Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Reduced knocking tendency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

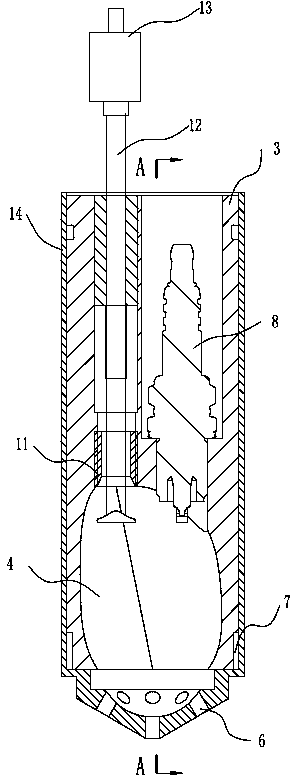

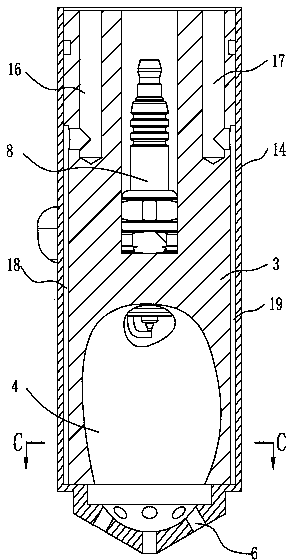

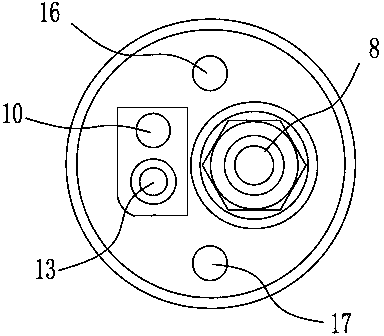

Pre-combustion generator

ActiveCN103821606AHigh thermal efficiencyReduce R&D costsInternal combustion piston enginesCombustion chamberDiesel engine

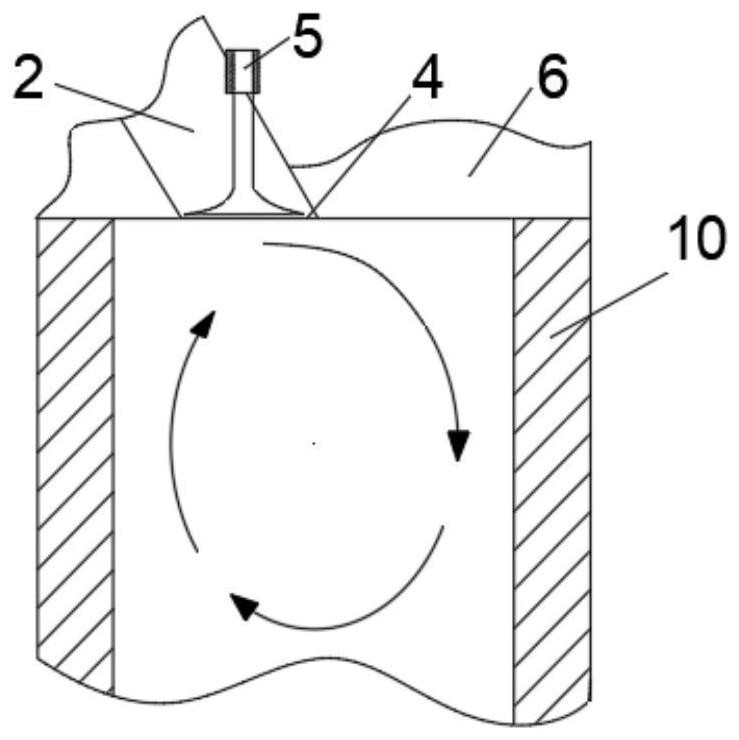

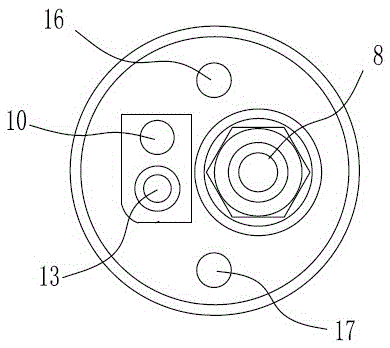

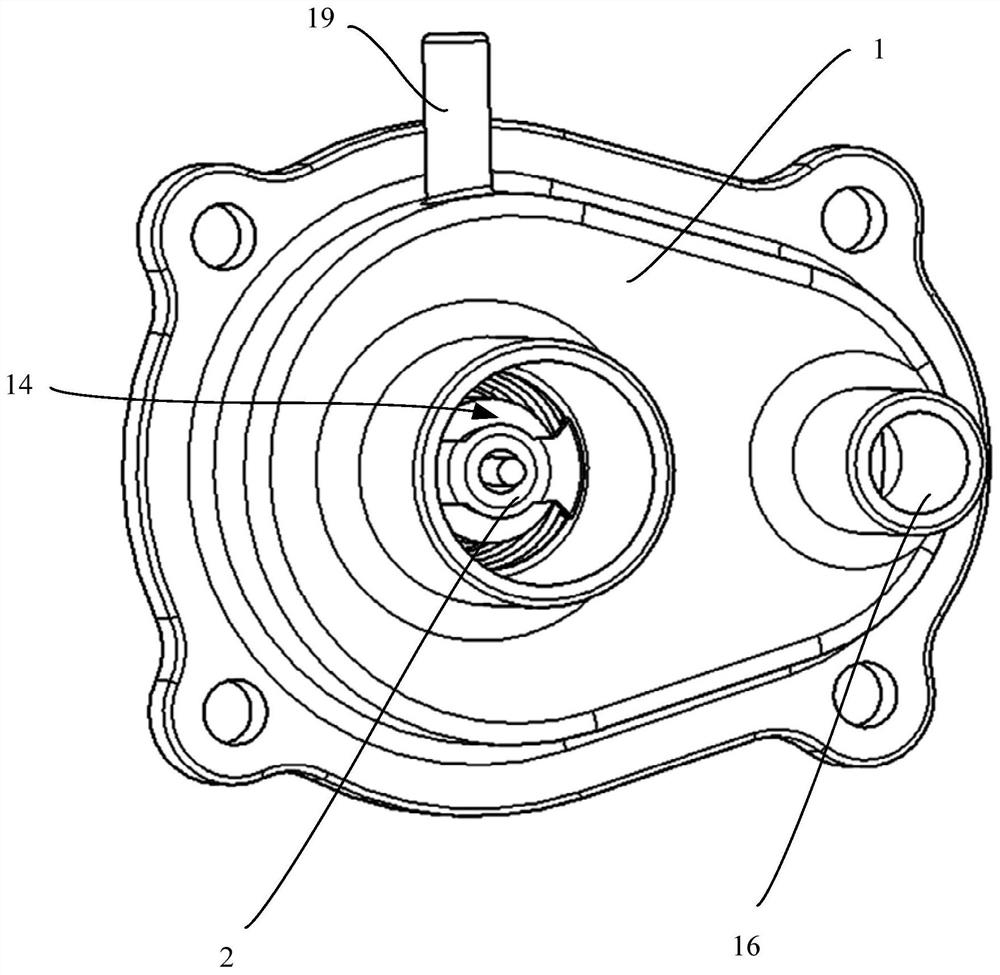

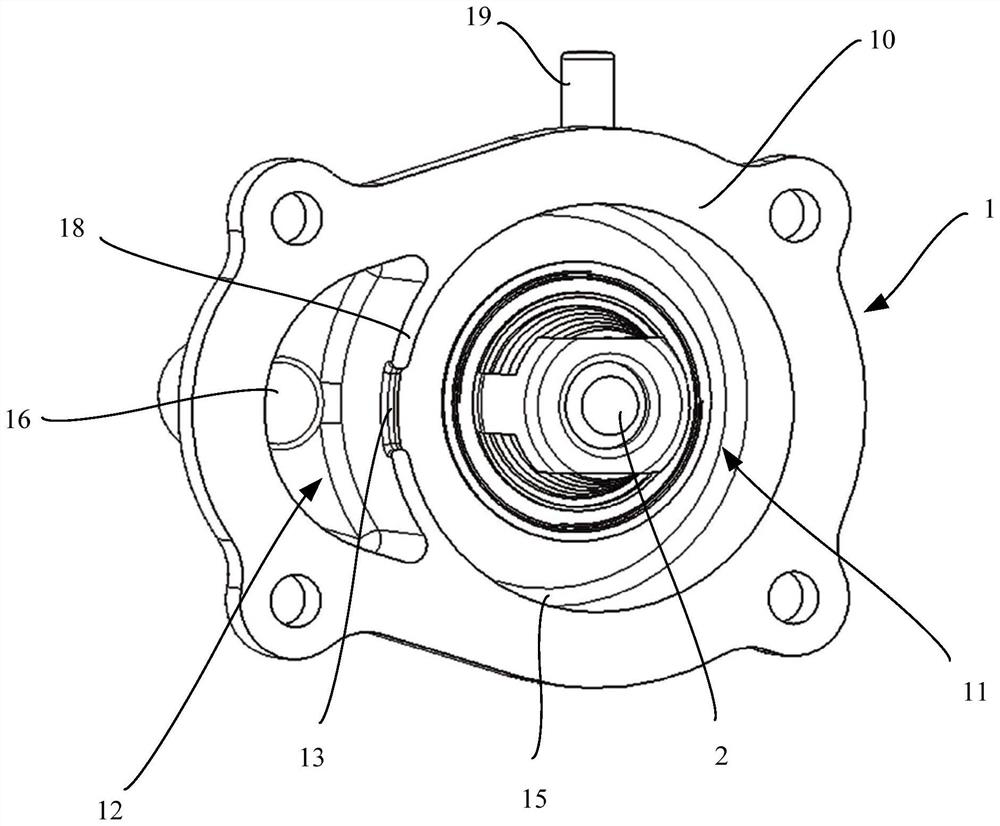

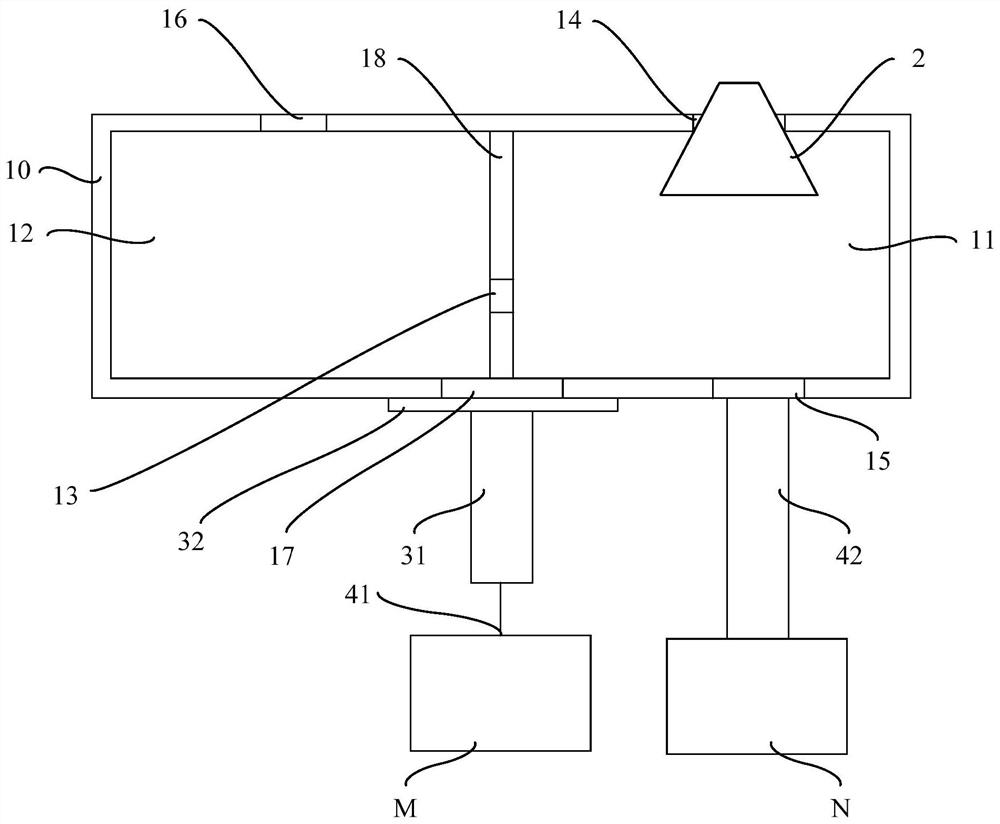

The invention discloses a pre-combustion generator. The pre-combustion generator is mounted in an oil spraying device mounting hole on an engine cylinder cover, and comprises a pre-combustion generator body, wherein the pre-combustion generator body is provided with a pre-combustion chamber; the pre-combustion generator body is provided with a spraying hole for communicating the pre-combustion chamber with a combustion chamber; the pre-combustion generator body is further provided with a gas supplying device for supplying gas to the pre-combustion chamber; the pre-combustion chamber is provided with a sparking plug mounting hole; the sparking plug mounting hole is internally provided with a sparking plug; the pre-combustion generator body is further provided with a cooling device. The pre-combustion generator is provided with an independent cooling system, a gas feeding system and a control system so that one independent product is formed and the product can be conveniently applied to a diesel engine to be refitted into a gas engine; the tendency of detonation in a main combustion chamber can be reduced and the compression ratio of the existing gas engine can be increased; a piston and the cylinder cover do not need to be redesigned to change the compression ratio; the heat efficiency of the gas engine can be effectively improved and energy sources are saved.

Owner:WEICHAI XIGANG NEW ENERGY POWER

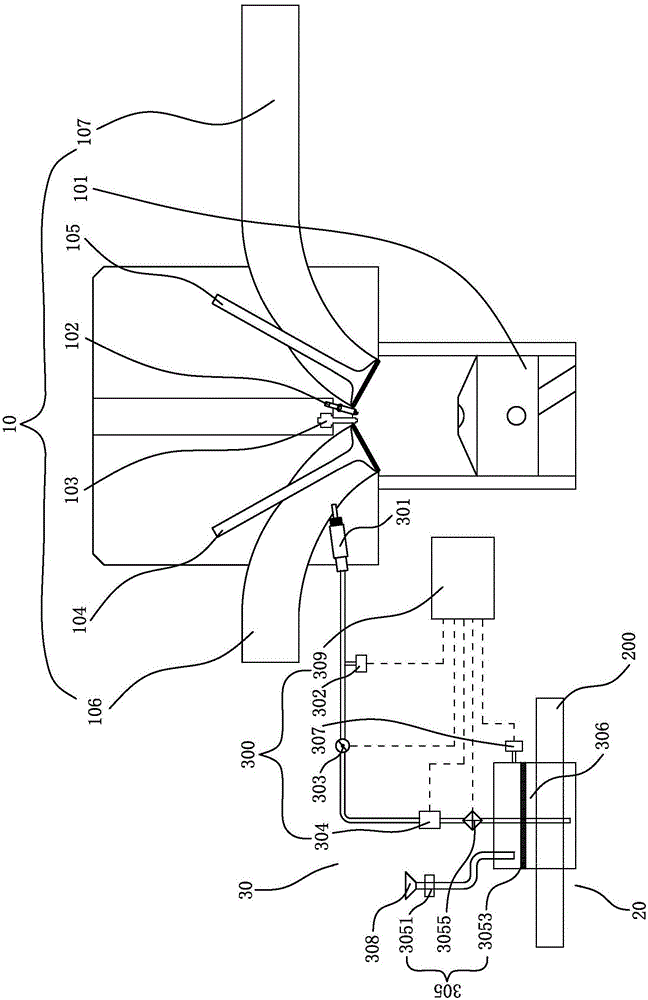

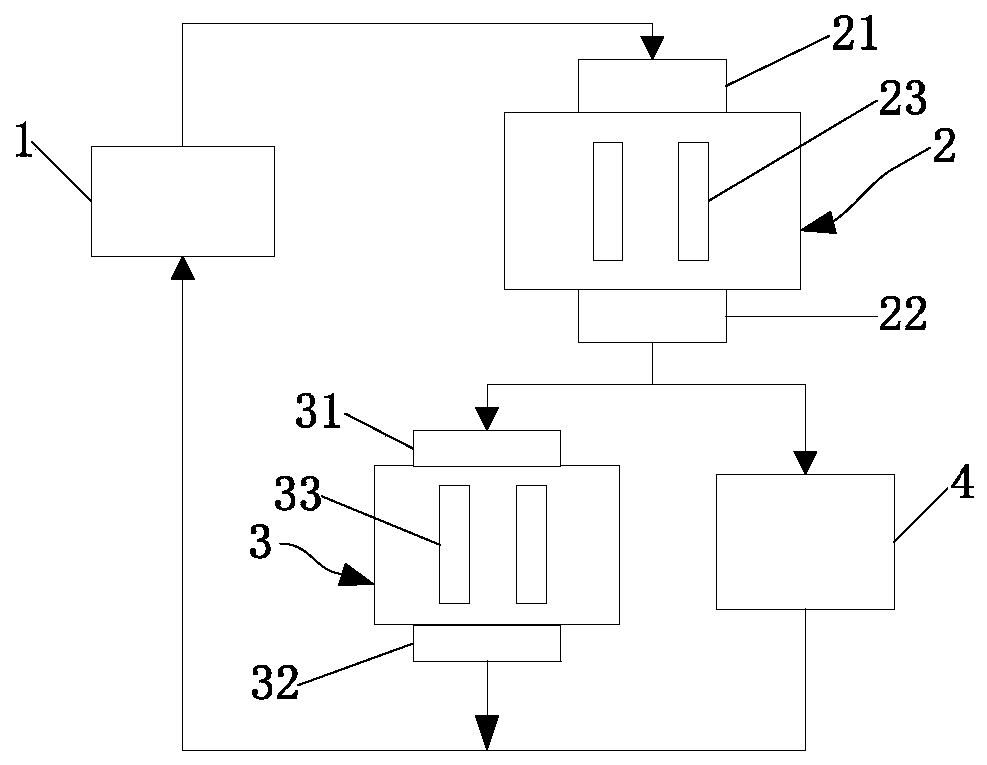

Engine

InactiveCN106762237AReduce indoor temperatureImprove combustionCoolant flow controlInternal combustion piston enginesCombustion chamberSolenoid valve

The invention provides an engine which comprises an engine combustion system, a cooling system and a water spraying system. The water spraying system is formed by sequentially connecting a water sprayer, a water pressure sensor, a solenoid valve, a water pump, a filter water tank, a water level sensor and a water injector through water pipes. The water spraying system further comprises a control system. The control system forms a closed-loop control loop through the water pressure sensor, the water level sensor, the solenoid valve, the water pump and an electronic control unit. According to feedback of the water pressure sensor, the water pumping pressure of the water pump is controlled through the electronic control unit, and therefore the water spraying pressure is changed; and the opening angle of the solenoid valve is controlled through the electronic control unit to control the water spraying amount. According to the engine, water enters a combustion chamber along with fresh air through the water spraying system, the in-cylinder combustion condition is improved, and the functions of reducing the temperature in the combustion chamber and restraining knocking are achieved.

Owner:ZHEJIANG GEELY HOLDING (GROUP) CO LTD +1

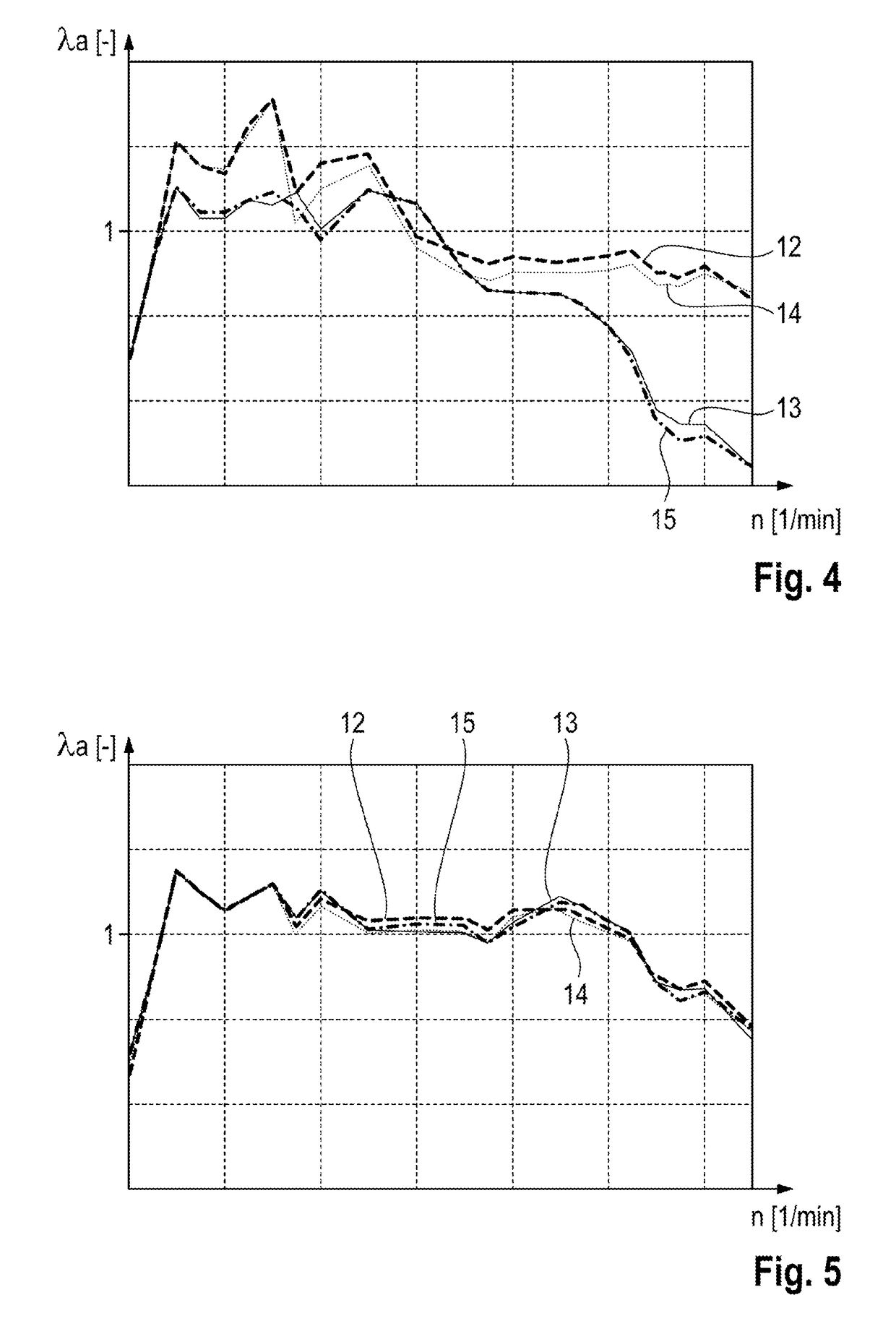

Method for operating an internal combustion engine

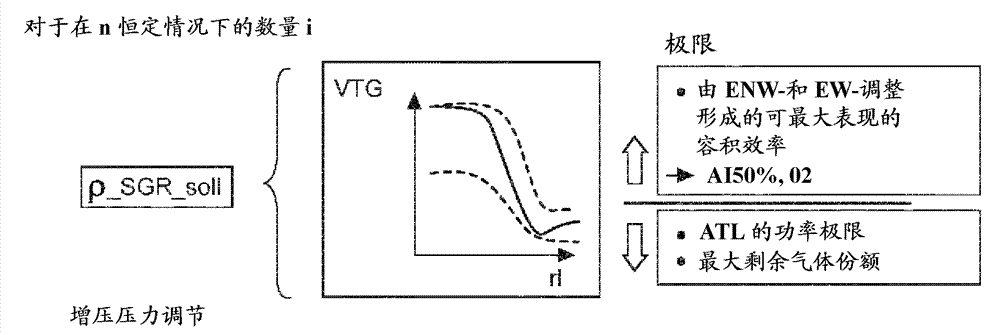

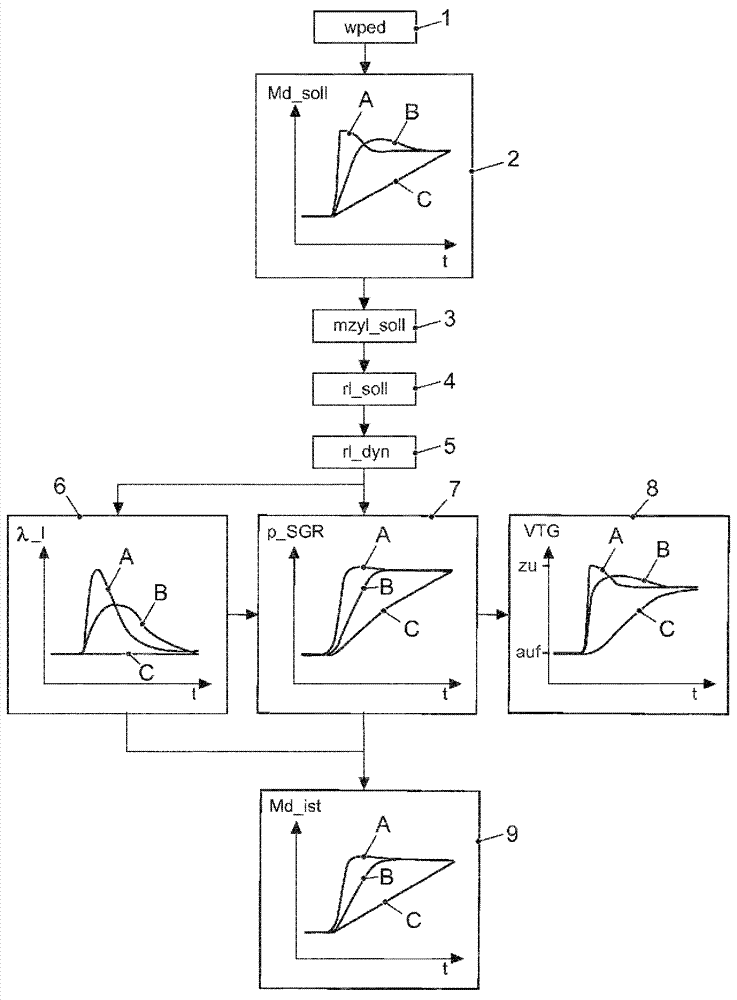

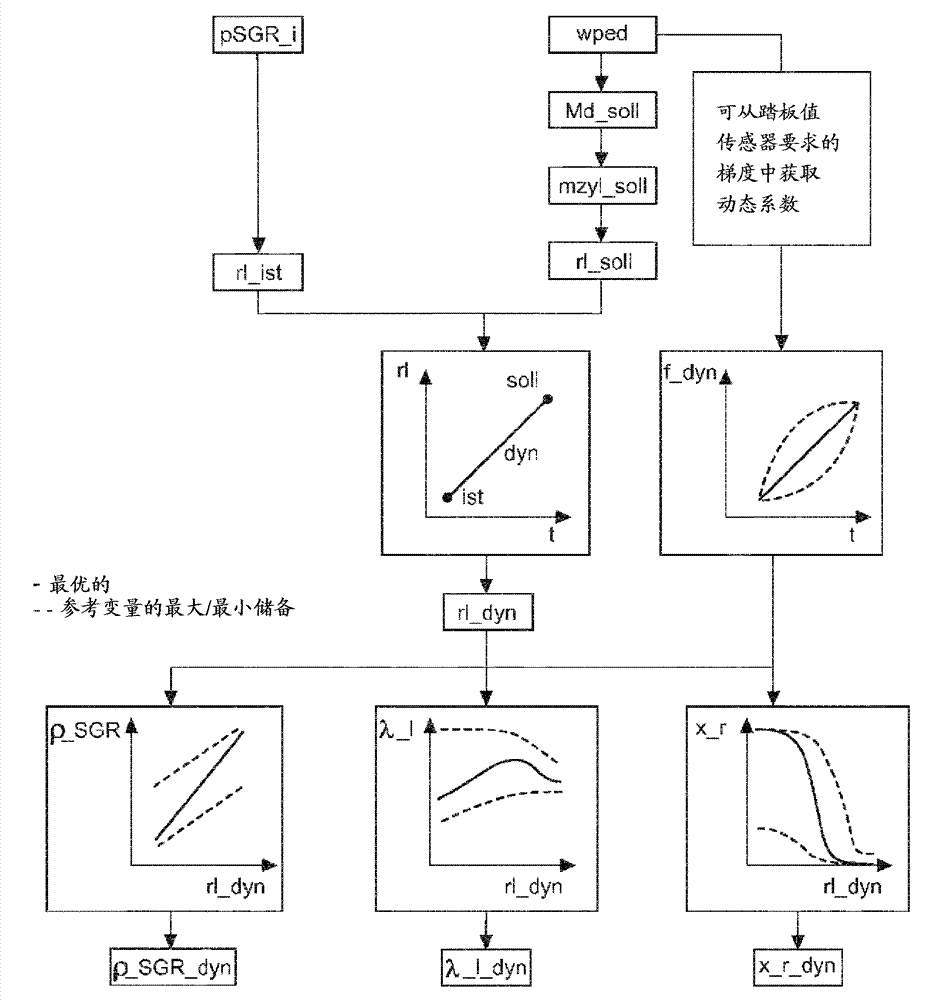

ActiveCN104508282AImprove dynamic characteristicsImprove efficiencyValve arrangementsElectrical controlCurrent loadExternal combustion engine

The present invention relates to a method for operating an internal combustion engine (51). The internal combustion engine (51) comprises a compressor (52) for setting a charge density (p_SGR) in an intake pipe of the internal combustion engine and adjusting means (53), for example variable valve gear, for setting a volumetric efficiency (lambda_Iota) of the internal combustion engine (51). In the method, a dynamic setpoint value (rl_dyn) is determined for the internal combustion engine (51) as a function of a difference between a load request (rl_soll) on the internal combustion engine (51) and a current load output (rl_ist) of the internal combustion engine (51). The volumetric efficiency (lambda_Iota) and the charge density (p_SGR) are set as a function of the dynamic setpoint value (rl_dyn).

