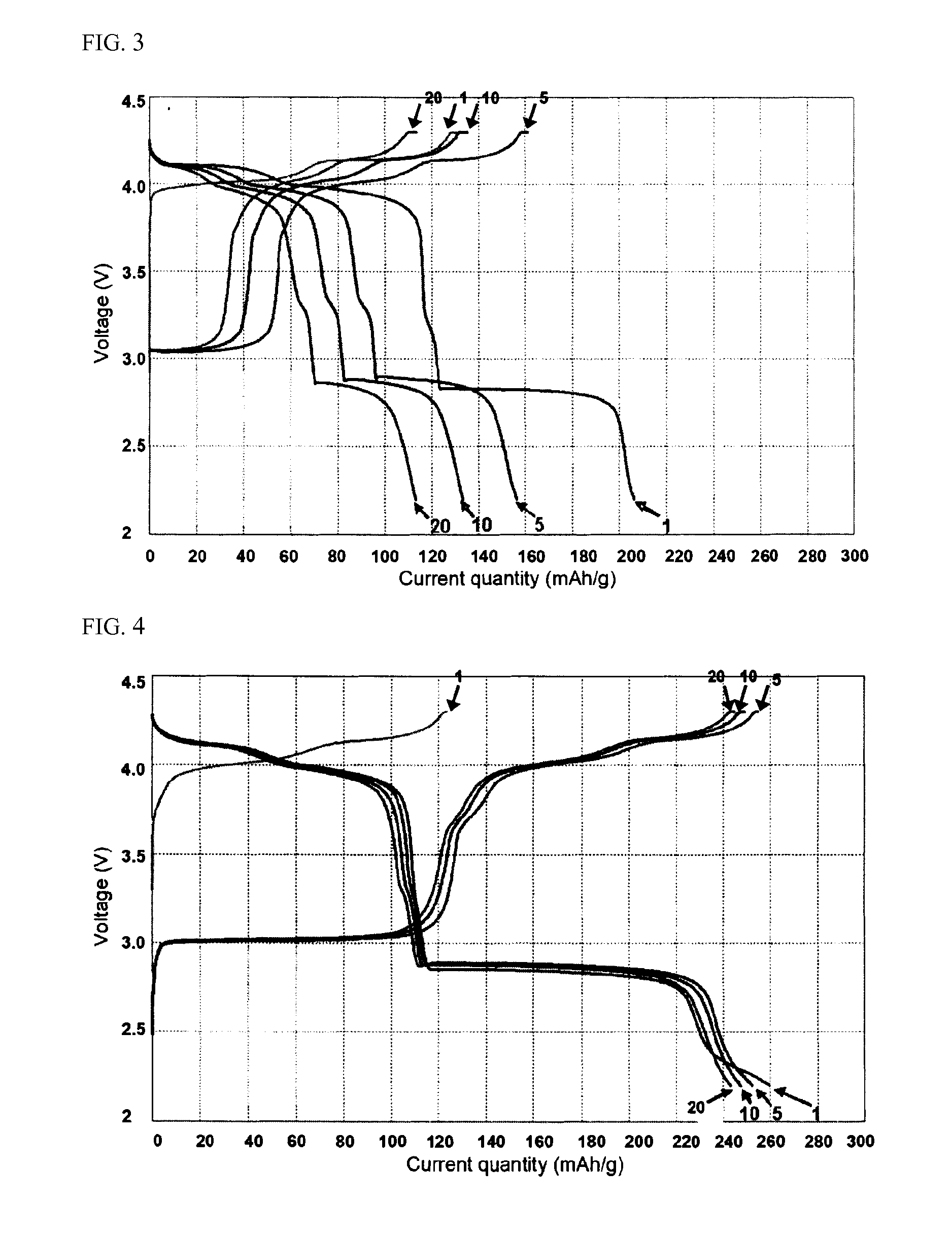

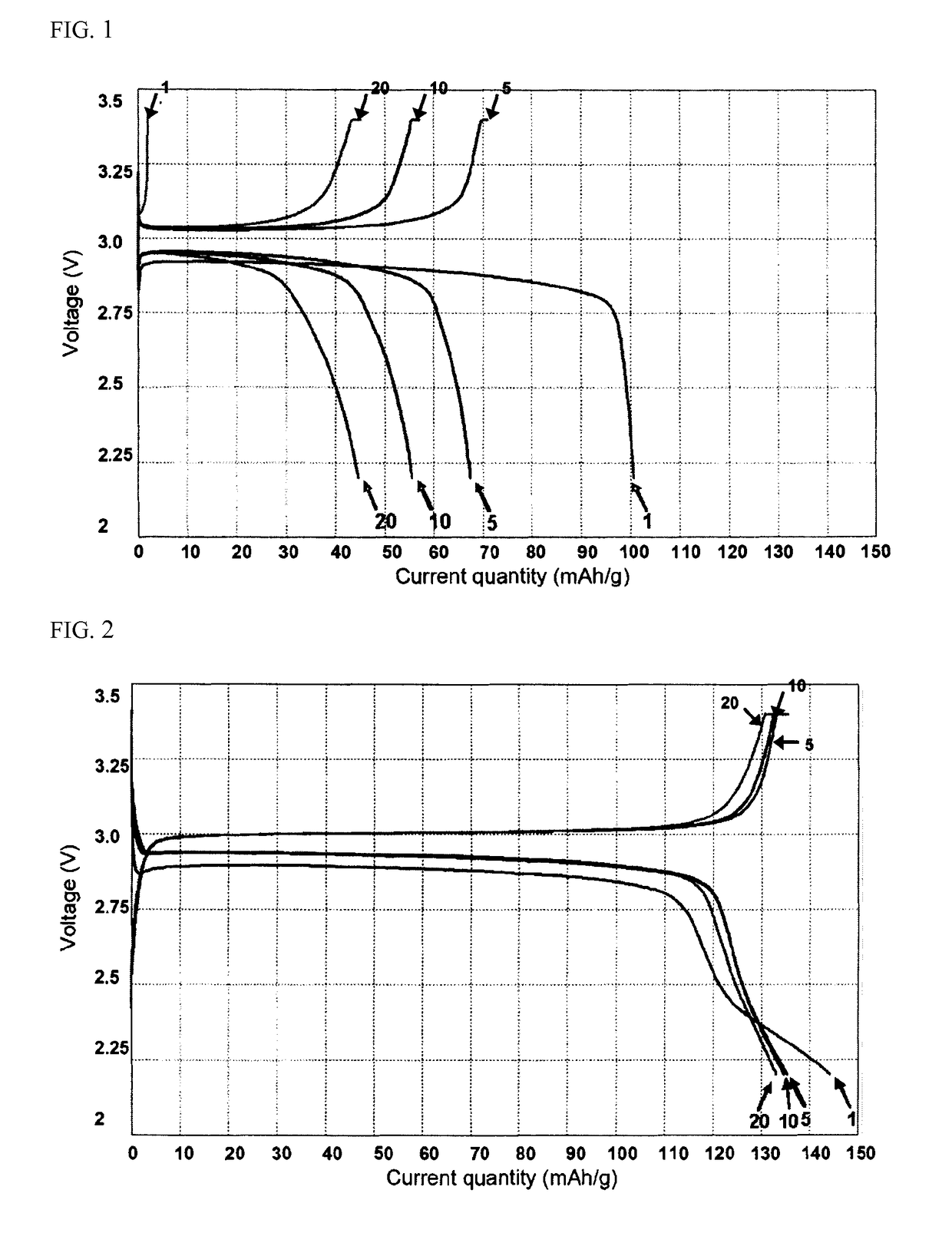

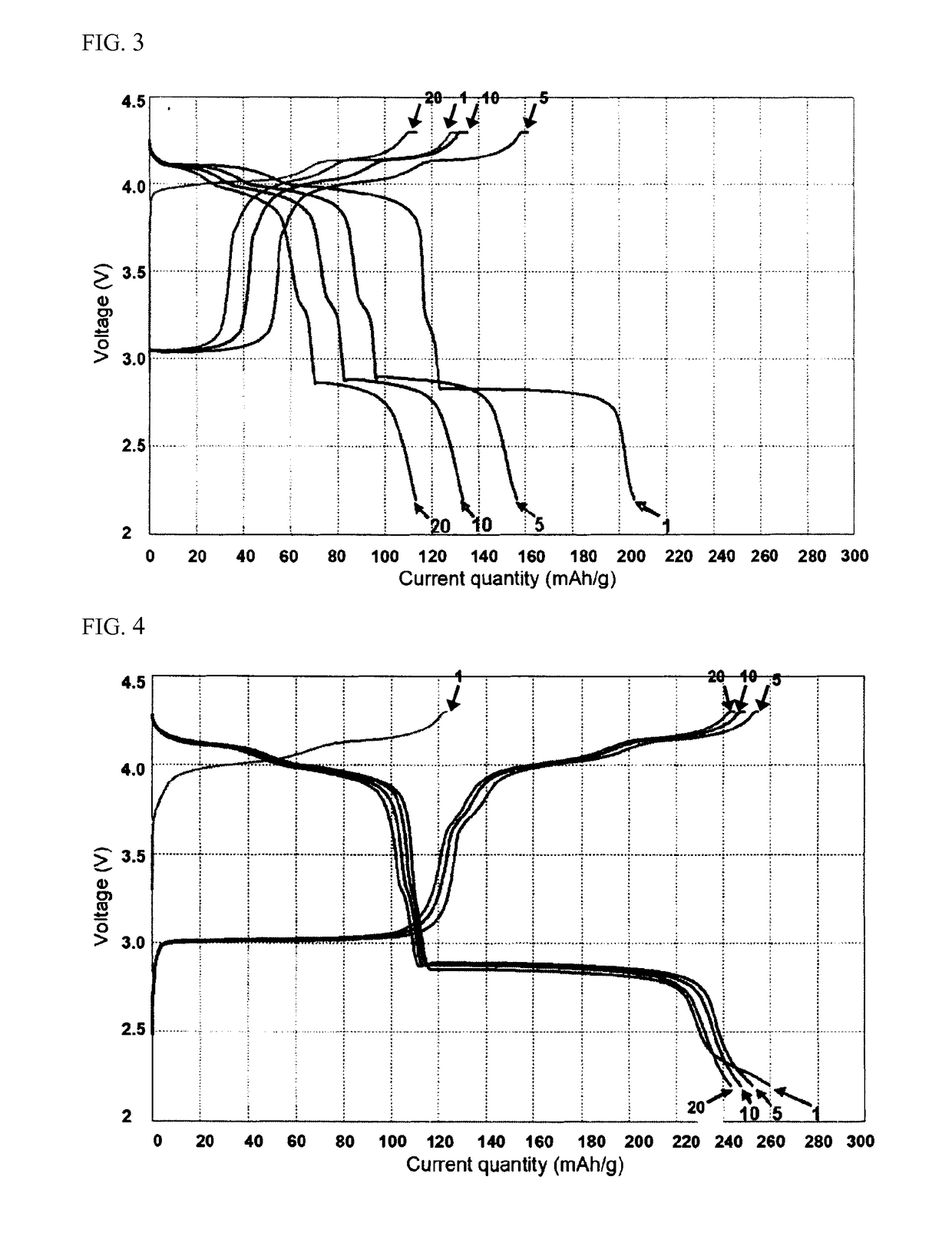

Cathode active material comprising lithium manganese oxide capable of providing excellent charge-discharge characteristics at 3v region as well as 4v region

ActiveUS20130022872A1Maximize its usefulnessImprove conductivityNon-aqueous electrolyte accumulator electrodesLi-accumulatorsConductive materialsCharge discharge

Disclosed herein is a cathode active material including a lithium manganese oxide, in which the lithium manganese oxide has a spinel structure with a predetermined constitutional composition represented by Formula 1 described in the detailed description, wherein a conductive material is applied to the surface of lithium manganese oxide particles, so as to exhibit charge-discharge properties in the range of 2.5 to 3.5V as well as in the 4V region.

Owner:LG ENERGY SOLUTION LTD

Lithium secondary battery and electrode for lithium secondary battery

InactiveUS8822077B2Improve battery safetyImprove suppression propertiesSolid electrolyte cellsLi-accumulatorsElectrical batteryPhysical chemistry

Owner:OHARA

Non-aqueous electrolyte secondary battery and method for producing the same

ActiveUS20110223469A1Increase battery capacityImprove featuresFinal product manufacturePrimary cellsLutetiumPhosphate

A positive electrode active material with least part of a surface coated with a surface treatment layer composed of a phosphate compound. The phosphate compound contains at least one element selected from the group consisting of neodymium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, ytterbium, and lutetium.

