Method and system for diagonal blow-through exhaust gas scavenging

A diagonal, exhaust valve technology, applied in electrical control, machine/engine, output power, etc., can solve problems such as increasing the amount of boosted air, limiting the amount of boosting, etc., to reduce excess heating, improve fuel economy, The effect of reducing the incidence of knocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

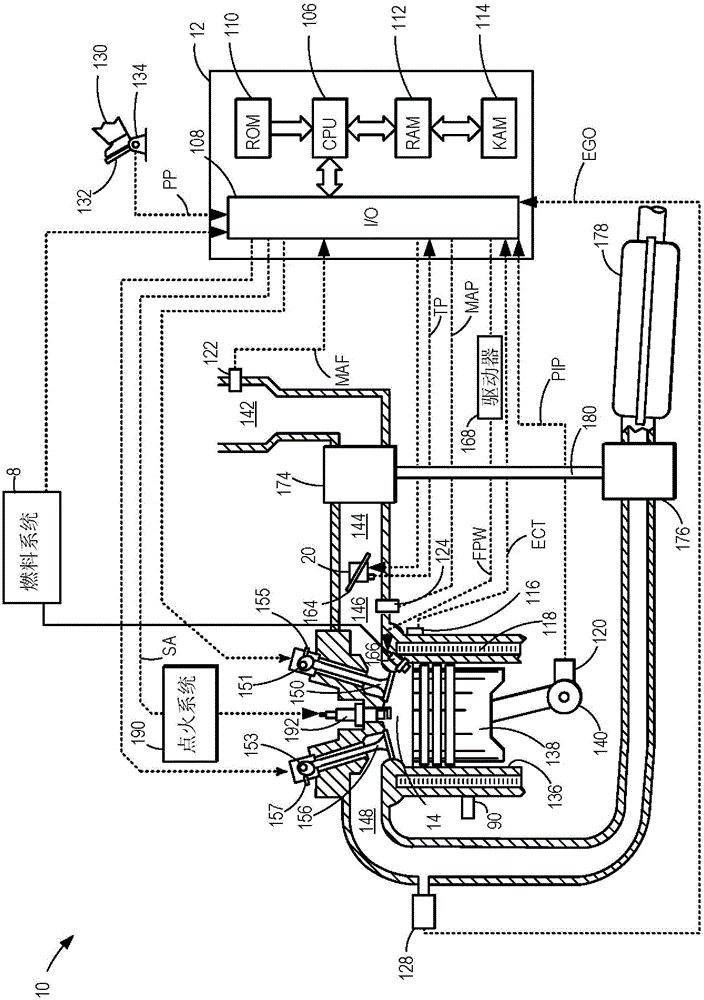

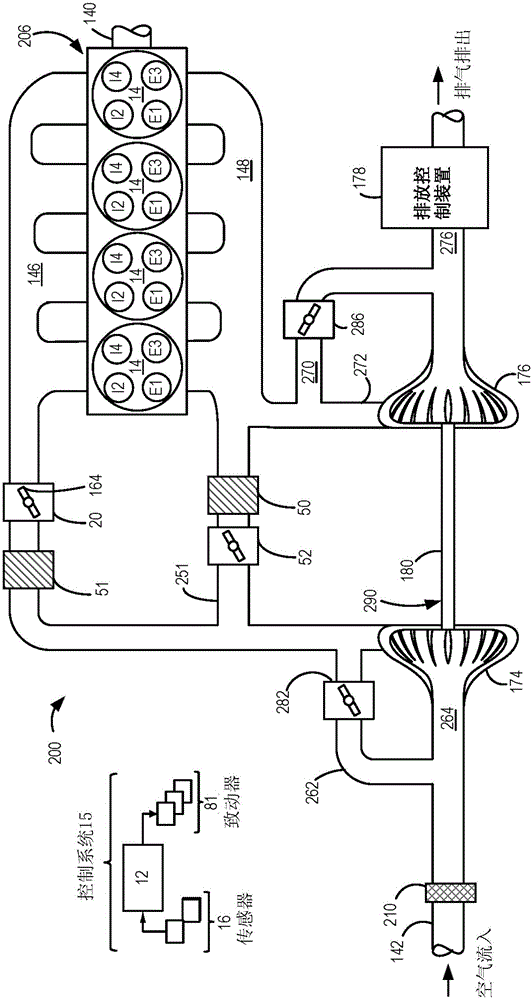

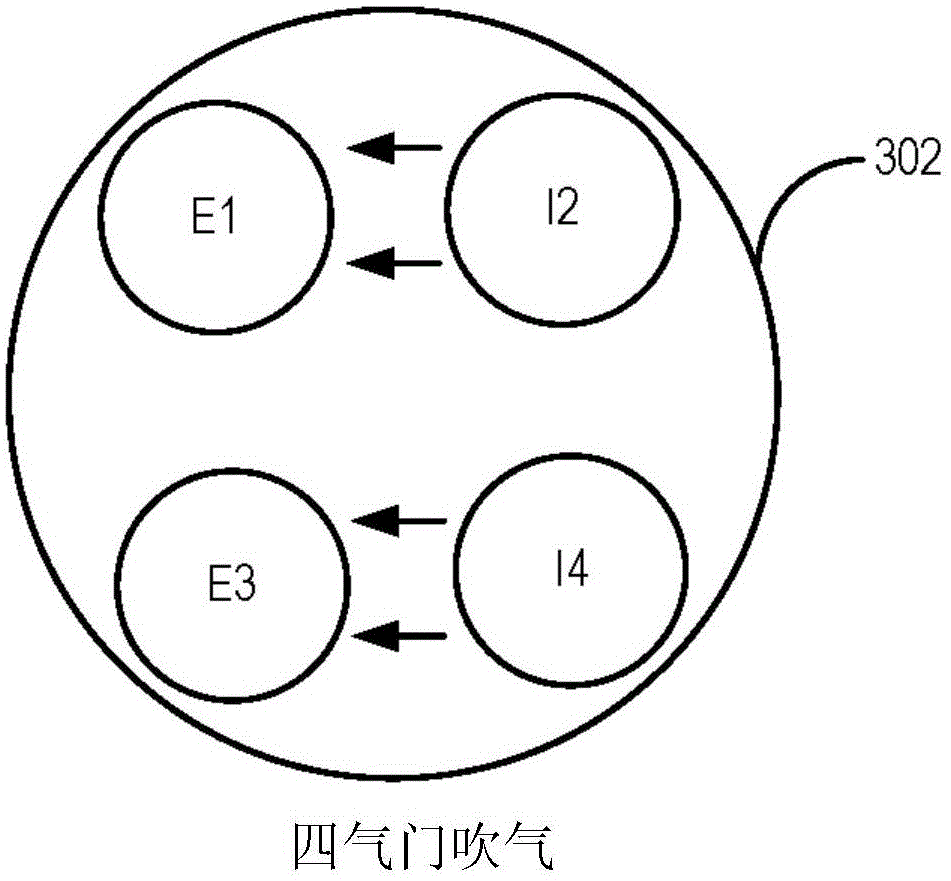

[0020] This instruction manual refers to the Figure 1-2 Methods and systems for improving scavenging in a turbocharged engine system as shown in . The engine controller can be configured to execute control routines such as Figure 4-6 to determine the type of blowing (two-valve diagonal blowing or four-valve blowing) and to operate the engine in the determined blowing mode. can be used as in Figure 3B Two-valve diagonal blowing pattern shown to increase the gas flow distance from the first intake valve to the first exhaust valve, thereby improving mixing of gases for more efficient purge and by reducing leakage to the exhaust manifold The amount of blown air in to increase the cylinder air charge. When the temperature of one or more valves is greater than the threshold degradation temperature to reduce the degradation of the valves used for blowing, it can be used as in Figure 3A A four-valve blowing pattern is shown instead of a two-valve blowing pattern. In one examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com