Owner:VOLKSWAGEN AG

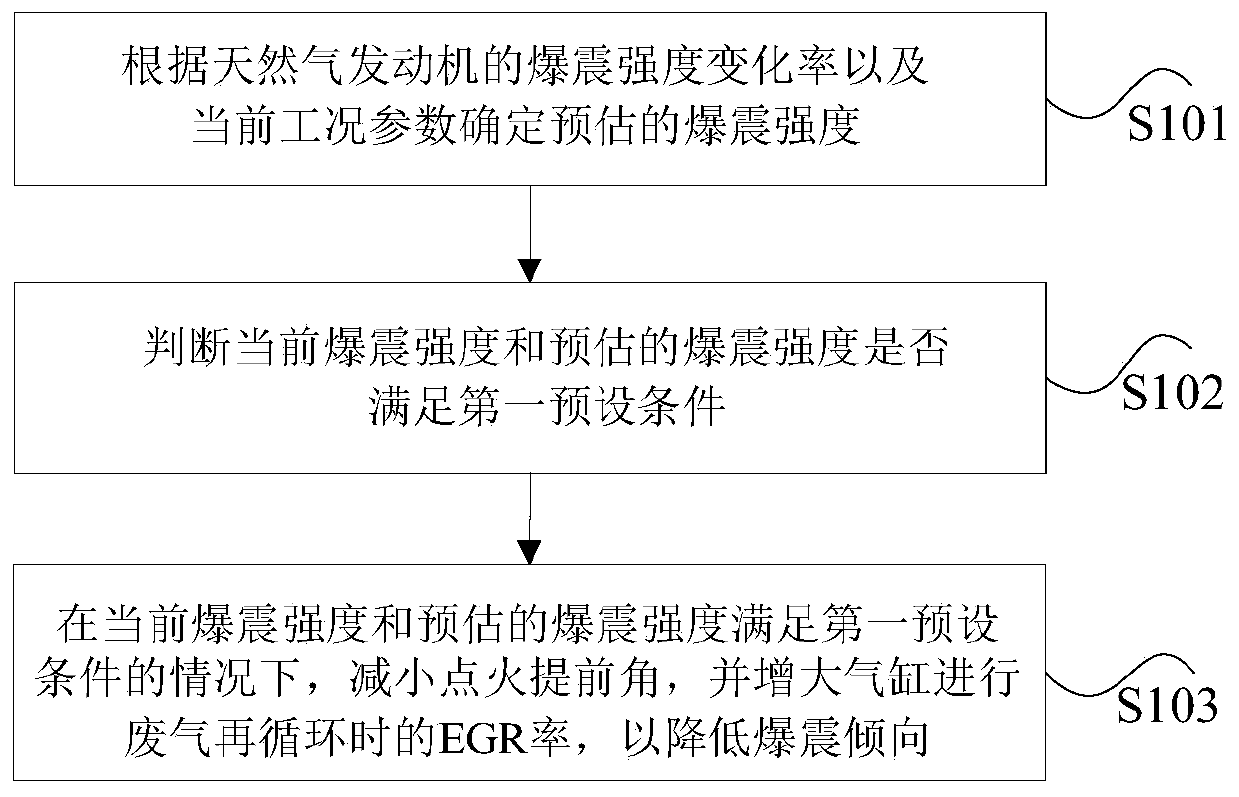

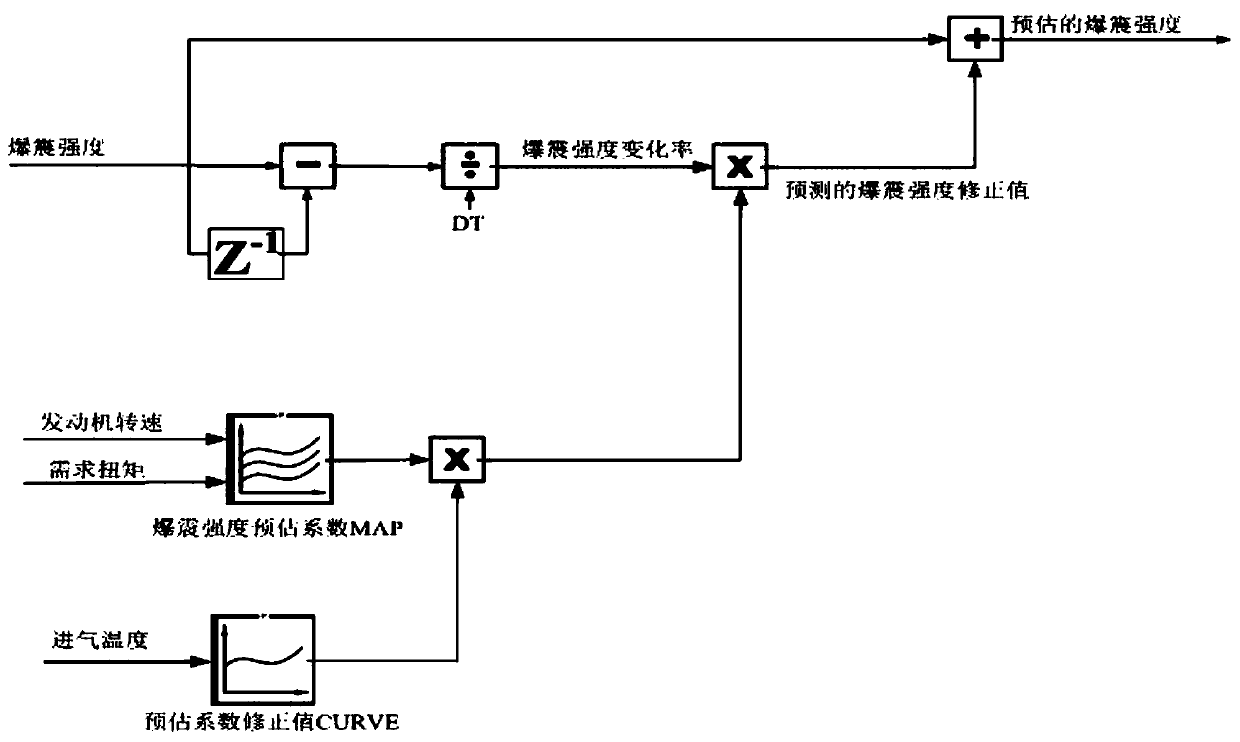

Control method and device of natural gas engine, storage medium and processor

ActiveCN111396210AIncrease EGR rateDecrease the ignition advance angleElectrical controlInternal combustion piston enginesThermodynamicsExhaust fumes

The invention discloses a control method and device of a natural gas engine, a storage medium and a processor. The method comprises the following steps: determining the estimated knock intensity according to the knock intensity change rate of the natural gas engine and the current working condition parameter; judging whether the current knock intensity and the estimated knock intensity meet a first preset condition or not; and when the current knock intensity and the estimated knock intensity meet the first preset condition, reducing an ignition advance angle, and increasing the EGR rate of acylinder during exhaust gas recirculation, so that the knock tendency is reduced. Through the application, the problems in the related art that knocking tendency is weakened by adjusting the ignitionadvance angle after the engine knocks and the knocking tendency is difficult to reduce before knocking are solved.

Owner:WEICHAI POWER CO LTD

Overhead-valve combustion chamber of two-stroke gasoline direction injection engine

InactiveCN106640338AReduce bumpsMiniaturizationInternal combustion piston enginesCylinder headsCombustion chamberExhaust valve

The invention discloses an overhead-valve combustion chamber of a two-stroke gasoline direction injection engine. The overhead-valve combustion chamber is a cavity encircled by a cylinder cover, an intake valve, an exhaust valve, a piston, a cylinder sleeve, a gasoline injector and a spark plug. The inclined surface of a ceiling at the intake side of the cylinder cover is composed of two connected inclined surfaces having different included angles with the axis of the piston, and a spherical gasoline avoiding pit is sunken in the inclined surface; the position of an intake door seat is higher than the ceiling at the intake side in a vertical direction, and the intake door seat and the ceiling form a step; the gasoline injector is a piezoelectric crystal outwards-opening gasoline injector and arranged at the centre of the cylinder with the spark plug; and the centre of the piston is bulged, the top surface of the bulge is inclined, and a spherical pit is sunken in the top surface. According to the overhead-valve combustion chamber disclosed by the invention, reverse tumble scavenging is realized through the step on the ceiling, and intake short-circuit is reduced; wall wetting due to fuel oil is reduced through the gasoline avoiding pit, the top surface of the bulge of the piston and the pit of the piston; and a layered mixed gas is organized through the outwards-opening gasoline injector arranged at the centre. The overhead-valve combustion chamber disclosed by the invention is capable of realizing efficient scavenging for the two-stroke gasoline engine, optimizing the layering of the fuel oil and reducing the wall wetting due to the fuel oil, and beneficial to realizing the miniaturization of the gasoline engine.

Owner:TIANJIN UNIV

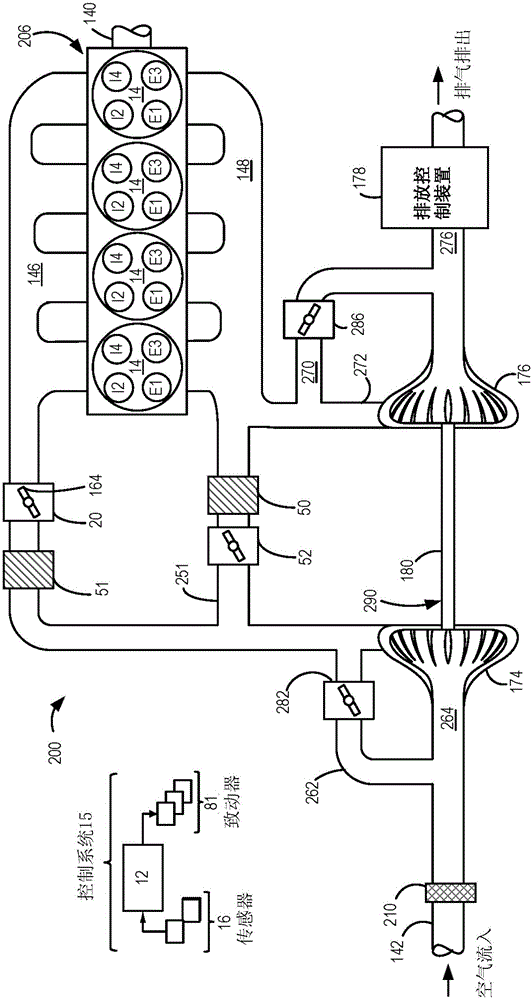

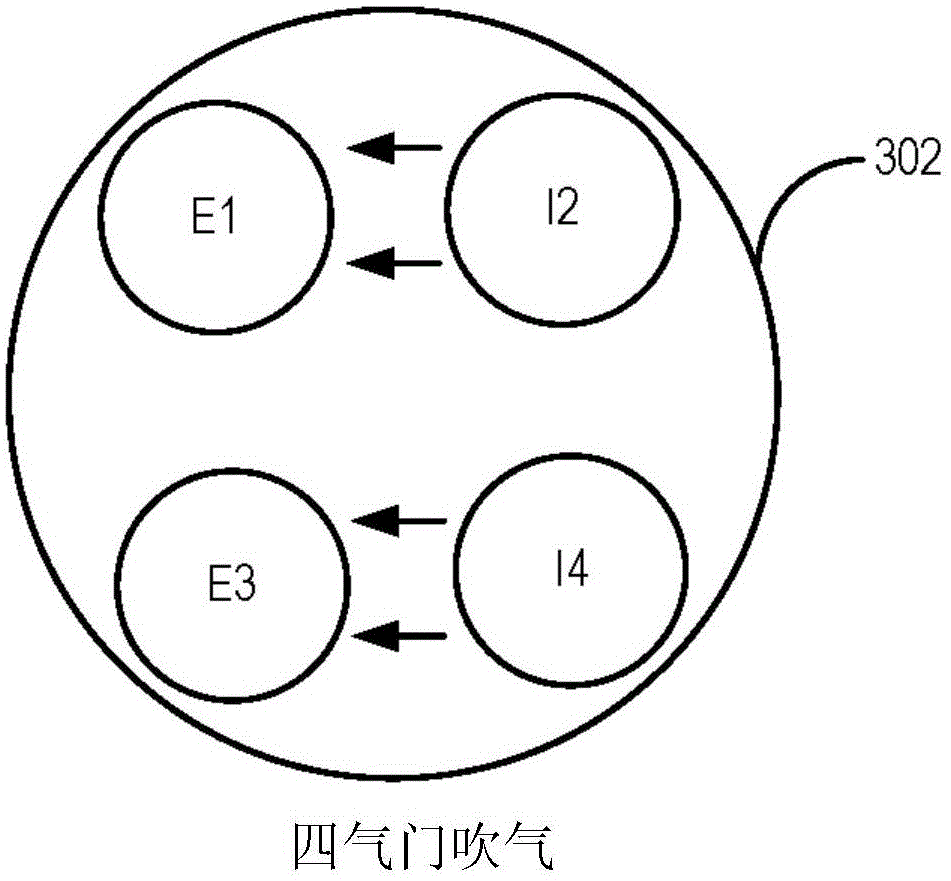

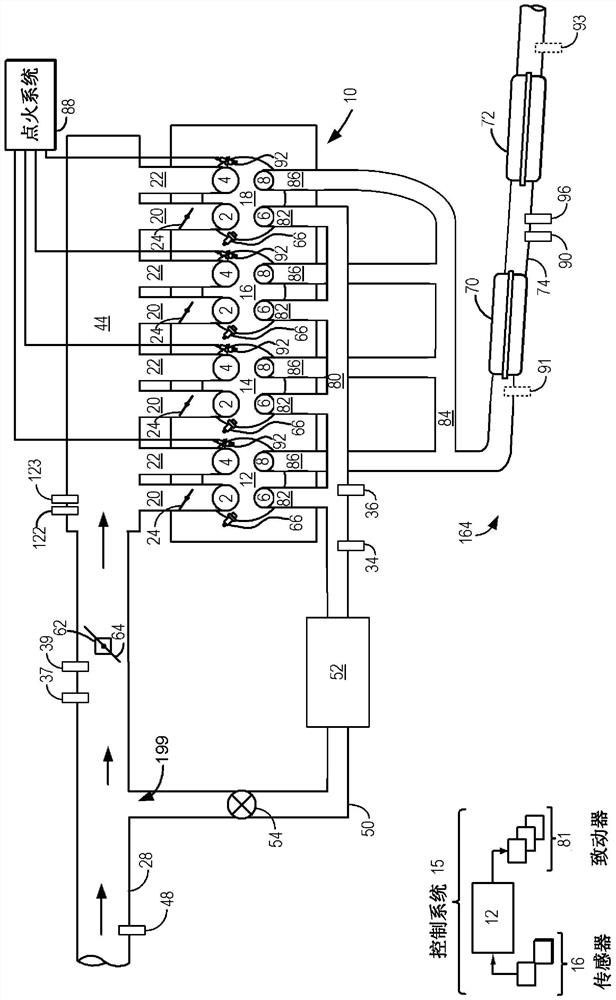

Method and system for diagonal blow-through exhaust gas scavenging

ActiveCN105317564AImprove economyEfficient removalValve arrangementsElectrical controlExhaust valveInlet valve

The invention relates to methods and systems for diagonal blow-through exhaust gas scavenging. Methods and systems are provided for operating an engine in a two-valve diagonal blow-through mode during which a majority of blow-through is directed via a first intake valve positioned diagonally across a first exhaust valve in order to increase a distance of flow path from the intake valve to the exhaust valve.