Owner:PANASONIC ENERGY CO LTD

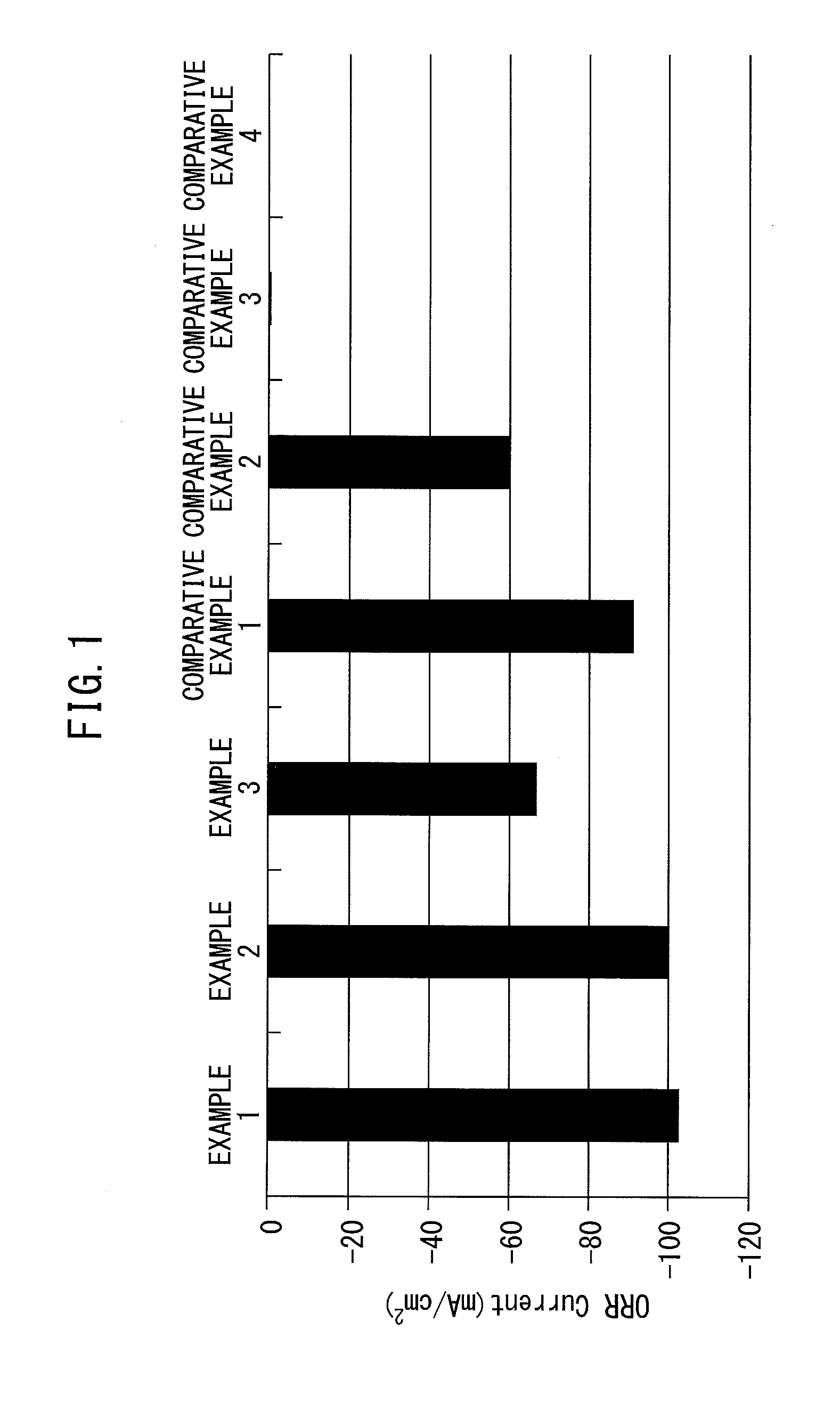

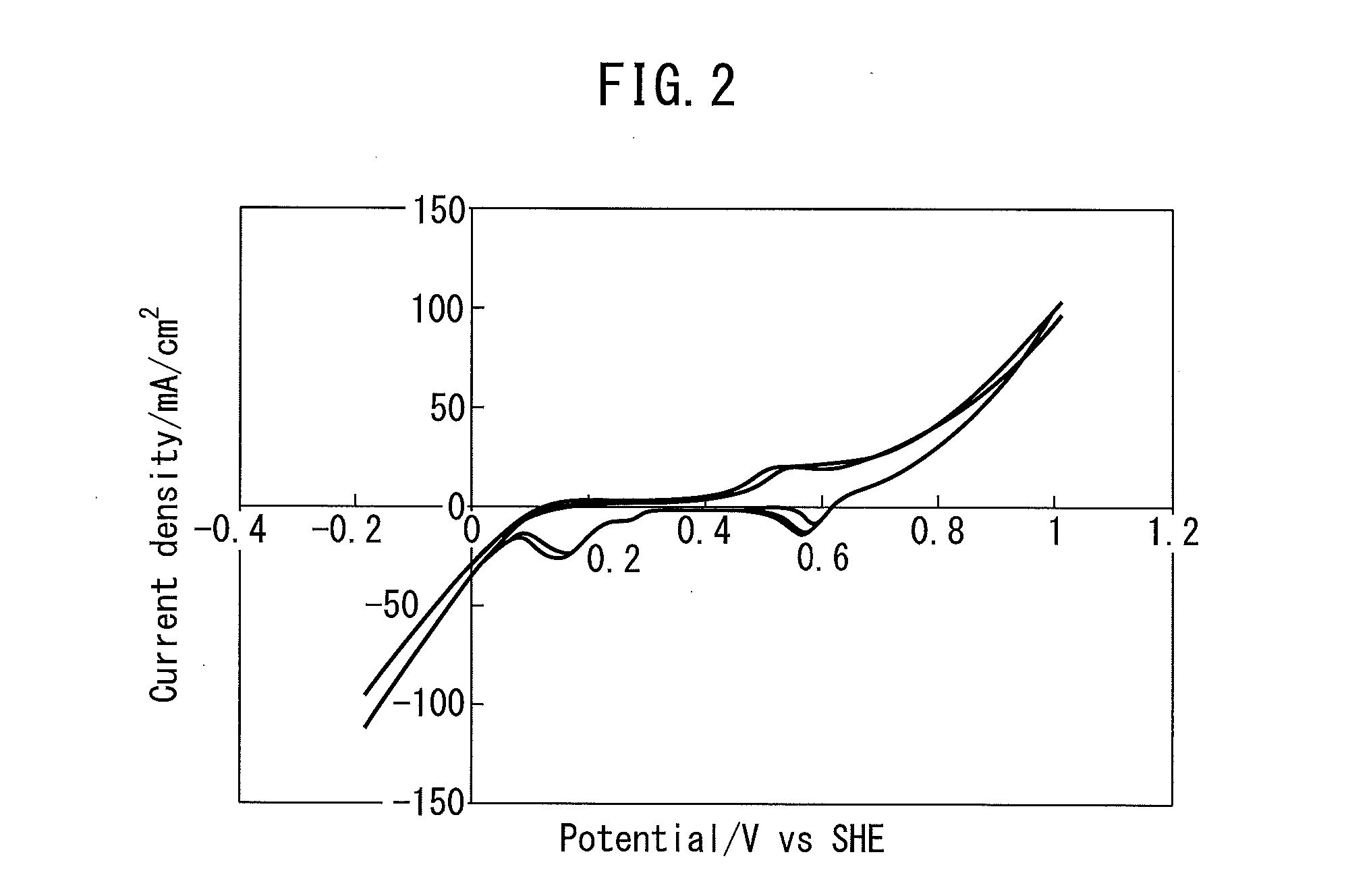

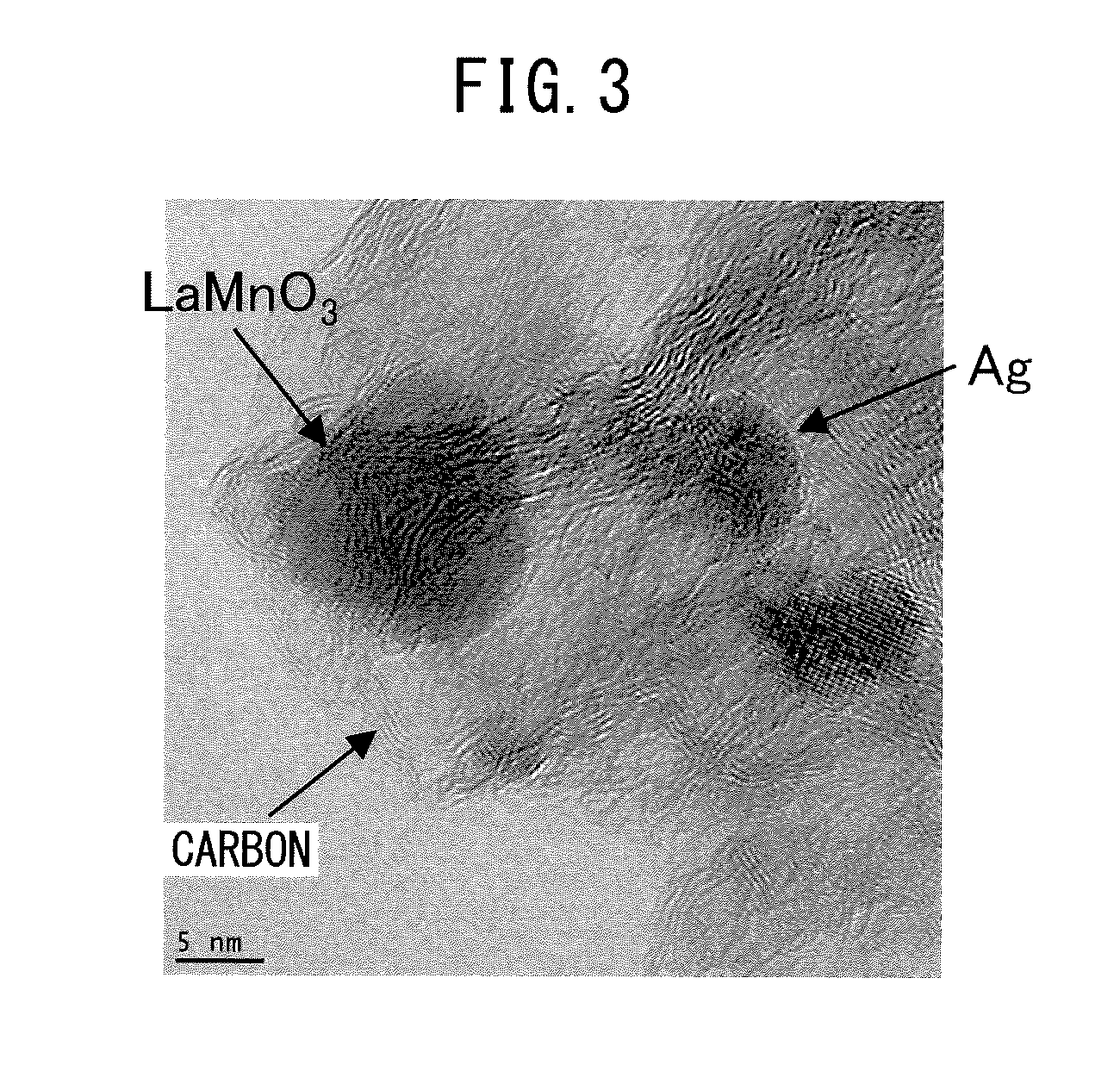

Electrode catalyst

InactiveUS20160104897A1Increase ORR activityHigh oxygen dissociation capacityFuel and primary cellsHeterogenous catalyst chemical elementsMetal catalystManganese

An electrode catalyst includes a carbon (C) carrier; a perovskite-type oxide catalyst containing lanthanum (La), manganese (Mn), and oxygen (O) elements; and a metal catalyst containing a silver (Ag) element. The perovskite-type oxide catalyst is located on the carrier and the metal catalyst is also located on the carrier.

