Method and control device for operating a gas engine

A gas engine, mode control technology, applied in the direction of engine control, combustion engine, internal combustion piston engine, etc., can solve the problems of low knock tendency, poor main combustion chamber, etc., achieve high engine efficiency, low knock tendency, reduce The effect of exhaust gas recirculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The invention relates to a method for operating a gas engine and to a device for carrying out said method.

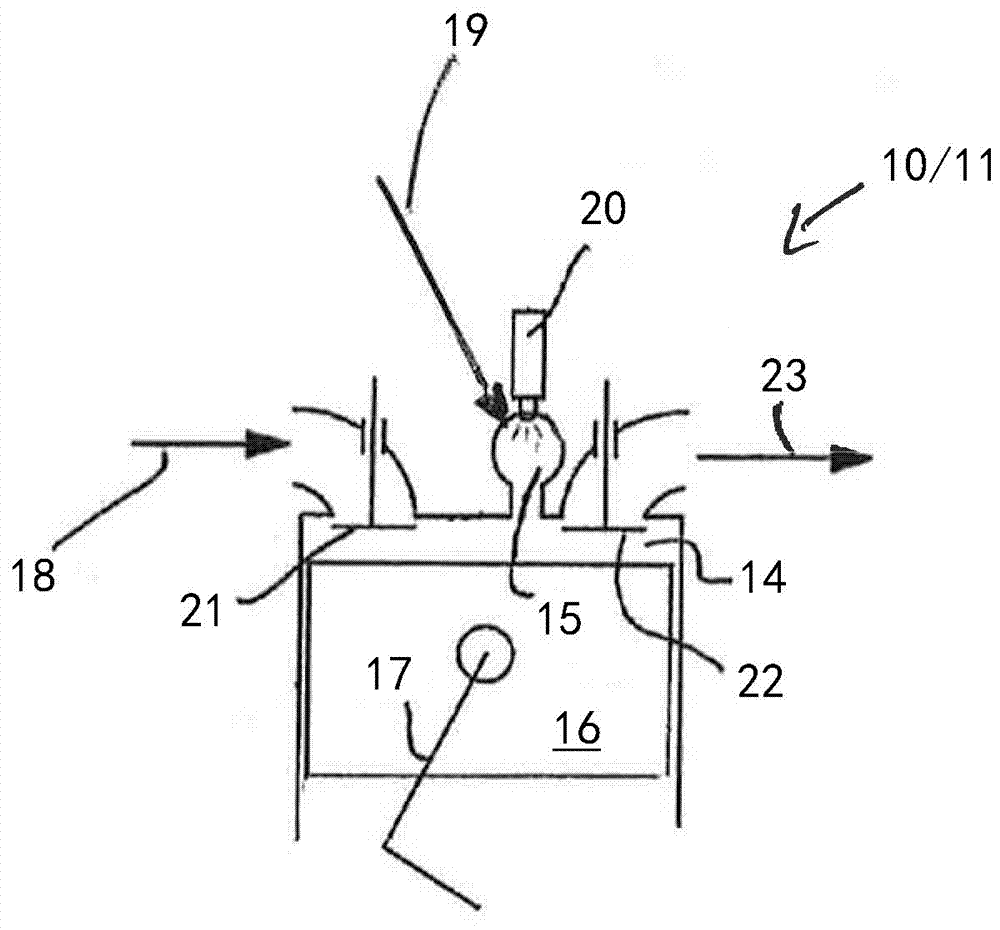

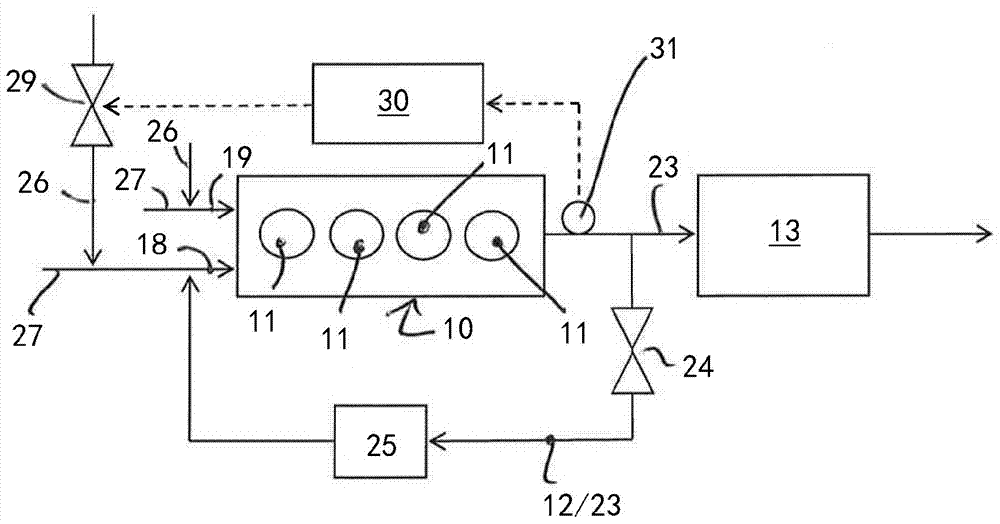

[0020] figure 1 A highly schematic block diagram of a gas engine 10 with a plurality of cylinders 11 , with an exhaust gas recirculation device 12 and an exhaust gas catalytic converter 13 is shown. figure 2 A detail of the gas engine 10 is shown in the region of the cylinders 11 of said gas engine 10 .

[0021] Each cylinder 11 of the gas engine 10 includes a main combustion chamber 14 and a pre-combustion chamber 15 coupled to the main combustion chamber 14 . In the main combustion chamber 14 , the pistons 16 of the respective cylinders 11 move up and down, wherein the pistons 16 are coupled to a not shown crankshaft via connecting rods 17 .

[0022] The gas / air mixture 18 combusted in the main combustion chamber 14 of the respective cylinder 11 may be fed to the main combustion chamber 14 of the cylinder 11 of the gas engine 10 . A further gas / air mixture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com