Owner:FORD GLOBAL TECH LLC

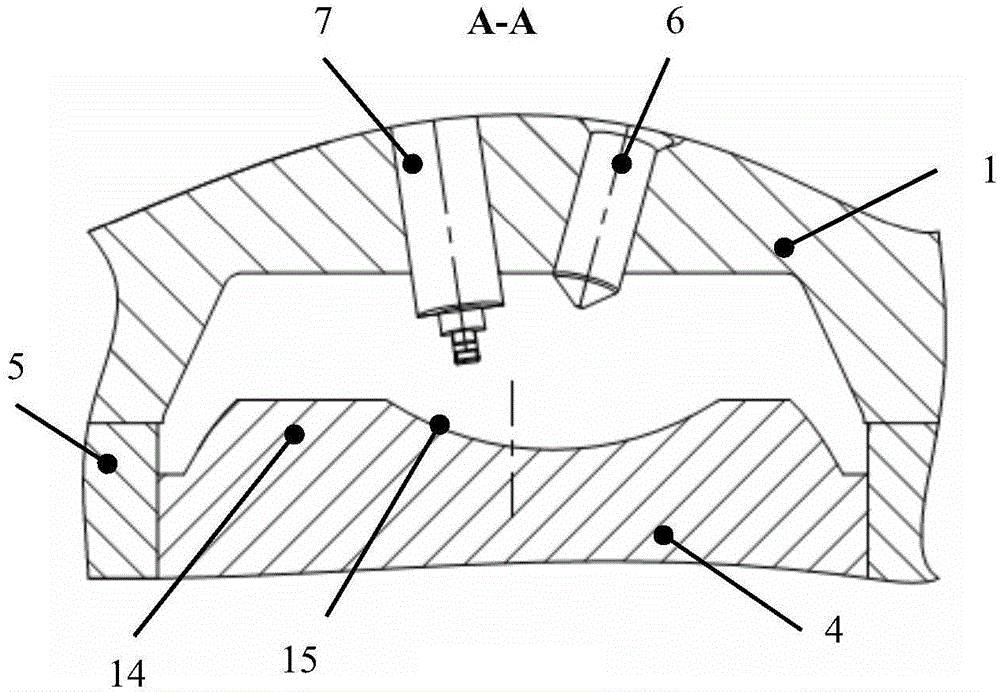

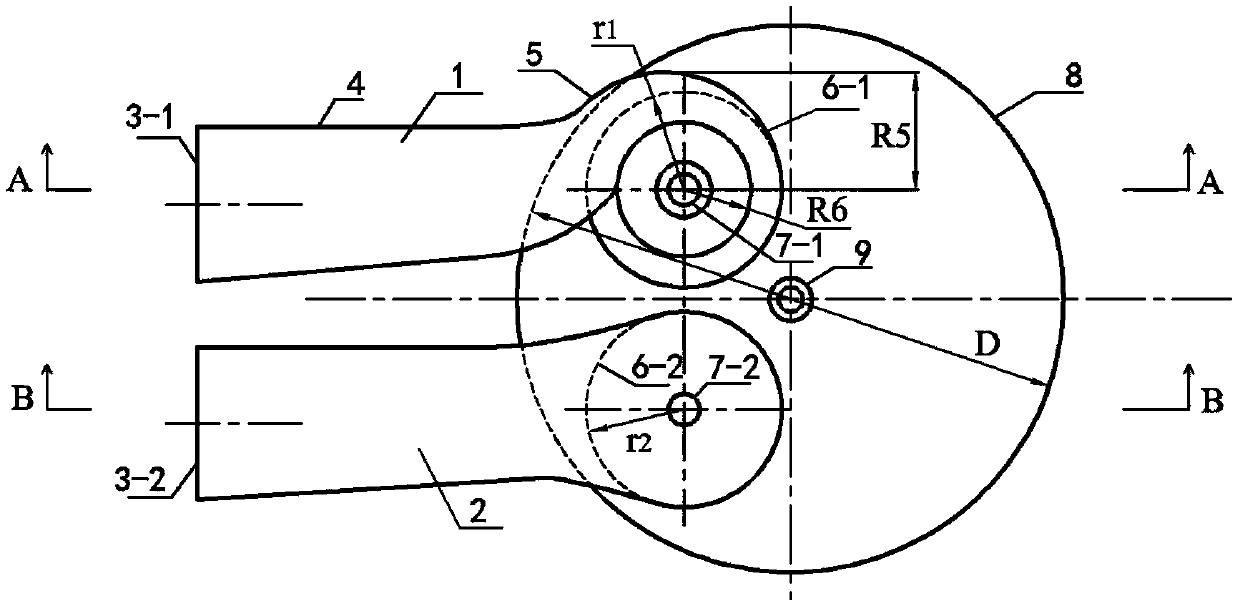

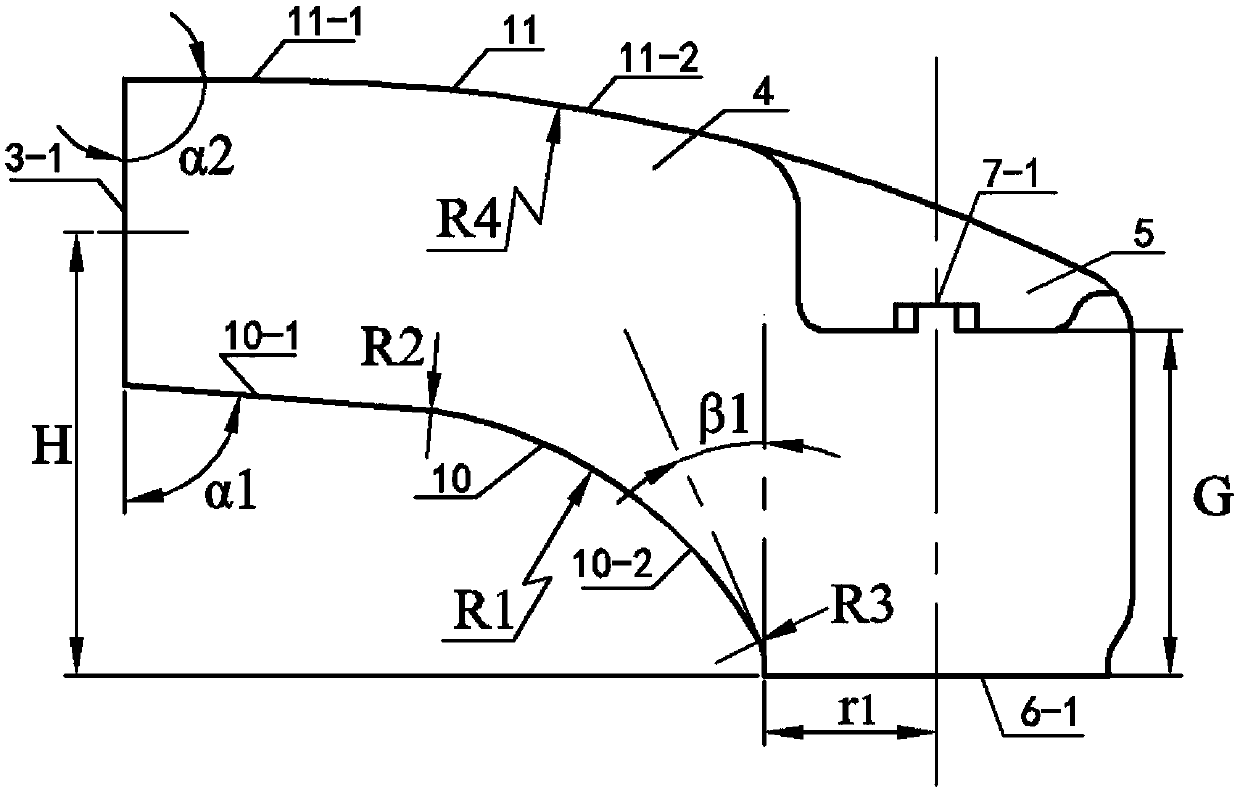

Heavy natural gas engine combustion system

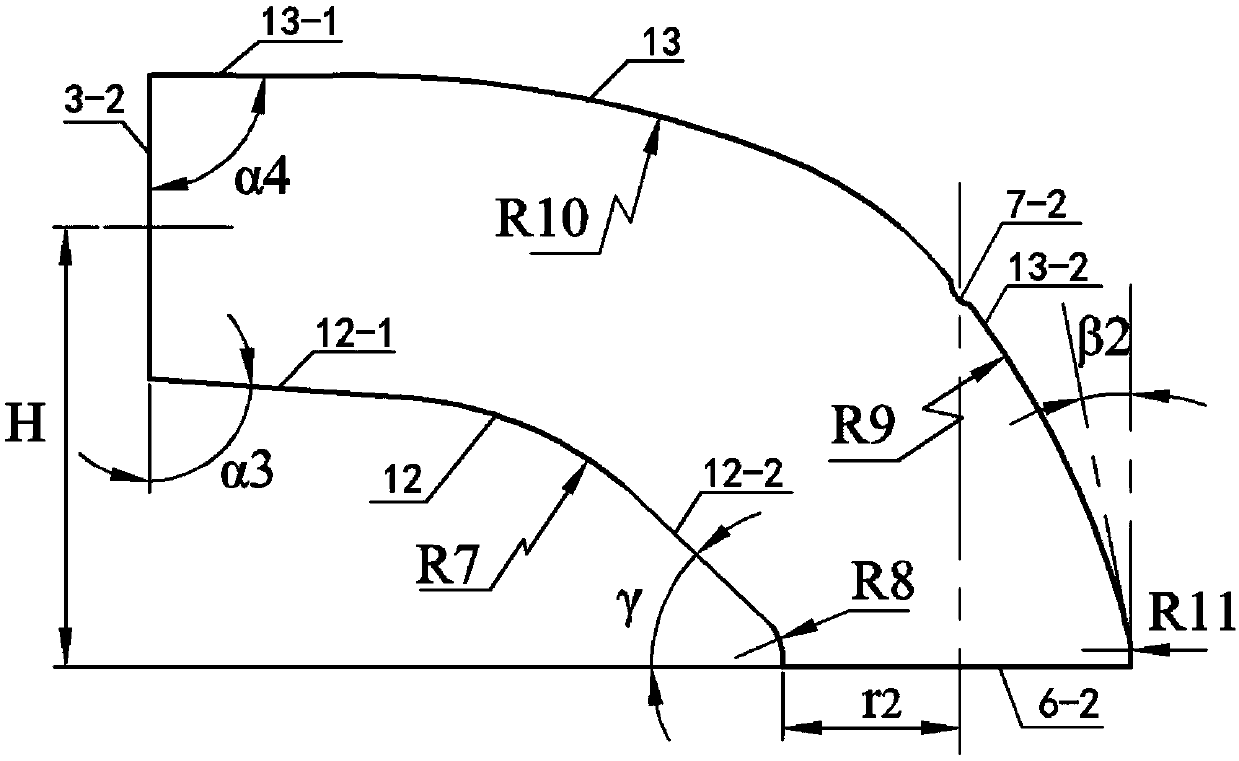

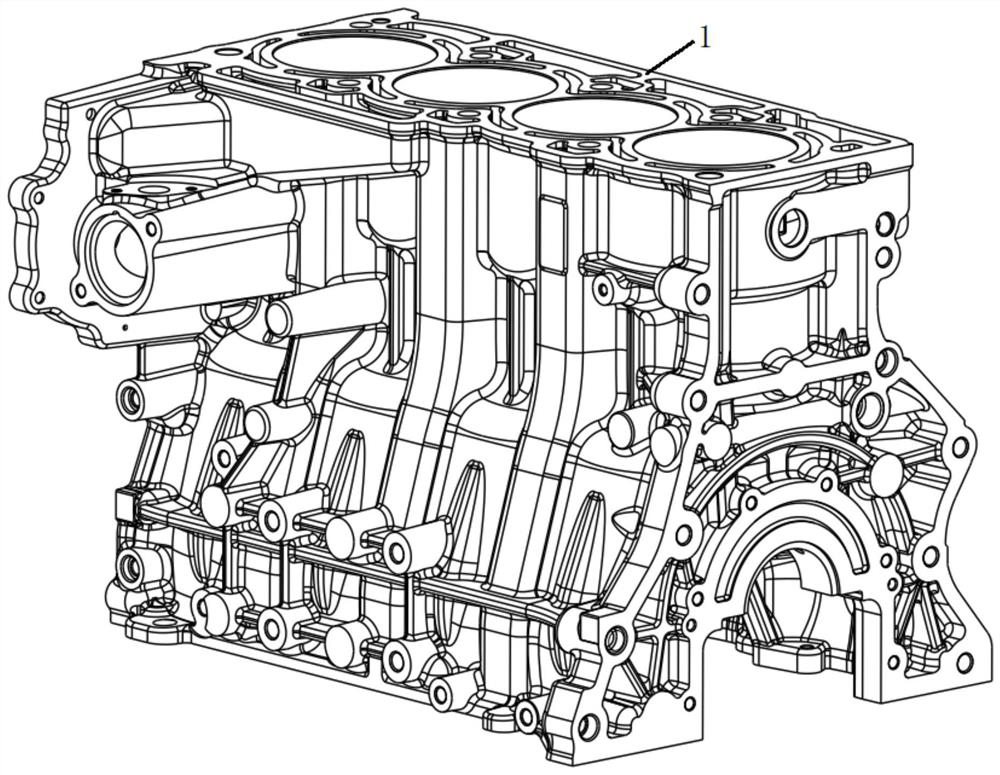

PendingCN113685264AImprove scalabilityPromote disseminationInternal combustion piston enginesCylinder headsCombustion systemCombustion chamber

The invention discloses a heavy natural gas engine combustion system. The system comprises an air cylinder and a cylinder cover covering the air cylinder, the cylinder cover is provided with a composite air inlet channel composed of a vortex air inlet channel and a straight tumble air inlet channel and communicates with the interior of the air cylinder through an air inlet gate provided with an air inlet valve, the air inlet valve is arranged on a valve seat, The air inlet gate is located in the whole valve seat, two exhaust passage inlets communicate with the interior of the air cylinder through exhaust valves arranged on the cylinder cover, a spark plug device is installed in the center of the bottom face of the cylinder cover, a steel piston is arranged in the cylinder cover, and the bottom face of the cylinder cover, the inner wall face of the air cylinder and the top face of the piston define a space which serves as a necking-down type combustion chamber, and gas supply and injection systems are respectively arranged on the two gas inlet channels or the bottom surface of the cylinder cover. The system is simple and compact in structure and convenient in manufacturing and assembly, low heat dissipation is achieved through the steel piston, meanwhile, inlet air flow can form oblique axis vortex around the central axis of the cylinder through the composite air inlet channel, turbulent kinetic energy in the cylinder is improved, and then heat efficiency is improved.

Owner:TIANJIN UNIV

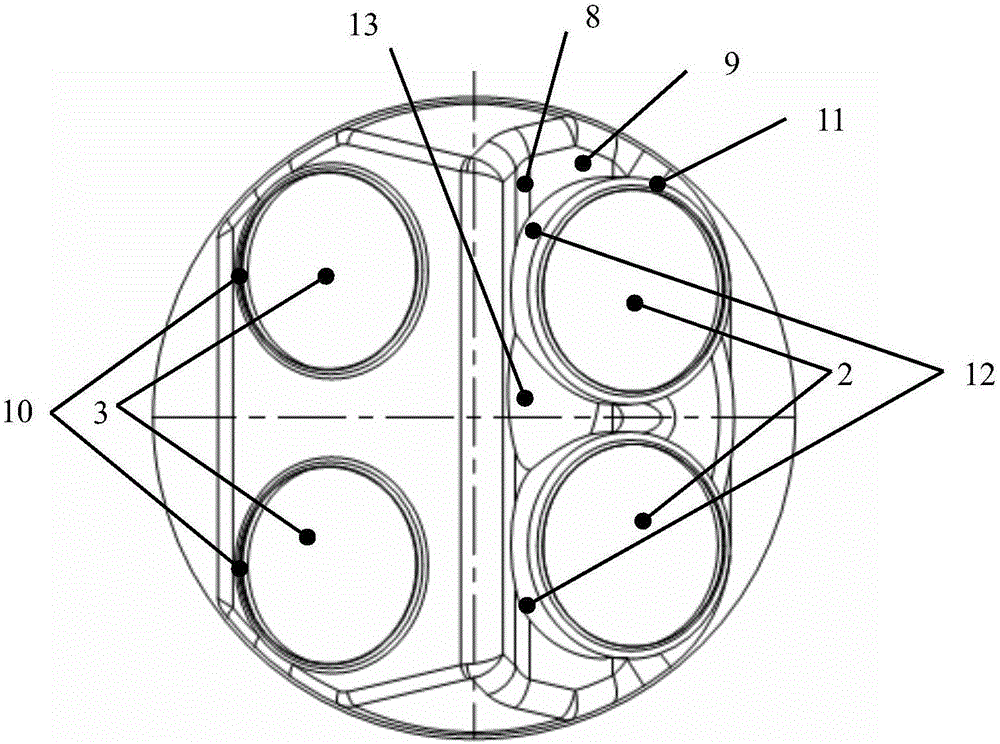

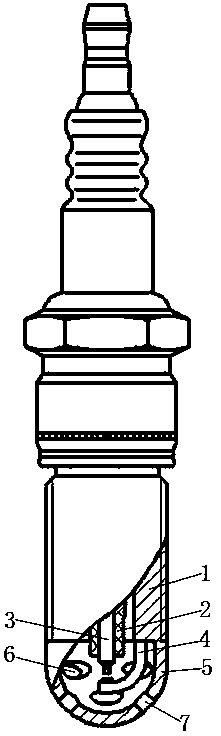

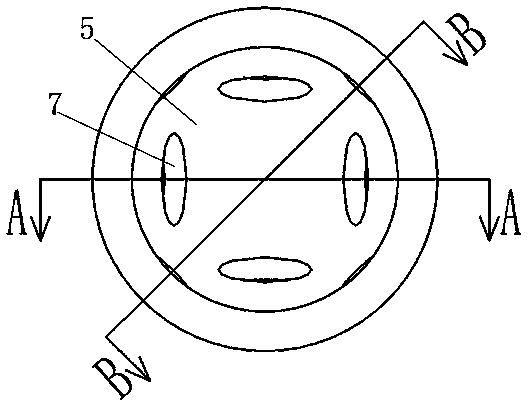

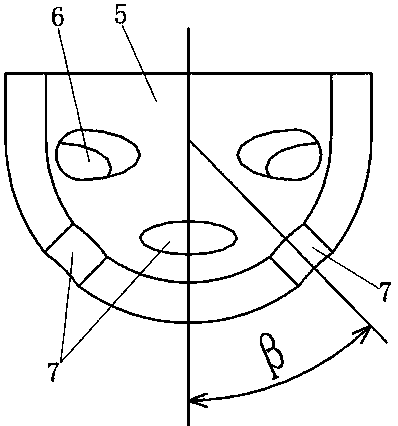

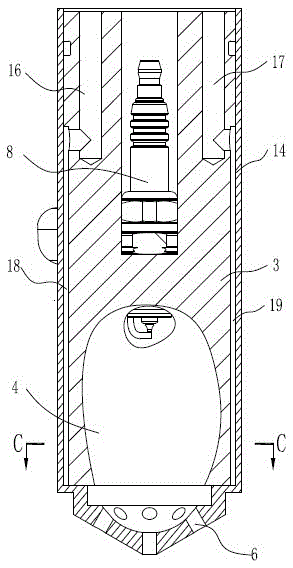

Spark plug with precombustion chamber structure

The invention relates to a spark plug with a precombustion chamber structure. The spark plug includes a tubular metal shell, an insulator fixed in the metal shell, a central hole arranged in the insulator, a central electrode mounted in the central hole and a side electrode connected to the metal shell. A spark plug gap is formed between the central electrode and the side electrode. A precombustion chamber shell is connected to the lower end of the metal shell. A precombustion chamber is defined by the lower ends of the precombustion chamber shell and the metal shell. The spark plug gap is located in the precombustion chamber. The precombustion chamber shell is provided with multiple upper spray holes and multiple lower spray holes. The multiple spray holes are located on the upper side ofthe multiple lower spray holes. The spark plug with the precombustion chamber structure can form up-down stratified jet flames with different spray cone angels during a combustion process of an engine, thereby accelerating the combustion of mixed gas, effectively solving the problem of decrease of burning rate when a gasoline engine adopts a Miller / Atkinson cycle, ensuring the ignition stability,and avoiding carbon deposition blockage.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Mixed oil gas combustion adjuvant for ongine

A combustion aid for the oil-gas mixed fuel of engine features that it contains multi-layer or single-layer carbon tubes for increasing the electric conductivity and combustion performance of fuel oil. Its advantages are less explosion of fuel, less exhausted CO and HC, and high octane value of fuel.

Owner:孙文郁 +1

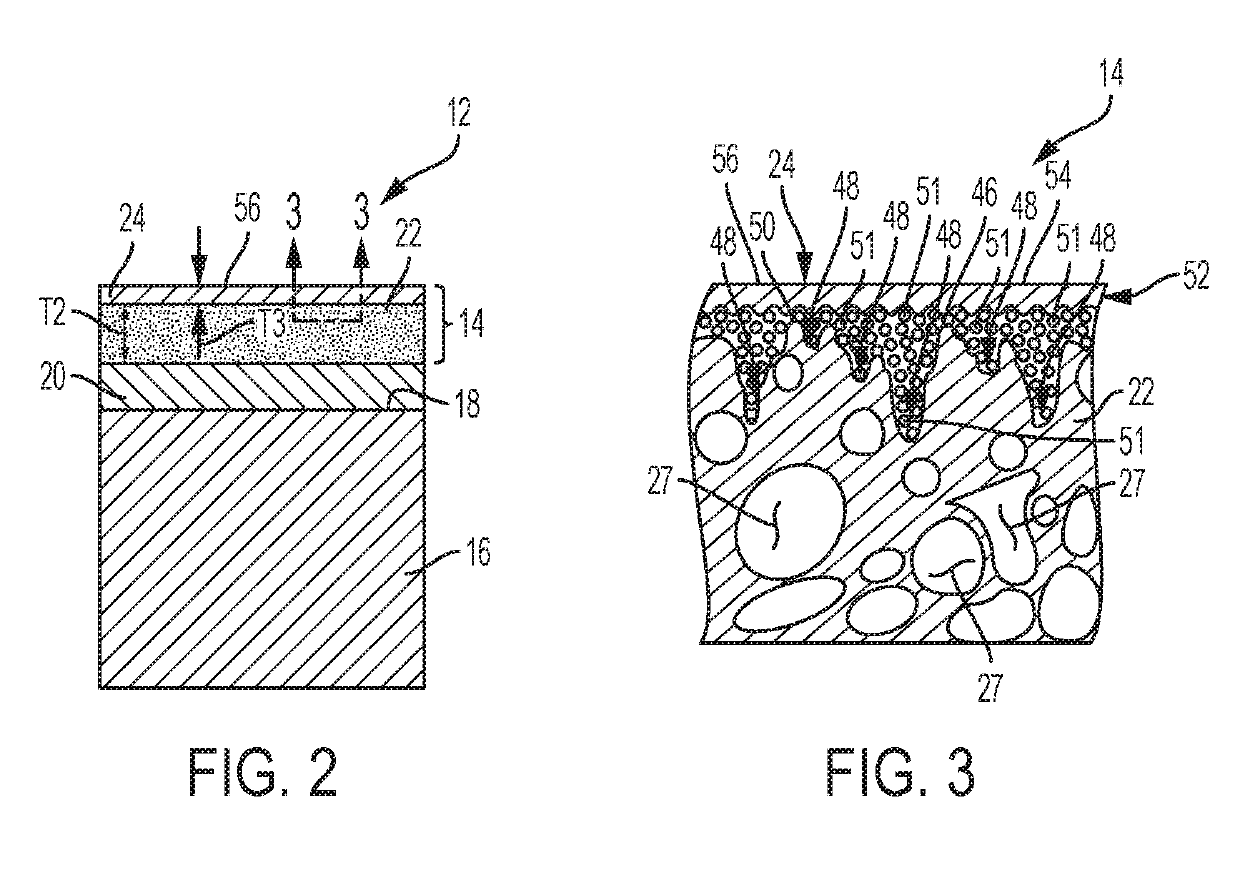

Gap-filling sealing layer of thermal barrier coating

InactiveUS20190194812A1Robust surface contactEffective combinationSuperimposed coating processMetal layered productsMetal particleThermal barrier coating

A multi-layer thermal barrier coating is provided that includes an insulating layer having an outer surface defining a plurality of crevices therein and a sealing layer bonded to the outer surface of the insulating layer. The sealing layer is substantially non-permeable and is configured to seal against the insulating layer. The sealing layer fills in at least a portion of the crevices. A method of forming a thermal barrier coating is also provided, which includes a step of providing a plurality of hollow round microstructures bonded together, each having a diameter in the range of 10 to 100 microns to create an insulating layer. The method further includes depositing a plurality of metal particles onto the insulating layer and heating the plurality of metal particles to form a substantially non-permeable sealing layer over the insulating layer.

Owner:GM GLOBAL TECH OPERATIONS LLC

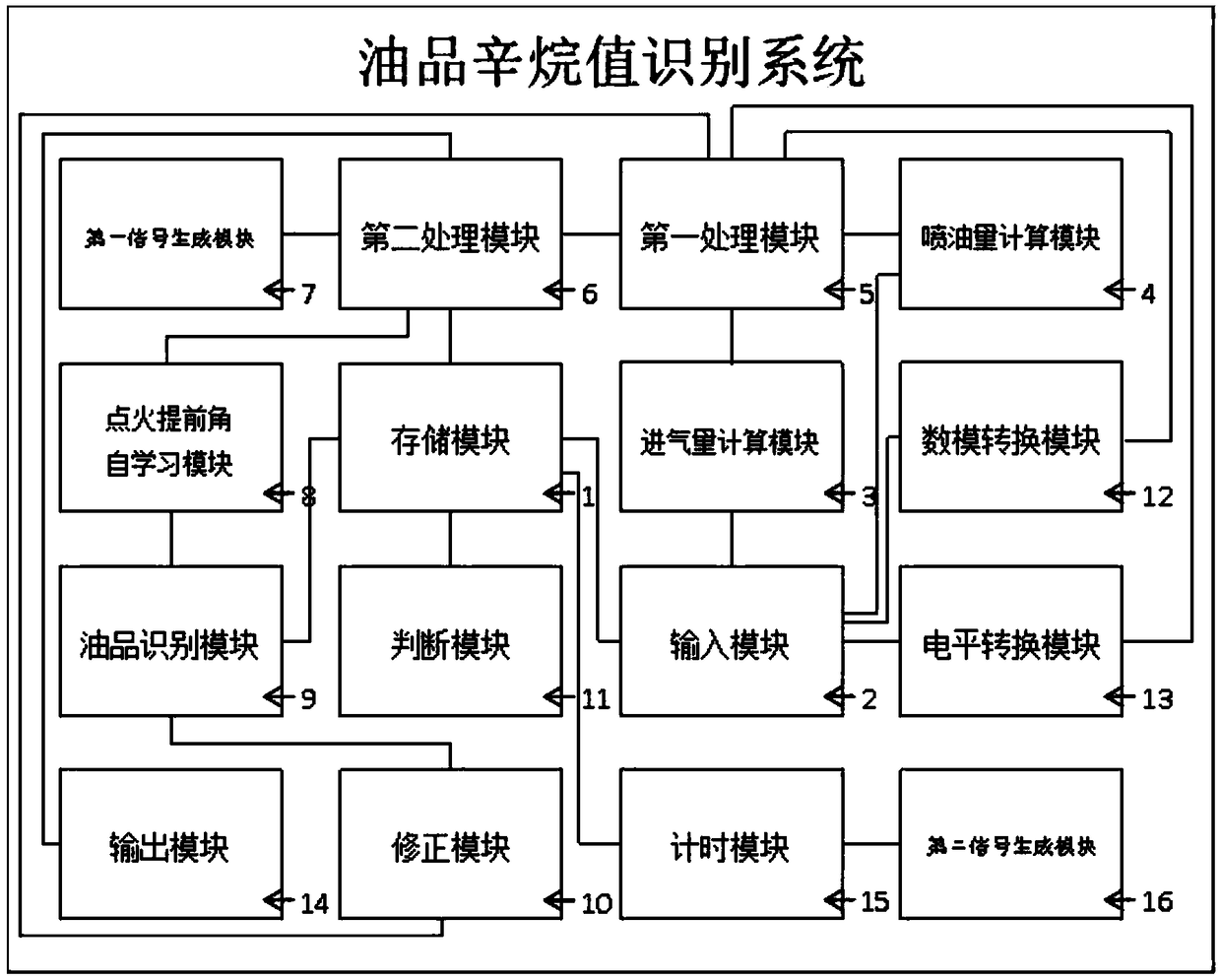

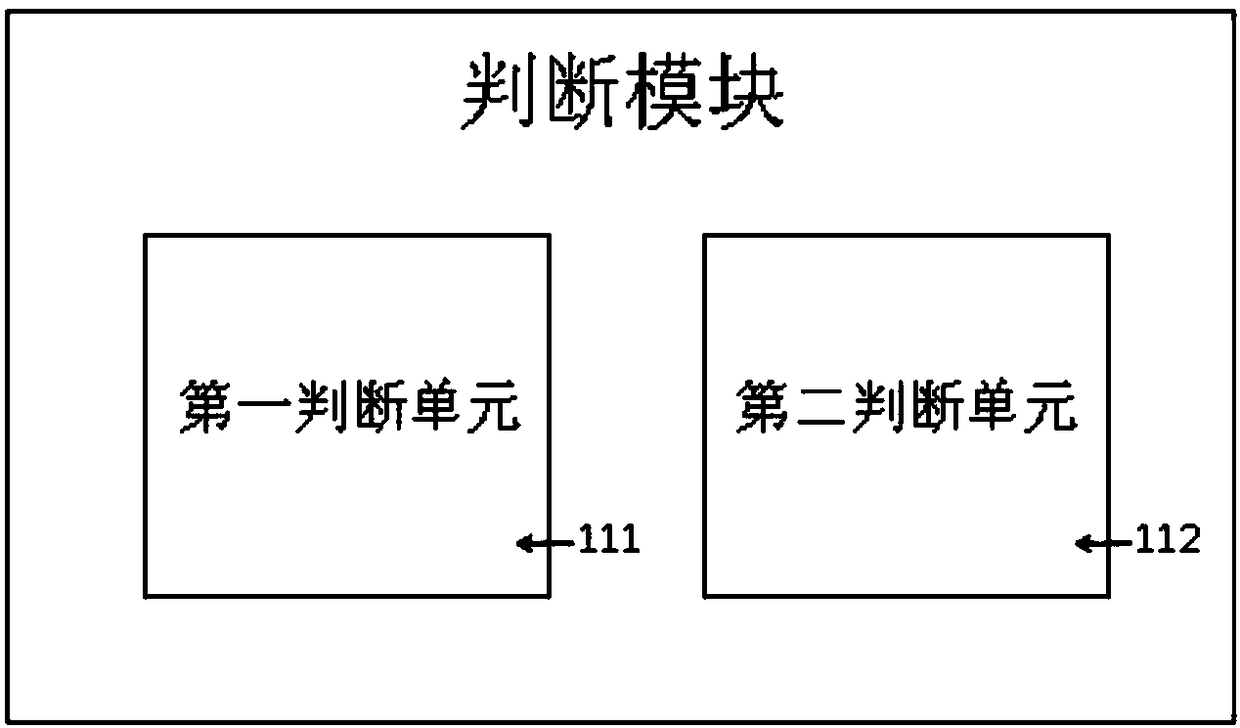

Oil octane number recognition system

ActiveCN109340013AReduced knocking tendencyMachines/enginesIgnition automatic controlComputer scienceAutomotive engine

The invention discloses an oil octane number recognition system, and is suitable for recognizing the oil octane number of an automobile engine. The oil octane number recognition system comprises a storage module, an input module, an air intake calculation module, an oil injection calculation module, a first processing module, a second processing module, a first signal generating module, an ignition advance angle self-learning module, an oil recognition module, a correction module and a judgment module, wherein the first processing module is used for presetting a torque model, inputting air inflow and oil injection quantity and calculating the actual torque of the automobile engine; the second processing module is used for calculating the ignition advance angle of the automobile engine; thefirst signal generating module and the ignition advance angle self-learning module are used for calculating and outputting the average correction of the ignition advance angle; the oil recognition module is used for recognizing the oil octane number according to the average correction of the ignition advance angle; the correction module is used for correcting the torque model according to the oiloctane number; and the judgment module is used for judging the quality of oil. The oil octane number recognition system has the beneficial effects that the oil octane number is recognized by softwarein an electronic control unit, the ignition advance angle of the engine is dynamically adjusted, and the knock tendency of the engine is reduced.

