Composite gas inlet path of modifying gasoline ignition engine based on diesel engine

A technology for air intakes and diesel engines, applied to combustion engines, machines/engines, internal combustion piston engines, etc., can solve problems such as increased knocking tendency, reduced flame propagation speed, and limited flame radial propagation, etc., to increase explosion pressure, Improves the speed of flame propagation and promotes the formation of fire cores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

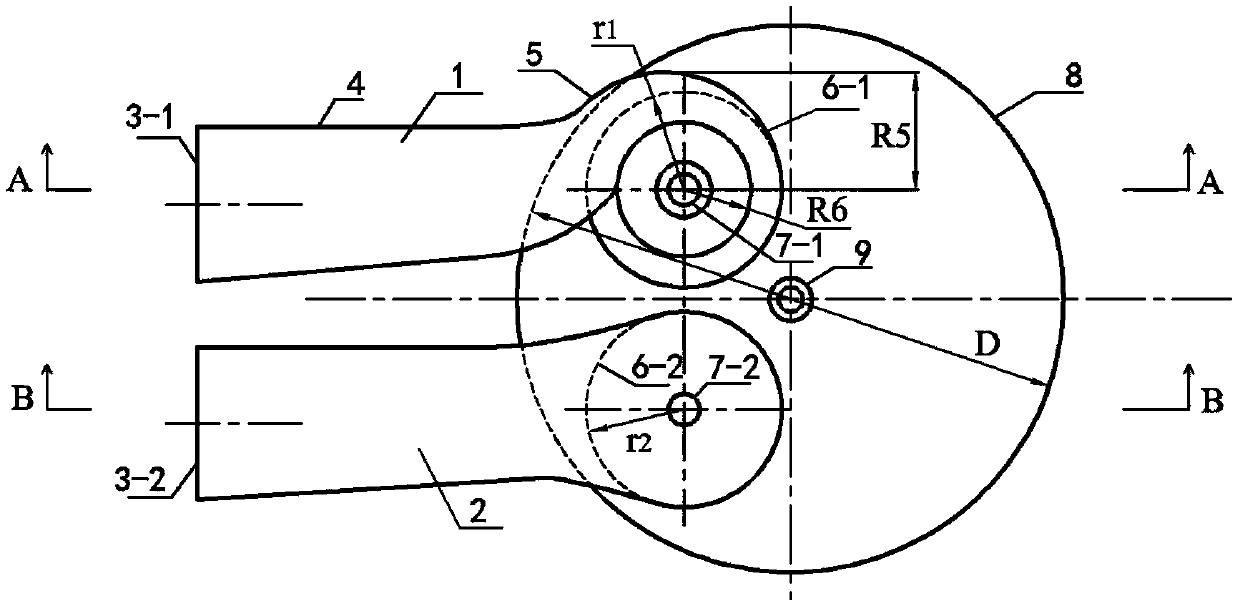

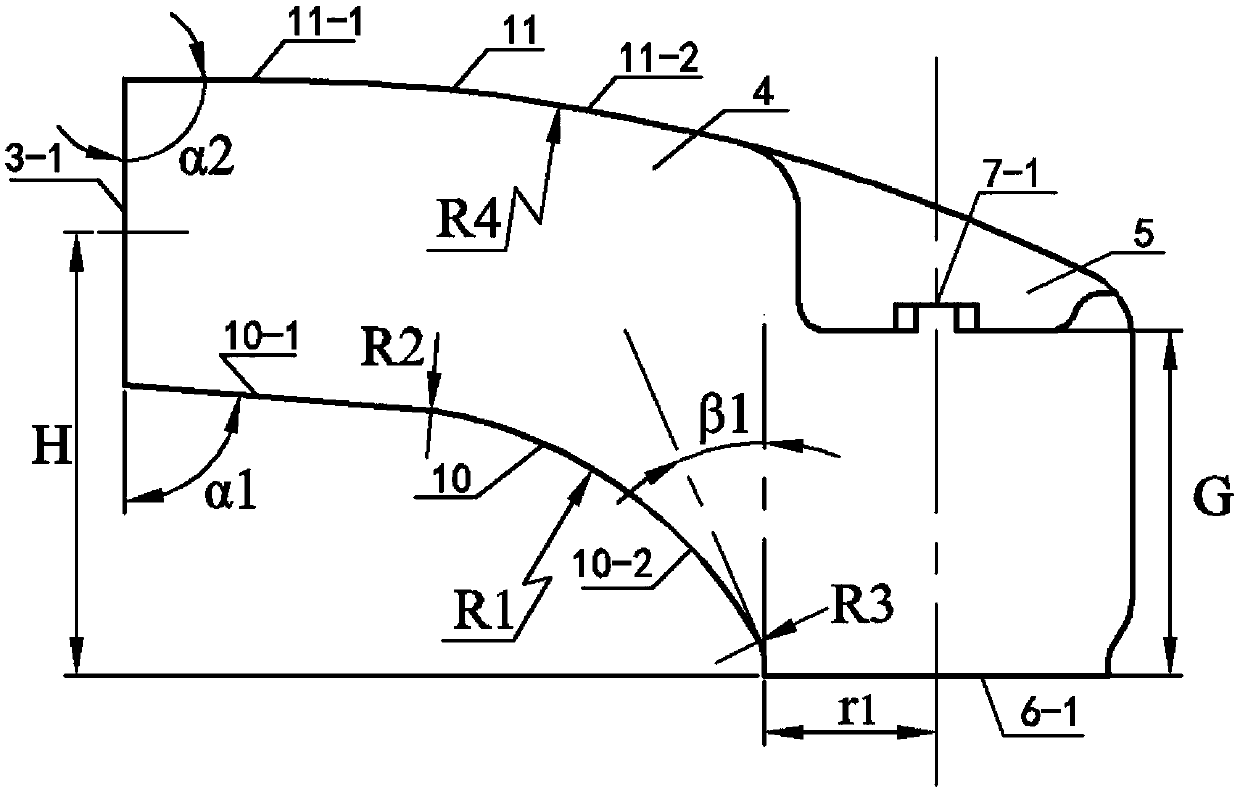

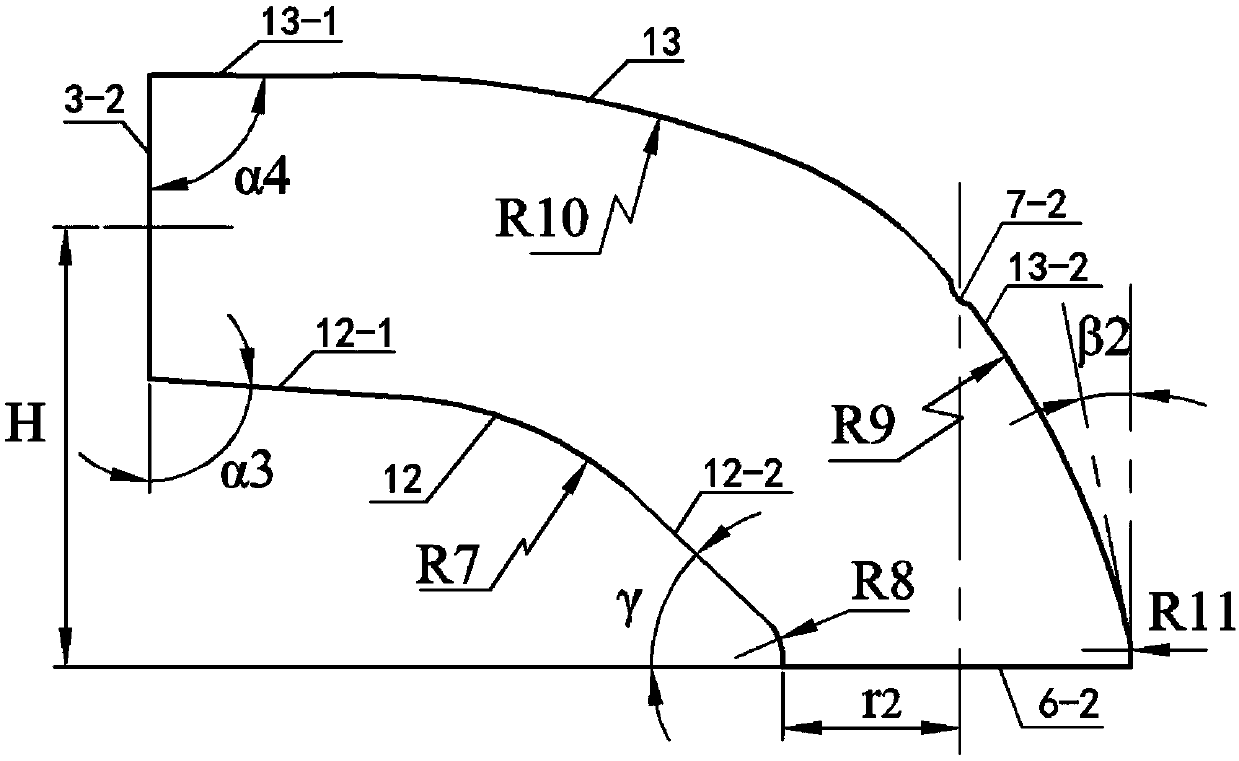

[0033] In this embodiment, the engine cylinder diameter D is 90 mm, the compression ratio is 12, and the cylinder head is a four-valve structure. like figure 1 As shown, the composite intake port of the engine is composed of a spiral intake port 1 and a tangential intake port 2 . The spiral inlet 1 is composed of a straight-line section 4 connected in sequence, a spiral section 5 spiraling downward and an outlet 6-1 of the spiral inlet. The spiral section 5 is located above the cylinder head 8 of the cylinder. The inlet end of the straight-line section 4 is the inlet 3-1 of the spiral air inlet. The outlet of the spiral inlet port 6-1 is arranged on the cylinder head 8 and communicates with the cylinder. The bottom surface of the cylinder head 8 is a plane arranged in the horizontal direction, and a spark plug 9 is installed at the center of the cylinder head 8 . The top of the helical section 5 is provided with a first circular hole 7-1 for fixing and guiding the valve ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com