Owner:TOYOTA JIDOSHA KK

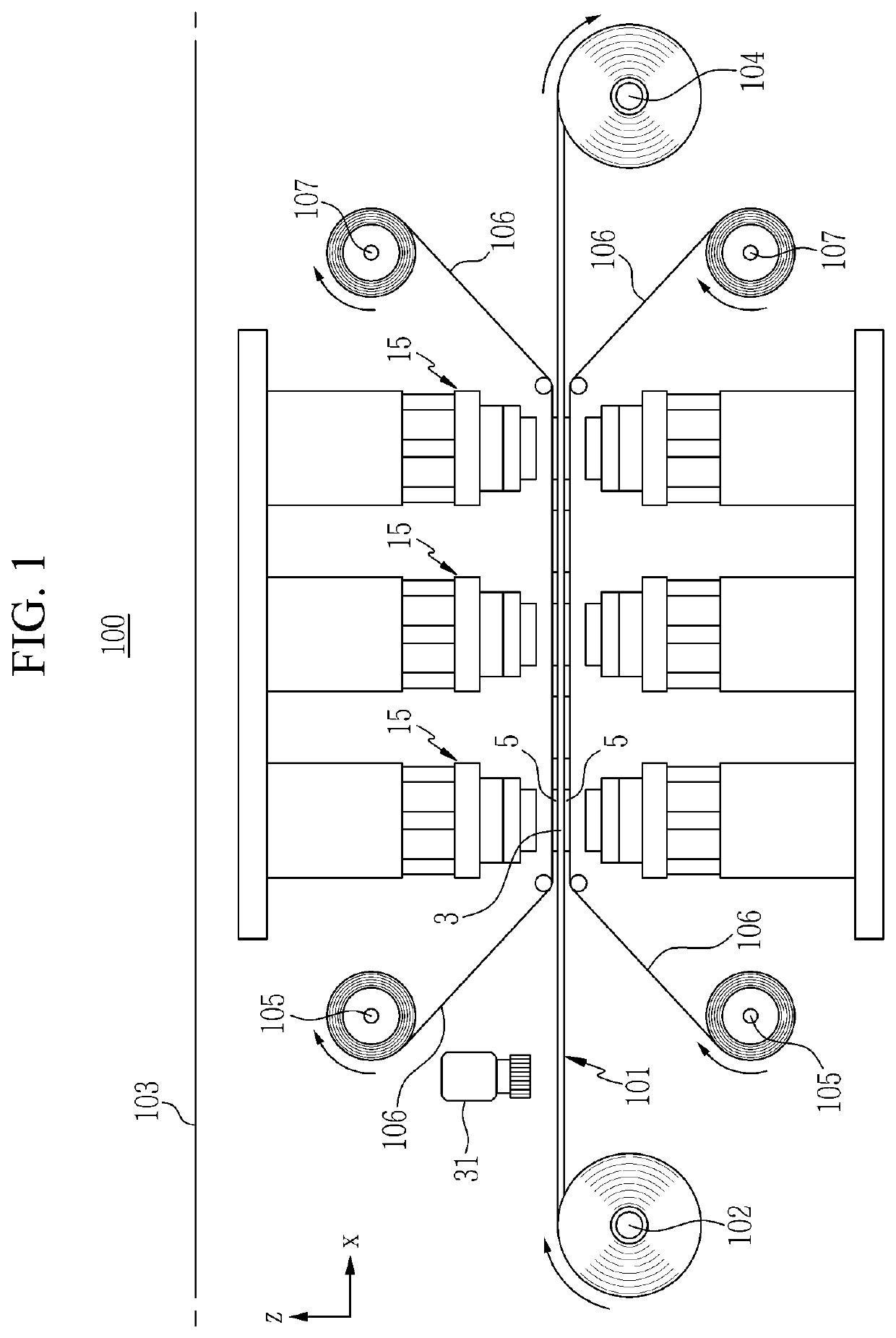

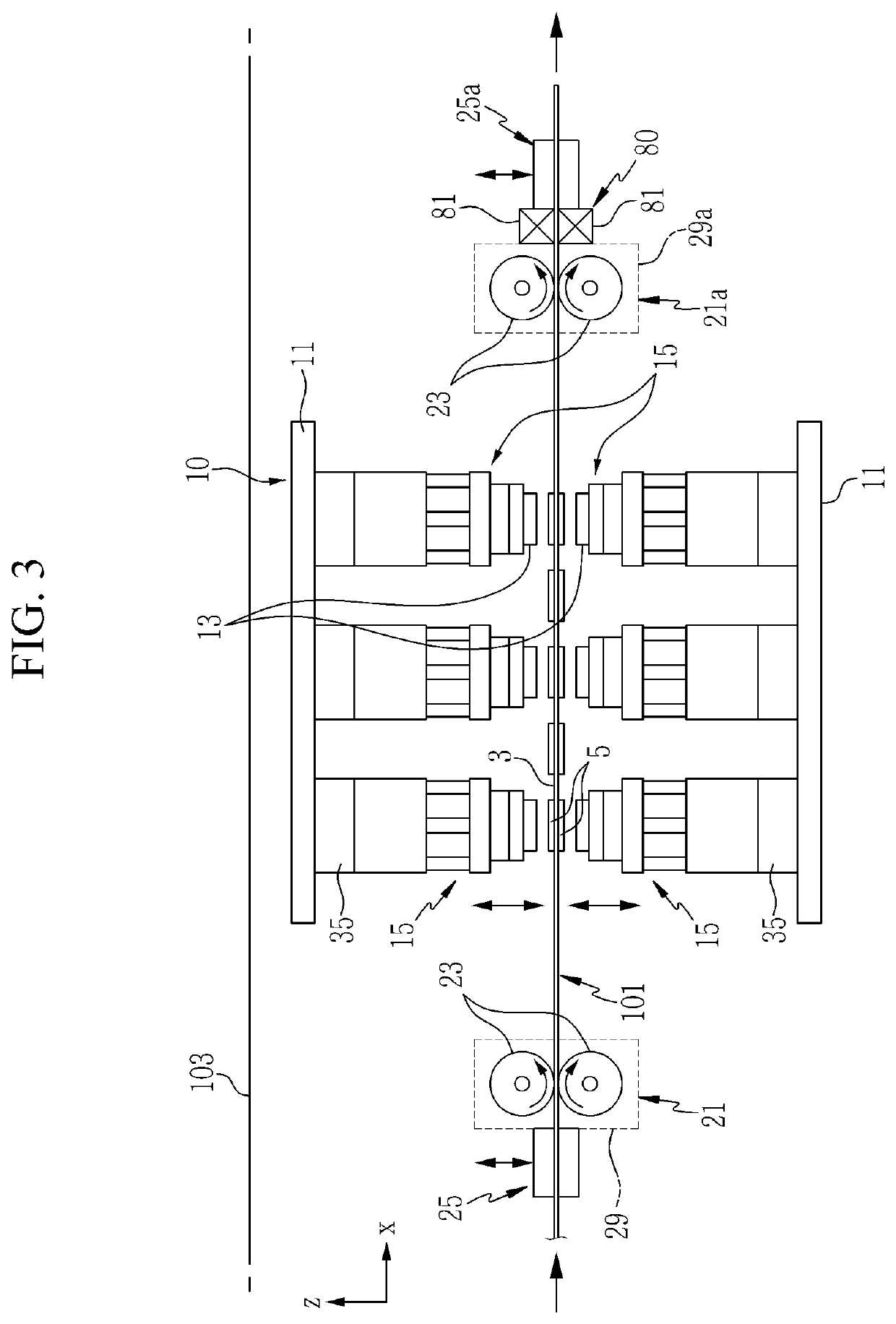

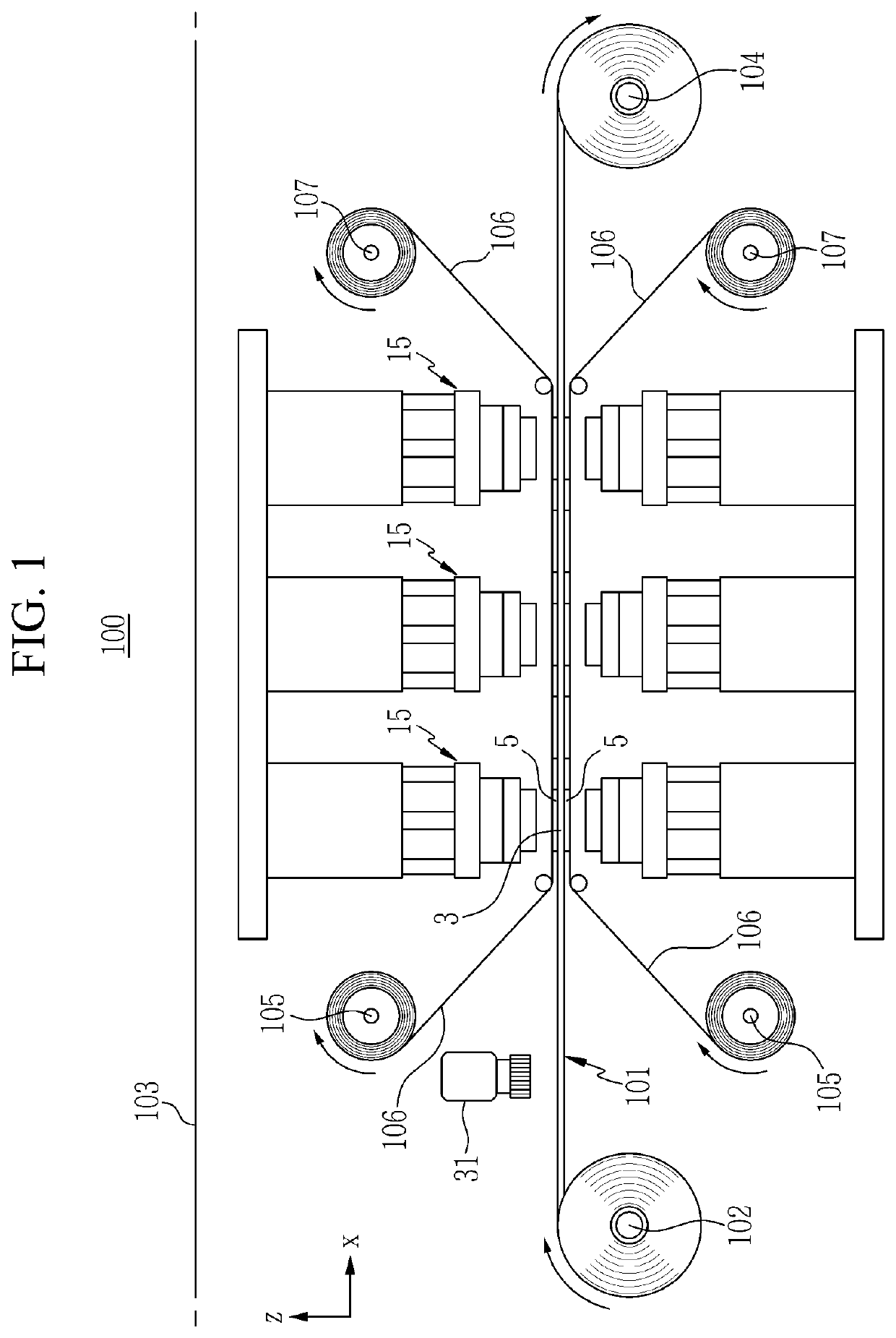

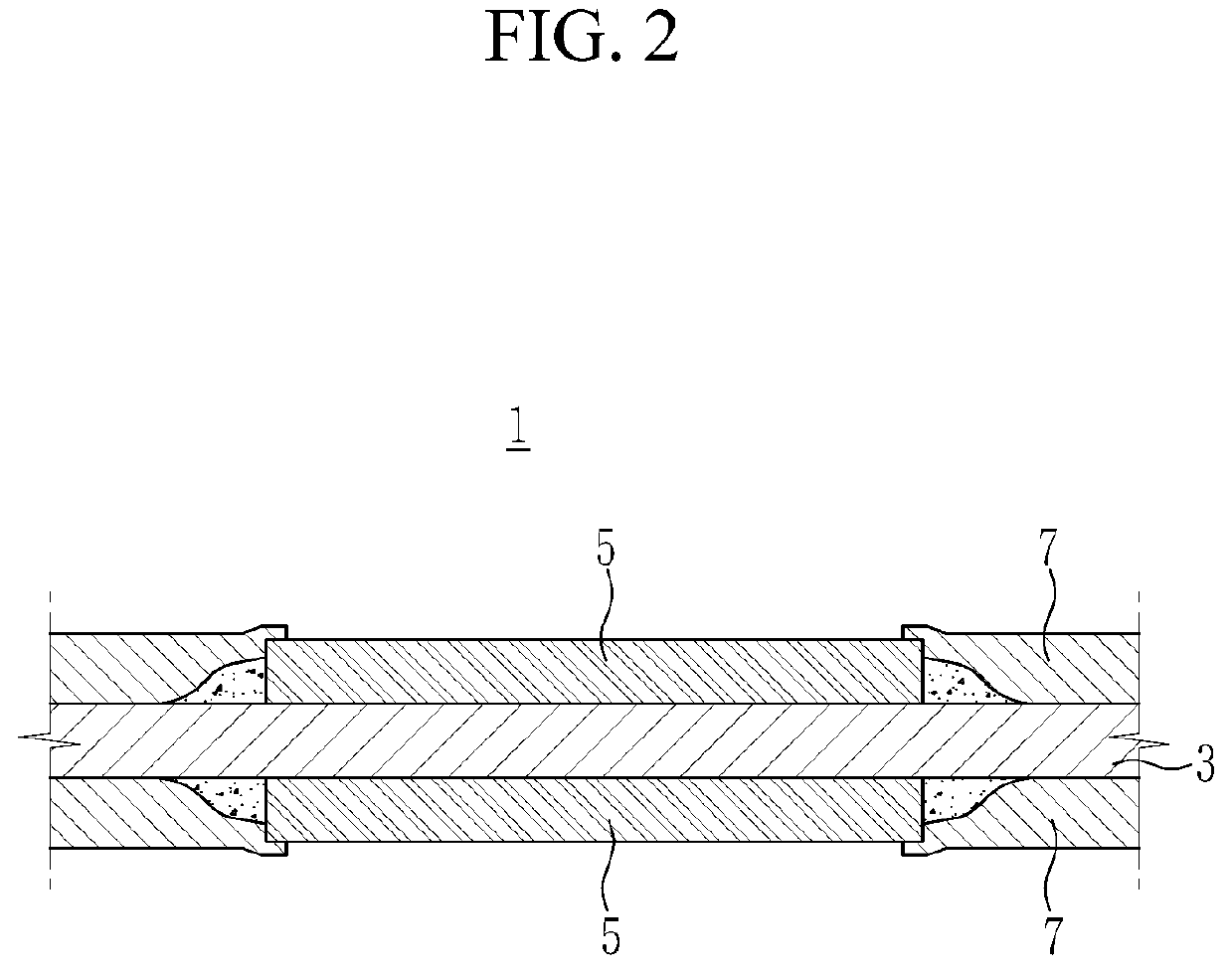

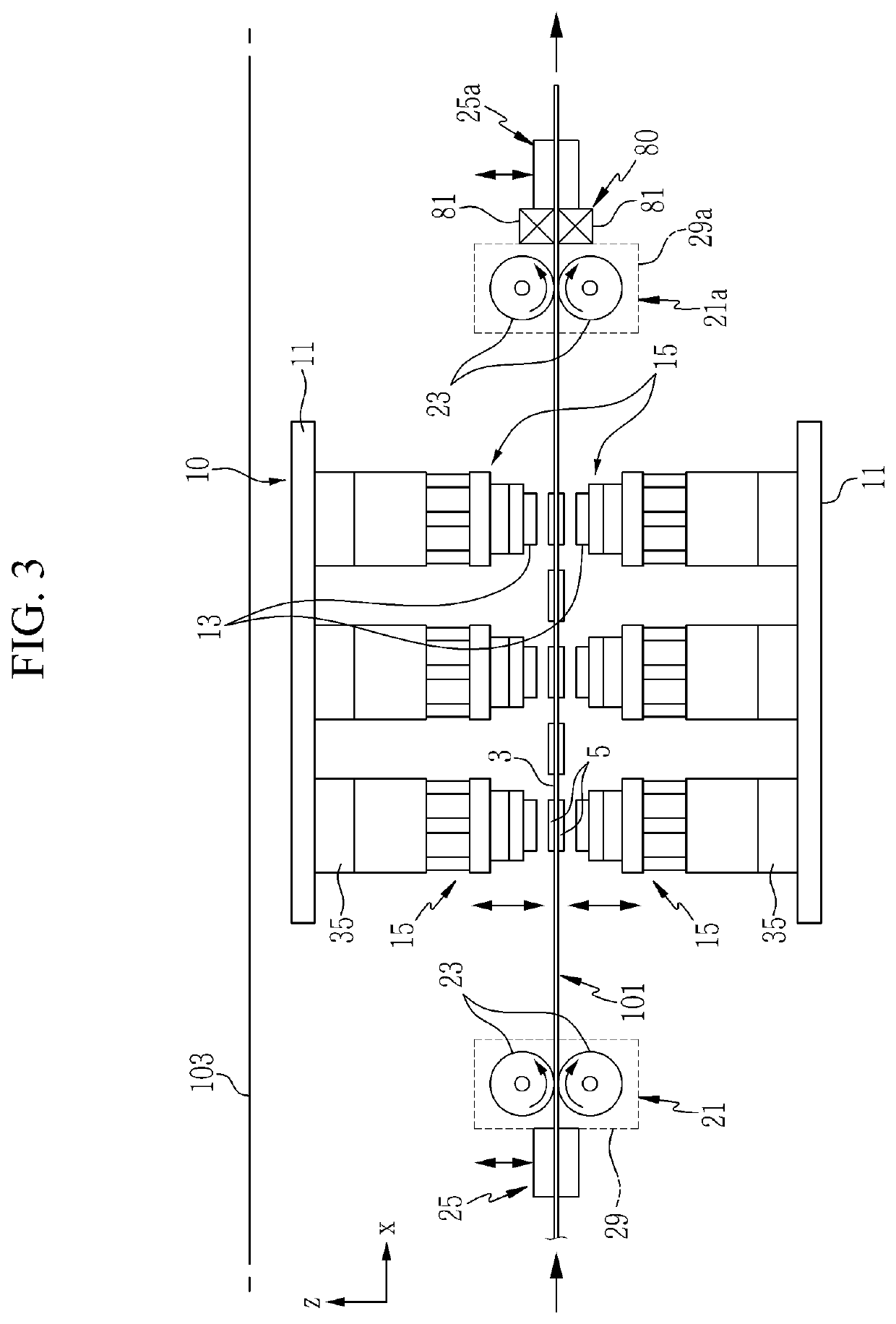

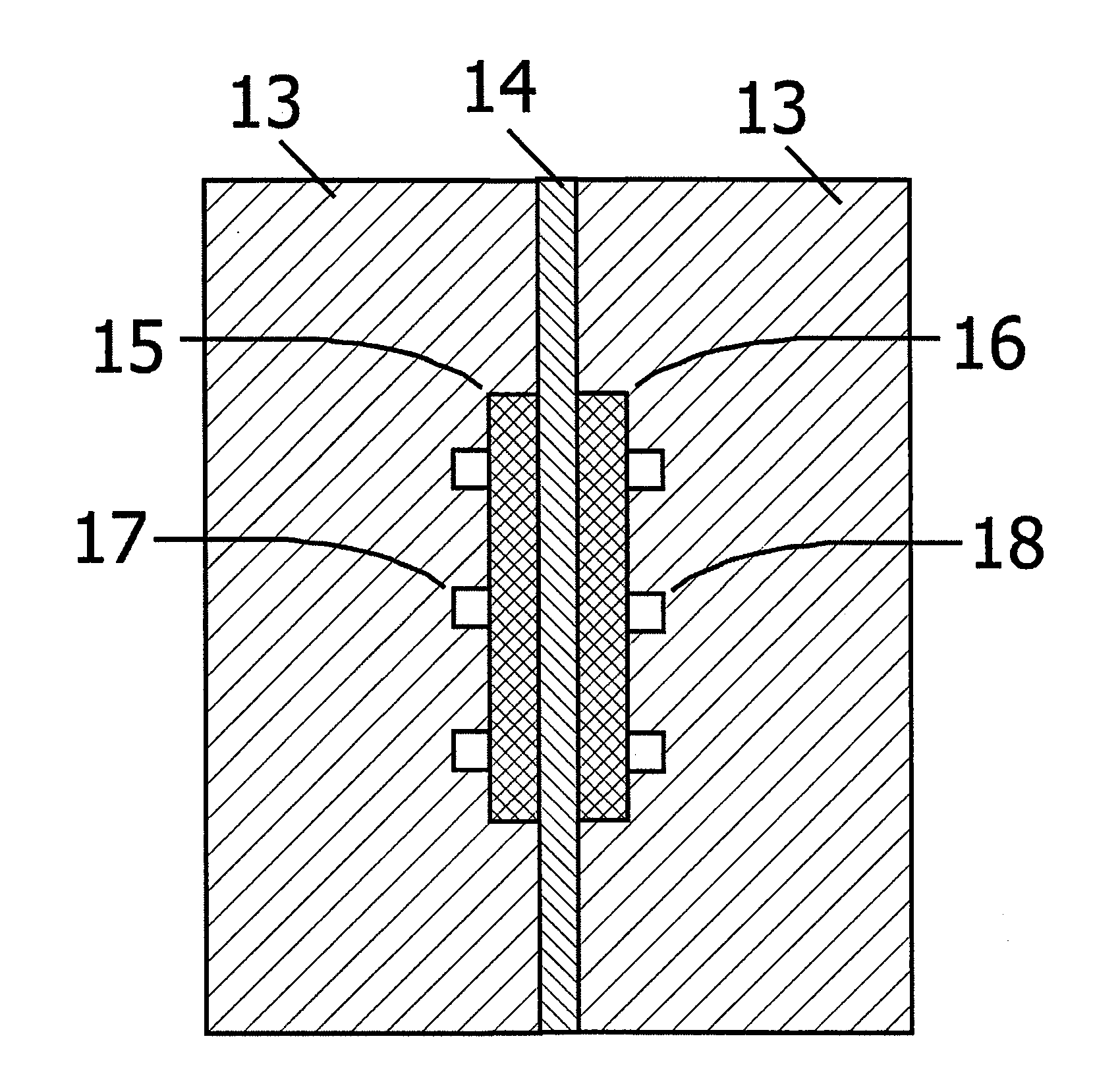

Heat treatment apparatus of mea for fuel cell

ActiveUS20200153017A1Avoid deformationIncreased durabilityLaminationLamination apparatusFuel cellsPtru catalyst

A heat treatment apparatus for a fuel cell membrane-electrode assembly is provided. The heat treatment apparatus includes a hot press installed on upper and lower sides of feeding path to move in the vertical direction on a frame and which presses the electrode catalyst layers on upper and lower surfaces of the membrane-electrode assembly sheet. A plurality of gripper modules are installed at set intervals in a base member along a feeding direction of the membrane-electrode assembly sheet, and selectively grip both side edges of the membrane-electrode assembly sheet. A driving unit reciprocally moves the base member in a direction perpendicular to the feeding direction of the membrane-electrode assembly sheet and in the feeding direction of the membrane-electrode assembly sheet.