Owner:MARELLI CHINA

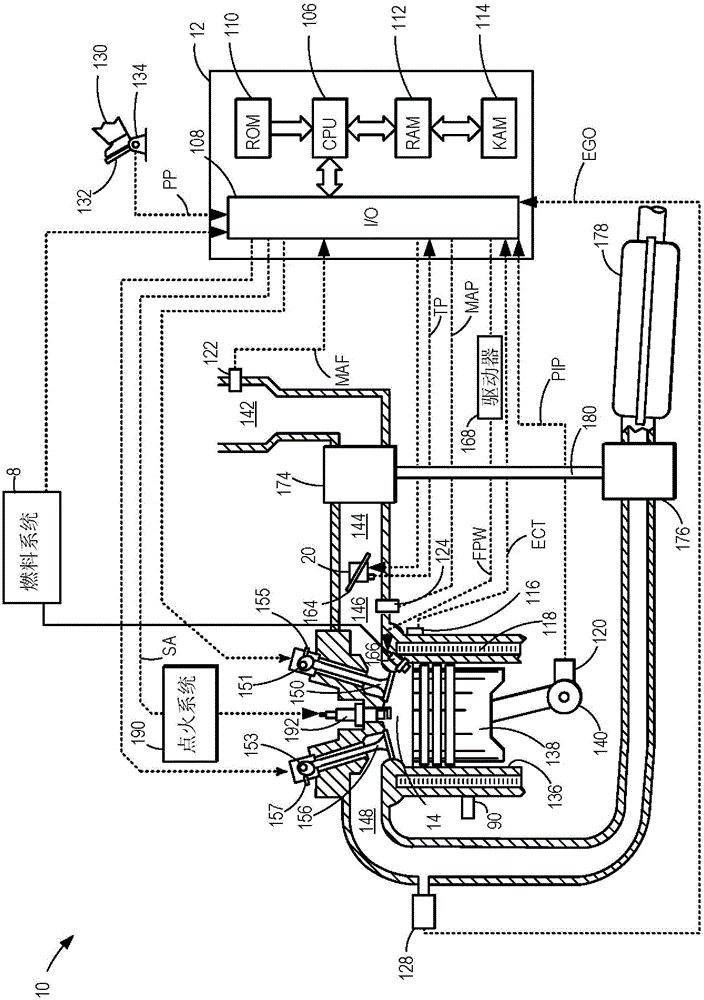

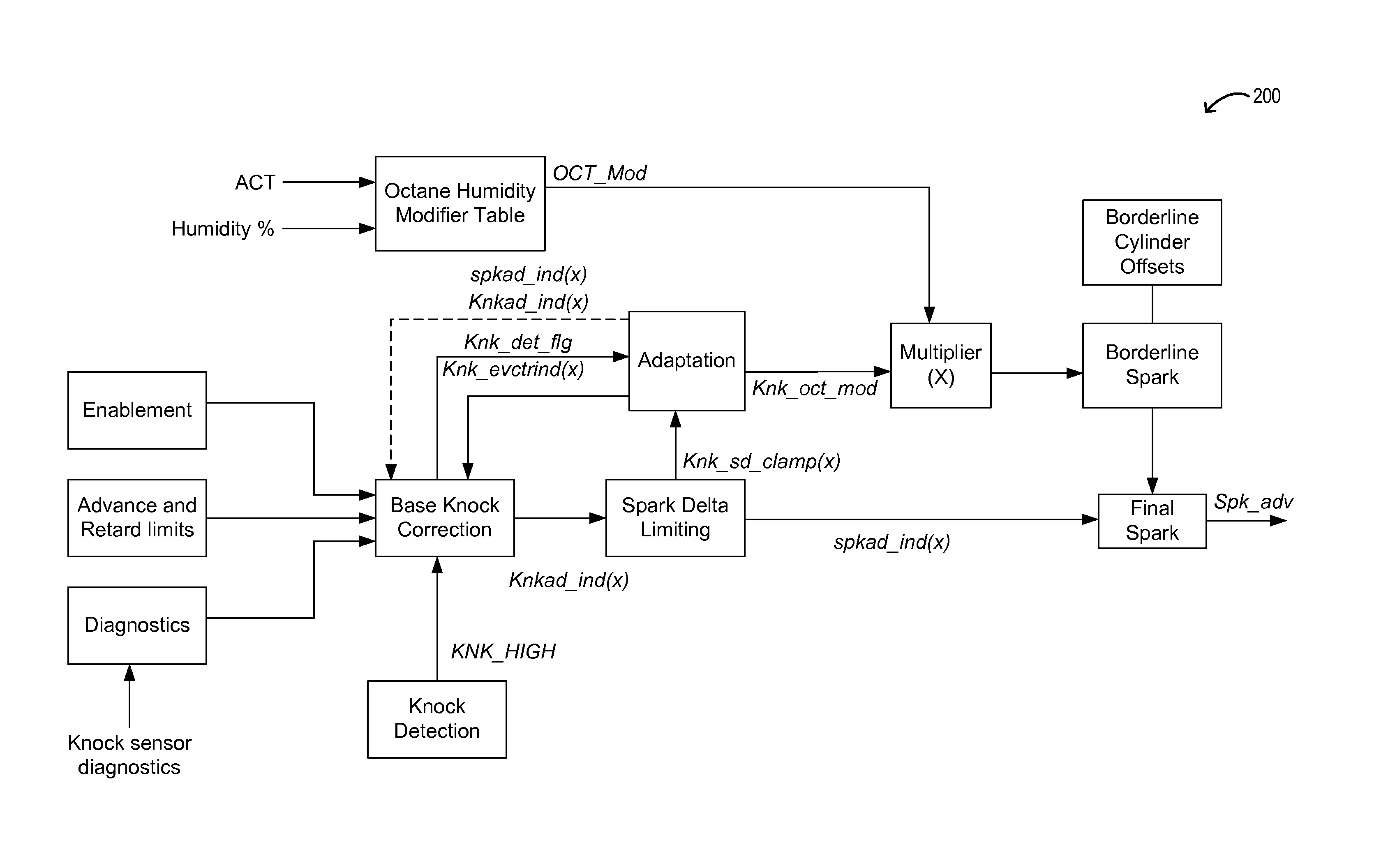

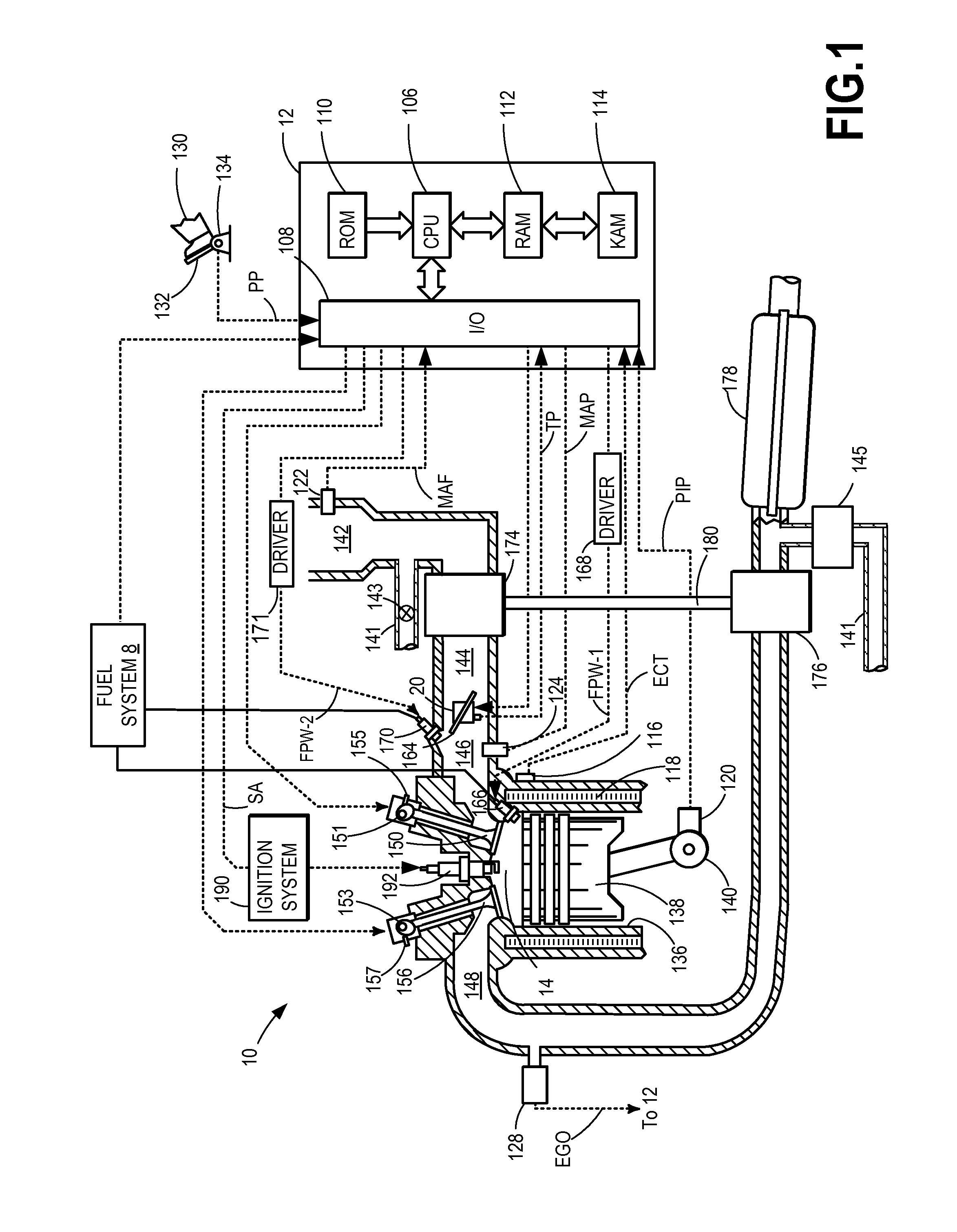

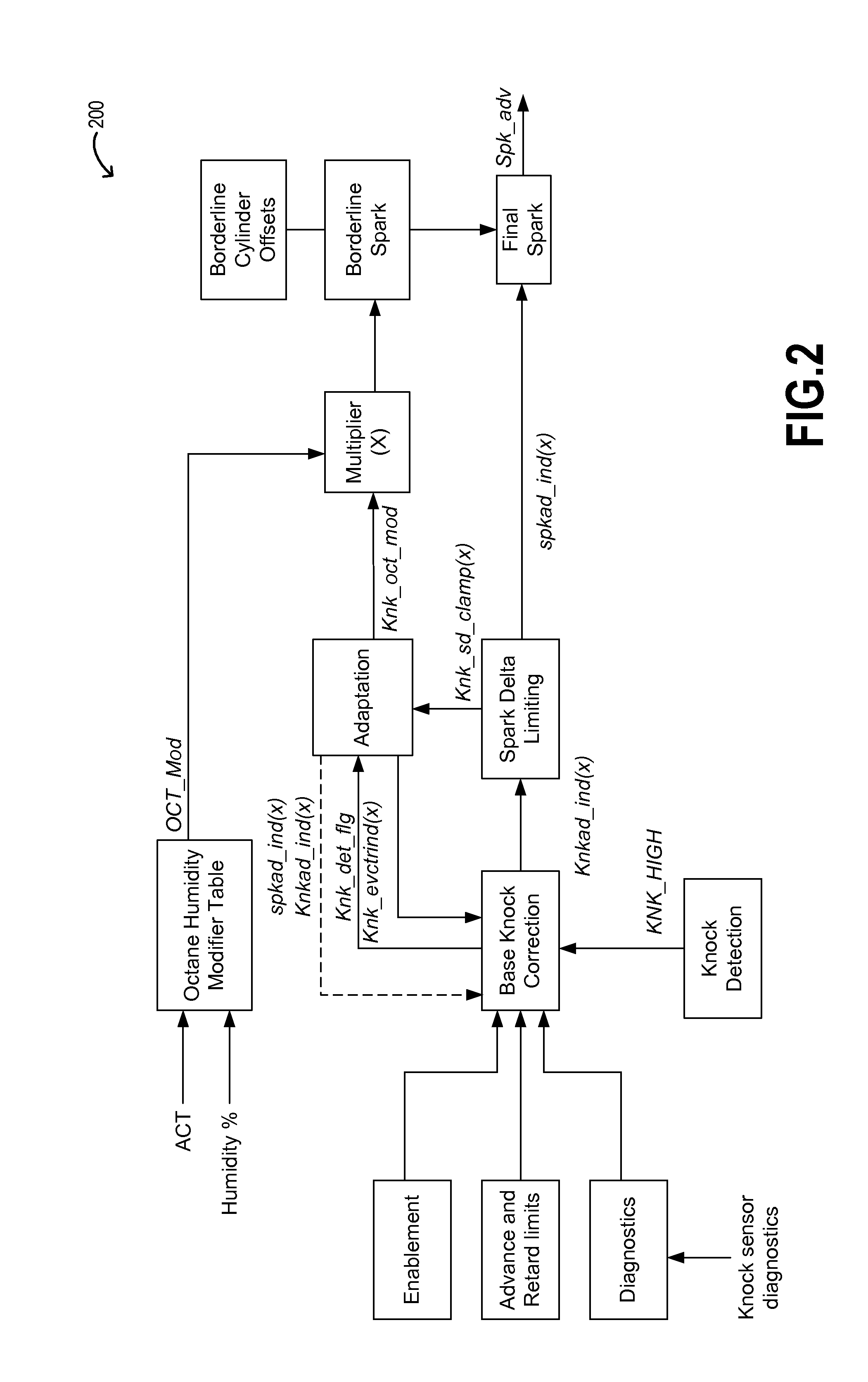

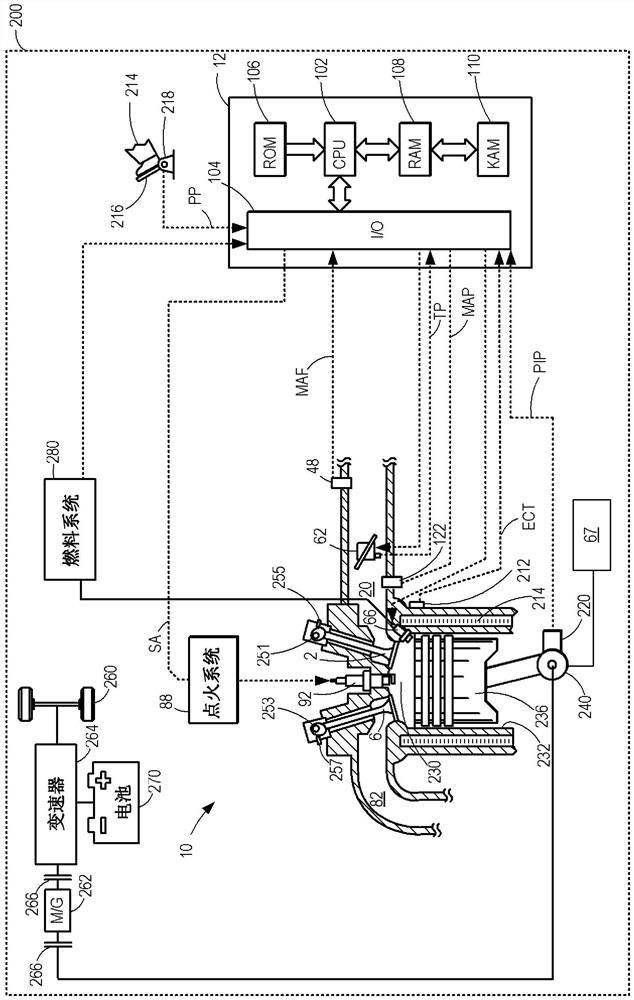

Method and system for engine control

ActiveUS20160369762A1Reduction in exhaust NOx emissionImprove fuel economyElectrical controlInternal combustion piston enginesAmbient humidityControl theory

Methods and systems are provided for improving engine spark and torque control. In one example, adaptive spark control of an engine may include a modifier that adjusts the inferred fuel octane estimate and a spark adaptation based on ambient humidity. The method allows the speed-load dependent variation in octane effect of humidity to be reduced.

Owner:FORD GLOBAL TECH LLC

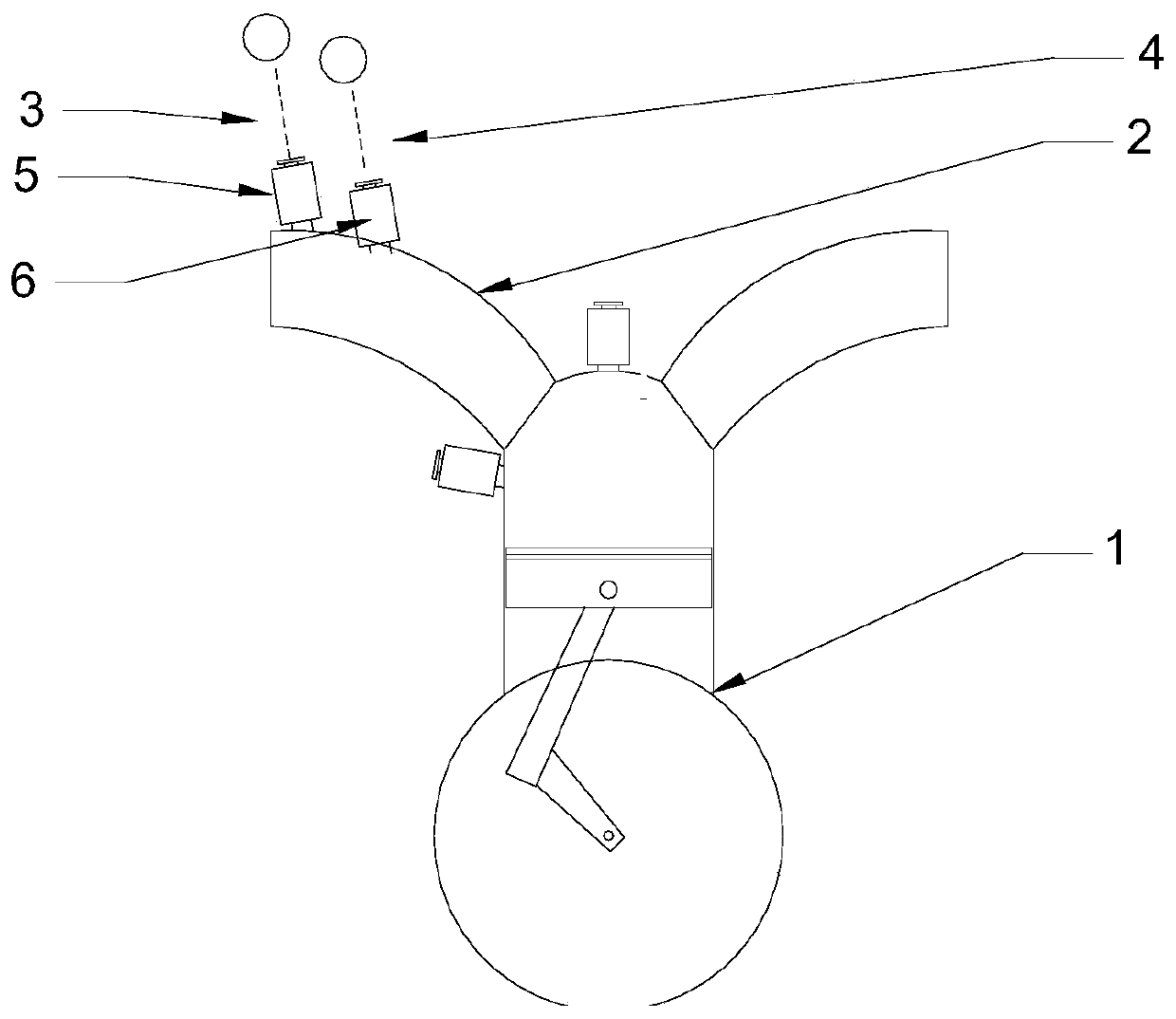

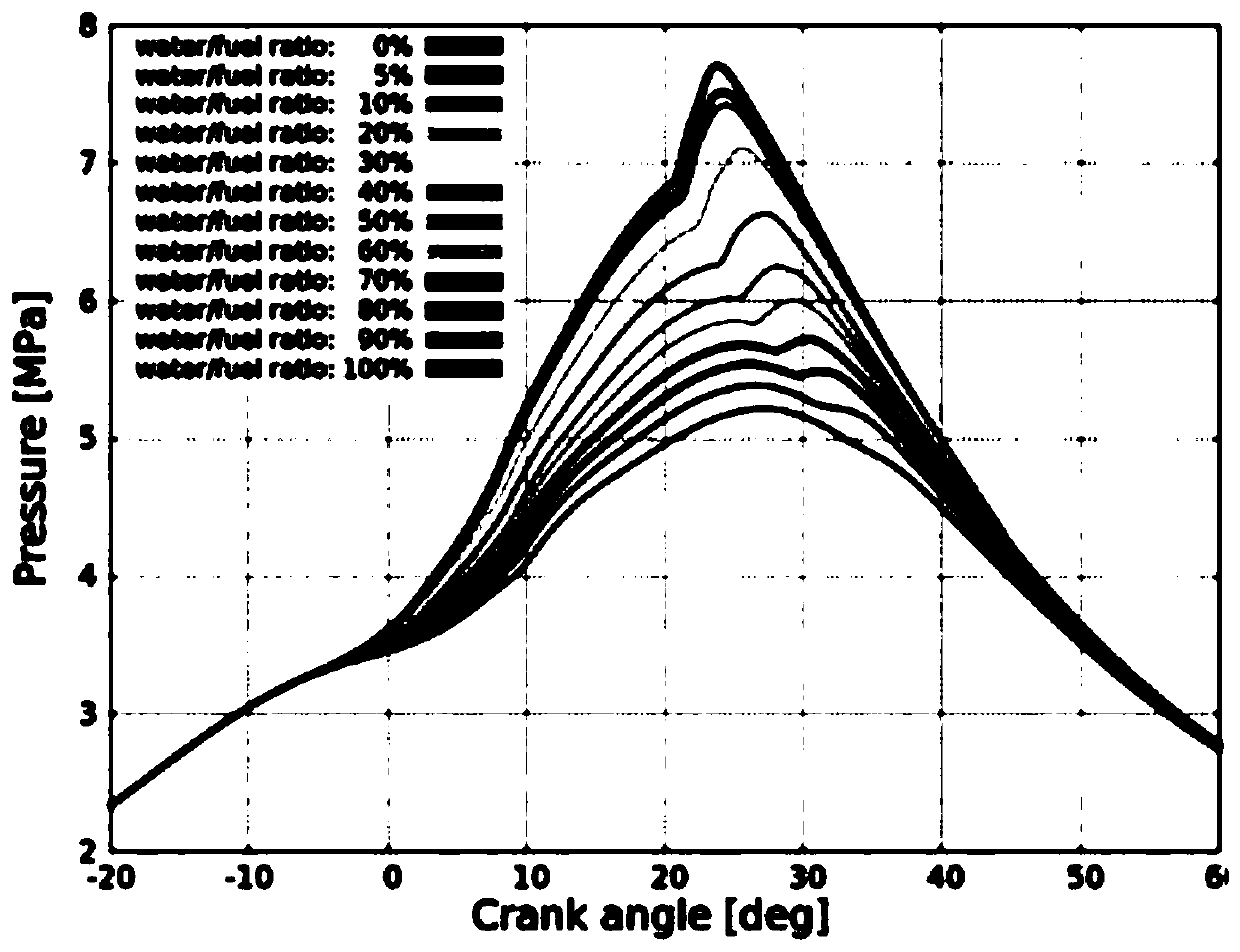

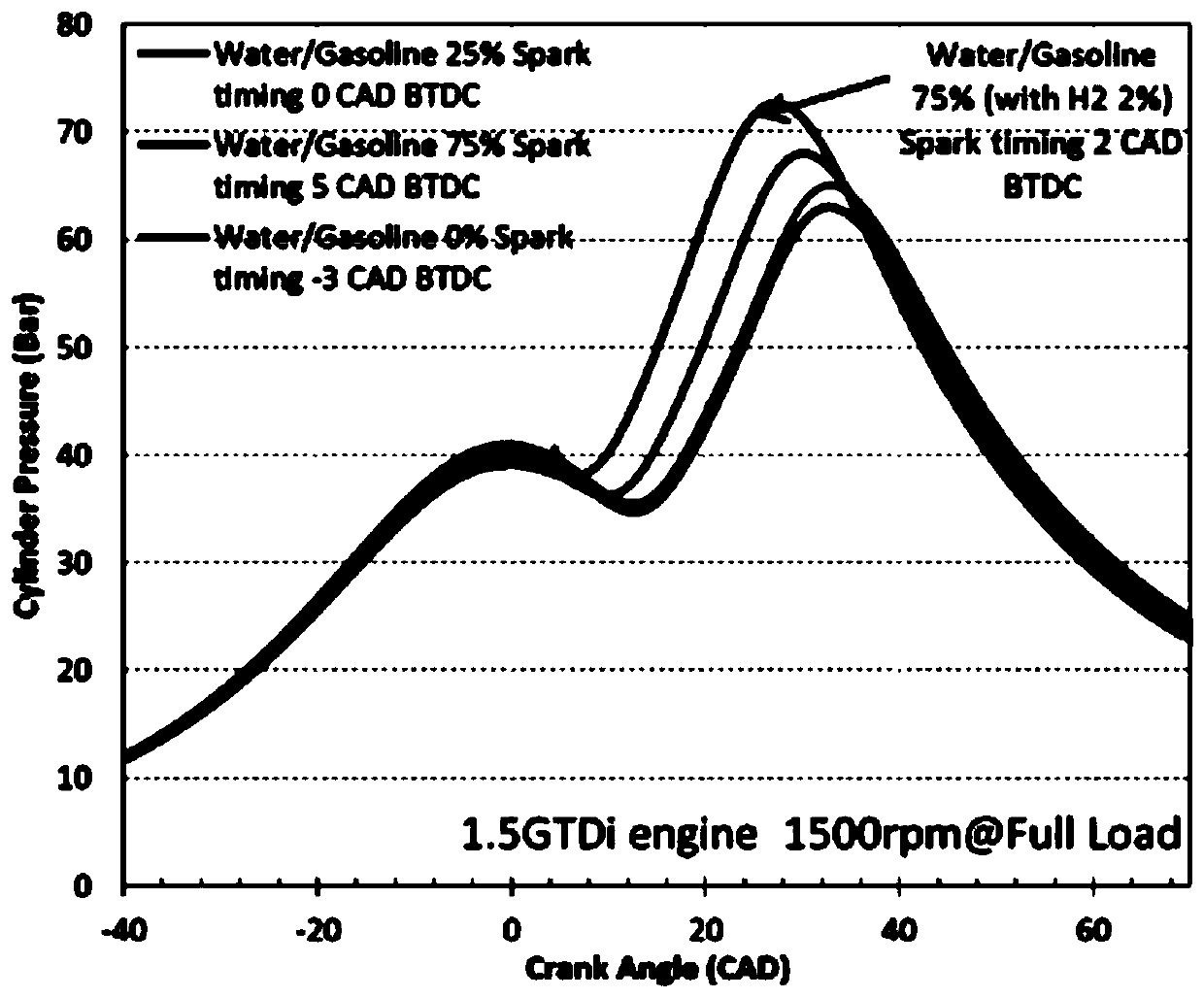

Engine intake physicochemical property adjusting structure

PendingCN110685827ABurn fasterImprove combustion efficiencyNon-fuel substance addition to fuelInternal combustion piston enginesPhysical chemistryEnvironmental engineering

The invention discloses an engine intake physicochemical property adjusting structure. The adjusting structure is arranged on an air inlet pipe of an engine and comprises a deionized water injection device and a hydrogen injection device. The deionized water injection device and the hydrogen injection device are electrically connected with an electronic control unit to control the injection amountof deionized water and hydrogen when the engine is under medium-and-small-load working conditions. Under high-load working conditions, the injection amount of the deionized water is controlled. By means of the adjusting structure, the combustion efficiency of the engine can be effectively improved, and the emission amount of carbon oxide is reduced.

