Exhaust gas device for separation of exhaust strokes of internal combustion engine with at least two cylinder groups

A technology for cylinder banks and internal combustion engines, which can be used in exhaust devices, internal combustion piston engines, noise reduction devices, etc., and can solve problems such as limiting the working capacity of internal combustion engines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

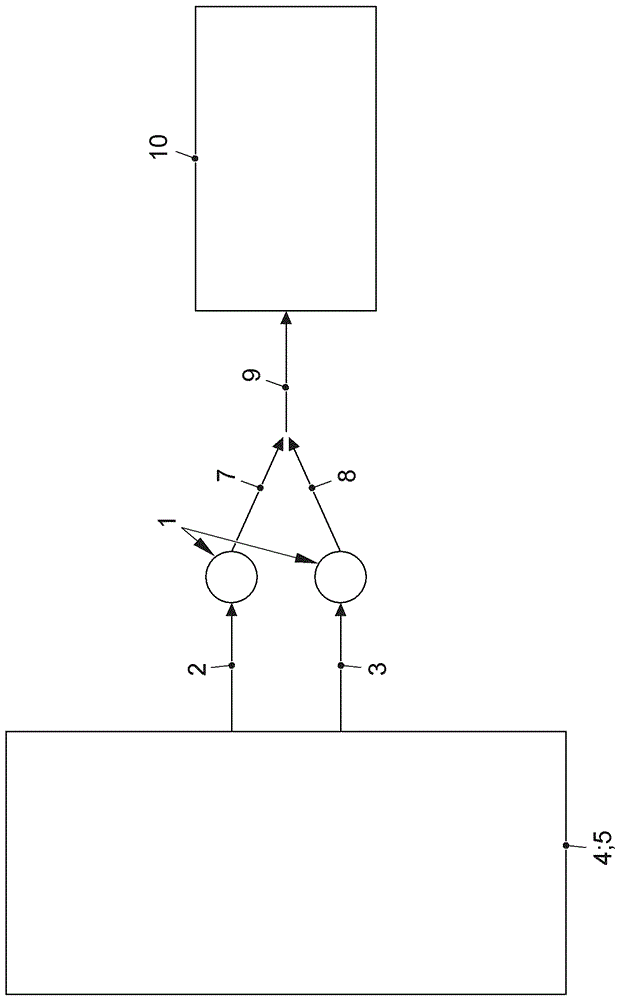

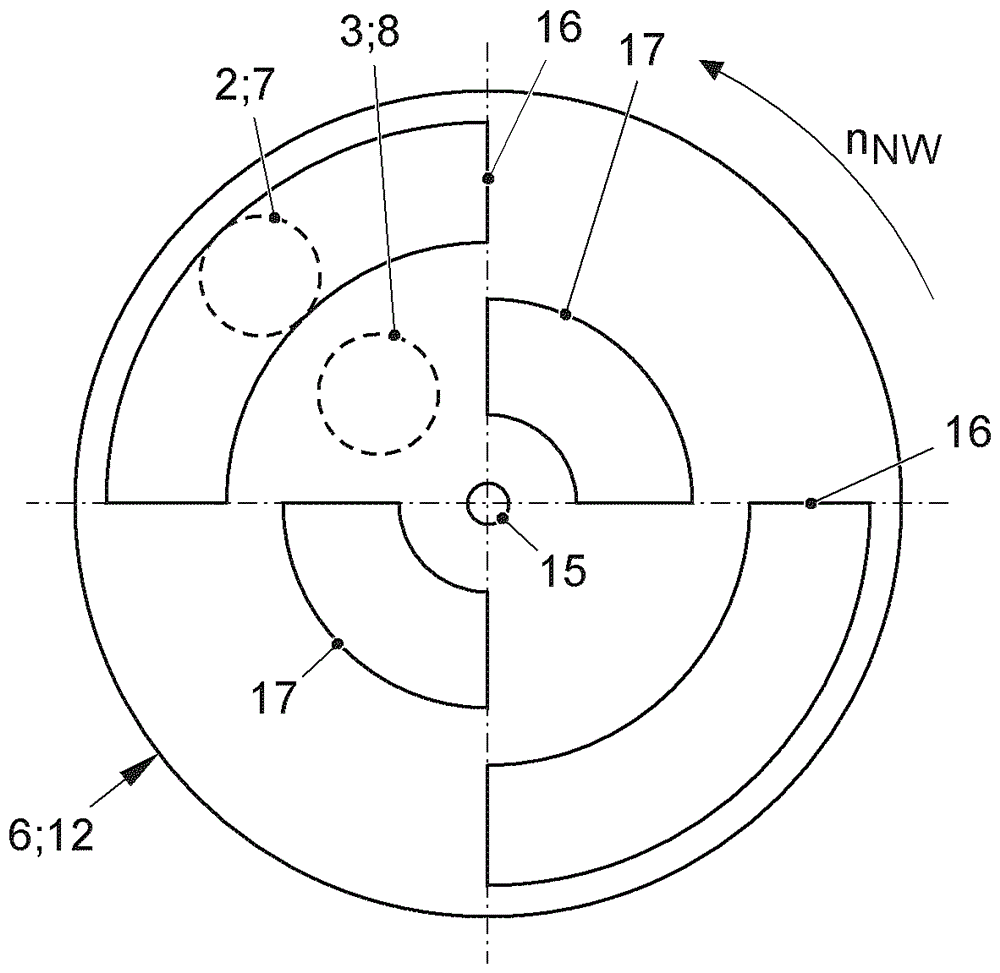

[0063] exist figure 1 and 2 The exhaust gas system 1 for separating the exhaust gas flows 2 , 3 of an internal combustion engine 4 is shown very schematically in FIG. The internal combustion engine 4 has a cylinder head 5 with an exhaust manifold (not shown in detail). The internal combustion engine 4 can have, for example, four cylinders, namely a first, second, third and fourth cylinder. The exhaust gas of the first and fourth cylinder is conducted via the exhaust gas flow 2 and the exhaust gas of the second and third cylinder is conducted via the exhaust gas flow 3 .

[0064] The internal combustion engine 4 thus has two cylinder banks, namely a first cylinder bank with the first and fourth cylinders and a second cylinder bank with the second and third cylinders. In alternative configurations it is conceivable for internal combustion engine 4 to have more than two cylinder banks, ie three or four cylinder banks. Each cylinder bank has at least one cylinder. The cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com