Owner:HYUNDAI MOTOR CO LTD +1

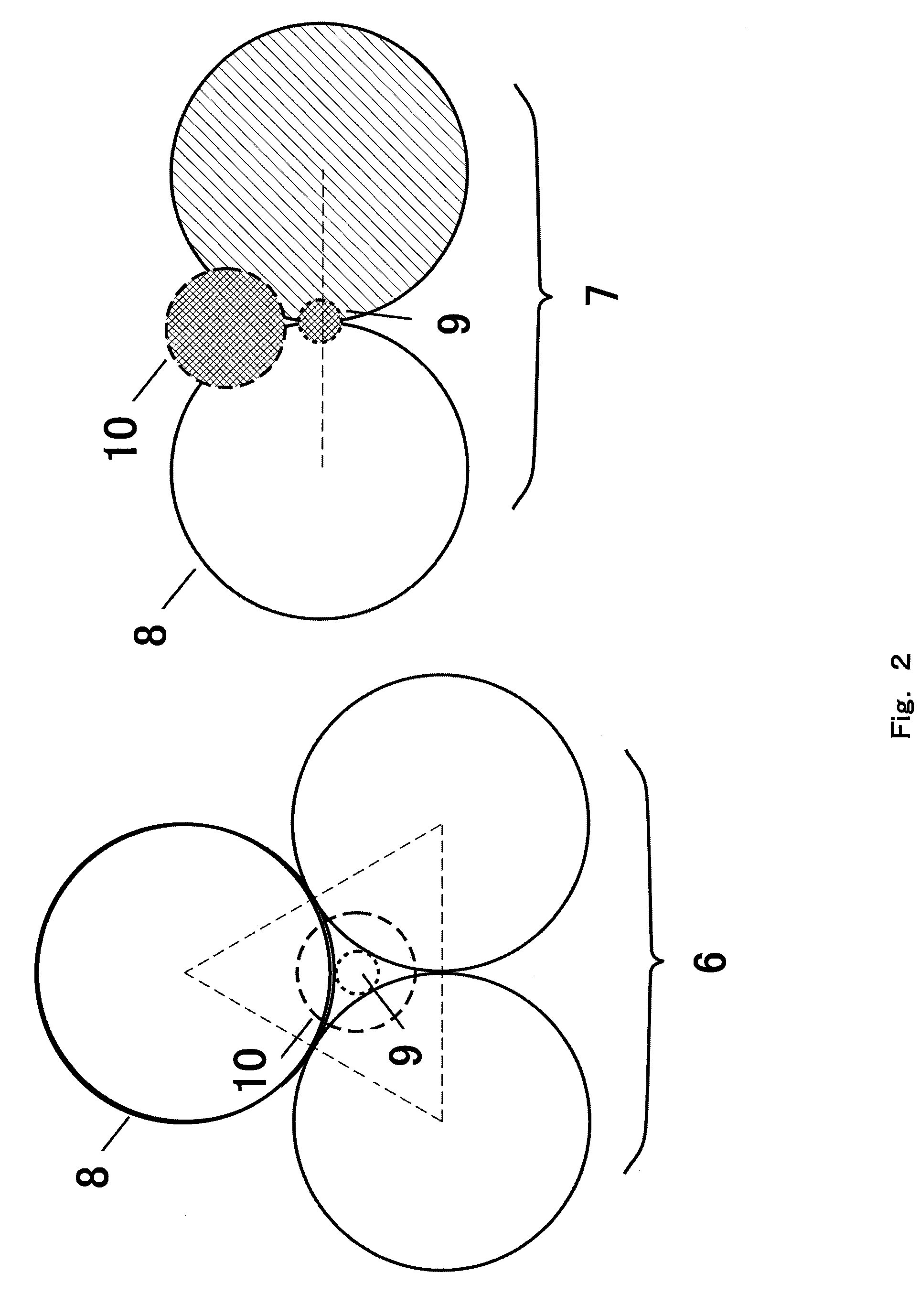

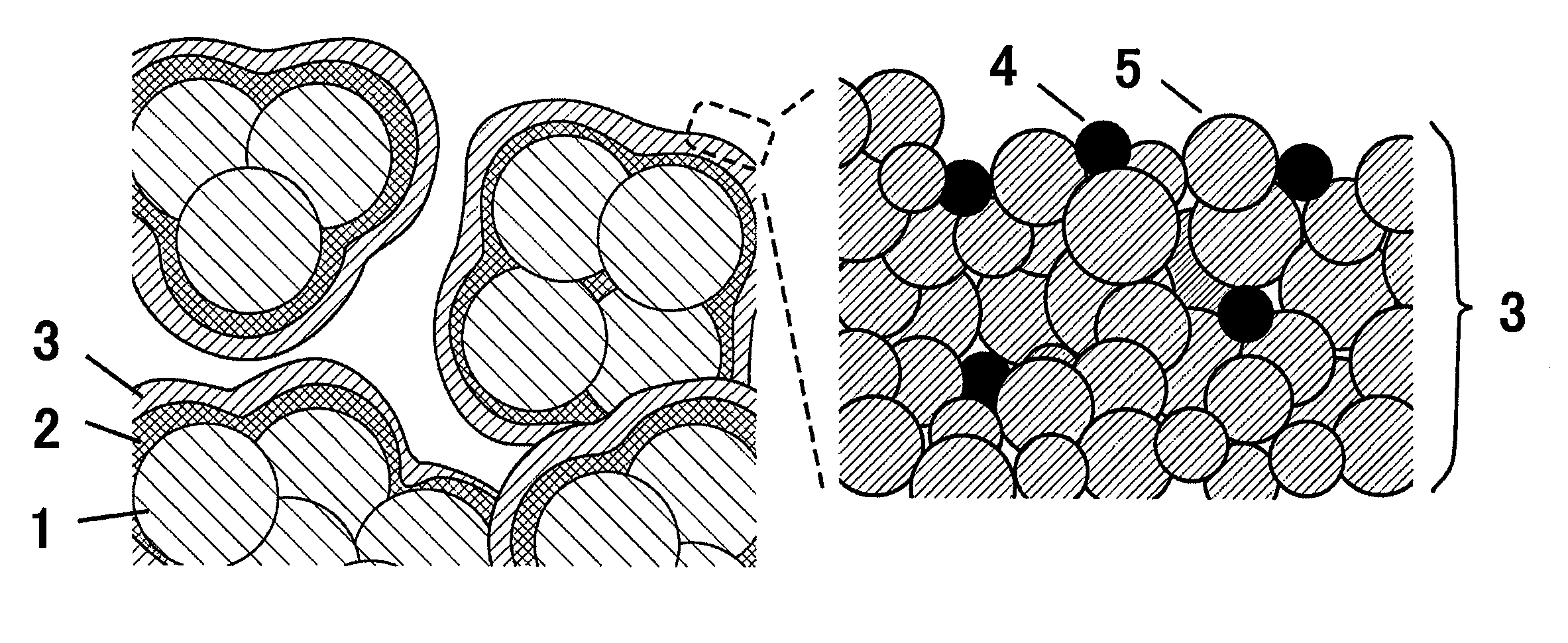

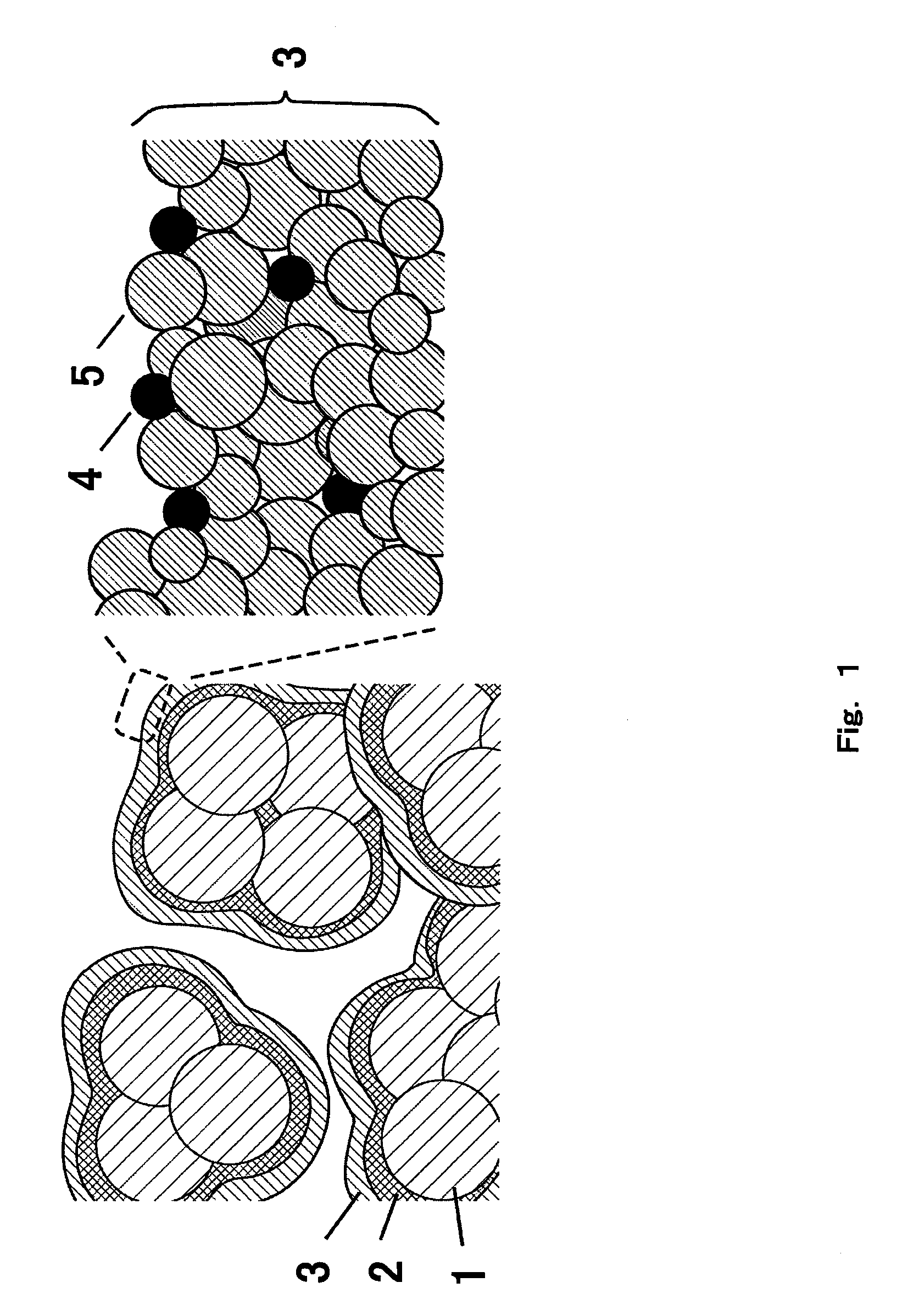

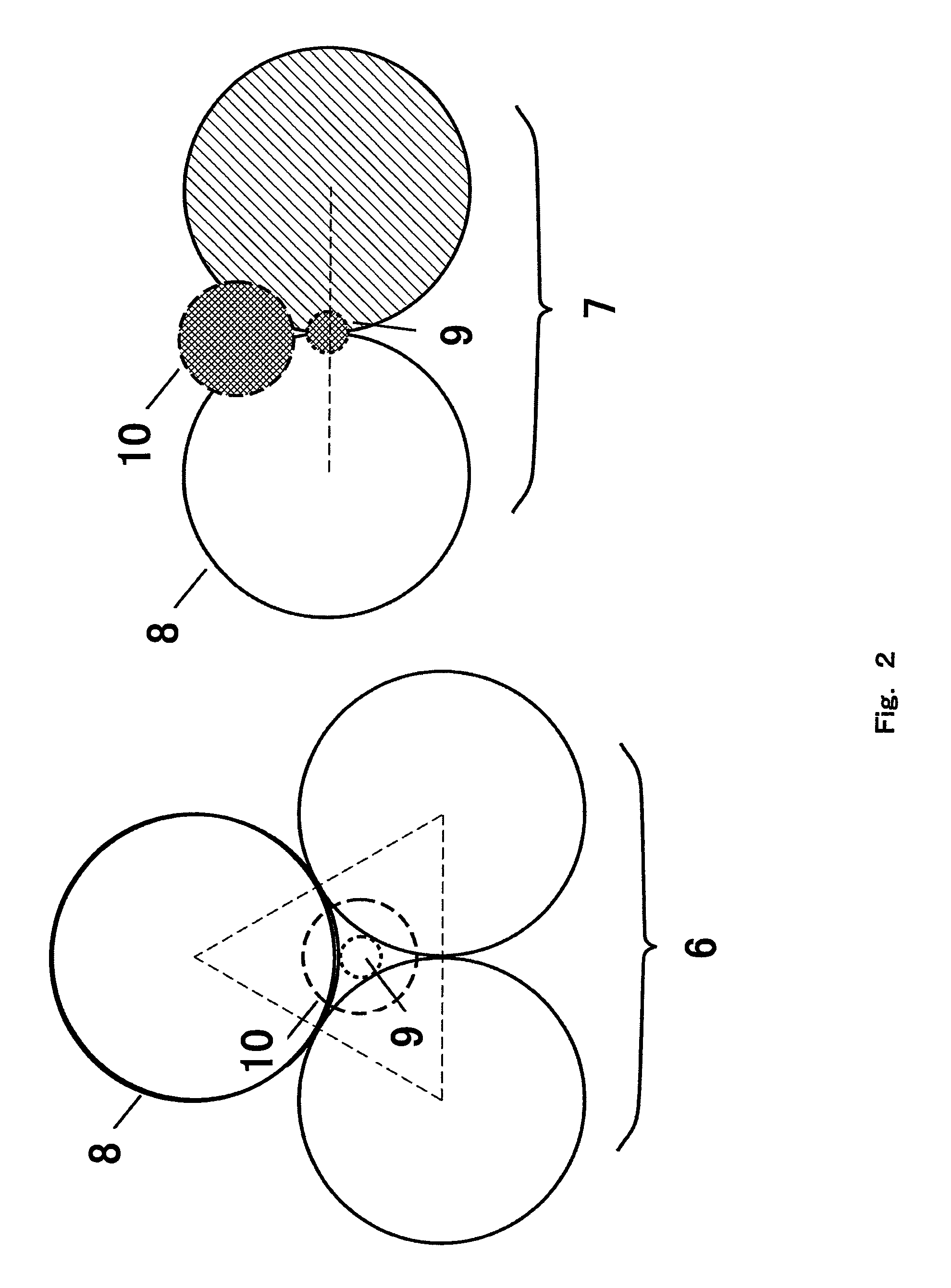

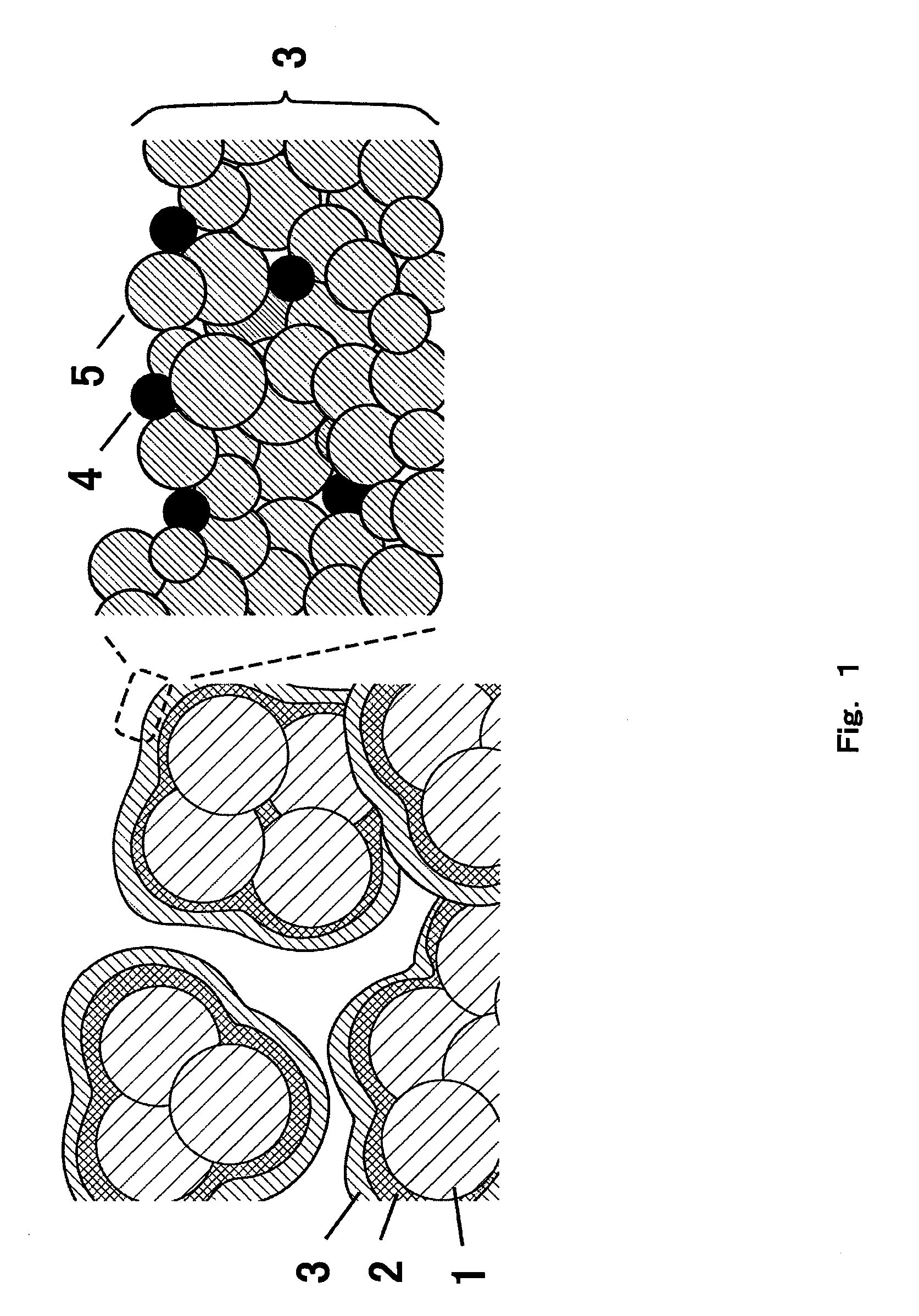

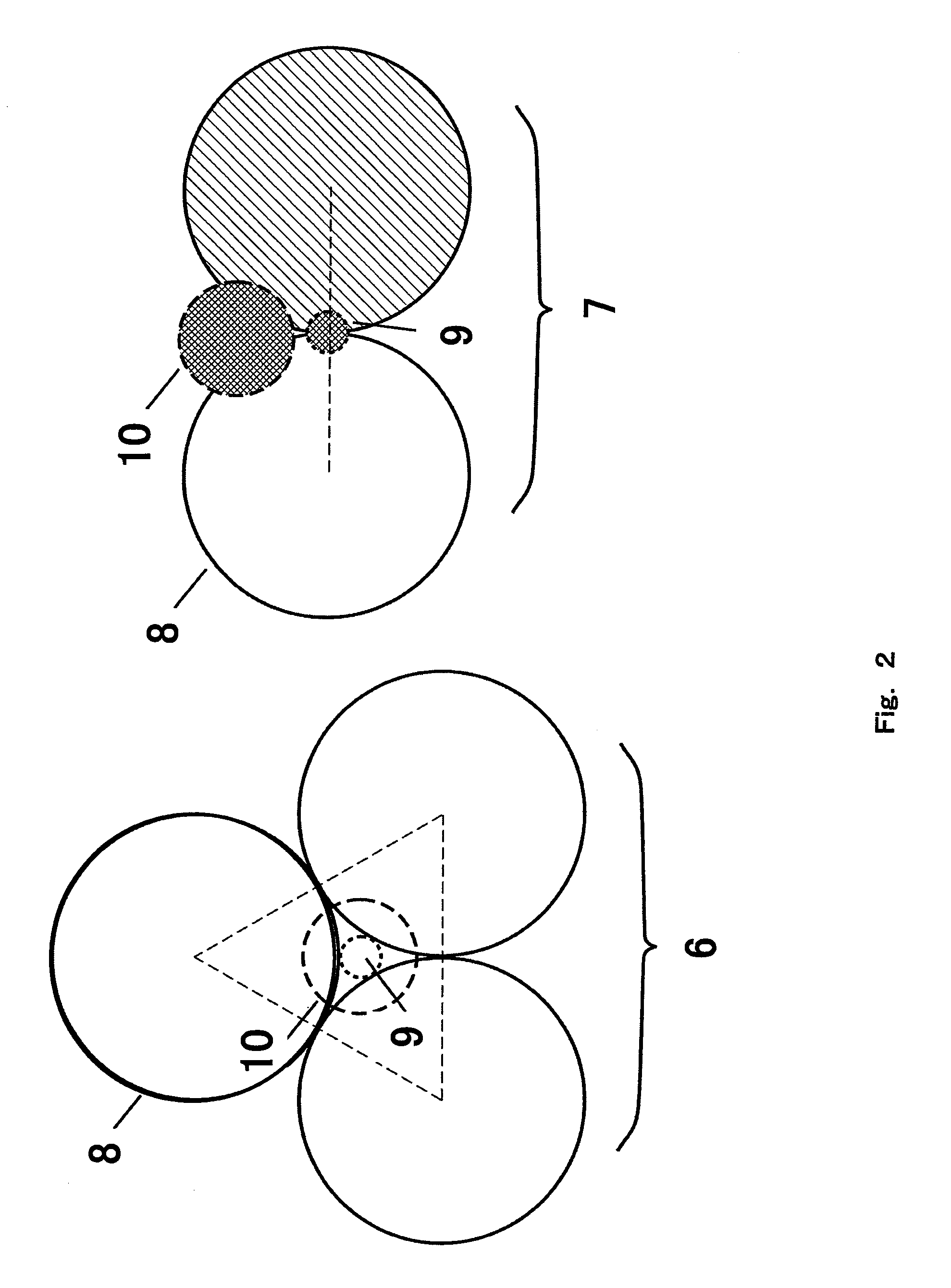

Fuel cell comprising oxygen electrode with surface nanostructure

InactiveUS20100104915A1Uniform reaction rateAccurate operationActive material electrodesSolid electrolyte fuel cellsCarbon NanoparticlesNanometre

The present invention is aimed to realize, in a fuel cell with an oxygen electrode (a catalytic electrode), both catalytic function and immobilization of the catalyst nanoparticles when the catalyst nanoparticles are very small nanoparticles in the size of 1-3 nm.Oxygen electrode used in the fuel cell according to the present invention is an oxygen electrode comprising a plurality of carbon particles, a carbon thin-film, and surface nanostructure, wherein the carbon particles are bonded to one another with the carbon thin-film 2, the surface nanostructure is formed on the surface of the carbon thin-film, the surface nanostructure comprises catalyst nanoparticles made of platinum (Pt) and carbon nanoparticles, diameter of each of the carbon particles is 30 nm or more and 100 nm or less, diameter of the catalyst nanoparticle is 1.7 nm or more and 3.1 nm or less, and diameter of the carbon nanoparticle is 1.0 nm or more and 11.2 nm or less. According to this combination of these elements, the catalyst nanoparticles are confined within three-dimensional structure to be formed by the carbon nanoparticles and are immobilized without losing space which allows any reactant to be accessed to the surface of the catalyst nanoparticles.

Owner:PANASONIC CORP

Nonaqueous electrolyte secondary battery

ActiveUS7455932B2Suppress gas evolutionImprove featuresNon-aqueous electrolyte accumulatorsSmall-sized cells cases/jacketsComposite oxidePurified water

A nonaqueous electrolyte secondary battery wherein a material capable of occluding / discharging lithium is used as a negative electrode material and a lithium-transition metal composite oxide which contains Ni and Mn as the transition metal and has a layered structure is used as a positive electrode material is characterized in that a lithium-transition metal composite oxide having a BET specific surface area less than 3 m2 / g and a pH of 11.0 or less when 5 g of the lithium-transition metal composite oxide is immersed in 50 ml of purified water is used as the positive electrode active material.