Owner:HEFEI UNIV OF TECH

Engine cooling system for vehicle and vehicle

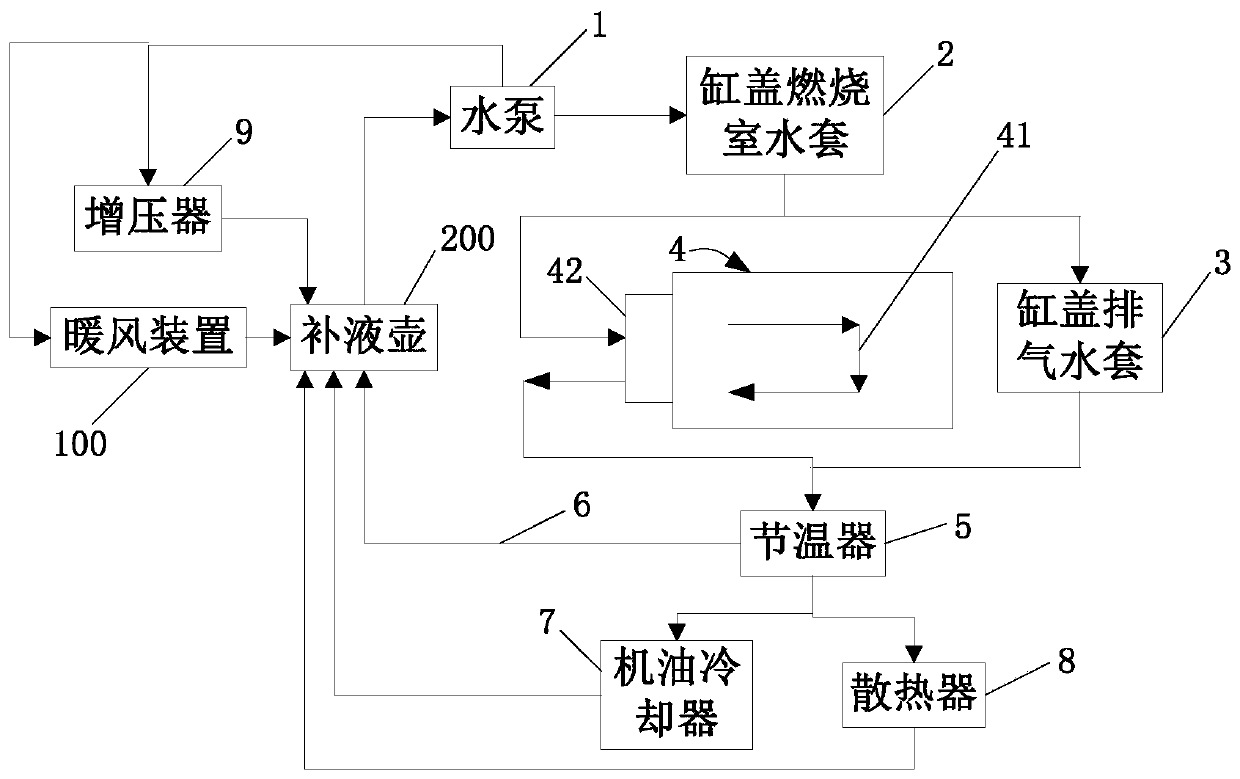

ActiveCN110242396AImprove cooling effectReduce the temperatureLiquid coolingCoolant flow controlCombustion chamberPulp and paper industry

The invention provides an engine cooling system for a vehicle and the vehicle, and relates to the field of the vehicles. The engine cooling system for the vehicle comprises a water pump, a cylinder cover combustion chamber water jacket, a cylinder cover exhaust water jacket and a cylinder body water jacket; the cylinder cover exhaust water jacket and the cylinder body water jacket are connected in parallel between the water pump and the cylinder cover combustion chamber water jacket; the cylinder cover combustion chamber water jacket is provided with a cylinder cover combustion chamber water jacket exhaust side and a cylinder cover combustion chamber water jacket intake side; the cylinder cover combustion chamber water jacket is provided with at least two independent cylinder cover combustion chamber water channels communicating the cylinder cover combustion chamber water jacket exhaust side and the cylinder cover combustion chamber water jacket intake side; the cylinder cover exhaust water jacket is provided with a cylinder cover exhaust water jacket exhaust side and a cylinder cover exhaust water jacket intake side; and the cylinder cover exhaust water jacket is provided with at least two independent cylinder cover exhaust water channels communicating the cylinder cover exhaust water jacket exhaust side and the cylinder cover exhaust water jacket intake side. The invention also provides the vehicle comprising the engine cooling system. The performance of an engine can be greatly improved.

Owner:ZHEJIANG GEELY HOLDING (GROUP) CO LTD +1

Internal combustion engine

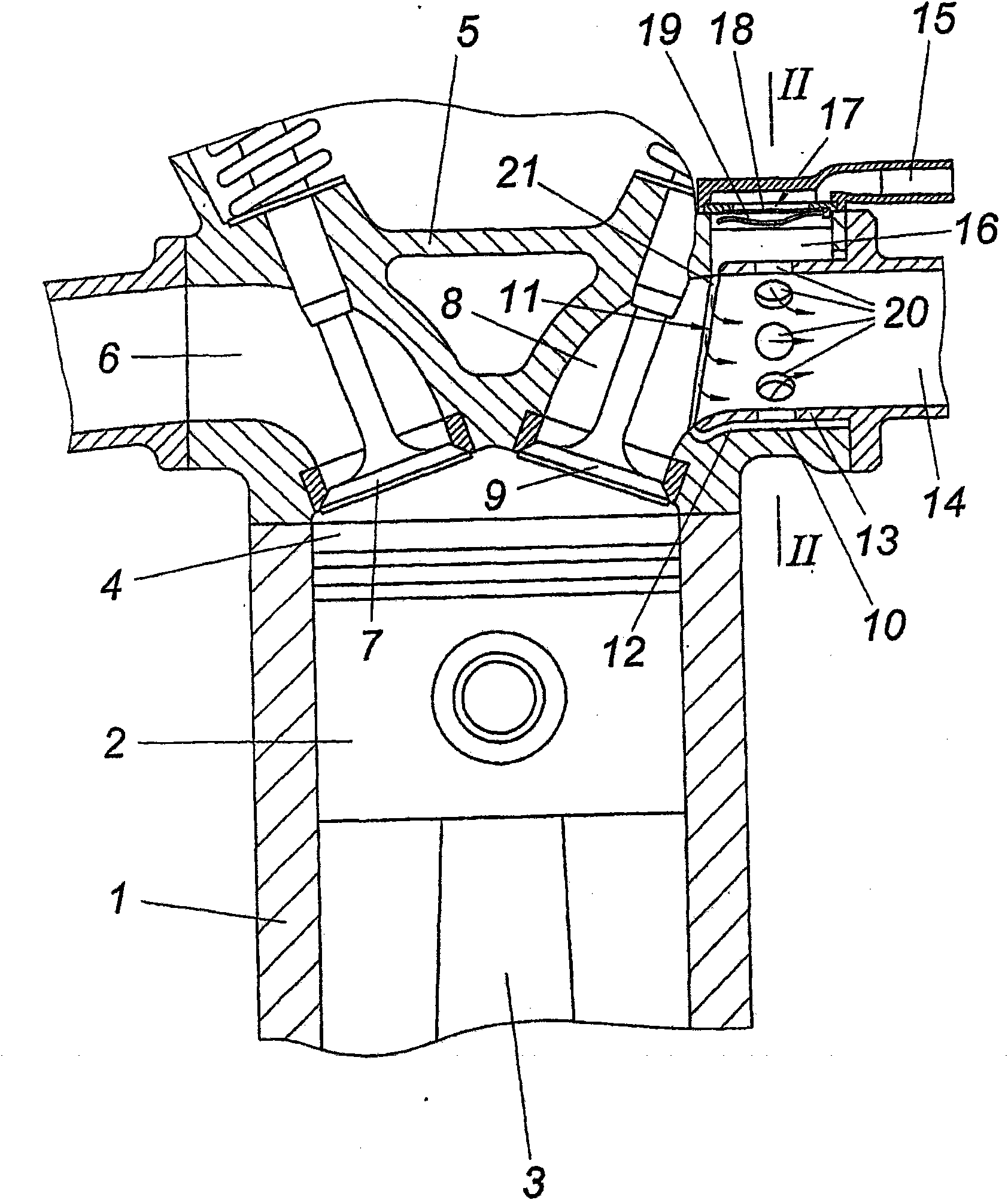

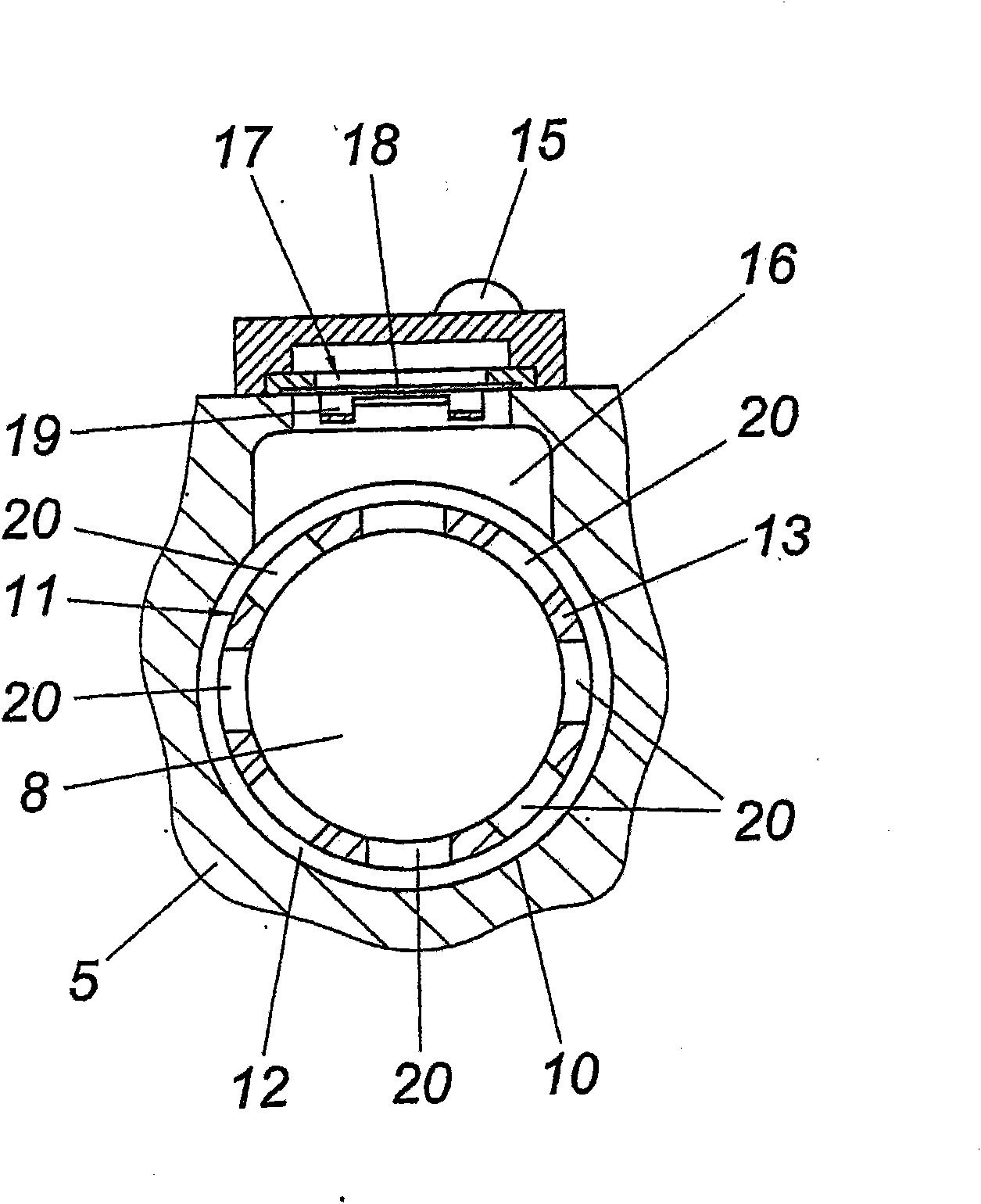

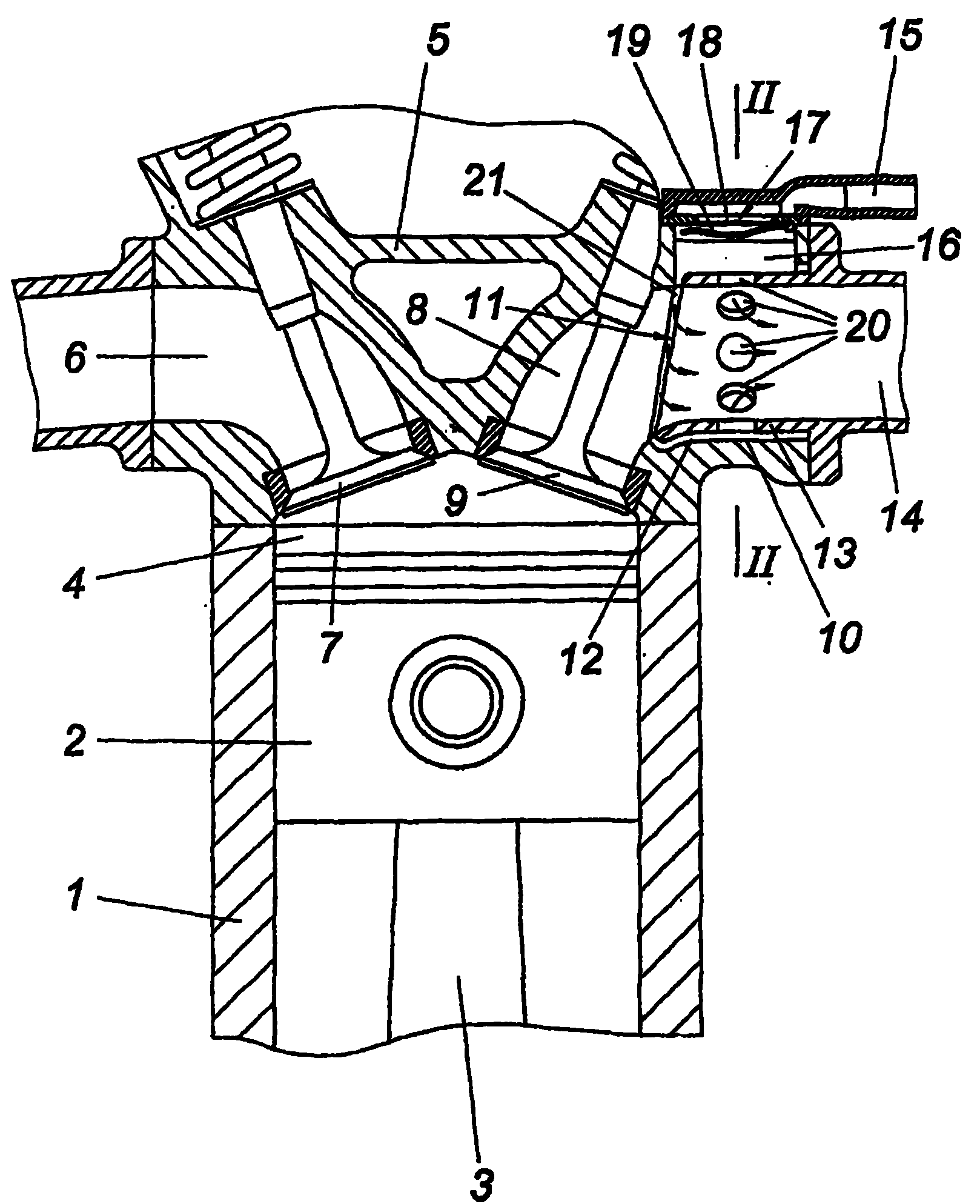

InactiveCN101835964ASimple structureSupport heat conductionInternal combustion piston enginesExhaust apparatusCylinder headDiaphragm valve

An internal combustion engine is described having at least one cylinder (1), the cylinder head (5) of which forms at least one outlet channel (8) which merges into an exhaust-gas section (14) and comprises a tubular insert (11) which is arranged within a cylinder-head opening (10) with the formation of an annular gap (12), wherein the annular gap (12) which is fluid-connected to the outlet channel (8) is attached to an air line (15). In order to provide advantageous air feed conditions, it is proposed that the tubular insert (11) is part of the exhaust-gas section (14), and that the annular gap (12) is widened in the opening region of the air line (15) to form a chamber (16) which is delimited by a diaphragm valve (17) with respect to the air line (15).

Owner:罗兰・柯克伯格

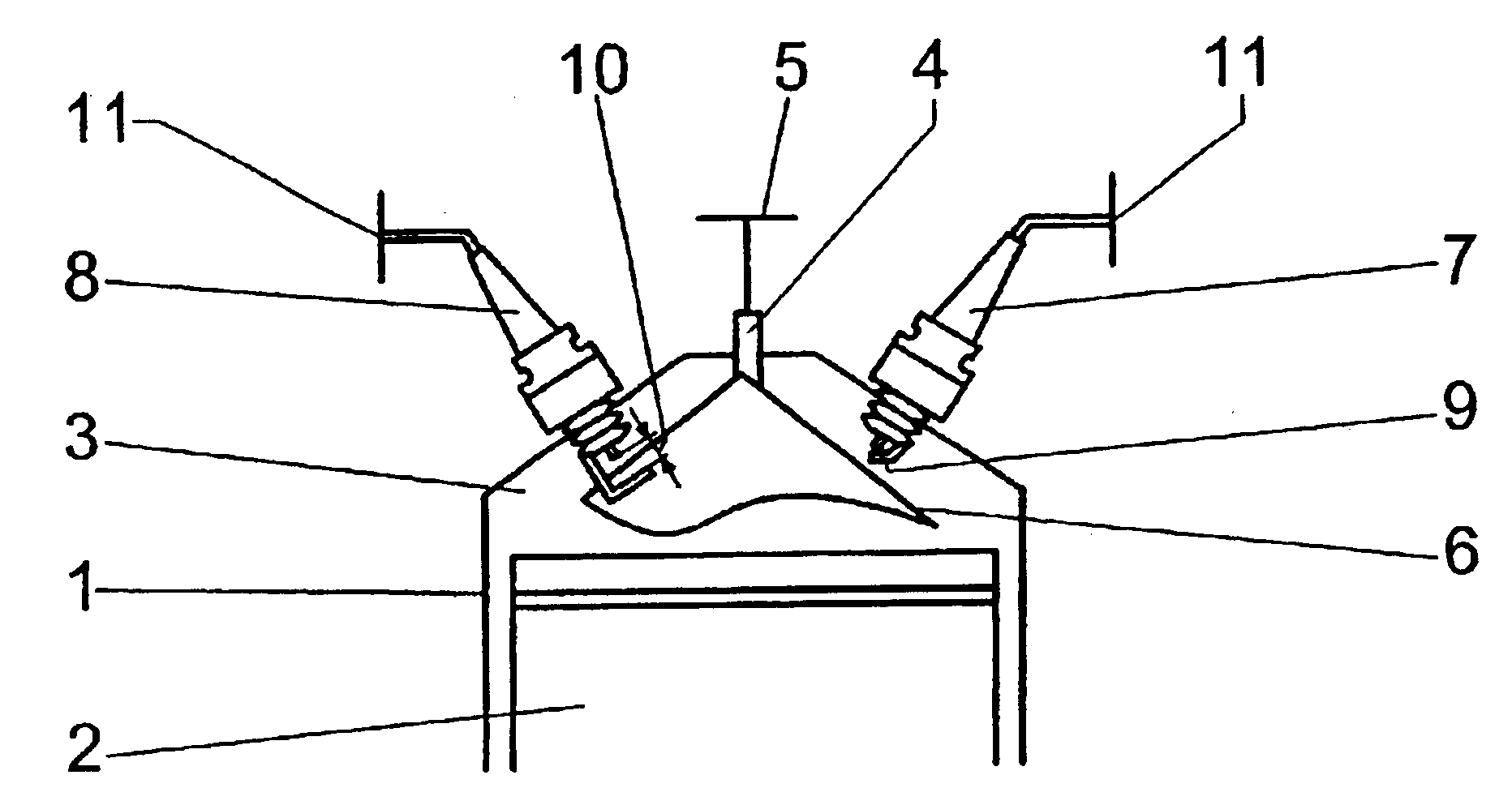

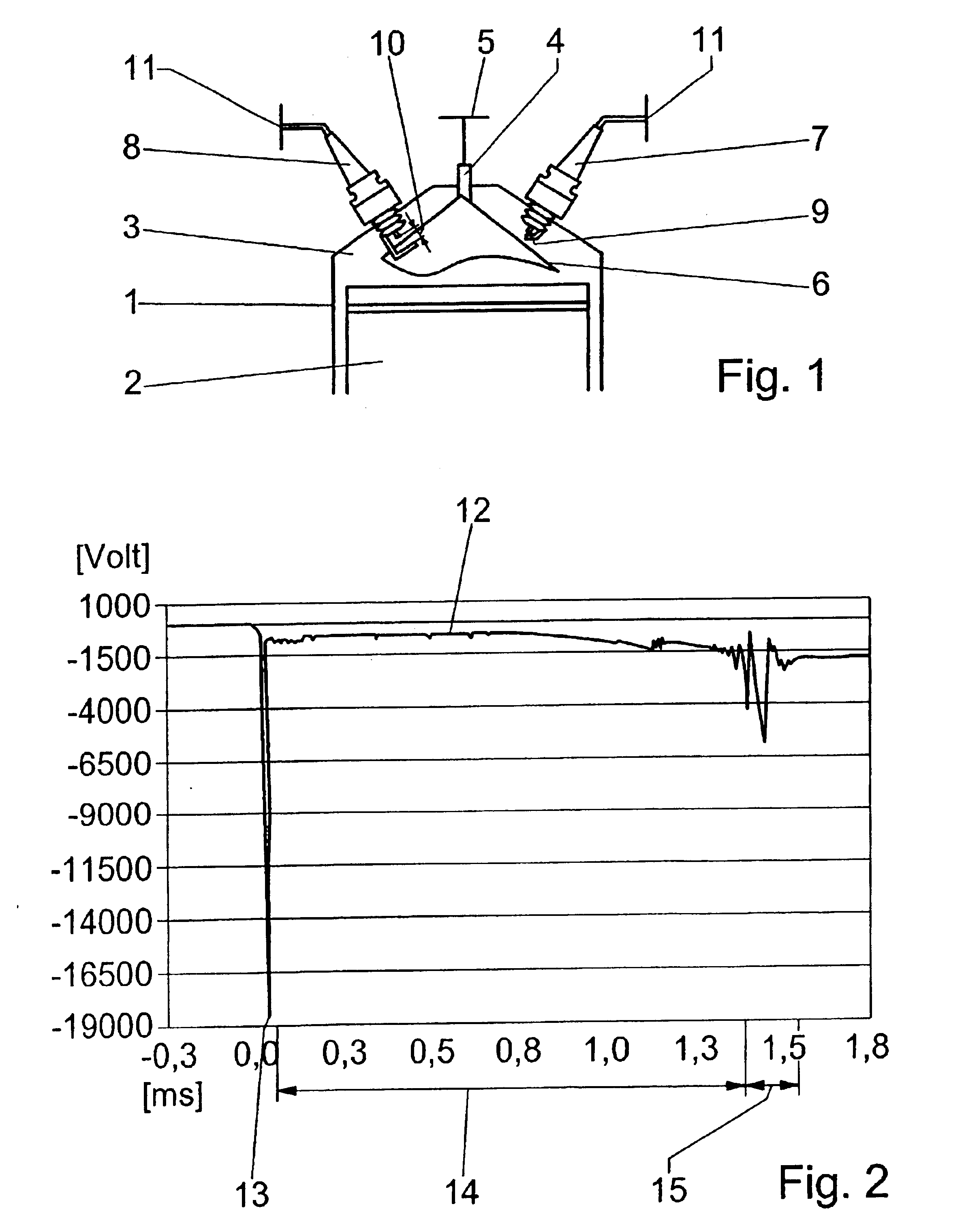

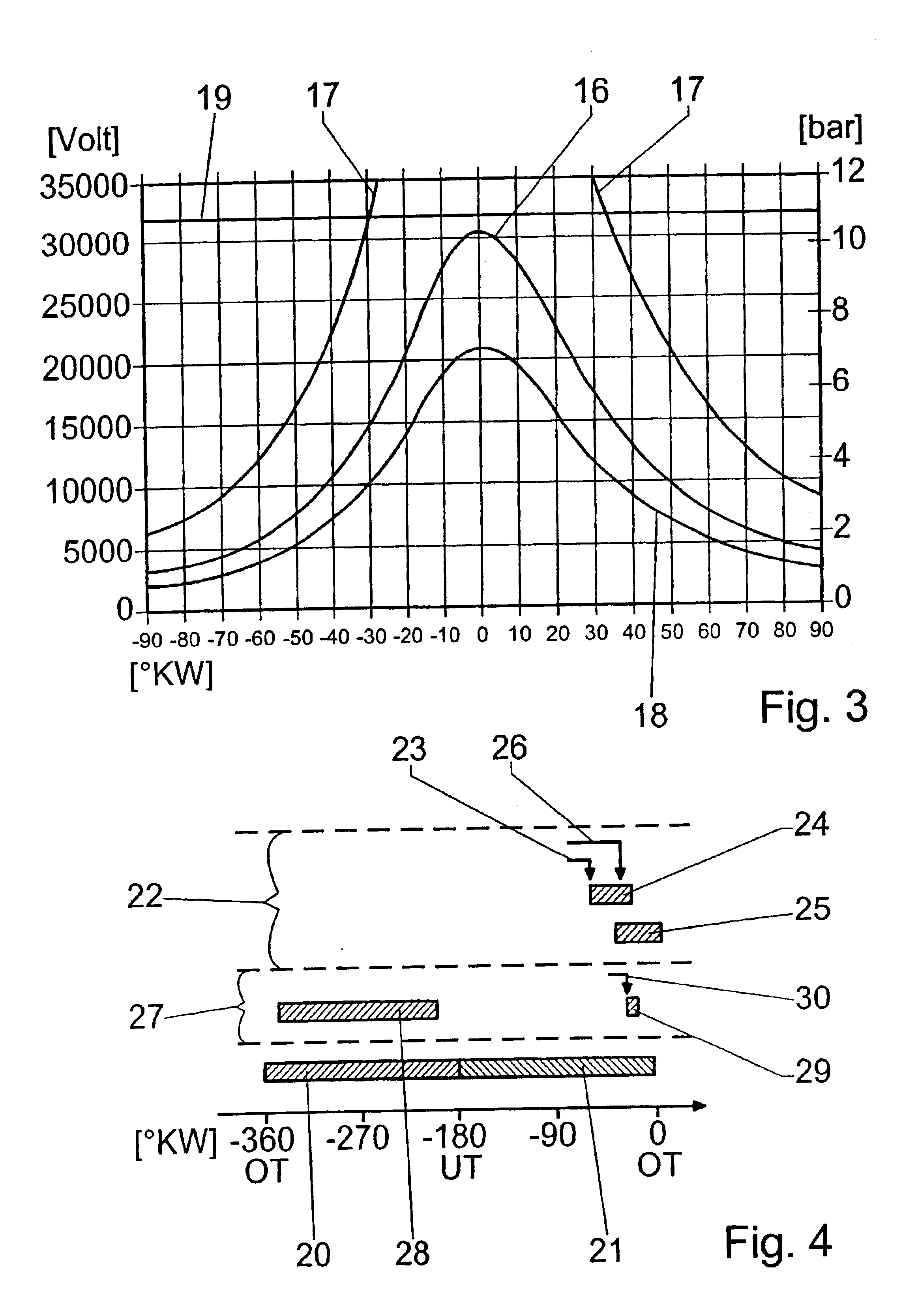

Internal combustion engine with direct injection

InactiveUS6848415B2High spark gapMixture accessibilitySparking plugsElectrical controlCombustionExternal combustion engine

A four-stroke reciprocating-piston internal combustion engine includes a fuel injection device, which is arranged centrally in a combustion space and which introduces the fuel in the form of an injection cone into the combustion space, and includes at least one spark plug for each combustion space, the electrodes of which spark plug are arranged at the edge of the injection cone. At least two spark plugs are provided, of which the second spark plug has a markedly higher spark gap than the first spark plug.

