Method for operating an internal combustion engine

A technology for an internal combustion engine and a compressor, applied in the field of high-compression gasoline engines, can solve the problem of not getting engine efficiency loss and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

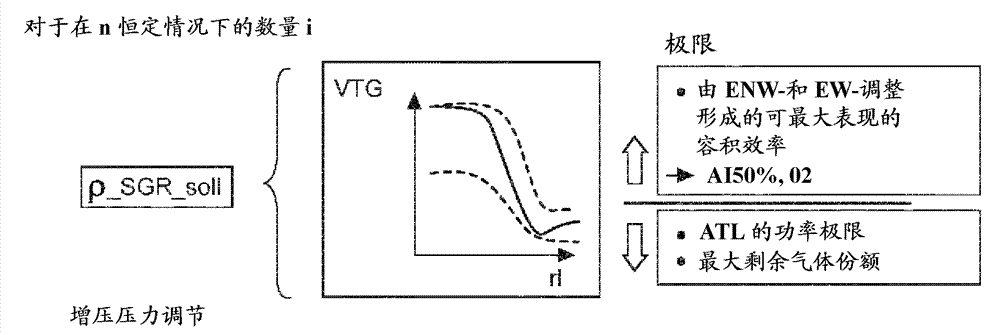

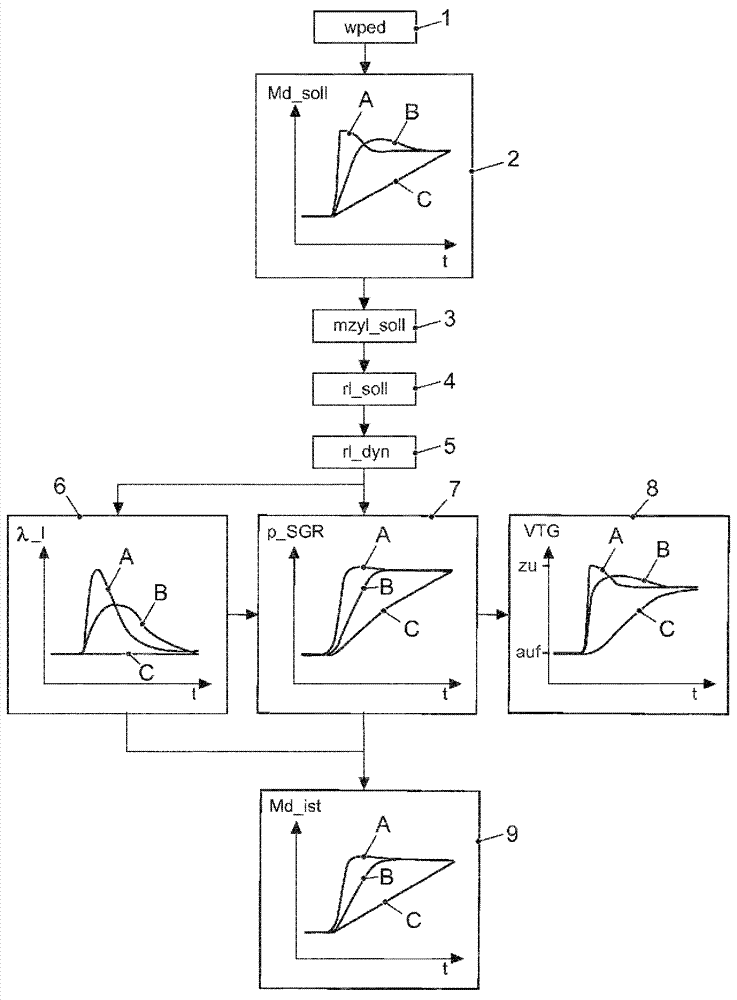

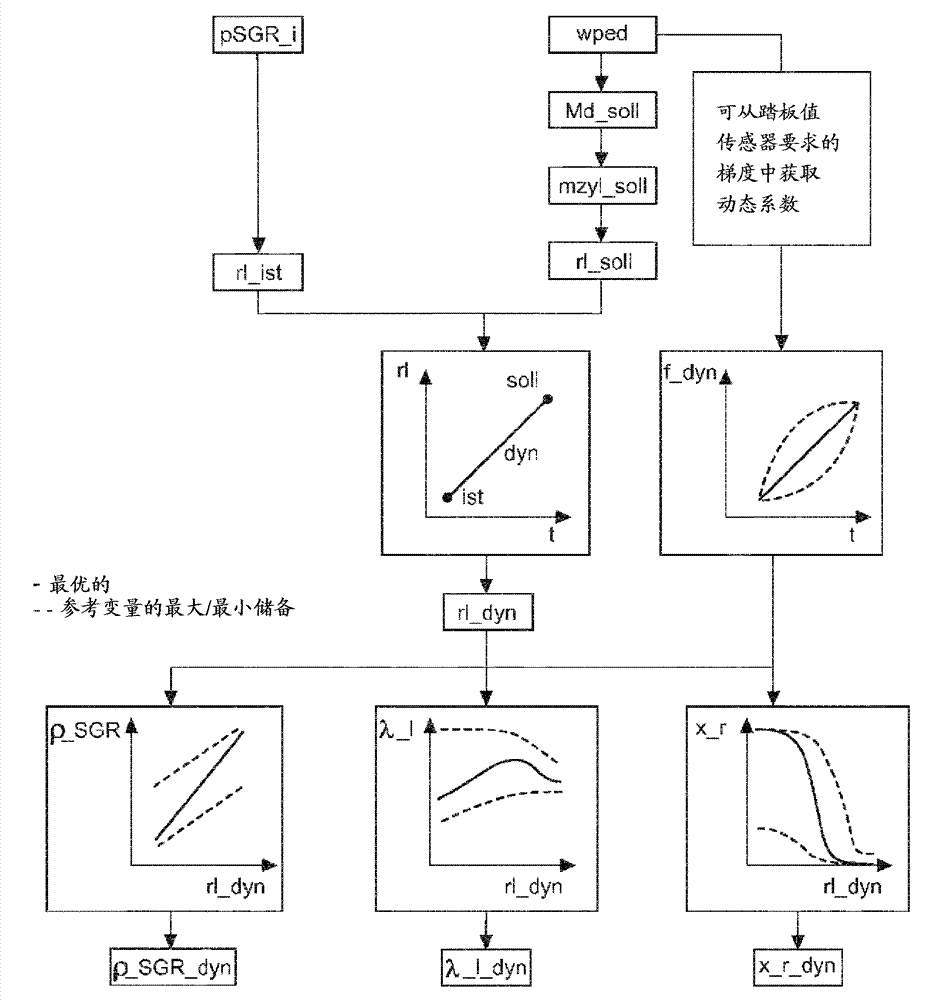

[0024]In conventional Otto engines, the thermodynamic efficiency is limited by the reduced compression ratio to avoid engine knocking and the necessary throttling for quantitative load control. The so-called Miller method or Atkinson method designates a method for reducing throttling in part-load operation and for achievably increasing the geometric compression ratio. In this case, the volumetric efficiency and effective compression are reduced by closing the intake valve early or late. As a result, the engine is throttled down and the compression temperature and thus the tendency to knock is reduced or the geometric compression is increased. The volumetric efficiency (which represents the ratio of the air mass trapped in the cylinder to the theoretical air mass in the cylinder determined from the thermal state in the intake manifold after a possible charge air cooler) can be obtained by the Miller method, for example from 0.95 reduced to 0.6 to 0.8. However, power losses ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com