Owner:PANASONIC ENERGY CO LTD

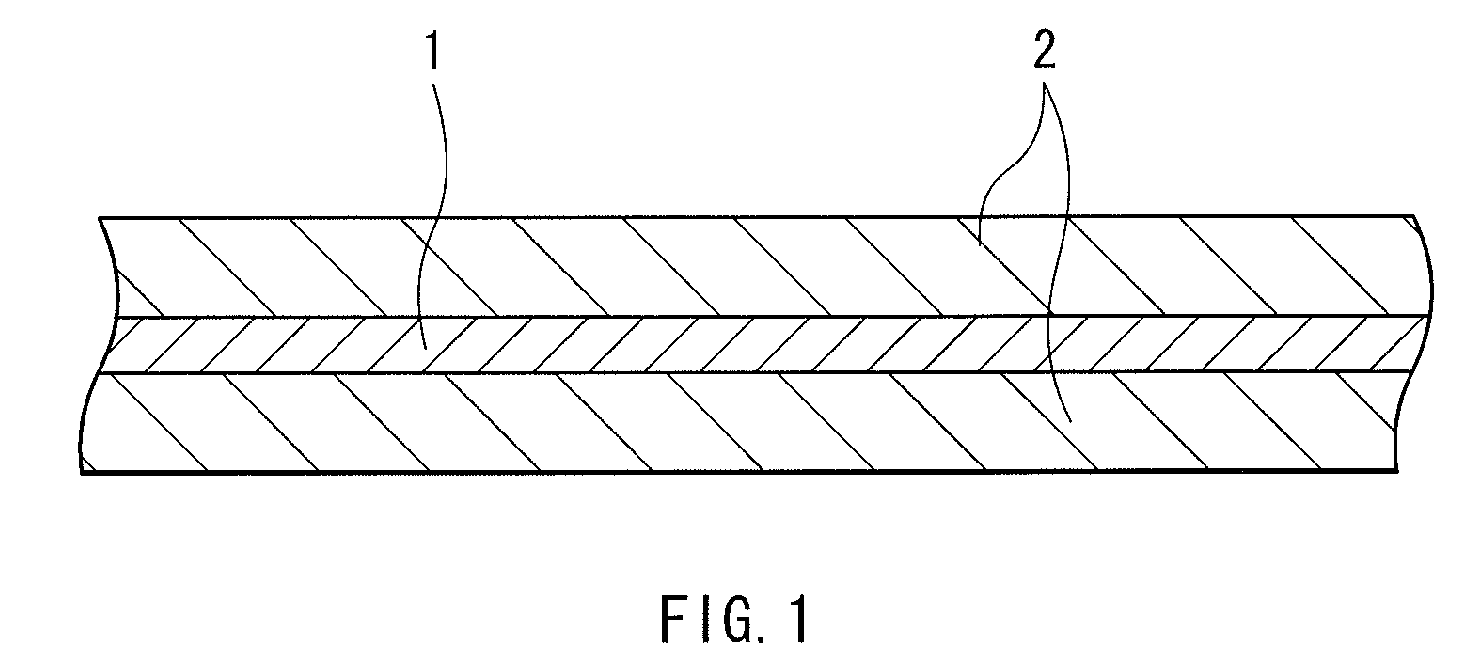

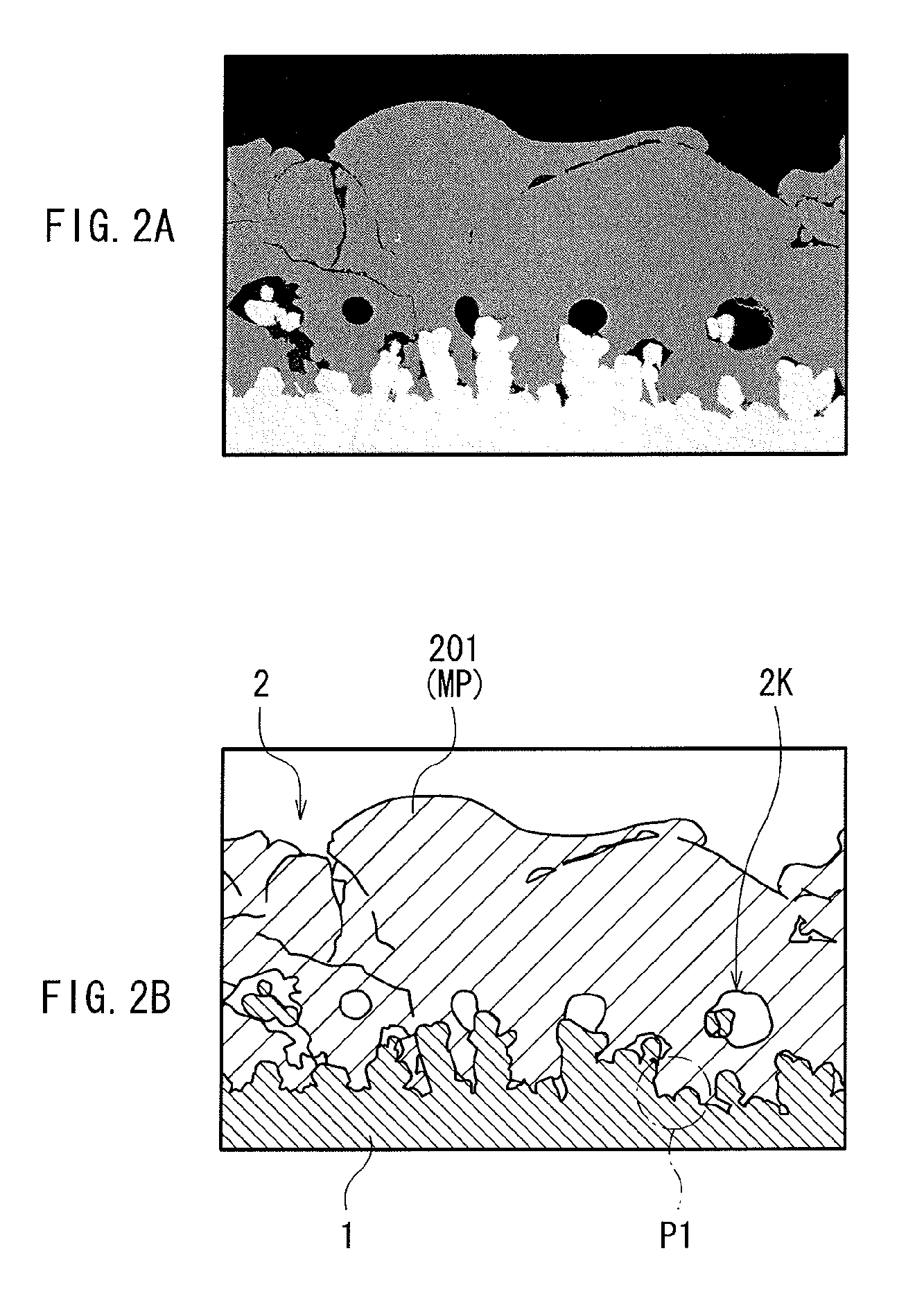

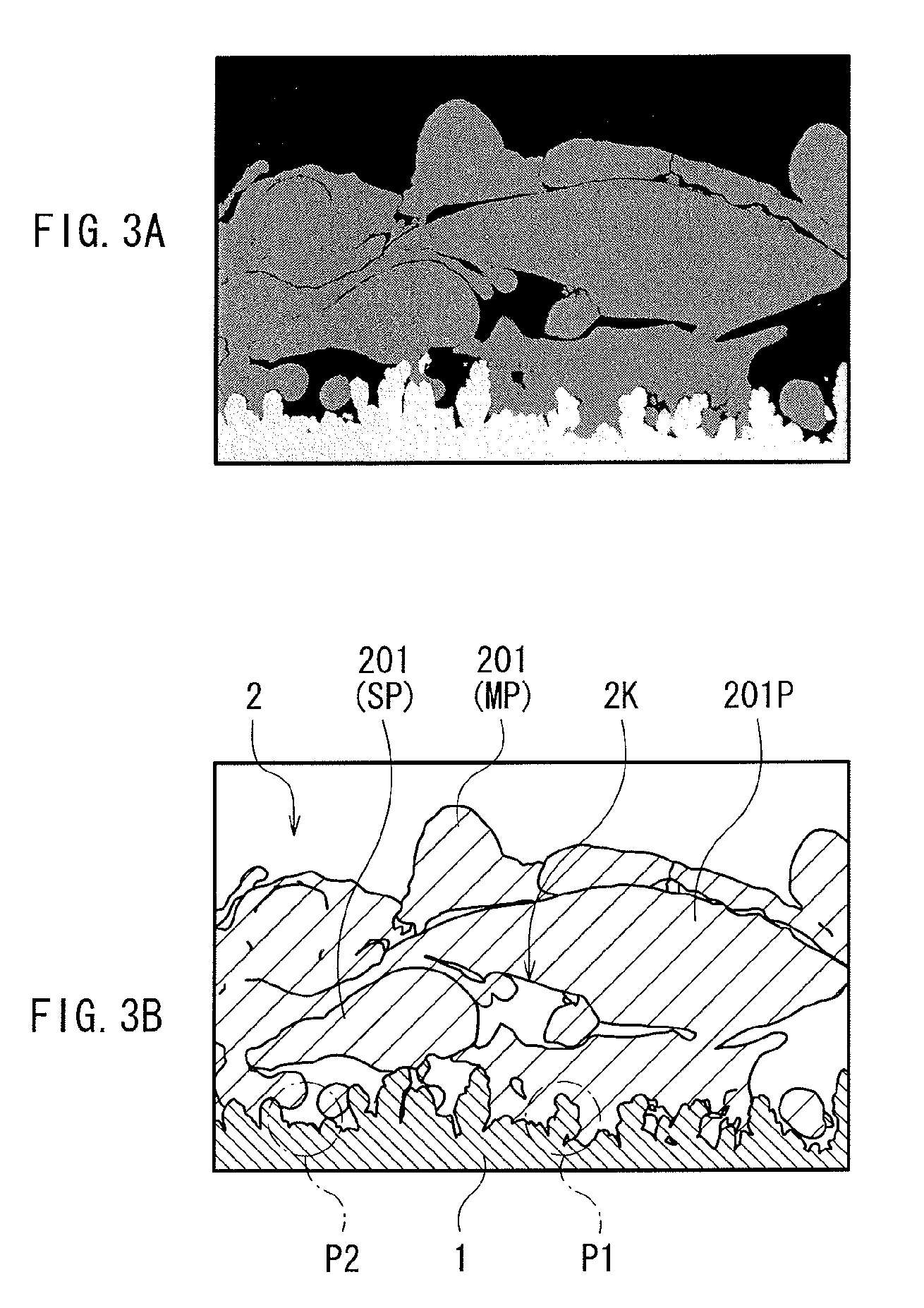

Fuel cell comprising oxygen electrode with surface nanostructure

ActiveUS8318374B2Reduced reaction areaImproved and stable power generation performanceCell electrodesSolid electrolyte fuel cellsPlatinumFuel cells

An oxygen electrode used in the fuel cell and includes a plurality of carbon particles, a carbon thin-film, and surface nanostructure. The carbon particles are bonded to one another with the carbon thin-film, and the surface nanostructure is formed on the surface of the carbon thin-film. The surface nanostructure comprises catalyst nanoparticles made of platinum (Pt) and carbon nanoparticles. According to this combination of these elements, the catalyst nanoparticles are confined within three-dimensional structure to be formed by the carbon nanoparticles and are immobilized without losing space which allows any reactant to be accessed to the surface of the catalyst nanoparticles.

Owner:PANASONIC CORP

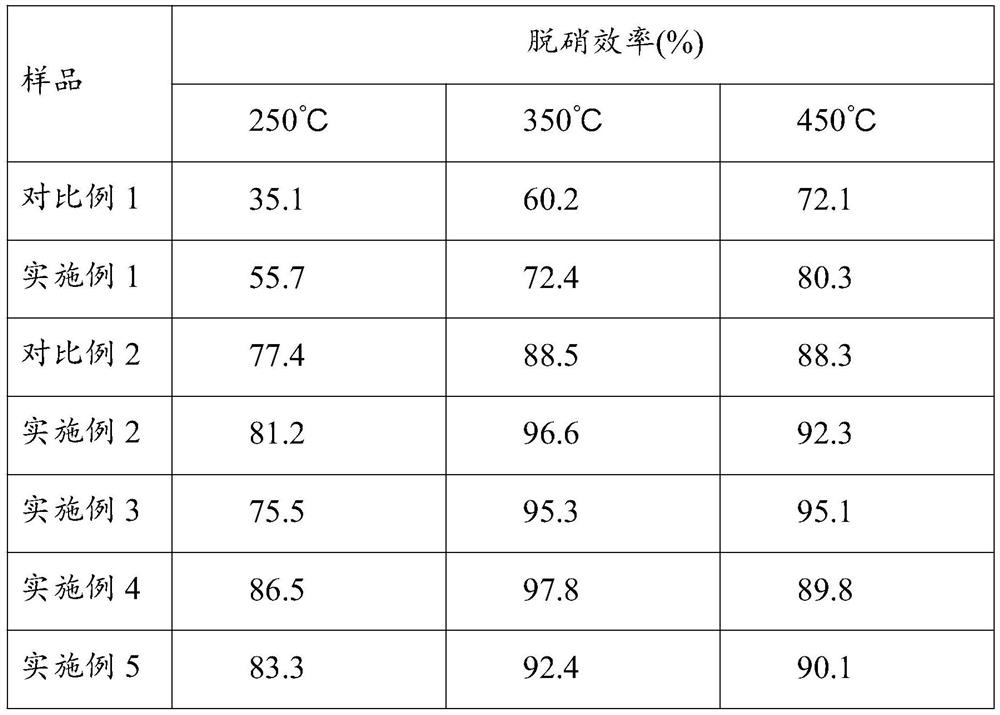

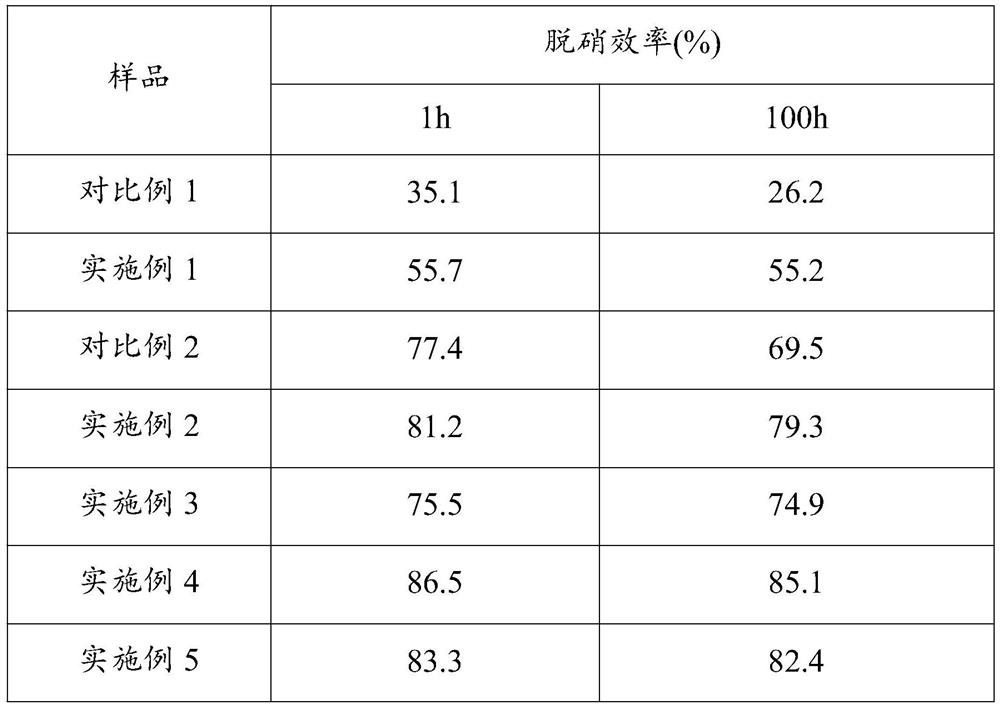

Preparation method of anti-ammonium bisulfate flat plate type denitration catalyst and obtained catalyst

ActiveCN112973766AReduce generationReduce adsorptionMolecular sieve catalystsDispersed particle separationMolecular sievePtru catalyst

The invention relates to the technical field of selective catalytic reduction catalysts, in particular to a preparation method of an anti-ammonium bisulfate flat plate type denitration catalyst and the obtained catalyst. According to the preparation method, a preparation process of firstly preparing the catalyst single plate for forming and then impregnating the active component is adopted, the catalyst single plate is calcined at a relatively high calcination temperature, the wear resistance of the catalyst is improved, the activity of the catalyst is ensured, the active component is mainly distributed on the surface of the paste material, the reaction area of SO2 on the monolithic catalyst is effectively reduced, and the SO2 / SO3 conversion rate is reduced. A hydrophobic molecular sieve and a competitive adsorbent are also added, so that the adsorption of H2O in flue gas on the surface of the catalyst is reduced, the capture of SO2 is realized, the contact between SO2 and active components of the catalyst and the generation of SO3 are reduced, the SO2 reaction area is reduced, and the ammonium bisulfate resistance of the catalyst is improved.

Owner:DATANG NANJING ENVIRONMENTAL PROTECTION TECH

Non-aqueous electrolyte secondary battery and method for producing the same

ActiveUS9331337B2Increase battery capacityImprove featuresFinal product manufacturePrimary cellsLutetiumPhosphate

A positive electrode active material with least part of a surface coated with a surface treatment layer composed of a phosphate compound. The phosphate compound contains at least one element selected from the group consisting of neodymium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, ytterbium, and lutetium.

Owner:PANASONIC ENERGY CO LTD

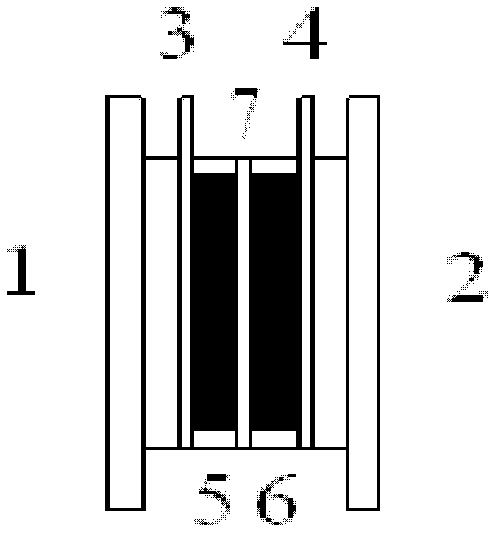

Electrochemical device

InactiveCN107112447AReduced reaction areaSolve the problem of accelerated capacity degradationCell electrodesFinal product manufactureEngineeringSide reaction

An electrochemical device of the present invention comprises: a case; an electrode assembly disposed inside the case and comprising a positive electrode, a negative electrode, and a separator interposed between the negative electrode and the positive electrode; and an electrolyte injected into the case, wherein, on the basis of the total volume (CV) of an empty space inside the case according to equation 1 below, the volume (EV) of a free space according to equation 2 below is 0-45 vol%. The contents of equations 1 and 2 are the same as disclosed in the specification. The electrochemical device can solve a problem of accelerating the capacity degradation, causing by reducing the reaction area on surfaces of the electrodes and further increasing the side reaction, through the gas generated from an oxidation reaction of the electrolyte due to a high voltage.