Owner:DAIMLER AG

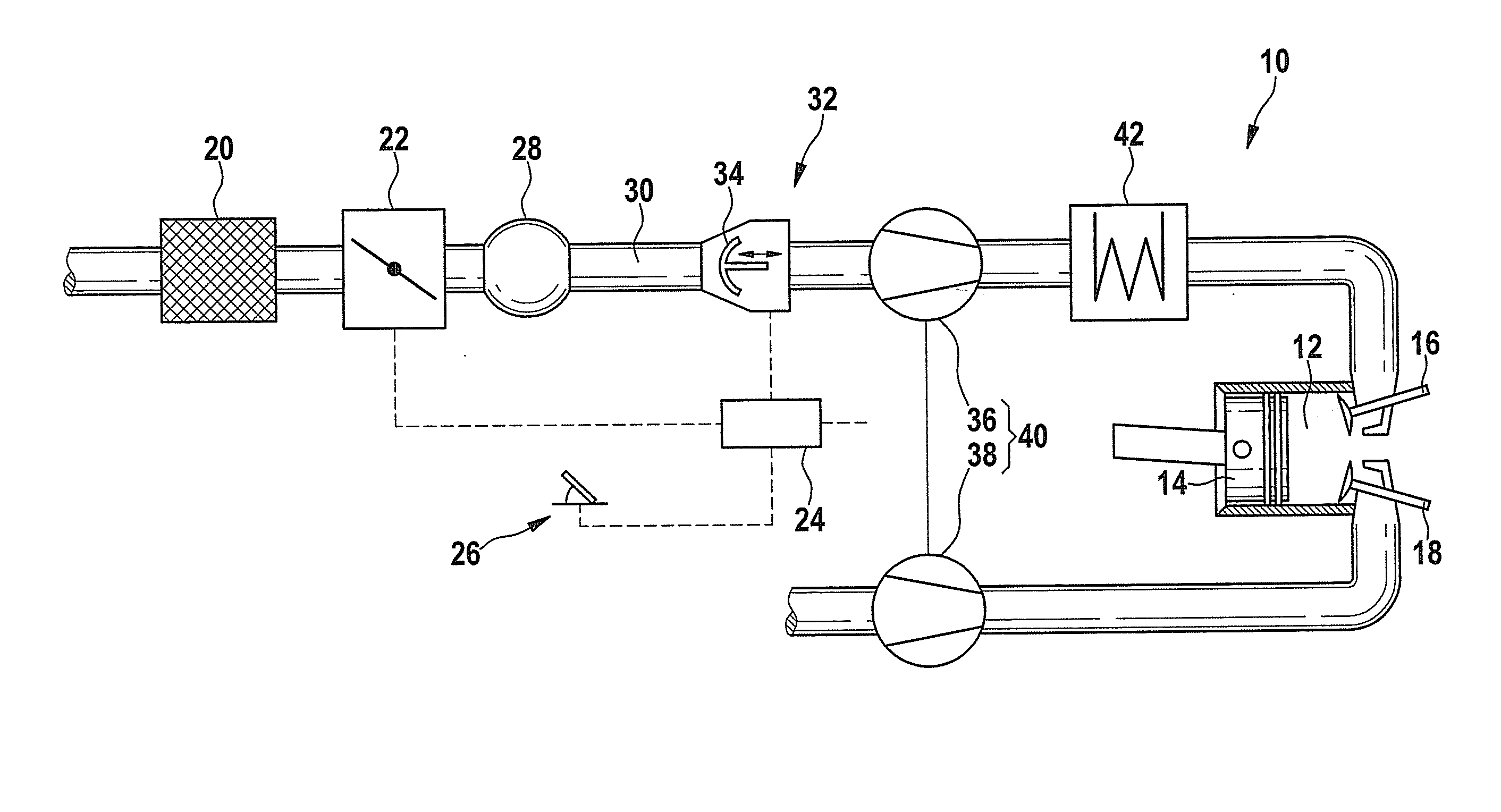

Method for operating an internal combustion engine

InactiveUS20110004393A1Improved response behaviorReduced knocking tendencyAnalogue computers for vehiclesElectrical controlExternal combustion engineTurbocharger

A method for operating an internal combustion engine in which combustion air is supplied to a combustion chamber of the internal combustion engine, which air is compressed with the aid of a pulse supercharger, the pulse supercharger being controlled in such a way that optionally, in a first operating mode, the combustion air is compressed in order to support a compressor of a turbocharger, or in a second operating mode, the combustion air compressed with the aid of the compressor is cooled.

Owner:ROBERT BOSCH GMBH

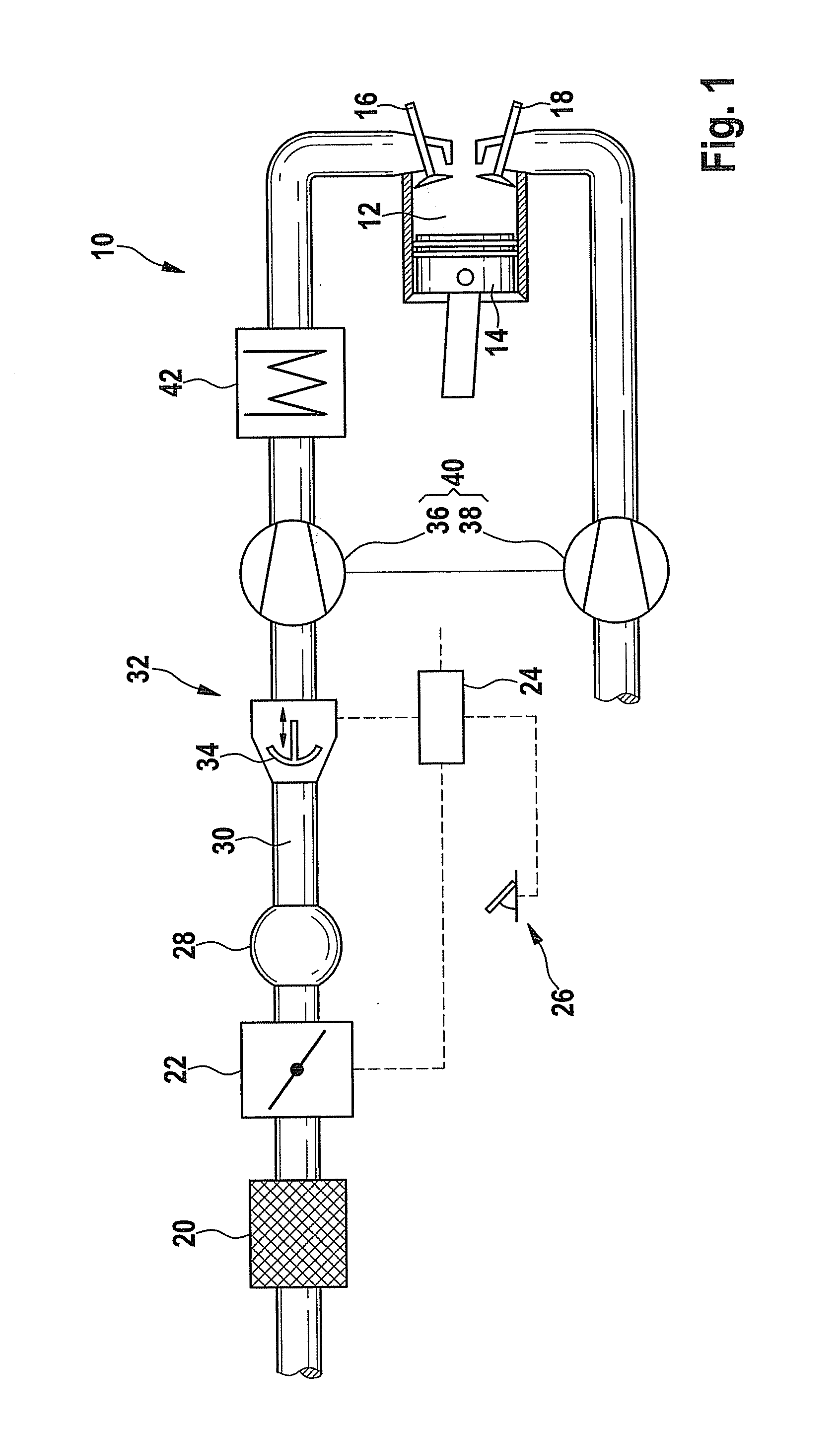

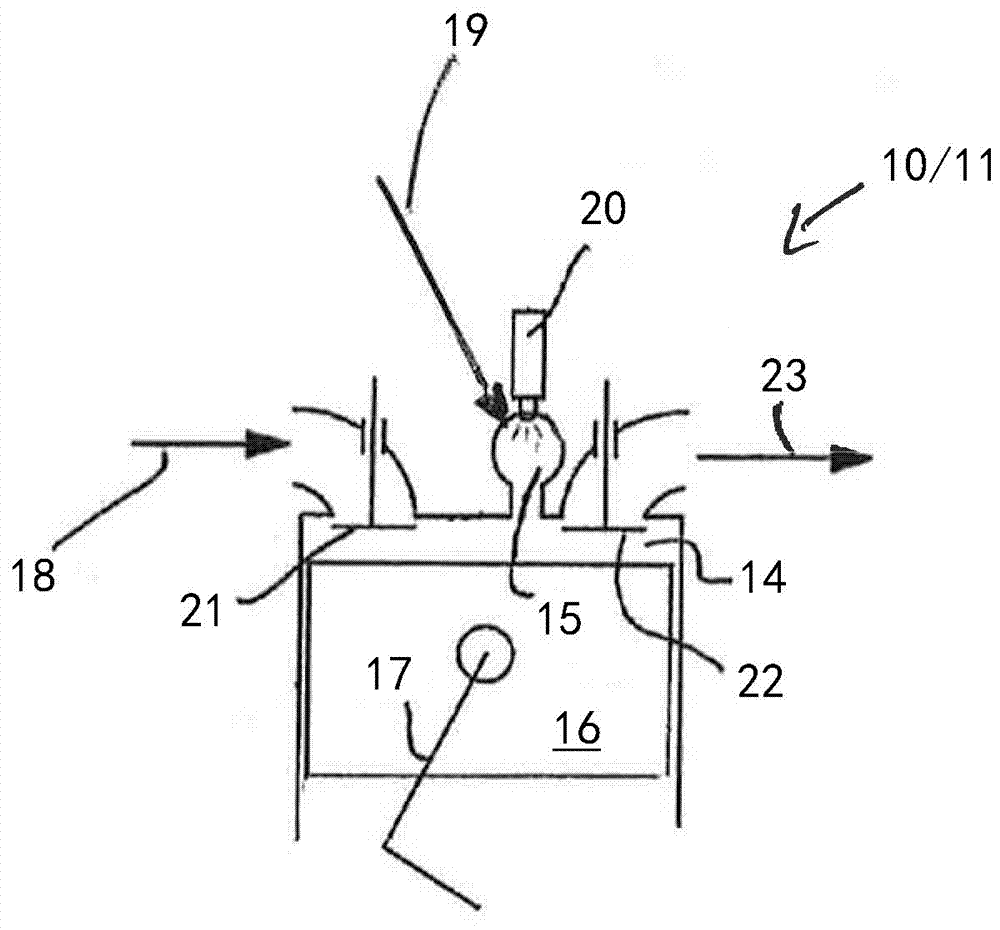

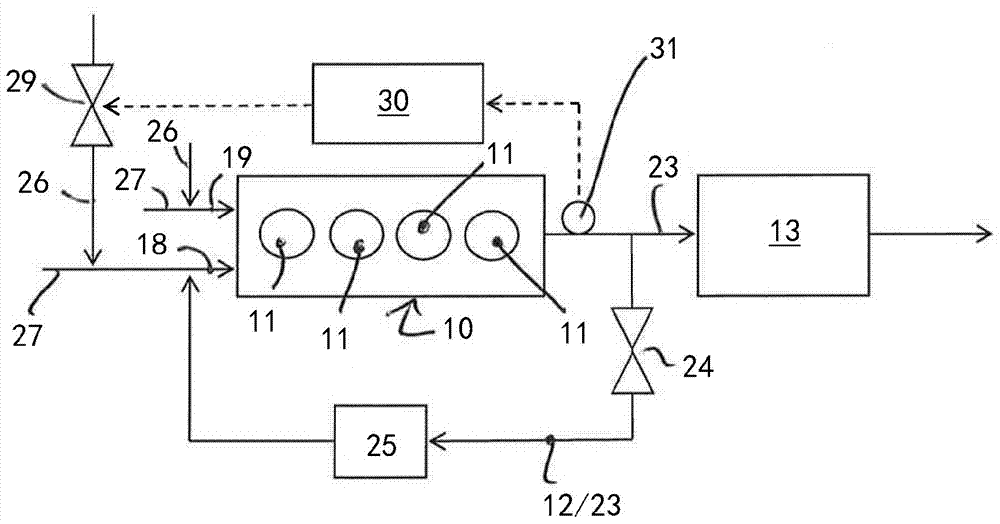

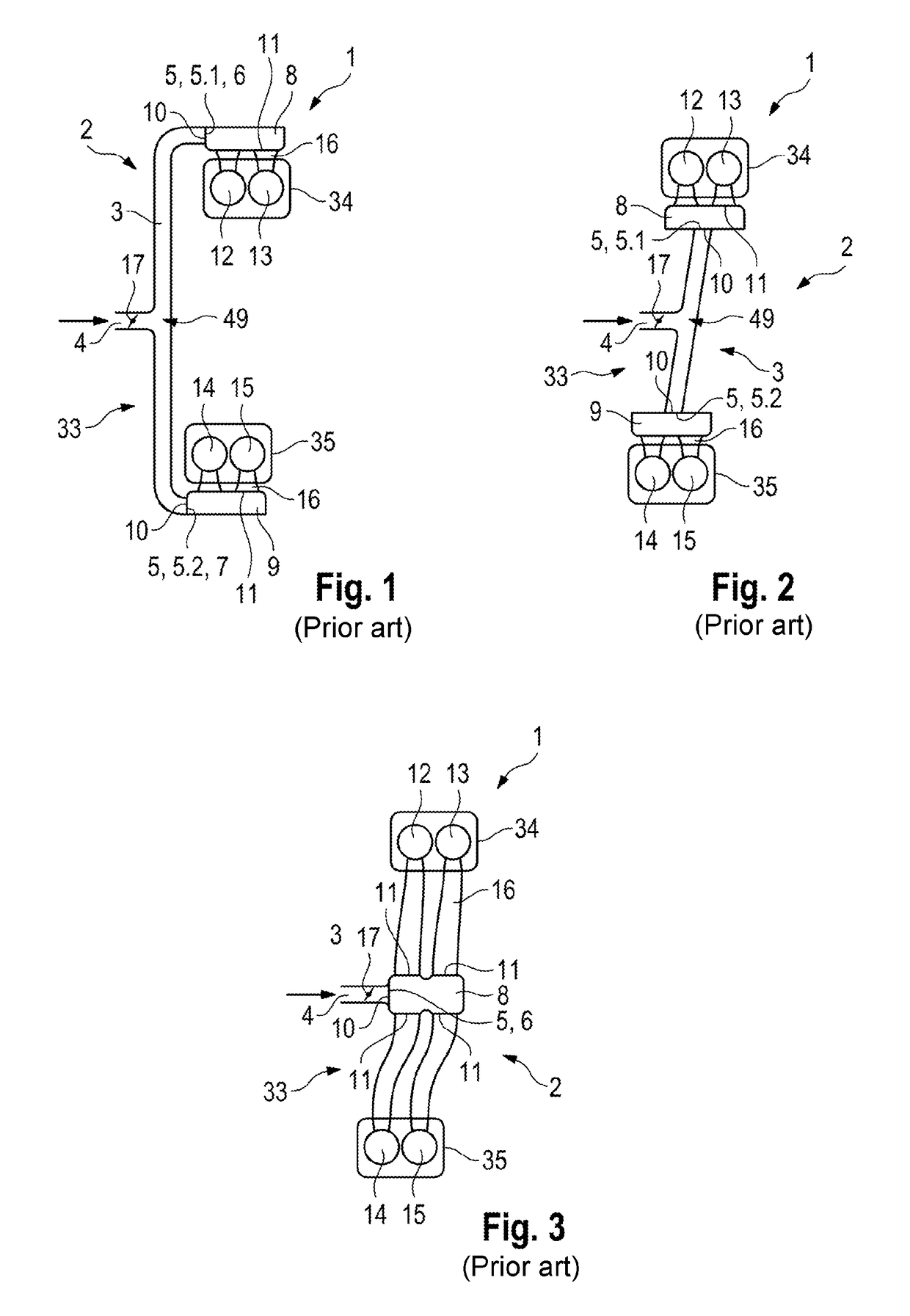

Method and control device for operating a gas engine

InactiveCN107304726AEasy to operateImprove efficiencyElectrical controlInternal combustion piston enginesCombustion chamberExhaust gas recirculation

A method for operating a gas engine (10) with an exhaust gas catalytic converter (13) and with an exhaust gas recirculation (12), wherein the gas engine (10) comprises cylinders (11), which comprise a main combustion chamber (14) and a precombustion chamber (15), wherein the exhaust gas (23) leaving the cylinders (11) is conductible via the exhaust gas catalytic converter (13), and wherein a part of the exhaust gas (23) leaving the cylinders, is conductible via the exhaust gas recirculation (12) in the direction of the cylinders (11). In a first operating strategy, the gas engine (10) is operated in such a manner that exhaust gas (23) conducted via the exhaust gas recirculation (12) is conducted in the direction of the main combustion chambers (14) of the cylinders, so that the gas / air mixture (18) to be fed to the main combustion chambers contains exhaust gas; that exhaust gas (23) conducted via the exhaust gas recirculation is not conducted in the direction of the precombustion chambers (15) of the cylinders, so that the gas / air mixture (19) to be fed to the precombustion chamber does not contain any exhaust gas; that the gas proportion of the gas / air mixture (18) to be fed to the main combustion chambers (14) of the cylinders (11) is controlled in such a manner that the combustion in the cylinders takes place at a stoichiometric combustion air ratio or a lambda value of 1.