Owner:LG CHEM LTD

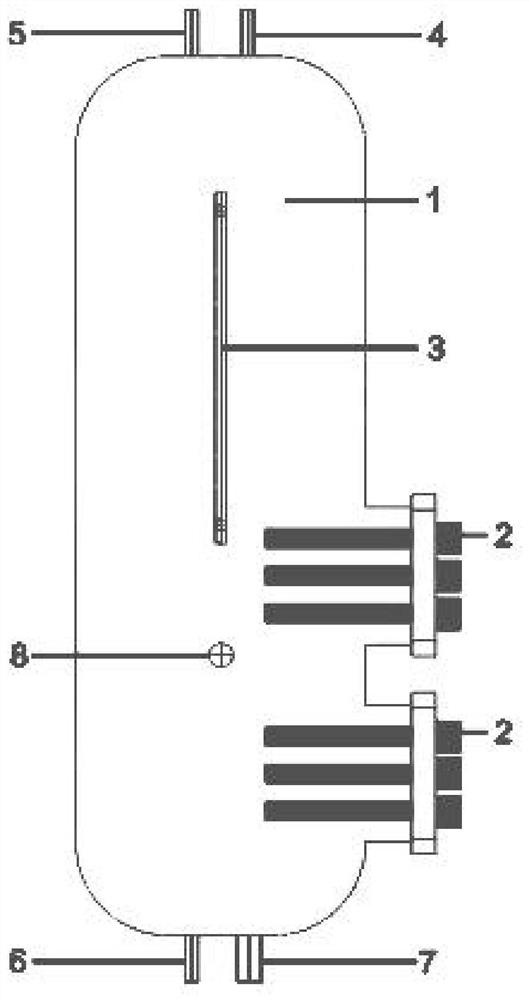

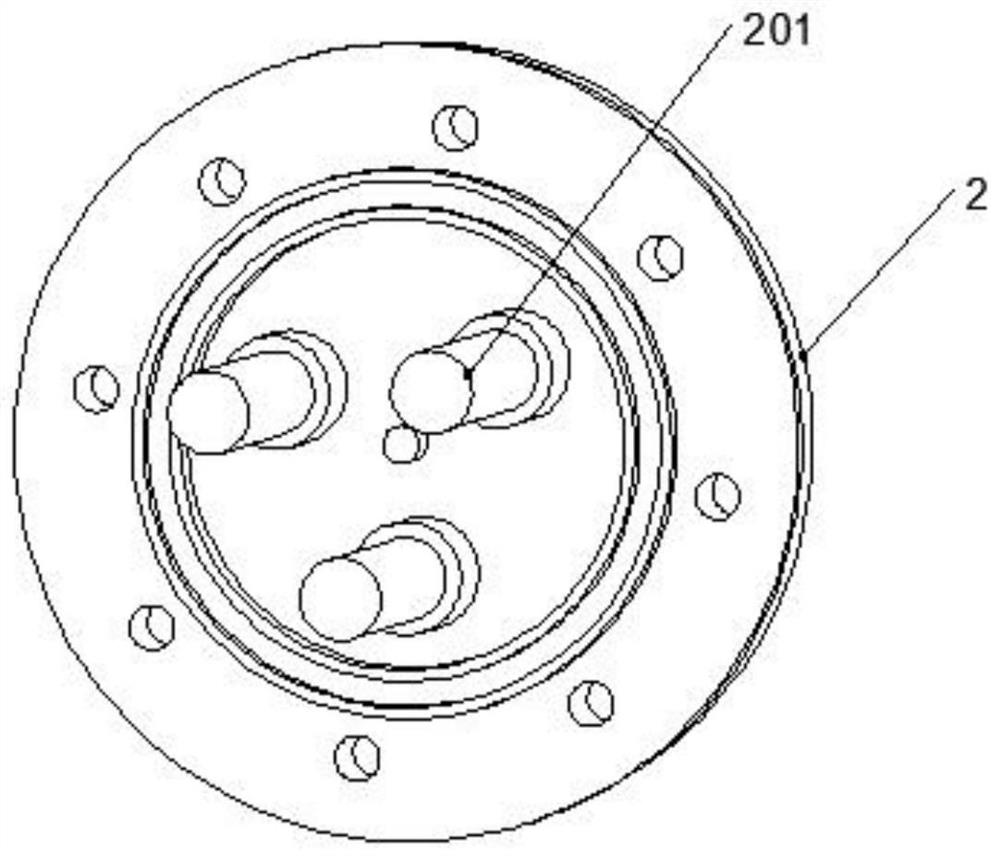

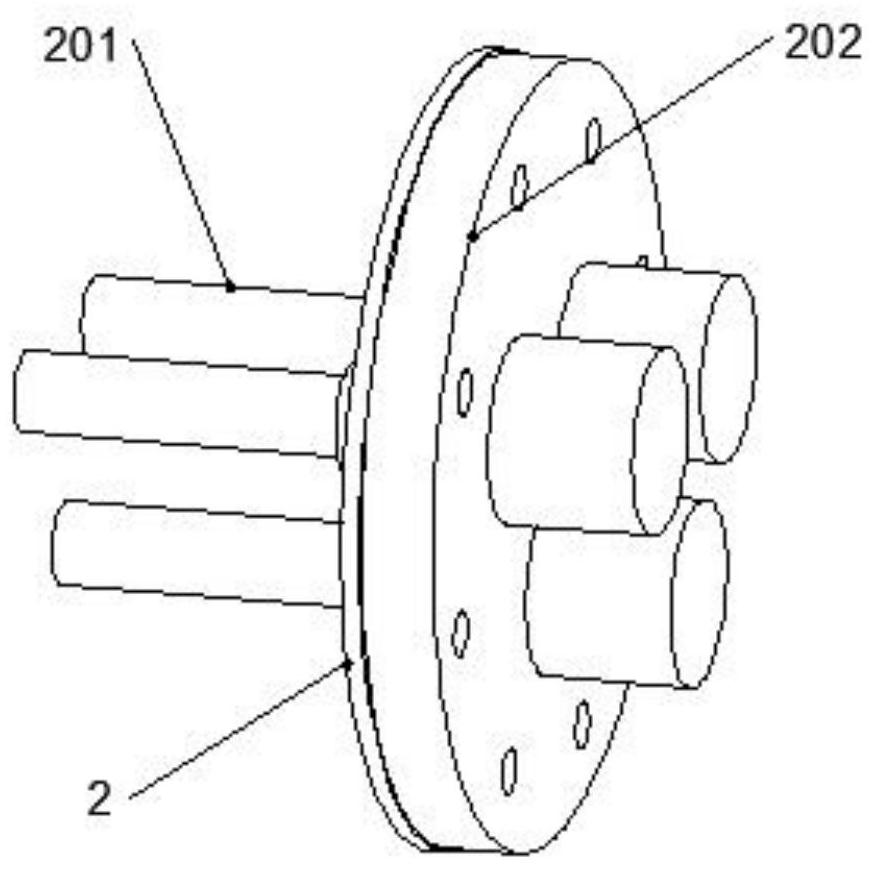

Electric ion evaporator

PendingCN111878791AImprove efficiencyRaise the water temperatureElectric discharge heatingElectrode boilersElectrolysed waterLow voltage

The invention discloses an electric ion evaporator. The evaporator comprises a steam generation furnace body, a steam outlet is formed in the right side of the top of the steam generation furnace body, a water supplementing opening is formed in the left side of the bottom of the steam generation furnace body, a sewage draining opening is formed in the right side of the bottom of the steam generation furnace body, a low-voltage electrode electric ion heating body is installed on the right side of the steam generation furnace body, and a zero line protection terminal is mounted on the steam generation furnace body. Water is heated through the low-voltage electrode electric ion heating body, electric energy is directly and efficiently converted into heat energy, water molecules are promoted to be split into positive and negative electric ions in the heating process, the positive and negative electric ions flow between a positive electrode and a negative electrode, therefore energy is released, no intermediate medium is needed in the heating process, water becomes electrolyzed water in the heating process, scaling is avoided, the evaporator does not work in the absence of water, and the problem of breakdown due to water shortage is solved.

Owner:北京火龙升腾科技有限公司

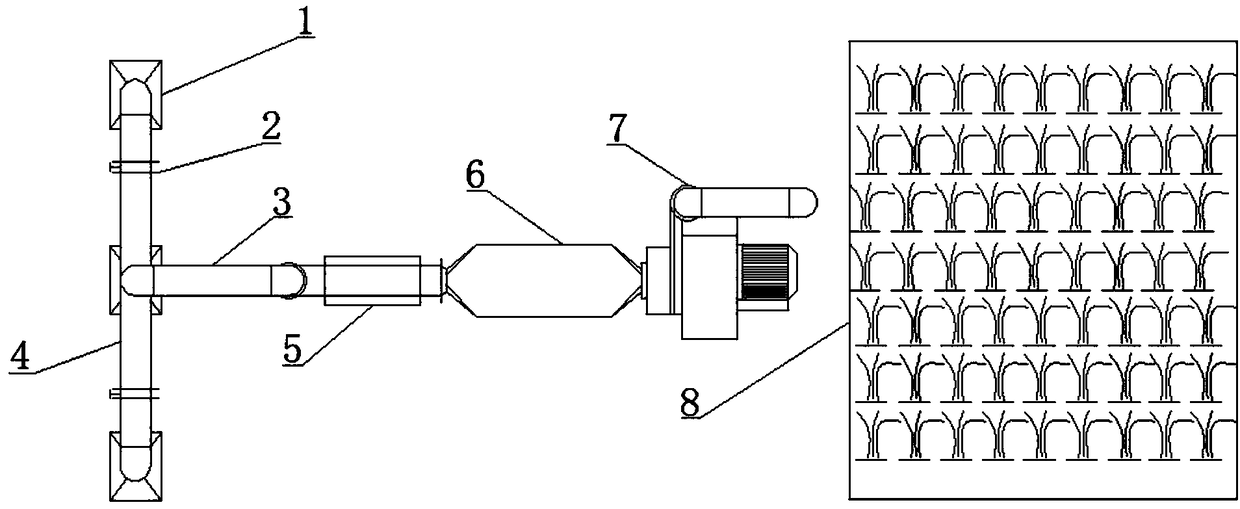

Device and process for treating odorous waste gas based on plasma technology in cooperation with biodegradation

PendingCN109499350ACompletely degradedDegradation: exhaust gas is thoroughly treated by low-temperature plasma exhaust gasGas treatmentDispersed particle filtrationTreatment completedSoil treatment

The invention relates to a device and a process for treating odorous waste gas based on a plasma technology in cooperation with biodegradation. The device comprises a low-temperature plasma waste gastreatment complete device; a collecting system is arranged at the upstream of the low-temperature plasma waste gas treatment complete device, an induced draft fan is arranged at the downstream of thelow-temperature plasma waste gas treatment complete device and is connected with a biological soil treatment system through a connecting pipeline, a discharge system is arranged at the downstream of the biological soil treatment system, and a de-fogging system is arranged between the low-temperature plasma waste gas treatment complete device and the collecting system; the low-temperature plasma generation adopts a double dielectric barrier generation technology; a gas collecting hood performs accurate collection on an odorous source, the control over air volume is realized by an adjusting valve, odorous waste gas is deeply treated by the biodegradation technology after being treated by the low-temperature plasma treatment technology, the treated odorous waste gas can be directly dischargedfrom a lawn above biological soil, and the standard requirements for unorganized discharge can be met.

Owner:CAS NEW WORLD HEFEI ENVIRONMENTAL PROTECTION TECH CO LTD

Support member for an electrochemical cell and electrochemical hydrogen compressor

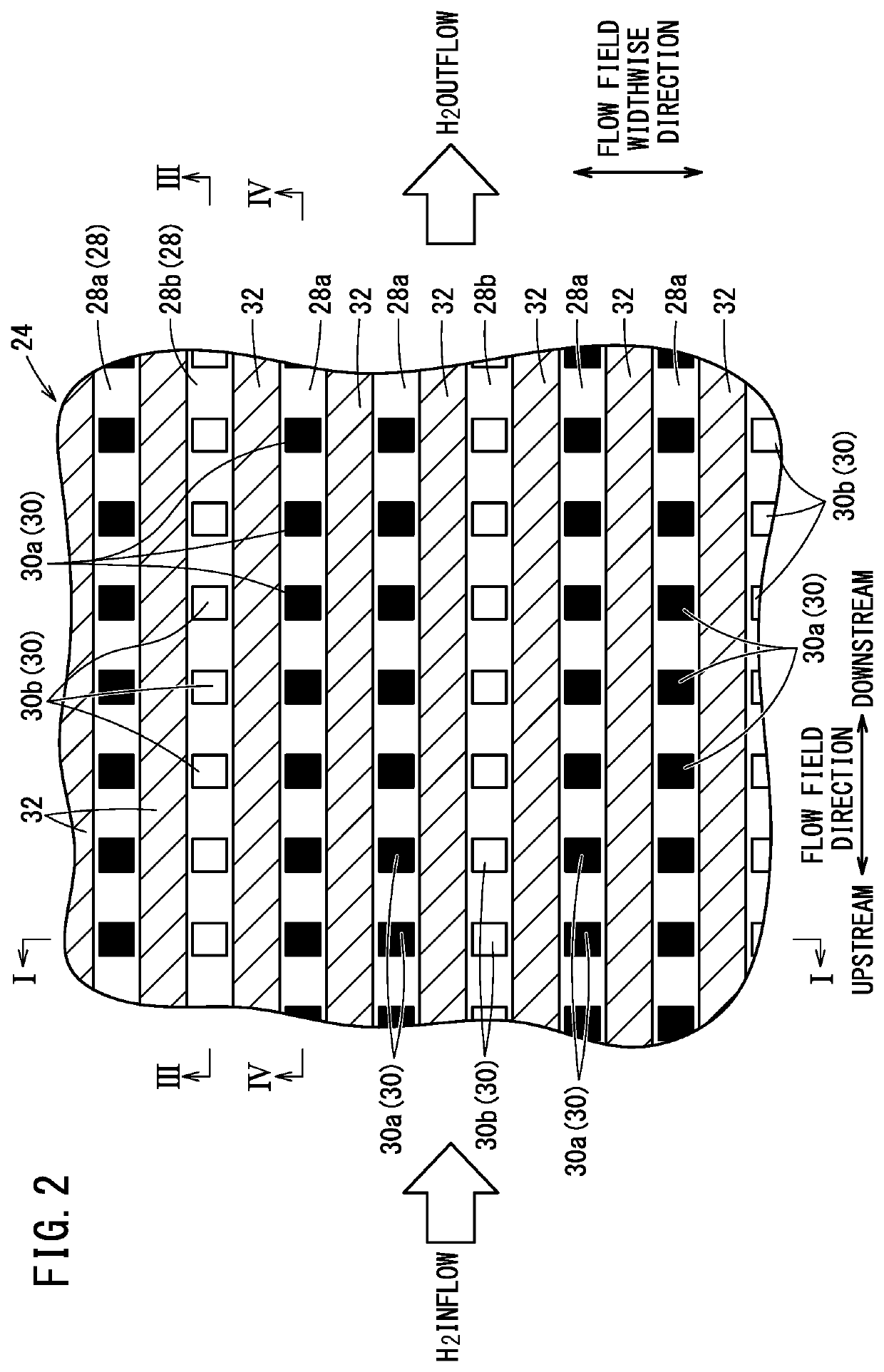

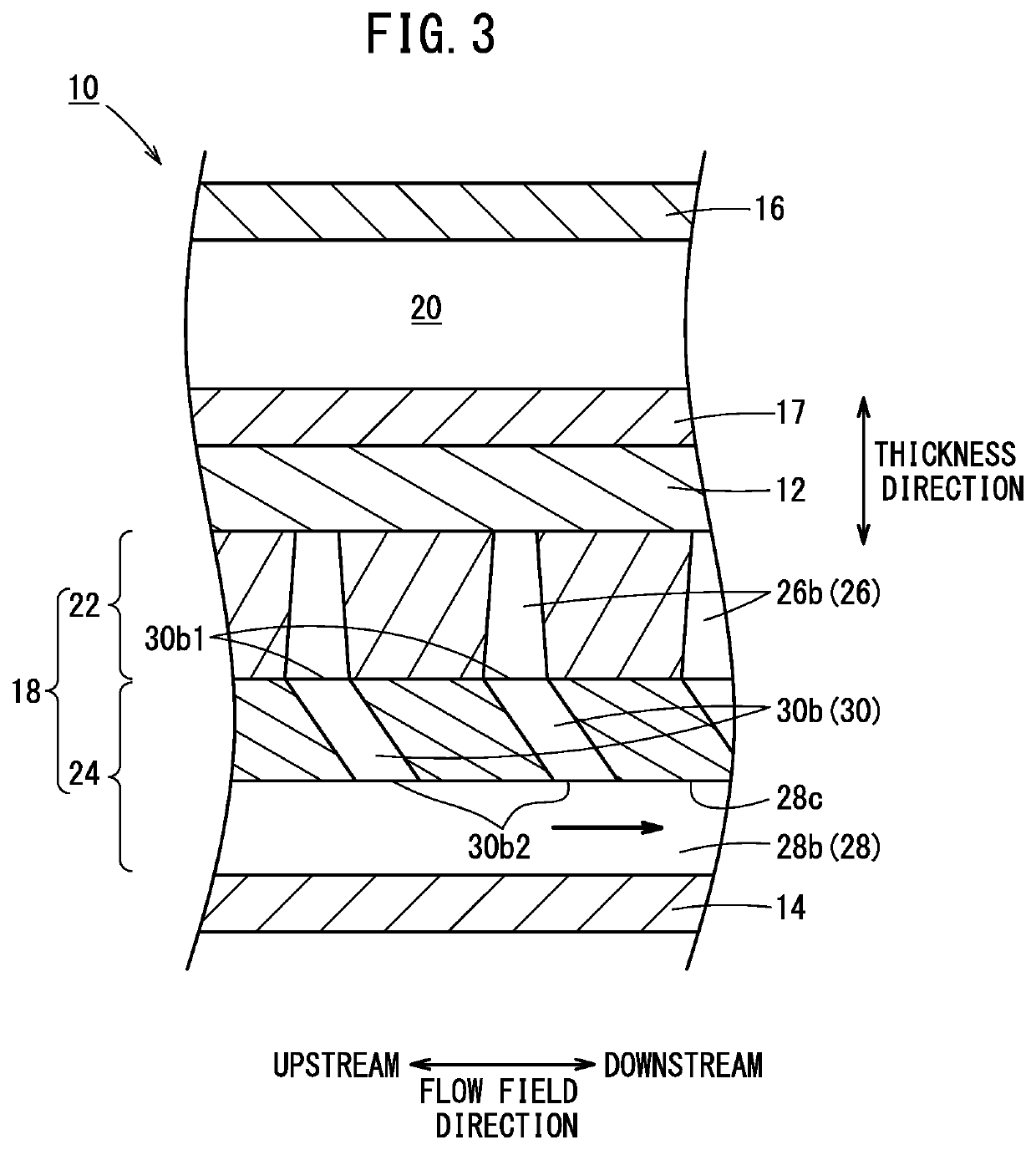

PendingUS20220307487A1Improve the immunityLow efficiencyReactant parameters controlPumpsChemical physicsElectrical conductor

An electrochemical hydrogen compressor and a support member for an electrochemical cell include, in a flow field member, flow field grooves through which an anode gas (for example, a hydrogen gas) is allowed to flow in a predetermined direction, and a plurality of through holes one ends of which open in the flow field grooves, and other ends of which are in communication with ventilation holes of an anode current conductor. At least a portion of the through holes (for example, discharge through holes) are inclined at an acute angle with respect to an upstream side of the flow field grooves (for example, discharge flow field grooves).

Owner:HONDA MOTOR CO LTD

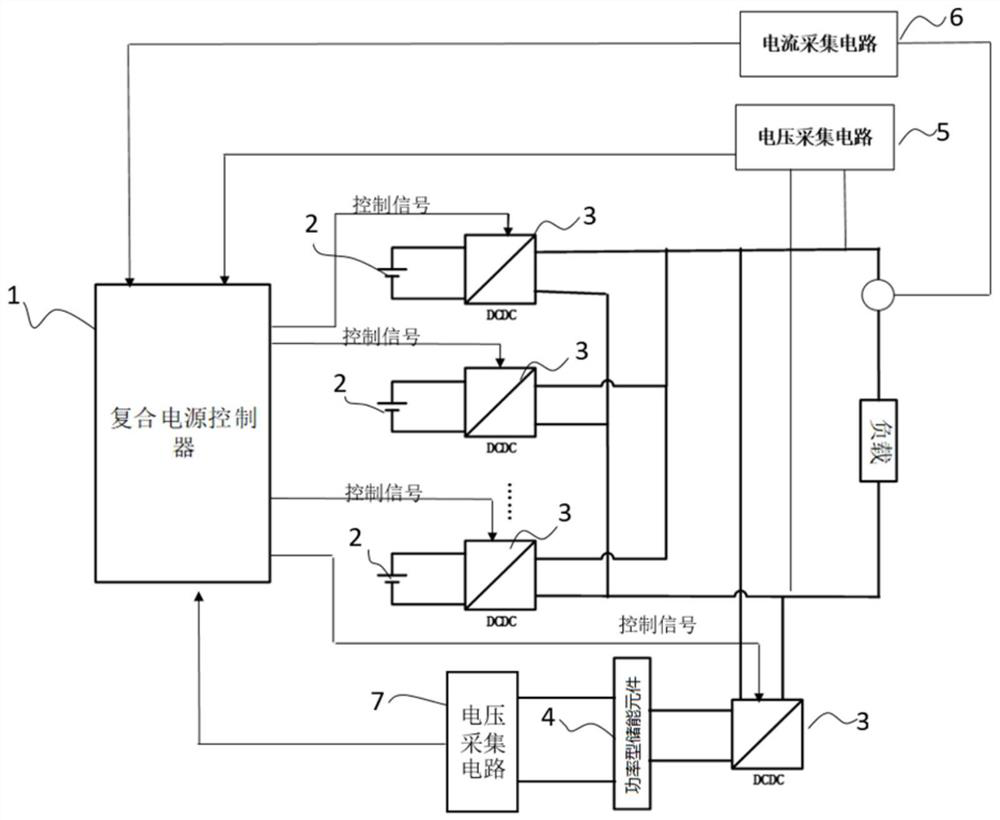

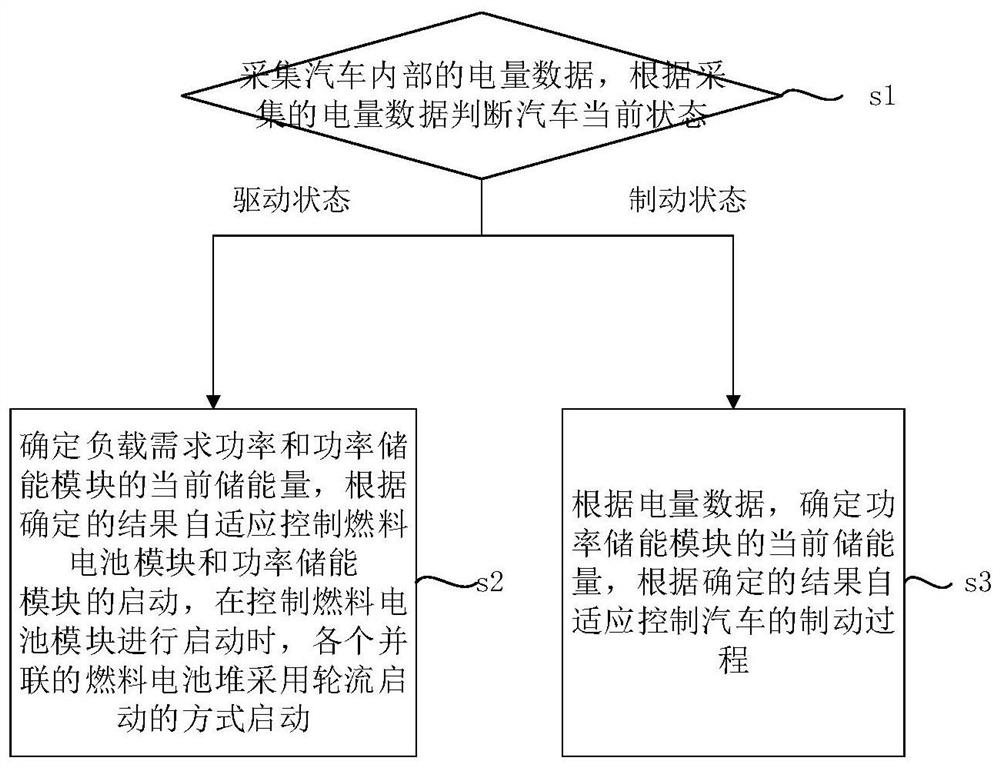

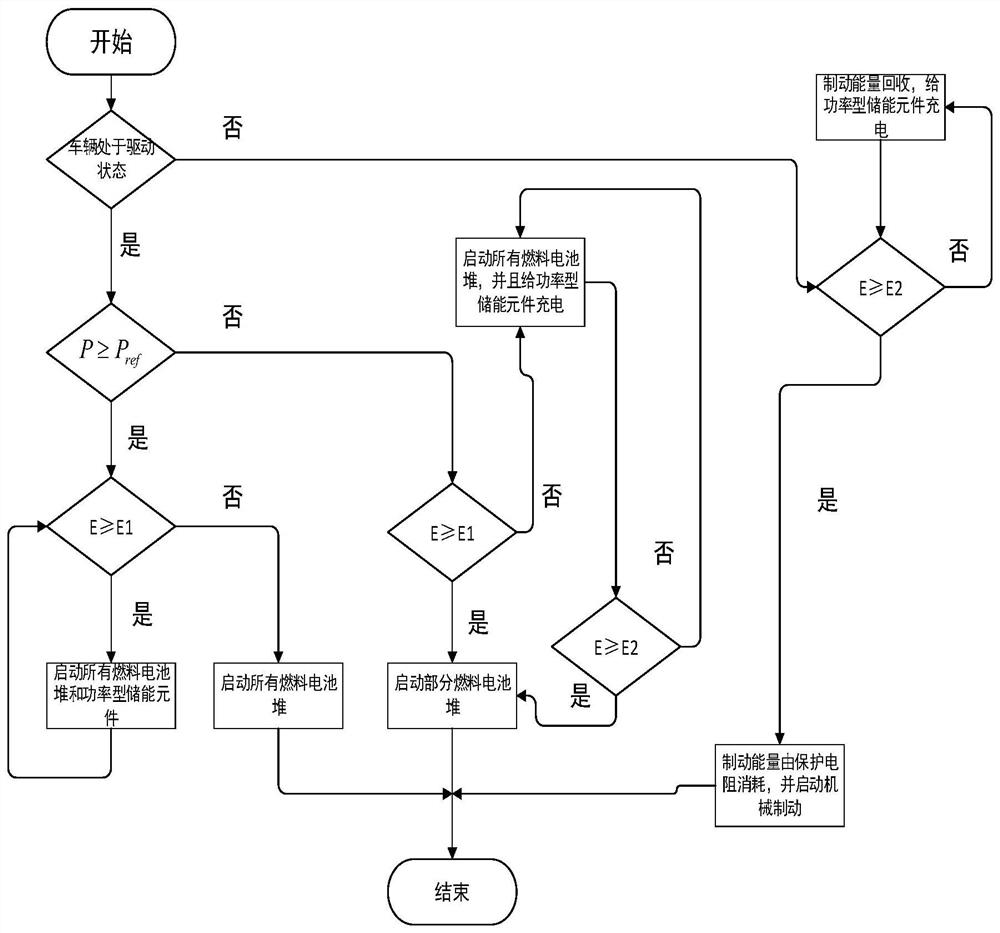

A composite fuel cell power system and control method

ActiveCN108215894BReduced reaction areaImprove consistencyPropulsion by batteries/cellsBattery/fuel cell control arrangementPower controllerFuel cells

The invention relates to a composite fuel cell power supply system and a control method. The system includes: a fuel cell module including a plurality of fuel cell stacks connected in parallel; a power storage module; connection; the composite power controller is respectively connected with the fuel cell module, the power storage module and the data acquisition module; the method includes: collecting the power data inside the car, judging the current state of the car according to the collected power data, and determining the load demand if it is in the driving state After the current stored energy of the power and power energy storage modules, adaptively control the startup of the fuel cell module and the pure power module; if it is in the braking state, after determining the current stored energy of the power energy storage modules, adaptively control the braking process of the car. Compared with the prior art, the invention has the advantages of good consistency, low manufacturing cost, rapid cold start, long service life and strong reliability.

Owner:TONGJI UNIV

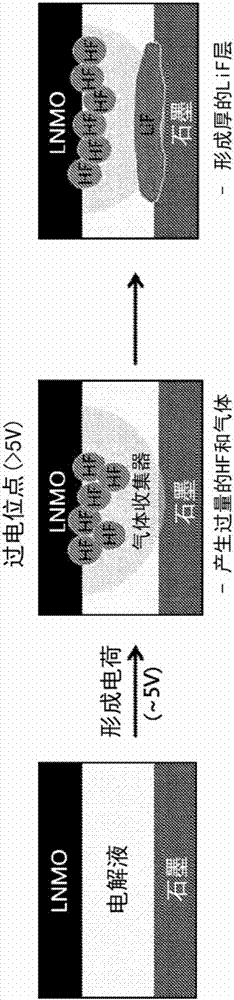

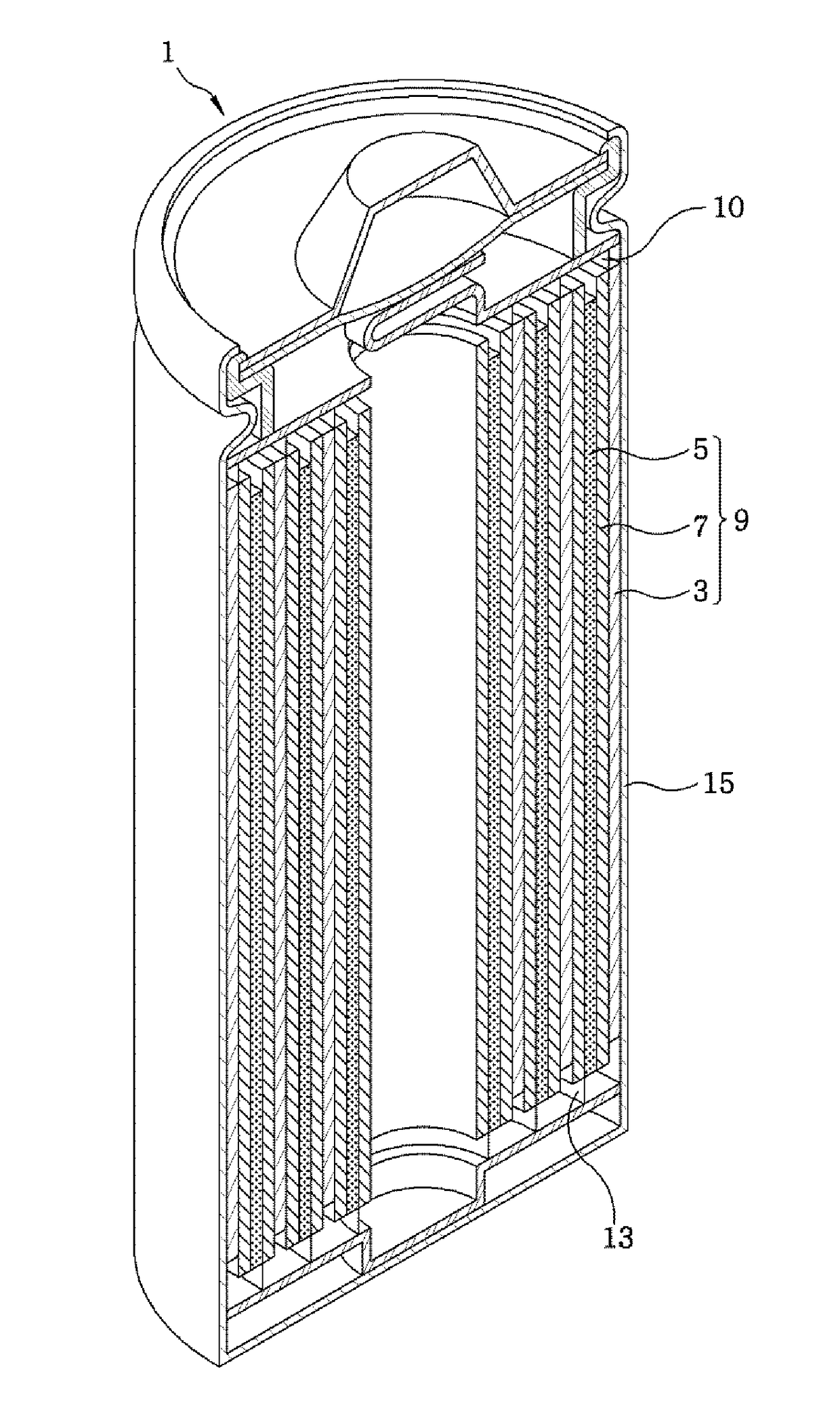

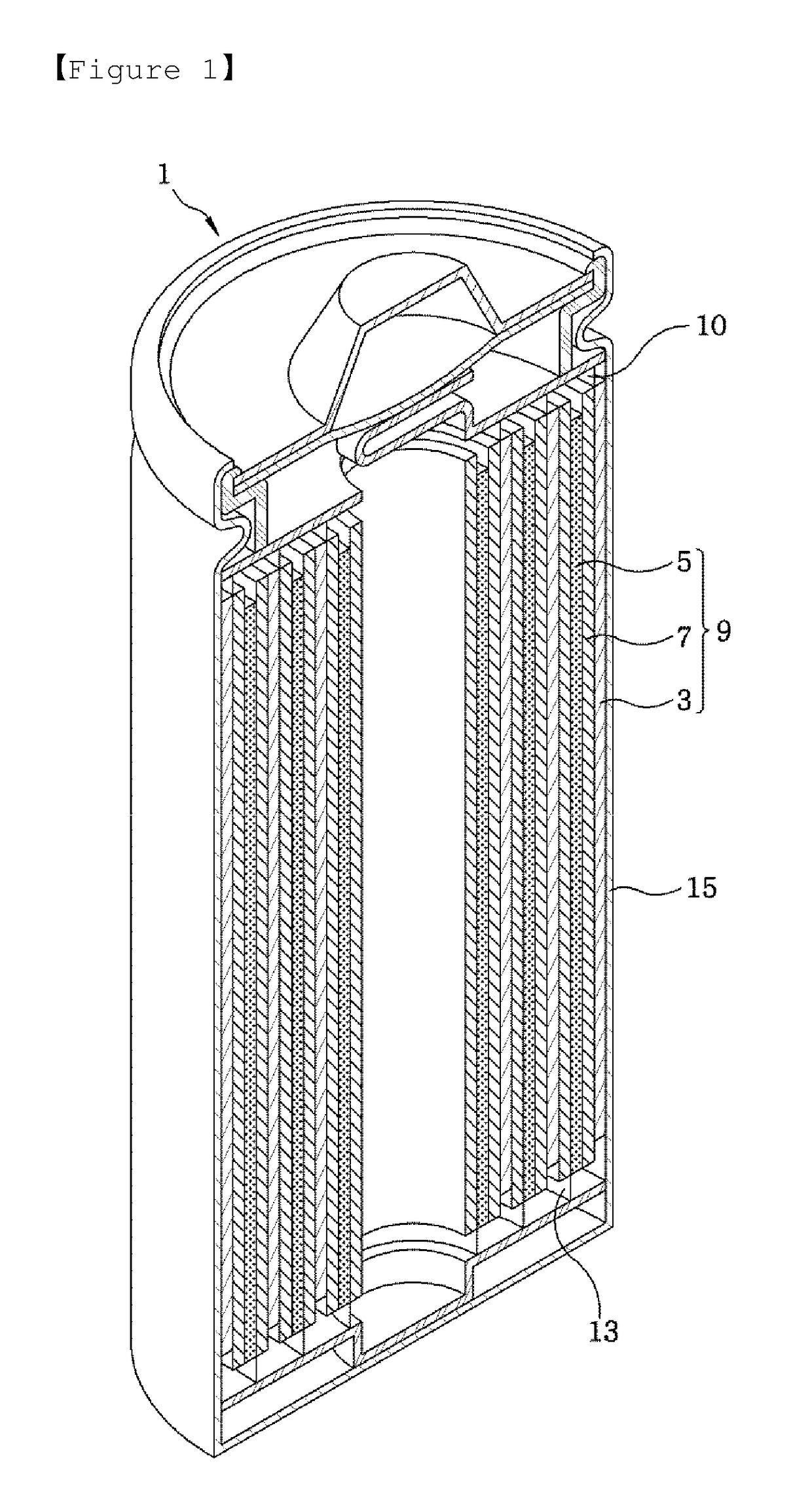

Lithium-ion secondary battery, anode for lithium-ion secondary battery, power tool, electric vehicle and energy storage system

ActiveUS9214667B2Reduced reaction areaImprove featuresElectrode thermal treatmentFinal product manufactureElectrolytic agentElectrical battery

A lithium-ion secondary battery allowed to improve cycle characteristics and initial charge-discharge characteristics is provided. The lithium-ion secondary battery includes: a cathode; an anode including an anode active material layer; and an electrolytic solution. The anode active material layer includes an anode active material and an inorganic compound, and the inorganic compound includes one or both of an alkoxysilane compound and a hydrolysate thereof.