Owner:MAN ENERGY SOLUTIONS SA

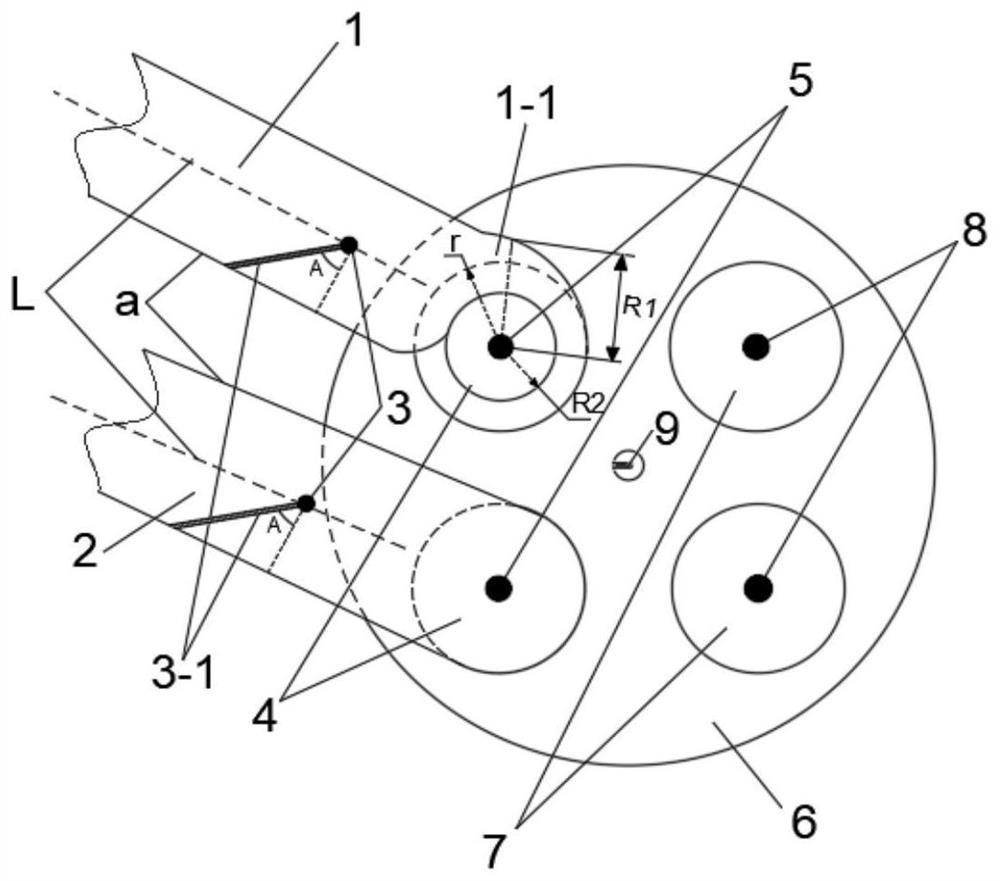

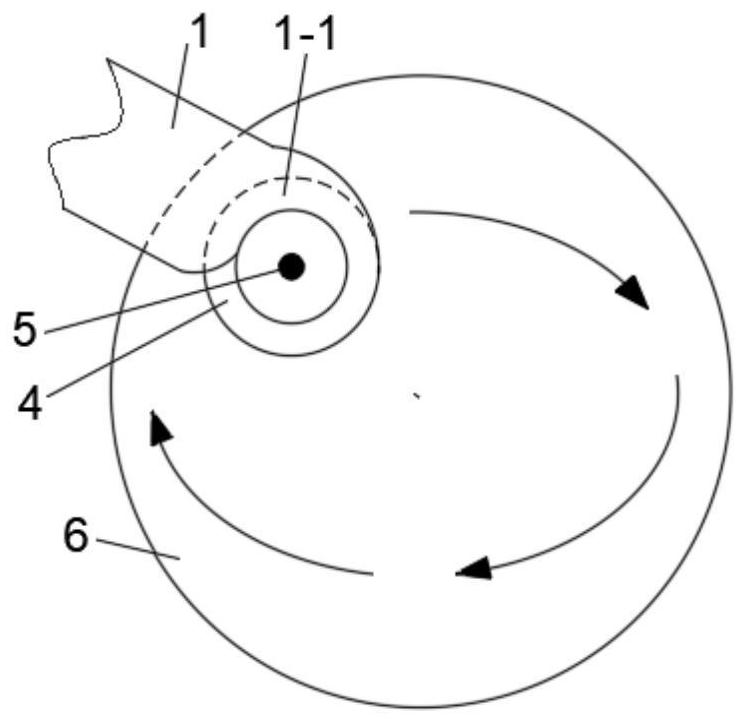

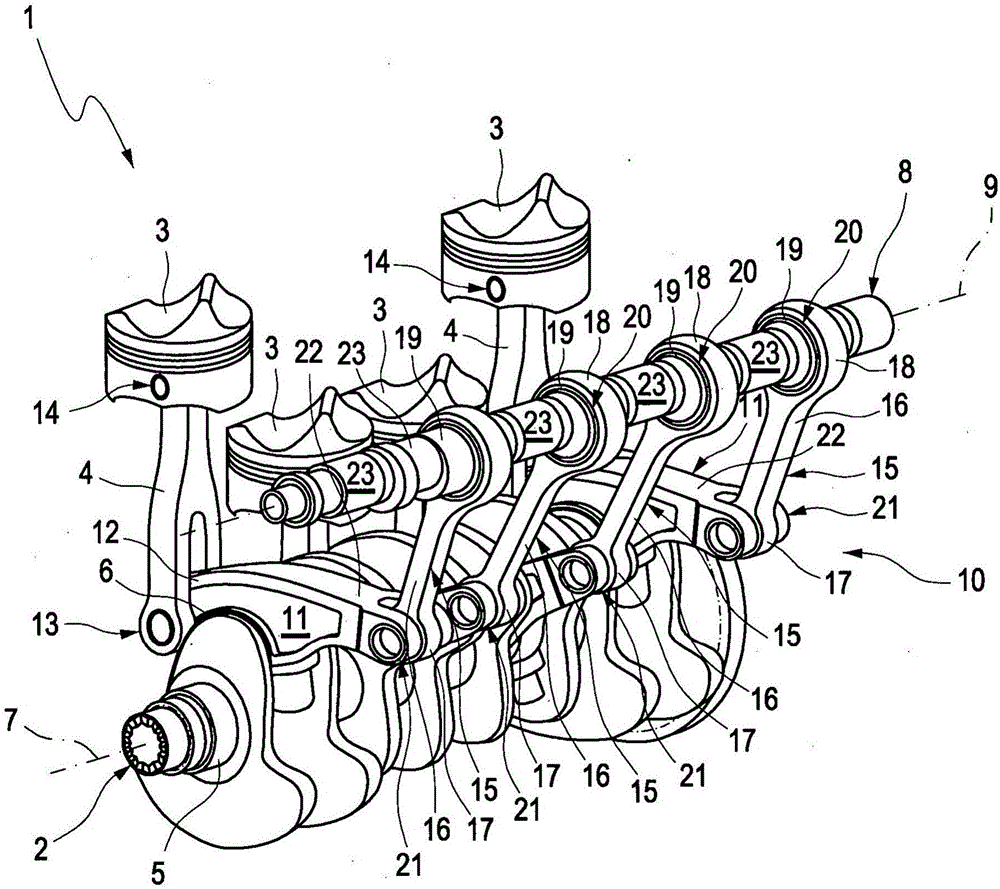

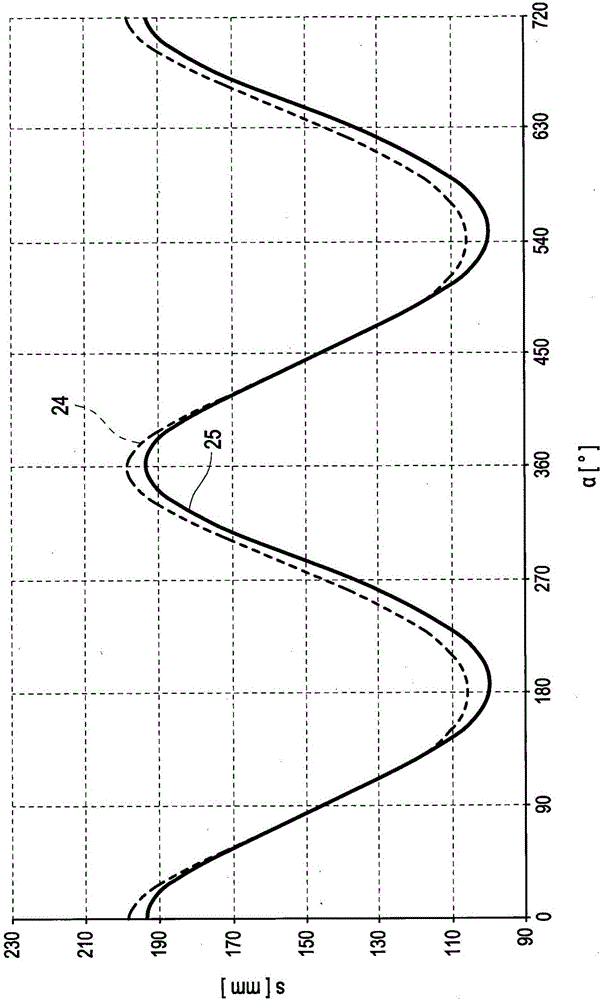

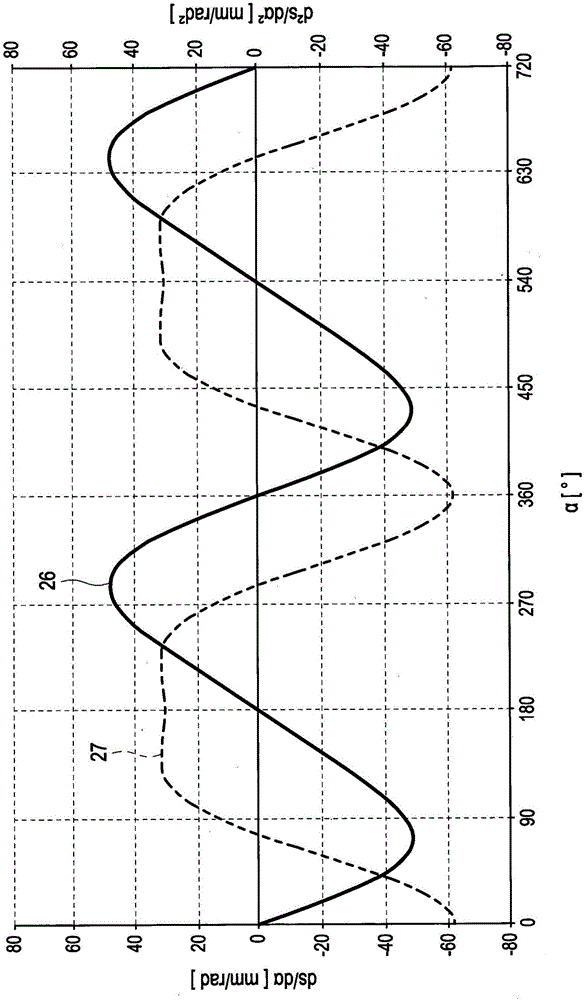

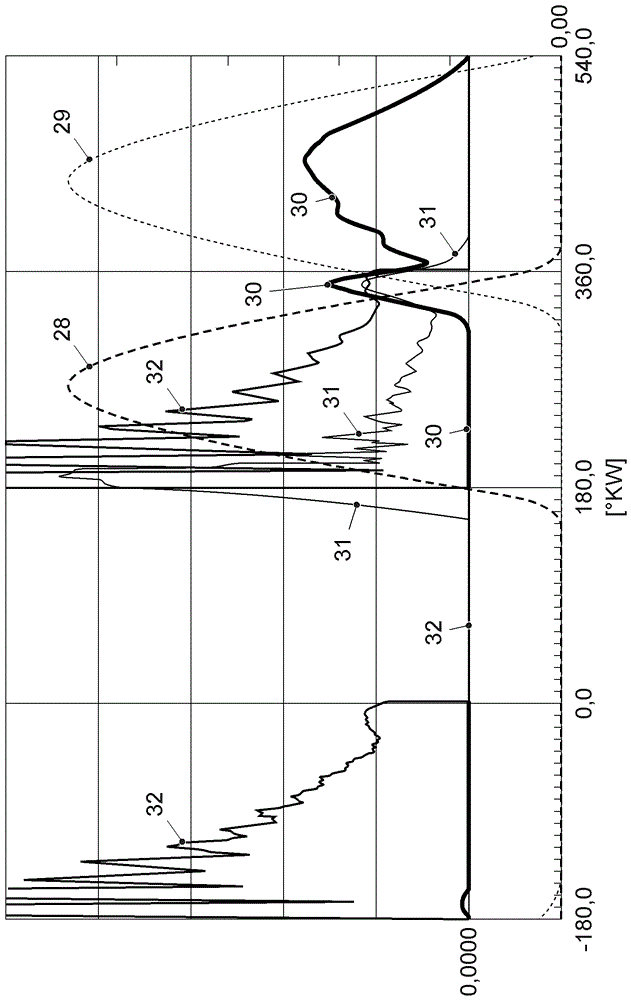

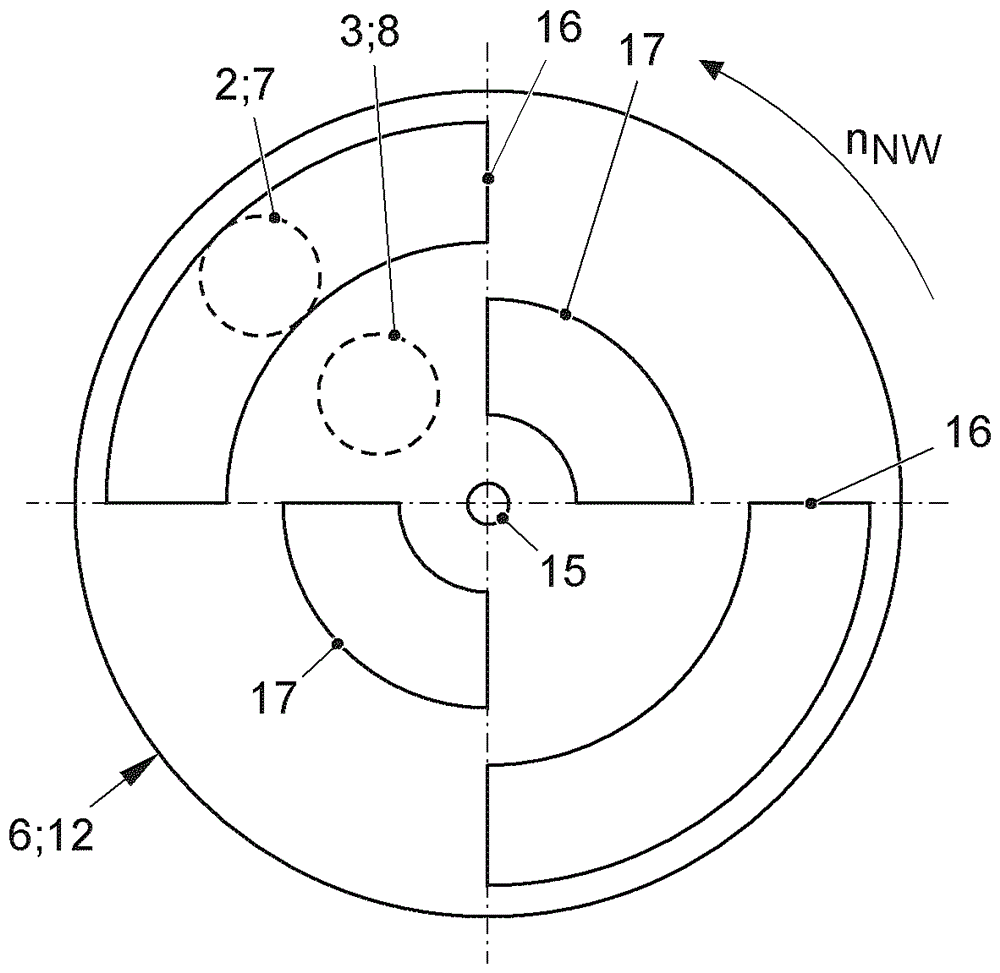

Multi-joint crank drive of an internal combustion engine and method for operating a multi-joint crank drive

ActiveCN105723071ASmall inertia forceReduce ventilation lossCombustion enginesExpansion phaseEngineering

The invention relates to a multi-joint crank drive (10) of an internal combustion engine (1), comprising a plurality of coupling members (11) rotatably supported on crank pins (6) of a crankshaft (2) and a plurality of articulation connecting rods (15) rotatably supported on crank pins (19) of an eccentric shaft (8), wherein each of the coupling members (11) is pivotably connected to a piston connecting rod (4) of a piston (3) of the internal combustion engine (1) and to one of the articulation connecting rods (15). According to the invention, in order to reduce free mass forces of the second order, the multi-joint crank drive (10) is designed or adjusted in such a way that a crankshaft rotational angle range of an intake phase is greater than 180 degrees; that a crankshaft rotational angle range of a compression phase is less than 180 degrees; that a crankshaft rotational angle range of an expansion phase is greater than 180 degrees; and that a crankshaft rotational angle range of an exhaust phase is less than 180 degrees. The invention further relates to a method for operating a multi-joint crank drive (10) of an internal combustion engine (1).

Owner:AUDI AG

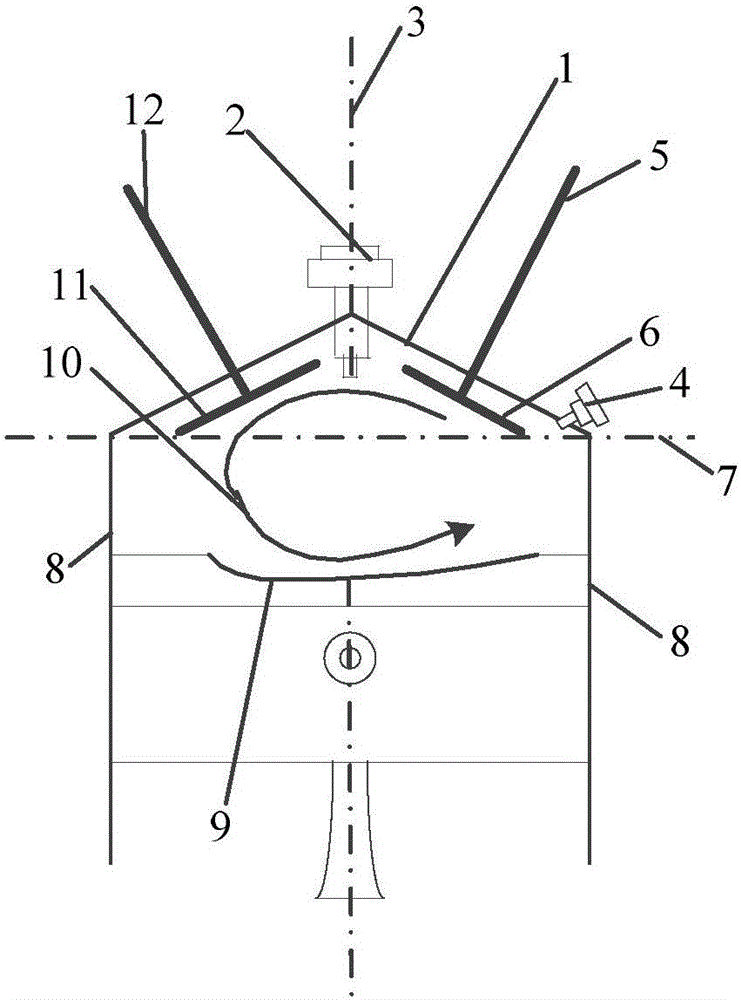

Anticlockwise-tumble-ratio combustion system for automotive engine

InactiveCN106640337AEasy to useBurn quicklyInternal combustion piston enginesCombustion systemExhaust valve

The invention relates to an anticlockwise-tumble-ratio combustion system for an automotive engine. The anticlockwise-tumble-ratio combustion system comprises a combustion chamber roof, a cylinder wall, an exhaust valve, a pit piston, an exhaust-side oil sprayer, an intake valve seat ring and a vertical intake channel, wherein the exhaust valve, the exhaust-side oil sprayer, an asymmetrical intake valve rod and an asymmetrical intake valve are arranged on the combustion chamber roof; the included angle between the central line of the vertical intake channel and the central line of the intake valve seat ring is 15-25 degrees; fresh air enters through the vertical intake channel, and more gases flow towards the right under the action of the asymmetrical intake valve, collide with the pit piston to be reflected, and form serious clockwise rotating tumble in a cylinder through the guide of the cylinder wall and the combustion chamber roof, for improving flowing at the exhaust side, reducing a detonation trend and accelerating combustion. The anticlockwise-tumble-ratio combustion system disclosed by the invention is capable of effectively reducing the detonation of a lateral direct-injection gasoline engine in the cylinder, improving the strength of the tumble in the cylinder, and accelerating the combustion.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

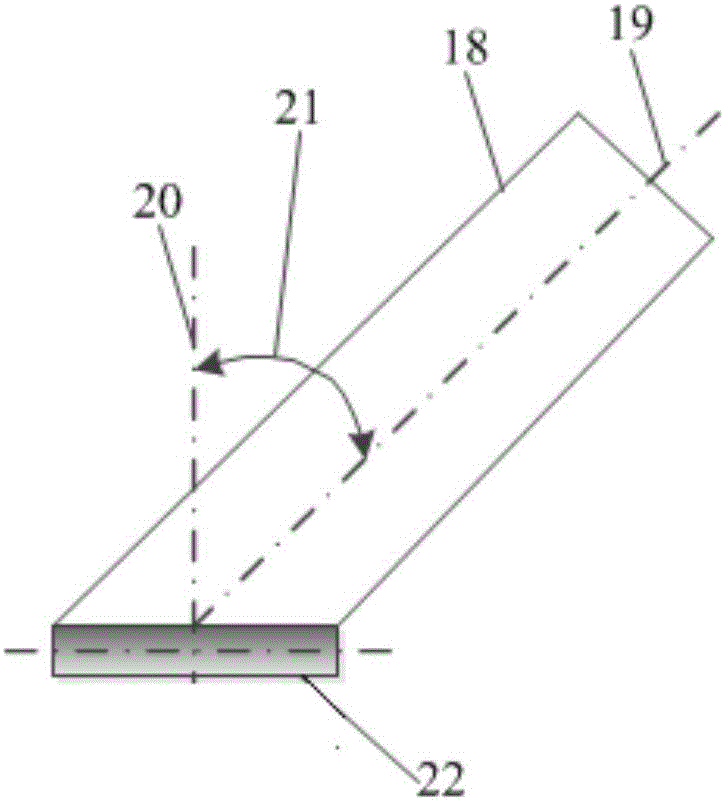

Guide element for a pressure system of an internal combustion engine, pressure system for an intake tract of an internal combustion engine, and internal combustion engine with a supercharging unit

ActiveUS20170234279A1Reduce the temperatureIncreasing charge pressureInternal combustion piston enginesExhaust apparatusPressure systemEngineering

A guide element for a pressure system of an internal combustion engine has a hollow body with a guide element inlet (27), a guide element outlet (28) and a longitudinal axis (26). The guide element (25) is designed so that flow can pass through it along its longitudinal axis (26). To eliminate disruptive oscillations, the guide element (25) is of streamlined form in a flow direction from the guide element inlet (27) to the guide element outlet (28). A pressure system for an intake tract of an internal combustion engine and an internal combustion engine with a supercharging unit also are provided.

Owner:DR ING H C F PORSCHE AG

Exhaust gas device for separation of exhaust strokes of internal combustion engine with at least two cylinder groups

ActiveCN106050436AAvoid crosstalkCrosstalk freeInternal combustion piston enginesExhaust apparatusExhaust valveExternal combustion engine

The present invention relates to an exhaust gas device for separation of exhaust strokes of an internal combustion engine with at least two cylinder groups, wherein each of the cylinder groups is associated with an exhaust gas flow section (2, 3) which can be alternatively connected to an exhaust system (7, 8, 9) on at least one output side by means of a separator assembly (6). The crosstalk between the exhaust gas flow sections (2, 3) of the different cylinder groups is thereby reduced, i.e. adjacent cylinders in the firing sequence are associated with different cylinder groups, wherein the separator assembly (6) can operate according to the exhaust valve control time of the cylinder groups, wherein the cylinder group which discharges exhaust gas is connected to the exhaust gas flow (7, 8) on the output side through the separator assembly (6), and wherein the cylinder group which do not discharge exhaust gas is separated from the exhaust system (7, 8) on the output side through the separator assembly (6).

Owner:VOLKSWAGEN AG

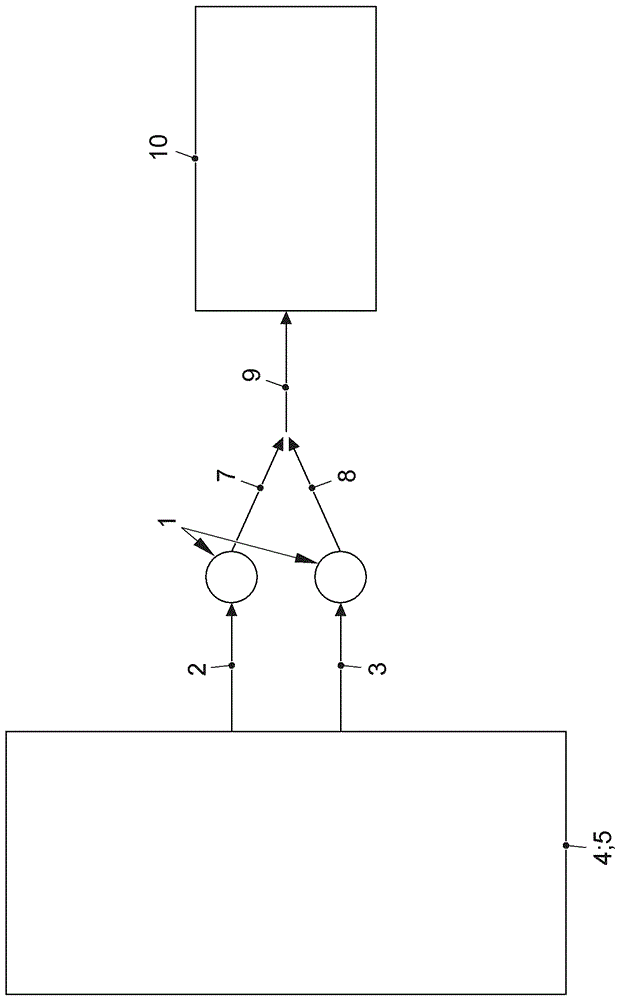

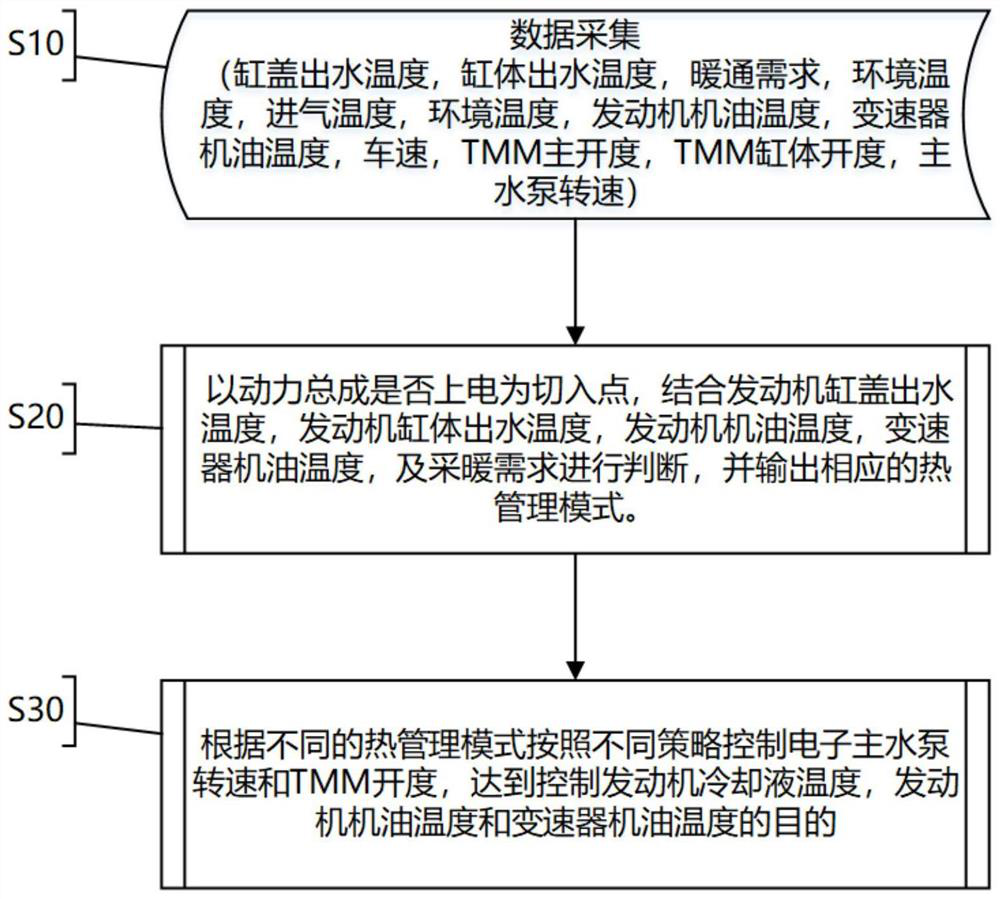

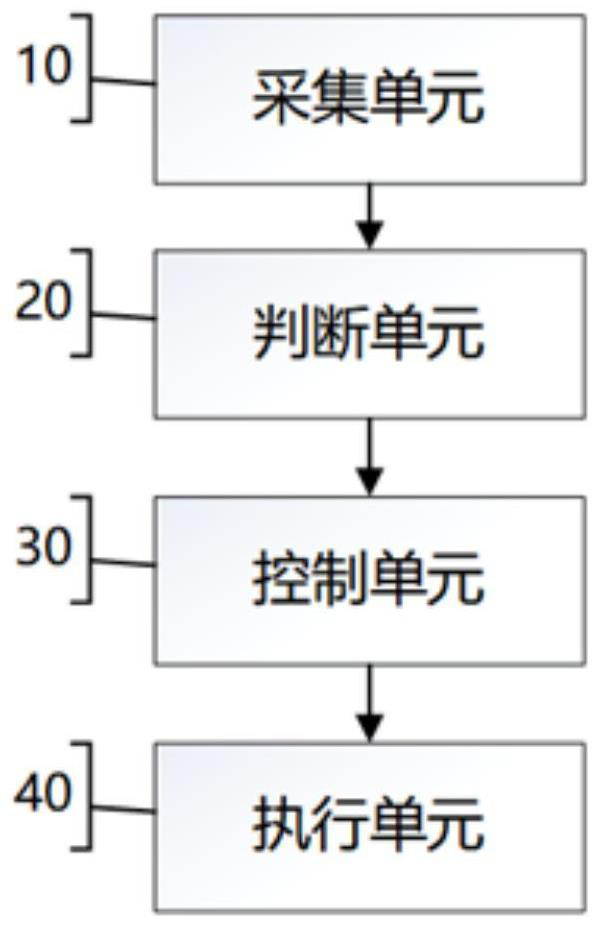

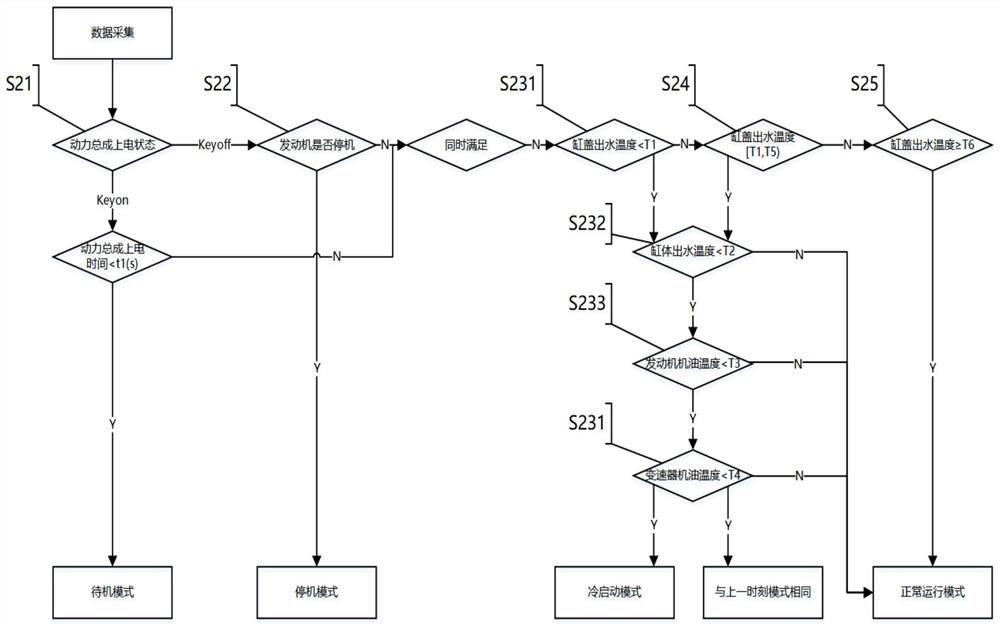

Power assembly intelligent thermal management control method and system, and storage medium

ActiveCN114003076AQuick responseGuaranteed Thermal Management RequirementsCoolant flow controlInternal combustion piston enginesHeat managementEngineering

The invention discloses a power assembly intelligent thermal management control method. The method comprises the steps that: 1, a cylinder cover outlet water temperature, a cylinder body outlet water temperature, a heating and ventilation requirement, an engine oil temperature, a transmission engine oil temperature, a TMM main opening degree, a TMM cylinder cover opening degree and an electronic main water pump rotating speed are collected; 2, according to the fact that whether a power assembly is powered on or not is a cut-in point, judgment is conducted by combining the engine cylinder cover outlet water temperature, the engine cylinder body outlet water temperature, the engine oil temperature, the transmission engine oil temperature and heating requirements, and different heat management modes are output, wherein the heat management modes at least comprise a standby mode, a cold start mode, a normal operation mode and a shutdown mode; and 3, the electronic main water pump rotating speed and the TMM opening degree are controlled according to the different thermal management modes and different strategies, the flow and flow resistance of all branches of a thermal management system are adjusted, and the purpose of controlling an engine coolant temperature, the engine oil temperature and the transmission oil temperature is achieved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Composite gas inlet path of modifying gasoline ignition engine based on diesel engine

PendingCN109630328AIncreased turbulence intensitySpread fastInternal combustion piston enginesAir intakes for fuelFlame propagationGasoline fuel

The invention discloses a composite gas inlet path of modifying a gasoline ignition engine based on a diesel engine. On the basis of keeping a flat-bottom cylinder bottom of the original diesel engine, the spiral and tangential composite gas inlet path is adopted to improve longitudinal tumble intensity in a cylinder, so that inclined swirl is formed in the cylinder. The composite gas inlet path can promote radial propagation of flame while improving turbulence intensity in the cylinder, and increases flame propagation speed, so that the engine is guaranteed to still have relative good dynamicproperty and economical efficiency after gasoline fuels are modified, and therefore, performances and emission requirements of a medium-heavy commercial vehicle engine are met while a post-treatmentsystem is greatly simplified in a mode that the engine is matched with a three-way catalyst.