Owner:MURATA MFG CO LTD

Heat treatment apparatus of MEA for fuel cell

ActiveUS11251456B2Avoid deformationIncreased durabilityLaminationLamination apparatusFuel cellsPtru catalyst

A heat treatment apparatus for a fuel cell membrane-electrode assembly is provided. The heat treatment apparatus includes a hot press installed on upper and lower sides of feeding path to move in the vertical direction on a frame and which presses the electrode catalyst layers on upper and lower surfaces of the membrane-electrode assembly sheet. A plurality of gripper modules are installed at set intervals in a base member along a feeding direction of the membrane-electrode assembly sheet, and selectively grip both side edges of the membrane-electrode assembly sheet. A driving unit reciprocally moves the base member in a direction perpendicular to the feeding direction of the membrane-electrode assembly sheet and in the feeding direction of the membrane-electrode assembly sheet.

Owner:HYUNDAI MOTOR CO LTD +1

Electrode for zinc bromine storage battery and zinc bromine storage battery assembled by the same

ActiveCN103137941BAvoid osmosisSimplified VentSecondary cellsActive material electrodesElectrochemical responseHydrogen

The invention provides an electrode for a zinc bromine storage battery and a zinc bromine storage battery assembled by the same. Due to the characteristic that the zinc bromine storage battery is free of electrolyte flow, the method that a base body is matched with electrode paste is adopted. A battery active substance with high thickness is mixed in the electrode paste and a complexing agent and a hydrogen evolution inhibitor are added into the electrode paste. The problem that energy density is low caused by the fact that electrolyte of the zinc bromine storage battery can not flow, and bromine permeation and hydrogen separation of the battery are restricted so that an exhaust vent of the battery is simplified. Meanwhile, the characteristic that an electromechanical reaction concentrates on two sides of a separating film is combined so that the electrode paste of the electrode is in graded distribution inside the base body. The quantity of the electrode paste close to an electrolyte film is large and the quantity of the electrode paste close to a current collector is small so that the active substance inside the electrode paste is capable of participating in the electromechanical reaction, meanwhile a reaction area inside the electrode is not reduced and use ratio of the active substance is improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Electrochemical device

InactiveUS20170170512A1Reduced reaction areaIncreased side reactionFinal product manufactureCell electrodesElectrolytic agentSurface reaction

The electrochemical device of the present invention comprises: a case; an electrode assembly positioned within the case, the electrode assembly comprising a positive electrode, a negative electrode and a separator interposed between the positive electrode and the negative electrode; an electrolyte which is injected into the case, wherein the volume EV of a free space calculated from Equation 2 is 0-45 volume % with respect to the entire volume CV of an empty space within the case calculated from Equation 1. The contents of Equations 1 and 2 are as set forth in the description. The electrochemical device can solve the problem of gases produced by an oxidation reaction of the electrolyte due to high voltage leading to a reduction in reaction areas on the surfaces of the electrodes and to an increase in side reactions, resulting in accelerated deterioration of capacity.

Owner:LG CHEM LTD

Compound bricks of phosphogypsum, and producing method

This invention discloses a method for producing phosphogypsum composite bricks, which are produced from: steam-cured phosphogypsum 30-55 parts, gel material 10-30 parts, curing agent 5-15 parts, aggregrate 5-37 parts, and reinforcer 1-5 parts. The method comprises: (1) steam-curing phosphogypsum, mixing and strring with the other raw materials; (2) adding water so that the water content is 12-20%; (3) molding under 10-80 MPa; (4) steam-curing at high temperatures and high pressure for 5-24 h. The composite bricks have such advantages as high flexural strength, high compressive strength and good freeze resistance, thus can be used on main walls. The method efficiently and largely consumes phosphogypsum, thus saving soil resources and preventing environmental pollution by phosphogypsum piling. Besides, the method has high profit, and is environmentally friendly.

Owner:HUAZHONG UNIV OF SCI & TECH

Cathode active material comprising lithium manganese oxide capable of providing excellent charge-discharge characteristics at 3V region as well as 4V region

ActiveUS9911977B2Maximize its usefulnessImprove conductivityLi-accumulatorsNon-aqueous electrolyte accumulator electrodesPhysical chemistryLithium manganese oxide

Disclosed herein is a cathode active material including a lithium manganese oxide, in which the lithium manganese oxide has a spinel structure with a predetermined constitutional composition represented by Formula 1 described in the detailed description, wherein a conductive material is applied to the surface of lithium manganese oxide particles, so as to exhibit charge-discharge properties in the range of 2.5 to 3.5V as well as in the 4V region.

Owner:LG ENERGY SOLUTION LTD

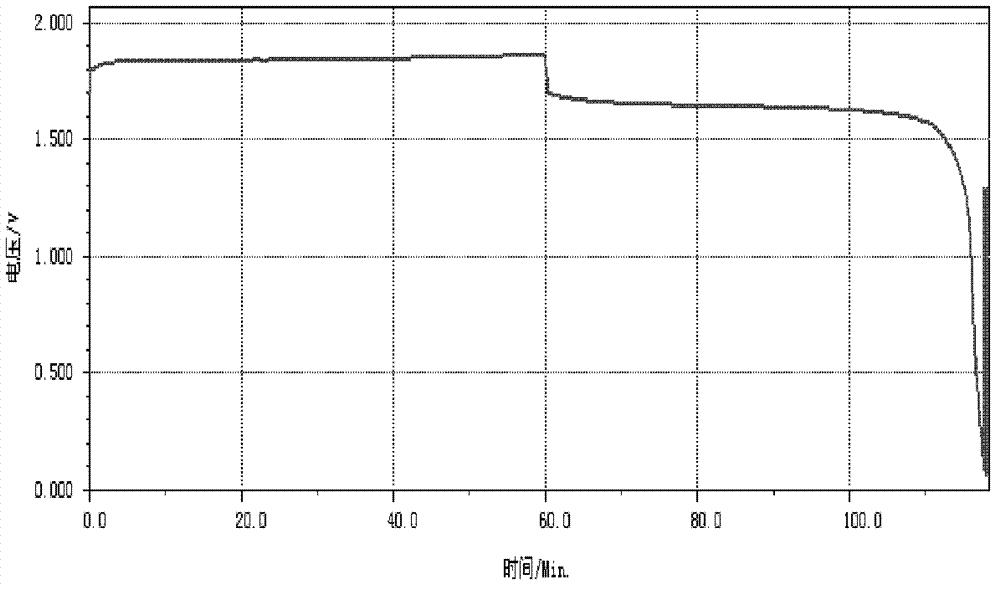

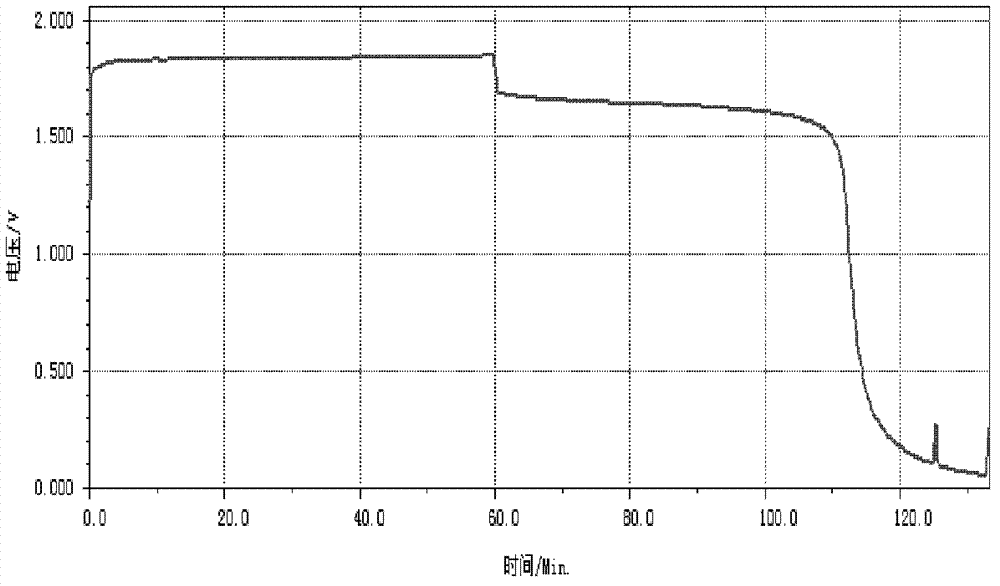

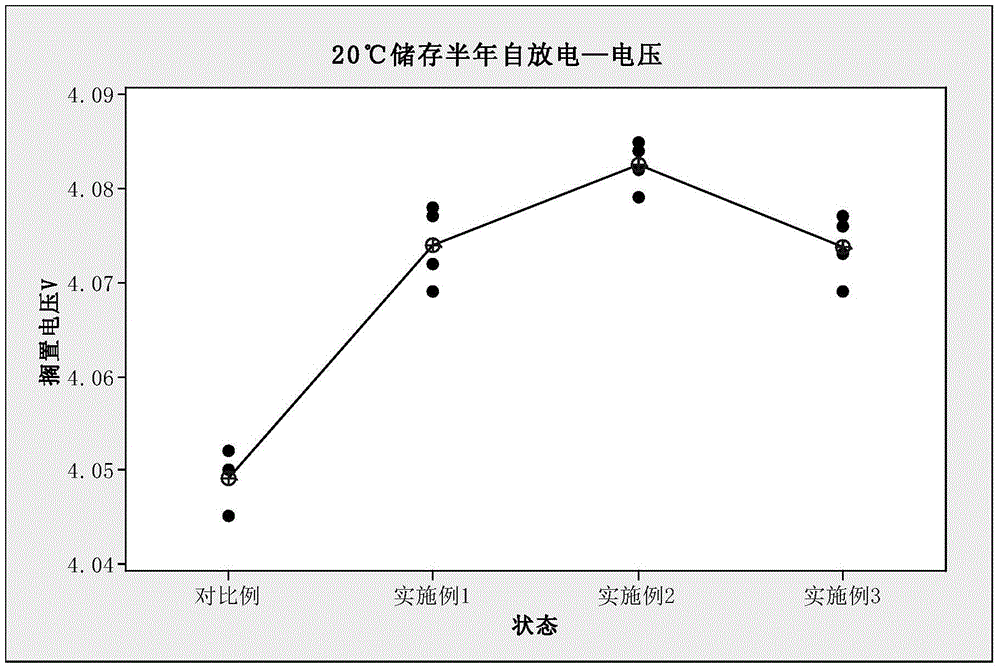

Long-storage lifetime lithium-ion battery and treatment method therefor

InactiveCN105552252ALow self-discharge rateExtended shelf lifeSecondary cellsJackets/cases materialsBiochemical engineeringLithium-ion battery

The invention relates to a long-storage lifetime lithium-ion battery and a treatment method therefor, and belongs to the technical field of lithium-ion batteries. The long-storage lifetime lithium-ion battery is characterized in that the inner wall of a steel shell for the long-storage lifetime lithium-ion battery is coated with an insulating coating. The treatment method for the long-storage lifetime lithium-ion battery is characterized by comprising the following treatment processes: coating the inner wall of the steel shell for the lithium-ion battery with the insulating coating; drying the insulating coating and finishing insulating treatment of the shell; and assembling the shell and a battery core. By a coating technology, the stability of the steel shell for the lithium-ion battery during storage and long-term cycle can be ensured; the lifetime characteristics of the battery are greatly improved; meanwhile, the safety performance of the battery is improved; and the long-storage lifetime lithium-ion battery has the advantages of being simple in structure, convenient to operate and the like.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Fuel cell comprising oxygen electrode with surface nanostructure

ActiveUS20100239951A1Reduced reaction areaImproved and stable power generation performanceCell electrodesSolid electrolyte fuel cellsPlatinumFuel cells

An oxygen electrode used in the fuel cell and includes a plurality of carbon particles, a carbon thin-film, and surface nanostructure. The carbon particles are bonded to one another with the carbon thin-film, and the surface nanostructure is formed on the surface of the carbon thin-film. The surface nanostructure comprises catalyst nanoparticles made of platinum (Pt) and carbon nanoparticles. According to this combination of these elements, the catalyst nanoparticles are confined within three-dimensional structure to be formed by the carbon nanoparticles and are immobilized without losing space which allows any reactant to be accessed to the surface of the catalyst nanoparticles.

Owner:PANASONIC CORP

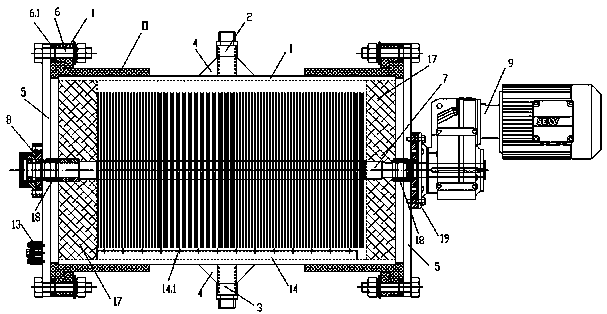

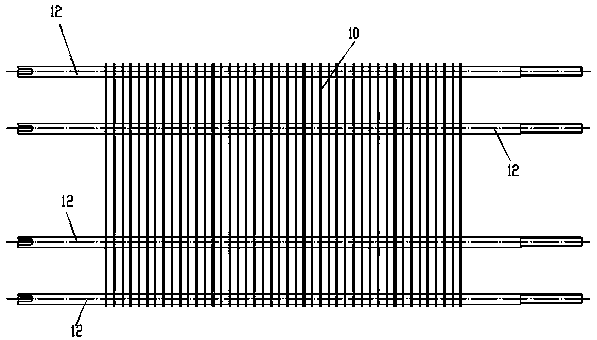

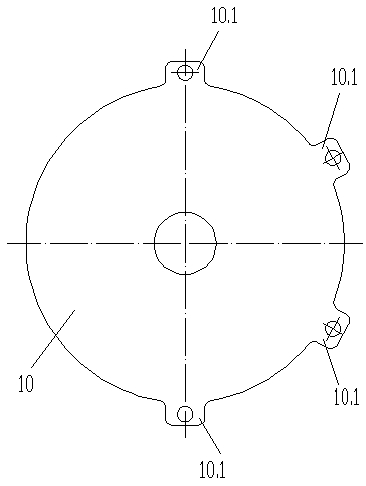

High-efficiency self-controlled horizontal rotary electrode electrocatalytic oxidation decontamination device

ActiveCN105905991BImprove processing efficiencyReduce foulingWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by oxidationEngineeringCathode

The invention discloses a high-efficiency self-control horizontal rotary-electrode electro-catalysis oxidation dirt removal device. The high-efficiency self-control horizontal rotary-electrode electro-catalysis oxidation dirt removal device comprises a cylinder; an end cover is arranged at each of the two ends of the cylinder for sealing; a central rotating shaft is arranged in the centre of the cylinder; an electrode group is arranged on the central rotating shaft in a sleeving manner; the two ends of the central rotating shaft penetrate out of the end covers at the two ends; one end of the central rotating shaft is connected with a shaft seat at the tail end, and the other end of the central rotating shaft is connected with a driving device; the cylinder is placed horizontally; the electrode group comprises a plurality of electrode plates which are arranged in parallel on the central rotating shaft in a sleeving manner at intervals; the electrode plates consist of sacrificial anode plates and cathode plates; the anode plates and the cathode plates are arranged alternately; the sacrificial anode plates and the cathode plates are disc plates with equal diameter; the central rotating shaft is arranged in central holes of the anode plates in a sleeving manner and is fixedly connected with the central holes of the anode plates in a contact manner; a plurality of convex bumps are arranged on the edge of each sacrificial anode plate and around the centre of a circle; a connecting hole is formed in each convex bump; the convex bumps on each sacrificial anode plates correspond to one another; an anode energizing shaft penetrates through each connecting hole; the two ends of each anode energizing shaft are connected with the end covers at the two ends of the cylinder; the central rotating shaft is arranged in the central holes of the sacrificial anode plates in the sleeving manner.

Owner:YIXING LINGTAI ENVIRONMENTAL PROTECTION

Long-service-life electrode boiler electrode bar and preparation method thereof

InactiveCN111363979AGood resistance to electrochemical corrosionExtended service lifeManganeseElectrochemical corrosion

The invention aims to provide a long-service-life electrode boiler electrode bar and a preparation method thereof. The long-service-life electrode boiler electrode bar is remarkably prolonged in service life because of high electrochemical corrosion resistance. The long-service-life electrode boiler electrode bar is composed of, by weight, equal to or smaller than 0.0015% of oxygen, equal to or smaller than 0.05% of carbon, 0.16% to 0.26% of silicon, 0.29% to 0.40% of manganese, 0.018% of phosphorus, 0.0015% of sulfur, 0.001% to 0.002% of aluminum, and the balance iron. The ferritic structurein the long-service-life electrode boiler electrode bar is no smaller than 85%, and the surface smoothness of the long-service-life electrode boiler electrode bar is N5 or higher. The service life ofthe long-service-life electrode boiler electrode bar can be ten years or more. An electrode bar in the prior art is seriously corroded after being used for three years and needs to be replaced. Therefore, the long-service-life electrode boiler electrode bar has the characteristic of being remarkably prolonged in service life because of high electrochemical corrosion resistance.

Owner:北京火龙升腾科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com