Owner:TIANJIN UNIV

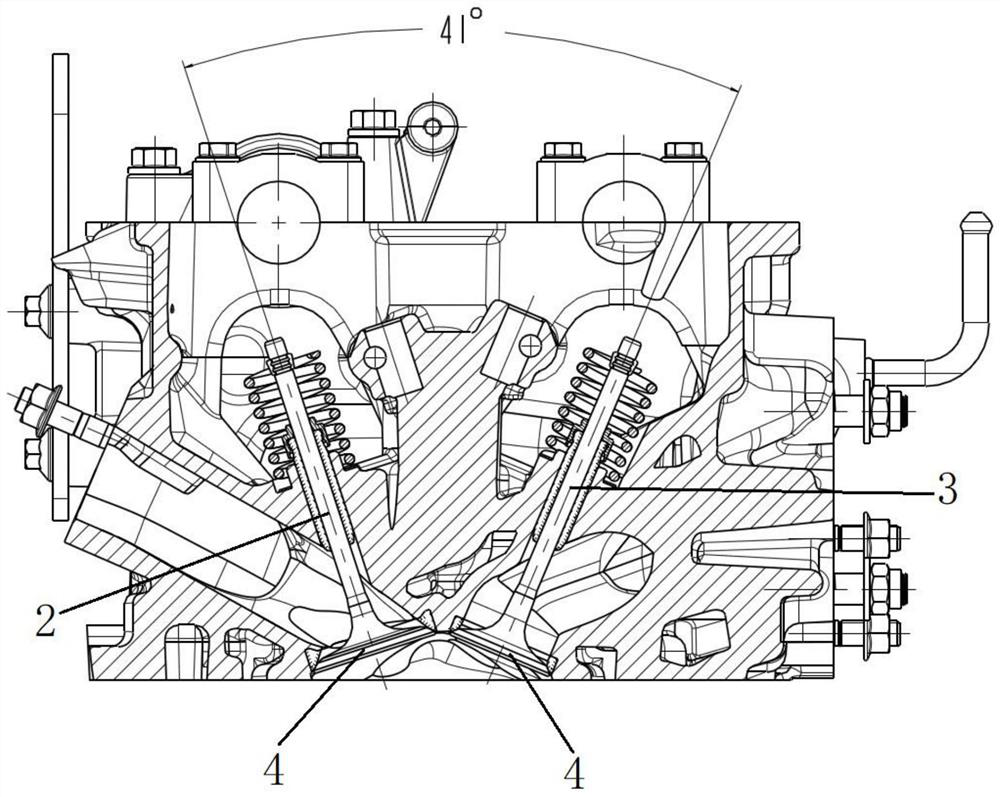

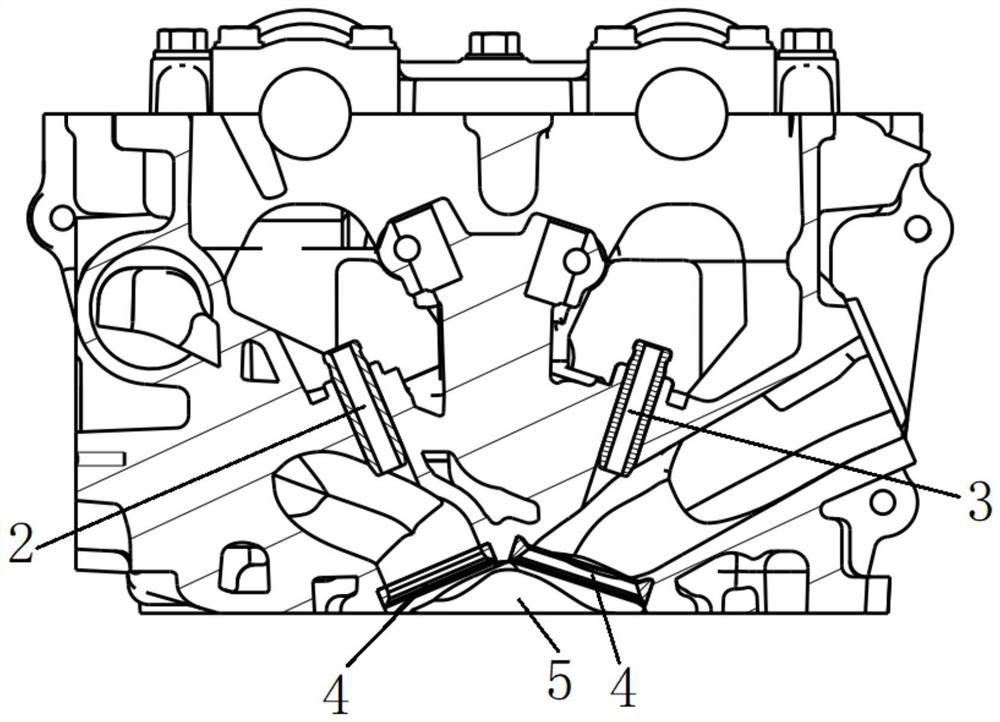

Natural gas engine

InactiveCN113482765AIncrease the angleSpread fastInternal combustion piston enginesCombustion-air/fuel-air treatmentCombustion systemCombustion chamber

The invention discloses a natural gas engine which comprises a cylinder body. The cylinder body comprises an exhaust system, wherein the exhaust system comprises an intake valve and an exhaust valve, the included angle between the intake valve and the exhaust valve is 41 degrees, the included angle of the intake valve is 18 degrees, the included angle of the exhaust valve is 23 degrees, valve seat rings are arranged at the joint of the intake valve and an engine cylinder cover and the joint of the exhaust valve and the engine cylinder cover, three pressing faces are arranged on the side, facing the cylinder cover, of each valve seat ring and form a continuous stepped structure, and an air inlet of the intake valve is further connected with an air inlet manifold, and the whole air inlet manifold is of an Archimedes spiral structure; and a gas system, wherein the gas system comprises a combustion chamber and a piston, the face, facing the piston, of the combustion chamber is an inverted arc face, the top face, facing the combustion chamber, of the piston is provided with a concave part, and the concave part is matched with the arc face. The natural gas engine is a large-power and large-displacement gas engine which is large in cylinder diameter and long in cylinder sleeve. The inevitable problems of easy knocking and difficult combustion of a large-cylinder-diameter engine are solved from the aspects of a combustion system, an ignition system and the like.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

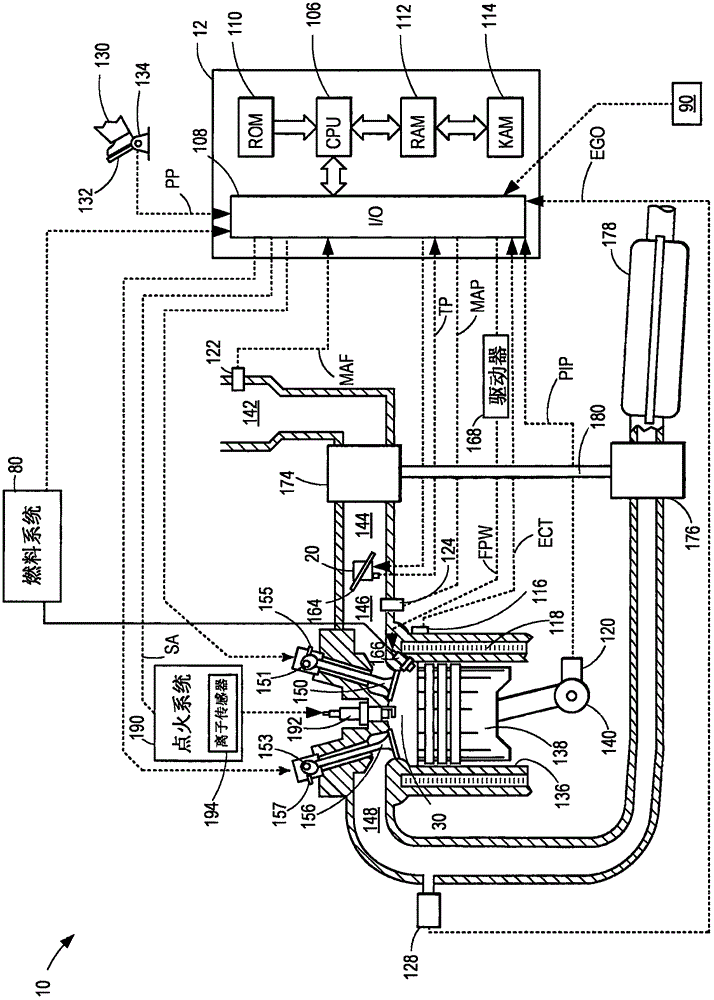

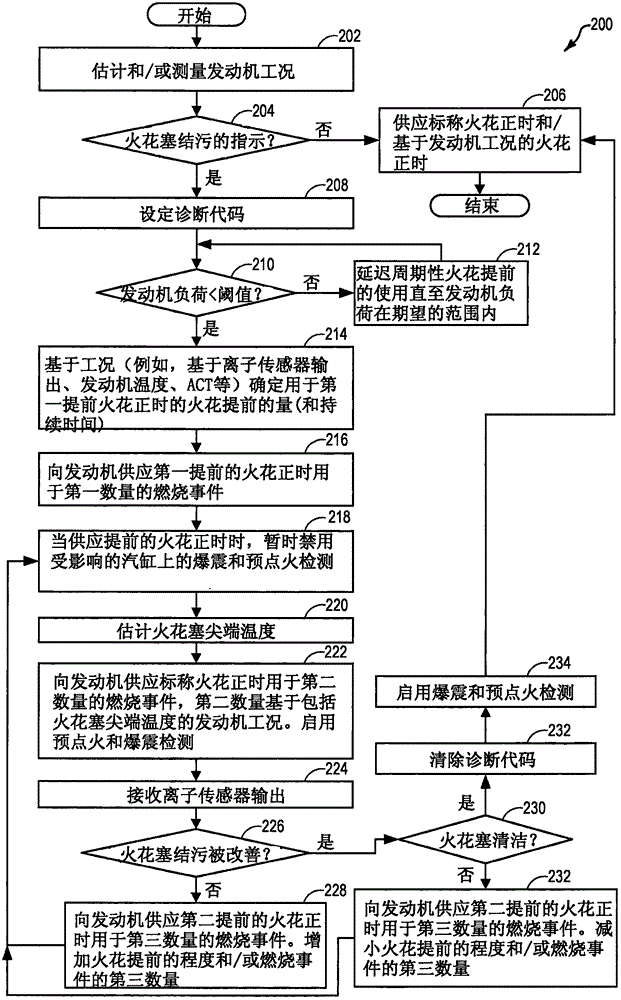

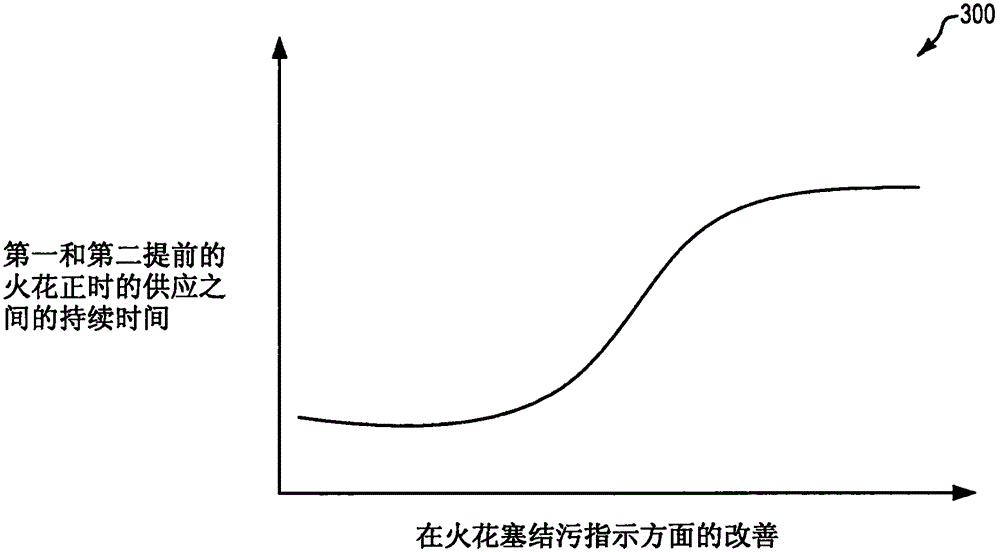

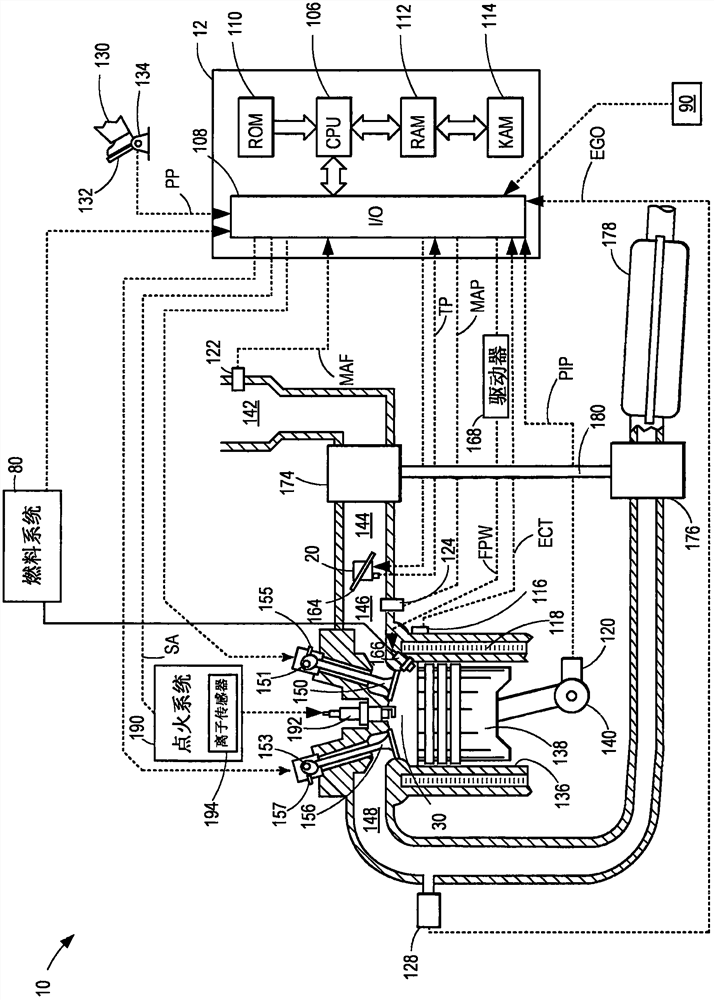

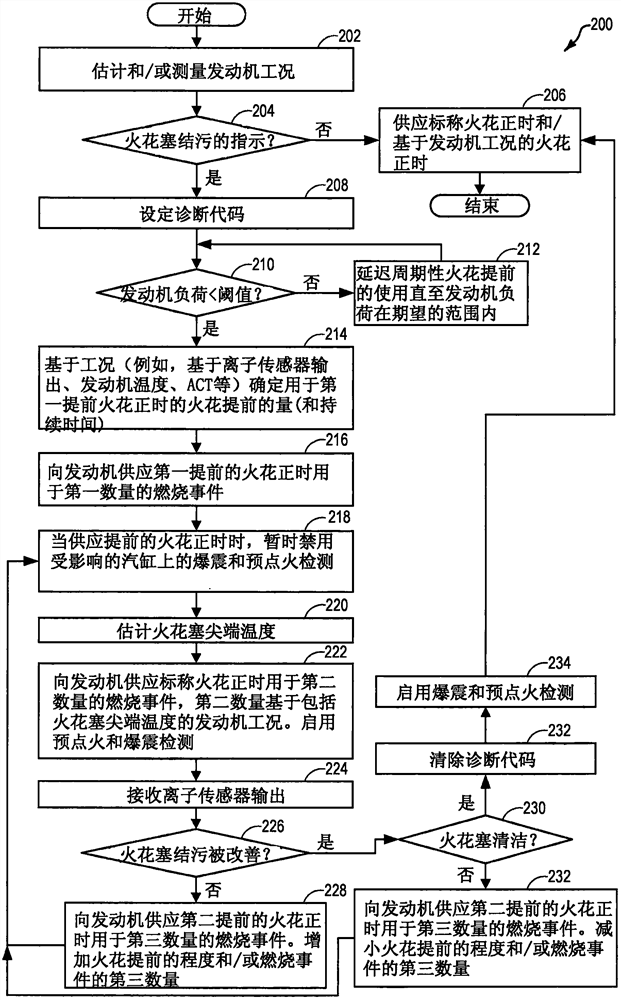

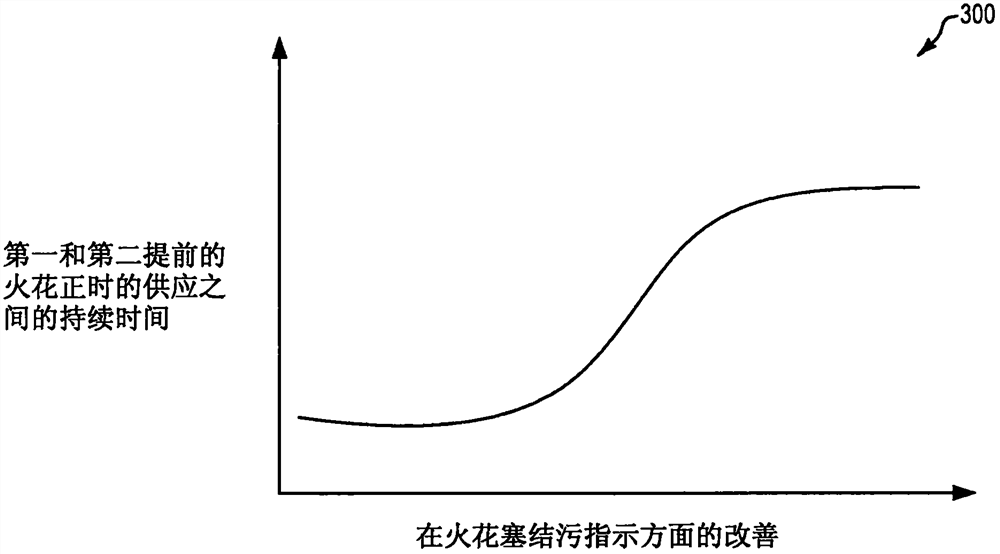

Method and system for ignition control

ActiveCN106401776AReduce overheatingImproved fouling controlElectrical controlInternal combustion piston enginesIgnition coilEngineering

The invention relates to a method and system for ignition control. Methods and systems are provided for addressing spark plug soot fouling. In one example, a method may include alternating one or more combustion events with spark timing advanced with one or more combustion events with nominal spark timing. The approach allows spark plug over-heating, and related issues such as knock, to be reduced.

Owner:FORD GLOBAL TECH LLC

pre-combustion generator

ActiveCN103821606BHigh thermal efficiencyReduce R&D costsInternal combustion piston enginesDetonationCombustion chamber

The invention discloses a pre-combustion generator. The pre-combustion generator is mounted in an oil spraying device mounting hole on an engine cylinder cover, and comprises a pre-combustion generator body, wherein the pre-combustion generator body is provided with a pre-combustion chamber; the pre-combustion generator body is provided with a spraying hole for communicating the pre-combustion chamber with a combustion chamber; the pre-combustion generator body is further provided with a gas supplying device for supplying gas to the pre-combustion chamber; the pre-combustion chamber is provided with a sparking plug mounting hole; the sparking plug mounting hole is internally provided with a sparking plug; the pre-combustion generator body is further provided with a cooling device. The pre-combustion generator is provided with an independent cooling system, a gas feeding system and a control system so that one independent product is formed and the product can be conveniently applied to a diesel engine to be refitted into a gas engine; the tendency of detonation in a main combustion chamber can be reduced and the compression ratio of the existing gas engine can be increased; a piston and the cylinder cover do not need to be redesigned to change the compression ratio; the heat efficiency of the gas engine can be effectively improved and energy sources are saved.

Owner:WEICHAI XIGANG NEW ENERGY POWER

Thermostat assembly, cooling system, engine and car

ActiveCN112065565BImprove combustion efficiencyReduce friction workCoolant flow controlMachines/enginesCylinder headCoolant flow

The present disclosure provides a thermostat assembly, a cooling system, an engine, and an automobile. The thermostat assembly includes: a thermostat housing having a first inner chamber, a second inner chamber and communicating with the first inner chamber and The shut-off channel of the second inner cavity, the thermostat housing has a first opening, a second opening, a third opening and a fourth opening, the first opening and the second opening are both connected to the first inner cavity, and the third opening is connected to the second inner cavity The two inner chambers communicate, the fourth opening communicates with the first inner chamber and the second inner chamber at the same time, the first opening communicates with the radiator, the second opening communicates with the cylinder water jacket, and the third opening communicates with the automobile The heater is connected, and the fourth opening is used to communicate with the water jacket of the cylinder head; the thermostat is connected with the thermostat housing and is located at the first opening, and is used to control the on-off of the first opening. The present disclosure can adopt a single thermostat to configure the coolant flowing out of the water jacket of the cylinder block and the water jacket of the cylinder head, thereby reducing the energy consumption and cost of the engine.

Owner:CHERY AUTOMOBILE CO LTD

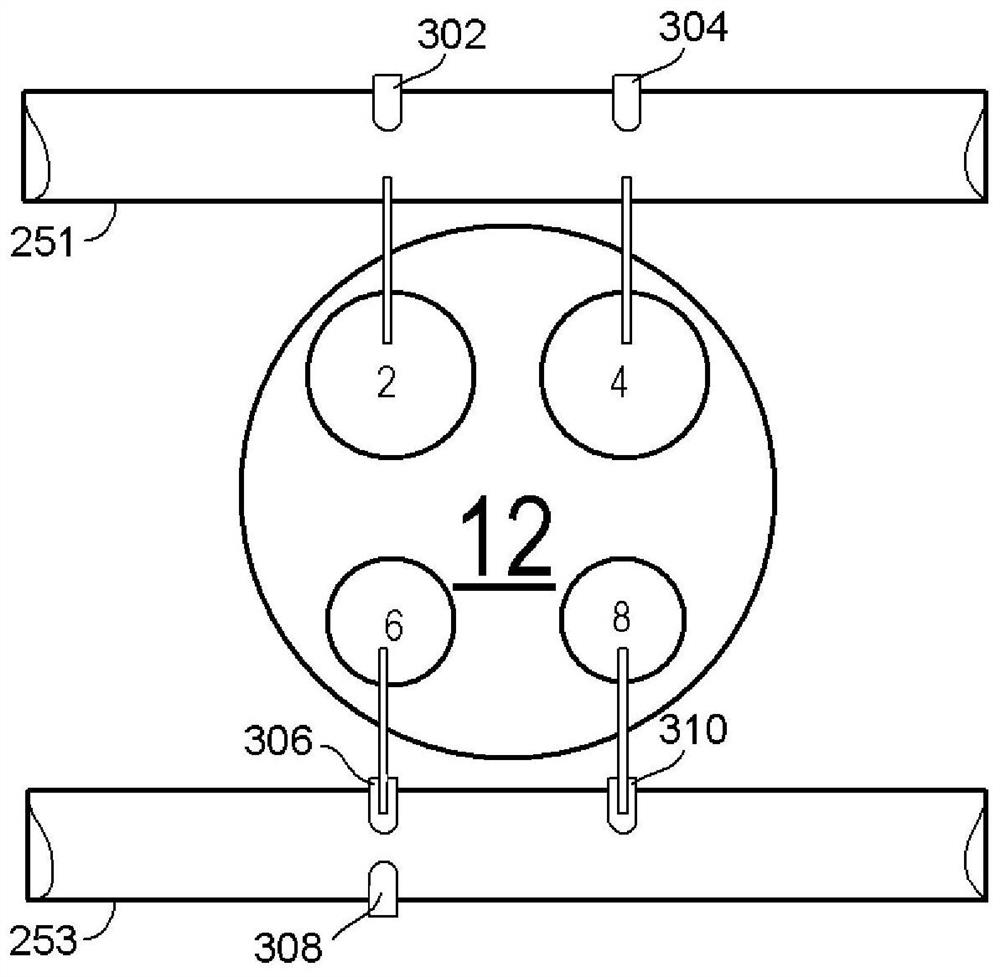

System and method for providing egr to engine

ActiveCN108204296BReduce pumping workReduced knocking tendencyElectrical controlInternal combustion piston enginesExhaust valveFresh air

The present invention relates to systems and methods for providing EGR to an engine. A method and system for providing exhaust gas recirculation to a naturally aspirated internal combustion engine is provided. In one example, exhaust is recirculated to the engine intake via a dedicated scavenge manifold and scavenged exhaust valve. Because exhaust and fresh air are returned to the engine intake at a pressure greater than atmospheric pressure, exhaust and fresh air that did not participate in combustion can be recirculated to the engine cylinders even at high engine loads.

Owner:FORD GLOBAL TECH LLC

Method and system for ignition control

ActiveCN106401776BAvoid overall overheatingPrevent inductionElectrical controlInternal combustion piston enginesSootSpark plug

The present invention relates to methods and systems for ignition control. Methods and systems are provided for addressing spark plug soot fouling. In one example, a method may include alternating one or more combustion events with advanced spark timing with one or more combustion events with nominal spark timing. This approach allows spark plug overheating and related problems such as knocking to be reduced.

Owner:FORD GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com